RFID-based Production Data Analysis in an IoT-enabled Smart Job-shop

2018-01-26KaiDingandPingyuJiang

Kai Ding and Pingyu Jiang

I.INTRODUCTION

INTERNET of things(IoT)is the network of physical objects embedded with radio frequency identification(RFID),embedded systems,sensors,network,and software that enable physical objects to collect and exchange data for a common goal[1].Under industry 4.0,IoT,together with cyber-physical systems(CPS)and internet of services(IoS),plays an important role in production management in smart job-shops.Generally,a smart job-shop is based on the advanced sensor and information technology(e.g.,IoT and CPS),which connects raw materials,work-in-progress(WIP),machine tools,vehicles,forklifts,cutting-tools,operators,production lines,and other production-related physical as sets with the enterprise information systems(e.g.,enterprise resource planning-ERP,manufacturing execution system-MES,customer relationshipmanagement-CRM).When applied in manufacturing,IoT makes it possible for intelligent identification,tracking and tracing,monitoring,and production control in smart jobshops.The reason is that IoT helps accumulate numerous and diversities of production data via RFID devices and sensors,which improves the transparency,accuracy,and efficiency of production control.

RFID technology,as the core of IoT,acts as the link of process flow data and physical asset data.All the physical asset data can be associated with the process nodes based on RFID.For example,RFID-equipped machine tools can monitor the physical asset data of whatWIP enters or leaves its working place via RFID reader,which indicates the start time or finish time of a machining process in the process flow.As to the operating mechanism,RFID tags are attached to the WIPs,forming smart WIPs.RFID readers and antennas are deployed in the fixed or moving working places to monitor the entrance or exit of smart WIPs[2].Through wireless identification,smartWIPs can communicate with RFID readers to get the real-time data and decide the optimal material flow[3].

Both the academia and industry have devoted much work on the RFID applications in manufacturing,e.g.,RFID-enabled MES[4],material flow monitoring system[5],[6],inventory management system[7],[8],planning and scheduling decision support system[9]−[11],quality assurance system[12],[13],and object locating[14].Zhonget al.developed an RFID-enabled real-time manufacturing execution system for a mass customization production shop-floor where real-time production data are collected to monitor the material flow of WIPs and make optimal production scheduling decisions[4].Quet al.discussed a case of implementing RFID-based realtime shop-floor material management for household electrical appliance manufacturers,and the RFID-tagged materials are monitored visually in the shop-floor by deploying RFID readers in expected monitoring places[5].Ozguvenet al.proposed a closed loop feedback-based emergency inventory control framework by integrating RFID technology for realtime tracking and tracing[8].Guoet al.proposed an RFID-based intelligent decision support system architecture to handle the real-time production monitoring and scheduling in a distributed manufacturing environment[11].Lyu et al.studied a framework of quality assurance system that integrates with RFID technology and discussed the applications of this system in tire industry and power industry[12].Caiet al.discussed a BConTri algorithm that combines a boundary condition method and the trilateration concept to estimate RFID tag location in the three-dimensional(3D)realworld coordinates from four or more RFID readers equipped with GPS[14].

Although RFID technology has been widely applied in manufacturing,the current researches only use the functionality of unique identification of passive RFID tags.The data storage and data interaction functionalities of active RFID tags,which are exactly the most important characteristics of smart objects in IoT and industry 4.0,are seldom utilized.Passive RFID tags have relatively low storage space,which cannot adapt to the complex dynamic manufacturing environment where numerous real-time production data should be collected and stored in time.Besides,they require global and effective network connectivity to index the data on network for production decision-making,which causes the pressure of communication and network bandwidth when there are many RFID tags in the distributed manufacturing environment[15].While active RFID tags,which always have high-volume storage space,ensure smart objects can interact with machine tools,operators,and others to react to unexpected events,and be aware of when and how they are made,and where they are delivered.In our previous work,a hybrid-data-on-tag approach was proposed for active RFID tag applications to deal with the shortcomings of passive RFID tags and the data-on-network approach[15].

On the other hand,when IoT and RFID are applied in manufacturing,large amount of real-time heterogeneous RFID-based production data are generated and collected,which are so-called industrial big data.However,due to the characteristics of sparsity,repeatability,variety,and the lack of effective data analysis methods,the value of correlated RFID production data is seldom exploited,and little hidden know ledge and few rules for supporting production decision-makings are excavated.Aggarwal and Han provided a broad overview and survey of a variety of RFID data management,m ining,and processing techniques[16].Recently,the big data approach has been applied as trials in RFID-based data analysis.Zhonget al.proposed a big data approach to visualize and analyze the RFID logistics data in shop floors,based on which the invaluable logistics trajectories are discovered for logistics optimization and shop floor layout optimization[17],[18].Katchasuwanmaneeet al.developed a big data approach to acquire numerous data from inside and outside the factory in order to analyze the correlations between workflow,data flow,and energy flow for real-time decision-making[19].However,these researches ignore the correlations among more holistic heterogeneous production data in IoT-enabled smart job-shops.A uniform RFID-based production data model is needed.

In this work,two problems are solved:1)how to formalize the data stored in the active RFID tags and correlate them in a uniform model;2)how to analyze the real-time production data for the judgement of process command execution and excavate the hidden information,know ledge,and rules from the big RFID-based production data for decision makings.This work firstly discusses the framework,RFID devices configuration,and operation logic in the IoT-enabled smart job-shop production,which is the application scene of RFID production data analysis method.Secondly,a formalized schematic method is applied to describe the relationships between process flows and RFID-equipped physical assets,based on which heterogeneous RFID-based production data can be extracted from the IoT-enabled smart job-shops.Besides,an RFID-based production data model(i.e.,hybrid-data-on-tag model)is built to correlate the real-time RFID-based production data.Thirdly,an event-driven method is proposed to exploit and analyze the numerous RFID-based production data,based on which some invaluable information,know ledge,and rules can be found to assist production decision-makings.

The rest of this work is organized as follows:Section II describes the scene of IoT-enabled smart job-shop production.Section III proposes the RFID-based production data model.Section IV presents the event-driven RFID-based production data analysis method to excavate the hidden information,know ledge,and rules.Section V studies a demonstrative case to verify the feasibility and efficiency of the proposed model and methods.Finally,discussion and conclusion are given in Sections VIand VII,respectively.

II.IOT-ENABLED SMART JOB-SHOP PRODUCTION

IoT enables all the production-related physical assets in smart job-shops be interconnected.Thus,real-time production data can be collected.Fig.1 describes the systematic view of an IoT-enabled smart job-shop.Firstly,RFID devices and other IoT facilities are deployed onto certain workstations in the smart job-shop.Based on that,a ubiquitous and transparent manufacturing environment is generated for intelligent production control.Furthermore,wireless network(e.g.,ZigBee,Wifi,Bluetooth)enables all the RFID-equipped physical assets interact with each other to collect the realtime production data collaboratively and automatically.The following section details the IoT-enabled smart job-shop from two aspects:1)deployment of RFID devices and network;and 2)production operation logic in IoT-enabled smart job-shop.

A.Deployment of RFID Devices and Network

RFID readers,antennas,and active tags are deployed onto physical assets to endow them with automatic identification capability and interaction intelligence.

Firstly,active RFID tags are attached to raw materials or WIPs.There are two kinds of RFID tag configuration schemes:

1)One-to-one Mapping:For one-of-a-kind production(OKP)or high-value,individualized products,each WIP should be attached with an active RFID tag,to become a smart WIP.After it has finished the process in a certain workstation,it will communicate with machine tools available in the IoT-enabled smart job-shop and select one to which it will be delivered to undertake its next process.Thus,it can be uniquely identified to track and trace its physical routings,production progress,quality,and other information.Except for that,each operator,cutting-tool,and measuring-tool is attached with a passive RFID tag to identify their work plans from production commands and record their workload.

2)Many-to-one Mapping:For mass production or small batch and medium-batch production,WIPs are classified into several batches.Each batch is uniformly flowing with a tray or pallet,which is attached with an active RFID tag to form a smart object.Only after all the WIPs in a batch have finished a certain process,they will communicate with machine tools and select one to which it will be delivered to undertake the next process.

Fig.1.IoT-enabled smart job-shop production.

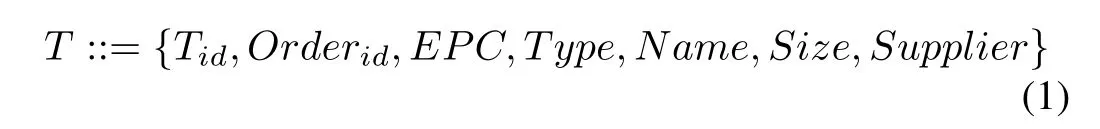

Based on that,smartWIP(i.e.,RFID-tagged WIP)can be formalized as

where the set elements represent the Tag ID of smart WIP,order ID it belongs to,current process ID,its unique EPC code,its material type,name,geometrical size,and supplier.

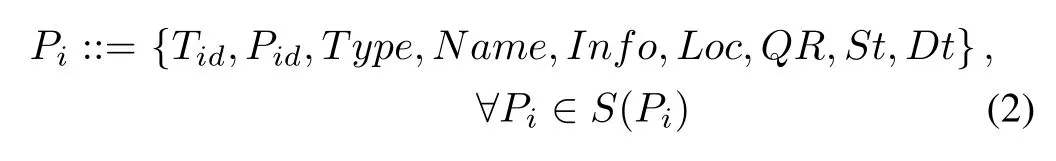

During the production stage,the processes of smart WIP are executed sequentially.The detailed information of each process can be referred as

whereTidis the targeted physical object,PidandTyperepresent the process ID and process type ofPi,N am eandInfoas its name and detailed content.Loc,QR,St,andD tstand for its occurrence location,quality requirements,start time,and duration time.S(Pi)represents the process set.

Secondly,fixed RFID readers/antennas,hand-held RFID readers,and vehicle-mounted RFID readers/antennas are deployed in the workstations,forklifts,and other equipment.For each work station,three RFID antennas are deployed separately in its in-buffer,machine tool’s place,and out-buffer[2].They are connected to a mutual RFID reader and their collected data are transferred via a mutual RFID middle ware.Besides,each quality inspection workbench is equipped with a hand-held RFID reader to check WIPs quality and upload their quality information.Each forklift is equipped with a suit of vehicle mounted RFID reader and antenna to check the production logistics task and manage its processes.

Other IoT facilities such as sensors and actuators are deployed around the machine tool in each work station.They can sense the production-related data such as vibration,humidity,and on-site video,and execute process commands from active RFID tags(i.e.,smart WIPs).When smart WIPs interact with them,they will communicate with each other and react to the requests from smart WIPs.Based on this mechanism,they collaborate to finish the production tasks intelligently.Note that all the RFID readers share a common wireless frequency for smooth communication.

Thirdly,network connectivity is guaranteed by deploying Internet facilities in the IoT-enabled smart job-shop.Fixed RFID reader/antenna and machine tools can access Internet via cable network.While moving RFID reader/antenna,smart WIPs,and other moving RFID-tagged physical assets connect to wireless network via ZigBee,Wifi,and Bluetooth,which are cost-effective and easy-to-use ways for anytime and anywhere network access.Except for that,production database is configured in the smart job-shop to store production commands and real-time RFID-based production data.

After the above three steps,an IoT-enabled smart job-shop is generated.The purple lines in Fig.1 illustrate the schematic w iring relationship of RFID-equipped physical assets.

The following section describes the logic of production operations in the smart job-shop.

B.Operation Logic in the IoT-enabled Smart Job-shop

The logic of production operations in the IoT-enabled smart job-shop is described as follows:

Step 1:Raw materials are checked in the warehouse and are selected for a production order.Before they are delivered to the IoT-enabled smart job-shop,they are firstly configured with active RFID tags according to the two configuration schemes.The active RFID tags store production commands,quality requirements,and other information for dynamic production coordination.

Step 2:Logistics operator uses external RFID-equipped forklift to transport RFID-tagged raw materials from warehouse to job-shop.The transportation task is assigned to the forklift through vehicle-mounted computer,and the vehicle mounted RFID reader is responsible for identifying whether the raw materials and operator in its RFID detecting space are in accordance with the transportation commands.

Step 3−9:When RFID-tagged raw materials enter the smart job-shop,they become smart WIPs and interact with the RFID-equipped machine tools and other equipment to execute production plans and commands consecutively. Kanban in each workstation is used for operators to display the detailed process commands.For example,if the process command requires the first process is at workstation 1,then the smart WIPs will be delivered to the in-buffer of workstation 1.After the RFID antenna detects the entrance event,they will be unloaded and wait for all the required RFID-tagged tools(e.g.,operator and cutting-tool)arrive and are ready for manufacturing.Afterwards,they are produced in the machine tool,and delivered to the out-buffer for quality check after finishing machining.If qualified,they will communicate and interact with other machine tools for the next process.Then they are loaded and delivered to the next workstation by internal RFID-equipped forklifts.Otherwise,they will be transported directly to the defective products area.Their quality information is recorded in the production database via hand-held RFID reader.During the processes,production data are collected from IoT facilities in real-time,and transferred to the upper information system through RFID middleware that are installed in the job-shop’s embedded systems such as Raspberry Pior just in the on-site computer.Note that if production disturbances or unexpected events occur,smart WIPs will communicate with available machine tools proactively,adjust production plans,and upload them to the upper information system.The proactive communication and autonomous decision-makings of smart WIPs make production control intelligent.The only thing need to do to support is analyzing the real-time RFID-based production data instantly and excavate the hidden information,know ledge,and rules.

Step 10:After all the processes are finished,smart WIPs become RFID-tagged finished products.They are transported to the finished product warehouse via external RFID-equipped forklifts.

The red arrow lines in Fig.1 describe the process flow(also material flow)during production.After the IoT-enabled smart job-shop is configured and the production operation logics are analyzed,the next important work is to design proper data model to formalize and store the real-time production data,and develop efficient data analysis method to exploit hidden information,know ledge,and rules inside the historical production big data.

III.RFID-BASED PRODUCTION DATA MODEL

A.Formalization of RFID-based Production Data

It must be mentioned that all the real-time production data are originally discrete and uncorrelated.For example,the data collected from a machine tool can only show its workload and work status.The relationships with other production data are seldom revealed.Actually,all the discrete production data can be correlated to the process flow.Thus,it will provide deep insight into the comprehensive production status.

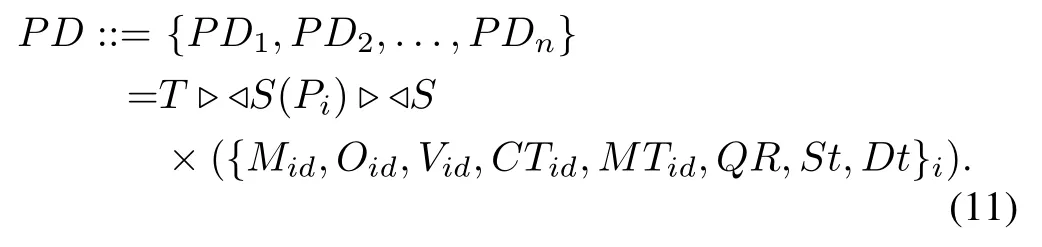

As shown in Fig.2,at the process flow layer,different production orders are planned with different process flows.Each node in the process flow stands for a process,and the arrow lines between two nodes represent their time-sequential relationships.Actually,each node in the process flow will be arranged with a series of process commands that indicate this process is settled at which work station,which kind of operator,cutting-tool,and other tools should be taken to assist it,what is the requirement of ambient manufacturing environment and so on.Based on the process commands,mapping relationships between processes and RFID-equipped physical assets are built,as described as the red arrow lines in Fig.2.Thus,the process-centered RFID-based production data stored in the active tag can be formalized as

Fig.2.RFID-based production data formalization.

wherePD iis the RFID-based production data ofith process.▷◁represents the natural connection in relational algebra.M i,Oi,Vi,CTi,andM Tistand for the RFID tag ID of the used machine tool,operator,vehicle/forklift,cutting-tool,and measuring-tool,QR,St,andD tstand for the actual quality results,start time and duration time ofPi.Note thatPD iis a reflection of the mapping relationships illustrated in Fig.2.

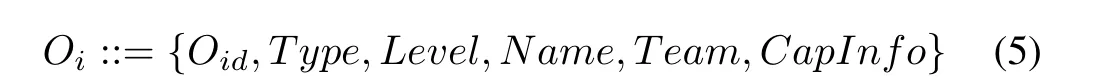

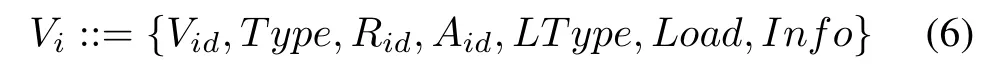

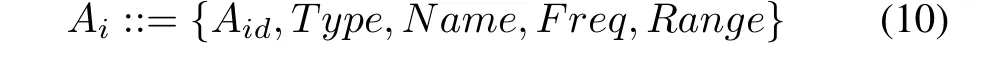

According to the ID numbers in(3),relevant data of RFID-equipped physical assets stored on network can be referred,as described in(4)−(10).

where the set elements represent the machine tool’s ID,type,name,parameters,machining capability,location,binding RFID reader,binding RFID antenna,and current state,respectively.

where the set elements represent the operator’s ID,type of work,technical level,name,work team,and capability,respectively.

where the set elements represent the vehicle’s ID,type(e.g.,forklift,AGV,and truck),binding RFID reader,binding RFID antenna,logistics type(external logistics or internal logistics),load capacity,and descriptive information,respectively.

where the set elements represent the cutting-tool’s ID(i.e.,RFID tag ID),type,name,cutting parameters,and tools life,respectively.

where the set elements represent the machine tool’s ID(i.e.,RFID tag ID),type,name,measuring range,and measuring accuracy,respectively.

Besides,machine tools and vehicles are equipped with RFID readers and antennas to communicate with the smart WIP and RFID-tagged operator,cutting tool,and measuring tool.The binding RFID reader and antenna can be formalized in(9)and(10).

where the set elements represent the RFID reader’s ID,type(moving or fixed),name,amount of interfaces to connect RFID antennas,and radio frequency,respectively.

where the set elements represent the RFID antenna’s ID,type(moving or fixed),name,radio frequency,and monitoring range,respectively.

Except for the above RFID-equipped physical assets,others can be formalized in a similar way.Particularly,the data of sensors that sense energy usage,vibration,speed,temperature,humidity,noise,illumination,and so on are correlated to the machine tool’s data.

From the view of a process flow,the time-sequential process flow-ordered RFID-based production data flow is a set ofPD i.

On the other hand,the incidence relationships between different physical assets can be established according to the capability matching of different physical assets,which are illustrated in the RFID-equipped physical assets layer(see Fig.2).These matching rules can be defined as the preliminary know ledge.For example,an operator can operate two machine tools,and then he/she will build two incidence relationships with these two machine tools.Physical assets build incidence relationships with each other in a machine tool-centered manner.Note that for clarity reason,we just list three kinds of physical assets in Fig.2.Actually,all kinds of RFID-equipped or RFID-tagged physical assets mentioned above can be listed in this layer,and their incidence relationships should be built.

Thus,a global physical assets set in the IoT-enabled smart job-shop is generated as

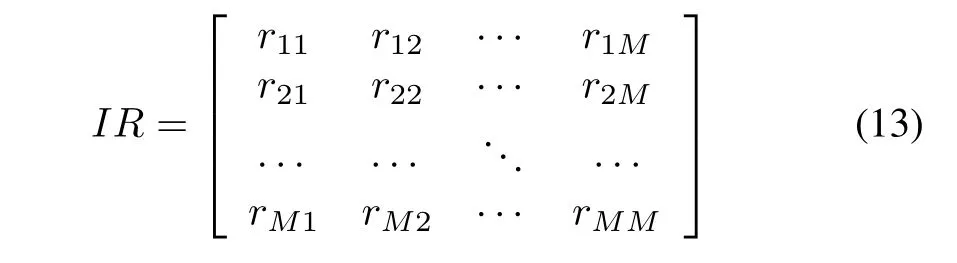

The incidence relationships among these physical assets are described as

whererijrepresents the incidence relationship between theith physical assetPAiand thejth physical assetPAj,rij=0 or 1.Mis the total amount of physical assets.

B.RFID-based Production Data Relationship Model

After data formalization,RFID-based production data relationship model should be built to store and query the realtime data collected from the IoT-enabled smart job-shop.The process-centered RFID-based production dataPD iare stored in the active RFID tags,while the other relevant physical asset information are stored on network.Thus,the RFID-based production data relationship model can be described in Fig.3.The data sheet in blue background takes the data-ontag mode,and the data sheets in grey and green background take the data-on-network mode.Besides,data sheetRelationin green background stores the incidence relationship matrix of different physical assets,wherePA1id,PA2idrepresent two foreign keys from data sheetM,O,V,CT,M T,Reader,Antenna,Sensor,and so on.Fig.3 is a formalized description of the mapping relationships and the incidence relationships in Fig.2.

IV.EVENT-DRIVEN PRODUCTION DATA ANALYSIS

A.RFID Event Construction

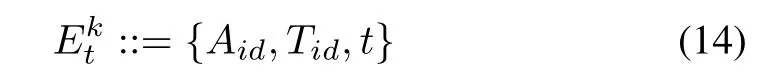

One of the intrinsic attributes of RFID-enabled applications is the event-triggering attribute,which means RFID event triggers the consecutive change of state,position,and other attributes of RFID-tagged raw material and WIP[2],[20].Definition 1:The basic RFID event is defined as a communication activity between RFID reader and RFID tag,and is described as a triple set that is composed of RFID antennaRFID tagTid,and occurence timestampt.

wherekis equal to the ID of RFID antennaAid.An RFID reader can communicate with RFID tags via multiple channels(i.e.,antennas)to save cost and improve efficiency.It should be mentioned that the basic RFID events are derived from the RFID antennas,which means they are RFID antenna-specific.

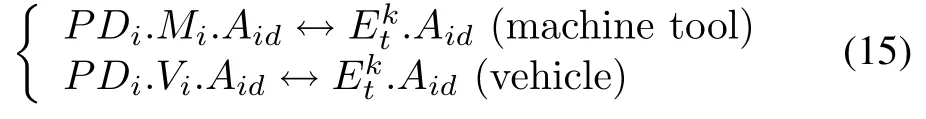

The mapping relationships between basic RFID events and RFID-based production data can be formalized as

Fig.3.RFID production data relationship model.

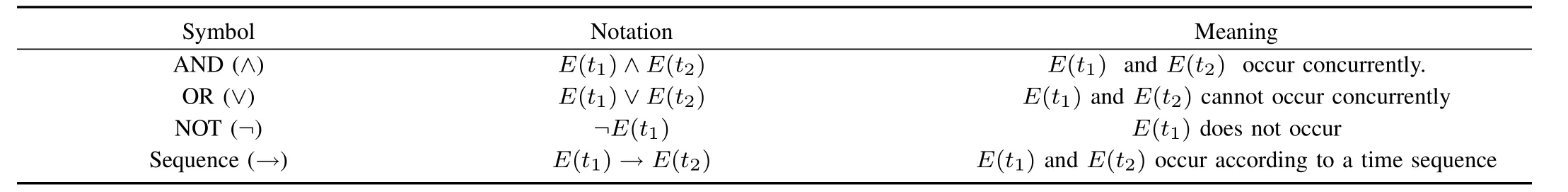

TABLE I THE NOTATIONS AND MEANINGS OF LOGIC OPERATORS

1)Mapping relationship MR1:

2)Mapping relationship MR2:

where MR1 indicates the RFID antenna ID recorded in the basic RFID event is in correspondence with that of machine tool’s or vehicle’s binding RFID antenna in the RFID-based production data.MR2 indicates the RFID tag ID recorded in the basic RFID event is in correspondence with the smart WIP’s,operator’s,cutting tool’s,and measuring tool’s RFID tag ID in the RFID-based production data.

Definition 2:The logic operators are defined as a series of characters that describe the relationships and operations between two ormore basic RFID events.There are four kinds of logic operators,i.e.,AND operator(∧),OR operator(∨),NOT operator(¬),and sequence operatorThe priority of these logic operators is set asTable I lists the notations and meanings of these logic operators.

Definition 3:The complex RFID event is composed of multiple basic RFID events that are linked by logic operators.The complex RFID events can reveal the judgement rules for process command execution.

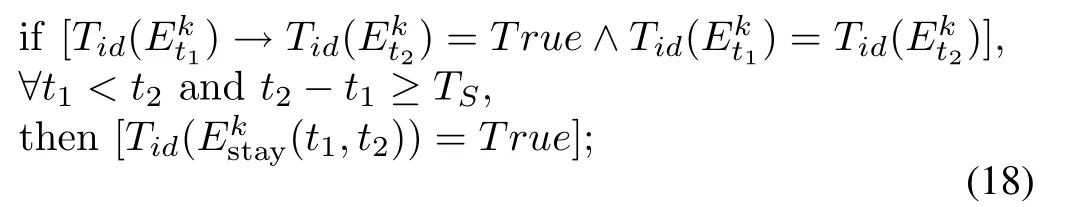

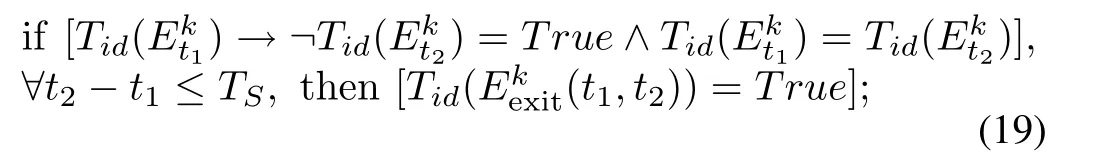

In industrial applications,there are four kinds of complex RFID events,i.e.,tag-moving-in,tag-staying-in,tag-moving out,and tag-passing-through[2],[3],which indicate that RFID-tagged WIP enters the RFID detecting space,stays in the RFID detecting space,leaves the RFID detecting space,passes through the RFID detecting space,respectively.We take the “event/condition-action”mode to express the rules:

1)tag-moving-in

2)tag-staying-in

3)tag-moving-out

4)tag-passing-through

whereTSis a time threshold that is preset according to the shared radio frequency of RFID readers and antennas.

B.Event-driven Judgement Rules for Process Command Execution

Firstly,the process commands are clarified.Because they can be viewed as the preset version of RFID-based production dataPD i,their description is similar toPD ias follows:

It should be mentioned thatPCimay differ from the realPD ibecause smart WIPs with active RFID tags may communicate with other RFID-equipped physical assets in the smart job-shop autonomously to adjust the production plans.

The basic and complex RFID events generate the original real-time RFID-based production data that are stored in the production database.Based on that,the judgement rules for monitoring the process command execution can be exploited.The event-driven judgement is a kind of stream computing method to handle the real-time RFID-based production data.

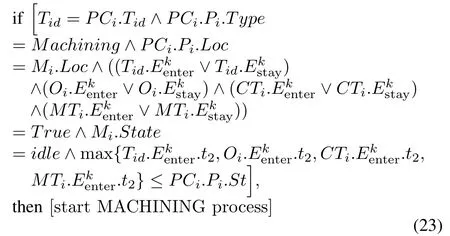

1)Judgement Rule for Monitoring the Machining Process Command Execution:During the process command execution,a comprehensive judgement rule should be set to verify whether all the conditions for a machining process are ready.The principles are:a)the smart WIP is the right object for the next process;b)the next process occurs at this machine tool’s workstation;c)the machine tool is just idle for this machining process;d)the RFID-tagged operator,cutting-tool,measuring-tool,and other assistant tools have arrived at the machine tool’s workstation;and e)the arrival time of all the needed RFID-tagged physical assets is prior to the start time of the process command.Thus,the judgement rule can be described as

wherekis the ID number of RFID antenna deployed at the machine tool.

2)Judgement Rule for Monitoring the Transportation Process Command Execution:After a machining process is finished,the used physical asset IDsM id,Oid,Vid,CTid,M Tid,quality resultsQR,process start timeSt,and process duration timeD tof the process are updated.The process IDPidincreases by one,and a transportation process is planned to deliver the RFID-tagged WIP to the next process.The principles are:a)the smart WIP is the right object for the next process;b)the next process is a transportation process;c)the RFID-equipped operator and forklift/vehicle have arrived at the workstation’s out-buffer;d)the smart WIP is under the staying state at the out-buffer;and e)the delivery time is prior to the deadline of the transportation process command.Thus,the judgement rule is described as

Here,kis the ID number of RFID antenna deployed at the workstations out-buffer.

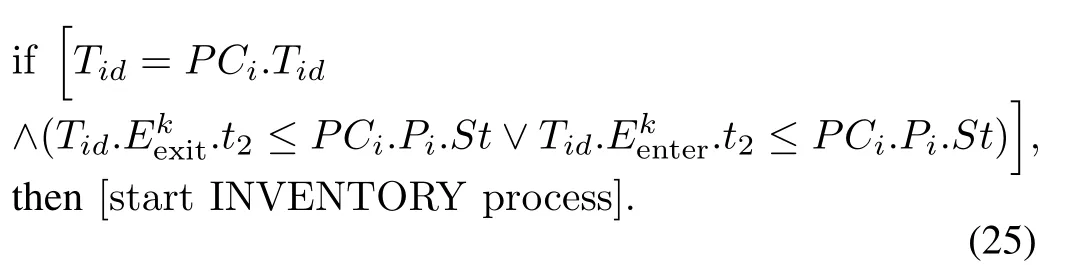

3)Judgement Rule for Monitoring the Inventory Process Command Execution:The inventory process can be classified into two kinds,i.e.,out-warehouse of RFID-tagged raw materials and in-warehouse of RFID-tagged finished products,which are monitored by the RFID-equipped warehouse gateway.After the in-warehouse or out-warehouse process commands are transmitted to the warehouse,the judgement principles are:a)the RFID-tagged raw material or finished product is the right object for the inventory process;and b)the in-warehouse or out-warehouse time is prior to the deadline of the commands.Thus,the judgement rule is described as

4)Judgement Rule for Monitoring Other Process Command Execution:Except for the machining,transportation,and inventory processes,there are many random processes such as quality inspection and regular inventory check.These processes also need to meet the process commands.The general principle is that the RFID-tagged object is the right thing for the process and the time,amount,quality,and other attributes should satisfy the requirements in the process commands.The judgement rules can be described similar to the above rules.Here,we will not list them for brevity reason.

C.Semantic Analysis of the Historical RFID-based Production Data

The above section discusses the function of event-driven judgement rules for process command execution.The key to realize it is the utilization of real-time RFID-based production data.Another important function for IoT-enabled smart jobshop production is to excavate hidden value from the big historical RFID-based production data.

Big data approach is a prevailing and efficient way to handle the heterogeneous,sparse,large-volume historical production data[21].However,the data types handled in the existing researches are limited,and the data heterogeneity(process command data,RFID data,sensor data,etc.)and data correlation are seldom considered in the IoT-enabled smart jobshop.In this work,a near big data approach is used to exploit hidden values from historical RFID-based production data.Four steps are taken sequentially,including data cleansing,data integration,data processing,and data interpretation,Fig.4 shows the four steps and their input/output.

1)Data Cleansing:There are large-volume historical production data in the IoT-enabled smart job-shop.They are generated automatically from the RFID devices and IoT facilities,and they are correlated with each other in line with the process flow.However,due to the discrete and random characteristics of RFID events,there may be numerous incomplete,inaccurate,and duplicated data.Thus,a comprehensive data cleansing method integrating sorted neighbourhood method(SNM)and duplication elimination SNM(DE-SNM)[22],manifold learning[23],and clustering algorithms should be applied to clean the unwanted data.The input is the numerous raw RFID-based production data from production database,while the output is the valid production data set without incomplete,inaccurate,and duplicated data.

Fig.4.Steps for historical RFID-based production data mining.

2)Data Integration:This step re-organizes the valid data by correlating them in the process flow order and the time sequence order,which is helpful to transform the valid data into meaningful engineered information and know ledge.The input is the cleaned valid data,and the output is the process flow-ordered production data flow.The mapping relationshipPDand the incidence relationship matrixIRin the RFID production data model are used to correlate the valid data.For example,the overall production data of a machining process can be described as DATA=HF003472,4,MT003,R021,XD8162,10.06,20160112 16:31,35,which means that No.4 process of part HF003472 is executed at machine tool MT003,the operator is R021,the cutting-tool used is XD8162,and the final quality result shows the average diameter value is 10.06,and this process starts at January 12,2016,PM 16:31,and it lasts 35 minutes.Based on the machine tool ID MT003,the sensor data can be further correlated as Sensor DATA=1.3A,220.2V,32.1%RH,15.1°C,95.6dB,which records the average value of current,voltage,humidity,temperature,and noise during the machining process.

Except for the machine tool ID for indexing sensor data,other physical asset ID can be used to index more industrial data during the machining process according to the mapping relationship matrix and the incidence relationship matrix.By connecting the data from all processes in the process flow order,the valid production data are integrated horizontally and vertically and are organized as a process flow-ordered production data flow(in accordance with the RFID-based production data model).

3)Data Processing:The purpose of this step is to transform the process flow-ordered production data flow into meaningful information in order to support production control and decision-makings for the IoT-enabled smart jobshop managers.For example,by classifying and aggregating the process duration time of each smart WIP at a certain workstation,the workload of machine tool at this workstation can be achieved,which will provide suggestions to balance the machine tools’workload.The input is the process flow-ordered production data flow,and the output is the useful attributes and information derived from the data.Methods such as C4.5[24],support vector machine(SVM)[25],k-means clustering algorithm[26],and deep neural network(DNN)[27]can be applied to process the big RFID-based production data.Based on the processing results,know ledge,patterns,and rules can be excavated.The following gives two processing examples to achieve the production information.

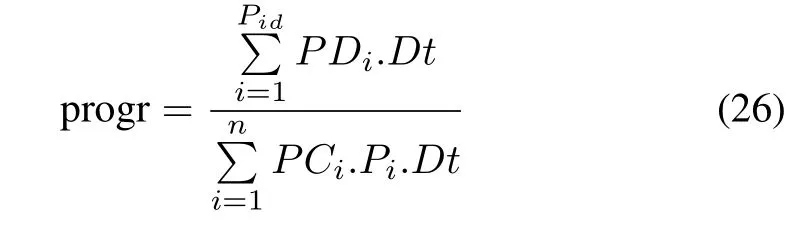

a)Production progress:Because the active RFID tag stores and updates the key production dataPD i,the production progress of RFID-tagged WIP can be achieved as

wherePidrepresents the ID of the current process.

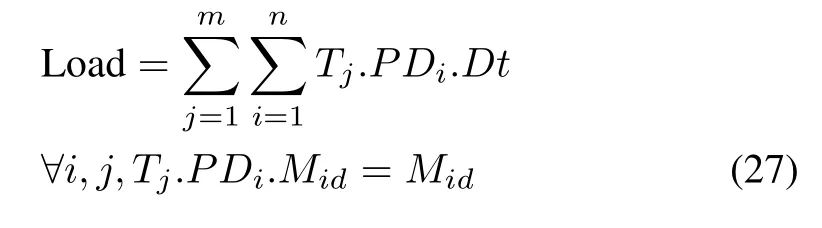

b)Workload calculation:By classifying the process duration time of each smart WIP at a certain workstation,the workload of machine tool at this workstation can be calculated as

wheremandnrepresent the total number of smart WIPs and their separate processes,M idis the certain ID number of machine tool.The constraint is that each process of smart WIPs must be executed at the machine toolM id.

c)Data interpretation:After data processing,another important work is to interpret the achieved information,know ledge,patterns,and rules in a pellucid and straightforward way.Based on that,smart WIPs can proactively interact and negotiate with the RFID-equipped physical assets to adjust their production plans,and the smart job-shop managers can make instant responses and decisions to the production disturbances.On one hand,these information and know ledge should be visualized in Kanbans or mobile devices in the job-shop.On the other hand,they act as the input to dynamic production decision-makings.

V.CASE STUDY

This section develops a prototype for IoT-enabled smart jobshop production and discusses a demonstrative case to verify the feasibility and efficiency of the proposed data analysis method.We have configured an IoT-enabled smart job-shop in our Lab,together with a smart warehouse,as shown in Fig.5.There are three workstations in the job-shop,i.e.,EMCOM ill 55,MANIX 360,and XianDao C56A.Each workstation is deployed with RFID readers,RFID antennas,sensors,and other IoT facilities according to the proposed configuration scheme.A Web-based system is developed by using Java/-JavaScript,MySQL,and Jquery.Besides,the network and database are configured in the job-shop.The parts need to be produced are A-type and B-type shafts from an outsourced order,and each of them is attached with a unique active RFID tag because they need to be separately monitored during their production processes.There are more than 30 types of collected heterogeneous production data.To better understand the production status in this smart job-shop,we take the proposed methods to analyze the collected data.

Fig.5.Physical configuration of smart job-shop and warehouse.

Firstly,when smart WIPs enter the smart job-shop,they communicate and interact with machine tools and other physical assets according to the process commands stored in the active RFID tags.If all the required physical assets are right and ready,the first process will be executed and then the next.

Secondly,during the production processes,RFID readers and antennas collect the real-time data of position changes of smart WIPs,vehicles,operators,cutting-tools,and other flowing physical assets.Other IoT facilities collect real-time data from ambient environment and machining status.These real-time production data are stored in the manufacturing database according to the proposed production data model.

Thirdly,by applying the proposed data analysis method,the collected real-time production data are merged into the real-time production statuses,such as progress,current process,workload of machine tool and operator,and material flow.Besides,the collected historical RFID-based production data are excavated to generate production-related information,know ledge,and rules,which can be utilized for production control and decision-makings.

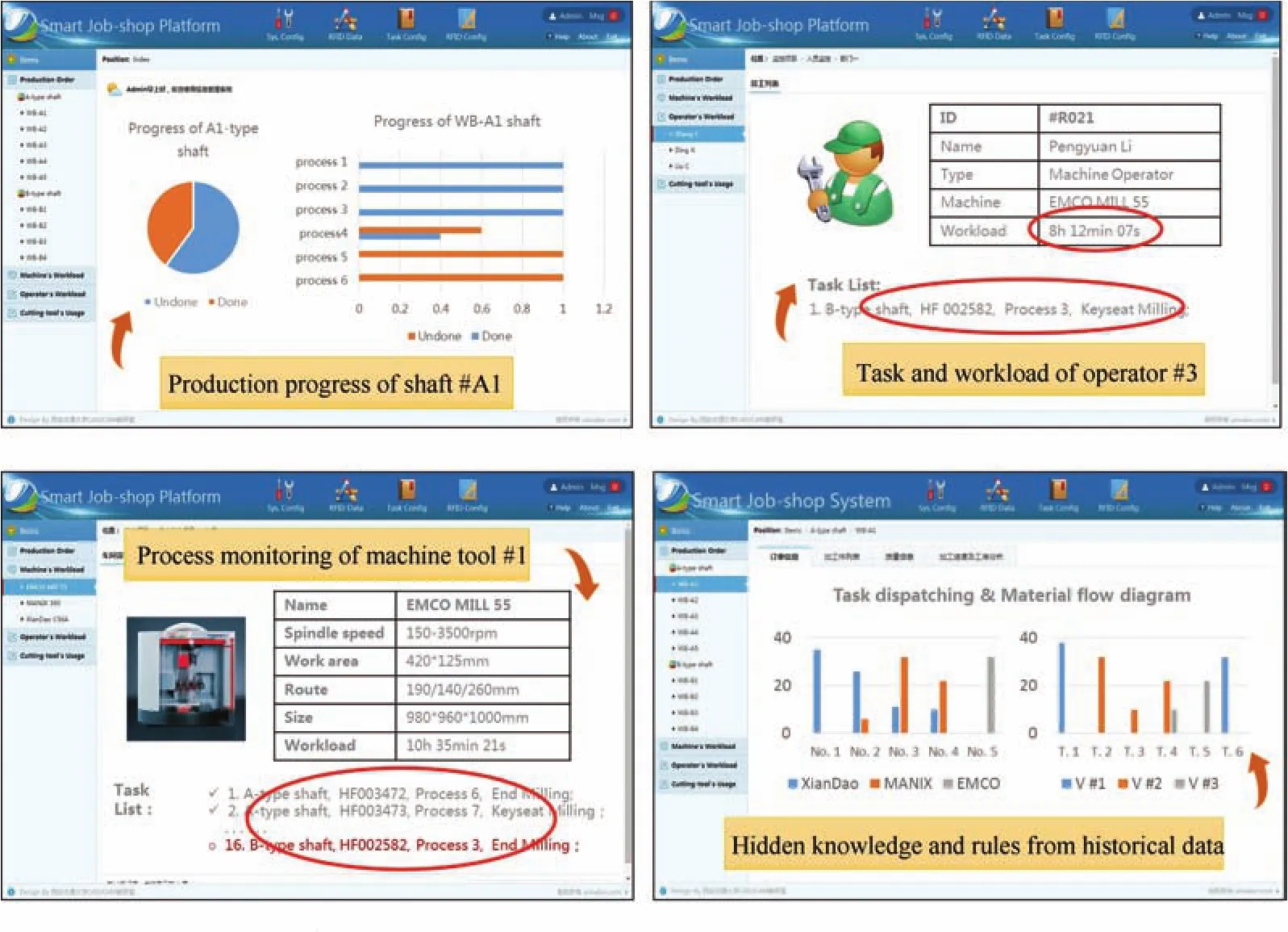

Fig.6 illustrates four snapshots of the prototype system for the demonstrative case.From the case,it can be seen that there are total six processes for shaft#A1.The production progress of#A1 reaches the fourth process,and this process has finished 40%(achieved by comparing the finished process time and the undone process time).Based on that,the total production progress of#A1 has reached 63%.The production information of other A-type shafts can be achieved too.From the view of workload,the detailed profile of operator#R021 is listed and his workload is 8h-12min-7s on that day,which is achieved by calculating the duration time of processes he undertakes(these data are derived from the RFID production data).The current task for him is No.3 process(keyseat milling)of the B-type shaft.Another kind of workload is the machine tool’s workload.The profile of EMCO M ill 55 is listed and its workload is 10h-35min-21s on that day.The current task of it is No.16 process(end milling)of the B-type shaft.This also can be used for process monitoring.

Fig.6.The snapshots of the demonstrative case.

Except for the above managerial implications,the realtime production control can be realized.For example,a data record in the database implies that#A2 shaft arrives at the wrong workstation,and the machine tool at this workstation cannot undertake its next process.Thus,an alert with detailed log pops up instantly in the system,which reminds the managers of unexpected events.Then,the smart WIP starts communicating with other machine tools in the smart jobshop to find a proper one according to the preset rules and incidence relationship matrix.After that,the process command is updated in the smart WIPs active RFID tag.Note that this kind of production control is real-time,autonomous,and transparent.

Finally,through big data analysis,some hidden rules and know ledge are achieved.As shown in Fig.6(d),the dispatching of different production processes can be exploited.For example,No.1 processes(end face rough turning)of A-type shafts are all taken by XianDao C56A.No.2−No.4 processes(excircle rough-turning,excircle semi-finishing-turning,and grooving)are taken by XianDao C56A and MANIX 360.The dispatching of these processes reveals the workload balance and the capability difference between these two machine tools.The mined information can be used for dynamic production plan and scheduling,which will lead to a harmonious production orchestration.From the view of transportation,the workload of vehicles and the transportation trajectories can be excavated from the transportation processes data,as shown in Fig.6(d).Vehicle#1 undertakes the external transportation tasks between warehouse and smart job-shop,while vehicle#2 and#3 undertake the internal transportation tasks among machine tools.It can be seen that vehicle#2 has bigger workload than vehicle#3,which causes disequilibrium between them.Thus,their work dispatching rules must be optimized to avoid transportation blocking.Except for that,some other know ledge and rules can be exploited from the historical data to assist production control.For example,by calculating the residence time of smart WIPs in the in-buffer and out-buffer of workstations,the production blocking in different workstations can be revealed.By establishing a deep neural network(DNN)-based processing time evaluation model,the standard machining time for different features with different machining parameters on different machine tools can be predicted.By calculating the workload of different cutting-tools,the cutting tool lifetime prediction model can be built to rem ind the tool changing.

V I.DISCUSSION

The shaft production in the IoT-enabled smart job-shop is described to verify the proposed model and methods.The collected production data are analyzed to excavate the hidden values,which assists the production control.From the results,it can be seen that the proposed model and methods are suitable for job-shop production management.However,there are still four issues of the proposed model and methods which need to be discussed and solved further:

1)Referring to the judgement rules discovering in the IoT-enabled smart job-shop production,the judgement conditions considered in this work is limited.More conditions and criteria derived from the real-time IoT data(e.g.,sensor data and actuator data)should be considered.It will make the process command execution and historical data mining more realistic and accurate.

2)This work gives limited alerts during production processes.A comprehensive alert system should be further developed to cooperate with the proposed system for real-time production control.If unexpected events or disturbances occur,the alert system will instantly send a message to relevant managers and smart WIPs.Furthermore,smart WIPs will coordinate with machine tools and other physical assets to adjust their plans,which is the quintessence of active RFID tags’autonomy feature.

3)This work considers a simple production case and a simple data collection environment in the IoT-enabled smart job-shop.Thus,the managerial implications from the case are limited.Actually,a more complex production environment of smart job-shop with more machine tools and physical assets,more kinds of smart WIPs,and more unexpected events such as order inserting and canceling should be discussed to test the stability and usability of the proposed model and methods.

4)This work just considers the intra-enterprise production situation.Under current social manufacturing environment[28],[29],the inter-enterprise production and collaboration are prevailing.Thus,a broader IoT-enabled collaborative manufacturing network should be developed for information sharing,and a broader data analysis method should be studied to analyze more inter-enterprise production data.Besides,the data interfaces and authority management need to be solved.

Combined with the issues above,our future work will be devoted to:1)the extension of the proposed model and methods to adapt to broader and more complex production situations at both the intra-enterprise level and the interenterprise level,2)the exploration of more judgement rules and managerial implications from industrial cases,and 3)the configuration optimization of IoT-enabled smart job-shops.A ll of them will embody the value of big RFID-based production data collected from the IoT-enabled smart job-shops.

V II.CONCLUSION

This work aims to provide an insight into the RFID-based production data analysis for production control in the IoT-enabled smart job-shops.The big RFID-based production data are excavated to find the hidden information,know ledge,and rules,which are invaluable for real-time production control and decision-makings.The scene of IoT-enabled smart job-shop production is firstly described,together with the configuration of RFID devices and other IoT facilities.Then,an RFID-based production data model is established to build the relationships among the heterogeneous production data.Based on that,the event-driven production data analysis method is discussed to judge the process command execution,and a near big data approach is applied to exploit information,know ledge,and rules from the historical production data.Based on that,the real-time production control can be realized,and production decision-makings can be optimized with the aid of the numerous hints from historical RFID-based production data.The demonstrative case has verified the feasibility and efficiency of our proposed model and methods.Finally,unsolved issues and future work are discussed to improve the proposed model and methods.

[1]ITU.Internet of Things Global Standards Initiative,2015.[Online].Available:http://www.itu.int/en/ITU-T/gsi/iot/Pages/default.aspx

[2]K.Ding,P.Y.Jiang,P.L.Sun,and C.Wang,“RFID-enabled physical object tracking in process flow based on an enhanced graphical deduction modeling method,”IEEE Trans.Syst.Man Cybern.Syst.,vol.47,no.11,pp.3006−3018,2017.doi:10.1109/TSMC.2016.2558104

[3]P.Y.Jiang and W.Cao,“An RFID-driven graphical formalized deduction for describing the time-sensitive state and position changes of work-inprogress material flows in a job-shop floor,”J.Manuf.Sci.Eng.,135,3,pp.031009,May 2013.

[4]R.Y.Zhong,Q.Y.Dai,T.Qu,G.J.Hu,and G.R.Huang,“RFID-enabled real-time manufacturing execution system for mass customization production,”Robot.Comput.-Integr.Manuf.,vol.29,no.2,pp.283−292,Apr.2013.

[5]T.Qu,H.D.Yang,G.Q.Huang,Y.F.Zhang,H.Luo,and W.Qin,“A case of implementing RFID-based real-time shop-floor material management for household electrical appliance manufacturers,”J.Intell.Manuf.,vol.23,no.6,pp.2343−2356,Dec.2012.

[6]F.Q.Zhang,P.Y.Jiang,M.Zheng,and W.Cao,“A performance evaluation method for radio frequency identification-based tracking network of job-shop-type work-in-process material flows,”Proc.Inst.Mech.Eng.Part B:J.Eng.Manuf.,vol.227,no.10,pp.1541−1557,Sep.2013.

[7]C.Saygin, “Adaptive inventory management using RFID data,”Int.J.Adv.Manuf.Technol.,vol.32,no.9,pp.1045−1051,Apr.2007.

[8]E.E.Ozguven and K.Ozbay,“An RFID-based inventory management framework for emergency relief operations,”Transp.Res.PartC:Emerg.Technol.,vol.57,pp.166−187,Aug.2015.

[9]R.Y.Zhong,Z.Li,L.Y.Pang,Y.Pan,T.Qu,and G.Q.Huang,“RFID-enabled real-time advanced planning and scheduling shell for production decision making,”Int.J.Comput.Integr.Manuf.,vol.26,no.7,pp.649−662,Jan.2013.

[10]W.K.Wong,Z.X.Guo,and S.Y.S.Leung,“Intelligent multi-objective decision-making model with RFID technology for production planning,”Int.J.Product.Econom.,vol.147,pp.647−658,Jan.2014.

[11]Z.X.Guo,E.W.T.Ngai,C.Yang,and X.D.Liang,“An RFID-based intelligent decision support system architecture for production monitoring and scheduling in a distributed manufacturing environment,”Int.J.Product.Econom.,vol.159,pp.16−28,Jan.2015.

[12]J.Lyu,Jr.,S.Y.Chang,and T.L.Chen,“Integrating RFID with quality assurance system – framework and applications,”Exp.Syst.Appl.,vol.36,no.8,pp.10877−10882,Oct.2009.

[13]Y.B.Fu and P.Y.Jiang,“RFID based e-quality tracking in serviceoriented manufacturing execution system,”Chin.J.Mech.Eng.,vol.25,no.5,pp.974−981,Sep.2012.

[14]H.B.Cai,A.R.Andoh,X.Su,and S.Li,“A boundary condition based algorithm for locating construction site objects using RFID and GPS,”Adv.Eng.Inform.,vol.28 no.4,pp.455−468,Oct.2014.

[15]C.Wang,P.Y.Jiang,and K.Ding,“A hybrid-data-on-tag-enabled decentralized control system for flexible smart workpiece manufacturing shop floors,”Proc.Inst.Mech.Eng.Part C:J.Mech.Eng.Sci.,to be published.doi:10.1177/0954406215620452

[16]C.C.Aggarwal and J.W.Han.A survey of RFID data processing,”inManaging and Mining Sensor Data,C.C.Aggarwal,Ed.New York:Springer,2013,pp.349−382.

[17]R.Y.Zhong,G.Q.Huang,S.L.Lan,Q.Y.Dai,X.Chen,and T.Zhang,“A big data approach for logistics trajectory discovery from RFID-enabled production data,”Int.J.Product.Econom.,vol.165,pp.260−272,Jul.2015.

[18]R.Y.Zhong,S.L.Lan,C.Xu,Q.Y.Dai,and G.Q.Huang,“Visualization of RFID-enabled shopfloor logistics Big Data in Cloud Manufacturing,”Int.J.Adv.Manuf.Technol.,vol.84,no.1,pp.5−16,Apr.2016.

[19]K.Katchasuwanmanee,R.Bateman,and K.Cheng,“Development of the Energy-smart Production Management system(e-ProMan):A big data driven approach,analysis and optim isation,”Proc.Inst.Mech.Eng.Part B:J.Eng.Manuf.,vol.230,no.5,pp.972−978,May 2016.

[20]P.Y.Jiang,Y.B.Fu,Q.Q.Zhu and M.Zheng,“Event-driven graphical representative schema for job-shop-type material flows and data computing using automatic identification of radio frequency identification tags,”Proc.Inst.Mech.Eng.Part B:J.Eng.Manuf.,vol.226,no.2,pp.339−352,Feb.2012.

[21]I.A.T.Hashem,I.Yaqoob,N.B.Anuar,S.Mokhtar,A.Gani,and S.U.Khan,“The rise of ig data on cloud computing:Review and open research issues,”Inform.Syst.,vol.47,pp.98−115,Jan.2015.

[22]M.A.Hernandez,“A generalization of band joins and the merge/purge problem,”Department of Computer Science,Columbia University,Technical Report CUCS-005-1995,1995.

[23]C.Wang and P.Y.Jiang,“Manifold learning based rescheduling decision mechanism for recessive disturbances in RFID-driven job shops,”J.Intell.Manuf.,to be published.doi:10.1007/s10845-016-1194-1

[24]J.R.Quinlan,C4.5:Programs for Machine Learning.San Mateo,CA:Morgan Kaufman Publishers Inc.,1993.

[25]Y.-R.Shiue,“Data-mining-based dynamic dispatching rule selection mechanism for shop floor control systems using a support vector machine approach,”Int.J.Prod.Res.,vol.47,no.13,pp.3669−3690,Jul.2009.

[26]H.N.Chen,Y.L.Zhu,K.Y.Hu,and T.Ku,“RFID network planning using a multi-swarm optimizer,”J.Netw.Comput.Appl.,vol.34,no.3,pp.888−901,May2011.

[27]D.Cires¸an,U.Meier,J.Masci,and J.Schm idhuber, “Multi-column deep neural network for traffic sign classification,”Neural Netw.,vol.32,pp.333−338,Aug.2012.

[28]P.Y.Jiang,K.Ding,and J.W.Leng,“Towards a cyber-physical social-connected and service-oriented manufacturing paradigm:Social Manufacturing,”Manuf.Lett.,vol.7,pp.15−21,Jan.2016.

[29]P.Y.Jiang,J.W.Leng,K.Ding,P.H.Gu,and Y.Koren,“Social manufacturing as a sustainable paradigm for mass individualization,”Proc.Inst.Mech.Eng.PartB:J.Eng.Manuf.,vol.230,no.10,pp.1961−1968,Sep.2016.

杂志排行

IEEE/CAA Journal of Automatica Sinica的其它文章

- Encoding-Decoding-Based Control and Filtering of Networked Systems:Insights,Developments and Opportunities

- Internet of Vehicles in Big Data Era

- Residential Energy Scheduling for Variable Weather Solar Energy Based on AdaptiveDynamic Programming

- From Mind to Products:Towards Social Manufacturing and Service

- Analysis of Autopilot Disengagements Occurring During Autonomous Vehicle Testing

- A Methodology for Reliability of WSN Based on Software De fined Network in Adaptive Industrial Environment