From Mind to Products:Towards Social Manufacturing and Service

2018-01-26GangXiongFeiYueWangTimoNybergXiuqinShangMengchuZhouZhenShenShuangshuangLiandChaoGuo

Gang Xiong,Fei-Yue Wang,Timo R.Nyberg,Xiuqin Shang,Mengchu Zhou,Zhen Shen,Shuangshuang Li,and Chao Guo

I.INTRODUCTION

BEFORE 1760s,many wanted products could not be made out at all;some domestic articles like clothing,shoes and knives,were made by producers one by one at either home or private workshop manually or with simple tools,for themselves or customers nearby,which was named as a craft production(CP)mode.The first industrial revolutionstarted from UK in the 17th century.The new equipment like steamers and other machinery led to a mechanical Mass Production(MP)mode.Scarce products like carriages were made in public factories by producers for more customers;the second industrial revolution happened during 1870s-1980s,internal combustion engine,electrical devices and production lines led to an electrical MP mode.Mass products like cars and airplanes were made by manufacturers in mass factories to fulfill the customers’common requirements;a MP mode is suitable for standardized products in big quantities.It represented a main stream before 1980s.The third industrial revolution happened during 1980s-2010s,the new tools like electrics,automatic devices and production lines,and manufacturing management systems led to a mass customization(MC)mode[1]−[5],where mass customized products like shoes and clothes are designed and made by the networked factories to fulfill the different product needs of different customers.The MC mode is suitable for mass customized products or services.It has been adopted by more and more industries to meet mass customer-specific requirements since 1980s.The development history of industrial manufacturing can be summarized as Fig.1.

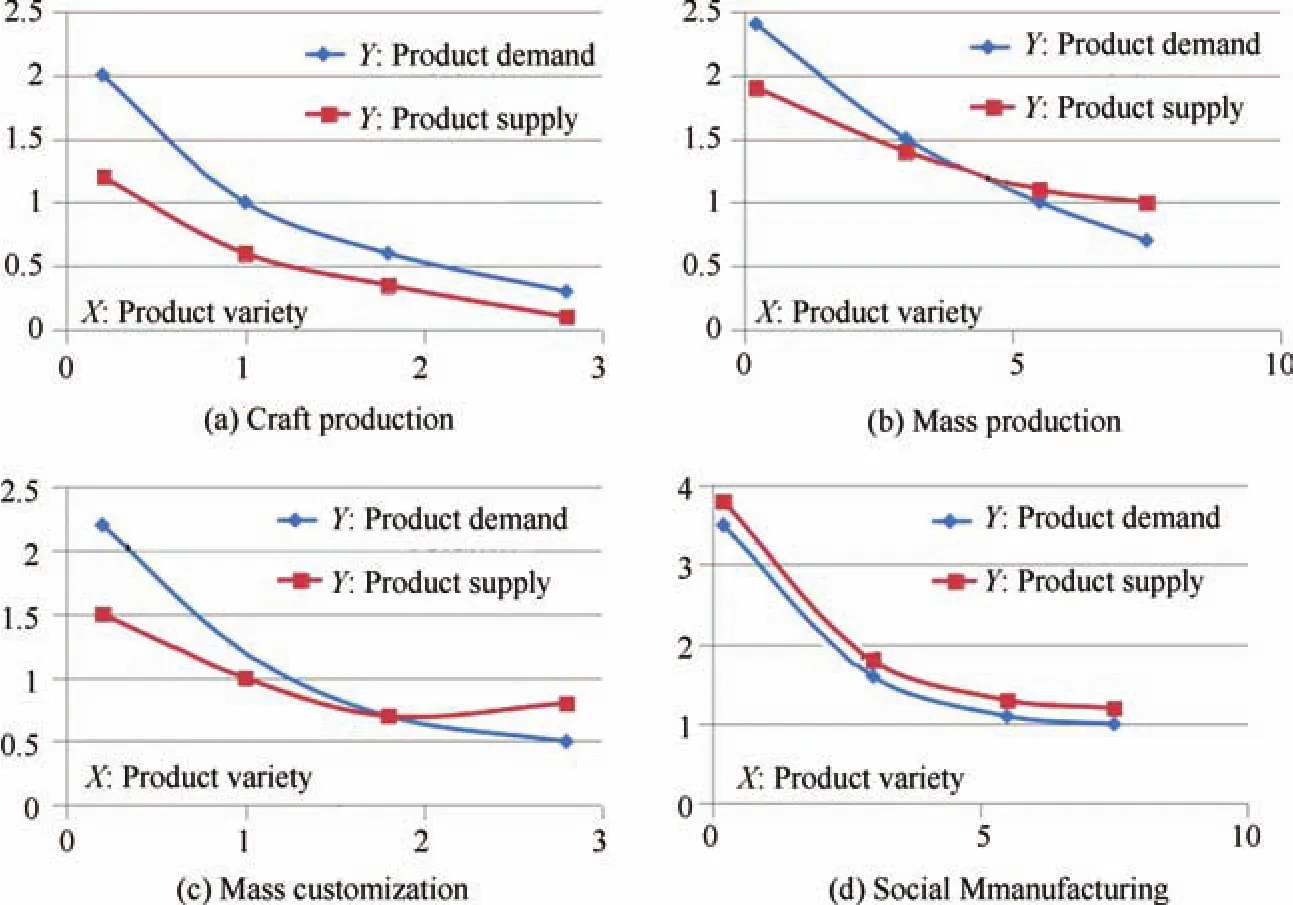

The demand and supply relationship for a single customer under different manufacturing modes of CP,MP,MC and SM is shown in Fig.2.If the supply volume approximates the demand volume,it means that the supply can meet the demand;otherwise supply cannot meet the demand.Take clothing industry as an example,CP could not make enough clothing to meet customers’needs.MP could make enough clothing to meet their common and material need,but could not meet their customized or spiritual needs.MC could make enough clothing to meet the predefined material and spiritual needs,but still could not meet their personalized and spiritual needs completely.For personal consumption articles like clothing,their spiritual needs like suiting the fashion become more important than their material needs like body protection and keeping warm.The newly emerging SM,however,promises to enable to satisfy their personal needs completely.

This paper is organized as follows:Section I retrospect the manufacturing history.Section II presents the state of manufacturing industry and describes the need for SM and service in both demand and technical aspects.Section III introduces the basic theory,key technologies and system platform of SM.Section IV proposes three types of SM modes.Section V concludes this paper and gives future work.

Fig.1.Development history of industrial manufacturing.

Fig.2.Demand and supply relationship for a single customer under different manufacturing modes.

II.SOCIAL MANUFACTURING AND SERVICE

In 1990s,shortage of light industries in various degrees was experienced in the global market,especially in the developing countries market.Customers outnumbered the amount of products the manufactures could make.Those manufacturers in developing countries,like China and Mexico,started to win the marketing competitiveness in middle and low-end products,because they could apply the MP mode to make much cheaper mass products with lower labor,R&D,material and production cost and looser environment protection regulation.The manufacturers in the developed countries and regions had to transform into MC mode to keep their marketing competitiveness in high-end products.From 2010,product surplus appeared in the global market.In other words,global manufacturers made more products than customers could buy and consume.MP and MC migated to those new region,e.g.,Vietnam and African countries.So,a novel production mode should be created for those manufacturers in developed and some previous developing countries like China.

Since 2010s,cyber-physical system(CPS),cyber-physical social system(CPSS)and Industry 4.0/5.0 have emerged and become hot research and industrial practice topics[6]−[9].In manufacturing industry,the latest supporting technologies like Internet of Things(IoT),social networks,cloud computing,3D Printing,and knowledge based intelligent systems,led to an innovative SM mode[10]−[14],where physical manufacturing facility,capacity and social factors are reflected into a manufacturing cyber space.There appears a new concept called a“prosumer”,a person who consumes and produces a product and service[15],[16].It is derived from “prosumption”,a dotcom era business term meaning “production by consumers”.These terms were coined by American futurist Alvin Toffler[17],and were widely used by many technology writers of the time.Every prosumer can design the personalized products like apparel,shoes,or portraiture online for his/her own need with some way like game playing.A personalized product can be made by pressing a “MAKE”button while the actual“making”requires intelligent SM facilities like cloud based virtual factories and the networked 3D printers.It is likely that 3D printing and SM together represent a new wave of industrial revolution.

In an SM era,the coordinative creativity of common crowd can be stimulated with the aid of SM platforms and newly emerging nonhierarchical organizations.The increasingly networked global economy is forcing companies and nations to think beyond the concepts of traditional supply chains,and view their environment as rapidly evolving business ecosystems in which suppliers and customers are embedded into a network to co-create product values.At the end of the traditional value chain is a customer whose needs are fulfilled through mass-customization.In an SM value chain,by contrast,a customer is not only a “product or service taker”at the end of the chain,but also be significantly involved in the preceding phases,such as R&D,design,component manufacturing,logistics,sales and marketing,after-sales services and product recycling.And the customer needs are sought and fulfilled through the co-created and distributed value networks.In the SM paradigm,the importance and utilization of design,social connectedness,and latent resources are accentuated with the help of the latest supporting technologies.Successful businesses built upon such paradigm have already appeared in the fields like finance,healthcare,and transportation:new bank(ING Direct)was born without physical branch of fices;the world’s greatest hotel chain(AirBnB)does not own a single room,and a taxi company(like Uber or Didi)does not have its own cars or drivers.How could this new paradigm be employed elsewhere?Currently,over 70%of shoes do not fully fit feet of customers,many clothing do not fully fit a customer’s body and other requirements.Hence,SM becomes useful for apparel and fashion industry.SM is not simply a technological revolution,but also a social and economic transformation of changing our organizing way to produce what we need in human societies.

An SM mode can help the sustainable,healthy and green development of human societies[18].SM satisfies a customer’s individual needs and effectively meets the customer’s material needs.So it can save material and energy,and reduce the environmental pollution accordingly.With the support of SM platforms including a social network,cloud platform,and smart mobile terminals,all SM stakeholders like consumers,designers,players,makers,suppliers,brokers,and different service providers,can join win-win collaboration by simply clicking those different function buttons.

Production automation relieves people’s physical labor work using their hands,and knowledge automation partially relieves people’s innovative work using their brains.With the continuous accumulation of manufacturing related knowledge,experience,and wisdom of all the human beings in an SM’s cyber space,most manufacturing participants will become game players in some part of their working time.Nearly any kind of products or services can be produced by a prosumer from the SM’s cyber space on demand.

SM is an important trend of manufacturing[19]−[20],which is proven by other similar manufacturing modes,like sustainable production[21],cloud manufacturing[22]−[25],mass personalization[26],and customization.

A.SM VS MC

SM brings social networks into the manufacturing field.More and more people can complete SM’s activities together online,like product design,communication and data exchange,and product evaluation.

Through network technology,crowd sourcing and 3D printing,dynamically networked crowd can participate in various product lifecycle processes,e.g.,personalized product design,modeling,and manufacturing.In the SM mode,search engine is the core across all the manufacturing processes.Traditional manufacturing is transformed into intelligent manufacturing that can actively collect and respond to a customer’s demand for a personalized product or service.

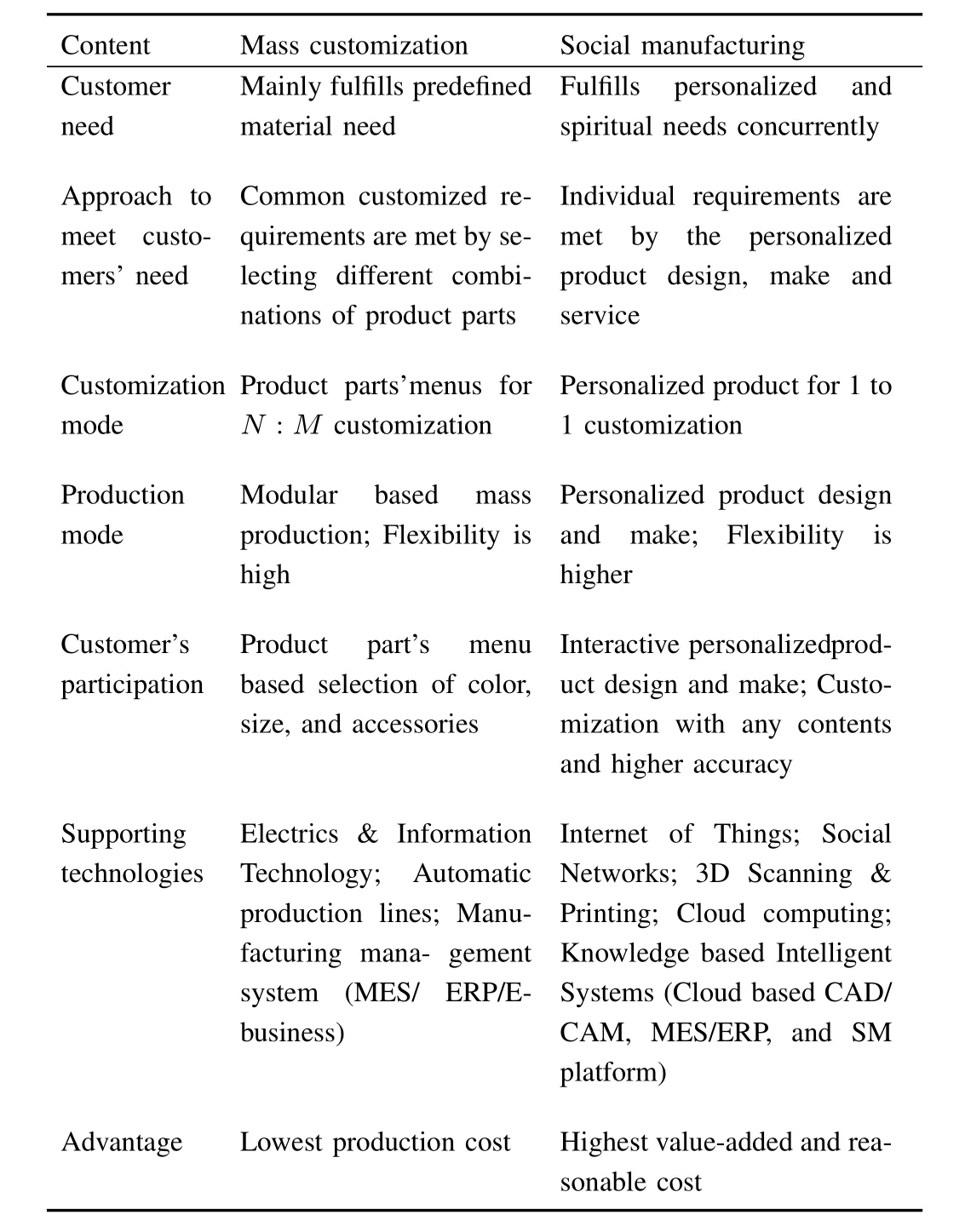

Comparison results between MC and SM are summarized in Table I.The traditional manufacturing industry mainly considers scale in order to reduce the product cost rather than the customers’individual demands.MC can meet simple individual demands like the colors and sizes.However,SM is making every effort to overcome the weaknesses of traditional manufacturing by fully realizing the long tail value[27]−[28]as shown in Fig.3.More specifically,by using MC,one common product can only be divided into the sub-group products whose count is denoted as parameterNaccording to different requirements of different customers’groups whose count is defined as parameterM,where MC becomes more expensive ifNandMare smaller numbers.MC becomes impossible whenNandMexceed their minimum limitation.SM aims to fulfill every customer’s personalized needs through fully personalized(or tailored)products or service,where previousN:Mbecomes 1:1.By using additive manufacturing,the manufacturing cost of personalized products can be reduced,to meet nearly all needs of product users,and can thus improve the manufacturing competitiveness greatly.

Fig.3.SM vs traditional manufacturing.

In MC,a customer can choose the product parts and configuration,but not a product design.The product is designed by the product designers normally hired by manufacturers,not by customers or social designers.An SM platform can be updated from MC,where a product can be designed by customers or according to their instruction across the Internet.In SM,customer can self design his/her product or buy product designs, find and choose product makers or service providers.Social designers can show and sell the product designs and services to customers and makers.

TABLE I COMPARISON BETWEENSMANDMC

3D technologies,like 3D scanner,3D CAD/CAM software,3D display,and virtual reality,support the interactive 3D design of a personalized product.Additive manufacturing can support enormous and various manufacturing tasks.Additive manufacturing includes 3D printing and rapid prototyping technology.

B.From Social Computing to Social Manufacturing

As social computing[29]lets everyone obtain computing capacity in the society,SM lets everyone obtain innovation and manufacturing capacity.In an SM era,personalized products become popular and profitable,where social customers’needs are seamlessly linked with the SM industry’s supply capacity in real-time.Most resources about product innovation,manufacturing and consumption can be found by searching Internet.Internet based search is clearly an important capability.Reductive manufacturing depends on the production scale to reduce the cost.But vast majority of the personalized products belong to Long Tail in Fig.3,which were classified as handmade luxury items in the past.For personal demand,3D printing has become an economic solution of SM products,e.g.,the foot last in footwear industry,while most mass production modes become outdated.

3D printing becomes a popular manufacturing mode with its performance improvement and cost decline.Future giant companies are expected to enter the additive manufacturing industry.They will likely grow up into today’s Microsoft,Amazon,Google,Facebook,and Alibaba.Google relies on computer server array scale to meet users’information search needs,thus changing the human life and work greatly.In the same way,large-scale SM arrays as illustrated in Fig.4,consisting of 3D printers and cloud-based production innovation and manufacturing platforms,can meet the personalized product needs conveniently in real-time,and thus change our society profoundly.As shown in Fig.4,designer,consumer and producer work online,while 3D printers are distributed like the servers in cloud computing.This is why 3D printing will change our manufacturing world;and why SM may bring about another industrial revolution.

Fig.4.Social manufacturing array with 3D printing centers.

Clearly,the biggest advantage of SM is its capability to transform mind into products directly,and so anyone can participate in the whole process like product design,improvement,publicity,promotion,and marketing through social media and other forms of crowd sourcing package,and can share the product pro fits according to every partner’s contribution.In other words,SM realizes the personalized,realtime,economical production and consumption patterns via 3D printing,network technology,social media,crowd sourcing,etc.to enable everybody on the earth to fully participate in the whole manufacturing lifecycle processes of his/her personalized product.

SM meets some challenges,for example how to“make initial match”between social demands and manufacturing ability in real-time,and how to support the conversion process from product demand to product supply effectively.After the transformation from social computing to SM is realized,the network space and social media can provide the basic conditions and more favorable guarantee for the corresponding integration task of a product’s full lifecycles,e.g.,product,design,manufacturing and service.

Compared with the cloud manufacturing(CM)[22]−[25],[30],[31],SM is very different.CM does not change the manufacturing mode but puts the traditional manufacturing activities on line by using the cloud technology,while SM completely changes the manufacturing mode,and from design to manufacturing,all activities can be executed online by crowd sourcing.In short,social computing and 3D printing are the important supporting technologies for SM to become a popular production mode for the future.Only after embedding social computing method in an SM process,the additive manufacturing and SM can possibly lead to a great industrial revolution.

III.BASIC THEORIES AND SUPPORTING TECHNOLOGIES

A.Key Research Themes and Disciplines

The key research topics of SM are shown in Table II[32]−[34].They include four research themes, five disciplines,and their corresponding research issues.The four research themes are discussed next.

1)Network structure for SM:How will the manufacturing globalization trend continue?The future may bring a new wave of manufacturing localization that can take place either in certain clusters or globally.Hence,the suitable SM’s network structures,the most promising trends and their interrelations with the chosen theme areas,should be researched through multidisciplinary investigations,and then further operational business planning can be performed.

2)SM agility:Manufacturing networks,in their desired state,need to be so agile that no matter what the future global trend driving the location and network structure decisions will be,SM adapts to the emerging trends and requirements.SM networks provide a new networking paradigm under which they co-evolve with the environment,and then a loss of fit can be prevented from occurring.Transdisciplinary investigation and a unique set of methodological tools should increase the understanding of factors affecting and driving the agility of SM networks.

3)Consumer-driven value creation and value capture dynamics:The traditional fixed production paradigm is production-driven.In contrast,SM networks are inherently consumer-driven and consequently their whole structure,organization,and processes,i.e.,R&D,production,and marketing,are derived backwards from the customer needs and related business opportunities.SM networks are proactive,and always ready to satisfy the emerging needs.Thus,consumer-driven value creation and capture dynamics should be understood,by utilizing a set of purpose-specific tools and methods built with knowledge from multi-disciplines.

4)Individuals,societies,cultures,and nations in SM networks:Traditionally,the focus on network paradigms and related industrial designs has mainly been on processes and their corresponding equipment,thus paying no attention to the role of individuals and related collective entities.In the future,however,the individualistic factor will likely play an increasingly critical role.Therefore,the role of human factors in SM networks should be unraveled,based mostly on psychology and cognitive sciences.In order to achieve and maintain the proactive mode,solution providers need relevant individual and collective human behavior knowledge that has some early strategic value.These future knowledge demands and needs for data sharing business model innovations should be analyzed.

B.Basic Theories

1)Modeling and analysis of SM system:Main system functions include SM’s big data acquisition and social computing analysis;SM’s human behavior modeling and analysis;SM’s enterprise behavior modeling and analysis;complex dynamic modeling technology and system analysis of all SM’s components;infrastructure design and analysis including all SM’s components;SM’s industry chain,value chain and business mode design and analysis;SM’s intelligent manufacturing systems,smart enterprise design and analysis;SM’s control and management;and SM’s knowledge management and strategy management.

2)SM system development and pilot verification:Main research topics include the upon four points.

a)Social design of complex personalized products in a network environment,including 3D scanning and modeling;human-machine interaction for personalized product testing by using 3D virtual reality;and social design platform for complex personalized products in a network environment.

b)SM of complex personalized products in a network environment,including a product’s customization for everyone via 3D printing;and intelligent manufacturing technologies like IoT,3D modeling,Product Lifecycle Management(PLM),and dynamic partnership.

c)Social service of complex personalized products in a network environment,including E-business;demand supply chain;and personalized service.

d)Pilot verification of SM,including an integrated platform for social product design,manufacturing and service.For example,personalized wearable products can be selected as a pilot project to verify the actual application value of the R&D results.

C.Supporting Technologies

SM includes some key technologies like collaborative technology,service oriented architecture(SOA),work flow technology,model driven architecture(MDA)technology,collaborative management systems,enterprise modeling methods,and additive manufacturing,which together make everyone in the whole society possess manufacturing capacity.Networkbased collaborative manufacturing service and 3D printing technologies are the important symbols of SM.The SM’s main research challenge is how to effectively make use of dynamic netizen group(DNG)[35]−[37],which can be defined as the person groups who dynamically access the same Internet for the similar interests or purposes.Through DNG’s crowd sourcing and distributed cooperative forms,the combination of network-based collaborative manufacturing services and 3D printing technology can be realized.Several supporting technologies are discussed.

1)DNG detection:With data collection,storage,fusion and analysis,we can detect DNG’s hot trend,its dissemination and evaluation;DNG’s population types,distribution,organizational structure and social network relationship;the interactivebehavior and product consumption trait of individual Internet user.

TABLE II FOUR RESEARCH THEMES,FIVE DISCIPLINES,AND THEIR RESEARCH ISSUES

2)SM’s modeling for system construction:For SM’s system construction and verification,we should research the evolution modeling of DNG’s online/offline behavior and SM’s hot trends,the crowd sourcing modeling and simulation of SM’s ecosystem.To provide the decision-making basis for SM’s control and management,we need to reveal the relationship between SM’s complex network structure characteristics and social media communication mechanisms.

3)SM’s system analysis and evaluation:The analysis and evaluation of DNG’s management mechanisms and strategies help explore the hot spot formation mechanism and development trend in the network society.The analysis and performance evaluation of SM’s distributive cooperation mechanisms and logistics processes help explore its dynamic response and corresponding control and management method.

4)Collaborative modeling of DNG and 3D printing:With more ICT technologies and social factors being introduced,the existing business modeling framework has deficiencies for modeling SM’s new factors.For example,the SM network is more complex than the most of existing frameworks,which refers to social networks,IoT,3D printing and so on.In order to overcome such deficiencies,we have to develop collaborative models and modeling systems for DNG’s collaboration and 3D printing collaboration.

5)Collaborative mechanism of DNG and 3D printing:Based on the collaborative mechanism and model of crowd sourcing,a work flow engine and service oriented SM framework can support the collaboration among DNGs by providing such functions as the collaboration of crowd sourcing processes,the service calls and their combination,the distributed and cooperative 3D printers,and human-computer interaction.Then,DNG can help for product innovation,design,manufacturing,and service.

D.Social Manufacturing Platform

An SM platform integrates business processes including product demand,design,R&D,make,to provide services to consumers,designers,makers and shop operators.It is composed of the following five subsystems:

1)Big data analysis subsystem:There is a free,orderly,increasingly fierce “collision”among all kinds of social resources,thereby producing the big data with dynamics,diversity,actual and virtual interactions,complexity,uncertainty,and explosive growth.In order to make effective use of big data,the theory and technology like machine learning,data mining,pattern recognition,and artificial intelligence,should be researched to find intelligent information processing mechanisms suitable for SM big data.

2)Business intelligence subsystem based on cyber-enabled movement organizations(CMO):In order to meet the personalized needs of billions of customers,previous“passive response to a customer’s product needs”should be changed into“active search for a customer’s product needs”in an SM mode.We have to monitor the business focus area,i.e.,the interest points of DNG should be monitored constantly and identified quickly and accurately.This requires a business intelligence subsystem based on CMO which consists of massive data and high speed circulation analysis,CMO modeling component,its artificial system,and computational experiments.

3)Personalized recommendation subsystem:The subsystem is an advanced business intelligence platform built upon the big data analysis subsystem,to provide the individualized decision support and information service for SM platform users.Its personalized promotion function can provide the innovation or product recommendations according to the user’s behavioral characteristics,and realize the personalized advertisement display function dynamically for an intelligent advertisement marketing system.The user behavior data collected by the subsystem,as well as the resource data in the SM platform,should be processed for the structured storage into the existing databases and servers.The subsystem provides recommendation rules suitable for user’s behavior,customer demand and commodity attributes.The subsystem recommends users the needed products,innovation and advertisements,according to their current behavior and demand preference changes.

4)Intelligent advertisement marketing subsystem:By using the user interest models in the personalized recommendation subsystem(PRS),the subsystem can accurately calculate the user type,interests,and features of suitable advertisements.By integrating all of its online advertisements,we enable the products or innovations of the SM platform to attract more users and promote the purchasing by using more accurate network marketing,like search bidding,real-time auction,SNS marketing,search engine optimization,mobile advertisement,and advertisement display.

IV.TOWARDS SOCIAL MANUFACTURING AND3D PRINTING

There exist three types of SM modes:Type 1 SM mode is supported by traditional(reductive)manufacturing;Type 2 SM mode is supported by 3D printer(additive manufacturing);and Type 3 SM mode is supported by both the reductive manufacturing and additive manufacturing,where some parts of a product should be made by Type 1 SM mode,and others made by Type 2 SM mode.

A.Type 1 SM Mode

Type 1 SM mode is supported by reductive manufacturing.Traditionally,a customer selects and buys a product that was designed and made by manufacturers.The customer can go to a shopping mall,select and test a product,pay and own it.Alternatively,the customer can login to an E-business platform like eBay or Alibaba etc.,select and pay for the product.Then the product is delivered to the customer-supplied address by logistics provider,like DHL or EXPRESS etc.

In Type 1 SM mode,we take shoes as an example.When every shoe designer and maker provides 3D model data with every pair of shoes on his/her SM platform’s account,every customer provides 3D model data of his/her feet and save the data into his/her SM platform’s account.Then,SM platform can compare 3D model data of the selected shoe and his/her feet automatically;the customer then can easily find his/her fittest shoes.When the customer wants to design and make his/her personalized shoes with the support of SM platform,he/she should measure and save the 3D model data of his/her feet first,then can create a desired shoes design or buy from others, find the shoe maker,pay for the shoe making,and then the product is made and delivered to the given address.The detailed technologies,solution and application case is described in our new paper of“Moving from mass customization to social manufacturing:a footwear industry case study”.And,our research and development result about the SM for apparel industry is written as our new paper“Social manufacturing cloud for high-end apparel customization”[13].

Fig.5.Type 1 SM platform without 3D printing.

As shown in Fig.5,product design and management functions are added to the existing e-business platform,where every customer can design his/her personalized product interactively by measuring all parameters and deciding many options;and send the product data to a product maker whenever necessary.Since CAD/product data management(PDM)tool,product data and supporting functions exist in the SM platform and terminals,customers can easily join a product design/choice process,and product design cost can be reduced from a product maker’s viewpoint.

B.Type 2 SM mode

Type 2 SM mode is supported by 3D printer.3D scanning and display technology can greatly enhance the“humanmachine interaction”quality.A complex and personalized product can be designed online,and a customer’s spiritual need can be met;during the product design stage,a product can be tested and its user experience can be achieved virtually and interactively with 3D model display.The user’s desires can be simulated and product consumption is then increased.When a product is wanted,customers just open the product data file and press“PRINT”button,and then the product can be printed out.

To support the three types of users including product consumers,designers or creators,and online shop operators,the SM platform team at Institute of Automation,Chinese Academy of Sciences has developed such functions as“3D Mall”, “Innovation Bar”,and “Online Shop Operators”.In addition,the SM platform also contains a 3D model search engine-“Search 3D”as shown in Fig.6.

1)3D mall:3D Mall provides consumers with various types of services especially for 3D E-business affairs,like 3D model printing.Consumers can purchase the products existing in the 3D mall;or print out the product by using their own 3D model file.Consumers can also provide their product specification and specify their demands.Then,the operator of the SM platform reviews and con firms the demand,organizes creators to design 3D product models to meet their demands.

Fig.6.Type 2 SM platform with 3D printing.

2)Innovation bar:Innovation Bar provides a 3D product design and communication online channel,where creators can propose and submit their 3D product innovation,and then the operator decides to improve or not,and to print it into a 3D product or not by using an online voting way.In the business operation process,every valuable creator can earn the corresponding income through selling the innovations existing in any process from its birth to move towards the market.As long as members provide a positive contribution to the creative product,they will obtain the corresponding creativity scores according to their contribution.Real-time measurement of the creativity scores can be executed in such processes as the innovation submission,innovation improvement,product naming,product slogans,voting,and comments.After the innovation or 3D products are sold,all contributing members can earn the corresponding income according to their creativity scores.

3)Online shop operators:The module provides a platform to Online Shop Operators,through the third party’s audit.Everyone can open his/her own online shop,and provides different services and products about 3D printing.

4)Search 3D:Search 3D is a search engine specifically for 3D model file search,and such files can support users with direct online-printing or download for offline-printing.It can obtain 3D product printing capability automatically,without the interaction with a service provider.

C.Type 3 SM mode

Type 3 is supported by both the reductive manufacturing and additive manufacturing,where some parts of a product should be made by Type 1 SM mode,and others made by Type 2 SM mode.So,if the reductive manufacturing plays a dominant role in the whole manufacturing,Type 3 SM mode changes into Type 1 SM mode.If the additive manufacturing plays a dominant role in the whole manufacturing,Type 3 SM mode changes into Type 2 SM mode.

For every industry and enterprise,suitable transformation mode should be selected from Type 1,2 or 3 SM mode.In the case of footwear industry mainly supported by the reductive manufacturing,suitable transformation mode is Type 1 SM mode.While if the sole and insole parts of shoes are made mainly by 3D printer,then the suitable transformation mode of footwear industry should be Type 3 SM mode.

V.CONCLUSION AND FUTURE WORK

IoT and social networks connect nearly everyone and everything,cloud-based intelligent systems help prosumers design and enjoy any kind of personalized products,and 3D printer can make many products designed online.All of them are important parts to support SM.In SM,the traditional relationships among customer,designer,manufacturer and seller are transformed dramatically through the SM platforms.Customers become prosumers,and prosumers’innovation capacity motivates the whole SM process,instead of only a producer’s capacity in traditional manufacturing.Through bidding strategies,product manufacturers can provide online product innovation and design platforms for customers and external designers with the existing internal E-business or platforms.Platforms can be integrated into their internal information system and external customer service platform,to provide all necessary functions of a complete demand supply network to external partners.So,SM platform can be built up reasonably for SM business operation.

Definitively,SM is coming with the increasing demands for the personalized products and services.In the future,SM has more and more applications and prospects in the personalized products and services,such as wearable product,consumer electronics,jewelry,medical product,and even education etc.It is of profound theoretical and practical significance to further research the SM’s key theories and technologies,and construct and operate SM’s key application platforms.

[1]A.Kumar,S.Gattoufi,and A.Reisman,“Mass customization research:Trends,directions,diffusion intensity,and taxonomic frameworks,”Int.J.Flex.Manuf.Syst.,vol.19,no.4,pp.637−665,Dec.2007.

[2]T.Blecker and G.Friedrich,“Guest editorial:Mass customization manufacturing systems,”IEEE Trans.Eng.Manage.,vol.54,no.1,pp.4−11,Feb.2007.

[3]G.Xiong,D.Fan,S.Liu,T.R.Nyberg,and F.Y.Wang,“Mass customization manufacturing solution for cell phone production,”inProc.IEEE International Conf.Automation and Logistics,Hong Kong,Macau,China,2010,pp.518−523.

[4]F.S.Fogliatto,G.J.C.da Silveira,and D.Borenstein,“The mass customization decade:An updated review of the literature,”Int.J.Prod.Econ.,vol.138,no.1,pp.14−25,Jul.2012.

[5]L.J.Anderson-Connell,P.V.Ulrich,and E.L.Brannon,“A consumerdriven model for mass customization in the apparel market,”J.Fashion Mark.Manage.,vol.6,no.3,pp.240−258,2002.

[6]H.Kagermann,W.Wahlster,and J.Helbig,“Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0:Securing the future of German manufacturing industry,”National Academy of Science and Engineering,Mnchen,Germany,Final Report of the Industries 4.0 Working Group,2013.

[7]National Science Foundation, “Cyber-physical systems(CPS),”US National Science Foundation, Program Solicitation NSF 10−515, Mar. 11, 2010. [Online]. Available:http://www.nsf.gov/pubs/2008/nsf08611/nsf08611.htm.

[8]H.Hoenninger and J.Angel,“Industrial visions for cyber-physical systems(CPS),”inInternational Conference on Cyber-Physical Systems:Uplifting Europe’s Innovation Capacity,Brussels,Oct.29−30,2013.[Online].Available:http://ec.europa.eu/digital-agenda/.

[9]F.Y.Wang,“The emergence of intelligent enterprises:From CPS to CPSS,”IEEE Intell.Syst.,vol.25,no.4,pp.85−88,Jul.-Aug.2010.

[10]F.Y.Wang,“From social computing to social manufacturing:The coming industrial revolution and new frontier in cyber-physical-social space,”Bull.Chin.Acad.Sci.,vol.27,no.6,pp.658−669,2012.

[11]X.Q.Shang,X.W.Liu,G.Xiong,C.J.Cheng,Y.H.Ma,and T.R.Nyberg,“Social manufacturing cloud service platform for the mass customization in apparel industry,“inProc.IEEE International Conf.Service Operations and Logistics,and Informatics,Dongguan,China,2013,pp.220−224.

[12]G.Xiong,Y.R.Chen,X.Q.Shang,X.W.Liu,and T.R.Nyberg,“AHP fuzzy comprehensive method of supplier evaluation in social manufacturing mode,”InProc.11th World Congress on Intelligent Control and Automation,Shenyang,China,2014,pp.3594−3599.

[13]X.Q.Shang,F.Y.Wang,G.Xiong,T.R.Nyberg,Y.Yuan,S.Liu,C.Guo,and S.Bao,“Social manufacturing for high-end apparel customization,”IEEE/CAA J.Autom.Sin.,2018

[14]Institute for the Future(IFTF).“Social manufacturing:Alternative paths to development,”IFTF,Accessed on:Sep.22,2014.[Online].Available:http://www.iftf.org/ fileadmin/userupload/downloads/researchagendas/social manufacturing alt paths to dev 7.19lg.pdf..

[15]G.Ritzer and N.Jurgenson,“Production,consumption,prosumption:The nature of capitalism in the age of the digital’prosumer’,”J.Consum.Cult.,vol.10,no.1,pp.13−36,Mar.2010.

[16]The Economist, “A third industrial revolution,”2012,Accessed on:May 21,2014.[Online].Available:http://web.mit.edu/pie/news/Economist.pdf.

[17]T.Alvin,The Third Wave.New York,USA:Bantam Books,1981.

[18]A.Rusinko,“Green manufacturing:An evaluation of environmentally sustainable manufacturing practices and their impact on competitive outcomes,”IEEE Trans.Eng.Manage.,vol.54,no.3,pp.445−454,Aug.2007.

[19]F.Tao,Y.Cheng,L.Zhang,and A.Nee,“Advanced manufacturing systems:Socialization characteristics and trends,”J.Intell.Manuf.,vol.28,no.5,pp.1079−1094,Jun.2017.

[20]P.Y.Jiang,K.Ding,and J.W.Leng,“Towards a cyber-physicalsocial-connected and service-oriented manufacturing paradigm:Social Manufacturing,”Manuf.Lett.,vol.7,pp.15−21,Jan.2016.

[21]R.Böer,S.Dulio,and F.Jovane,“Editorial:Shoe design and manufacturing,”Int.J.Comput.Integr.Manuf.,vol.17,no.7,pp.577−582,Oct.-Nov.2004.

[22]B.H.Li,L.Zhang,S.L.Wang,F.Tao,J.W.Cao,X.D.Jiang,X.Song,and X.D.Chai,“Cloud manufacturing:A new service-oriented networked manufacturing model,”J.Comput.Integr.Manuf.Syst.,vol.16,no.1,pp.1−7,16,Jan.2010.

[23]F.Tao,Y.Cheng,L.D.Xu,L.Zhang,and B.H.Li,“CCIoT-CMfg:Cloud computing and internet of things-based cloud manufacturing service system,”IEEE Trans.Ind.Inform.,vol.10,no.2,pp.1435−1442,May 2014.

[24]F.Tao,Y.Zuo,L.D.Xu,and L.Zhang,“IoT-based intelligent perception and access of manufacturing resource toward cloud manufacturing,”IEEE Trans.Ind.Inform.,vol.10,no.2,pp.1547−1557,May 2014.

[25]X.Xu, “From cloud computing to cloud manufacturing,”International Journal of Rob.Comput.-Integr.Manuf.,vol.28,no.1,pp.75−86,Feb.2012.

[26]A.Kumar,“From mass customization to mass personalization:A strategic transformation,”Int.J.Flex.Manuf.Syst.,vol.19,no.4,pp.533−547,Dec.2007.

[27]B.Anderson, “The long tail,”Bus.Book Summ.,vol.11,no.1,pp.1−20,2008.

[28]C.Anderson,The Long Tail:Why the Future of Business is Selling Less of More.New York,USA:Hyperion,2006.

[29]F.Y.Wang,“Social computing:Concepts,contents,and methods,”Int.J.Intell.Contr.Syst.,vol.9,no.2,pp.91−96,Jan.2004.

[30]T.Chen and Y.C.Wang,“Estimating simulation workload in cloud manufacturing using a classifying artificial neural network ensemble approach,”Rob.Comput.-Integr.Manuf.,vol.38,pp.42−51,Apr.2016.

[31]X.F.Yao,H.Jin,and J.Zhang,“Towards a wisdom manufacturing vision,”Int.J.Comput.Integr.Manuf.,vol.28,no.12,pp.1291−1312,Dec.2015.

[32]SoMa2020, “Social manufacturing and intelligent systems,”Finnish TEKES’s FiDiPro project report,Aalto University,2014.

[33]B.Mohajeri,T.R.Nyberg,J.Karjalainen,T.Tukiainen,M.Nelson,X.Q.Shang,and G.Xiong,“The impact of social manufacturing on the value chain model in the apparel industry,”inProc.2014 IEEE International Conf.Service Operations and Logistics,and Informatics,Qingdao,China,2014,pp.378−381.

[34]B.Mohajeri,“Paradigm shift from current manufacturing to social manufacturing,”M.S.thesis,Aalto University,Espoo,Finland,Jun.2015.

[35]J.Wind and A.Rangaswamy,“Customerization:The next revolution in mass customization,”J.Interact.Mark.,vol.15,no.1,pp.13−32,2001.

[36]F.Piller,A.Vossen,and C.Ihl,“From social media to social product development:The impact of social media on co-creation of innovation,”Unternehmung,vol.66,no.1 pp.7−27,2012.

[37]H.F.Liu, “Netizen group economy-next internet revolution,”Feb.2,2015.[Online].thebibliography.

杂志排行

IEEE/CAA Journal of Automatica Sinica的其它文章

- Encoding-Decoding-Based Control and Filtering of Networked Systems:Insights,Developments and Opportunities

- Internet of Vehicles in Big Data Era

- Residential Energy Scheduling for Variable Weather Solar Energy Based on AdaptiveDynamic Programming

- Analysis of Autopilot Disengagements Occurring During Autonomous Vehicle Testing

- A Methodology for Reliability of WSN Based on Software De fined Network in Adaptive Industrial Environment

- Data Gathering in Wireless Sensor Networks Via Regular Low Density Parity Check Matrix