蜂王浆三针夹取式拣虫机的设计与试验

2017-11-17王明旭李建永高兴华罗春阳

王明旭,李建永,高兴华,罗春阳,杨 泽

蜂王浆三针夹取式拣虫机的设计与试验

王明旭,李建永※,高兴华,罗春阳,杨 泽

(北华大学机械工程学院,吉林132021)

蜂王浆拣虫是挖浆前必须完成的工序。由于蜜蜂幼虫个体较小、数目庞大,因此人工拣虫过程劳动强度非常大;然而中国养蜂人员老龄化日益严重,且目前蜂王浆拣虫机械化尚未成熟。该文针对中国养蜂现状提出一种以三针夹取的方式将王台中蜜蜂幼虫夹出的方法。以三针夹取的拣虫方式构建蜂王浆拣虫机整机方案。三根针在王台孔内壁同时做向心运动或分离运动,将蜜蜂幼虫夹住或松开。对传动机构中球面槽轮和凸轮的参数进行计算。通过有限元分析得出动力输入端脚踏板受力情况。计算得出球面槽轮圆柱销弧长7.5π,槽深20.68 mm;得出凸轮的理论廓线;有限元分析结果得出动力输入方式可靠。该机器在保留蜂王浆幼虫完整的前提下,一次性将整条王台(64孔)中蜜蜂幼虫全部拣出,可实现连续作业,拣虫效率为10条/min时为人工的10倍,克服了蜂场手工作业时间长和劳动强度大问题。对扩大中国蜂业养蜂规模有着极大的促进作用。

机械化;设计;运动学;蜂王浆拣虫机;三针夹取;向心运动;理论廓线

0 引 言

2015年中国约有2万个大型蜂场生产蜂王浆,200群左右的蜂场若全年满负荷生产蜂王浆,产量可达1 t[1-3]。自生产蜂王浆以来,费时、费力、费工成为制约中国蜂王浆产量的三大因素,严重阻碍了蜂场规模化饲养的发展[4-6]。拣虫(将2~3日龄左右的蜜蜂幼虫从王台中拣出[7-8])工序是挖浆前必须完成的步骤,且一直以人工拣虫为主,增加了挖浆前的准备时间和人工劳动强度[9-12]。

蜂王浆夹虫的方式直接影响了拣虫效率和蜂王浆的质量。浙江三庸蜂业科技有限公司和福建农林大学共同研制的钳虫机,采用双针夹虫方式,人工分别操控操纵杆的方式实现双针下压、夹虫、上升、放虫动作。上述拣虫装置操作过于复杂,为此本文提出一种仿人手式三针拣虫方式,并且对主要部件进行了分析计算。该机器操作简单,对整条王台内蜜蜂幼虫一次性全部拣出,可实现对王台的连续作业,减少人工劳动强度和缩短挖浆前准备时间。通过蜂场现场试验验证拣虫作业效果,研究结果为蜂王浆的拣虫工序机械化提供了参考。

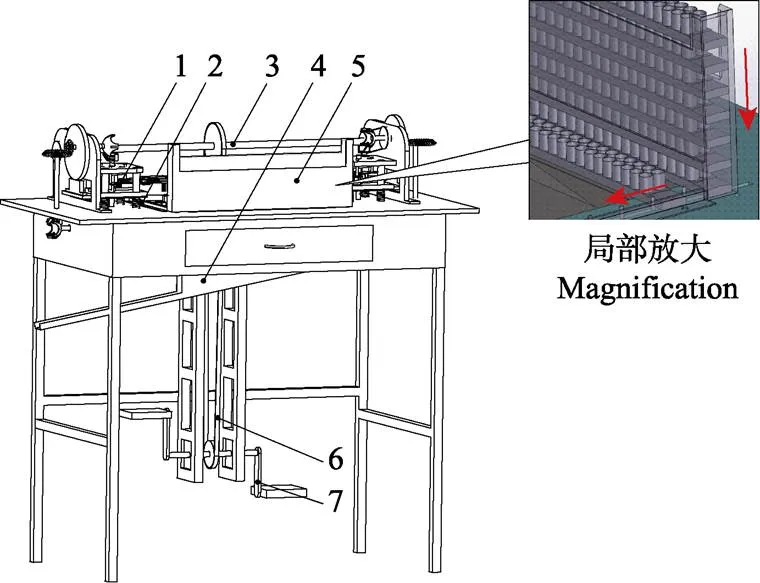

1 蜂王浆拣虫机的组成及工作原理

蜂王浆拣虫机采用人工作业方式。将王台放入竖直王台导槽内,转动踏板,由带传动带动主动轴转动,主轴将动力分别传给传动单元和拣虫单元。由传动单元齿形带将王台导槽内的王台传送到拣虫单元(导槽内王台因自重下落,实现王台自动补给,如图1局部放大所示),由拣虫单元(每个王台孔内壁均分的三根针做向心运动,三针合拢夹取蜜蜂幼虫)完成拣虫动作,拣取的蜜蜂幼虫由接虫箱收集,拣虫后的王台被传出,完成整个拣虫过程。本装置操作简单,结构紧凑,适合蜂农野外作业。蜂王浆拣虫机组成如图1所示。

1. 夹虫单元 2. 传动单元 3. 主轴 4. 接虫箱 5. 王台导槽 6. 传动链 7. 踏板

2 传动单元设计及分析计算

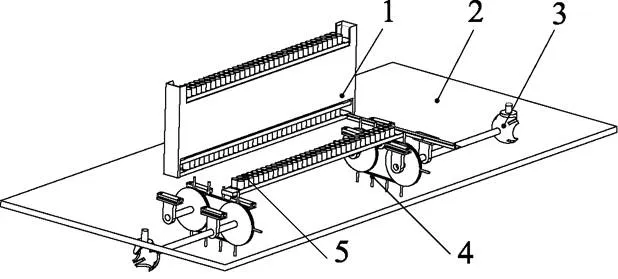

2.1 传动单元的设计

蜂王浆拣虫机的传动单元主要包括王台导槽、桌面、槽轮和齿形带等部件组成。王台导槽安装在桌面的上方,其他部件安装在桌面的下方。将待拣虫的王台连续放入导槽内,由齿形带传送至下一工位;踏板转动实现王台连续进给。由于拣虫过程需要王台静止,所以主轴与齿形带之间由槽轮机构[13-17]配合使用,实现齿形带间歇转动,为拣虫过程提供时间,如图2所示。

1. 王台导槽 2. 桌面 3. 槽轮 4. 齿形带 5. 王台

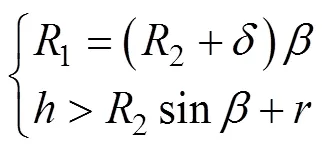

2.2 球面槽轮参数确定

传送单元的间歇运动是主动轴配合球面槽轮的运动实现的。图3为槽轮的原理图。由机器结构可确定以下参数:槽轮半径2= 25 mm;球面到圆柱销顶端间隙= 5 mm;圆销半径= 3 mm。由机器运行时拣虫单元和传动单元配合,球面槽轮[18-20]为四槽槽轮,槽间角2= 90°。由以上参数可确定圆销的弧长1;槽深(槽轮轴线方向)范围。

由式(1)计算可得1=7.5π;>20.68 mm,实现间歇式运动,为拣虫提供5 s的时间。

注:1为圆柱销的弧长(mm);2为球面槽轮半径(mm);为圆销半径(mm);为槽轮轴线方向深度(mm);为槽间角(°);为球面到圆柱销顶端间隙(mm)。

Note:1is arc length of straight pin(mm);2is radius of spherical groove wheel(mm);is radius of straight pin(mm);is depth of groove wheel axis(mm);is slot angle (°);is spherical to cylinder tip clearance(mm).

图3 球面槽轮原理图

Fig.3 Principle diagram of space sheave

3 仿人工拣虫单元设计及分析

目前,蜂农养蜂所采用的王台[21-22]条是仿造蜂房结构,多数是双排孔构造,每个王台条上有64个王台孔,每个王台孔为Φ10 mm×12 mm的圆柱形结构。2~3日龄的蜜蜂幼虫长约11 mm,蜷缩在王台孔中心。手工拣虫作业时,蜂农用镊子逐一将王台中蜜蜂幼虫夹出。如何高效、可靠替代人工拣虫成为技术成败的关键。

3.1 仿人工拣虫原理

拣虫单元由凸轮、导柱、回复弹簧、基座、针板、导槽等部件组成。当王台被传动机构传送到针板下方,球面槽轮机构使传动单元静止,同时随着凸轮小径转至大径并下压基座,使得基座带动针板下压至王台孔中。三块针板在导槽中滑动,使三针机构合拢并夹住幼虫,此时凸轮由大径转到小径,带动三针机构和幼虫上升至原始位置,上升力由回复弹簧提供,此时传动机构开始转动,将拣虫完毕的王台传送至出料口,三针机构打开,幼虫掉至收虫箱中,完成拣虫动作。拣虫单元结构组成如图a所示,拣虫步骤如图b所示。

1. 回复弹簧 2. 基座 3. 导槽 4. 凸轮 5. 导柱 6. 针板 7. 王台

1. Return spring 2. Base 3. Guide groove 4. Cam 5. Guide post 6. Needle plate 7. Queen cell

图4 仿人工拣虫原理图

Fig.4 Schematic diagram of artificial picking larvae

3.2 三针机构设计

三针夹取机构是整个设备的核心。三针机构是由三块带有钢针的针板构成,每根钢针直径为 0.7 mm,以王台孔为中心,互成120°分布,均有向心运动的趋势。针板1和针板2分别开有避让针板3和针板2上钢针的长条孔。3根针为一组,每组针在王台孔内壁均布,均有向心运动的趋势。为避免蜜蜂幼虫被夹破。三针机构合拢后,其内切圆直径为3 mm。三针机构如图5所示。

图5 三针机构原理图

凸轮参数确定:针板的下压、上升动作是靠凸轮[23-24]的直径变换实现的。当凸轮转过90°时,针板上升= 15 mm;当凸轮继续转过90°时,针板静止不动;凸轮再继续转过60°时,针板下降15 mm;凸轮转过其余角度时,针板又停止不动。设凸轮基圆半径0=50 mm,针板上滚子半径r=10 mm,设推杆距离为,凸轮压力角为,如图6所示。

注:r0为凸轮基圆半径(mm);rr为滚子半径(mm);s为推杆距离(mm);a为凸轮压力角(°)。

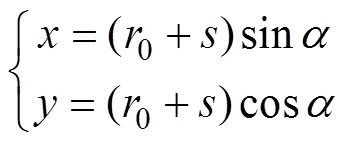

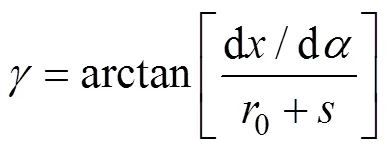

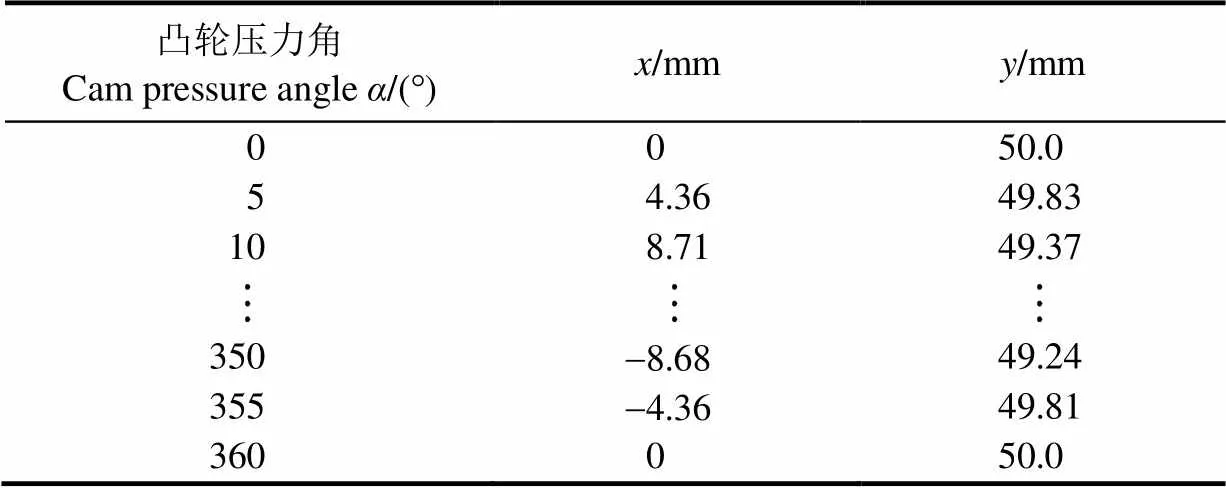

则凸轮理论廓线[25]坐标为:

式(2)中,位移应分段计算。

1)推程阶段1=90°=π/2

1=[(21/π)-sin(4α)-(2π)]1=[0,π/2]

2)远休止阶段2=90°=π/2

2=15 mm2=[0,π/2]

3)回程阶段3=60°=π/3

3=270(3)3/π3-1 215(3)4/π4+1 458(3)5/π5

3=[0,2π/5]

4)近休止阶段4=120°=2π/3

4=04=[0,2π/3]

5)推程段的压力角和回程段的压力角

式中为针板上升距离(mm)。

计算结果可得凸轮理论坐标如表1所示。r=10 mm,由作图法可得出凸轮运动的工作廓线[26]。

表1 凸轮理论坐标

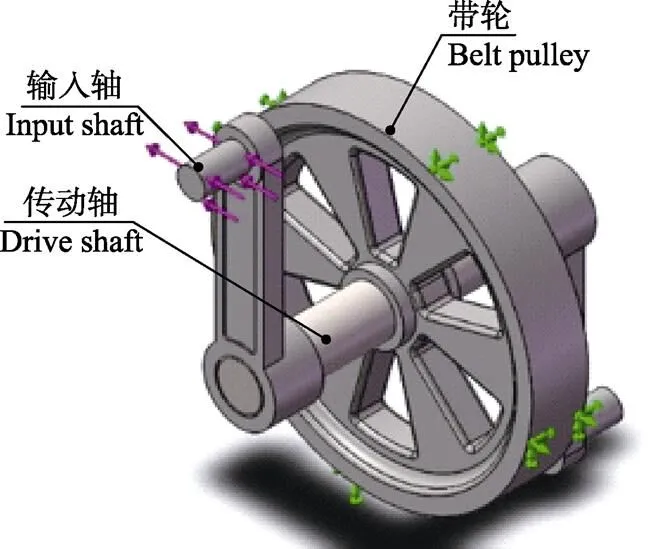

4 脚踏板静力学分析

脚踏板为动力输入端,整机主要受力部件,其强度与刚度决定了整机运行的可靠性及稳定性,对其进行有限元分析学分析[27-28]。其简化模型如图7所示。其中带轮直径为80 mm,材料为铸造碳钢;传动轴直径12 mm,材料为合金钢;输入轴直径7 mm,材料为普通碳钢。

图7 踏板简化模型图

该机构受最大应力为输入轴启动时瞬时应力,根据圣维南原理[29-31],由计算得输入轴启动瞬时拉力为89 N,仿真时按1.5倍安全系数施加133.5 N的力,方向垂直输入轴一个面,装配体所加边界条件如图7所示。分析等效应力和应变分布图如图8所示,最大应力为9.35´107N/m2,查表得普通碳钢许用应力2.21´108N/m2,所以符合使用要求。

图8 脚踏板静力学分析图

5 拣虫机试验结果

拣虫效率和拣虫后蜂王浆的质量是本机的关键。因此对拣虫机进行了性能测试。

5.1 试验方法

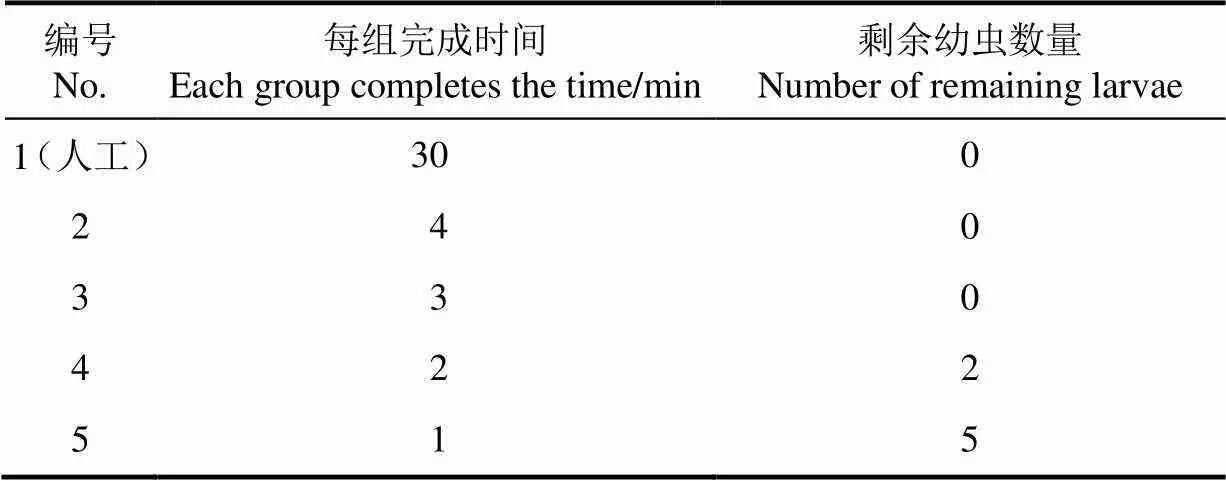

人工与机器进行拣虫试验对比,人工组分为第1组完成30个王台的拣虫;拣虫机为2~5组(每组拣虫速度不同),每组30个王台。试验结果如表2所示。

表2 拣虫机与人工拣虫试验结果对比

根据上表可知,人工拣虫王台中几乎无剩余幼虫,第2、3组拣虫和第1组人工拣虫结果最接近。由上表可算得2组拣虫速率(每分钟拣取王台数量)为7.5条/min;第3组拣虫速率为10条/min。当第4、5组拣虫速率增大至15条/min以上时,拣虫质量随之下降。

人工拣虫与机器拣虫后(拣虫速率≤10条/min)的蜂王浆质量无差别;人工拣虫幼虫剩余率几乎为零,拣虫效率1条/min;考虑到剩虫率和拣虫效率,本机将拣虫速率控制在10条/min为最佳,是人工拣虫速率的10倍。

5.2 经济效能分析

假设某蜂场每天需完成300个王台拣虫,按照吉林省雇工标准,雇佣拣虫人员约25元/h,共需花费近8 h,花费125元;而机器拣虫只需30 min即可完成。

6 结 论

针对蜂王浆拣虫工序,该文提出以三针机构构建拣虫机。该装置主要包括三针夹虫机构、球面槽轮传动机构、动力输入机构。三针机构由3块针板组成,每根钢针直径0.7 mm,以王台孔为中心,互成120°分布,均有向心运动的趋势;球面槽轮圆柱销弧长7.5p,槽深20.68 mm,实现间歇式运动,为拣虫提供5 s的时间;通过有限元分析得动力输入方式可靠,脚踏板传动轴12 mm。

该装置拣虫效率为10条/min,为人工拣虫效率的10倍,且不影响蜂王浆质量。可实现连续作业,克服了手工作业时间长、劳动强度大等问题。对扩大中国蜂业养蜂规模有着积极作用。

[1] 徐龙琴,李乾川,刘双印,等. 基于集合经验模态分解和人工蜂群算法的工厂化养殖pH值预测[J]. 农业工程学,2016,32(3):202-209. Xu Longqin, Li Qianchuan, Liu Shuangyin, et al. Prediction of pH value in industrialized aquaculture based on ensemble empirical mode decomposition and improved artificial bee colony algorithm[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(3): 202-209. (in Chinese with English abstract)

[2] 李海燕. 国内外养蜂政策现状及分析[J]. 中国蜂业,2012(43):43-46. Li Haiyan. Beekeeping policy at home and abroad present situation and the analysis[J]. Apiculture of China, 2012(43): 43-46. (in Chinese with English abstract)

[3] 宋心仿. 如何应用蜂王浆[J]. 中国蜂业,2012, 63(6): 16. Song Xinfang. How to apply the royal jelly[J]. Apiculture of China, 2012, 63(6): 16. (in Chinese with English abstract)

[4] 罗扬. 2010年蜂王浆产品贸易现状分析[J]. 中国蜂业,2011,62(4):9-10. Luo Yang . In 2010, royal jelly products trade status quo analysis[J]. Apiculture of China, 2011, 62(4): 9-10. (in Chinese with English abstract)

[5] 李海燕,刘凤彦,郝运坡. 北京市养蜂业发展研究——基于蜂农调查数据的分析[J]. 农业经济问题,2011,32(8):19-24. Li Haiyan, Liu Fengyan, Hao Yunpo, The development of beekeeping industry in Beijing - based on the analysis of the data of bee farmers[J]. Issues in Agricultural Economy, 2011, 32(8): 19-24. (in Chinese with English abstract)

[6] 房宇,陈健,白润成. 美国蜜蜂授粉概况[J]. 中国蜂业,2008(5):49. Fang Yu, Chen Jian, Bai Runcheng. American bee pollination[J]. Apiculture of China, 2008(5): 49. (in Chinese with English abstract)

[7] 方文富,国占宝,张文松. 意蜂采用2、3日龄工蜂幼虫产浆的研究[J]. 中国蜂业,2000(4):4-6. Fang Wenfu, Guo Zhanbao, Zhang Wensong. A study on the royal jelly production of apis mellifera with two and with three days old instars[J]. Apiculture of China, 2000(4): 4-6. (in Chinese with English abstract)

[8] 方文富,张文松,吉挺. 西方蜜蜂产浆适龄幼虫及取浆时间[J]. 福建农业大学学报,1996(2):109-112. Fang Wenfu, Zhang Wensong, Ji Ting. The time of the larvae and the pulping of western bees[J]. Journal of Fujian Agriculture and Forestry University, 1996(2): 109-112. (in Chinese with English abstract)

[9] 潘其忠,林金龙,吴小波. 蜂王浆机械化生产关键技术研究与应用(Ⅰ)[J]. 江西农业大学学报,2013,35(4):842-847, 857. Pan Qizhong, Lin Jinglong, Wu Xiaobo. Research and application of key technique for mechanized production of royal jelly (Ⅰ)[J]. Journal of Jiangxi Agricultural University, 2013, 35(4): 842-847, 857. (in Chinese with English abstract)

[10] 潘其忠,林金龙,吴小波. 蜂王浆机械化生产关键技术研究与应用(Ⅱ)(J). 江西农业大学学报,2013,35(5): 1036-1041. Pan Qizhong, Lin Jinglong, Wu Xiaobo. Research and application of key technique for mechanized production of royal jelly (Ⅱ)[J]. Journal of Jiangxi Agricultural University, 2013, 35(5): 1036-1041. (in Chinese with English abstract)

[11] 潘其忠,林金龙,吴小波. 蜂王浆机械化生产关键技术研究与应用(Ⅲ)[J]. 江西农业大学学报,2013, 35(6): 1261-1265. Pan Qizhong, Lin Jinglong, Wu Xiaobo. Research and application of key technique for mechanized production of royal jelly (Ⅲ)[J]. Journal of Jiangxi Agricultural University, 2013, 35(6): 1261-1265. (in Chinese with English abstract)

[12] 潘其忠,林金龙,吴小波. 蜂王浆机械化生产关键技术研究与应用(Ⅳ)[J]. 江西农业大学学报,2013,35(6): 1266-1271. Pan Qizhong, Lin Jinglong, Wu Xiaobo. Research and application of key technique for mechanized production of royal jelly (Ⅳ) [J]. Journal of Jiangxi Agricultural University, 2013, 35(6): 1266-1271. (in Chinese with English abstract)

[13] 章磊,赵鹏. 槽轮机构的运动分析与优化设计[J]. 科学技术与工程, 2011(18):4198-4202. Zhang Lei, Zhao Peng. Motion Analysis and optimization design of geneva mechanism[J]. Science Technology and Engineering, 2011(18): 4198-4202. (in Chinese with English abstract)

[14] 何亚凯,李树君,杨学军,等. 凸轮摆杆式栽植机构运动分析及性能试验[J]. 农业工程学报,2016,32(6):34-41. He Yakai, Li Shujun, Yang Xuejun, et al. Kinematic analysis and performance experiment of cam swing link planting mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(6): 34-41. (in Chinese with English abstract)

[15] 苑进,李扬,刘雪美,等. 禽蛋自动捡拾系统结构设计及机械手运动规划[J]. 农业工程学报,2016,32(8):48-55. Yuan Jin, Li Yang, Liu Xuemei, et al. Structure design of egg auto-picking system and manipulator motion planning[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(8): 48-55. (in Chinese with English abstract)

[16] 向晓汉,张锡清,陆彬. 改善槽轮机构动态特性的研究[J]. 机械设计与制造,2006(7):106-107. Xiang Xiaohan, Zhang Xiqing, Lu Bin. Research on the dynamic characteristics of tank wheel mechanism[J]. Machinery Design & Manufacture, 2006(7): 106-107. (in Chinese with English abstract)

[17] 杨良渠. 包机中内槽轮机构的运动和力分析[J]. 重庆工商大学学报,2005(4):390-393. Yang Liangqu, The motion and force analysis of the inner wheel mechanism in the charter[J]. Journal of Chongqing Technology and Business University, 2005(4): 390-393. (in Chinese with English abstract)

[18] 金国光,魏展,秦凯旋,等. 高速凸轮机构动力学分析及模态截断[J]. 机械工程学报,2015,51(13):227-234. Jin Guoguang, Wei Zhan, Qin Kaixuan, et al. Dynamic analysis and modal truncation of high-speed cam mechanism[J]. Journal of Mechanical Engineering, 2015, 51 (13): 227-234. (in Chinese with English abstract)

[19] 刘辰. 外槽轮机构设计分析[J]. 机电工程技术,2009,38(2):61-63,97,107. Liu Chen. Design analysis of outer slot wheel mechanism[J]. Mechanical & Electrical Engineering Technology, 2009, 38 (2): 61-63, 97, 107. (in Chinese with English abstract)

[20] 王良文,杜文辽,崔纪雷. 自动机械中槽轮机构的参数化设计与仿真[J]. 机械设计,2006(12):44-46. Wang Liangwen, Du Wenliao, Chui Jilei. Parametric design and simulation of slot wheel mechanism in automatic machine[J]. Journal of Machine Design, 2006(12): 44-46. (in Chinese with English abstract)

[21] 张传武,谢勇. 王台型蜂王浆的生产方法[J]. 中国蜂业,2015,66(1):18-19. Zhang Chuanwu, Xie Yong. Queen cell type of royal jelly production methods[J]. Apiculture of China, 2015, 66(1): 18-19. (in Chinese with English abstract)

[22] 郭业寨. 王台王浆的特点及其使用方法[J]. 蜜蜂杂志,2015,35(1):36-37. Guo Yezhai. Characteristics and usage of wang tai wang pulp[J]. Journal of Bee. 2015, 35(1): 36-37. (in Chinese with English abstract)

[23] 冷东,黄松和,朱鹏飞. 包装机凸轮连杆组合机构的动态特性分析[J]. 机械设计与制造,2015(6):188-189,193. Leng Dong, Huang Songhe, Zhu Pengfei. Dynamic characteristic analysis of the cam-link mechanism of the packaging machine[J]. Machinery Design & Manufacture, 2015(6): 188-189, 193. (in Chinese with English abstract)

[24] 张东远,何进,李洪文,等. 双凸轮连杆型排种施肥无级变速器设计与试验[J]. 农业工程学报,2013,29(9):9-17. Zhang Dongyuan, He Jin, Li Hongwen, et al. Design and experiment on double cam-link of continuously variable transmission for seeding and fertilizing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(9): 9-17. (in Chinese with English abstract)

[25] 陈俊华,汤腾跃,马永洲. 摆动从动件圆锥凸轮理论轮廓展开线曲率半径研究[J]. 机械工程学报,2015,51(1): 11-16. Chen Junhua, Tang Tengyue, Ma Yongzhou, Study on the curvature radius of the circular cone CAM theory[J]. Chinese Journal of Mechanical Engineering, 2015, 51(1): 11-16. (in Chinese with English abstract)

[26] 郑硕,李明滨,尹东文,等. 基于COSMOSMotion太阳能跟踪凸轮机构的设计[J]. 农业工程学报,2011,27(12):43-46. Zheng Shuo, Li Mingbin, Yin Dongwen, et al. Design of cam mechanism of solar tracking based on COSMOSMotion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(12): 43-46. (in Chinese with English abstract)

[27] 苗玉刚,赵峰,何斌. 基于Solidworks Simulation的工装压板有限元分析及优化设计[J]. 煤矿机械,2015,36: 192-194. Mian Yugang, Zhao Feng, He Bin. Finite element analysis and optimization design of tooling plateBased on solidworks simulation[J]. Coal mine machinery, 2015, 36: 192-194. (in Chinese with English abstract)

[28] 佟金,张智泓,陈东辉,等. 凸齿镇压器与土壤相互作用的三维动态有限元分析[J]. 农业工程学报,2014,30(10):48-58. Tong Jin, Zhang Zhihong, Chen Donghui, et al. Three-dimensional dynamic finite element analysis of interaction between toothed wheel and soil[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(10): 48-58. (in Chinese with English abstract)

[29] 康亚明. 理论分析与数值模拟相结合的圣维南原理教学方法探索[J]. 山东工业技术,2012(5),222. Kang Yaming, Theoretical analysis and numerical simulation combine principle teaching method exploration of Adhémar Jean Claude Barré de Saint-Venantp[J]. Shandong Industrial Technology, 2012(5), 222. (in Chinese with English abstract)

[30] 卢光耀,胡引翠,田冰. 电动车路径规划的影响因素研究[J]. 山东工业技术,2012(5),223. Lu Guangyao, Hu Yincui, Tian Bing. Research on the influence factors of electric vehicle path planning[J]. Shandong Industrial Technology, 2012(5), 223. (in Chinese with English abstract)

[31] 魏展,金国光,袁汝旺,等. 高速共轭凸轮打纬机构柔性动力学分析[J]. 机械工程学报,2017,53(3):81-89.

Wei Zhan, Jin Guoguang, Yuan Ruwang, et al. Flexible dynamic analysis of high-speed conjugate cam beating-up mechanism[J]. Journal of Mechanical Engineering, 2017, 53(3): 81-89. (in Chinese with English abstract)

王明旭,李建永,高兴华,罗春阳,杨 泽. 蜂王浆三针夹取式拣虫机的设计与试验[J]. 农业工程学报,2017,33(21):261-266. doi:10.11975/j.issn.1002-6819.2017.21.032 http://www.tcsae.org

Wang Mingxu, Li Jianyong, Gao Xinghua, Luo Chunyang, Yang Ze. Design and test of three-pin clip-picking royal jelly larvae sorting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(21): 261-266. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.21.032 http://www.tcsae.org

Design and test of three-pin clip-picking royal jelly larvae sorting machine

Wang Mingxu, Li Jianyong※, Gao Xinghua, Luo Chunyang, Yang Ze

(132021)

The royal jelly pick worm is a process that must be completed before harvesting pulp. Because of the larvae of bee are small and in a great deal of numbers, the labor intensity of the manual sorting process is very large. Moreover, the aging of Chinese beekeeping workforce is becoming increasingly serious in the bee keeping industry, and now the royal jelly picking worm have not yet reached mechanization, which hinders the production of royal jelly. In this paper, we developed a method for the present situation of Chinese beekeeping in a three-needle structural picking machine, which would not affect the quality of the royal jelly. First, the machine put the queen cell without beeswax one by one into the king's guide slot, then turned the pedal, the drive shaft was turned by pulley, and the main shaft would transfer the power to the drive unit and the picking worm unit. The toothed belt of the transmission unit transmitted the queen cell to the picking insect unit. Because of the its own weight, the queen cell which in guide groove was falling, implement automatic supply of queen cell, the action of picking worm was completed by pick worm unit, then bee larvae are collected by the insect collecting box. The queen cell was sent out after picking worm, thus finish the picking worm process. This device was easy to operate and had compact structure, suitable for the field operation for beekeepers. The machine was mainly used to construct the whole machine scheme of the three needles pick worm. The three needles were evenly distributed in the inner wall of queen cell, and at the same time, it also had a centripetal movement to clamp or loosen the bee. The three-needle mechanism was used for the coordination between the space sheave and cam mechanism, and the parameters of the space tank wheel and cam were calculated. The force situation of the foot pedal of the power input was obtained through finite element analysis. Finally, the arc length of the space slot was 7.5 PI, and the groove depth was 20.68 mm. The theoretical profile and work profile of the cam were obtained. The finite element analysis of the foot pedal was concluded that the actual stress was much less than the allowable stress of the material itself, which indicated that the method met the requirement of use. The experimental comparison and economic benefit of the artificial picking insects and the robot were summarized as follows: the machine will control the rate of worm picking at 10/min, 10 times the efficiency of manual sorting. The machine in royal jelly, royal jelly larvae preserved and did not affect the quality under the premise of one-time whole queen cell bee larvae all picked out of a hole (64), which realized continuous operation, greatly improved the efficiency of the pick of royal jelly, overcame long manual work time and labor intensity. It was very helpful to expand the scale of bee keeping in China.

mechanization; design; kinematics; royal jelly pick worm machine; three needles pick up; centripetal movement;theoretical contour line

10.11975/j.issn.1002-6819.2017.21.032

S896.3

A

1002-6819(2017)-21-0261-06

2017-03-13

2017-10-20

吉林省重点科技攻关项目(20150204046GX)

王明旭,男,吉林省桦甸市人。研究方向:机械电子工程。 Email:wangmxbh@163.com

※通信作者:李建永,男,辽宁沈阳人,教授。研究方向:特种机器人技术研究与应用。Email:lijy_2005@163.com