Effect of particle size of near-sphere gold powder on microstructure and cambering of Au-metallized low temperature cofired ceramics

2017-03-30LUOHuiLIShihongLIANGYunLIWenlinLIUJisongLIJunpeng

LUO Hui, LI Shihong, LIANG Yun, LI Wenlin, LIU Jisong, LI Junpeng

Effect of particle size of near-sphere gold powder on microstructure and cambering of Au-metallized low temperature cofired ceramics

LUO Hui, LI Shihong, LIANG Yun, LI Wenlin, LIU Jisong, LI Junpeng

(State Key Laboratory of Advanced Technologies for Comprehensive Utilization of Platinum Metals, Sino-Platinum Metals Co., Ltd, Kunming 650106, China)

The shrinkage behavior of low temperature co-fired ceramics (LTCC) during cofiring process and the main factors having an effect on cambering of metallized LTCC ceramics after cofiring were investigated. Six kinds of near-sphere gold powders with different average diameters, ranging from 0.7 µm to 2.3 µm, were chosen to formulate gold conductive pastes together with a proper organic vehicle and glass frit. The pastes were printed on LTCC green tapes, laminated and cofired according to conventional LTCC process. The microstructure and cambering of each ceramic, sheet resistance of each paste were measured and calculated respectively. Experimental results show that pastes formed with large particle size gold powder have advantages in bringing down the cambering extent of the ceramic, but the film shows poor sintering and densification as well as high sheet resistance.

metal materials; LTCC; near-sphere gold; cambering; particle size of powder; densification

Low temperature cofired ceramic (LTCC) technology was developed in 1960 s and had been widely used for fabrication of various miniaturized electronic devices. The main difference between LTCC and conventional thick film technology was in LTCC, passive components (conductors and resisters) and the substrates were cofired through one sintering cycle, while in conventional thick film technology the substrates were sintered previously and passive components were printed and sintered later on. Therefore, the common materials formulating pastes used in LTCC were quite different from those used in conventional thick film technology[1], which included a series of materials, such as, copper, silver, gold and their alloy powder, organic vehicle and glass powder. The firing process of LTCC differed from the conventional thick film technology in at least two aspects, those were, the cofiring process and a relatively longer period of burning out organic vehicle. These differences required extra consideration when developing pastes used in LTCC in order to avoid defects or even failure of the components. Mismatch between the ceramic and the paste after cofiring, was the most commonly detected defect, which may finally lead to cambering of the metallized ceramic. Thus, the pastes used in LTCC must be tailored to meet the demand of cofiring with the tape to avoid mismatch between the components and the substrates[2-4].

Typical pastes consisted of metal powder, glass frit and organic vehicle. To date, several reports have been made to investigate cambering of the metallized ceramic printed with paste. Many researches pointed out that thermal expansion coefficient between glass frit and the ceramic was related to cambering of the ceramic[5-7]. Bangali J et al[8]studied the effect of ink organics on cambering of an Ag-metallized LTCC by analyzing the microstructure of silver pastes with different formulations of organic vehicle and found that organic vehicle contributed to the cambering of the ceramic.Rane S et al[9]investigated organic vehicle, firing and processing and surfacants treatment on silver powder and their effect on microstructure and cambering of the ceramic. Li C F et al[10]studied the effect of Au powder morphology on properties of gold paste film. However, the effect of metal powder which took about 70% of the total weight of conductive paste on microstructure and cambering of the ceramic, was less investigated. This paper studied the effect of particle size of near-sphere gold powder on cambering of an Au-metallized LTCC.

In our previous work, six kinds of near-sphere gold powder with different average diameters ranging from 0.7 µm to 2.3 µm were prepared. These gold powders together with a proper organic vehicle and glass frit were used to form six gold pastes. The organic vehicle primarily consisted of ethyl cellulose, butyl carbitol and organic additives. The glass frit used was the same as that forming the LTCC ceramic in order to eliminate the difference of thermal expansion coefficient between glass frit and the ceramic. By comparing study and analysis of the cofired ceramics and films formed by these gold pastes, the effect of particle size of near-sphere gold powder on microstructure and cambering of an Au-metallized LTCC ceramics was investigated, although in practical design of a paste it was wiser to adopt powder with a relatively wider size distribution.

1 Experiment

1.1 Preparation of gold conductive paste

Gold conductive pastes s-01 to s-06 were prepared using 5% (mass fraction) of glass frit (received from Sino Platinum Metals, SG11) with a mean particle size of about 17 µm, 20% (mass fraction) of organic vehicle (received from Sino Platinum Metals, V01) and 75% (mass fraction) of near-sphere gold powders with different average diameters (prepared in author’s previous work(Tab.1), all calculated in total weight of each paste. The materials were mixed for 30 min by hand and then dispersed on three roll mill to get a fineness of 15-20 µm.

1.2 Printing and cofiring

The pastes were applied and screen-printed on LTCC green tape(78 cm×88 cm), using a standard 325-mesh (44mm) stainless steel screen and KEKO P-200 AVFTH screen printing machine, the printing graphic was 75 cm×85 cm by size for testing cambering at four corners, and standard 100 squares for tesing sheet resistance. The printed ceramics were levelled at room temperature for 15 min and dried at 70 ℃ for 15 min in air, laminated and pressed at 21 MPa for 15 min, and then cofired according to this process:0.6 ℃/min from 25 ℃to 450℃, dwell at 450 ℃for 120 min, 8℃/min from 450℃ to 850℃, dwell at 850℃for 15 min, and cool down at 15℃/min from 850℃ to 25℃.

The microstructures of each film were examined by scanning electronic microscope (Hitachi X-650). Cambering of the ceramics at four corners were tested using a plug gauge. Sheet resistance of each paste were tested on resistance meter (Tianjin Wireless Factory) and calculated on average of 10 results with a standard thickness of 25.4 µm.

2 Results and discussions

2.1 Microstructure analysis

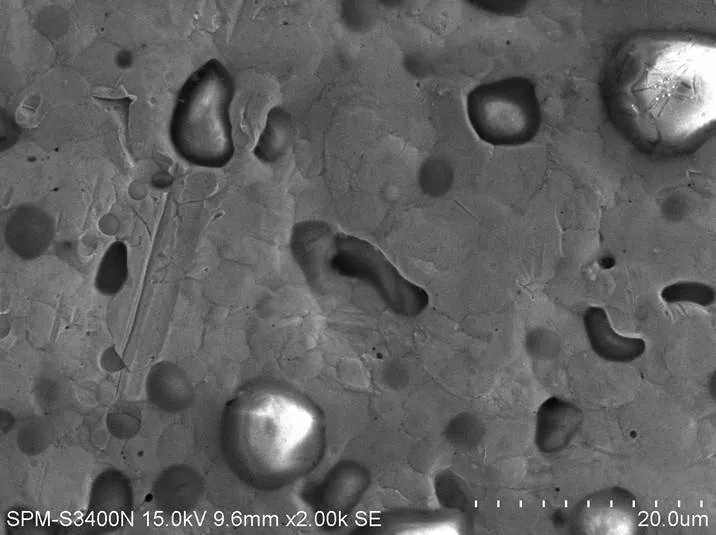

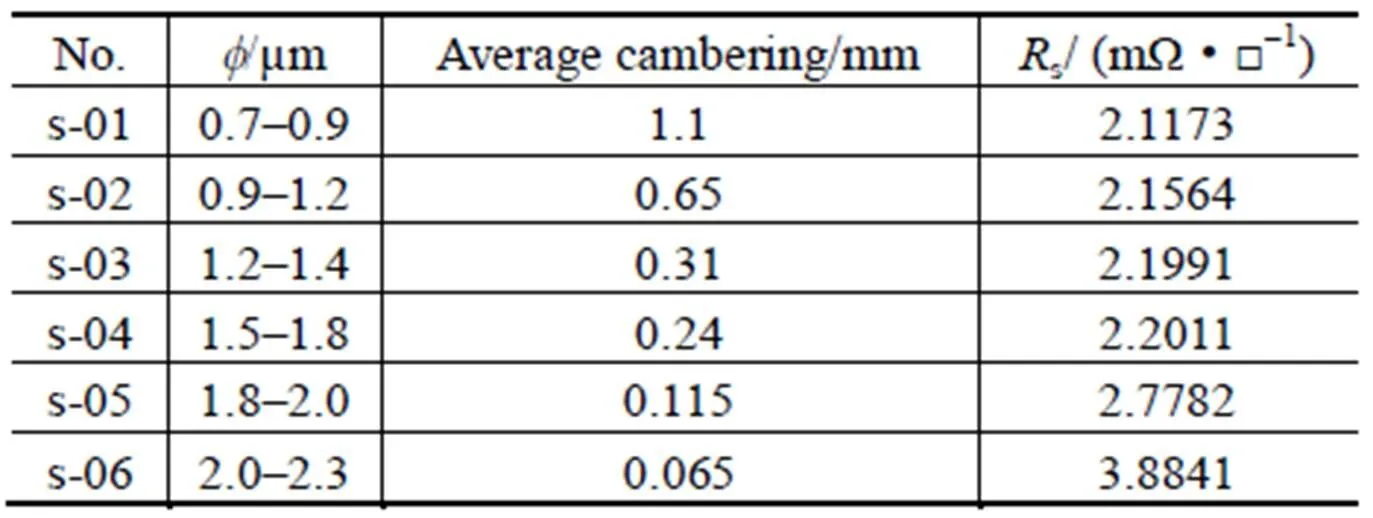

The microstructures of the cofired films formed by gold pastes s-01 to s-6 were shown in Fig.1. As shown in Fig.1, the surface morphologies of the sintered film varied with different gold powder adopted. Films prepared with fine gold powder((a).s-01 and (b).s-02) showed better sintering extent and densification than those prepared with coarse gold powder. In (e).s-05 and (f).s-06 minor voids and coarse grain could be observed which indicated inadequate sintering and poor densification of the film. This was because fine particles were more likely to proceed good grain development during cofiring into continuous and densified film. To confirm this, the sheet resistance of each paste(Tab 1) were tested and calculated. The sheet resistance of each paste increased with the size of the gold powder used(Fig.2). High sheet resistance indicated poor sintering densification and continuity of the film. The increase of sheet resistance showed that gold pastes formed with large size gold powder had poor sintering densification and continuity.

2.2 Cambering test

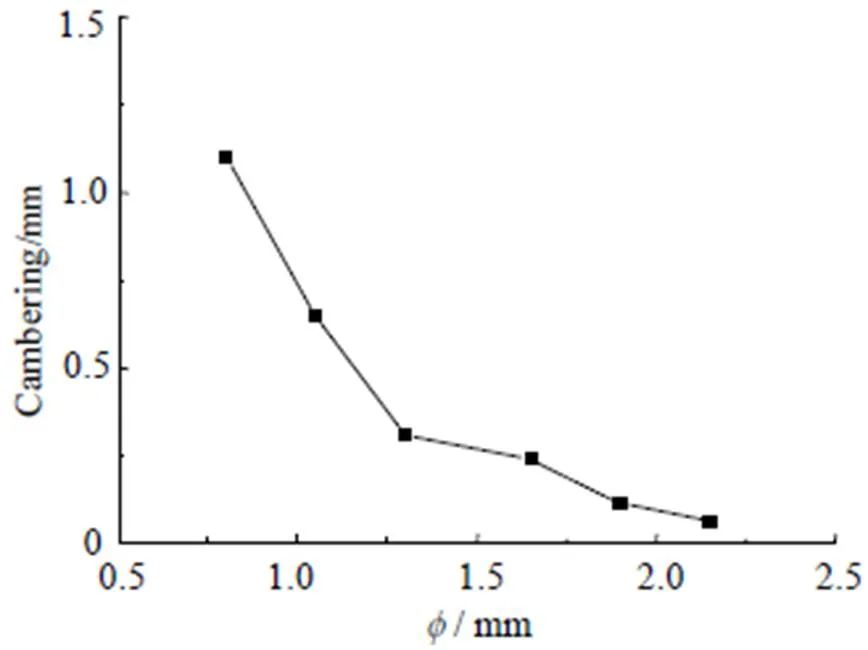

Cambering extent of each ceramic printed with pastes formulated by near-sphere gold powders with different diameters was tested and calculated at four corners of the ceramic, and the results were shown in Tab.1. The most severe cambering (1.1 mm on average) was observed in s-01, which adopted the finest gold powder. Cambering extent of the ceramic decreased with the increase of diameter of gold powder. In s-06 gold powder with a diameter from 2.0 µm to 2.3 µm was used and the average cambering of the ceramic at four corners was only 0.065 mm which was qualified for the most practical use. Fig.3 showed the relationship between cambering and the diameter of gold powder. This indicated that the particle size of gold powder played a major role in deciding the cambering extent of the ceramic as well and coarse gold powder (more than 1.8 µm in diameter) showed advantages in bringing down cambering extent of the ceramic. This was because gold powder with larger particle size began to sinter and densify at a higher temperature which was closer to the sintering and densification temperature of the ceramic.

(a) s-01 (b) s-02 (c) s-03

(d) s-01 (e) s-02 (f) s-03

Fig.1 SEM images of cofired films of pastes from s-01 to s-06

Tab.1 Pastes formed with different diameters() of gold powder, average cambering of four corners of each ceramic and sheet resistance of each paste

Fig.3 Relationship between cambering extent and diameter (f) of gold powder

3 Conclusion

Fine gold powder showed better sintering extent and densification during cofiring than coarse gold powder, thus films formed by fine gold powder showed better continuity and densification, and exhibited lower sheet resistance. The particle size of gold powder played a major role in deciding the cambering extent of the ceramic and large particle size gold powder showed better properties in bringing down cambering extent of the ceramic than fine gold powder. In practical design of a paste, all of film quality, sheet resistance and cambering of the ceramic should be taken into consideration. Gold powder with an average size of 2.0 µm and a wider size distribution should be used.

[1] DERNOVSEK O, NAEINI A, PREU G. LTCC glass-ceramic composites for microwave application [J]. J Eur Ceram Soc, 2001, 21: 1693-1697.

[2] JAU H J, CHANG C R, CHEN Z C. Effect of densification mismatch on camber development during cofiring of nickel-based multilayer ceramic capacitors [J]. J Am Ceram Soc, 1997, 80(9), 2401-2406.

[3] BESENDORFER G, ROOSEN A, MODES C. Factors influencing the green body properties and shrinkage tolerance of LTCC green tapes [J]. J Appl Ceram Technol, 2007, 4(1): 53-59.

[4] RAUSCHER M, ROOSEN A. Influence of low temperature co-fired ceramics green tape characteristics on shrinkage behavior [J]. J Appl Ceram Technol, 2007, 4(5): 387-397.

[5] YAJIMA K, YAMAGUCHI T. Sintering and microstructure development of glass bonded silver thick films [J]. Mater Sci, 1984, 19: 777-784.

[6] RAUSCHER M, ROOSEN A. Effect of particle shape on anistropic packing and shrinkage behavior of tape-cast glass-ceramic composites [J]. Appl Ceram Technol, 2009, 6(1): 24-34.

[7] BIROL H, MAEDER T, JACQ C, et al. Investigation of interaction between co-fired LTCC components [J]. J Eur Ceram Soc, 2005, 25: 2065-2069.

[8] BANGALI J, RANE S, PHATAK G. Effect of ink organics on cambering of an Ag-metallized low temperature co-fired ceramics(LTCC) [J]. J Mater Sci, 2009, 20: 455-460.

[9] RANE S, SETH T, PHATAK G, et al. Influence of surfacants treatment on silver powder and its thick films [J]. Mater Lett, 2003, 57: 3096-3100.

[10] 李程峰, 王海珍, 郭明亚, 等. 金粉形貌对金导体浆料印刷膜层性能的影响 [J]. 电子元件与材料, 2016, 35(10): 63-66.

[10] LI C F, WANG H Z, GUO M Y, et al. Effect of Au powder morphology on properties of gold paste film [J]. Electron Compon Mater, 2016, 35(10): 63- 66.

类球形金粉粒径对Au-金属化低温共烧陶瓷微观结构及翘曲度的影响

罗 慧,李世鸿,梁 云,李文琳,刘继松,李俊鹏

(贵研铂业股份有限公司 稀贵金属综合利用新技术国家重点实验室,云南 昆明 650106)

研究和探讨了低温共烧陶瓷(LTCC)共烧过程中的收缩现象及LTCC陶瓷金属化后翘曲的主要影响因素。采用六种不同平均粒径(0.7~2.3 µm)的类球形金粉、玻璃粉及一种合适的有机载体分别制备成金导体浆料。将制备成的金导体浆料印刷在LTCC 生瓷膜上,按LTCC常规工艺叠层、共烧。分析了不同粒径金粉制备的浆料印刷在瓷片上烧结后的微观结构,测量了各瓷片的翘曲度及各浆料的方阻。实验发现采用大粒径的类球形金粉有利于减小瓷片的翘曲度,但烧结膜层致密性变差,方阻也变大。

金属材料;低温共烧陶瓷;近球形金粉;翘曲; 粉体粒径;致密度

(编辑:唐斌)

TM241

A

1001-2028(2017)03-0007-04

10.14106/j.cnki.1001-2028.2017.03.002

2016-11-21

LUO Hui

Fundation:The Fund of the State Key Laboratory of Advanced Technologies for Comprehensive Utilization of Platinum Metals (No. SKL-SPM- 201532); Key Technologies of Preparing LTCC Electronic Pastes and Their Industrial Applications(No. 2015020211); Development & Industrialization of Precious Metal Pastes Used in Integrated Chip Components(No. 2016020201)

Biography:LUO Hui(1986-), female, engineer, master, E-mail:estron@126.com .

Network publishing time:2017-03-10 11:35

Network publishing address:http://kns.cnki.net/kcms/detail/51.1241.TN.20170310.1135.002.html