轴流式和切流式机械脱粒对稻谷损伤及加工品质的影响

2017-09-15李毅念陈俊生丁启朔丁为民

李毅念,陈俊生,丁启朔,丁为民

轴流式和切流式机械脱粒对稻谷损伤及加工品质的影响

李毅念,陈俊生,丁启朔,丁为民

(南京农业大学工学院,南京 210031)

为确定不同机械脱粒滚筒收获方式对收获后稻谷品质性状的影响,以手工收获方式稻谷为对照组,对轴流式和切流式脱粒滚筒收获方式收获稻谷的品质性状进行研究,检测不同收获方式稻谷的裂纹率、裂颖率、发芽率、幼苗生长、腹部与背部作为承压面糙米的三点弯曲破碎力、加工品质指标等。测试结果表明:机械脱粒方式收获稻谷与手工收获方式相比,裂颖率增加,发芽和幼苗生长、三点弯曲破碎力和加工品质降低,其中裂颖率最大增加约35.6%,发芽率降低最大达53%,茎秆长度最大降低15 mm,根数量最大降低2.4个,腹部和背部三点弯曲破碎力减小最大值为4.5和3.8 N,整精米率最大降低12.11%;而切流式脱粒滚筒收获方式收获稻谷与轴流式相比,裂颖率较大,发芽率降低达34%~51%,茎杆长度降低最大达12.6 mm,根数量降低最大达1.8个,腹部和背部三点弯曲破碎力差异较小,整精米率降低10.38%。总体来说不同机械脱粒收获方式对稻谷的品质性状影响具有差异性,轴流式脱粒收获方式对稻谷的机械损伤小于切流式脱粒收获方式,机械脱粒损伤稻谷品质性状的评价应该根据稻谷具体使用目的进行客观全面的评价。

机械化;农作物;加工;稻谷轴流式脱粒;切流式脱粒;脱粒损伤;加工品质

李毅念,陈俊生,丁启朔,丁为民. 轴流式和切流式机械脱粒对稻谷损伤及加工品质的影响[J]. 农业工程学报,2017,33(15):41-48. doi:10.11975/j.issn.1002-6819.2017.15.005 http://www.tcsae.org

Li Yinian, Chen Junsheng, Ding Qishuo, Ding Weimin. Effects of axial flow and tangential flow mechanical threshing on rice damage and milling quality[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 41-48. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.15.005 http://www.tcsae.org

0 引 言

机械脱粒损伤是稻谷收获过程中最为重要的损伤源头,对稻谷籽粒产生的损伤包括外部损伤和内部损伤,外部损伤例如稻壳破裂(裂颖)或破(脱)壳、糙米破碎等,内部损伤是一种隐形的损伤,例如内部裂纹或裂缝等[1],这种隐形损伤一般不能从表面观察获得,需要借助仪器或间接的方式进行检测。与此同时脱粒损伤对稻谷籽粒品质性状产生一系列影响,例如水稻种子发芽势和发芽率降低[2],幼苗生长性能降低,糙米裂纹率增加等[3]。

不同收获方式或脱粒方式对稻谷籽粒的脱粒损伤作用可能存在较大差别。割晒收获与直接收获方式之间加工品质的整精米率差异明显[4-5]。脱粒方式对稻谷籽粒裂纹也存在影响,裂纹米率:大型直收机>小型直收机>人工脱粒机,截流滚筒式机械>轴流滚筒式机械[6]。收获时期稻谷籽粒水分含量和脱粒滚筒转速对籽粒破碎率和裂纹率都具有影响,速度越大且水分含量越小破碎率和裂纹率越大,反之亦然[7-8]。

现阶段对于稻谷脱粒的研究主要关注脱粒装置的未脱净损失、夹带损失、功耗等性能指标[9],主要研究脱粒装置的结构、运动参数与脱粒损伤之间的相关关系[10-13],但对稻谷和水稻种子机械脱粒损伤的系统全面研究仍然较少。针对现阶段水稻收获的2种主要机械脱粒方式切流式加双轴流板齿分离滚筒和轴流式脱粒滚筒,以3个品种稻谷为样本,手工收获为对照组,对此2种机械脱粒收获方式产生的稻谷籽粒损伤进行全面系统的对比研究,测试了稻谷裂纹率、裂颖率、发芽势和发芽率、幼苗生长、力学性能以及加工品质等指标,为建立准确评价稻谷机械收获脱粒损伤品质性状指标和选择合适的机械脱粒方式提供参考。

1 材料与方法

1.1 试验材料

试验稻谷样品包括3个粳稻品种,淮稻5号、南粳51、南粳9108,本试验的水稻种子的采集地点为江苏省盐城市大丰区上海农场,采集时间为2015年10月下旬,每个品种分别按3种收获方式:手工收获、脱粒滚筒为切流式加双轴流板齿分离滚筒结构的大型联合收获机收获(简称切流式)、脱粒滚筒为轴流式的中型联合收获机收获(简称轴流式),共9个样品。收获后阴干到稻谷安全贮藏含水量,为避免稻谷种子休眠对种子发芽性能试验的影响,在低温环境下密封贮藏了5个月后进行试验。试验前清理出样品中受到机械收获损伤的破碎、脱壳等糙米籽粒以及发霉变质等非正常的稻谷籽粒,避免对有关试验测试品质性状指标的影响。

1.2 水分含量测试

根据文献[14]中方法对稻谷籽粒含水量进行试验。每个稻谷样品取10 g,在130 ℃下烘24 h,试验重复3次,水稻样品的含水量以湿基表示。

1.3 裂颖率与裂纹率测试

每个样品随机抽样100粒,直接通过目测法检测稻谷的裂颖情况,试验重复5次,取其平均值得该样品的裂颖率。每个样品随机抽样100粒,手工剥去稻谷颖壳获取糙米,利用通光法检测糙米的裂纹情况,试验重复5次,取其平均值得该样品的裂纹率。

1.4 发芽率与幼苗生长性能测试

取100粒稻谷在去离子水中浸泡3 h,然后均匀地排布在透明发芽盒内湿润的发芽纸床上,粒与粒之间应保持一定间距,按国标GB/T3543.4-1995[15]中规定的条件进行培养,在5 d后计算每个样本的发芽势,14 d后计算发芽率,试验重复3次。每个样本随机抽取10株幼苗,测试每株幼苗的叶片数目、叶片长度、茎杆高度、根长、根数等幼苗生长指标[16]。

1.5 三点弯曲破碎力测试

糙米抗弯折断力学性能试验采用三点弯曲测试方法[17]。为测试糙米籽粒腹部和北部三点弯曲破碎力,且能够使糙米在腹部和背部方向固定,在试验装置宽3.4 mm的槽两端加工出三角形的型槽,便于糙米腹部或背部作为承压面进行测试。试验装置结构参见文献[18]。试验使用TMS-PRO型质构仪(美国FTC公司)对籽粒力学性能进行测试,压头加载速度设置为30 mm/min,压头宽为1.2 mm,长度为10 mm。

试验前从试验样品中随机取出稻谷籽粒,先人工剥去籽粒外部的颖壳,再分别以每个样品糙米的腹背、背部作为承压面来进行试验。每个样品腹部、背部测试籽粒数量各100粒,计算腹部、背部破碎力的平均值和不同受力段籽粒个数的分布情况。

1.6 加工品质测试

根据国标GB/T 5495-2008[19]和国标GB/T 21719-2008[20]对3个品种稻谷样品的加工品质指标进行了测试。稻谷加工设备为试验用砻谷机(型号:THU35C,佐竹机械(苏州)有限公司)和试验用碾米机(型号:CBS300AS,佐竹机械(苏州)有限公司)。试验每次加工100 g以上的稻谷籽粒,净稻谷经试验砻谷机脱壳后得到糙米,计算糙米率指标。将得到的糙米进行3 min的碾米加工,用筛子将碎米筛选出来后得到精米率、整精米率和碎米率指标。试验重复3次,误差在准许范围内则可取其平均值作为加工品质指标。

2 结果与分析

2.1 水分含量

含水率在一定程度上会影响稻谷的加工品质与力学特性,因此试验前对含水率进行测定并分析。不同脱粒收获方式水稻含水率检测结果如表1所示。

3种脱粒方式采集得到的淮稻5号的平均含水率约为13.88%,南粳51的平均含水率约为14.16%,南粳9108的平均含水率约为13.86%。3种脱粒收获方式采集的淮稻5号的含水率最大相差0.12%,南粳51含水率最大相差0.27%,南粳9108含水率最大相差0.42%,总体来说,切流式、轴流式、手工收获稻谷水分含量依次减小,其中南粳51和南粳9108稻谷2个品种手工收获与切流式收获差异显著,但每个品种在不同脱粒方式下得到的样品含水率在一定范围内,对其加工品质和力学特性影响较小。总体来说,切流式收获稻谷籽粒中稻壳脱离和破碎籽粒较多,导致籽粒间间隙较小,孔隙率变小,空气流动性降低[21],与手工收获相比较含水量稍大。水分含量差异越接近对加工品质和力学性能测试影响越小[22-23]。

2.2 裂颖率与裂纹率分析

3个品种3种脱粒收获方式下水稻样品的裂颖率和裂纹率指标如表1所示。

由表1可知,淮稻5号手工收获较轴流式收获裂颖率低35.6%,南粳51手工收获较轴流式收获裂颖率低8.4%,而南粳9108手工收获与轴流式收获相当;3个品种中,手工收获较切流式收获裂颖率低,淮稻5号低14.4%,南粳51低23.2%,南粳9108低7.5%,轴流式与切流式相比较,南粳51低14.8%,南粳9108低10.3%,而淮稻5号高21.2%。总体来说,机械脱粒收获对稻谷颖壳产生脱粒作用力使其颖壳开裂,导致裂颖率增加,其中切流式脱粒方式对稻谷颖壳产生的损伤作用较大,其裂颖率大于轴流式脱粒方式(除淮稻5号品种轴流式裂颖率较大外)。切流式和轴流式脱粒使糙米裂纹率增加,淮稻5号和南粳51品种,切流式裂纹率最大,轴流式其次,而南粳9108品种轴流式裂纹率最大,但与手工和切流式比较差异不大。除南粳51品种手工收获与切流式收获差异显著外,其他所有品种3种收获方式裂纹率差异性不显著。机械脱粒过程中对糙米产生机械力作用,从糙米裂纹率来看,由于糙米表面颖壳保护,机械作用对糙米裂纹损伤程度较低,但对稻谷颖壳损伤程度较高。

2.3 发芽和幼苗生长分析

水稻种子发芽势和发芽率测试结果如表2所示。切流式收获的水稻种子的发芽势和发芽率较轴流式、手工收获相比均明显偏低,具有显著差异,切流式与手工收获相比较,淮稻5号发芽势和发芽率差异最大达52%和 53%,南粳9108发芽势和发芽率差异最小达32%和34%。在3个品种中,轴流式收获与手工收获水稻种子的发芽势和发芽率较接近或略小,差异不明显。在发芽试验过程中发现,切流式收获的种子幼苗较其他2种收获所得的种子的幼苗相比,叶片有轻微发黄现象。

轴流式收获和手工收获方式水稻种子幼苗生长的茎杆长度和平均根数量均大于切流式收获方式,且轴流式与人工收获方式较接近。切流式与手工收获相比较,茎秆长度相差最大的为淮稻5号15 mm,根数量相差最大的为南粳51达2.4个,茎秆长度相差最小的为南粳51达7 mm,根数量最小的为淮稻5号达1.6个。轴流式收获与切流式收获比较,茎杆长度差异最大的是淮稻5号达12.6 mm,根数量差异最大是南粳9108达1.8个。3种收获方式下水稻种子幼苗生长的平均根长度、平均叶片数量和叶长度无明显差异。其中南粳51品种幼苗茎杆长度切流式与轴流式和人工收获方式差值较小,南粳9108其次,淮稻5号差异最大,说明不同品种水稻种子对机械损伤特性存在差异。

通过种子发芽和幼苗生长分析可以看出,总体来说切流式机械脱粒收获对水稻种子产生的机械损伤大,而轴流式机械脱粒收获对水稻种子产生的机械损伤较小。轴流式脱粒与人工收获水稻种子的发芽和幼苗生长较好,并且比较接近,因此在水稻种子机械收获可考虑采用轴流式脱粒方式收获机械,以减小机械收获对水稻种子发芽和幼苗生长产生的损伤。

2.4 三点弯曲破碎力分析

在糙米籽粒进行三点弯曲破碎力学性能试验时,以腹部作为承压面时,腹部受压应力,背部受拉应力;相反之,当以背部作为承压面时,则背部受压应力,腹部受拉应力。籽粒压应力强度极限远远大于拉应力强度极限[24-25],故籽粒首先应从籽粒承受拉应力一侧断裂并且向另一侧延伸,直至籽粒完全断裂。糙米腹部、背部作为承压面的三点弯曲破碎力平均值如表3所示,除南粳51糙米籽粒腹部破碎力3种脱粒方式接近外,其他手工收获方式的腹部和背部破碎力均大于机械收获方式;糙米腹部作为承压面的三点弯曲破碎力大于背部作为承压面的三点弯曲破碎力,根据稻谷籽粒拉压强度极限值,可推测糙米籽粒背部的拉应力强度大于腹部的拉应力强度,即籽粒背部结构强度大于腹部结构强度[26]。机械收获导致糙米籽粒腹部和背部三点弯曲破碎力与人工收获相比较减小,淮稻5号切流式腹部和背部减小4.5和3.8 N,轴流式腹部和背部减小2.6和1.1 N;南粳9108切流式腹部和背部减小0.3和2.9 N,轴流式腹部和背部减小3.5和3.1 N;南粳51切流式和轴流式腹部与人工收获变化不大,近似相等,背部减小1.7和2.3 N;说明机械脱粒对稻谷籽粒产生了损伤使其结构强度降低从而使三点弯曲破碎力减小。

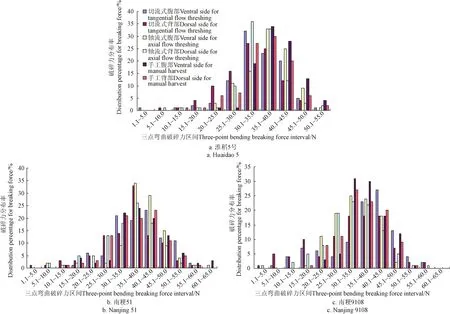

淮稻5号3种收获方式的糙米腹部、背部受力的三点弯曲破碎力区间分布特性如图1a所示,很明显手工收获腹部破碎力区间分布率在破碎力较大一侧大于切流式和轴流式腹部破碎力分布率,说明手工收获糙米籽粒腹部破碎力值较大部分比例较大,而切流式和轴流式收获糙米籽粒腹部破碎力值较小部分比例较大;手工背部破碎力分布率与切流式和轴流式背部分布率相类似。机械收获糙米籽粒腹部和背部作为承压面的三点弯曲破碎力整体小于手工收获稻谷籽粒三点弯曲破碎力,因此机械脱粒收获对糙米籽粒的力学强度产生了损伤。手工收获糙米籽粒腹部三点弯曲破碎力整体分布率较背部破碎力分布率偏向破碎力较大一侧,说明籽粒腹部作为承压面的三点弯曲破碎力大于背部破碎力。

南粳51和南粳9108不同脱粒收获方式的糙米籽粒腹部、背部受力的三点弯曲破碎力分布特性如图1b和1c所示,不同脱粒收获方式腹部、背部三点弯曲破碎力分布情况同样亦存在差异,三点弯曲破碎力分布特性与淮稻5号不同收获脱粒方式类似。

2.5 加工品质指标分析

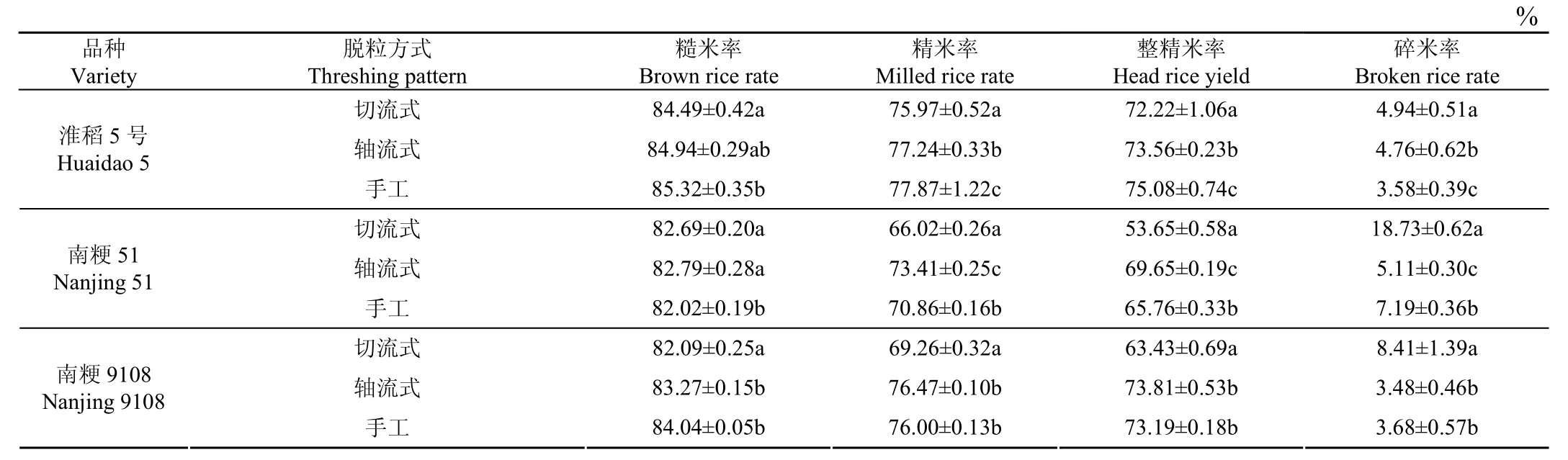

评价稻谷的加工品质的相关指标有糙米率、精米率、整精米率和碎米率,测试结果如表4所示。

图1 不同机械脱粒收获方式糙米籽粒腹部、背部三点弯曲破碎力分布特性Fig.1 Distribution features of three-point bending breaking force on ventral side and dorsal side of brown rice under different mechanical threshing patterns

表4 不同机械脱粒方式稻谷加工品质Table 4 Milling quality of rice under different mechanical threshing patterns

由表4可知,3个品种稻谷在不同脱粒收获方式下所得的糙米率基本相当,糙米率均大于80%,相差较小。3个品种稻谷在不同脱粒收获方式下所得的精米率和整精米率有所差异。切流式和轴流式收获的淮稻5号与手工收获比较,切流式精米率和整精米率最小,轴流式其次,切流式相差1.90%和2.86%,轴流式相差0.63%和1.52%。另外2个品种切流式收获与轴流式和手工收获相比较其精米率和整精米率相差较大。对于南粳51,切流式收获样品与轴流式相比,精米率低7.39%,整精米率低16.00%;切流式收获与手工收获相比,精米率低4.82%,整精米率低12.11%;而对于南粳9108,切流式收获样品与轴流式相比,精米率低7.12%,整精米率低10.38%;切流式收获与手工收获相比,精米率低6.71%,整精米率低9.76%。3个品种稻谷样品,轴流式收获与手工收获所得精米率和整精米率之间差值较小,南粳9108差异性不显著,而南粳51和淮稻5号差异性显著;切流式收获与手工收获所得精米率和整精米率之间差值较大,差异性均显著;轴流式收获与切流式收获所得精米率和整精米率之间差值亦较大,3个品种差异性均显著。相应的整精米率高,碎米率就低,轴流式和人工收获稻谷碎米率都较低。

切流式收获得到的精米与其他2种收获所得精米相比,颜色偏黄,有较大差异,轴流式和手工收获水稻的加工品质效果较接近。机械收获对稻谷籽粒有一定的机械损伤,经碾米加工,损伤稻谷籽粒更容易破碎,造成碎米率增加,整精米率降低。切流式脱粒收获方式在脱粒过程中稻谷籽粒受到的损伤程度更大,其裂颖率和裂纹率都较大,从而导致机械加工过程中受到损伤的稻谷籽粒易破碎,整精米率降低和碎米率增加。轴流式脱粒收获方式在脱粒过程中稻谷籽粒受到的损伤程度较小,其裂颖率和裂纹率较小,在机械加工过程中糙米籽粒不易破碎,整精米率降低较小或碎米率不高。因此,选择合适的收获方式是获得优质大米的有效方法之一,为减小稻谷脱粒损伤可以选用轴流式收获方式。从加工品质整精米率来看,机械脱粒收获对糙米内部产生了较大的损伤,因此整精米率下降较大,但从糙米裂纹率来看各种收获方式下降并不是较大,差异性并不显著,说明机械脱粒损伤仍然可能以比较隐形的方式存在于糙米内部,因此这种机械损伤如何评价和衡量有待进一步分析。

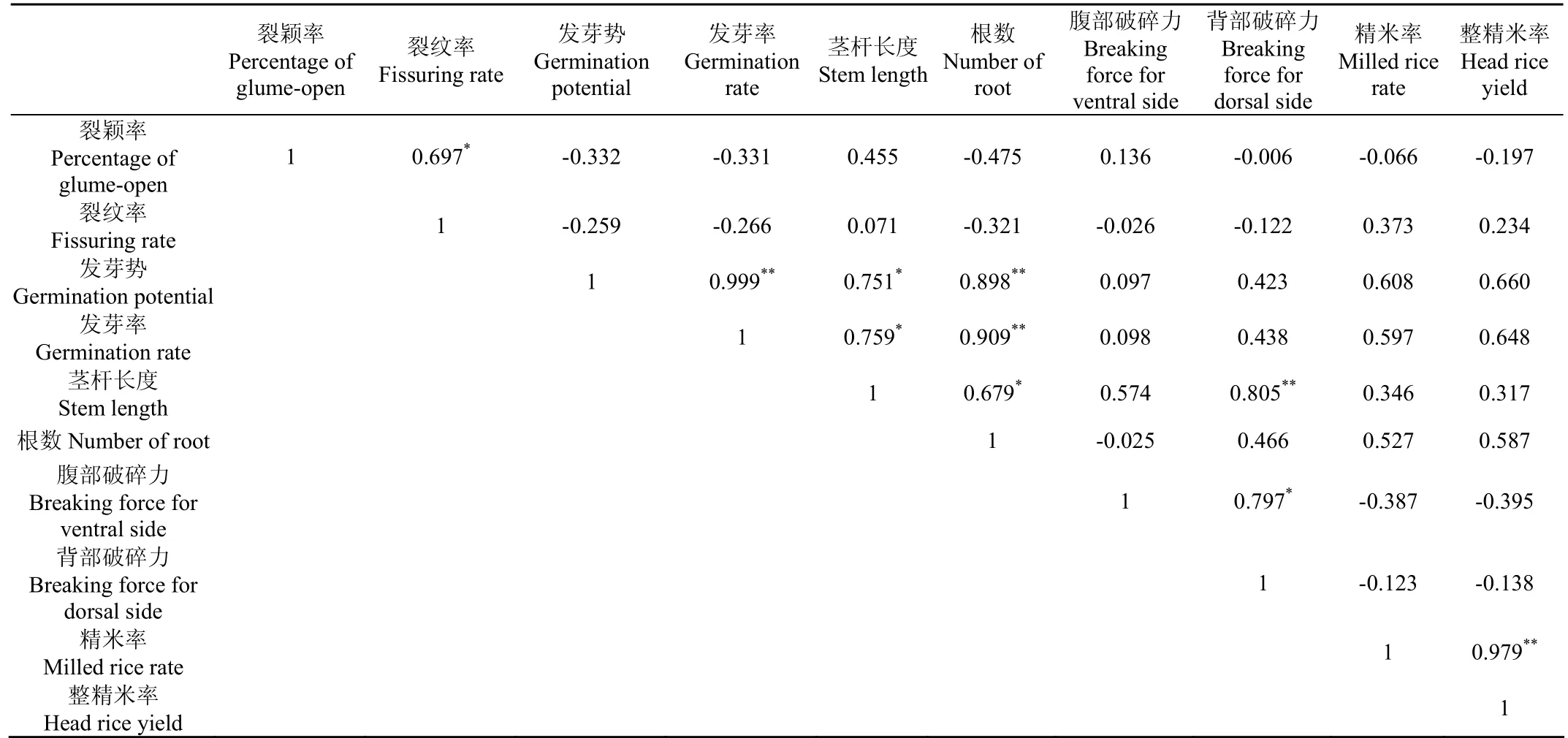

2.6 稻谷籽粒品质性状评价指标之间相关关系分析

稻谷籽粒在机械脱粒过程中产生损伤,其中稻谷籽粒的脱壳、破碎、裂颖和裂纹损伤,这是一种显性的损伤,与此同时通过测试机械脱粒稻谷籽粒发芽性能、幼苗生长、力学性能和加工品质指标降低才能获知其品质性状的称为隐形损伤,稻谷籽粒产生了某种隐形损伤导致这些相应的表观指标下降。通过对这些品质性状指标的相关分析(表5)可以看出,显性损伤品质指标裂颖率和裂纹率之间互相关,而显性损伤品质指标与隐形损伤指标之间却不相关;表现水稻种用性能的发芽势、发芽率、幼苗茎杆长度和根数各指标之间互相关,除茎杆长度与背部三点弯曲破碎力互相关外,其他表现种子种用性能的指标与所有其他品质指标均不相关;腹部三点弯曲破碎力与背部三点弯曲破碎力互相关,力学性能指标与其他品质指标都不相关;精米率与整精米率互相关,加工品质指标与其他指标都不相关。

表5 不同机械脱粒方式下稻谷籽粒品质评价指标之间相关关系分析Table 5 Correlation analysis of appraise indices for rice quality under different mechanical threshing patterns

2.7 讨 论

机械收获稻谷籽粒的裂颖率和裂纹率增加,发芽性能、幼苗生长、力学性能和加工品质指标降低等与采用不同脱粒收获方式有关,轴流式脱粒滚筒脱粒的形式,滚筒转速505 r/min,对水稻损伤较小;切流式脱粒滚筒加双轴流板齿分离滚筒的组合结构,滚筒转速800~900 r/min,分离滚筒长度3 344 mm,且为双滚筒结构,分离面积更大,脱粒能力更强,稻谷籽粒和秸秆一起被送入脱粒装置进行脱粒,秸秆与稻谷籽粒缠绕在一起,脱粒需要较大的速度和撞击力,对稻谷籽粒作用时间亦较长,因此,对稻谷籽粒损伤也较严重。

通过本研究可以发现,稻谷收获机械脱粒损伤是不可避免的,其影响程度直接与收获机械脱粒方式有关,因此研究尽可能减少机械损伤的收获方式具有现实意义。为了降低水稻种子的裂纹率和裂颖率,提高发芽性能和加工品质等指标,根据本研究尽可能采用轴流式机械脱粒方式进行收获,也可采用以柔性材料做脱粒齿的柔性脱粒系统以减小脱粒过程中对种子的损伤[27-30]。目前虽然国内有从事柔性脱粒方面的研究[31],并且已经证明柔性机械脱粒能够减少对种子的损伤,提高种子发芽性能[2],但仍然需要对此类机械脱粒方式稻谷品质性状损伤程度进行全面分析。

现阶段稻谷机械脱粒收获后对稻谷的检测主要侧重于谷外糙米含量(脱壳)、破碎等外在损伤方面,通过本研究可以看出,收获机械作用在对稻谷籽粒产生外在损伤的同时对其内部亦产生损伤,导致稻谷籽粒在裂颖率和裂纹率增加的同时,发芽性能降低,三点弯曲破碎力降低和加工品质降低,因此现阶段对稻谷收获机械脱粒损伤定量化研究的指标仍然不够客观全面。对于水稻种子的机械收获要求更高,在检测机械收获后水稻种子谷外糙米含量、破碎等指标基础上,应同时考虑测试收获机械脱粒后种子裂颖率、裂纹率、发芽势和发芽率、幼苗生长性能,对于主要用于食用的稻谷,可考虑测试收获后裂颖率、裂纹率、力学性能和加工性能等。因此收获机械脱粒性能评价应考虑收获后机械脱粒损伤对稻谷的品质性状指标影响。

从试验数据和显著性分析可以看出,稻谷籽粒机械收获产生脱粒损伤表现为裂颖率和裂纹率增加,发芽率降低,幼苗生长性能下降,糙米力学强度降低,加工性能降低等,并且切流式与轴流式2种机械脱粒方式差异性显著,但发芽和幼苗生长性能降低与脱粒损伤中何种特性有关有待进一步研究。

稻谷籽粒在脱粒过程中受到脱粒机械作用力,导致糙米籽粒产生损伤,力学性能降低,稻谷的整精米率降低,因此糙米的整精米率与其籽粒力学强度可能存在一定的相关关系,糙米的整精米率与籽粒在两平面间的压缩性能相关性较小[32],与籽粒抵抗三点弯曲破碎力强度大于20 N的百分率密切相关,即此百分率越大稻谷的加工整精米率越大[33],但本研究中相关性仍然较低,因此有待进一步研究。

3 结 论

1)机械脱粒收获稻谷籽粒裂颖率较手工收获大,裂颖率最大增加约35.6%,机械脱粒收获稻谷发芽势和发芽率降低,切流式与手工收获相比较发芽势和发芽率降低最大达52%和53%,最小达32%和34%;幼苗生长性能亦降低,茎秆长度最大降低15 mm,最小7 mm,根数量最大降低2.4,最小1.6个;切流式脱粒滚筒收获方式收获稻谷与轴流式相比,裂颖率较大,发芽率降低达34%~51%,茎杆长度降低最大达12.6 mm,根数量降低最大达1.8个;

2)机械脱粒收获糙米腹部和背部三点弯曲破碎力小于手工收获糙米腹部和背部三点弯曲区破碎力,切流式脱粒收获破碎力降低最大,腹部和背部减小最大值为4.5和3.8 N,轴流式脱粒收获其次,腹部和背部减小最大值为3.5和3.1 N,因此机械脱粒对稻谷籽粒结构强度产生了损伤;切流式脱粒滚筒收获方式收获稻谷与轴流式相比,腹部和背部三点弯曲破碎力差异较小;

3)机械脱粒收获稻谷的加工品质较手工收获方式降低,其整精米率降低,碎米率增加,切流式脱粒收获方式整精米率最低,与手工收获相比较最大差异为12.11%,最小为2.86%,轴流式脱粒收获方式其次;切流式脱粒滚筒收获方式收获稻谷与轴流式相比,整精米率降低10.38%;

4)通过对比分析切流式、轴流式和手工3种脱粒收获方式,机械脱粒收获对稻谷籽粒产生了损伤,切流式脱粒收获对稻谷的损伤最大,轴流式收获方式对稻谷籽粒的机械损伤较小,水稻种子机械收获宜选用轴流式脱粒收获方式。机械脱粒损伤稻谷品质性状的评价应根据稻谷具体使用目的进行客观全面的评价。

[1] 徐立章,李耀明,王显仁. 稻谷脱粒损伤的量化与检测方法[J]. 农业机械学报,2007,38(11):185-188.

[2] 谢方平,罗锡文,苏爱华,等. 刚性弓齿与杆齿及柔性齿的脱粒对比试验[J]. 湖南农业大学学报,2005,31(6):648-651.

Xie Fangping, Luo Xiwen, Su Aihua, et al. Contrastive experiment on threshing by using rigid wire-loop, rigid pole tooth and flexible pole tooth[J]. Journal of Hunan Agricultural University, 2005, 31(6): 648-651. (in Chinese with English abstract)

[3] Javid H, Esfahani M, Sabouri S. Effect of three threshing methods on kernel fissuring, seed germination and seedling growth in rice (oryza sativa l.) cv. Hashemi[J]. Seed and Plant Production Journal, 2011, 27(1): 57-72.

[4] 苗得雨,魏玉光,贺海生. 不同收获时期和收获方式对水稻碾米品质和产量的影响[J]. 北方水稻,2007(4):25-27.

Miao Deyu, Wei Yuguang, He Haisheng. Effect of harvesting time and pattern on milling quality and yield of rice[J]. North Rice, 2007(4): 25-27. (in Chinese with English abstract)

[5] 张振宇,党姝,林秀华,等. 不同收获时间和方式对水稻外观品质及加工品质的影响[J]. 黑龙江农业科学,2010(2):22-24.

Zhang Zhenyu, Dang Shu, Lin Xiuhua, et al. Effect of the different harvest time and method on processing quality and appearance quality in rice[J]. Heilongjiang Agricultural Sciences, 2010(2): 22-24. (in Chinese with English abstract)

[6] 张国民,李锐,刘士勇,等. 寒地稻区水稻裂纹米发生机理及其防御对策的研究Ⅱ栽培措施和收获加工措施对裂纹米率的影响[J]. 黑龙江农业科学,2006(2):13-16.

Zhang Guomin, Li Rui, Liu Shiyong, et al. Study on occurrence mechanism and preventive measure ofcrackle-rice in cold region Ⅱ the influence of cultivation, harvest and processing methods on the rate of crackle-rice[J]. Heilongjiang Agricultural Sciences, 2006(2): 13-16. (in Chinese with English abstract)

[7] Sharma A D, Kunze O R, Sarker N N. Impact damage on rough rice[J]. Transactions of the ASAE, 1992, 35(6): 1929-1934.

[8] Alizadeh M R, Khodabakhshipour M. Effect of threshing drum speed and crop moisture content on the paddy grain damage in axial-flow thresher[J]. Cercetări Agronomice în Moldova, 2010, 43(4): 5-11.

[9] 李耀明,陈洋,徐立章,等. 斜置切纵流联合收获机脱粒分离装置结构参数优化[J]. 农业机械学报,2016,47(9):56-61.

Li Yaoming, Chen Yang, Xu Lizhang, et al. Optimization of structural parameters for threshing and separating device in oblique tangential-longitudinal combine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 56-61. (in Chinese with English abstract)

[10] 徐立章,李耀明,李洪昌. 水稻谷粒脱粒损伤的影响因素分析[J]. 农业机械学报,2008,39(12):55-59.

Xu Lizhang, Li Yaoming, Li Hongchang. Analysis on factors affecting performance of rice kernel damage during threshing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(12): 55-59. (in Chinese with English abstract)

[11] 王显仁,李耀明,徐立章. 水稻脱粒破碎率与脱粒元件速度关系研究[J]. 农业工程学报,2007,23(8):16-19.

Wang Xianren, Li Yaoming, Xu Lizhang. Relationship between thresher velocities and rice grain broken rate [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(8): 16-19. (in Chinese with English abstract)

[12] 徐立章,李耀明,丁林峰. 水稻谷粒与脱粒元件碰撞过程的接触力学分析[J]. 农业工程学报,2008,24(6):146-149.

Xu Lizhang, Li Yaoming, Ding Linfeng. Contacting mechanics analysis during impact process between rice and threshing component[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(6): 146-149. (in Chinese with English abstract)

[13] 徐立章,李耀明. 水稻谷粒冲击损伤临界速度分析[J]. 农业机械学报,2009,40(8):54-57.

Xu Lizhang, Li Yaoming. Speed of impact damage on a rice kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(8): 54-57. (in Chinese with English abstract)

[14] Jindal V K, Siebenmorgen T J. Effects of oven drying temperature and drying time on rough rice moisture content determination[J]. Transactions of the ASAE, 1987, 30(4): 1185-1192.

[15] 全国农作物种子标准化技术委员会. 农作物种子检验规程:发芽试验:GB/T3543.4-1995[S]. 北京:中国标准出版社,1995.

[16] 申宝营,李毅念,赵三琴,等. 暗期补光对黄瓜幼苗形态调节效果及综合评价[J]. 农业工程学报,2014,30(22):201-208.

Shen Baoying, Li Yinian, Zhao Sanqin, et al. Effect of dark period lighting regulation on cucumber seedling morphology and comprehensive evaluation analysis and comprehensive evaluation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(22): 201-208. (in Chinese with English abstract)

[17] ASAE. Shear and three point bending test of animal bone: ASAE Standards S459[S]. American Society of Agricultural Engineers, St. Joseph, MI. 2001.

[18] 李毅念,徐小琴,丁为民. 糙米三点弯曲破碎力学性能试验分析[J]. 农业机械学报,2010,41(8):121-124.

Li Yinian, Xu Xiaoqin, Ding Weimin. Experiment analysis on three-point bending breaking force of brown rice[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(8): 121-124. (in Chinese with English abstract)

[19] 全国粮油标准化技术委员会. 粮食检验 糙米出糙率检验:GB/T 5495-2008[S]. 北京:中国标准出版社,2009.

[20] 全国粮油标准化技术委员会. 稻谷整精米率检验法:GB/T 21719-2008[S]. 北京:中国标准出版社,2008.

[21] 袁越锦,杨彬彬,徐英英,等. 非固结多孔介质干燥的双尺度孔道网络模型与模拟[J]. 工程热物理学报,2010,31(2):302-306.

Yuan Yuejin, Yang Binbin, Xu Yingying, et al. Dual-scale pore network simulation on drying of unconsolidated porous media[J]. Journal of Engineering Thermophysics, 2010, 31(2): 302-306. (in Chinese with English abstract)

[22] Kamst G F, Bonazzi C, Vasseur J, et al. Effect of deformation rate and moisture content on the mechanical properties of rice grains[J]. Transactions of the ASAE, 2002, 45(1): 145-151.

[23] 贾富国,南景富,白士刚. 糙米的含水率与其碾米性能的影响规律研究[J]. 东北农业大学学报,2006,37(5):665-668.

Jia Fuguo, Nan Jingfu, Bai Shigang. Study on the relationship between the moisture content of rice and milling characteristics[J]. Journal of Northeast Agricultural University, 2006, 37(5): 665-668. (in Chinese with English abstract)

[24] Kamst G F, Vasseur J, Bonazzi C, et al. A new method for the measurement of the tensile strength of rice grains by using the diametral compression test[J]. Journal of Food Engineering, 1999, 40(4): 227-232.

[25] Bamrungwong S, Satake T, Vargas D, et al. Fundamental studies on mechanical properties of long-grain rice varieties: II. Bending properties of long-grain rice[J]. Japanese Journal Tropical Agriculture, 1988, 32(1): 6-15.

[26] 李毅念,丁为民. 稻谷腹部、背部微观结构差异性分析[J].中国农业科学,2010,43(16):3473-3480.

Li, Yinian, Ding Weiming. Analysis on microstructure difference of ventral and dorsal side of rice grain[J]. Scientia Agricultura Sinica, 2010, 43(16): 3473-3480. (in Chinese with English abstract)

[27] 谢方平,罗锡文,卢向阳,等. 柔性杆齿滚筒脱粒机理[J].农业工程学报,2009,25(8):110-114.

Xie Fangping, Luo Xiwen, Lu Xiangyang, et al. Threshing principle of flexible pole-teeth roller for paddy rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(8): 110-114. (in Chinese with English abstract)

[28] 师清翔,姬江涛,刘师多,等. 小麦的控速喂入柔性脱粒试验研究[J]. 农业工程学报,1995,11(2):183-188.

Shi Qingxiang, Ji Jiangtao, Liu Shiduo, et al. The experimental studies on speed-controlled feed and soft threshing for wheat[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1995, 11(2): 183-188. (in Chinese with English abstract)

[29] 师清翔,刘师多,姬江涛,等. 控速喂入柔性脱粒机理研究[J]. 农业工程学报,1996,12(2):173-176.

Shi Qingxiang, Liu Shiduo, Ji Jiangtao, et al. Studies on the mechanism of speed-controlled feed and soft threshing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1996, 12(2): 173-176. (in Chinese with English abstract)

[30] 师清翔,刘师多,姬江涛,等. 水稻的控速喂入柔性脱粒试验研究[J]. 农业机械学报,1996,27(1):41-45.

Shi Qingxiang, Liu Shiduo, Ji Jiangtao, et al. Research onspeed-control feed and soft threshing for rice[J]. Transactions of the Chinese Society of Agricultural Machinery, 1996, 27(1): 41-45. (in Chinese with English abstract)

[31] 任述光,谢方平,罗锡文,等. 柔性齿与刚性齿脱粒水稻功耗比较分析与试验[J]. 农业工程学报,2013,29(5):12-18.

Ren Shuguang, Xie Fangping, Luo Xiwen, et al. Analysis and test of power consumption in paddy threshing using flexible and rigid teeth[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(5): 12-18. (in Chinese with English abstract)

[32] Siebenmorgen T J, Qin G. Relating rice kernel breaking force distributions to milling quality[J]. Transactions of the ASAE, 2005, 48(1): 223-228.

[33] Lu R, Siebenmorgen T J. Correlation of HRY to selected physical and mechanical properties of rice kernels[J]. Transactions of the ASAE, 1995, 38(3): 889-894.

Effects of axial flow and tangential flow mechanical threshing on rice damage and milling quality

Li Yinian, Chen Junsheng, Ding Qishuo, Ding Weimin

(School of Engineering, Nanjing Agricultural University, Nanjing 210031, China)

Rice grains would be damaged by the mechanical threshing equipment during harvesting, and mechanical damage extent of rice grains was directly correlated to the threshing cylinder patterns and operating parameters of threshing cylinder, such as roration speed of cylinder and threshing time. On the other hand, there were not objective and whole indices to appraise the mechanical threshing damage extent of rice grains. In order to ascertain the effect of harvest pattern with different mechanical threshing cylinder on rice quality characters, taking manual harvesting rice as control group, the quality characters of the rice harvested by axial flow and tangential flow mechanical threshing cylinder were investigated. The appraisal indices of rice quality characters, fissuring rate and glume-opening rate, germination potential and rate and seedling growth properties, three-point bending breaking force, head rice yield and broken rice rate, were selected and tested according to relevant methods and standards. Experiment results show that the fissuring rate and glume-opening rate for mechanically harvesting rice are higher than that for the hand-harvested rice, and the maximum difference of glume-opening rate is about 35.6%; the fissuring rate and glume-opening rate for axial flow mechanical threshing cylinder are less than that for tangential flow mechanical threshing cylinder. But the germination potential and rate for mechanically harvested rice are lower than that for the hand-harvested rice, and the maximum difference of germination rate is 53%. The germination potential and germination rate for axial flow mechanical threshing cylinder are larger than that for tangential flow mechanical threshing cylinder, and the maximum difference of germination rate is 34%-51%. The stem length and number of roots of rice seedling for axial flow mechanical threshing cylinder and that of the hand-harvested rice are larger than that for tangential flow mechanical threshing cylinder. The maximum differences of the stem length and number of roots between tangential flow mechanical threshing cylinder harvesting and hand-harvesting are respectively 15 mm and 2.4, and those between tangential flow threshing cylinder and axial flow threshing cylinder are respectively 12.6 mm and 1.8. The stem length and number of roots of rice seedling for axial flow mechanical threshing cylinder are adjacent to that for the hand-harvested rice. There are not significant differences for root length and number of leaves and leaves length between the hand-harvested rice and mechanical threshing harvested rice. The three-point bending breaking force for mechanical harvested rice is also lower than that for the hand-harvested rice, and the maximum differences of the three-point bending breaking force for ventral side and dorsal side are 4.5 and 3.8 N respectively. There is not large difference for the three-point bending breaking force between axial flow and tangential flow mechanical threshing cylinder harvesting. The milling quality of hand-harvested rice is also superior to mechanically harvested rice, and the maximum difference of the head rice yield between them is 12.11%. The head rice yield for axial flow mechanical threshing cylinder is 10.38% higher than that for tangential flow mechanical threshing cylinder. The broken rice rate for the hand-harvested rice is correspondingly lower than that for mechanically harvested rice. Cross correlation analysis for all appraisal indices of rice quality characters manifests that the fissuring rate and glume-opening rate are cross-correlated, the germination potential, germination rate and stem length and number of roots for rice seedling are cross-correlated, the three-point bending breaking force for ventral side and dorsal side are cross-correlated, and the milled rice rate and head rice yield are cross-correlated. The mechanical threshing harvest causes the damage to rice quality, and the damage extent of rice quality for different mechanical threshing cylinder harvesting is different. The threshing damage to rice quality for axial flow threshing harvest cylinder is lower than that for tangential flow threshing harvest cylinder. Rice seeds should be harvested by using harvester with axial flow threshing cylinder. On the other hand, the appraisal indices of quality characters of rice seeds harvested by the mechanical threshing cylinder should select the fissuring rate and glume-opening rate, germination potential and rate and seedling growth properties. The appraisal indices of quality characters of food rice harvested by the mechanical threshing cylinder should be the fissuring rate and glume-opening rate, three-point bending breaking force, head rice yield and broken rice rate. The appraisal indices for the rice harvested by mechanical threshing cylinder should been wholly determined according to the used aim of rice.

mechanization; crops; processing; rice axial flow threshing; tangential flow threshing; threshing damage; milling quality

10.11975/j.issn.1002-6819.2017.15.005

TS212.2

A

1002-6819(2017)-15-0041-08

2017-01-13

2017-05-07

江苏省政策引导类计划(产学研合作)——前瞻性联合研究项目(BY2016060-01);中央高校基本科研业务费专项资金资助项目(KYZ201161);高等学校博士学科点专项科研基金资助课题(20130097110042)

李毅念,男,副教授,主要从事农产品加工及其品质方面的研究。南京 南京农业大学工学院,210031。Email:liyinian@163.com