热源井抽灌同井连续取/放热特性试验

2017-07-12宋伟,倪龙,姚杨

宋 伟,倪 龙,姚 杨

(1. 北方工业大学土木工程学院,北京 100144;2. 哈尔滨工业大学市政环境工程学院,哈尔滨 150090)

热源井抽灌同井连续取/放热特性试验

宋 伟1,2,倪 龙2※,姚 杨2

(1. 北方工业大学土木工程学院,北京 100144;2. 哈尔滨工业大学市政环境工程学院,哈尔滨 150090)

针对抽灌同井连续运行特性的研究不足,利用单井循环地下换热系统砂箱试验台,以沈阳和上海2地采暖期和空调期的时间尺度为依据,分别开展了连续取热和连续放热2种运行模式下抽灌同井运行特性的试验研究。结果表明,抽灌同井在该试验条件下对取热工况更加敏感,取热比放热更为困难。在连续取热工况下,含水层在受到外界初次干扰的影响更为明显,第2个运行周期的累计取热量降幅为6个运行周期累计取热量降幅的57.1%。在热/冷负荷占优的地区,应根据建筑负荷采取辅助手段及时对含水层进行热量/冷量补给,保证热泵机组高效运行。

井;地下水;水源热泵系统;抽灌同井;砂箱试验;含水层;连续运行

0 引 言

抽灌同井作为单井循环地下换热系统的一种热源井形式,最早于1992年应用在丹麦技术大学的一次足尺寸的试验研究中[1]。由于课题负责人的变故,该项研究未能继续深入,很长时间没有相关的研究报道。张远东对抽灌同井进行了相关模拟研究,其中包括地下水的参数、井的结构参数、抽水量等因素对含水层的温度影响,但该模型并未得到试验验证[2]。倪龙等对抽灌同井进行了较深入的研究,包括季节储能特性的分析[3],含水层参数对抽灌同井的影响[4],地下水渗流理论研究[5],热负荷对系统的影响[6],多层含水层中系统的特性[7],井参数对系统的影响[8],以及相关的模拟研究[9]。王玉林等[10-11]对抽灌同井地下水三维非稳定流动的三维数学模型通过Laplace变换、分离变量法以及傅里叶延拓等方法得出了水头变化的解析表达式。

相关的理论与试验[12-14]对单井循环地下换热系统的特性进行了探索性的研究,数学模型优化[15-19]与实际运行特性[20-24]所研究的热源井类型主要针对抽灌同井的原型—循环单井。通过对热源井的热力特性分析[25-28],抽灌同井由于中间隔断区的存在,回水几乎完全进入含水层,使得热源井的热贯通量较低,在单井循环地下换热系统中具有明显优势。鉴于其连续运行试验研究的缺乏,本文选取抽灌同井作为研究对象,根据沈阳和上海2地采暖期和空调期的时间尺度,开展了连续取热和连续放热2种不同运行模式下抽灌同井运行特性的试验研究。

1 室内砂箱试验

1.1 砂箱试验台

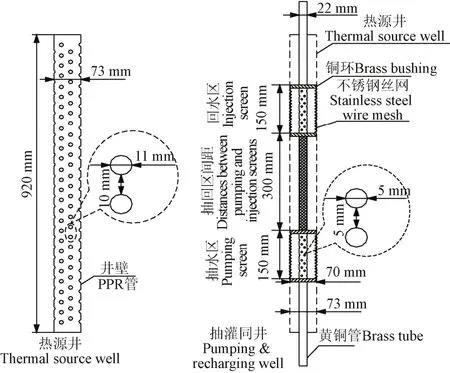

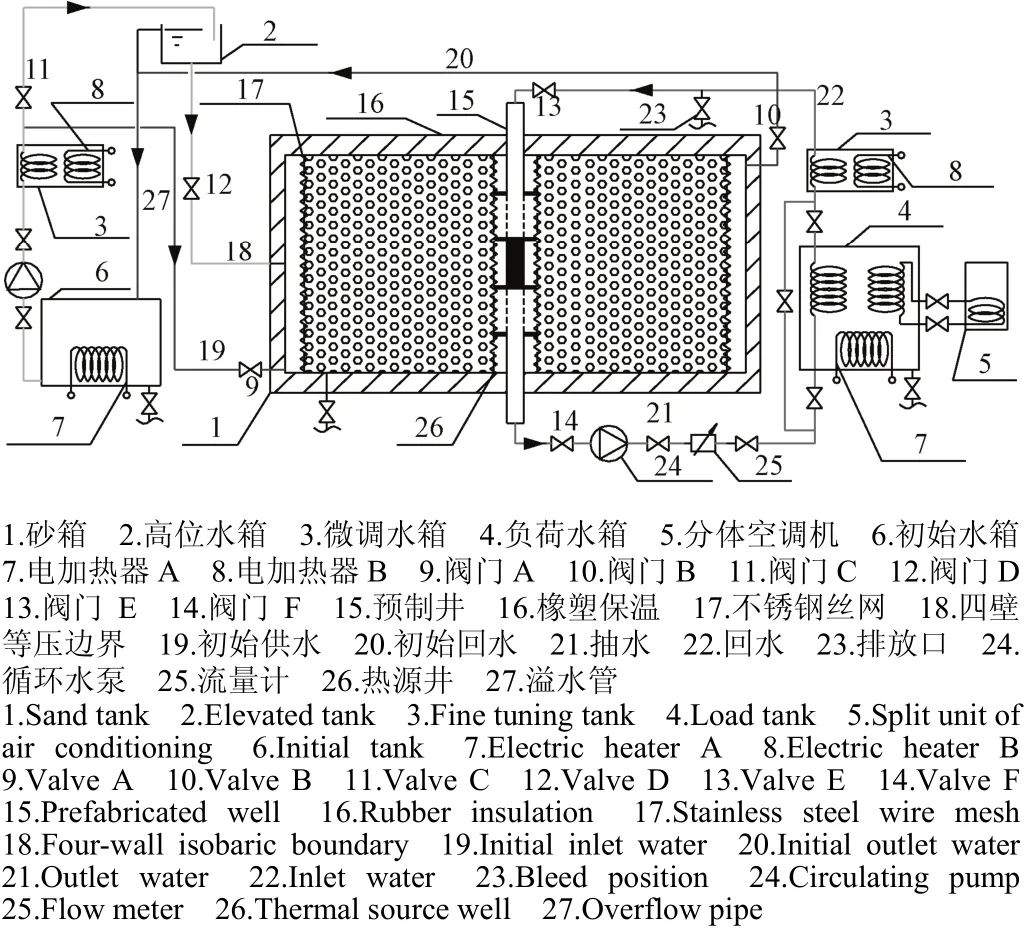

在地下水运动特性的研究中,通常将含水层远端边界考虑成等压、等温边界。所以在试验过程中,保持砂箱的等压、等温的边界条件是实现可信模拟的关键。文中试验台通过初始水箱、高位水箱和橡塑保温板等来维持砂箱的等压、等温边界条件,模拟含水层边界;采用电加热器、负荷水箱和分体空调机来制造抽回水温差,模拟热源井承担的建筑冷/热负荷。单井循环地下换热系统的热源井与抽灌同井结构图如图1所示,砂箱试验台系统图如图2所示,砂箱试验台各部件参数如表1所示。

其中,砂箱箱体采用聚丙烯PPR板,砂箱外壁采用橡塑保温,砂箱内壁四周加设不锈钢丝网,砂箱内装填洗涤干净的粗砂,经筛分称重,该规格粗砂中各类型砂子质量百分数分别为0.63%(Ф≤1 mm)、31.72%(1 mm<Ф<2 mm)、67.65%(Ф≥2 mm),Ф为砂子的粒径。热源井也采用聚丙烯PPR管开孔,在热源井外壁缠绕一层不锈钢滤网,100目,用于截留直径在0.15 mm以上的砂粒。采用黄铜管模拟抽灌同井,其高度与含水层厚度相当,抽/回区间距为300 mm,抽水区和回水区开孔长度均为150 mm[29]。井的开孔区上下两端各焊有直径为70 mm的铜环,并开槽加装密封圈,模拟抽灌同井的中间隔断区。

图1 热源井与抽灌同井结构图Fig.1 Structure of thermal source well and pumping and recharging well

图2 砂箱试验台系统图示意图Fig.2 Schematic diagram of sand tank experimental table system

表1 砂箱试验台各部件参数Table 1 Each component parameters of sand tank experiment

1.2 试验方案

本文砂箱试验台几何比例为1:100,根据相似理论,按照雷诺数相等推算,时间比例应为1:10 000,模拟全年8 760 h的试验持续时间仅为53 min,因此冬季采暖期、夏季空调期和2个恢复期,每个运行工况的持续时间不到15 min。为了能够更加清晰的观察不同运行模式对抽灌同井的影响,增加累计取热量和放热量,经过前期试验探索,适当延长系统运行时间,也能保证砂箱试验台远端边界不受影响。为此,将试验持续时间增加1倍,近似取120 min。即将各工况时间比例放大到1:4 320,用120 min模拟实际工程中抽灌同井运行1 a。

对于给定的建筑负荷,含水层温度的高低虽与初始地温有很大的关系,但其温度变化幅度与初始地温关系不大,因此试验过程中初始地温保持不变。另外,本试验台提供的建筑负荷发生情况与实际抽灌同井系统有较大差别。在实际工程中,热源井的负荷是为了满足建筑的需要,与地区、天气、建筑功能等有关,但基本与含水层初始地温无关,且不具备重复性。然而本试验台中,负荷是通过砂箱中抽出的“地下水”与负荷水箱中的冷/热水换热产生的,与初始地温关系较大。当负荷水箱中的冷/热水温度保持基本不变时,维持初始地温不变,负荷的变化就不会很大,能够创造近似的相同负荷,便于突出运行模式的影响。

本次试验模拟抽灌同井的全年工况,负荷水箱温度针对取热工况和放热工况分别设定为4和30 ℃,砂箱初始地温设定为20 ℃,循环水泵流量设定为0.54 m3/h,砂箱满水压力为17.4 kPa。试验设计时以沈阳和上海两地采暖期和空调期时间分配为对象,分别进行连续取热/放热工况的试验测试,每个试验工况均分为6个周期,每个周期均为120 min,各工况的启停时间按照各自地区采暖期、空调期和恢复期的相同时间比例确定,各工况的时间分配如表2所示,其中累计换热量由下式计算

式中Tg为抽水温度,℃;Tr为回水温度,℃;t为时间,s;Q为热源井的累计换热量,kJ;Cw为水的容积比热容,kJ/m3·℃;Qw,p为抽水流量,m3/s。

1.3 试验步骤

试验测试前,首先打开初始供水阀门A与初始回水阀门B,缓慢地自下而上充水,并经阀门B溢流进入初始水箱,该饱水过程一般约需24 h[30],充分排除砂箱中的气泡。其次,调试试验工况,关闭砂箱底部进水阀门A,打开阀门D,改由高位水箱供水,持续15 min,使砂箱中的“地下水”处于稳定状态,溢水管始终保持有水流溢出,控制边界水头恒定。最后,打开抽灌同井的进出口阀门E和阀门F,开启循环水泵,开始测试。

表2 沈阳和上海全年工况实际/模拟时间分配Table 2 Actual/simulation time distribution of annual operating condition in Shenyang and Shanghai

2 试验结果与分析

2.1 连续取热工况

图3给出了抽灌同井在连续取热工况下6个周期抽水温度的变化情况。该工况按照沈阳地区采暖期和空调期的时间分配进行试验,每个周期冬季取热时间为48.3 min,恢复期为71.7 min。从图3中可以看出,6个周期的抽水温度整体呈现下降趋势。说明在模拟抽灌同井运行6 a的过程中,由于地下含水层自然恢复时所补充的热量不足,导致抽灌同井的抽水温度逐年降低。

图3 连续取热工况下的抽水温度Fig.3 Temperature of outlet water in continuous heating condition

虽然各周期的抽水温度呈逐年下降趋势,但是在每个周期内,除第1个周期的抽水温度一直下降外,其余运行周期的抽水温度均先下降后略有上升。说明在第1个周期的试验中,热源井承担的负荷较大,致使其抽水温度逐渐下降;而在第2至第6个运行周期中,在系统运行平稳后,其抽水温度几乎保持不变,说明在本周期内地下含水层所提供的热量与当时所模拟的建筑负荷大小相当,并未导致抽水温度一直下降。从而可以推断,在此试验条件不变的情况下继续试验,由于并没有其他热量对含水层进行补充,系统的抽水温度还会继续下降。

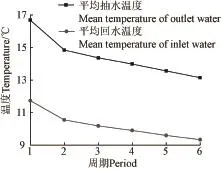

图4给出了抽灌同井在连续取热工况下6个周期的平均抽回水温度的变化情况。从图4中可以清晰的看出在6个测试周期内抽灌同井的平均抽回水温度逐年下降。在模拟系统6 a的运行过程中,系统的平均抽水温度从第1个周期的16.7 ℃逐渐降低到第6个周期的13.1 ℃,热源井的平均抽水温度降低了3.6 ℃,降低幅度达21.6%;系统的平均回水温度从第1个周期的11.7 ℃逐渐降低到第6个周期的9.3 ℃,热源井的平均回水温度降低了2.4 ℃,降低幅度为20.5%。这说明抽灌同井在模拟热负荷占优地区的运行过程中,在自然恢复期内,地下含水层并不能恢复到最初状态。平均抽水温度的降低会影响热泵机组的运行效率,所以在该地区需要特别注意这种抽水温度逐年降低的情况,并采取辅助手段及时对地下含水层进行热量补给,否则将导致整个热泵系统无法正常运行。

图4 连续取热工况下的平均抽/回水温度Fig.4 Mean temperature of outlet/inlet water in continuous heating condition

图5 给出了抽灌同井在连续取热工况下6个周期的累计取热量的变化情况。从图5中可以看出,在6个测试周期内抽灌同井的累计取热量与平均抽水温度一样呈逐年下降趋势。在模拟系统6 a的运行过程中,热源井的累计取热量从第1个周期的8 890.0 kJ逐渐降低到第6个周期的6 841.1 kJ,热源井的累计取热量降低了2 048.9 kJ,降低幅度高达23.0%。其中,第2个运行周期的累计取热量为7 720.6 kJ,较第1个运行周期的累计取热量降低了1 169.4 kJ,其降幅为6个运行周期累计取热量降低幅度的57.1%,这也是第1个运行周期抽水温度一直下降的原因,说明地下含水层在受到外界初次干扰的影响最为明显。

图5 连续取热工况下的累计取热量Fig.5 Accumulative heat absorption quantities in continuous heating condition

2.2 连续放热工况

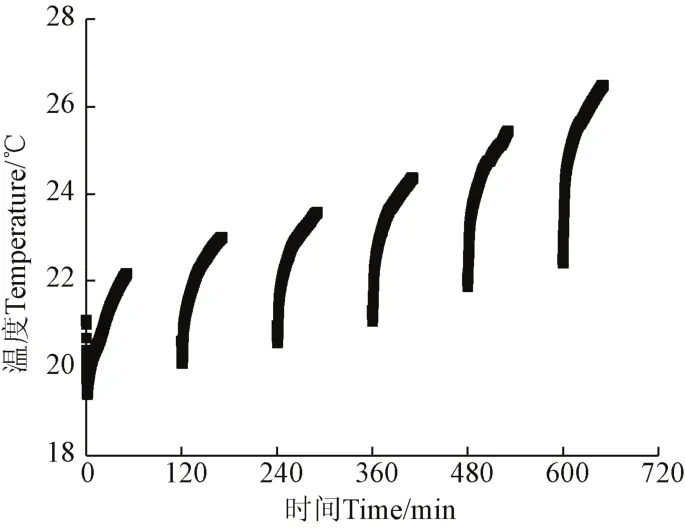

图6给出了抽灌同井在连续放热工况下6个周期抽水温度的变化情况。该工况按照上海地区采暖期和空调期的时间分配进行试验,夏季放热时间为50 min,恢复期为70 min。从图6中可以看出,6个周期的抽水温度逐渐升高,说明在模拟抽灌同井运行6 a的过程中,由于地下含水层自然恢复时所补充的冷量不足,导致抽灌同井的抽水温度逐年升高。从图6中还可以看出,各个周期的抽水温度不但呈逐年上升趋势,在每个周期内,热源井的抽水温度也呈逐渐上升趋势。说明在1个周期内,地下含水层所提供的冷量并不能满足当时所模拟的建筑负荷的要求,从而导致抽水温度急剧上升。与连续取热工况类似,如果试验条件不变试验继续进行,由于并没有其他冷量对含水层进行补充,系统的抽水温度还会继续升高。

图6 连续放热工况下的抽水温度Fig.6 Temperature of outlet water in continuous cooling condition

图7 给出了抽灌同井在连续放热工况下6个周期的平均抽回水温度的变化情况。从图7中可以清晰地看出在6个测试周期内,抽灌同井的平均抽回水温度逐年升高。在模拟系统6 a的运行过程中,系统的平均抽水温度从第1个周期的21.1 ℃逐渐升高到第6个周期的25.6 ℃,热源井的平均抽水温度升高了4.5 ℃,升高幅度达21.3%;系统的平均回水温度从第1个周期的25.9 ℃逐渐升高到第6个周期的30.6 ℃,热源井的平均回水温度升高了4.7 ℃,升高幅度为18.1%。同连续取热工况,抽灌同井在仅放热运行过程中,靠地下含水层自然恢复也不能使其恢复至最初状态。平均抽水温度的升高同样会影响热泵机组的运行效率,所以在仅放热运行时需要注意这种抽水温度逐年升高的情况,并适当采取辅助手段及时对地下含水层进行冷量补给。

图7 连续放热工况下的平均抽/回水温度Fig.7 Mean temperature of outlet/inlet water in continuous cooling condition

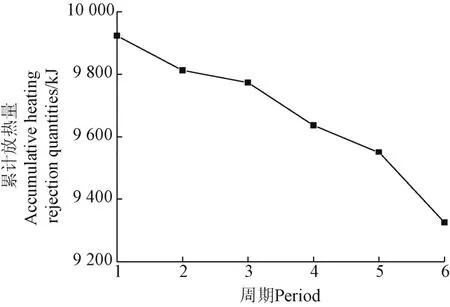

图8 给出了抽灌同井在连续放热工况下6个周期的累计放热量的变化情况。从图8中可以看出在6个测试周期内抽灌同井的累计放热量呈逐年下降趋势。在模拟系统6 a的运行过程中,系统的累计放热量从第1个周期的9 923.2 kJ逐渐降低到第6个周期的9 324.9 kJ,热源井的累计放热量降低了598.3 kJ,降低幅度仅为6.0%,每个周期平均降幅1%。与该系统在沈阳地区运行模式中的6个周期累计取热量降幅23.0%相比,地下含水层仅通过自然恢复期即能使自身得到较好的恢复。可见,抽灌同井对取热工况更加敏感,取热比放热更为困难。因此,在连续取热工况条件下,应对含水层热量的补充给予足够的重视。

图8 连续放热工况下的累计放热量Fig.8 Accumulative heat rejection quantities in continuous cooling condition

3 结 论

1)抽灌同井在模拟热/冷负荷占优的地区运行过程中,地下含水层在自然恢复期内均不能恢复到最初状态。连续运行6个周期累计取热量降幅23.0%,相比连续放热工况,热源井的累计放热量降低幅度仅为6.0%,每个周期平均降幅1%。在该试验条件下,该热源井对取热工况更加敏感,取热比放热更为困难。

2)在连续取热/放热工况中,系统运行6个周期的平均抽水温度降低/升高的幅度分别为21.6%和21.3%。在连续取热工况下,地下含水层在受到外界初次干扰的影响更为明显。系统在第2个运行周期的累计取热量降幅为六个运行周期累计取热量降低幅度的57.1%。

3)在该试验条件下,地下含水层所提供的热量或冷量均不能满足模拟建筑负荷的要求,并导致抽水温度下降或急剧上升。在实际工程中,应根据建筑负荷采取辅助手段及时对地下含水层进行能量补给,保证热泵机组高效运行。

[1] Sorensen S N, Reffstrup J. Prediction of long-term operational conditions for single-well groundwater heat pump plants[C]//The 27th Intersociety Energy Conversion Engineering Conference, San Diego, CA, USA, 1992.

[2] 张远东. 单(多)井抽灌对浅部地温场的影响研究[D]. 北京:中国科学院地质与地球物理研究所,2004. Zhang Yuandong. Thermal Impact of Energy Abstraction on Geo-Temperature Field of Shallow Groundwater Aquifers by Single Well, Double and Muti-Well Systems[D]. Beijing: Institute of Geology and Geophysics, Chinese Academy of Sciences, 2004. (in Chinese with English abstract)

[3] 倪龙,姜益强,姚杨,等. 抽灌同井季节性储能分析[J]. 哈尔滨工业大学学报,2010,42(8):1287-1291. Ni Long, Jiang Yiqiang, Yao Yang, et al. Analyses of seasonal thermal energy storage for a pumping & recharging well[J]. Journal of Harbin Institue of Technology, 2010, 42(8): 1287-1291. (in Chinese with English abstract)

[4] 倪龙,马最良. 含水层参数对同井回灌地下水源热泵的影响[J]. 天津大学学报,2006,39(2):229-243. Ni Long, Ma Zuiliang. Effect of aquifer parameters on groundwater heat pump with pumping and recharging in the same well[J]. Journal of Tianjin University, 2006, 39(2): 229-243. (in Chinese with English abstract)

[5] 倪龙,马最良. 同井回灌地下水源热泵地下水渗流理论研究[J]. 太阳能学报,2006,27(12):1219-1224. Ni Long, Ma Zuiliang. Study on the seepage theory for groundwater heat pump with pumping & recharge in the same well[J]. Acta Energiae Solaris Sinica, 2006, 27(12): 1219-1224. (in Chinese with English abstract)

[6] 倪龙,马最良. 热负荷对同井回灌地下水源热泵的影响[J].暖通空调,2005,35(3):12-14. Ni Long, Ma Zuiliang. Effect of heating load on the groundwater source heat pump system with pumping and recharging in same well[J]. HV&AC, 2005, 35(3): 12-14. (in Chinese with English abstract)

[7] 倪龙,马最良. 多层含水层中同井回灌地下水源热泵特性分析[J]. 建筑热能通风空调,2005,24(3):10-13. Ni Long, Ma Zuiliang. The analyses of characteristic on groundwater heat pump with pumping & recharging in the same well in multilayer aquifer[J]. Building Energy & Environment, 2005, 24(3): 10-13. (in Chinese with English abstract)

[8] 倪龙,马最良. 井参数对同井回灌地下水源热泵的影响[J].流体机械,2006,34(3):65-69. Ni Long, Ma Zuiliang. Effection of well parameters on groundwater heat pump with pumping & recharging in the same well[J]. Fluid Machinery, 2006, 34(3): 65-69. (in Chinese with English abstract)

[9] Ni Long, Li Haorong, Jiang Yiqiang, et al. A model of groundwater seepage and heat transfer for single-well ground source heat pump systems[J]. Applied Thermal Engineering, 2011, 31(14/15): 2622-2630.

[10] 王玉林. 承压地下水开采井流模型及其渗流理论研究[D].杭州:浙江大学,2011. Wang Yulin. Studies on Models and Theories for Well Flow Due to Confined Water Exploitation[D]. Hangzhou: Zhejiang University, 2011. (in Chinese with English abstract)

[11] 王玉林,谢康和,李传勋,等. 抽-灌同轴非完整井承压层非稳定流模型及解析解[J]. 水利学报,2012,43(1):60-67. Wang Yulin, Xie Kanghe, Li Chuanxun, et al. A mathematical model and its analytical solution for confined aquifer subjected to pumping and recharge implemented by a single partially penetrating well[J]. Journal of Hydraulic Engineering, 2012, 43(1): 60-67. (in Chinese with English abstract)

[12] 倪龙,姜益强,姚杨,等. 循环单井与含水层的原水交换[J].太阳能学报,2010,31(6):743-748. Ni Long, Jiang Yiqiang, Yao Yang, et al. Original groundwater exchange of a standing column well with aquifer[J]. Acta Energiae Solaris Sinica, 2010, 31(6): 743-748. (in Chinese with English abstract)

[13] Lee K S. Modeling on The cyclic operation of standing column wells under regional groundwater flow[J]. Journal of Hydrodynamics, 2011, 23(3): 295-301.

[14] Vasile M. Experimental investigation of the reliability of residential standing column heat pump systems without bleed in cold climates[J]. Applied Thermal Engineering, 2013, 52(1): 230-243.

[15] Bose J E, Ledbetter C W, Partin J R. Experimental results of a low-cost solar-assisted heat pump system using earth coil and Geo-Thermal Well Storage[C]//The 4th Annual Heat Pump Technology Conference, Stillwater, OKC, USA, 1979.

[16] Braud H, Klimkowski H, Oliver J. Earth source heat exchanger for heat pumps[J]. ASAE Transactions, 1983, 26: 1818-1822.

[17] Mei V C, Fisher S K. Vertical concentric tube ground-coupled heat exchangers[J]. ASHRAE Transactions, 1983, 89(2B): 391-406.

[18] Mikler V. A Theoretical and Experimental Study of The Energy Well Performance[D]. Master thesis, Pennsylvania State University, 1993.

[19] Yuill G K, Mikler V. Analysis of the effect of induced groundwater flow on heat transfer from a vertical open-hole concentric-tube thermal well[J]. Ashrae Transactions, 1995, 101(1): 173-185.

[20] Orio C D. Geothermal heat pumps and standing column wells[J]. Geothermal Resources Council Transactions, 1994, 18: 375-379.

[21] Orio C D. Design, use & example of standing column wells[C]//IGSPHA Technical Meeting, Stillwater, OKC, USA, 1995.

[22] Orio C D.Geothermal heat pump applications industrial/commercial[J]. Energy Engineering, 1999, 96(3): 58-66.

[23] Orio C D, Johnson C N, Rees S J, et al. A Survey of standing column well installations in North America[J]. Ashrae Transactions, 2005, 111(2): 109-121.

[24] Orio C D, Johnson C N, Poor K D. Geothermal standing column wells: Ten years in a new England school[J]. Ashrae Transactions, 2006, 112(2): 57-64.

[25] 宋伟,倪龙,姚杨. 单井循环系统在不同初始地温下的特性[J]. 哈尔滨工程大学学报,2014,35(3):342-346. Song Wei, Ni Long, Yao Yang. Characteristics of single well systems in different initial aquifer temperatures[J]. Journal of Harbin Engineering University. 2014, 35(3): 342-346. (in Chinese with English abstract)

[26] 宋伟,倪龙,姚杨. 不同抽回间距的单井循环地下水源热泵系统试验[J]. 农业工程学报,2014,30(2):205-211. Song Wei, Ni Long, Yao Yang. Experiment on single well groundwater heat pump systems in different distances between pumping and injection screens[J]. Transactions ofthe Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(2): 205-211. (in Chinese with English abstract)

[27] 宋伟,倪龙,姚杨. 单井循环地下水源热泵换热特性CFD模拟与验证[J]. 农业工程学报,2015,31(24):201-206. Song Wei, Ni Long, Yao Yang. CFD Simulation and experiment of heat exchanger characteristic for single well cycling underground heat pump[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(24): 201-206. (in Chinese with English abstract)

[28] 宋伟,倪龙,姚杨. 单井循环地下水源热泵热源井排放实验[J]. 太阳能学报,2016,37(11):2843-2848. Song Wei, Ni Long, Yao Yang. Thermal well bleed experiment for single well cycling groundwater heat pump[J]. Acta Energiae Solaris Sinica, 2016, 37(11): 2843-2848. (in Chinese with English abstract)

[29] 倪龙,宋伟,唐明宇,等. 单井循环地下换热系统初步试验研究[J]. 建筑科学,2012,28(增刊2):195-197. Ni Long, Song Wei, Tang Mingyu, et al. Preliminary experimental study on single well cycling ground heat exchanger system[J]. Building Science. 2012, 28(Supp.2): 195-197. (in Chinese with English abstract)

[30] 陈崇希,万军伟,詹红兵,等. “渗流-管流耦合模型”的物理模拟及其数值模拟[J]. 水文地质工程地质,2004(1):1-8. Chen Chongxi, Wan Junwei, Zhan Hongbin, et al. Physical and numerical simulation of seepage-pipe coupling model[J]. Hydrogeology & Engineering Geology. 2004(1): 1-8. (in Chinese with English abstract)

Experiment on characteristics of continuous heat absorption/release for pumping and recharging in same thermal well

Song Wei1,2, Ni Long2※, Yao Yang2

(1. School of Civil Engineering, North China University of Technology, Beijing 100144, China; 2. School of Municipal and Environmental Engineering, Harbin Institute of Technology, Harbin 150090, China)

Groundwater heat pump system is an ideal approach to heat and cool the building due to its attractive advantages. When using groundwater as a primary energy source in combination with heat pump, the groundwater is pumped from the pumping area, heated/cooled in the heat exchanger of the heat pump, and then reinjected into the irrigation area. Single well groundwater heat pump (SWGWHP) is a new member of groundwater heat pump, which has become increasingly popular for using because of the economic advantages. In general, SWGWHP includes standing column well (SCW), pumping & recharging well (PRW), and forced external circulation standing column well (FECSCW). Their pumping and injection pipes are placed in a same well, the low part of which is pumping water and the top part recharging water. The SCW needs to drill hole in the bedrock directly, and then most of the water circulates in the well bore and the heat exchange takes place in the well wall, while small part of water goes out of the borehole and exchanges the heat with aquifer raw water. There are some clapboards in PRW that make the thermal well divided into 3 parts, i.e. injection zone (in the top part), seal zone (in the middle part), and production zone (in the low part). The FECSCW is similar to PRW. The difference between them is that the diameter of borehole in FECSCW is larger than the one in PRW. Moreover, the gap of borehole in FECSCW is filled with sorted gravel. Through previous research on the thermal features of three kinds of thermal wells, PRW has obvious advantages in 3 kinds of SWGWHP. Because its middle partition area exists, the backwater is reinjected into the aquifer completely, while thermal transfixion occurs rarely. In view of less experimental research on continuous operation, this paper selects the PRW as the research object. According to the heating/cooling period in Shenyang and Shanghai, 2 different modes of continuous operation in PRW have been carried out using a physical simulation experimental sandbox of SWGWHP, which can accurately reflect the actual physical phenomena. In this experimental research, time of operating condition has been distributed by heating season, air-conditioning season, and recovery season, while 2 test conditions are continuous heating mode and continuous cooling mode. In the heat/cold load dominant area, the results show that the aquifer can’t be restored to its original state during the natural recovery period. In continuous heating conditions of 6 cycles, the decreasing amplitude of accumulative heat absorption quantities of 6 cycles reaches 23.0%. Compared to the cooling condition, the decreasing amplitude of accumulative heat rejection quantities in 6 cycles is only 6.0%. These data show that the PRW is more sensitive in heating mode, while the heat absorption is more difficult than heat rejection. Additionally, in continuous heating condition, the aquifer is more obvious in the initial disturbance. The reduced amplitude of cumulative heat in the second operating cycle is 57.1% of all reduced amount in 6 cycles. Thus, in the heat/cold load dominant area, it is necessary to carry on the energy recharge to the aquifer in time according to the building load, in order to ensure the system in a long-term reliable operation.

wells; groundwater; heat pump systems; pumping and recharging well; experimental sandbox; aquifer; continuous operation

10.11975/j.issn.1002-6819.2017.11.032

TK529

A

1002-6819(2017)-11-0248-06

宋 伟,倪 龙,姚 杨. 热源井抽灌同井连续取/放热特性试验[J]. 农业工程学报,2017,33(11):248-253.

10.11975/j.issn.1002-6819.2017.11.032 http://www.tcsae.org

Song Wei, Ni Long, Yao Yang. Experiment on characteristics of continuous heat absorption/release for pumping and recharging in same thermal well[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(11): 248-253. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.11.032 http://www.tcsae.org

2017-01-03

2017-02-27

国家自然科学基金资助项目(41002085, 41602278);中国博士后科学基金资助项目(2016M601129);供热供燃气通风及空调工程北京市重点实验室研究基金资助课题;北方工业大学青年拔尖人才培育计划资助项目(XN018032)

宋 伟,男,讲师,博士,主要从事浅层地热能的开发与利用。北京 北方工业大学土木工程学院,100144。Email:stillwater2013@163.com※通信作者:倪 龙,男,副教授,博士生导师,主要从事热泵空调的应用研究。哈尔滨 哈尔滨工业大学市政环境工程学院,150090。

Email:nilonggn@163.com