生物质混合燃料在柴油机喷嘴内流动特性模拟

2017-11-17耿莉敏魏有涛

耿莉敏,王 城,魏有涛,李 琪

生物质混合燃料在柴油机喷嘴内流动特性模拟

耿莉敏,王 城,魏有涛,李 琪

(长安大学陕西省交通新能源开发、应用与汽车节能重点实验室,西安 710064)

为了研究燃料物性差异对喷孔内流动特性的影响,通过GAMBIT软件建立三维喷嘴模型,利用FLUENT软件采用混合多相流模型,对柴油、生物柴油、生物柴油/乙醇混合燃料的喷孔内压强分布、速度分布和空化程度进行仿真分析。结果表明:燃油在压力室与喷孔入口衔接处压强迅速下降,进入喷孔后压强趋于稳定,在喷孔出口处压强略有上升;生物柴油的压强降幅最大,在喷孔不同截面处,与柴油相比生物柴油的压强平均下降了23.91%;生物柴油/乙醇混合燃料与柴油的压强降幅差别不大。燃油流速在喷孔入口处迅速增加,进入喷孔后增速放缓,在喷孔出口处燃油流速略有下降;在喷孔径向方向,由于壁面黏滞力作用导致速度从中心轴线向外围呈递减趋势;在喷孔不同截面处柴油的流速最快,其在喷嘴出口处的流速为229.8 m/s;生物柴油/乙醇混合燃料在喷嘴出口处的流速为223.1 m/s;生物柴油的流速最小, 其在喷嘴出口处的流速为214.9 m/s。空穴现象首先发生在喷孔入口拐角处,随后向喷孔出口发展,并逐渐减弱。喷孔不同截面处,柴油的气相体积分数最大,生物柴油的气相体积分数最小,其气相体积分数比柴油平均下降了11.1%,与柴油相比生物柴油的空化程度较弱;生物柴油/乙醇混合燃料的气相体积分数与柴油差别不大,仅降低了1.8%,在生物柴油中添加乙醇能够降低燃料的密度、粘度和表面张力,改善燃料在喷孔内的流动特性,促进空化产生,喷孔内的空化现象能够为圆射流喷雾提供初始扰动,促进燃油雾化。该研究可为生物柴油/乙醇混合燃料流通特性研究提供理论支持。

生物燃料;乙醇;模拟;混合燃料;喷嘴内空穴流动

0 引 言

随着社会经济的发展,能源危机和环境污染已经成为全球亟待解决的问题。各国纷纷致力于新型替代能源的研究,生物柴油与柴油理化特性相近,不需要对现有柴油机进行改造便可直接应用,受到各国研究人员的青睐[1-4]。内燃机的动力性、经济性和排放特性与燃油的喷雾特性密切相关,研究表明分析喷嘴内部结构[5-7]和燃料性质[8]对喷孔内部流动特性的影响并对其进行优化控制能够改善燃料的喷雾特性。

目前国内外对生物柴油喷雾特性的研究相对较多,主要有利用定容弹模拟发动机缸内环境,采用CCD(charge coupled device)相机捕捉喷雾发展过程图像,研究菜籽油甲脂、豆油甲脂与柴油混合燃料的喷雾特性[9];利用高速摄像机和可视化燃烧室对多种生物质燃油的喷雾特性进行试验研究[10];利用单缸光学发动机测试了第一代生物柴油(大豆油甲酯和菜籽油甲酯)和第二代生物柴油(天然气合成油)的喷雾特性[11];利用激光测试技术对生物柴油与柴油混合燃料的雾化质量进行试验研究[12];利用高分辨率数码相机、高速摄像机等设备从燃料性质、喷射压力、喷孔直径和溶气喷射等多角度研究生物柴油的喷雾特性[13-15];利用高速摄像系统和激光粒度分析仪研究生物柴油与醇类,醚类掺混后的喷雾特性[16-17];利用相位多普勒粒子测试技术和高速摄影法,对棕榈油生物柴油、0#柴油以及混合燃料(生物柴油体积分数为30%)的喷雾特性进行研究[18];利用经过验证的数值模型和基于激光的米氏散射技术对柴油和生物柴油的喷嘴内流动特性和宏观喷雾特性进行对比研究[19];利用开源仿真软件KIVA-3V研究了燃油温度以及环境气体温度对生物柴油喷雾特性的影响[20-21];利用三维CFD(computational fluid dynamics)软件建立燃油自由喷雾计算模型对比分析生物柴油与柴油的喷雾特性[22],同时研究了喷孔直径对生物柴油喷雾特性的影响[23]。受喷嘴内可视化试验条件的限制,关于生物柴油喷嘴内流动特性的研究相对较少,Som等[24]利用FLUENT v6.3软件研究了生物柴油和柴油在喷孔内部的流动特性以及喷雾特性;谢阳等[25]利用计算流体力学软件模拟了燃油温度和背压对柴油喷孔内部流动特性的影响;Battistoni等[26]利用AVL FIRE软件对生物柴油与柴油的喷孔内流动特性和喷雾特性进行了对比研究,并分析了喷孔内部结构对空化的影响;邵壮[27]和姜光军[28]等利用透明喷嘴对生物柴油和柴油在喷孔内的流动特性进行试验研究。他们的研究发现,由于生物柴油的粘度和表面张力较大,与柴油相比生物柴油更不容易产生空化,因此,本文拟通过添加乙醇改善生物柴油喷孔内的空化流动,促进燃料雾化。

本文利用GAMBIT软件建立三维喷嘴模型,通过FLUENT软件采用混合多相流模型,对纯柴油BD0、纯生物柴油BD100和生物柴油/乙醇混合燃料BD70E30(混合燃料中乙醇的体积掺混比为30%)的喷孔内流动特性进行仿真分析,研究燃料物性差异对喷孔内压强分布、喷射速度和空化程度的影响。

1 计算域网格划分

1.1 喷嘴结构的几何模型

本文采用STD型标准单孔喷嘴,并对其进行适当简化,如图1所示,喷孔直径为0.366 mm,喷孔长度为1.464 mm,喷孔入口为锐角过渡,过渡圆角半径为0,针阀最大升程为0.3 mm。

注:D为喷孔直径,L为喷孔长度,R为过渡圆角半径,h为针阀最大升程。

1.2 网格划分

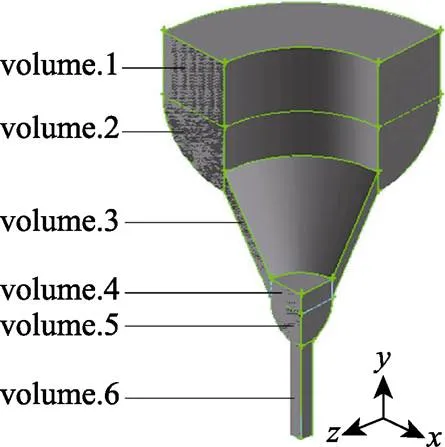

喷嘴为规则圆形结构,为节省计算机资源,提高仿真效率,在不影响模拟准确性的前提下,取1/4喷嘴进行网格划分。喷嘴三维结构如图2所示,为便于划分网格,利用“split volume”命令将整体分割成6块,由上而下依次定义为volume.1、volume.2、volume.3、volume.4、volume.5、volume.6。

图2 喷嘴三维模型

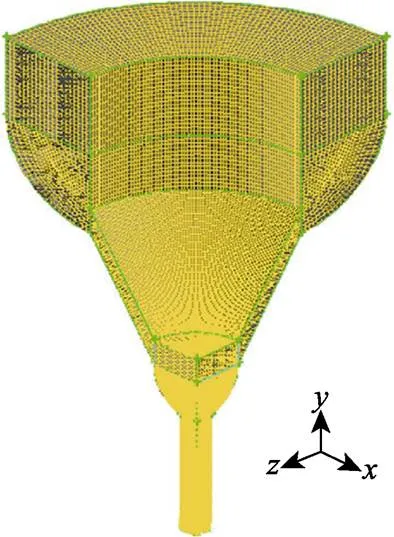

利用分块耦合的方法进行网格划分,划分结果如图3所示,网格总数为109.23万,Aspect Ratio小于2.4的网格总数达到99.6%,满足仿真计算的要求。为避免不同网格划分方法对流动特性的影响,必须对衔接区域进行合理过渡,保证流动方向一致,并对喷孔入口和喷孔内部流动状态复杂处进行网格加密。

图3 喷嘴计算网格

2 数学模型及参数设置

2.1 数学模型

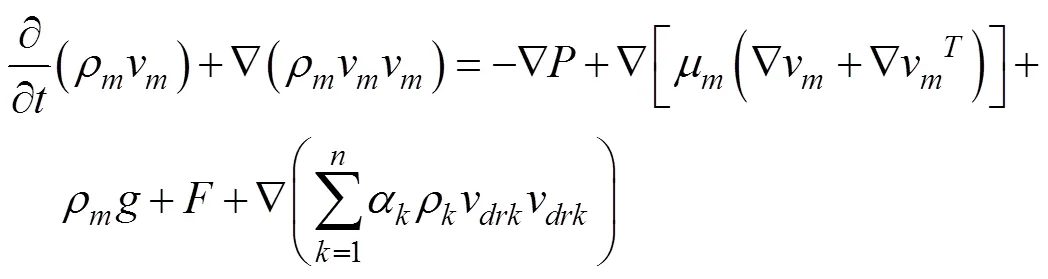

混合模型的连续性方程为

混合模型的动量方程为

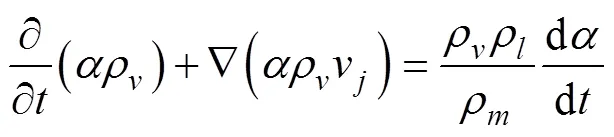

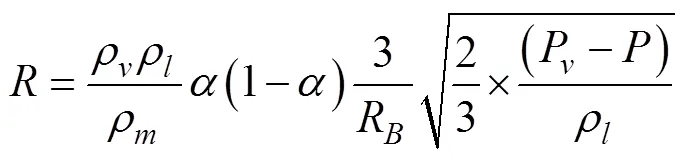

本文在模拟空化现象时,采用FLUENT软件的Schnerr and Sauer模型。

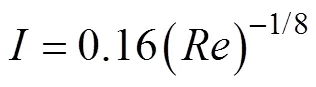

Schnerr and Sauer模型中蒸汽体积分数方程为

蒸汽体积分数与单位体积流体中所含气泡数量的关系为

模型中表示质量转移率的方程为

2.2 燃油物性参数

试验用油为柴油BD0、生物柴油BD100和生物柴油/乙醇混合燃料BD70E30。通过互溶性试验可知,生物柴油与无水乙醇的互溶性良好,在生物柴油中添加30%(体积比)的无水乙醇,放置一周及更长时间后观察,无分层现象发生。生物柴油采用以大豆油为原料通过酯交换法制成的脂肪酸甲酯,它是由多种不同碳链长度的饱和与不饱和脂肪酸甲酯组成,根据前期试验采用气相色谱法测得其中不同组分的含量见表1。由表1可知,该生物柴油中饱和脂肪酸甲酯的含量为30.3%,不饱和脂肪酸甲酯的含量为59.5%,其中亚油酸甲酯、油酸甲酯和棕榈酸甲酯是其主要成分。

表1 大豆油生物柴油的脂肪酸组成

根据前期试验结果,喷孔内多相流仿真需要用到BD0、BD100、BD70E30 3种燃油及其蒸汽的物性参数,通过试验测得3种燃油的密度、动力粘度和表面张力等物性参数;由于BD100和BD70E30的蒸汽参数难以获得,因此采用柴油蒸汽的物性参数计算,燃料的物性参数[30]如表2所示。

表2 燃油物性参数(20℃)

注:BD0为柴油燃料,BD100为生物柴油燃料,BD70E30为生物柴油-乙醇混合燃料,下同。

Note: BD0 is diesel fuel, BD100 is biodiesel fuel, BD70E30 is biodiesel-ethanol blend fuel, the same below.

2.3 边界条件

对于针阀和喷孔中的固定壁面采用不可渗透、无滑移的壁面边界条件,设定壁面温度为293.15 K,壁面法向和切向速度梯度为零,近壁区边界层采用标准壁面函数边界条件。

3 模型验证

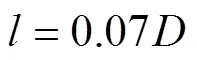

图4为CCD相机拍摄图像[27]与本文数值模拟所得柴油喷孔内空穴分布对比图。从图中可以看出,随着喷射压力的增大,斜单孔喷嘴内空穴分布区域逐渐增大,其内部流动由空穴初生发展为超空穴,数值模拟和试验结果得出的空穴分布区域基本一致。

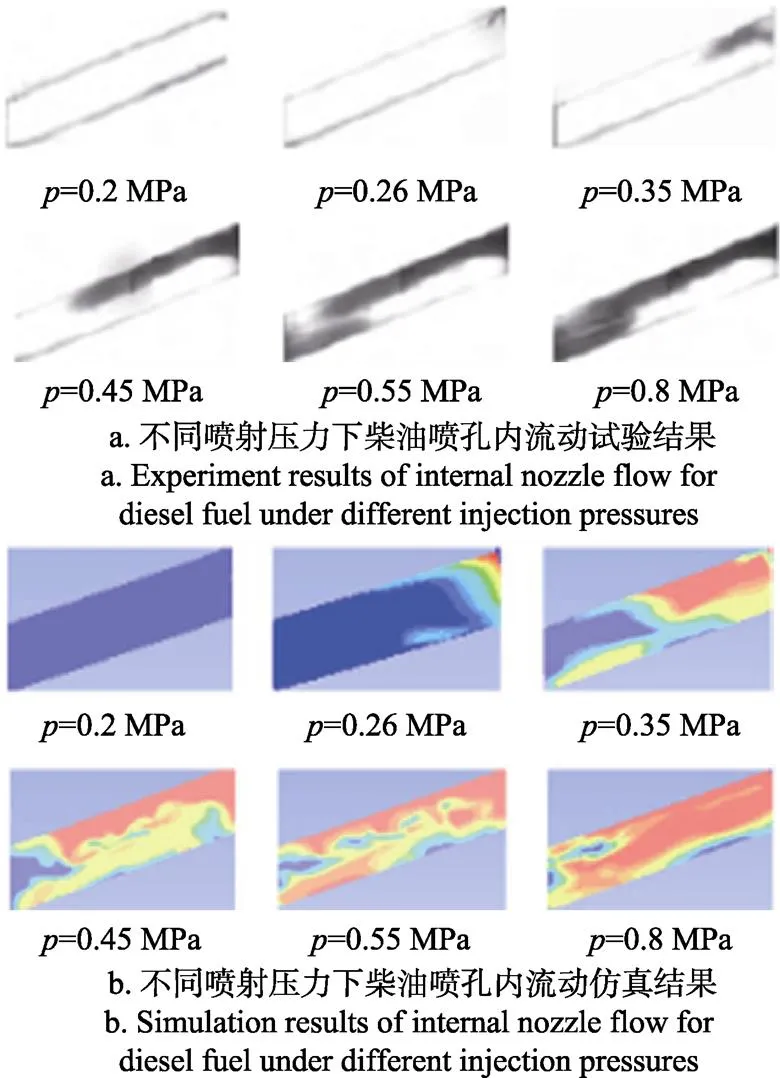

图5为柴油在喷孔内空化相对面积的试验与仿真结果对比。从图中可以看出,空化面积随着喷射压力的增大而增大,在喷射压力为0.35 MPa以下时,增速较慢,当超过此喷射压力时,空化面积急剧增大。仿真结果与试验结果的变化规律一致,数据吻合较好,验证了模型的准确性。但数值模拟相比于试验测定的空化面积稍大,这是由于试验过程中,沿程阻力损失大,使得试验中实际流经喷孔处的压力相比于数值模拟中的压力小,因此试验所得空化相对面积略小于数值模拟结果。

注:p为喷射压力。

图5 柴油空化相对面积的试验与仿真结果对比

4 结果与分析

4.1 压强分布

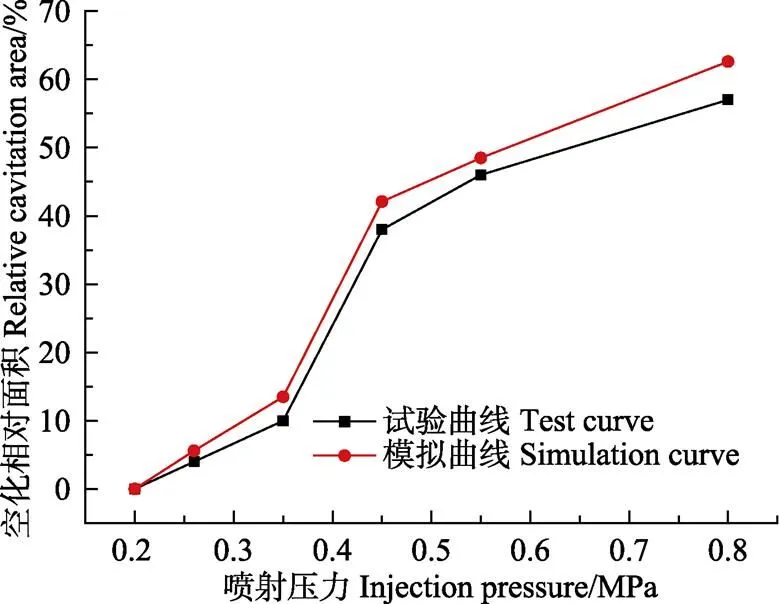

图6为柴油BD0、生物柴油BD100和生物柴油/乙醇混合燃料BD70E30 3种燃油在相同喷射条件下,喷孔内的压强分布云图;图7为3种燃油在不同截面的压强变化规律。可以看出:1)3种燃油压强分布情况相似,在压力室与喷孔入口衔接处,压强梯度很大,从30 MPa迅速下降到11.5 MPa左右;进入喷孔后,在拐角处压强首先下降到燃油的饱和蒸气压;随着燃油继续向出口流动,压强维持在饱和蒸气压,变化不大;在喷孔出口附近,压强略有上升。这是因为当燃油流经压力室到达喷孔入口附近时,流动方向发生改变并且流通截面急剧收缩,导致流动速度迅速增加,压强随之下降;在喷孔入口拐角处燃油流动速度和流动方向变化最为剧烈,首先在该区域达到燃油饱和蒸气压;进入喷孔后,燃油流速逐渐稳定,压强变化不明显;在喷孔出口附近,由于壁面对燃油的黏滞力和环境气压的影响,导致燃油流速下降,压强略有上升。2)BD100的压强下降幅度最大,在喷孔不同截面处,与BD0相比BD100的压强平均下降了23.91%;BD0和BD70E30的压强下降幅度非常接近。这是因为随着燃油流速的增加,压强逐渐下降到饱和蒸气压后才趋于稳定,而BD100的饱和蒸气压最小,稳定后的压强最小;BD70E30的饱和蒸气压与BD0比较接近,压强变化规律相似。

图6 3种燃油喷孔内压强分布云图喷射压力35 MPa

图7 3种燃油在喷孔不同截面处的压强变化

4.2 速度分布

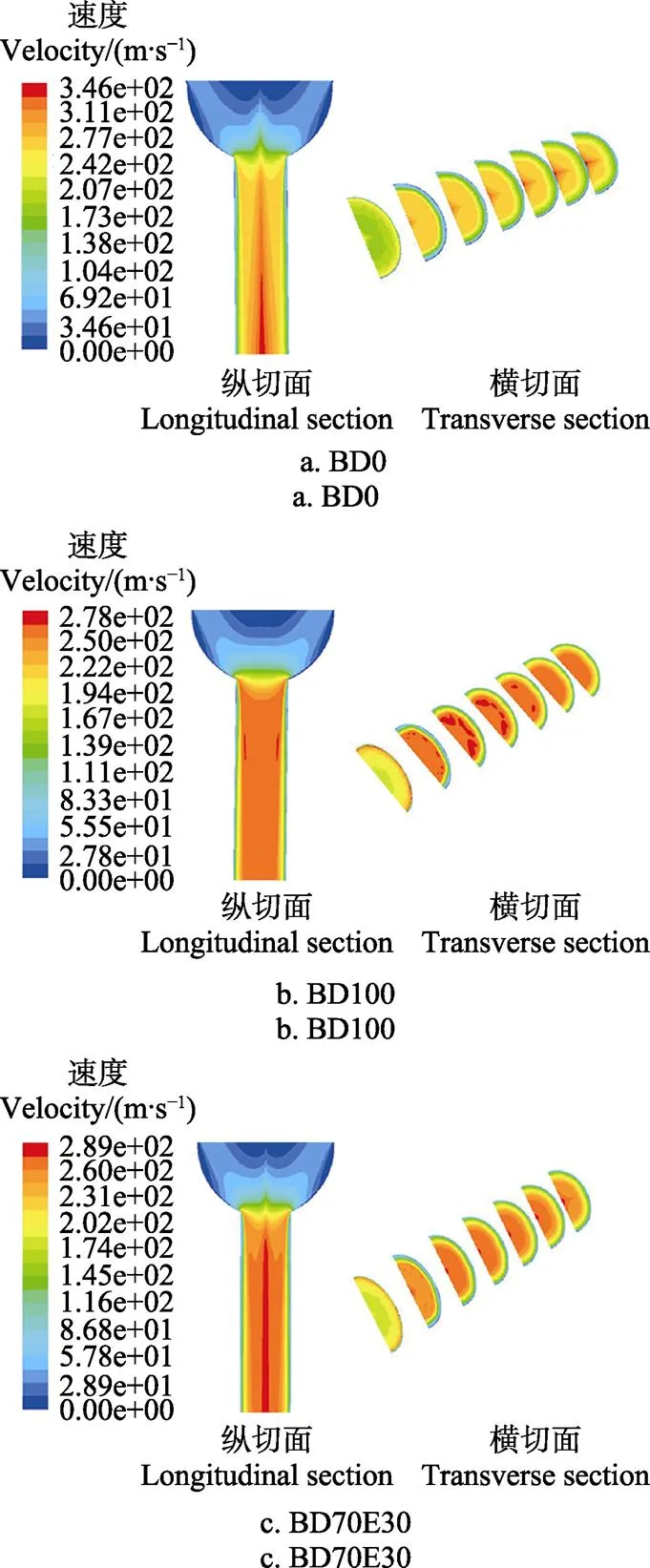

图8为3种燃油喷孔内的速度分布云图,图9为喷孔不同截面上的速度变化规律。从图中可以看出:1)3种燃油速度分布规律基本相同,都是先缓慢增加,在压力室与喷孔入口交界处,速度迅速增加;进入喷孔后,增速放缓,流速逐渐稳定在最大值;在喷孔出口附近,流速出现小幅度下降。这主要是因为燃油流经压力室,流通截面逐渐变小,流动的均匀性变差,方向逐渐改变,流速缓慢增加[31];喷孔入口附近流通截面积最小而且无光滑过渡圆角,流速迅速增加;进入喷孔后,流动截面不再变化,加之壁面对燃油的黏滞效应,流速缓慢增加并趋于稳定[32];喷孔出口附近,壁面黏滞力对流速的影响占据主导地位,流动损失增加,流速出现小幅减小。 2)喷孔径向,速度值由中心轴线向两侧呈递减趋势。这主要是因为燃油与壁面之间存在摩擦作用,导致喷孔中心速度最大,壁面附近速度最小[32]。3)3种燃油在喷孔不同截面处的平均速度不同,BD0的速度最大,其次是BD70E30,BD100的速度最小。在喷嘴出口处,柴油BD0的流速为229.8 m/s,生物柴油/乙醇混合燃料BD70E30的流速为223.1 m/s;生物柴油的流速为214.9 m/s。这主要是因为3种燃油的理化性质不同,BD100的密度、粘度和表面张力最大,流动损失较大,速度相对较小;BD70E30中添加了30%的无水乙醇,可有效降低生物柴油的密度、粘度和表面张力,提高燃油的流动特性,流速增加[33]。

注:横截面取从左到右依次距喷孔入口0、0.25、0.50、0.75、1.00、1.25、1.50 mm,下同。

4.3 空穴分布

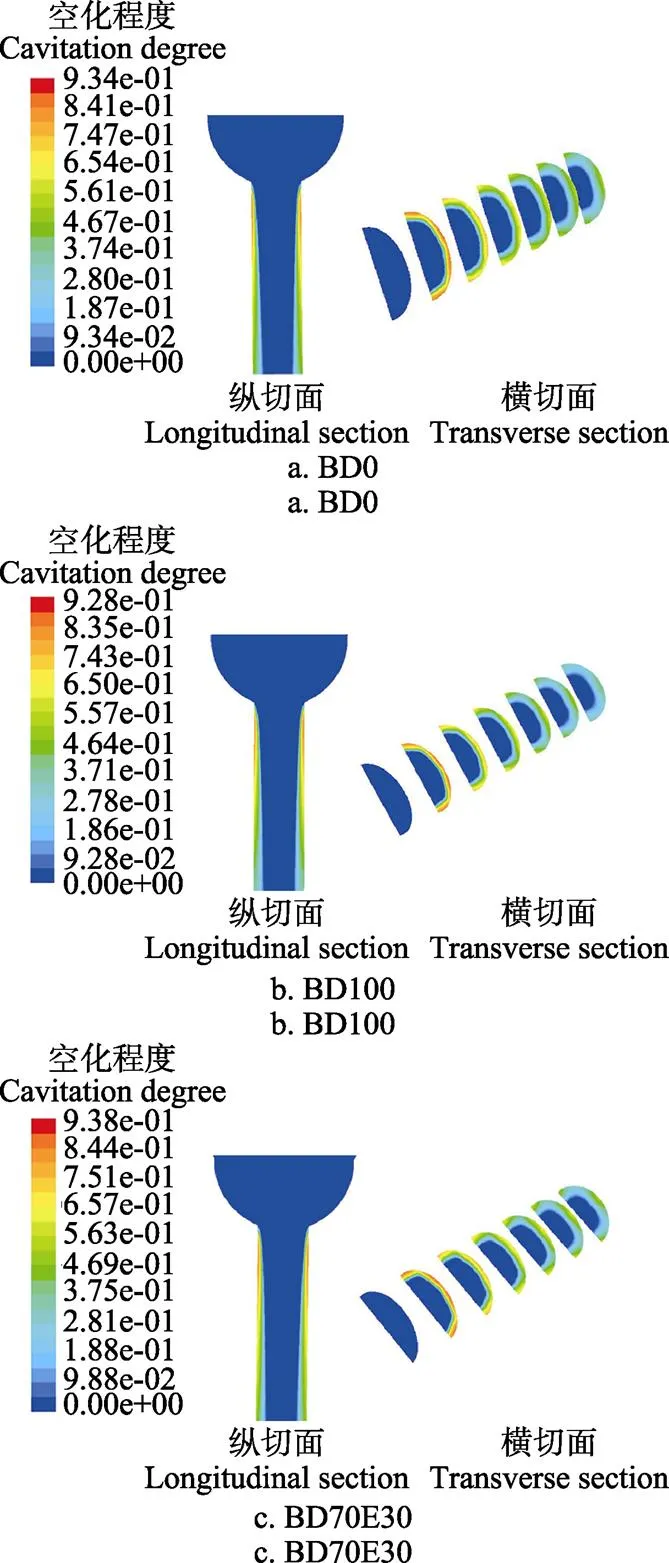

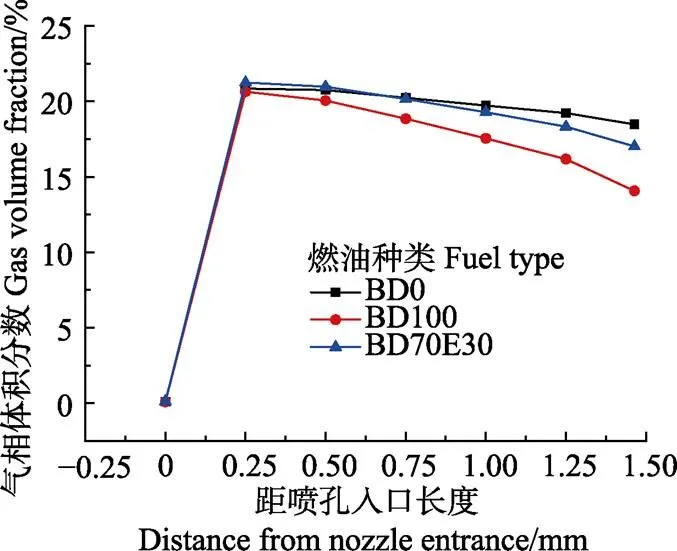

图10为3种燃油喷孔内空穴分布云图,图11为3种燃油在喷孔不同截面处的气相体积分数变化规律。1)由图10可以看出,3种燃油空穴分布规律基本一致,空穴现象首先发生在喷孔入口拐角处,随后向喷孔出口方向发展;空穴层厚度先增加后减小,并且越靠近喷孔壁面,气相体积分数越高[34];随着流动的进行,空穴现象逐渐减弱。这是因为当燃油流经喷孔入口附近时,流通截面急剧收缩,流动速度急剧上升,压力快速下降,并且在喷孔入口拐角处压力下降到燃油饱和蒸气压之下,形成空穴。空穴在射流的带动下向喷孔下游发展,由于空穴具有不稳定性,在发展过程中受到流体的扰动和压力作用,气泡发生溃灭,气相体积分数逐渐下降[34]。2)3种燃油在喷孔内不同截面上的气相体积分数不同,BD100的气相体积分数值最小,其气相体积分数比BD0平均下降了11.1%;BD70E30的气相体积分数与BD0差别不大,仅比BD0降低了1.8%。这是由于3种燃油理化特性不同,BD100的粘度和表面张力最大,饱和蒸汽压最低,不利于空穴现象的产生[28],同时也说明在生物柴油中掺加一定比例的乙醇对于提高燃油空化程度有积极作用。

图9 3种燃油在喷孔不同截面处的速度变化

图10 3种燃油喷孔内空穴分布云图

图11 3种燃油在不同截面处的气相体积分数变化

5 结 论

1)BD0、BD100和BD70E30 3种燃料在压力室与喷孔入口衔接处压强迅速下降;燃料进入喷孔后,压强维持在饱和蒸汽压,变化不大;在喷孔出口处,压强略有上升。BD100的压强降幅最大,在喷孔不同截面处,与柴油相比生物柴油的压强平均下降了23.91 %;BD70E30和BD0的压强下降幅度基本相同。

2)3种燃料的流速在喷孔入口处迅速增加,进入喷孔后增速逐渐放缓,达到最大值后趋于稳定,在喷孔出口处,流速略有下降;3种燃料的流速在喷孔径向从中心向外围呈递减趋势。在喷嘴出口处,BD0的速度最大,达到229.8 m/s;其次为BD70E30,流速为223.1 m/s;BD100的流速最小,其在喷嘴出口处的流速为214.9 m/s。

3)空穴首先发生在喷孔入口拐角处,随后向喷孔出口发展,空穴层厚度先增加后减小,随着流动的进行,空化逐渐减弱。在喷孔不同截面处,BD100的气相体积分数最小,其气相体积分数平均比柴油下降了11.1%,BD70E30的气相体积分数与柴油差别不大,仅比柴油低1.8%。在生物柴油中掺混乙醇可有效提高燃油的流动特性,促进空化现象的产生。

[1] Chauhan B S, Kumar N, Cho H M, et al. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends[J]. Energy, 2012, 37(1): 616-622.

[2] Adaileh W M, AlQdah K S, et al. Performance of diesel engine fuelled by a biodiesel extracted from a waste cooking oil[J]. Energy Procedia, 2012, 18(5): 1317-1334.

[3] McCarthy P, Rasul M G, Moazzem S, et al. Analysis and comparison of performance and emissions of an internal combustion engine fuelled with petroleum diesel and different biodiesels[J]. Fuel, 2011, 90(6): 2147-2157.

[4] Qi D H, Geng L M, Chen H, et al. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil[J]. Renewable Energy, 2009, 34(12): 2706-2713.

[5] 张军,杜青,杨延相,等. 柴油机不同类型喷嘴内部空化流动特性的研究[J]. 内燃机学报,2010,28(2):133-140.Zhang Jun, Du Qing, Yang Yanxiang, et al. Study on cavitating flow in different types of diesel nozzle orifice[J]. Transactions of CSICE, 2010, 28(2): 133-140. (in Chinese with English abstract)

[6] Hassan Mohammadi, Parinaz Jabbarzadeh, Mehrnaz Jabbarzadeh, et al. Numerical investigation on the hydrodynamics of the internal flow and spray behavior of diesel fuel in a conical nozzle orifice with the spiral rifling like guides[J]. Fuel, 2017, 196(5): 419-430.

[7] Wu Shengqi, Xu Min, David L S Hung, et al. Effects of nozzle configuration on internal flow and primary jet breakup of flash boiling fuel sprays[J]. International Journal of Heat and Mass Transfer, 2017, 110(7): 730-738.

[8] Roberto Torelli, Sibendu Soma, Yuanjiang Pei, et al. Influence of fuel properties on internal nozzle flow development in a multi-hole diesel injector[J]. Fuel, 2017, 204(9): 171-184.

[9] Valentino G, Allocca L, Iannuzzi S, et al. Biodiesel/mineral diesel fuel mixtures: Spray evolution and engine performance and emissions characterization[J]. Energy, 2011, 36(6): 3924-3932.

[10] Galle J, Defruyt S, Maele C V D, et al. Experimental investigation concerning the influence of fuel type and properties on the injection and atomization of liquid biofuels in an optical combustion chamber[J]. Biomass & Bioenergy, 2013, 57(10): 215-228.

[11] Mancaruso E, Sequino L, Vaglieco B M. First and second generation biodiesels spray characterization in a diesel engine[J]. Fuel, 2011, 90(9): 2870-2883.

[12] Seunghun C, Youngtaig O. The spray characteristics of unrefined biodiesel[J]. Renewable Energy, 2012, 42(1): 136-139.

[13] 耿莉敏,汪月英,王城,等. 燃料物理性质差异对柴油机喷雾特性的影响[J]. 郑州大学学报(工学版),2014,35(4):14-18. Geng Limin, Wang Yueying, Wang Cheng, et al. Effects of physical properties of fuel on spray characteristics of diesel engine[J]. Journal of Zhengzhou University (Engineering Science), 2014, 35(4): 14-18. (in Chinese with English abstract)

[14] 汪月英. 生物柴油雾化质量改善方法研究[D]. 西安:长安大学,2012. Wang Yueying. Study on the Improvement Method of Biodiesel Atomization Quality[D]. Xi’an: Chang’an University, 2012. (in Chinese with English abstract)

[15] 耿莉敏,曹建明,王磊,等. 生物柴油-柴油混合燃料喷雾特性[J]. 长安大学学报(自然科学版),2009,29(3):89-92. Geng Limin, Cao Jianming, Wang Lei, et al. Atomization characteristics of biodiesel/diesel blend fuel[J]. Journal of Chang’an University(Natural Science Edition), 2009, 29(3): 89-92. (in Chinese with English abstract)

[16] 杨康康,李昕昕,李俊鸽,等. 醇类-生物柴油混合燃料喷雾特性的试验[J]. 内燃机学报,2016,34(3):260-267.Yang Kangkang, Li Xinxin, Li Junge, et al. Experiment on spray characteristics of alcohol and biodiesel blends[J]. Transactions of CSICE, 2016, 34(3): 260-267. (in Chinese with English abstract)

[17] 关力,汤成龙,杨柯,等. 添加二丁醚对生物柴油喷雾特性的影响[J]. 燃烧科学与技术,2015,21(5):453-457.Guan Li, Tang Chenglong, Yang Ke, et al. Effect of Di-n-Butyl ether blending with soybean-biodiesel on spray characteristics[J]. Journal of Combustion Science and Technology, 2015, 21(5): 453-457. (in Chinese with English abstract)

[18] 郭恒杰,李雁飞,李莉,等. 棕榈油生物柴油掺混燃料宏观与微观喷雾特性[J]. 内燃机学报,2015,33(5):385-392.Guo Hengjie, Li Yanfei, Li Li, et al. Experiment on macroscopic and microscopic spray characteristics of palm oil methyl ester[J]. Transactions of CSICE, 2015, 33(5): 385-392. (in Chinese with English abstract)

[19] Yu Shenghao, Yin Bifeng, Jia Hekun, et al. Theoretical and experimental comparison of internal flow and spray characteristics between diesel and biodiesel[J]. Fuel, 2017, 208(11): 20-29.

[20] Su H P, Kim H J, Suh H K, et al. Experimental and numerical analysis of spray-atomization characteristics of biodiesel fuel in various fuel and ambient temperatures conditions[J]. International Journal of Heat & Fluid Flow, 2009, 30(5): 960-970.

[21] 宋晓超,王天友,孟祥赞,等. 燃油温度对生物柴油喷雾特性影响的模拟[J]. 内燃机学报,2015,33(3):232-237.Song Xiaochao, Wang Tianyou, Meng Xiangzan, et al. Numerical investigation of the effect of fuel temperature on spray characteristics of biodiesel fuel[J]. Transactions of CSICE, 2015, 33(3): 232-237. (in Chinese with English abstract)

[22] 王忠,毛功平,袁银男,等. 生物柴油缸内喷雾特性的数值模拟[J]. 内燃机工程,2009,30(3):6-11. Wang Zhong, Mao Gongping, Yuan Yinnan, et al. Numerical simulation of spray characteristics of biodiesel fuel in cylinder[J]. Chinese Internal Combustion Engine Engineering, 2009, 30(3): 6-11. (in Chinese with English abstract)

[23] 姜磊,葛蕴珊,何超. 生物柴油喷雾特性的数值模拟[J]. 内燃机工程,2009,30(5):17-21. Jiang Lei, Ge Yunshan, He Chao. Numerical simulation on spray characteristics of biodiesel fuel[J]. Chinese Internal Combustion Engine Engineering, 2009, 30(5): 17-21. (in Chinese with English abstract)

[24] Som S, Longman D E, Ramírez A I, et al. A comparison of injector flow and spray characteristics of biodiesel with petrodiesel[J]. Fuel, 2010, 89(12): 4014-4024.

[25] 谢阳,姚子澍,麻剑,等. 柴油温度对喷孔内流动特性影响的仿真分析[J]. 浙江大学学报(工学版),2015,49(5):938-943. Xie Yang, Yao Zishu, Ma Jian, et al. Numerical study on internal nozzle flow characteristic of diesel under hot fuel conditions[J]. Journal of Zhejiang University(Engineering Science), 2015, 49(5): 938-943. (in Chinese with English abstract)

[26] Battistoni M, Grimaldi C N. Numerical analysis of injector flow and spray characteristics from diesel injectors using fossil and biodiesel fuels[J]. Applied Energy, 2012, 97(3): 656-666.

[27] 邵壮,何志霞,钟汶君,等. 柴油与生物柴油不同长径比喷嘴内空穴流动的试验[J]. 内燃机学报,2014,32(4): 322-327. Shao Zhuang, He Zhixia, Zhong Wenjun, et al. Visualization experiment on cavitating flow of different length-diameter ratios using diesel and biodiesel in diesel engine nozzles[J]. Transactions of CSICE, 2014, 32(4): 322-327. (in Chinese with English abstract)

[28] 姜光军,张煜盛,Medhat Elkelawy,等. 不同燃料的喷嘴内流动与喷雾形态可视化试验[J]. 农业机械学报,2014,45(5):22-29. Jiang Guangjun, Zhang Yusheng, Medhat Elkelawy, et al. Visualization experiment of internal flow of nozzle and spray construction for various fuels[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(5): 22-29. (in Chinese with English abstract)

[29] 解茂昭. 内燃机计算燃烧学(第2版)[M]. 大连:大连理工大学出版社,2005.

[30] 孙德魁,樊祥山,李俊鸽,等. 脂肪酸甲酯-乙醇混合燃料喷雾特性试验和数值模拟[J]. 内燃机学报,2015,33(2):144-153.Sun Dekui, Fan Xiangshan, Li Junge, et al. Experimental study and numerical simulation of spray characteristics of ethanol-fatty acid methyl ester(FAME)blends[J]. Transactions of CSICE, 2015, 33(2): 144-153. (in Chinese with English abstract)

[31] 张俊. 径向流空气纯化器内流场模拟与气流均布影响因素分析[D]. 天津:天津大学,2014. Zhang Jun. Simulation and Analysis of Gas Flow Distribution in Radial Flow Air Adsorber[D]. Tianjin: Tianjin University, 2014. (in Chinese with English abstract)

[32] 江宏俊. 流体力学(上、下册)[M]. 北京:高等教育出版社,1990.

[33] 王城. 生物柴油-乙醇混合燃料喷孔内流动及喷雾特性的仿真分析和试验研究[D]. 西安:长安大学,2017. Wang Cheng. Experiment and Simulation of Injector Flow and Spray Characteristics of Biodiesel-ethanol Blend Fuel[D]. Xi’an: Chang’an University, 2017. (in Chinese with English abstract)

[34] 张军. 柴油机喷嘴内空化效应的机理及射流破碎特征的研究[D]. 天津:天津大学,2010. Zhang Jun. Investigations of Cavitation in Nozzle and Characteristic of Breakup for Diesel Spray[D]. Tianjin: Tianjin University, 2010. (in Chinese with English abstract)

耿莉敏,王 城,魏有涛,李 琪. 生物质混合燃料在柴油机喷嘴内流动特性模拟[J]. 农业工程学报,2017,33(21):70-77. doi:10.11975/j.issn.1002-6819.2017.21.008 http://www.tcsae.org

Geng Limin, Wang Cheng, Wei Youtao, Li Qi. Simulation on internal flow characteristics of nozzle for diesel engine fueled with biomass blend fuel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(21): 70-77. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.21.008 http://www.tcsae.org

Simulation on internal flow characteristics of nozzle for diesel engine fueled with biomass blend fuel

Geng Limin, Wang Cheng, Wei Youtao, Li Qi

(710064,)

The internal turbulent flow and cavitation flow of the nozzle have effect on the fuel spray and atomization of diesel engine, and especially they have a great impact on the process of primary atomization. Biodiesel is a kind of renewable alternative fuel of diesel. Previous studies have shown that biodiesel has higher density, viscosity and surface tension. Compared with diesel, biodiesel is less likely to generate cavitation flow inside nozzle. Therefore, this paper intends to add ethanol to biodiesel so as to improve cavitation flow of biodiesel in nozzle and advance biodiesel atomization. The geometry of the actual nozzle is very small and visual experimental research on full-size jet nozzle is relatively difficult. Therefore, in this paper, the effects of the fuel properties on the internal flow characteristics of nozzle were studied by computational simulation approaches. A three-dimensional nozzle model was created by GAMBIT, in which, pressure distribution, velocity distribution and cavitation distribution of diesel, biodiesel and biodiesel/ethanol blended fuel in nozzle were simulated with the mixture multiphase model of FLUENT. During the simulation, for validating the mixture multiphase model, turbulence model and cavity model, the comparison between visual experiment and computational simulation results of diesel cavitation area was carried out under different injection pressures. These models were confirmed to be effective. The simulation results show that the pressure drops rapidly at the joint connecting the pressure chamber and nozzle entrance, and the pressure tends to be stable after entering the nozzle, while the pressure increases slightly near nozzle exit. The pressure decline range of biodiesel is the greatest. Compared with diesel, the pressure of biodiesel reduces by 23.91% at the different cross section of nozzle. The pressure decline range is comparable between diesel fuel and biodiesel/ethanol blended fuel. The fuel flow velocity increases rapidly at the entrance of the nozzle, and the flow velocity rises slowly after entering the nozzle, while the fuel flow velocity slightly decreases near the nozzle exit. From the nozzle center to the nozzle periphery, the fuel flow velocity gradually reduces owing to viscous force of the nozzle wall. At the different cross sections of the nozzle, the flow velocity of diesel is the fastest and its flow velocity reaches 229.8 m/s at the nozzle outlet. The flow velocity of biodiesel/ethanol blended fuel is slower than that of diesel and its flow velocity is 223.1 m/s at the nozzle outlet, while the flow velocity of biodiesel is the slowest among the 3 kinds of fuels, and its flow velocity is 214.9 m/s at the nozzle outlet. The cavitation first occurs at the corner of the nozzle entrance, and then it develops to nozzle exit and gradually weakens. At the different sections of nozzle, the gas volume fraction of diesel is the greatest and that of biodiesel is the smallest. The gas volume fraction of biodiesel drops on the average by 11.1% compared with that of diesel and the cavitation of biodiesel is relatively weaker than that of diesel. However, the gas volume fraction of biodiesel/ethanol blended fuel is nearly comparable with that of diesel and there is only 1.8% difference between blended fuel and diesel fuel. Adding ethanol to biodiesel can reduce fuel density, viscosity and surface tension, improve fuel flow characteristics and promote the cavitation of biodiesel in the nozzle. The cavitation in the nozzle can provide initial disturbance for the circular jet spray and promote fuel atomization.

biofuels; ethanol; simulation; blended fuel; internal cavitation flow of nozzle

10.11975/j.issn.1002-6819.2017.21.008

TK6

A

1002-6819(2017)-21-0070-08

2017-07-27

2017-10-10

陕西省交通新能源开发、应用与汽车节能重点实验室开放课题资助项目基金项目(310822161121);中央高校基本科研业务费资助项目(310822172203)

耿莉敏,副教授,主要从事汽车代用燃料喷雾与燃烧特性研究。Email:genglimin@chd.edu.cn