Entropy generation analysis for the peristaltic flow of Cu-water nanofluid in a tube with viscous dissipation*

2017-03-09NoreenSherAkbarAdilWahidButt

Noreen Sher Akbar, Adil Wahid Butt

1. DBS & H, CEME, National University of Sciences and Technology, Islamabad, Pakistan, E-mail:noreensher1@gmail.com

2. DBS & H, MCE, National University of Sciences and Technology, Islamabad, Pakistan

(Received October 16, 2014, Revised December 24, 2016)

Entropy generation analysis for the peristaltic flow of Cu-water nanofluid in a tube with viscous dissipation*

Noreen Sher Akbar1, Adil Wahid Butt2

1. DBS & H, CEME, National University of Sciences and Technology, Islamabad, Pakistan, E-mail:noreensher1@gmail.com

2. DBS & H, MCE, National University of Sciences and Technology, Islamabad, Pakistan

(Received October 16, 2014, Revised December 24, 2016)

The purpose of the current investigation is to examine the influence of different physical parameters on the entropy generation. The entropy generation number due to heat transfer and fluid friction is formulated. The velocity and temperature distributions across the tube are presented along with pressure attributes. Exact analytical solution for velocity and temperature profile is obtained. It is found that the entropy generation number attains high values in the region close to the walls of the tube, while it falls to low values near the center of the tube.

Entropy generation, heat transfer, nanofluid, Cu-water, uniform tube

Introduction

The topic of peristaltic flow was first presented and framed by Latham[1]. After the Latham’s study, this topic gained dynamic importance. During the last few years research had been carried out in this area because of its great significance in numerous fields such as manufacturing, physiology and ecology. Such claims for peristaltic flow seem in the transportation of irritability in the wrath duct, vasomotion of the small blood vessels, the transport of urine from kidney to the bladder, the movement of eggs in the fallopian tube, the transport of the spermatozoa in cervical canal, the chyme movement in the intestine, and the transport of intra-uterine fluid within the cavity of the uterus. Several articles discussing the application of peristalsis are given in Refs.[2-8].

Tryouts have led to the study of flows preceding acquiescent precincts, i.e., blood flow in arteries, dolphin propulsion etc. Srinivasacharya et al.[9]delibera-ted the Stimulus of wall possessions on peristalsis in the occurrence of compelling field. Radhakrishnamacharya and Srinivasulu[10]gave the effect of wall properties on peristaltic transportation with heat transfer. From them originated a theory that heat transmission rises with flexible tautness and mass exemplifying structures. Muthu et al.[11]examined the peristaltic gesticulation of micro glacial fluid in spherical cylindrical pipes with consequence of wall properties. According to them in the situation of viscoelastic wall, wall properties affect the fluid flow significantly. Conclusions about the effect of heat and mass allocation on MHD peristaltic movement in a porous space smeared with slip complaint are drawn by Srinivas and Kothandapani[12]and Srinivas et al.[13]. Heat transfer analysis of the peristaltic instinct of biviscosity fluid with the impact of thermal and velocity slips is studied by Akbar and Khan[14]. Very recently some noteworthy hypothetical exertions depleted the acquiescent walls examination has been done by Nadeem et al.[15].

In thermodynamics, entropy is a measure of the number of specific ways in which a thermodynamic system may be arranged, often taken to be a measure of disorder, or a measure of progressing towards thermodynamic equilibrium. Non-Newtonian fluid flow in a pipe system with entropy generation has been considered by Pakdemirli and Yilbas[16].According to them entropy number increases with increasing Brinkman number. Souidi et al.[17]discussed entropy generation rate for a peristaltic pump. They also did analytical study. The analysis reveals that peristaltic pumps generate more entropy than steady walled tubes and are not, from this point of view, competitive devices. Abu-Hijleh et al.[18]investigated numerical prediction of entropy generation due to natural convection from a horizontal cylinder. The reason for this high-energy degradation is found in the dynamic behavior. Abu-Nada[19]discussed numerical prediction of entropy generation in separated flows. In another article[20], he presented entropy generation due to heat and fluid flow in backward facing step flow with various expansion ratios. He studied numerical solutions with computational algorithm.

Entropy generation for peristaltic flow is not explored so far, to fill this gap we have investigated the entropy generation for peristaltic flow in a tube with nanofluid. The coupled differential equations are simplified under long wave length and low Reynolds number assumptions. Exact solutions are obtained for reduced coupled differential equations. The entropy generation is computed by evaluation of thermal and fluid viscosities contribution. The physical features of pertinent parameters have been discussed by plotting the graphs of velocity, temperature, entropy number and stream functions.

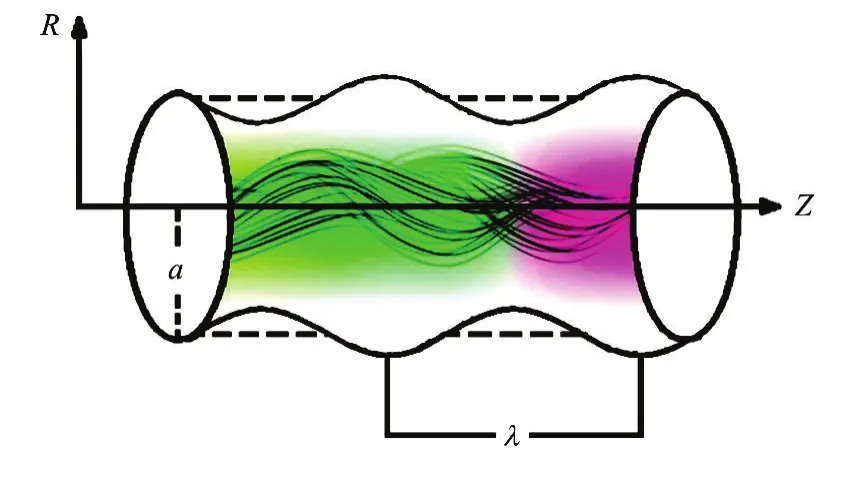

Fig.1 (Color online) Geometry of the problem

1. Problem formulation

Let us consider the incompressible, natural convective peristaltic flow of nanofluids in a horizontal tube. A sinusoidal wave is propagating along the walls of the tube. We choose a cylindrical coordinate system (,), where-axis lies along the center line of the tubes and-axis is normal to it. The wave is propagating with a velocitycalong the wall of the tube. With the view of analysis the geometry of the wall surface is defined as whereais the radius of the tube,bis the amplitude of the sinusoidal wave,cis the wave speed andλis the wavelength. The geometry of the flow is shown in Fig.1.

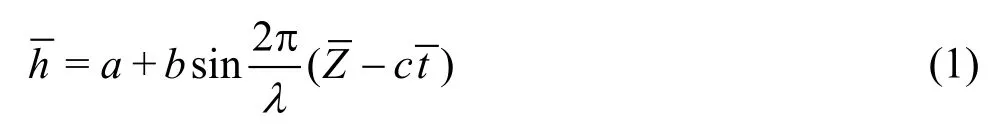

In the fixed coordinate system (,)flow between the tube is unsteady. It becomes steady in a wave frame(,)moving with the same speed as the wave moves in the-direction. The transformations between the two frames are:

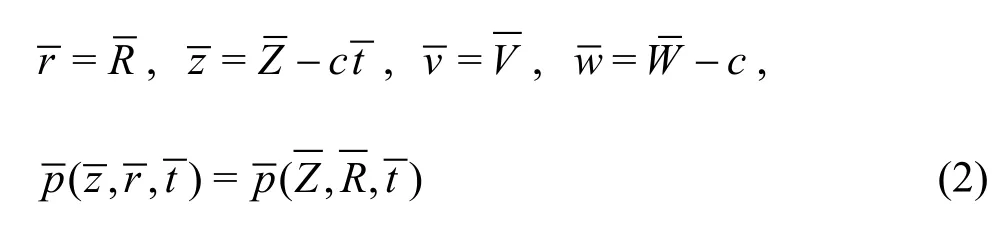

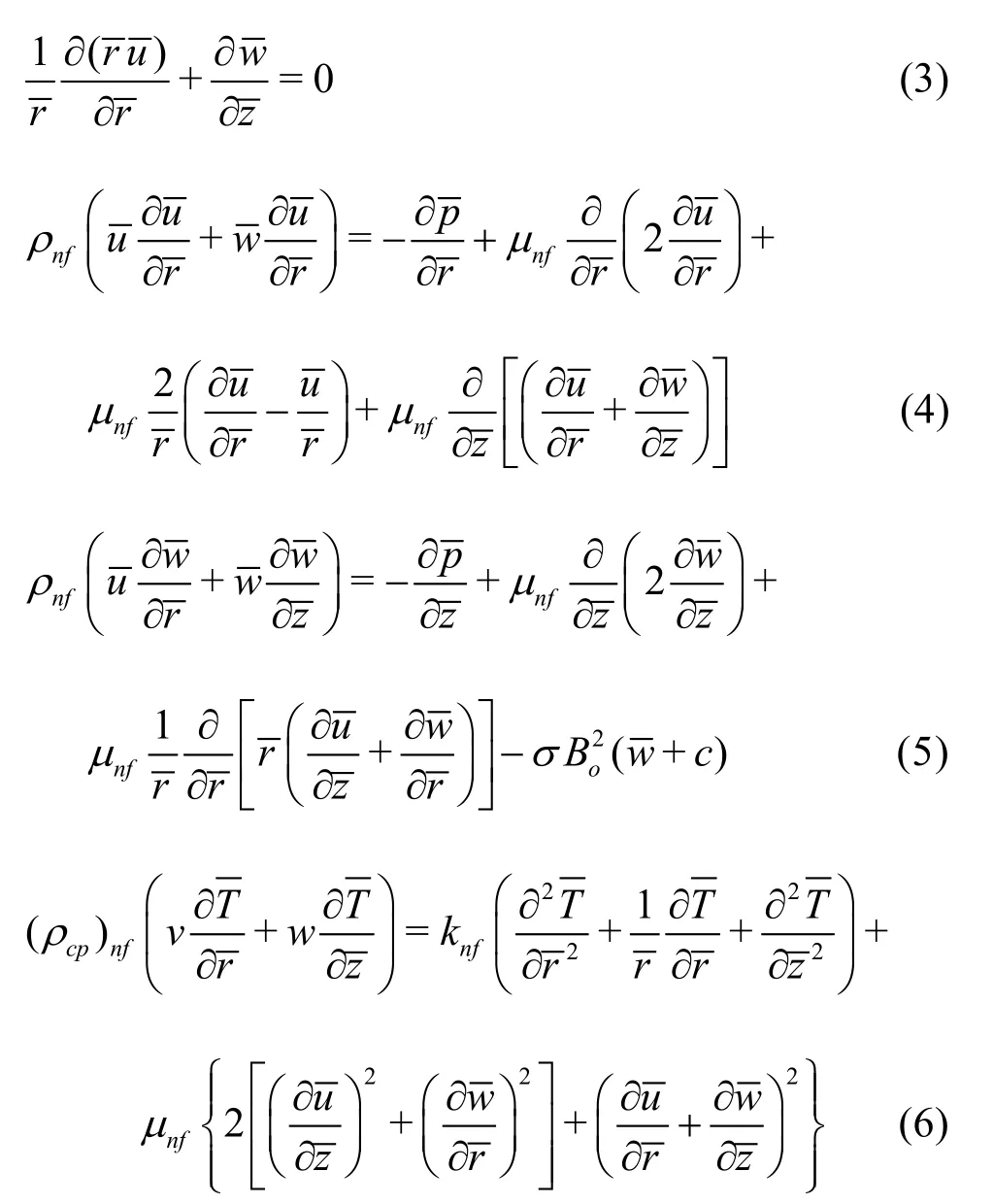

The governing equations for the flow of an incompressible nanofluid can be written as:

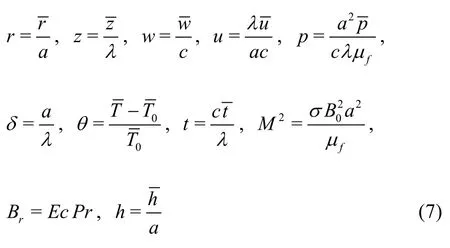

whereandare the coordinates,-axis is taken as the center line of the tube andtransverse to it,andare the velocity components in theanddirections respectively,is the local temperature of the fluid. Further,ρnfis the effective density,μnfis the effective dynamic viscosity,(ρcp)nfis the heat capacitance,αnfis the effective thermal diffusivity,knfis the effective thermal conductivity of the nanofluid, andis the pressure. We use the following non-dimensional variables:

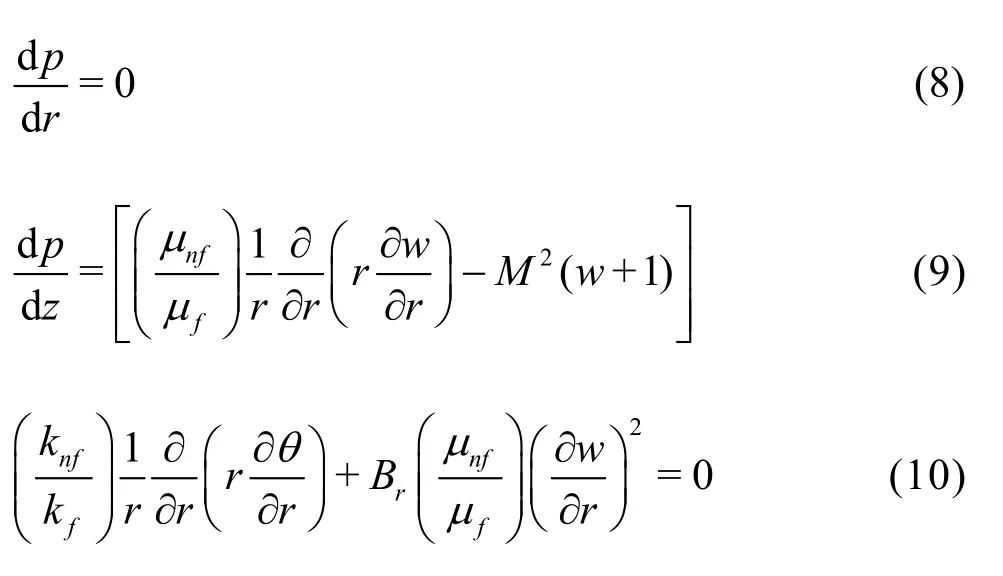

With the help of Eq.(7), Eqs.(3)-(6) can be written as follows:

The non-dimensionless boundary conditions are defined as follows:

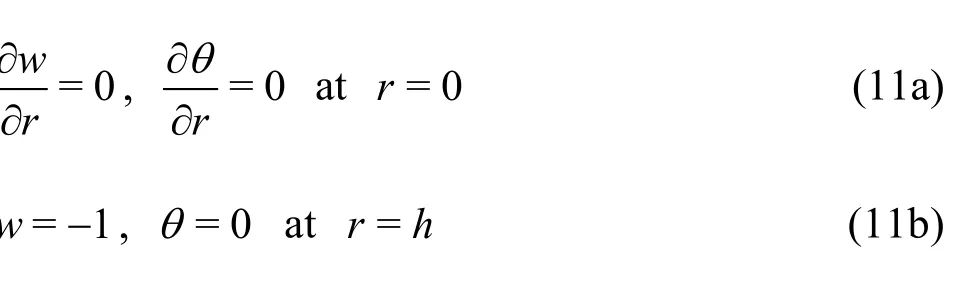

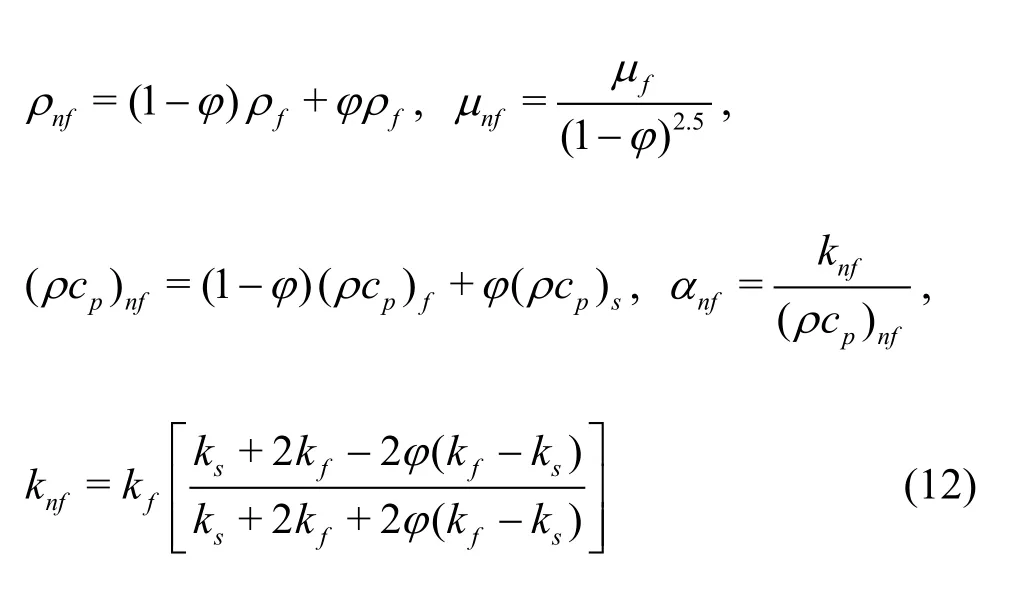

Thermal properties of the fluid are defined as follows[18-20]:

whereΜis the Hartman number,Bris the Brinkman number,Pris the Prandtl number andφis the nanoparticle volume fraction.

2. Entropy generation analysis

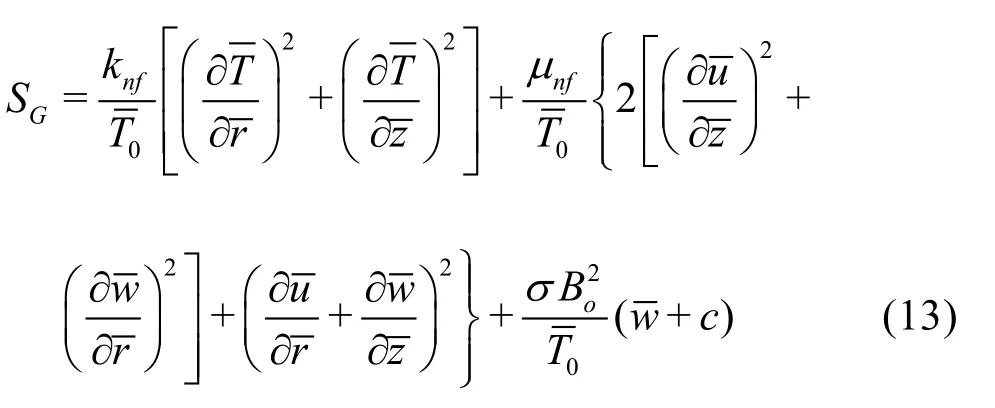

Entropy generation can be defined[16,17]as follows

Dimensionless form of the entropy generation with the help of Eq.(7) due to fluid friction and magnetic field is given as

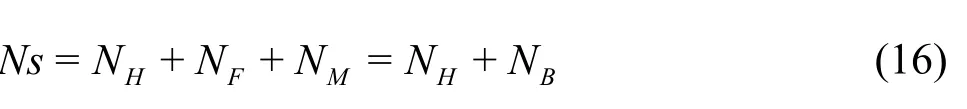

The dimensionless form ofSGis known as entropy generation numberNSwhich is the ratio of actual entropy generation rate to the characteristic entropy transfer rateSG0, which is defined as follows:

The total entropy generation in Eq.(14) can be written as the sum

whereNHis the entropy generation due to heat transfer,NFis the local entropy generation due to fluid friction irreversibility andNMis the entropy generation due to magnetic field caused by the motion of electrically conducting fluids under the magnetic field inducing electrical currents that circulates in the fluid. Further, the sum of second and third term in Eq.(16) can be treated as the entropy generationNBdue to combined effects of fluid friction and magnetic field

In order to see whether the one term is dominant to other a criterion namely irreversibility ratio, which is the ratio between entropy generation due to fluid friction and Joule dissipation to the total entropy generation due to heat transfer. The irreversibility ratioξis defined as

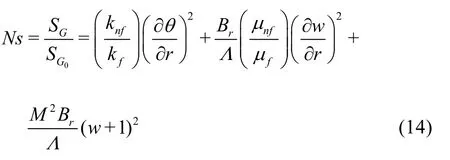

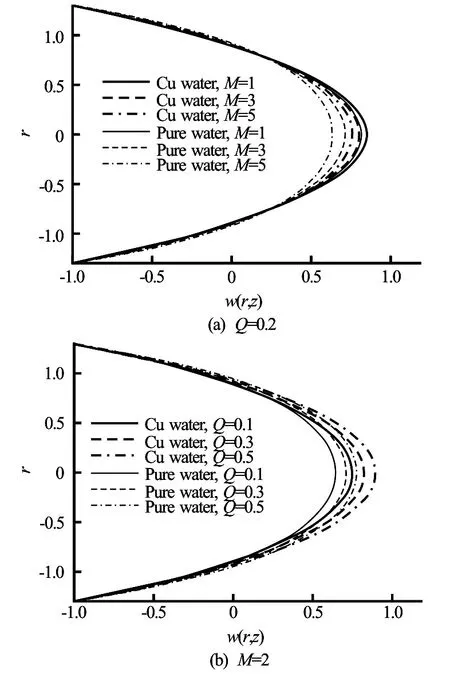

Fig.2 Velocity profilesw(r,z)against the radial distancer(z=1,ε=0.3)

Fig.4 Pressure rises ΔPagainst the flow rateQ

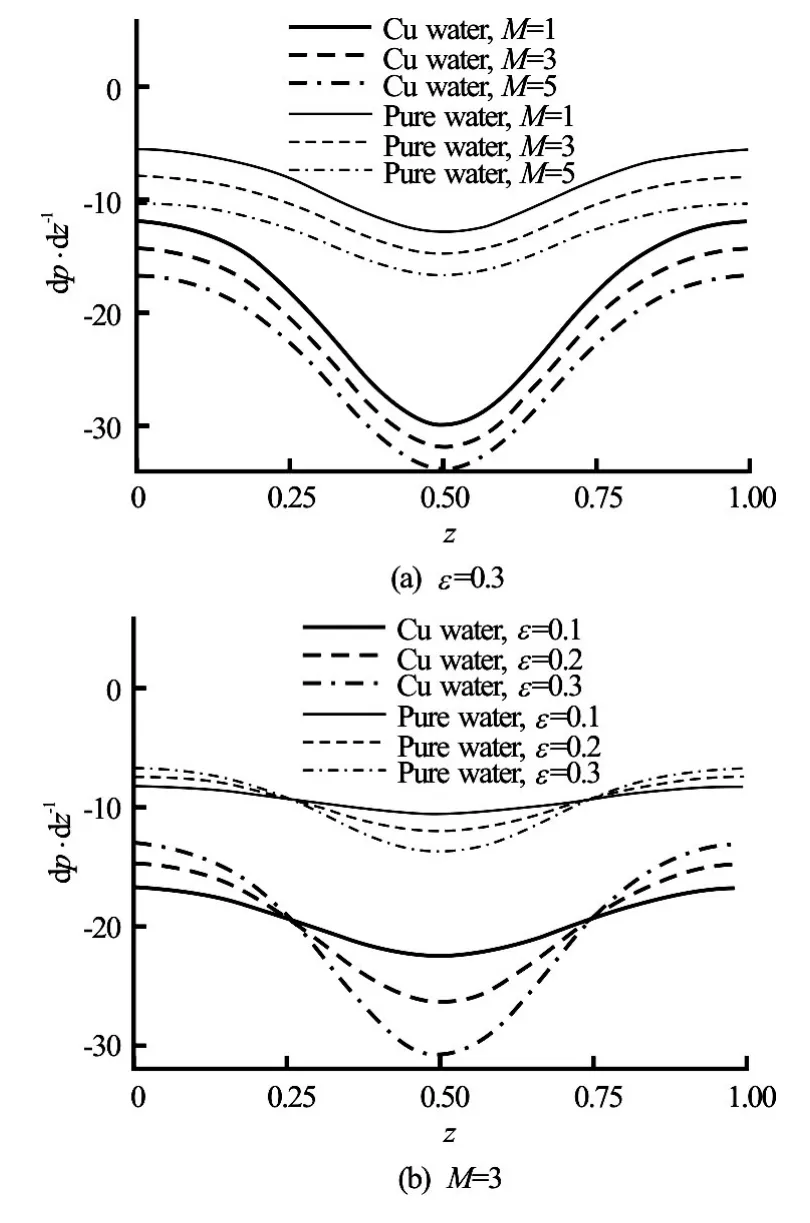

Fig.3 Pressure gradients dp/dzversusz(Q=0.1)

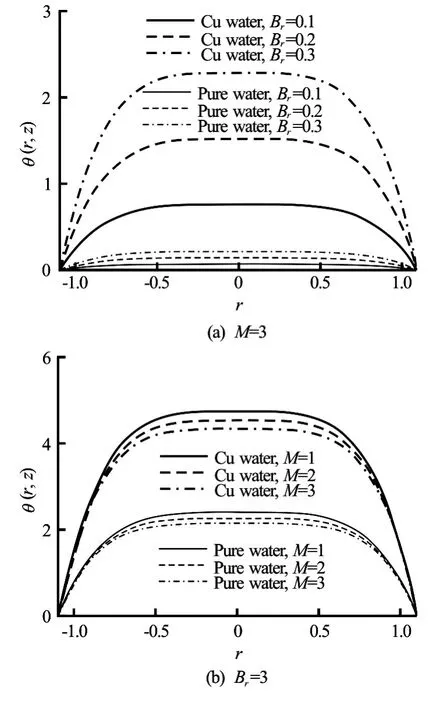

Fig.5 Temperature profilesθ(r,z)(z=1,ε=0.1,Q=0.2)

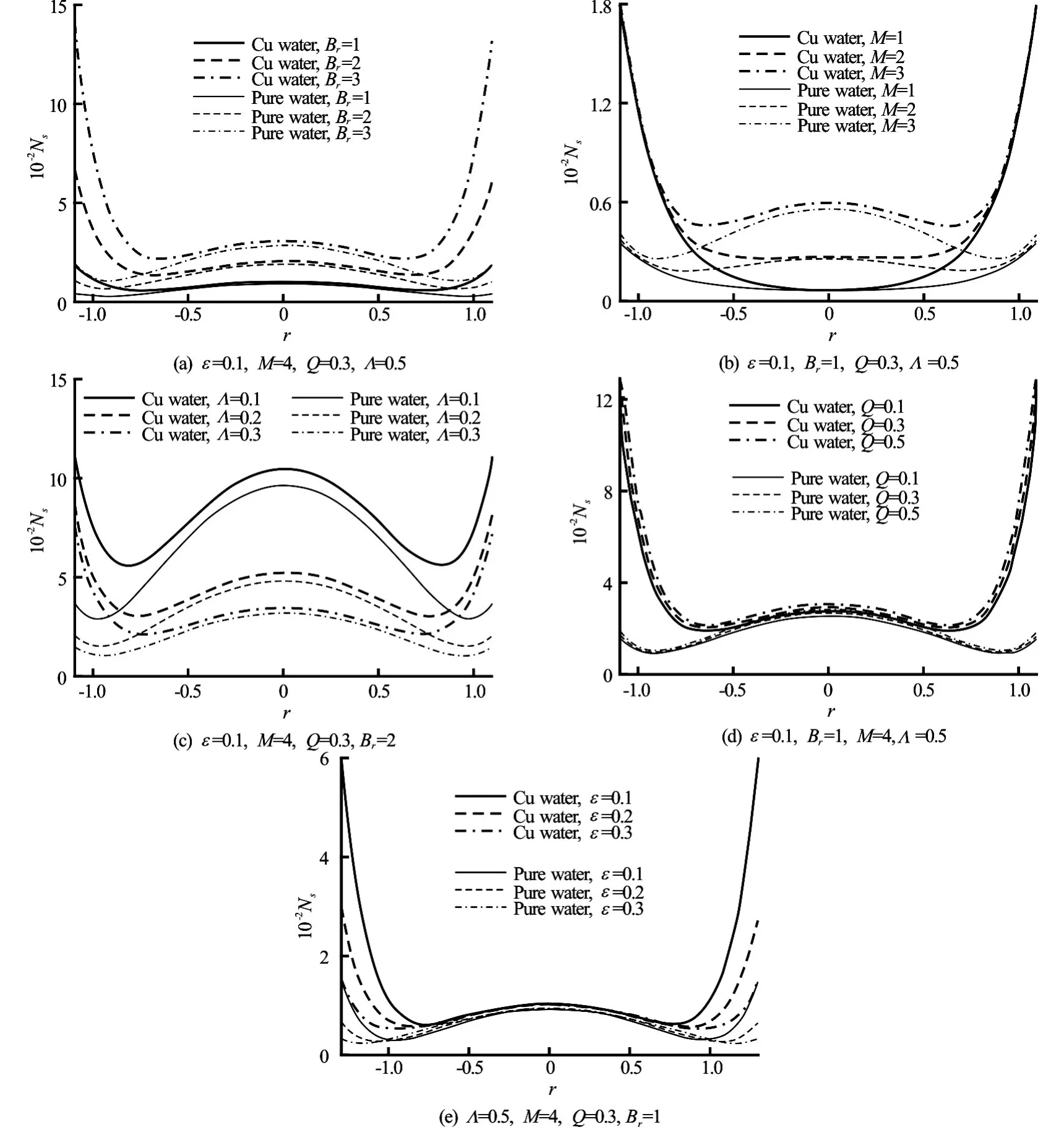

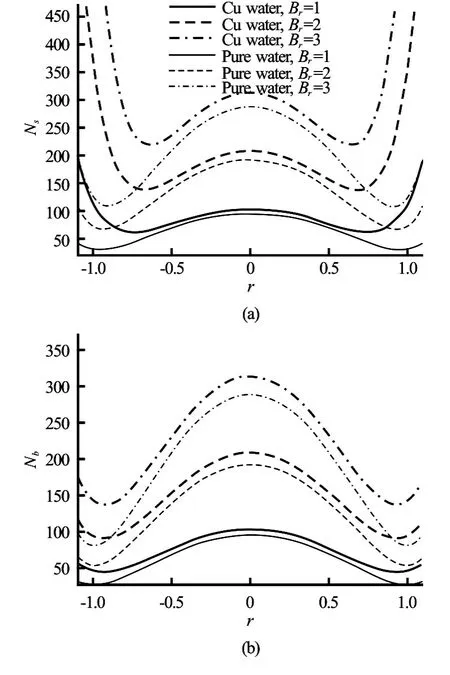

Fig.6 EntropiesNSagainst the radial distancesr(z=1)

Note that heat transfer irreversibility dominates in the range 0<ξ<1whereasξ>1indicates that irreversibility is solely due to the sum of fluid friction and magnetic field irreversibility, The contribution of heat transfer to entropy generation is same to the combined effects of fluid friction and magnetic field whenξ=1.

Alternatively, another irreversibility parameter is the Bejan number which is the ratio of heat transfer irreversibility to the total irreversibility due to heat transfer, fluid friction and magnetic field. Mathematically

From Eq.(19), it is clear that Bejan number ranges from 0 to 1. HereBe→0is the limiting case when the entropy generation due to combined effects of fluid friction and magnetic field is dominant,Be→1is the opposite limit where heat transfer irreversibility dominates andBe=0.5is the case where the contributions of both heat and fluid friction to entropy generation are equal.

3. Exact solutions

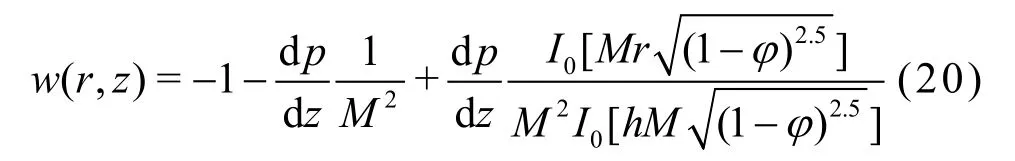

Exact solutions have been evaluated for velocity, temperature and pressure gradient from Eqs.(9) to (11):

Velocity of the fluid flow is

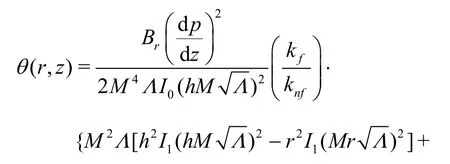

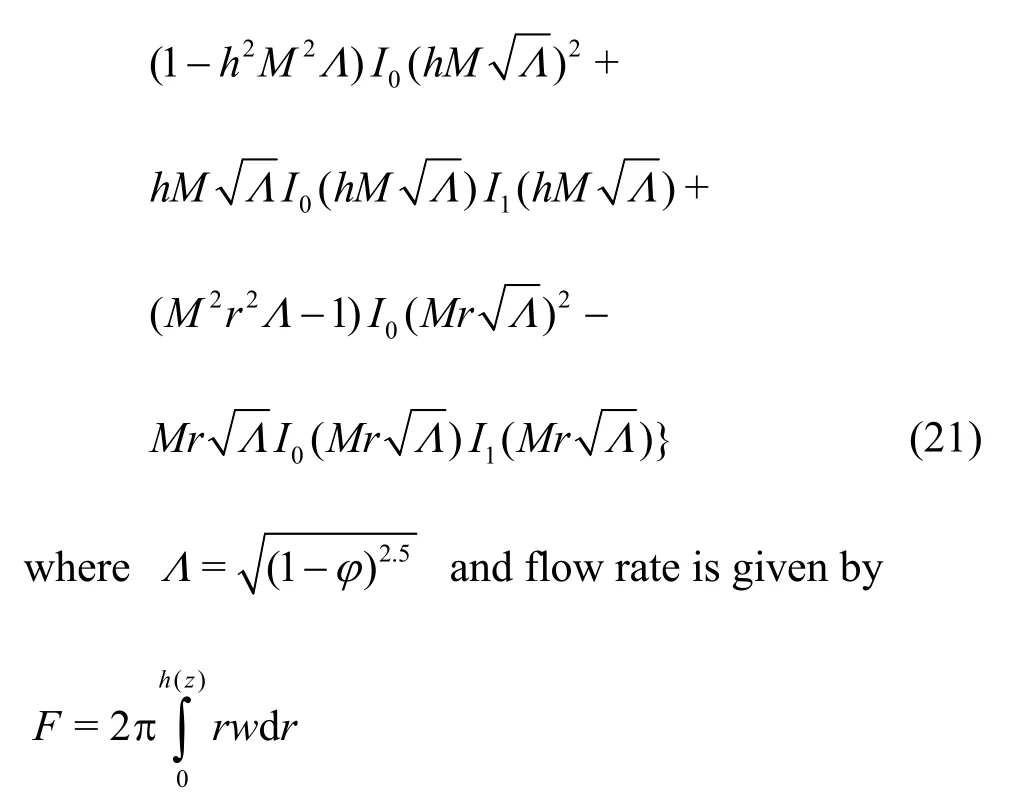

The temperature distribution is given as

this implies that

where the mean flow rateQis given as

Integrating Eq.(22) over the interval[0,1], we can find the pressure rise given by the expression

4. Results and discussions

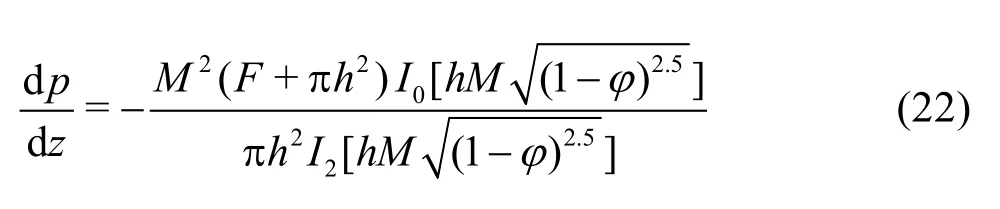

In this section, we present a brief g raphical analysis of the exact analytical solutions of the governing problem. Figures 2(a) and 2(b) represent the magnitude of the horizontal velocity of the fluid inside the tube. We see that with the increase in the Hartmann numberM, i.e., ratio of electromagnetic force to the viscous force, the velocity decreases in the center of the tube and increases near the walls of the tube, while as we increase the flow rateQ, the magnitude of velocity takes a positive shift all around the tube. In both cases, it is observed that Cu-water has more variation than that of Pure water. Also we note that the velocity attains its highest values in the center of the tube atr=0, while it sufficiently decreases at the walls of the tube. Figures 3(a) and 3(b) depict that with the addition of copper to the base fluid, the pressure gradually decreases. We note that the pressure gradient certainly decreases with a decrease in the Hartmann number. However a non-uniform behavior is seen in the case ofε. In that case pressure gradient seems to be directly proportional toεfor 0≤z<0.25and inversely proportional for0.25<z<0.75this behavior of pressure gradient is oscillating.

The pressure rise of in the fluid is shown in Figs.4(a) and 4(b), from the graphical demonstration, it is seen that pressure rise is directly proportional toM,εin the peristaltic pumping region and inversely proportional to the same in the augmented peristaltic region. In both cases, the change in case of Cu-water is observed to be more rapid as compared with Pure water. Temperature of fluid in the tube significantly increases with an increase in Brinkman numberBrand a decrease in Hartmann numberM. However with less copper in the fluid, the temperature substantially decreases inside the tube. In comparison with the walls of the tube, higher temperature exists in the center wherer=0. We note that with higher the values of the Brinkman number, i.e., the ratio of viscous heat generation to external heating, the lesser will be the conduction of heat produced by viscous dissipation and hence the larger the temperature rise see Figs.5(a), 5(b).

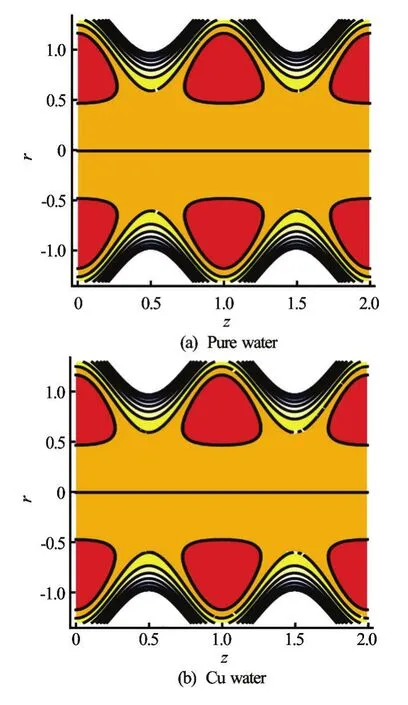

F ig.8 (Color online) Streamlines for pure water and Cu-water

Figures 6(a)-6(e) are prepared to analyze the entropy generation with respect to change in different physical constraints involved. Figures 6(a)-6(b) depict that entropy generation is directly proportional to both Hartmann number and Brinkman number, and that entropy generation for Cu-water is higher than that of Pure water. It has larger values near the walls of the tube as compared with the center of the tube. It is to be noticed that for significantly larger values of these two parameters, entropy generation can be larger in the center of the tube than those generated at the walls. The similar behavior is seen if we increase the flow rateQ. Nevertheless, the higher the values ofΛ,εthe smaller entropy generation. Rapid change in this case is seen in the center of the tube which implies that characteristic entropy transfer rate is predominant as compared with actual entropy generation rate with the rise inΛ,ε.

Figures 7(a)-7(e) are prepared to analyze the Bejan number with respect to change in different physical constraints involved. Figures 7(a)-7(e) show that with the increase in Hartmann number, Brinkmannumber, temperature difference, flow rate, and amplitude ratio, the heat transfer irreversibility is high as compare with the total irreversibility due to heat transfer, fluid friction and magnetic field.

Figure 8 shows streamlines for pure and Cu-water. It is seen that the size of trapped bolus for pure water is greater as compare with Cu-water. Figure 9 shows the entropy generation: (1)Nswith heat transfer, (2)NBwithout heat transfer. It is seen from the figures that the entropy generation with heat transfer is high near the tube walls as compare with the center of the tube, while entropy generation without heat transfer is high at center, and small entropy generation occurs near the tube walls.

Fig.9 EntropiesNSandNbwith heat transfer for varying Brinkman numbers (z=1,ε=0.1,M=4,Q=0.3,Λ=0.5)

5. Conclusion

An analysis of entropy generation in the peristaltic flow of Cu-water nanofluid in a tube with viscous dissipation has been made. We have found that with the increase in the Hartmann number the velocity decreases in the center of the tube and increases near the walls of the tube, while as we increase the flow rateQ, the magnitude of velocity takes a positive shift all around the tube. In both cases, it is observed that Cu-water has more variation than that of Pure water. Also we note that the pressure rise is directly proportional toM,εin the peristaltic pumping region and inversely proportional to the same in the augmented peristaltic region. In both cases, the change in the case of Cu-water is observed to be more rapid as compared with Pure water. Temperature of the fluid in the tube significantly increases with an increase in Brinkman numberBrand a decrease in Hartmann numberM. Rapid change in this case is seen in the center of the tube which implies that characteristic entropy transfer rate is predominant as compared with actual entropy generation rate with the rise inΛ,ε.

[1] Latham T. W. Fluid motion in a peristaltic pump [D]. Master Thesis, Cambridge, USA: MIT, 1966.

[2] Akbar N. S. MHD eyring Prandtl fluid flow with convective boundary conditions in small intestines[J].International Journal of Biomathematics, 2013, 6(5): 135-147.

[3] Akbar N. S. Endoscopic effects on the Peristaltic flow of Cu-water nanofluid [J].Journal of Computational and Theoretical Nanoscience, 2014, 11(4): 1150-1155.

[4] Akbar N. S. Peristaltic flow with Maxwell carbon nanotubes suspensions [J].Journal of Computational and Theoretical Nanoscience, 2014, 11(7): 1642-1648.

[5] Akbar N. S. Metallic nanoparticles analysis for the peristaltic flow in an asymmetric channel with MHD [J].IEEE Transactions On Nanotechnology, 2014, 13(2): 357-361.

[6] Akbar N. S. Heat and mass transfer effects on Careau fluid model for blood flow through tapered arteries with stenosis [J].International Journal of Biomathematics, 2014, 7(1): 1450004.

[7] Akbar N. S. MHD peristaltic flow with carbon nanotubes in an asymmetric channel [J].Journal of Computational and Theoretical Nanoscience, 2014, 11(5): 1323-1329.

[8] Akbar N. S. Peristaltic flow of tangent hyperbolic fluid with convective boundary condition [J].The European Physical Journal Plus, 2014, 129(10): ID214.

[9] Srinivasacharya D., Radhakrishnamarya G., Srinivasulu C. Influence of wall properties on peristalsis in the presence of magnetic field [J].International Journal of Fluid Mechanics Research, 2007,34(4): 374-386.

[10] RadhakrishnamacharyaG.,SrinivasuluC.Influenceof wall properties on peristaltic transport with heat transfer [J].Comptes Rendus Mecanique, 2007, 335(7): 369-373.

[11] Muthu P., Rathish B. V. K., Chandra P. Peristaltic motion of micropolar fluid in circular cylindrical tubes: Effect of wall properties [J].Applied Mathematical Modelling, 2008, 32(10): 2019-2033.

[12] Srinivas S., Kothandapani M. The influence of heat and mass transfer on MHD peristaltic flow through a porous space with compliant walls [J].Applied Mathematics and Computation, 2009, 213(1): 197-208.

[13] Srinivas S., Gayathri R., Kothandapani M. The influence of slip conditions, wall properties and heat transfer on MHD peristaltic transport [J].Computer Physics Commu-nications, 2009, 180(11): 2115-2122.

[14]Akbar N. S., Khan Z. H. Heat transfer analysis of the peristaltic instinct of biviscosity fluid with the impact of thermal and velocity slips [J].International Communications in Heat and Mass Transfer, 2014, 58: 193-199.

[15] Nadeem S., Maraj E. N., Akbar N. S. Theoretical analysis for peristaltic flow of Carreau nano fluid in a curved channel with compliant walls [J].Journal of Computational and Theoretical Nanoscience, 2014, 4(1): 85-92.

[16] Pakdemirli M., Yilbas B. S. Entropy generation in a pipe due to non-Newtonian fluid flow: Constant viscosity case [J].Sadhana, 2006, 31(1): 21-29.

[17] Souidi F., Ayachi K., Benyahia N. Entropy generation rate for a peristaltic pump [J].Journal of Non-Equilibrium Thermodynamics, 2009, 34(2): 171-194.

[18] Hijleh B. A., Abu-Qudais M., Abu-Nada E. Numerical prediction of entropy generation due to natural convection from a horizontal cylinder [J].Energy, 1999, 24(4): 327-333.

[19] Abu-Nada E. Numerical prediction of entropy generation in separated flows [J].Entropy, 2005, 7(4): 234-252.

[20] Abu-Nada E. Entropy generation due to heat and fluid flow in backward facing step flow with various expansion ratios [J].International Journal of Exergy, 2006, 3(4): 419-435.

* Biography:Noreen Sher Akbar (1984-), Female, Ph. D., Assistant Professor

Adil Wahid Butt, E-mail: adil.maths86@gmail.com

杂志排行

水动力学研究与进展 B辑的其它文章

- Large eddy simulation of free-surface flows*

- Effect of internal sloshing on added resistance of ship*

- Large eddy simulation of turbulent attached cavitating flow with special emphasis on large scale structures of the hydrofoil wake and turbulence-cavitation interactions*

- Assessment of the predictive capability of RANS models in simulating meandering open channel flows*

- The lubrication performance of water lubricated bearing with consideration of wall slip and inertial force*

- Ice accumulation and thickness distribution before inverted siphon*