Effects of different aging treatments on microstructures and mechanical properties of Al-Cu-Li alloy joints welded by electron beam welding

2018-03-21ShaogangWANGYanHUANGLiZHAO

Shaogang WANG,Yan HUANG,Li ZHAO

College of Material Science and Technology,Nanjing University of Aeronautics and Astronautics,Nanjing 211106,China

1.Introduction

Al-Li alloys have low density,high specific strength and specific modulus,excellent anti-fatigue performance,etc.When conventional aluminum alloys are replaced by these types of alloys in engineering structures,the weight of a component can be reduced by 10%–15%and its stiffness can be increased by 15%–20%respectively.Therefore,Al-Li alloys are the ideal light-weight and high-strength structural materials for the aerospace field.1–3A welded structure instead of a riveted structure can further reduce the weight of an Al-Li alloy component,and welding is one of the important processing technologies to reduce production cost and improve production efficiency in the aircraft industry.Compared with the second-generation Al-Li alloys,the chemical composition of the third-generation Al-Li alloys has been adjusted,and their properties are further improved by increasing the element mass fraction of Cu/Li.4

In recent years,much research has been carried out on the welding process and weldability of Al-Li alloys.Calogero et al.5studied the weldability of Al-Cu-Li alloy 2198.It was successfully welded by using gas tungsten arc welding(GTAW),and many strip precipitates in big sizes were generated at grain boundaries and within grains of the joint.The Al-Li alloy 2A97 was welded by using gas metal arc welding(GMAW),GTAW,and laser beam welding(LBW),respectively,6and the microstructures of welded joints were analyzed.Results showed that there was no precipitate within fine equiaxed grains in welded joints,and the grain boundary had a eutectic composition.The amount of precipitates in the fusion zone was greatly decreased compared with the matrix alloy.Gao et al.7found that there were two main reasons for the strength decrease of 2198 Al-Li alloy joints by friction stir welding(FSW).On one hand,the decrease of the joint strength was because phase T1(Al2CuLi)completely dissolved in the stir shoulder zone and the stir pin zone.On the other hand,the amount of phase T1decreased and the grain size changed obviously in the thermo-mechanical affected zone to generate stress concentration,which led to a decrease of the joint strength.Cui et al.8reported that the homogeneity of microstructure was improved in LBW joints of Al-Li alloys,and the hardness of joints increased by promoting more phases δ′(Al3Li)precipitated in weldment after PWHT.

Compared with other welding processes,electron beam welding(EBW)has some advantages,such as large weld depth to width ratio,small deformation of workpieces,high welding efficiency,stable weld performance,easy adjustment to welding parameters,good technological adaptability,and so on.Therefore,it has great advantages to weld Al-Li alloys.However,since it is similar to other fusion welding processes,the strength coefficient of an Al-Li alloy joint welded by EBW is still not high,because the formation of precipitates in the fusion zone is insufficient during the welding process.In order to further improve the microstructures of Al-Li alloy joints by EBW,so as to increase the mechanical properties of welded joints,in present work,two kinds of post-weld heat treatments including single and double aging treatments are carried out on welded joints respectively,and the effects of different aging treatments on microstructures and mechanical properties of joints are investigated.

2.Experimental material and procedure

The base metal is Al-Cu-Li alloy plate(condition T8)with a thickness of 4 mm,and the chemical composition is as follows(wt%): Al-3.2Cu-1.0Li-0.5Mg-0.4Ag-0.35Zn-0.11Zr-0.5Mn.The tensile strength of the base metal is 416.6 MPa.A welding sample is prepared with a dimension of 200 mm×110 mm×4 mm.A butt joint is used which is welded along the longitudinal direction with an LARA52 type vacuum EBW machine.A circular scanning pattern is used,with a scanning amplitude of 2%,and a scanning frequency of 500 Hz.The optimized welding parameters are determined as the following:vacuum degree 5×10-4Pa,working distance 20 mm,accelerating voltage 50 kV,electron beam current 17 mA,welding speed 300 mm/min,and beam focus current 412 mA.As a result,a sound joint is obtained,and no welding defects such as crack and pores are found in weldment.After welding,joint samples are divided into three groups:(1)without heat treatment,namely in the as-welded condition(AW);(2)with post-weld single aging treatment,namely solution treatment at 510°C for 1 h,water quenching,aging at 155°C for 16 h,and then air cooling;and(3)with post-weld double aging treatment,namely solution treatment at 510°C for 1 h,water quenching,aging at 155 °C for 16 h,aging at 130 °C for 12 h,and then air cooling.

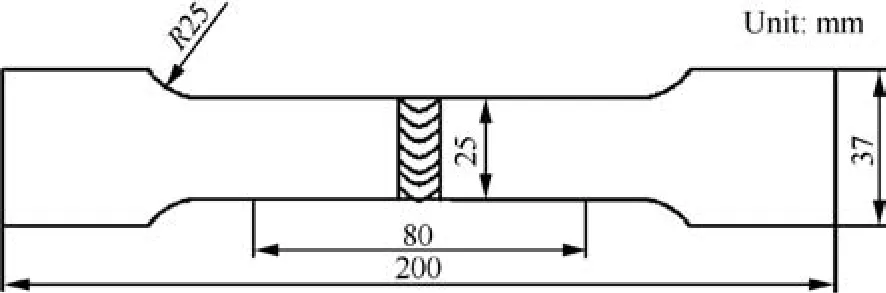

The microstructures and mechanical properties of welded joints before and after heat treatment are investigated respectively.The microstructures of joints are observed by using an MM6 type optical microscope.The tensile strengths of joints are tested by using a CMT-5105 type universal electronic machine with a maximal loading capacity of 10 kN.The dimension of a tensile sample is shown in Fig.1,and the tensile speed is 1 mm/min.The hardness measurement is performed by using an HXS-1000 A type hardness tester with a load of 200 g and a holding time of 15 s.The tensile fracture morphology of joints is observed by using a Quanta 200 type scanning electron microscope(SEM).The precipitates in weldment are observed by using an FEI Tecnai G2 type transmission electron microscope(TEM).

3.Results

3.1.Microstructures of welded joints

Metallographic specimens of Al-Cu-Li alloy joints are prepared in the following steps:grinding,polishing,and etching(Keller etchant:1 mL HF+2.5 mL HNO3+1.5 mL HCl+95 mL H2O).The optical micrographs of welded joints in different zones are observed respectively.The microstructure of the base metal is shown in Fig.2.It can be seen that the microstructure of the base metal is rolled grains,which presents the distribution of a long strip shape.

Fig.1 Dimension of a tensile sample for Al-Cu-Li alloy joints.

The microstructures of the weld metal before and after PWHT are shown Fig.3.In the AW condition,the microstructure of the fusion zone is an as-cast structure due to rapid solidification,and the fusion zone consists of a mixed microstructure including equiaxed grains and dendrites,as shown in Fig.3(a).Because the active element Li contained in Al-Cu-Li alloy is adsorbed on the surface of heterogeneous nucleation,it can activate nucleation and slow down the growth of crystal.At the same time,constitutional supercooling exists in the weld center,and the elements of Mg and Li can further increase the degree of constitutional supercooling;thus the nucleation rate increases.As a result,it promotes the formations of equiaxed grains and dendrites.After PWHT,the microstructure of joints is obviously improved,and it consists of equiaxed grains distributed uniformly,as shown in Fig.3(b)and(c).The network of dendrites is eliminated,and a large number of dispersed particles precipitate within grains.After post-weld double aging treatment,the grain size of weldment is obviously smaller than that after post-weld single aging treatment,as shown in Fig.3(c).

The microstructures of the joint transition zone before and after PWHT are shown in Fig.4.There exists a fine equiaxed grain zone(EQZ)near the fusion line,the same as in welded joints with other fusion welding processes,as shown in Fig.4(a).The formation of a fine EQZ in Al-Cu-Li alloy during fusion welding is related to β′(Al3Zr)particles and element Li contained in the base metal.During a welding process,the edge of weldment is under the condition of a low overheating degree,and the duration time of a molten pool is short;thus there are a lot of undissolved β′particles as the heterogeneous nucleation site of the fine EQZ,which increases the nucleation rate near the fusion line.Moreover,the cooling rate of the edge of weldment is much faster than that of the weld center.These two factors make the fine EQZ form and grow rapidly near the fusion line of an Al-Cu-Li alloy joint.After post-weld single aging treatment,from Fig.4(b),it can be seen that the fine EQZ is still retained near the fusion line,and some grains grow slightly.However,after post-weld double aging treatment,the fine EQZ disappears near the fusion line,and the microstructure of the transition zone is fine and homogeneous,as shown in Fig.4(c).

Fig.2 Microstructure of the base metal of Al-Cu-Li alloy.

3.2.TEM analysis of weldment substructure

The dark field(DF)TEM images and selected area electron diffraction(SAED)patterns of the grain boundary along direction 〈112〉αfor Al-Cu-Li alloy weldments are shown in Fig.5.It can be seen that the strengthening phase of the grain boundary in the weld metal is mainly the needle-like phase T1before and after PWHT.The DF distribution of phase T1in the grain boundary under the AW condition is shown in Fig.5(a).The coarsening strengthening phase T1distributes sparsely in the grain boundary,with a length of about 100 nm.After post-weld single aging treatment,the precipitation phase T1is fine and dispersed relatively,as shown in Fig.5(b).However,after post-weld double aging treatment,namely,a higher temperature aging followed by a lower temperature aging,phase T1of the grain boundary in weldment is more dispersed,and the volume fraction of phase T1is increased,as shown in Fig.5(c).

Bright field(BF)images within grains along direction〈112〉αfor Al-Cu-Li alloy weldments are shown in Fig.6.Based on the chemical composition of the experimental material in present work and some literature,7,9it can be seen that the precipitate within grains is less,and there are only a few horseshoe-shaped phase β′(Al3Zr)particles in the AW condition,as shown in Fig.6(a).After post-weld single aging treatment,there are not only more precipitates of phase β′particles but also a few needle-like phases T1within grains,as shown in Fig.6(b).After post-weld double aging treatment,there are still a few phases T1within grains;in addition,the number of phase β′particles further increases,as shown in Fig.6(c).

The TEM images of the grain boundary for Al-Cu-Li alloy weldments are shown in Fig.7.The strengthening phase T1precipitates in grain boundaries both in the AW condition and after PWHT,which has been confirmed in DF images(Fig.5),while the microstructure of the grain boundary in Al-Cu-Li alloy weldments is a little different.The elements are distributed uniformly near the grain boundary in the AW condition while a precipitate-free zone(PFZ)is formed in the grain boundary after PWHT.The PFZ after post-weld double aging treatment is wider than that after post-weld single aging treatment.Compared with post-weld single aging treatment,the aging time is obviously prolonged during post-weld double aging treatment.The more precipitates of phases T1in the grain boundary will absorb more Cu atoms,which widens the PFZ,as shown in Fig.7(b)and(c)respectively.

Fig.3 Microstructures of weldment of an Al-Cu-Li alloy joint before and after PWHT.

Fig.4 Microstructures of an Al-Cu-Li alloy joint near the fusion line before and after PWHT.

Fig.5 DF images and diffraction patterns of the grain boundary along direction 〈112〉α for Al-Cu-Li alloy weldments.

Fig.6 BF images within grains along direction 〈112〉α for Al-Cu-Li alloy weldments.

3.3.Mechanical properties of welded joints

3.3.1.Hardness profile

The hardness of Al-Cu-Li alloy joints before and after PWHT is measured along direction ‘base metal(BM) –heat-affected zone(HAZ)–weld metal(WM)–heat-affected zone(HAZ)–base metal(BM)”.The distribution curves of hardness are shown in Fig.8.The distribution curves are symmetrical along the weld center.In the AW condition,the average hardness of weldment is 68.6 HV,and that of the HAZ is 101.1 HV,which is close to the hardness value 105.1 HV of the base metal.It can be seen from Fig.8 that the hardness of the weld metal is relatively low in the AW condition,which indicates that there exists a softening phenomenon in Al-Cu-Li alloy joints.Because the Al-Cu-Li alloy is a kind of precipitation strengthening alloy,the supersaturated degree of solute elements Cu and Li is insufficient in solid solution under the condition of rapid cooling for weldment,which results in less precipitates in the weld metal.Namely,under-aging occurs to weldment in the AW condition.The hardness value near the fusion line increases evidently,which is because the precipitate grows up in the HAZ under the action of a weld thermal cycle,which produces a hardening effect to a certain extent.

Fig.7 TEM images of the grain boundary for Al-Cu-Li alloy weldments before and after PWHT.

Fig.8 Distribution curves of hardness for Al-Cu-Li alloy joints.

After PWHT,the hardness of a joint obviously increases,especially of a joint after post-weld double aging treatment.According to the above observation of microstructures,as shown in Fig.3(b)and(c),the microstructure of the fusion zone is equiaxed grains after PWHT,and a large number of dispersed particles precipitate within grains,so the hardness is higher.Under the condition of post-weld single aging treatment,the average hardness of weldment is 89.6 HV,which increases by about 31%compared with that of 68.6 HV in the AW condition,but the hardness values of both the base metal and the HAZ do not change obviously after post-weld single aging treatment.Under the condition of post-weld double aging treatment,recrystallization occurs to the weld metal,and the grains of the weld metal become finer,which results in an effect of refinement grain strengthening,and the average hardness of weldment increases to 92.5 HV.Consequently,PWHT plays an important role in the hardness of Al-Cu-Li alloy joints.

3.3.2.Tensile properties

The results of tensile tests of Al-Cu-Li alloy joints are given in Table 1,which are the averages of three measurements.It can be seen that the tensile fracture of joints is all in the weld metal,which means that weldment is the weakening zone of a welded joint.Compared with that of the base metal,the tensile strength of Al-Cu-Li alloy joints in the AW condition decreases to a certain extent.After PWHT,the tensile properties of welded joints are improved obviously.The strength coefficient of joints increases from 0.64 in the AW condition to 0.90 after post-weld double aging treatment.Compared with the joints in the AW condition,the tensile strength of joints increases obviously after PWHT,but the plasticity of joints loses a little,and the elongation of joints decreases from 4.5%in the AW condition to 3.0%after post-weld double aging treatment.

In order to deeply understand the relationship between microstructures and mechanical properties of Al-Cu-Li alloy joints,and to explore the fracture mechanism of welded joints before and after PWHT,the tensile fractures of joints are observed by using SEM.The fracture morphologies of joints are shown in Fig.9.It can be seen that there are many dimples on fracture surfaces of joints both in the AW condition and after PWHT,which demonstrates that obvious plastic deformation is generated to joints before a tensile fracture.At the bottom of dimples,there are strengthening-phase particles.It can be inferred that micro-pores are formed around the strengthening-phase particles under the action of tensile stress,a crack originates from second-phase particles,and then the coalescence of micro-pores causes a fracture finally.The depth of dimples is relatively shallow on fracture surfaces of joints in the AW condition,as shown in Fig.9(a),while the dimples are deeper after PWHT,as shown in Fig.9(b)and(c).The dissolution of supersaturated solid solution occurs to joints after PWHT,resulting in enrichment of Cu atoms,which promotes the formation of second-phase particles,thus the strength ofjoints improves,and the number of dimples on the fracture surface increases.There are a large number of strengthening phase particles at the bottom and on the walls of dimples,as shown in Fig.9(c).It can be concluded that the precipitation of a strengthening phase can be enhanced greatly by postweld double aging treatment.

Table 1 Results of tensile tests of Al-Cu-Li alloy joints.

Fig.9 SEM morphologies of tensile fractures of Al-Cu-Li alloy joints before and after PWHT.

4.Discussion

The mechanical property of a material depends on its microstructure,and the change of the material’s macroscopic property is reflected in the change of its microstructure.As to Al-Cu-Li alloy,precipitation strengthening is its main strengthening mechanism,and the quantity,size,shape,and distribution of precipitates directly influence the mechanical properties of Al-Cu-Li alloy.Therefore,the property of the material is determined by the combined influence of various precipitates.Usually,the strengthening phase precipitated in the alloy is closely related to the heat treatment process.

A small quantity of element Zr contained in Al-Cu-Li alloy can be combined with element Al to form phase β′.The primary phase β′precipitated in weldment can refine the as-cast structure and form fine and uniform equiaxed grains,and simultaneously,the dendritic segregation is eliminated.10–12As to Al-Cu-Li alloy which contains more element Mn compared with element Zr,the combined addition of elements Zr and Mn can increase the resistance to recrystallization of Al-Cu-Li alloy.13During the process of solution treatment,more element Mn in Al-Cu-Li alloy decreases the supersaturated degree of element Zr in the α(Al)matrix,and thus the precipitation of phase β′is reduced.The concentration of element Zr in the dendrites center of as-cast weldment is high,while that in the dendrites edge is low,and the concentration distribution cannot be changed even through solution treatment.14Tsivoulas and Robson10reported that phase β′in Al-Cu-Li alloy nucleated preferentially in quenching dislocations and distributed in grain boundaries and subgrain boundaries.Phase β′has a coherent relationship to the α(Al)matrix.The precipitation of phase β′can inhibit recrystallization due to its pinning effect on the grain boundary.From the BF images of precipitates in the weld metal,as shown in Fig.6,phase β′particles mainly distribute within grains,which is consistent with the results of literature.11Because precipitate containing element Zr nucleates in the dendrites center of weldment during the solidification process,and thus phase β′particles cannot pin the grain boundaries and inhibit recrystallization.After post-weld double aging treatment,recrystallization occurs to the fusion zone,which leads to grains refinement.

The study by Decreus et al.15shows that there are several types of strengthening phases such as θ′(Al2Cu),T1(Al2CuLi),δ′(Al3Li),etc.in an Al-Cu-Li alloy after solid solution and aging treatment.The strengthening effect of phase T1is the maximum among all kinds of precipitation phases.This is because the combined addition of elements Ag and Mg can increase the quantity of phase T1and lead to an effect of precipitation strengthening to achieve the maximum.16Usually,the nucleation and growth of phase T1are preferentially in dislocation,grain boundary,and subgrain boundary.17The weldment has an as-cast structure in the AW condition,so compared with the base metal with pre-deformation before welding,less dislocation exists in weldment without pre-deformation,not so many nucleation positions are available for phase T1,and thus the precipitation phase T1in weldment mainly distributes in the grain boundary.In the AW condition,the strengthening effect is finite due to sparse and coarsening phase T1in grain boundaries,and a few phase β′precipitates within grains.Therefore,the strength of a joint is relatively low in the AW condition,while the plasticity is better.According to the aforementioned hardness distribution curves(Fig.8)and TEM analyses(Fig.6),phase β′particles play an important role in the hardening effect,which is similar to the results of literature.18

After post-weld single aging treatment,more phase β′particles precipitate in weldment,as shown in Fig.6(b).Phase β′has the pattern of an L12structure,and its mismatch degree to matrix is very small,which is only 0.8%.19Under the action of external stress,dislocations cannot cut through phase β′particles,and they only go through in the way of bypassing,which is advantageous to improve the strength of joints.From the microstructure of the grain boundary,as shown in Fig.7,joints after post-weld single aging treatment form a narrower PFZ.Generally speaking,the PFZ has a great effect on the strain of the grain boundary.The wider the PFZ is,the higher the strain of the grain boundary is,which leads to an increase of the strain concentration degree of the grain boundary.As for a joint after post-weld single aging treatment,although the width of the PFZ is relatively small,it does not improve greatly the strength of joints.However,it can reduce strain localization caused by the pile-up of dislocations in the grain boundary during plastic deformation,and thereby the elongation of joints increases.Compared with a joint after post-weld double aging treatment,a joint after post-weld single aging treatment has better plasticity.

Dorin et al.20studied the formation kinetics of phase T1in Al-Cu-Li alloy by quantitative description.Aging at 155°C for 18 h,plenty of phases T1precipitated in the microstructure,and the volume fraction of phase T1in Al-Cu-Li alloy reached the maximum by subsequent aging at 190°C.Two stages are involved in the precipitation of phase T1.The monolayer phase T1nucleates and grows up,then its size gradually increases,and phase T1becomes thicker and thicker.The strengthening effect of needle-like phase T1with a large length to width ratio is better,so the coarsening of phase T1should be avoided as much as possible during heat treatment.The high temperature aging stage in post-weld double aging treatment promotes the precipitation of phase T1in the grain boundary and phase T1and β′particles within grains.The following low-temperature aging stage can slow down the growth rate of precipitate and inhibit the coarsening of precipitate.At the same time,the recrystallization process in weldment is fully completed,so as to refine the microstructure of joints and produce the effect of grain refinement strengthening.The increase of grain boundaries can provide more nucleation positions for phase T1,which promotes re-precipitation of phase T1in grain boundaries.As a result,the volume fraction of phase T1increases and the mechanical properties of joints improve significantly.However,the plasticity of joints decreases to a certain extent after post-weld double aging treatment.

5.Conclusions

(1)The tensile strength of an Al-Cu-Li alloy joint in an aswelded condition is 64%of that of the base metal.After PWHT,the joint strength is up to 82%of that of the base metal after post-weld single aging treatment,and it can be up to 90%of that of the base metal after post-weld double aging treatment.

(2)In the as-welded condition,the fusion zone consists of a mixed microstructure including equiaxed grains and dendrites.After PWHT,the microstructure of weldment transforms to equiaxed grains distributed uniformly.When a joint is conducted by post-weld single aging treatment,the fine equiaxed grain zone near the fusion line is still retained,while by post-weld double aging treatment,it disappears.

(3)PWHT can promote not only the fine needle-like phase

T1(Al2CuLi)precipitated substantially in grain boundaries,but also some horseshoe-shaped phase β′(Al3Zr)particles and a few phase T1precipitated within grains.As a result,the strength of welded joints is improved greatly.In particular,recrystallization occurs to the weld metal during the post-weld double aging process,and the microstructure of weldment is fine and distributes uniformly,which leads to an effect of grain refinement strengthening.Therefore,the strengthening effect is greater than that with post-weld single aging treatment.

Acknowledgements

This project was supported by the Aeronautical Science Foundation of China(No.2015ZE52048)and A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

1.Kostrivas A,Lippold JC.Weldability of Li-bearing aluminium alloys.Int Mater Rev1999;44(6):217–37.

2.Xu Y,Wang XJ,Yan ZT,Li JX.Corrosion properties of lightweight and high-strength 2195 Al-Li alloy.Chin J Aeronaut2011;24(5):681–6.

3.Li XQ,Song N,Guo GQ,Sun ZG.Predication of forming limit curve(FLC)for Al-Li alloy 2198–T3 sheet using different yield functions.Chin J Aeronaut2013;26(5):1317–23.

4.Rioja RJ,Liu J.The evolution of Al-Li base products for aerospace and space applications.Metall Mater Trans A2012;43(9):3325–37.

5.Calogero V,Costanza G,Missori S,Sili A,Tata ME.A weldability study of Al-Cu-Li 2198 alloy.Metallurgist2014;57(11–12):1134–41.

6.Fu BL,Qin GL,Meng XM,Ji Y,Zou Y,Lei Z.Microstructure and mechanical properties of newly developed aluminum-lithium alloy 2A97 welded by fiber laser.Mater Sci Eng A2014;617:1–11.

7.Gao C,Zhu ZX,Han J,Li HJ.Correlation of microstructure and mechanical properties in friction stir welded 2198–T8 Al-Li Alloy.Mater Sci Eng A2015;639:489–99.

8.Cui L,Ding HY,Chen L,He EG,Gu CS.Effects of post-weld heat treatment on microstructure of laser welded joints in an Al-Li alloy.T Mater Heat Treat2014;35(10):58–63[Chinese].

9.Shou WB,Yi DQ,Yi RW,Liu HQ,Bao ZH,Wang B.In fluence of electric field on microstructure and mechanical properties of an Al-Cu-Li alloy during ageing.Mater Des2016;98:79–87.

10.Tsivoulas D,Robson JD.Heterogeneous Zr solute segregation and Al3Zr dispersoid distributions in Al-Cu-Li alloys.Acta Mater2015;93:73–86.

11.Chen AT,Peng Y,Zhang L,Wu GH,Li YL.Microstructural evolution and mechanical properties of cast Al-3Li-1.5Cu-0.2Zr alloy during heat treatment.Mater Charact2016;114:234–42.

12.Liu X,Liu ZY,Yu DE,Liu CW,Xia P.Microstructure and analysis of Al3Zr precipitate of homogenized annealing 2099 aluminum-lithium alloy.Mater Sci Eng Powder Metall2013;18(3):333–40[Chinese].

13.Tsivoulas D,Robson JD,Sigli C,Prangnell PB.Interactions between zirconium and manganese dispersoid-forming elements on their combined addition in Al-Cu-Li alloys.Acta Mater2012;60(13–14):5245–59.

14.LuXY,Guo EJ,Rometsch P,Wang LJ.Effect of one-step and two-step homogenization treatments on distribution of Al3Zr dispersoids in commercial AA7150 aluminium alloy.Trans Nonferrous Met Soc China2012;22(11):2645–51.

15.Decreus B,Deschamps A,Donnadieu P.Understanding the mechanical properties of 2198 Al-Li-Cu alloy in relation with the intra-granular and inter-granular precipitate microstructure.J Phys:Conf Ser2010;240(1)012096.

16.Huang LP,Zheng ZQ.Alloying role of small additives of Ag and Mg in 2197 alloy.Heat Treat Met2005;30(4):21–5[Chinese].

17.Araullo-Peters V,Gault B,De Geuser F,Deschamps A,Cairney JM.Microstructural evolution during ageing of Al-Cu-Li-x alloys.Acta Mater2014;66:199–208.

18.Chen ZW,Zhao K,Fan L.Combinative hardening effects of precipitation in a commercial aged Al-Cu-Li-X alloy.Mater Sci Eng A2013;588:59–64.

19.Nes E.Precipitation of the metastable cubic Al3Zr-phase in subperitectic Al-Zr alloys.Acta Metall1972;20(4):499–506.

20.Dorin T,Deschamps A,De Geuser F,Lefebvre W,Sigli C.Quantitative description of the T1formation kinetics in an Al-Cu-Li alloy using differential scanning calorimetry,small-angle X-ray scattering and transmission electron microscopy.Philos Mag2014;94(10):1012–30.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- A self-similar solution of a curved shock wave and its time-dependent force variation for a starting flat plate airfoil in supersonic flow

- Robust Navier-Stokes method for predicting unsteady flowfield and aerodynamic characteristics of helicopter rotor

- Effects of trips on the oscillatory flow of an axisymmetric hypersonic inlet with downstream throttle

- Development of a coupled supersonic inlet-fan Navier–Stokes simulation method

- An equilibrium multi-objective optimum design for non-circular clearance hole of disk with discrete variables

- Shock/shock interactions between bodies and wings