微生物砂浆防护粉土坡面的强度与抗侵蚀性影响因素分析

2017-07-12邵光辉冯建挺赵志峰周宁娜

邵光辉,冯建挺,赵志峰,刘 鹏,李 泽,周宁娜

(1. 南京林业大学土木工程学院,南京 210037;2. 江苏省水土保持与生态修复重点实验室,南京 210037)

微生物砂浆防护粉土坡面的强度与抗侵蚀性影响因素分析

邵光辉1,2,冯建挺1,赵志峰1,2,刘 鹏1,2,李 泽1,周宁娜1

(1. 南京林业大学土木工程学院,南京 210037;2. 江苏省水土保持与生态修复重点实验室,南京 210037)

微生物砂浆表面防护处理是处理粉土边坡扬尘与水流侵蚀问题的新技术。采用微生物砂浆层对粉土表面进行防护处理试验,通过微型贯入试验、水稳定性试验以及模拟降雨冲刷试验,分析了微生物砂浆防护层厚度、CaCl2和尿素混合胶结溶液浓度、喷洒处理遍数等参数变化对微生物砂浆表面防护层的强度、水稳定性和土壤剥蚀率等性能的影响规律。结果表明,微型贯入仪可用于微生物砂浆表面防护层的强度测定,防护层的强度、水稳定性随胶结溶液浓度和喷洒处理遍数的增长而提高,最小有效厚度为5 mm。采用浓度为0.50 mol/L胶结溶液喷洒4遍,厚5 mm的防护层能够达到贯入阻力310 kPa,防护强度比77.5,崩解率2.3%,浸水强度损失率5.4%,具备较高的强度和较好的抗崩解性与强度水稳定性。粉土边坡在微生物砂浆防护前后,土壤剥蚀率能够从大于29.6降至6.8 g/(m2·s)以下。该研究表明,微生物砂浆层用于粉土表面防护具有较好的抗冲刷性;微生物诱导结晶的方解石形成包裹砂颗粒的胶结微结构,能够使表面防护砂浆层具备良好的抗水流侵蚀性。

粉土;侵蚀;砂浆; 诱导碳酸钙沉积;水稳定性;土壤剥蚀率;防护工程

0 引 言

在中国东部沿海吹填造陆区和黄河下游流域地区广泛分布的粉土具有结构松散、易冲刷的特点[1],水土流失的防控一直是这些地区面临的重要问题[2-3]。土颗粒间黏结力不足,难以抵抗水流剪切力是土壤侵蚀流失的重要原因[4],因此,增加土颗粒之间的黏结强度是提高土体抗侵蚀能力的重要手段,如向土中添加高分子聚合物能够有效减少地表径流和土壤流失[5-6]。而微生物固化松散土体是近年来发展起来的新技术[7],其基本原理是向松散土体中注入产脲酶微生物以及CaCl2和尿素的混合液,利用脲酶微生物促进尿素水解后产生CO32-,与Ca2+反应生成CaCO3结晶,实现胶结松散土颗粒的目的。与当前化学固化剂固土技术相比,具有环境污染少、低能耗、低排放的优势[8]。将微生物诱导方解石沉积(MICP)胶结松散砂形成的微生物砂浆[9]用于松散土体表面防护,以实现控制侵蚀的目的,是一项可能首先实现应用的微生物固土技术[7,10],在水土保持领域具有重要的潜在应用价值[11-12]。一些学者对此已经开展了相关的尝试,Bang等[13]研究发现,将菌液及胶结溶液均匀喷洒于砂土表面可形成具有一定硬度的胶结薄层,从而有效提高固化土体的抗风蚀性能。Dworatzek等[14]采用MICP技术对现场松散尾矿砂进行表面胶结固化,最终形成了2.5cm厚的坚硬胶结层,显著提高了松散矿砂的抗侵蚀能力。Salifu等[12]基于MICP固化砂土抵抗潮汐水流侵蚀的试验,认为MICP技术用于海岸边坡防护很有发展潜力。荣辉[15]通过室内试验对微生物喷洒表面胶结砂的硬度、抗水流冲刷性与植物生长适应性开展了初步研究,结果表明在微生物表面固化的砂土中,黑麦草依然能够出苗生长,微生物固砂层具备相应的抗冲刷性和生态相容性。Jiang等[16-17]研究表明,采用微生物固化处理的砂-高岭土混合物能大大降低被水流侵蚀带走的固体颗粒质量。粉土与砂土相比,具有土颗粒细小、矿物成分复杂、孔径尺寸小的特点。虽然通过微生物拌和掺入[18]或注浆[19-20]方式能够一定程度固化粉土,但强度提高有限[21]。同时,粉土较砂土毛细作用更为显著,采用表面直接喷洒微生物方式对粉土边坡表面固化防护难以获得理想的效果。而采用微生物砂浆防护层提高粉土边坡的抗侵蚀能力,是一种有发展潜力的粉土边坡表面防护新方法。

防护层的强度和稳定性是决定其防护能力的重要因素。土体表面微生物砂浆防护层通常呈薄壳状,在测定其强度时,难以制成标准试件进行抗压强度试验。虽然一些学者也尝试采用微小梁弯折试验[22-23]、硬度计测定[15]等方法来评价壳状微生物砂浆防护层的强度,但是,其测定与评价仍缺少统一的方法和标准。防护层强度、水稳定性与抗侵蚀性指标之间的关系也尚待进一步明确。

本文采用产脲酶微生物砂浆层进行粉土表面防护试验,针对粉土表面的微生物砂浆防护薄层的强度测定无统一方法和标准、抗侵蚀有效性及其影响因素不明确的问题,提出利用微型贯入试验测定微生物砂浆防护层强度,通过水稳定性试验以及模拟降雨冲刷试验,分析各因素影响下微生物砂浆表面防护层的崩解性、强度水稳定性和抗降雨冲刷性的变化规律。探讨微生物砂浆用于粉土边坡表面防护的有效性与适用性,为微生物固土防护技术应用于粉土地区坡面防护和水土保持工程提供科学依据。

1 试验材料

1.1 试验土样

粉土取自江苏省东台市沿海填海造陆地区,水力吹填而成。具有低塑性、低强度、易流失的特点。塑性指数Ip=7.8,黏粒质量分数低于4.17%,制样干密度1.46 g/cm3。

用于防护层的砂是石英质中砂,粒径分布在<0.075、0.075~0.25、>0.25~0.5、>0.5~1.0 mm的土壤颗粒质量分数分别为0.15%、9.19%、67.54%、23.12%。最大干密度是1.63 g/cm3,最小干密度是1.36 g/cm3。

1.2 微生物菌种与培养

本文所用菌种为巴氏芽孢杆菌(Sporosarcina pasteurii),来自德国菌种保藏中心(DSMZ33)。培养液为DSMZ推荐,每L培养液内含有胰蛋白胨(Tryptone,Oxoid LP0042)15.0g,大豆蛋白胨(Neutralised Soya Peptone,Oxoid LP0044)5.0 g,NaCl分析纯5.0 g,尿素20.0 g,并调节培养液pH值至7.3。将配制完成的培养液,置于高压灭菌锅内,121 ℃高温蒸汽灭菌20 min。待冷却后放置于4 ℃冰箱内备用。

将菌种按体积比1∶200接种至新鲜培养液中,以30 ℃,125 r/min培养条件进行培养。以恒温振荡培养24 h后的菌液(OD600约为1.3)用于喷洒制备微生物砂浆。

1.3 胶结混合液

胶结溶液是CaCl2和尿素的混合溶液,为MICP过程提供必需的氮源和钙源。尿素和CaCl2的浓度比为1∶1,按照0.25、0.50、0.75和1.00 mol/L浓度进行试验。

2 试验方法

2.1 微生物砂浆表面防护试验

压实粉土试样的干密度为1.46×103kg/m3,渗透系数k=4.0×10-4cm/s,置于直径19 cm的圆形铝质容器内,试样厚15 cm。采用落雨法[24]将中砂覆盖在粉土表面,中砂落距40 cm,对应堆积密度为1.55×103kg/m3,渗透系数k=1.6×10-2cm/s。根据试验方案,按照单位面积铺砂质量控制覆盖的防护砂层厚度分别取2.5、5.0、7.5和10.0 mm。每个砂层厚度水平制备2个试样开展平行试验。在20 ℃环境温度下,按照1 mL/cm2将菌液喷洒在中砂层上,让菌液自由浸润渗透入防护砂层,静置1 h,使微生物菌体能够充分吸附在砂颗粒表面。然后,按照1 ml/cm2将CaCl2和尿素胶结溶液喷洒在中砂层上,静置6 h,使微生物菌与胶结溶液之间发生脲酶反应并诱导CaCO3胶结物生成。按照上述步骤反复喷洒菌液和胶结溶液1~4遍,然后置于30 ˚C的烘箱中风干,最终在粉土表面形成微生物砂浆防护层。揭下微生物砂浆防护层,用软刷去除其下表面浮土。每个试样取3处采用游标卡尺测量表面防护层厚度,以平均值h作为实测厚度,取防护层实测厚度与目标厚度误差小于5%的试验组为有效组,进行后续分析。

2.2 微型贯入试验

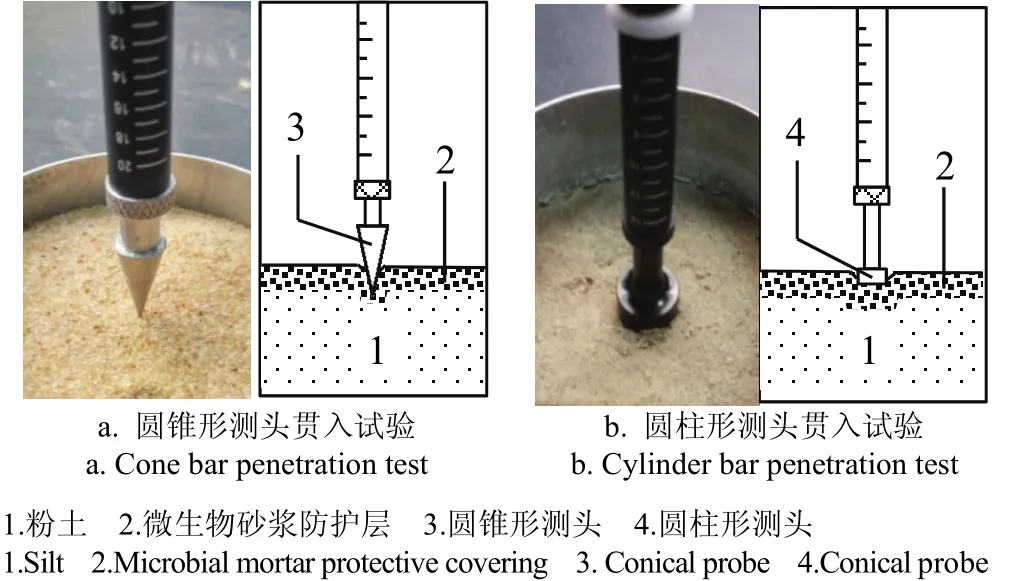

采用微型贯入试验,以测头贯入一定深度时的阻力作为防护层等效强度指标。仪器采用PS-MPT-A型微型贯入仪。根据贯入阻力量程,分别选用圆锥形测头(图1a)和圆柱形测头(图1b)。圆锥形测头锥角30°,标准贯入深度10 mm;圆柱形测头贯入端的底面为0.3 cm2圆面,标准贯入深度6 mm,测量误差±5%。

首先,测得未防护粉土贯入阻力作为基本贯入阻力S0,3组平行试验均值得S0=4 kPa。作为对比,再测定具有微生物砂浆表面防护层的粉土表面贯入阻力,达到标准贯入深度时(测头实际已穿透微生物砂浆防护层并进入粉土一定深度)对应的贯入阻力作为防护层贯入阻力Se。

图1 测定防护层强度的微型贯入试验Fig.1 Micro-penetration tests on surface protective covering strength

2.3 水稳定性测定

微生物砂浆防护层的水稳定性主要通过崩解率和浸水强度损失率来评价。崩解率反映土体由于浸水发生碎裂、散体的现象,作为评价土体可蚀性的指标[25]。参考简文彬等[26]提出的崩解率测试装置与方法,揭取微生物砂浆防护层得到片状样,烘干称重后装入尼龙网袋浸水12 h,取出后烘干称重,测定其在浸水前后的干质量损失率作为崩解率。将具有表面防护的粉土完全浸没在去离子水中,12 h后沥干自由水,置于30 ℃的烘箱中风干,再用微型贯入仪测定其等效强度,计算浸水前后强度损失率作为防护层强度水稳定性的评价指标。

2.4 降雨冲刷试验

本文采用室内模拟降雨冲刷试验测定冲刷量,采用可调坡度冲刷槽,长、宽、高尺寸分别为1 400、300、60 mm。在槽内铺设40 mm厚压实粉土(干密度为1.46×103kg/m3),按前文相同方法对粉土表面进行微生物砂浆防护后,置于模拟降雨装置的孔板雨滴发生器下模拟边坡降雨冲刷。降雨均匀系数[27]为0.92,降雨强度为6 mm/min。

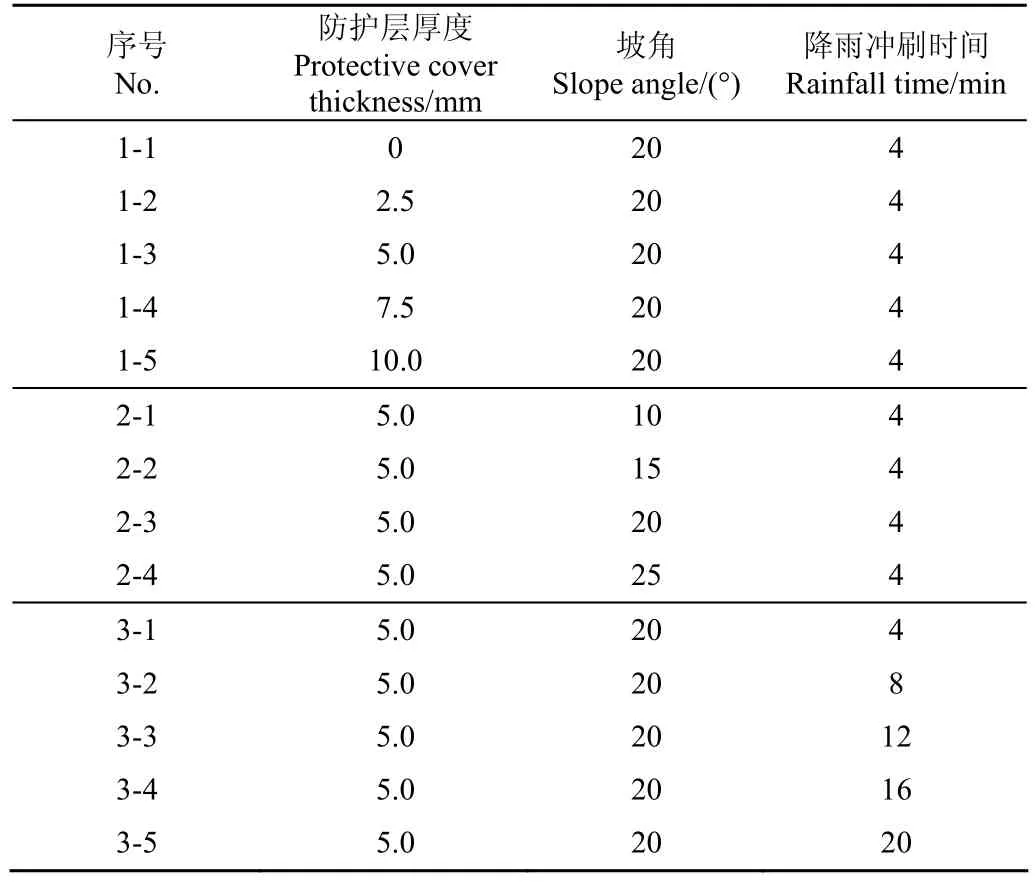

模拟降雨冲刷试验方案见表1,以分析不同防护层(胶结液浓度0.5 mol/L,喷洒4遍处理)厚度h、坡角β、降雨冲刷时间t等参数变化对粉土边坡抗冲刷稳定性的影响,评估微生物砂浆防护边坡抵抗连续性强降雨的能力。降雨历时为4到20 min,模拟中雨到大暴雨[28]。

表1 模拟降雨冲刷试验方案Table 1 Experiments protocol of simulated rainfall erosion

2.5 试验数据整理

1)防护强度比(R):表征防护层对粉土表层强度提高的程度。计算式为

式中Se为具有防护层的粉土表面贯入阻力,kPa;S0为无防护粉土表面的贯入阻力,kPa。

2)崩解率(A12h):微生物砂浆防护层浸水后的质量损失率。计算式为

式中m0和mw分别为微生物砂浆防护层浸水12 h前后的烘干质量,g。

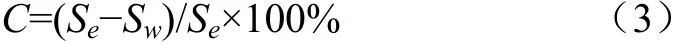

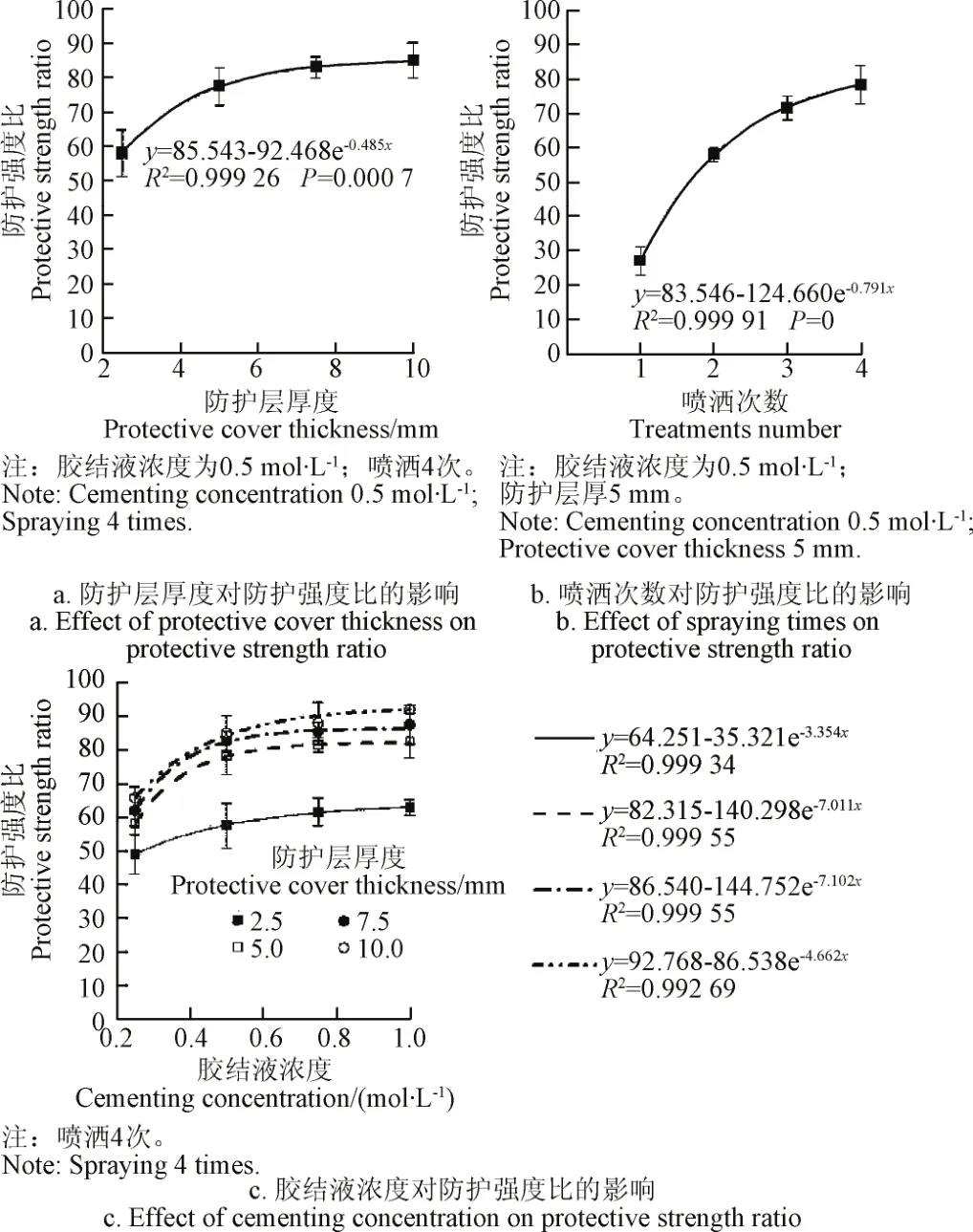

3)强度损失率(C):具有微生物砂浆防护层的粉土浸水前后表面贯入阻力损失率,计算式为

式中Sw为具有微生物砂浆防护层的粉土浸水12 h后表面贯入阻力,kPa;

4)土壤剥蚀率(Dr):坡面径流在单位时间、单位面积上所输移出的泥沙质量,计算式为[29]

式中Dr为土壤剥蚀率,g/(m²·s);M为测量时段t内的产沙量,g;b为过水断面宽度,m;L为坡长,m。

3 试验结果与分析

3.1 防护层强度

3.1.1 防护层厚度的影响

微生物诱导CaCO3结晶胶结的主要是粉土表面的中砂层,粉土并被胶结,因此实际的防护层厚度主要由中砂层厚度决定。防护强度比与防护层厚度之间的关系见图2a。防护强度比随着防护层厚度的增加而增加。防护层厚度由2.5 mm变化到5.0 mm时,防护层贯入阻力由232增加到310 kPa,防护强度比由58.0增加到77.5,增加了33.6%,提高显著(P=0.039 1)。而防护层厚度10.0比5.0 mm对应的防护强度比仅提高了9.6%。结果表明,防护层厚度超过5.0 mm后,防护强度比提高不显著。

3.1.2 喷洒遍数的影响

微生物菌液与胶结液的喷洒遍数直接影响防护层的强度(图2b)。采用浓度0.5 mol/L的胶结液分别喷洒1~4遍形成的表面防护层(厚度5.0 mm)防护强度比R分别为27.0、58.0、71.5、78.3。可见,防护强度比随着喷洒处理遍数的增加而增加。喷洒第1~4遍过程中,单次喷洒对防护强度比提高值分别为27.0、30.0、23.5、6.8。喷洒遍数大于2遍以后,每增加1遍对防护层强度提高的贡献越来越小。

3.1.3 胶结液浓度的影响

防护强度比与胶结液浓度的关系见图2c。胶结液浓度越大,形成的防护层防护强度比R越大。在不同防护层厚度条件下,厚度5.0、7.5和10.0 mm的防护层强度比R变化规律比较一致,胶结液浓度大于0.5 mol/L后对其防护强度比R的提高贡献不大。而厚度2.5 mm的防护层强度比R对胶结液浓度变化不敏感。从兼顾防护效果与节约材料用量角度考虑,采用浓度为0.5 mol/L的胶结液是比较合适的。

图2 不同因素对防护强度比的影响Fig.2 Effect of different factors on protective strength ratio

3.2 表面防护层的水稳定性

崩解率变化曲线见图3,随着喷洒遍数增加,防护层崩解率显著下降(P<0.05)。在同样喷洒遍数条件下,防护层厚度越大,崩解率越低。当防护层厚度不小于5.0 mm时,喷洒4遍处理的防护层崩解率降低到接近于0。防护层厚度2.5 mm时,即使喷洒4遍,依然存在近20%的崩解率,水中易碎裂、散体。用微生物胶结液喷洒4遍且厚度不小于5.0 mm的防护层,才能够具备较好的抗崩解性。

图3 崩解率变化曲线Fig.3 Variation curves of disintegration rate

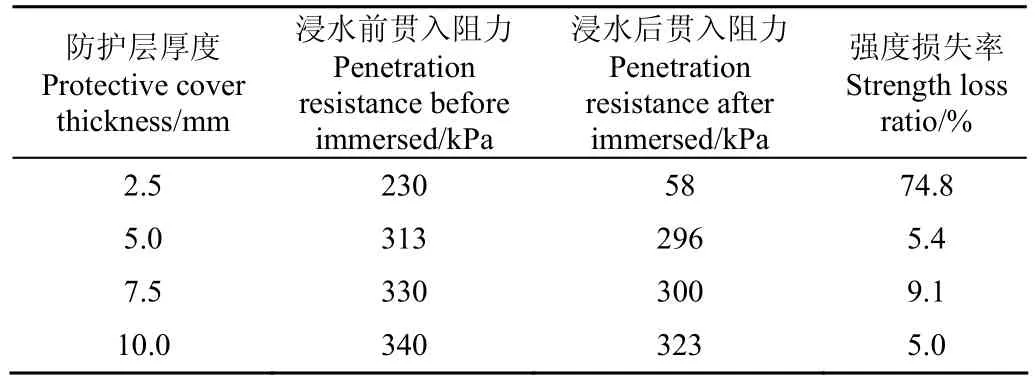

表2给出了不同防护层厚度下浸水前、后的贯入阻力与强度损失率。厚度2.5 mm的防护层强度损失率为74.8%,远超过其他各组试样。结果表明,要保证微生物砂浆层表面防护层有足够的强度水稳定性,其厚度应当不小于5.0 mm。

表2 表面防护层浸水前后强度变化量Table 2 Variation of strength before or after inundation for protective covering

3.3 表面防护层的抗冲刷稳定性

微生物砂浆防护边坡在降雨冲刷下的土壤剥蚀率如图4a所示。当防护层厚度为2.5 mm时,剥蚀率为26.7 g/(m2·s),只比裸露粉土边坡(防护层厚度0 mm)降低了5.1 g/(m2·s),防护效果弱;当防护层厚度为5 mm时,剥蚀率大幅降低到6.8 g/(m2·s),呈现出较好的抗冲刷防护能力;而当防护层厚度为7.5和10.0 mm时,剥蚀率进一步降低,但是对防护层厚度增加不再敏感(P=0.663 8>0.05)。上述变化表明,当微生物砂浆防护层厚度大于5.0 mm后,再增加防护层厚度对边坡的抗冲刷能力的提高有限。

土壤剥蚀率与防护强度比的关系见图4b。当防护强度比大于60后,土壤剥蚀率随防护强度比增大显著减小(P=0.022 4)。防护强度比达到80以上时,土壤剥蚀率低于5 g/(m2·s),防护层抗侵蚀作用显著(P=0.002 6)。也表明微生物砂浆表面防护层的强度是保证其在降雨冲刷作用下不被剥蚀的重要基础。

微生物砂浆防护边坡和裸露粉土边坡的土壤剥蚀率与坡角的关系见图4c。相同降雨条件下,坡角变化对裸露粉土边坡的冲刷影响很大,坡角越大,边坡冲刷越严重,坡角10°对应的剥蚀率为29.63 g/(m2·s),当坡角大于20°后,剥蚀率有所增加,坡角25°时剥蚀率达到37.3 g/(m2·s)。而不同坡角下微生物砂浆防护边坡的剥蚀率相差不大,分别为5.4、5.9、6.8和6.5 g /(m2·s)。表明微生物砂浆防护边坡的抗冲刷性对坡角变化不敏感(P=0.099 7>0.05)。

不同降雨冲刷时间下微生物砂浆防护粉土边坡的土壤剥蚀率如图4d所示。当降雨4、8和12 min时,微生物砂浆防护边坡的剥蚀率随降雨冲刷时间增长(R2=0.9758),分别为6.8、8.3和11.7 g/(m2·s);当降雨冲刷时间大于16 min以后,剥蚀率减小,冲刷形成的防护层裂缝宽度基本稳定,不再显著扩展。降雨冲刷20 min时剥蚀率仅为3.6 g/(m2·s)。表明微生物砂浆防护边坡对连续性强降雨冲刷具有一定的防护能力。

图4 不同影响因素下的土壤剥蚀率变化曲线Fig.4 Variation curves of soil detachment ratio with different factors

4 讨 论

4.1 MICP胶结结构对防护层水稳定性的影响

扫描电镜分析获得的5.0 mm厚微生物砂浆表面防护层中CaCO3胶结的微观形貌见图5。图5a是喷洒1遍0.5 mol/L胶结液处理的微生物砂浆微结构,在砂颗粒表面分散分布有一些CaCO3晶体,晶体为复三方偏三角面方解石。因为胶结物含量低,且没有形成有效联结,所形成的防护层崩解率大于55%。图5b是喷洒3遍等浓度胶结液处理的微生物砂浆微结构,可见方解石晶体已局部聚集,连片覆盖与砂颗粒表面,形成了一定的粒间胶结,崩解率降低至11.6%。图5c是喷洒4遍等浓度胶结液处理的微生物砂浆微结构,大量方解石晶体呈簇状完全包裹住石英砂颗粒,形成包裹型胶结,对应的崩解率仅为2.3%,浸水强度损失率仅为5.4%。图5d是包裹型胶结的石英砂颗粒从胶结体上剥离后呈现的断面,胶结物与砂颗粒表面形成了有效的大面积联结。试验也表明,崩解率高的微生物砂浆防护层基本不具备抗冲刷能力。微生物诱导结晶的方解石形成包裹型胶结是防护砂浆层具备良好表面防护作用的微观结构基础。

图5 微生物砂浆表面防护层中CaCO3胶结的微观形貌Fig.5 Microstructure of CaCO3cementing in microbial mortar surface protective covering

4.2 微生物砂浆防护层抗侵蚀机理

吴普特等[30]研究表明,雨滴击溅不但可以破坏土壤结构,引起雨滴击溅侵蚀,还可减少水流摩擦阻力,从而增加水流侵蚀动力。微生物砂浆防护层最上层表面为松散颗粒弱胶结结构,孔隙率大,且孔径也很大。在雨滴溅蚀及径流冲蚀作用下,首先发生部分弱胶结颗粒崩解与剥蚀,产物随径流迁移。所以在产流前期,剥蚀率随时间有所增长,但同时对坡面流的阻滞作用也相对较强,入渗比例较大,径流量小。随着表面松散弱胶结砂粒的剥蚀,防护层中部的包裹型强胶结结构砂粒逐渐裸露,因该部分微生物砂浆孔隙被胶结物填充较饱满,其孔隙率与孔径均较小,加之表面粗糙度下降,对坡面流的阻滞作用开始减弱,入渗比例显著减小,径流量加大,防护层的表层抗冲刷防护作用开始发挥。

Chu等[22]认为,MICP形成的微生物砂浆表面硬壳强度能够达到35.9 MPa,虽然很薄,但是其强度足以在堤岸抗侵蚀和边坡稳定等工程中发挥作用。荣辉[15]对微生物砂浆防护(微生物与胶结液喷洒4遍和10遍处理)的30°坡角砂土边坡进行坡面径流直接冲刷试验,土壤剥蚀率分别为9.3和5.6 g/(m2·s)。但是在坡面径流量100 L/h冲刷下,在2 min内即产生细沟、崩塌等现象,与本文试验结果对比存在不小差异。其原因可从边坡不同土质的冲刷破坏模式进行分析。因为喷洒形成的微生物砂浆本身具有良好的渗透性[13],当微生物砂浆防护层防护砂土边坡时,防护层下的砂也具有良好的渗透性,在入渗饱和后,很容易在层下形成快速渗流,细小颗粒易被带走,形成局部管涌掏空,进而发展为表面防护层脱空、塌陷,导致防护失效,破坏模式为层下渗流破坏,防护效果取决于防护层下砂土的抗渗流侵蚀稳定性。当微生物砂浆防护层防护粉土边坡时,因防护层下的粉土渗透系数远小于砂土,坡面入渗比例小,防护层面下渗流微弱,坡面径流占主导。所以表现为表层防护层先破坏,其后径流才能继续冲刷裸露粉土,造成防护失效,破坏模式为防护层强度破坏,防护效果取决于防护层本身的强度与稳定性。文献[15]还对喷洒微生物菌液与胶结液进行防护处理的30°坡角的细尘边坡进行1 min雨强42.6 mm/min的超强降雨冲刷,土壤剥蚀率为17.1 g/(m2·s)。表明利用MICP直接喷洒处理细尘也能够一定程度抵抗降雨冲刷,其防护层结构为强度较低的MICP胶结细尘粒。相比较而言,本文采用粉土表面铺砂形成的微生物砂浆防护层,能够将微生物砂浆的高强度与被防护边坡粉土的低渗透性有机结合,发挥粉土减渗与防护层抗径流冲刷的共同作用,以提高粉土坡面的抗侵蚀能力。

5 结 论

针对用于粉土表面防护的微生物砂浆防护层的强度、水稳定性与抗侵蚀性问题,本文通过室内指标测试和模拟降雨冲刷试验,研究了不同防护层参数和冲刷条件下微生物砂浆层强度、水稳定性与抗侵蚀性变化规律,主要得到以下3点结论。

1)微型贯入仪可以用于微生物砂浆表面防护层的强度测定,防护层强度与水稳定性随厚度、处理遍数、胶结液浓度的提高而提高,其最小有效厚度为5 mm。采用微生物菌液与0.50 mol/L胶结液喷洒4遍处理,厚度5.0 mm的微生物砂浆防护层即能够达到贯入阻力310 kPa,防护强度比77.5,崩解率2.3%,浸水强度损失率5.4%,具备较好的抗崩解性和强度水稳定性。

2)微生物砂浆防护粉土边坡较未防护边坡的抗降雨冲刷性显著提高,采用微生物菌液与0.50 mol/L胶结液喷洒4遍处理,厚度为5.0 mm的微生物砂浆防护前后土壤剥蚀率能够从大于29.6降至6.8 g/(m2·s)以下。坡角变化对防护边坡的土壤剥蚀率影响不大。微生物砂浆防护粉土边坡能够有效抵抗大暴雨侵蚀。

3)微生物砂浆防护粉土边坡抗降雨冲刷的机理在于微生物砂浆的高强度与被防护边坡粉土的低渗透性共同作用。微生物诱导结晶的方解石形成包裹砂颗粒的胶结微结构是表面防护砂浆层具备良好抗水流侵蚀的基础。

[1] 王海波,赵志峰,张甜. 季节性冻融对滞洪区改良路基性能的影响[J]. 南京林业大学学报:自然科学版,2016(3):156-162. Wang Haibo, Zhao Zhifeng, Zhang Tian. Performance of improved soil subgrade under freeze-thaw cycles in flood retarding basin[J]. Journal of Nanjing Forestry University: Natural Science Edition, 2016(3): 156-162. (in Chinese with English abstract)

[2] 徐东升. 黄河三角洲粉土的力学特性及改性研究[D]. 武汉:中国科学院研究生院(武汉岩土力学研究所),2010. Xu Dongsheng. Research on Mechanical Characteristics and Strengthen Method of Silt in Yellow River Delta[D]. Wuhan: Institute of Rock & Soil mechanics China Academy of Science, P.R. China, 2010. (in Chinese with English abstract)

[3] 王侠. 水土保持与黄河经济可持续发展[J]. 水土保持通报,1997(S1):80-84. Wang Xia. Soil conservation and sustained development of Yellow River economy[J]. Bulletin of Soil and Water Conservation, 1997(S1): 80-84. (in Chinese with English abstract)

[4] Foster G R, Huggins L F, Meyer L D. A laboratory study of rill hydraulics, II. Shear stress relationships[J]. Transactions of the ASAE, 1984, 27(3): 797-804.

[5] 吕威,李淑芹,李法虎,等. 聚丙烯酰胺对凹凸型坡土壤侵蚀影响的室内试验[J]. 农业工程学报,2016,32(10):122-128. Lü Wei, Li Shuqin, Li Fahu, et al. Laboratory study on soil erosion of loess convex and concave slopes with application of polyacrylamide[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(10): 122-128. (in Chinese with English abstract)

[6] Lentz R D, Sojka R E. Field results using polyacrylamide to manage furrow erosion and infiltration[J]. Soil Science, 1994, 158(4): 274-282.

[7] Dejong J T, Soga K S, Kavazanjian E, et al. Biogeochemical processes and geotechnical applications: progress, opportunities and challenges[J]. Geotechnique, 2013, 63(4): 287-301.

[8] 钱春香,王安辉,王欣. 微生物灌浆加固土体研究进展[J].岩土力学,2015,36(6):1537-1548. Qian Chunxiang, Wang Anhui, Wang Xin. Advances of soil improvement with bio-grouting[J]. Rock and Soil Mechanics, 2015, 36(6): 1537-1548. (in Chinese with English abstract)

[9] Zhang Y, Guo H X, Cheng X H. Role of calcium sources in the strength and microstructure of microbial mortar[J]. Construction & Building Materials, 2015, 77: 160-167.

[10] 何稼,楚剑,刘汉龙,等. 微生物岩土技术的研究进展[J].岩土工程学报,2016,38(4):643-653. He Jia, Chu Jian, Liu Hanlong, et al. Research advances in biogeotechnologies[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(4): 643-653. (in Chinese with English abstract)

[11] 谢兴华,谈叶飞,吴涛. 一种环境友好型微生物-植物联合护坡方法:102677683A[P]. 2012-09-19.

[12] Salifu E, Maclachlan E, Iyer K R, et al. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation[J]. Engineering Geology, 2015, 201(4): 96-105.

[13] Bang S C, Min S H, Bang S S. Application of microbiologically induced soil stabilization technique for dust suppression[J]. International Journal of Geo-Engineering, 2011, 3(2): 27-37.

[14] Dworatzek S M, Gomez M G, Martinez B C, et al. Field-scale bio-cementation tests to improve sands[J]. Proceedings of the Institution of Civil Engineers Ground Improvement, 2014, 168(3): 1-11.

[15] 荣辉. 微生物水泥的研制及胶结机理[D]. 南京:东南大学,2014. Rong Hui. Preparation and Binding Mechanism of Microbe Cement[D]. Nanjing: Southeast University, 2014. (in Chinese with English abstract)

[16] Jiang N, Soga K, Dawoud O. Experimental study of the mitigation of soil internal erosion by microbially induced calcite precipitation[C]// Proceedings of Geo-Congress 2014: Geo-Characterization and Modeling for Sustainability. Atlanta, 2014: 1586-1595.

[17] Jiang N J, Soga K, Kuo M. Microbially Induced Carbonate Precipitation (MICP) for Seepage-Induced Internal Erosion Control in Sand-Clay Mixtures[J]. Journal of Geotechnical & Geoenvironmental Engineering, 2016, 143(3): 04016100.

[18] 许朝阳,张莉,周健. 微生物改性对粉土某些特性的影响[J].土木建筑与环境工程,2009,31(2):80-84. Xu Zhaoyang, Zhang Li, Zhou Jian. Effect of microorganisms on some engineering properties of silt[J]. Journal of Journal of Civil, Architectural & Environmental Engineering, 2009, 31(2): 80-84. (in Chinese with English abstract)

[19] Ng W S, Lee M L, Tan C K, et. al. Factors affecting improvement in engineering properties of residual soil through microbial-induced calcite precipitation[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2014, 140(5): 1-11.

[20] Lee M L, Ng W S, Yasuo T. Stress-deformation and compressibility responses of bio-mediated residual soils[J]. Ecological Engineering, 2013, 60(2013): 142-149.

[21] 邵光辉,尤婷,赵志峰,等. 微生物注浆固化粉土的微观结构与作用机理[J]. 南京林业大学学报:自然科学版,2017,41(2):129-135. Shao Guanghui, You Ting, Zhao Zhifeng, et al. Microstructure and mechanism of microbial cementation silt treated by bio-grouting[J]. Journal of Nanjing Forestry University: Natural Science Edition, 2017, 41(2): 129-135. (in Chinese with English abstract)

[22] Chu J, Stabnikov V, Ivanov, V. Microbially induced calcium carbonate precipitation on surface or in the bulk of soil[J]. Geomicrobiology Journal, 2012, 29(6): 544-549.

[23] Chu J, Ivanov V, Stabnikov V, et al. Microbial method for construction of aquaculture pond in sand[J]. Geotechnique, 2013, 63(10): 871-875.

[24] Fretti C, Presti D C F L, Pedroni S. A pluvial deposition method to reconstitute well-graded sand specimens[J]. Geotechnical Testing Journal, 1995, 18(2): 292-298.

[25] 张抒. 广州地区花岗岩残积土崩解特性研究[D]. 武汉:中国地质大学,2009. Zhang Shu. A Study on Disintegration Behavior of Granite Residual Soil in Guangzhou[D]. Wuhan: China University of Geosciences, 2009. (in Chinese with English abstract)

[26] 简文彬,陈文庆,郑登贤. 花岗岩残积土的崩解试验研究[C]//中国土木工程学会第九届土力学及岩土工程学术会议,北京:2003:297-300. Jian Wenbin, Chen Wenqin, Zheng Dengxian. Experimental study on the collapse of the granite residual soil[C]// Proceeding of 9th National Soil Mechanics and Geotechnical Engineering Academic-China Civil Engineering Society. Beijing: Tsinghua University, 2003: 297-300. (in Chinese with English abstract)

[27] 苏溦娜,田一梅,高波,等. 人工模拟降雨装置的设计及其参数率定[J]. 水土保持通报,2015,35(6):120-123. Su Weina, Tian Yimei, Gao Bo, et al. Design and calibration of an artificial rainfall simulator[J]. Bulletin of Soil andWater Conservation, 2015, 35(6): 120-123. (in Chinese with English abstract)

[28] 马波,马璠,李占斌,等. 模拟降雨条件下作物植株对降雨再分配过程的影响[J]. 农业工程学报,2014,30(16):136-146. Ma Bo, Ma Fan, Li Zhanbin, et al. Effect of crops on rainfall redistribution processes under simulated rainfall[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(16): 136-146. (in Chinese with English abstract)

[29] 张乐涛,高照良,田红卫. 工程堆积体陡坡坡面土壤侵蚀水动力学过程[J]. 农业工程学报,2013,29(24):94-102. Zhang Letao, Gao Zhaoliang, Tian Hongwei. Hydrodynamic process of soil erosion in steep slope of engineering accumulation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(24): 94-102. (in Chinese with English abstract)

[30] 吴普特,周佩华. 黄土坡面薄层水流侵蚀试验研究[J]. 土壤侵蚀与水土保持学报,1996,2(1):40-45. Wu Pute, Zhou Peihua. Research on the sheet flow erosion of loess surface[J]. Journal of Soil and Water Conservation, 1996, 2(1): 40-45. (in Chinese with English abstract)

Influence factor analysis related to strength and anti-erosion stability of silt slope with microbial mortar protective covering

Shao Guanghui1,2, Feng Jianting1, Zhao Zhifeng1,2, Liu Peng1,2, Li Ze1, Zhou Ningna1

(1. School of Civil Engineering, Nanjing Forestry University, Nanjing 210037, China; 2. Jiangsu Province Key Laboratory of Soil and Water Conservation and Ecological Restoration, Nanjing 210037, China)

Microbial mortar protective covering is a new technology for controlling silt slope surface dust and water erosion. The anti-erosion performance of the protective covering depends to a large extent on the strength and stability of covering. However, the factors that govern the protective property of covering have not been fully studied. Based on microbial induced calcite precipitation (MICP) technology, the surface protective covering experiments were carried out to treat silt slope surface against rainfall erosion. Indoor model tests on silt surface protective covering by microbial mortar were performed to investigate the properties such as strength, water stability and anti-erosion. Sand was covered on dredger fill silt surface to form a thin layer, and then some Sporosarcina pasteurii and a kind of cementing solution containing a mixture of CaCl2 and urea were sprayed on the sand layer surface to obtain a crustose protective covering. The micro-penetration test was adopted to investigate the penetration resistances change of uncovered silt and protected silt covered with microbial mortar crust. The property of protective strength ratio measured by micro-penetration test was used to evaluate the strength of microbial mortar protective covering relative to uncovered silt surface. The collapse ratio and strength loss ratio were tested on the microbial mortar protective covering by immersed in water for 12 h to assess its water stability performance. The change laws of protective covering strength and water stability were drawn from different covering thickness, mixed cementing solution concentration of CaCl2and urea, and spraying times. On the basis of the tests of protective covering, the rainfall model experiments were conducted. A slope angle variable steel tank with the size of 1.4 m × 0.3 m× 0.06 m (length × width × height) was applied for holding test material and simulating the silt slope, which was subjected to strong rainfall scour under a rainfall simulating system. The soil detachment rates were investigated from the rainfall simulation experiment by changing slope angle from 5º to 25º and rainfall time from 4 to 20 min. The experimental results revealed that: 1) The minimum effective thickness of microbial mortar protective covering was 5 mm. The strength and water stability of protective covering increased with the cementing solution concentration, protective covering thickness and spraying times. 2) After treated 4 times with 0.50 mol/L cementing solution, a protective covering was formed, which had high strength, good anti-collapse property and excellent water stability. A 5 mm thick protective covering could reach penetration resistance of 310 kPa, protective strength ratio of 77.5, collapse ratio of 2.3%, and strength loss ratio of 5.4% when immersed in water. 3) Compared with untreated silt slope, the treated silt slope reduced soil detachment rate from over 29.6 g/(m2·s) to under 6.8 g/(m2·s). The soil detachment rate of treated silt slope was between 5.4 and 6.8 g/(m2·s) and insensitive to the slope angle. Under 20 min heavy rainfall scouring, the soil detachment rate of treated silt slope was only 3.6 g/(m2·s). The microbial mortar protective covering presented significant anti-erosion capacity. 4) The strength of protective covering and the permeability of substratum silt had coupling effect on the anti-erosion mechanism of microbial mortar protective covering. The coarse and porous covering played an important role in resisting raindrop splash and surface flow erosion by the high strength of crust. Meanwhile, the low permeability of silt under the covering resisted piping and suffusion erosion. The anti-erosion effectiveness of protective covering was dominated by the microbial mortar crust strength. For effective microbial mortar protection, at the microstructure level it was essential that the cement calcite from MICP formed surrounding cementation structure around soil particles surface. The results provide valuable information for applying MICP technology on silt slope anti-erosion.

silt; erosion; mortar; microbially induced carbonate precipitation (MICP); water stability; soil detachment rate; protective engineering

10.11975/j.issn.1002-6819.2017.11.017

S157.1

A

1002-6819(2017)-11-0133-07

邵光辉,冯建挺,赵志峰,刘 鹏,李 泽,周宁娜. 微生物砂浆防护粉土坡面的强度与抗侵蚀性影响因素分析[J]. 农业工程学报,2017,33(11):133-139.

10.11975/j.issn.1002-6819.2017.11.017 http://www.tcsae.org

Shao Guanghui, Feng Jianting, Zhao Zhifeng, Liu Peng, Li Ze, Zhou Ningna. Influence factor analysis related to strength and anti-erosion stability of silt slope with microbial mortar protective covering[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(11): 133-139. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.11.017 http://www.tcsae.org

2016-12-09

2017-04-20

国家自然科学基金项目(51578293);江苏高校优势学科建设工程资助项目(PAPD2015);国家大学生实践创新训练计划项目(201510298005Z)作者简介:邵光辉,男,湖北武汉人,博士,副教授,主要研究方向为微生物岩土工程、软土特性与地基处理。南京 南京林业大学土木工程学院,210037。Email:gh_shao@njfu.edu.cn。