利口乐草药中心,劳芬,瑞士

2017-02-08建筑设计赫尔佐格与德梅隆事务所

建筑设计:赫尔佐格与德梅隆事务所

利口乐草药中心,劳芬,瑞士

建筑设计:赫尔佐格与德梅隆事务所

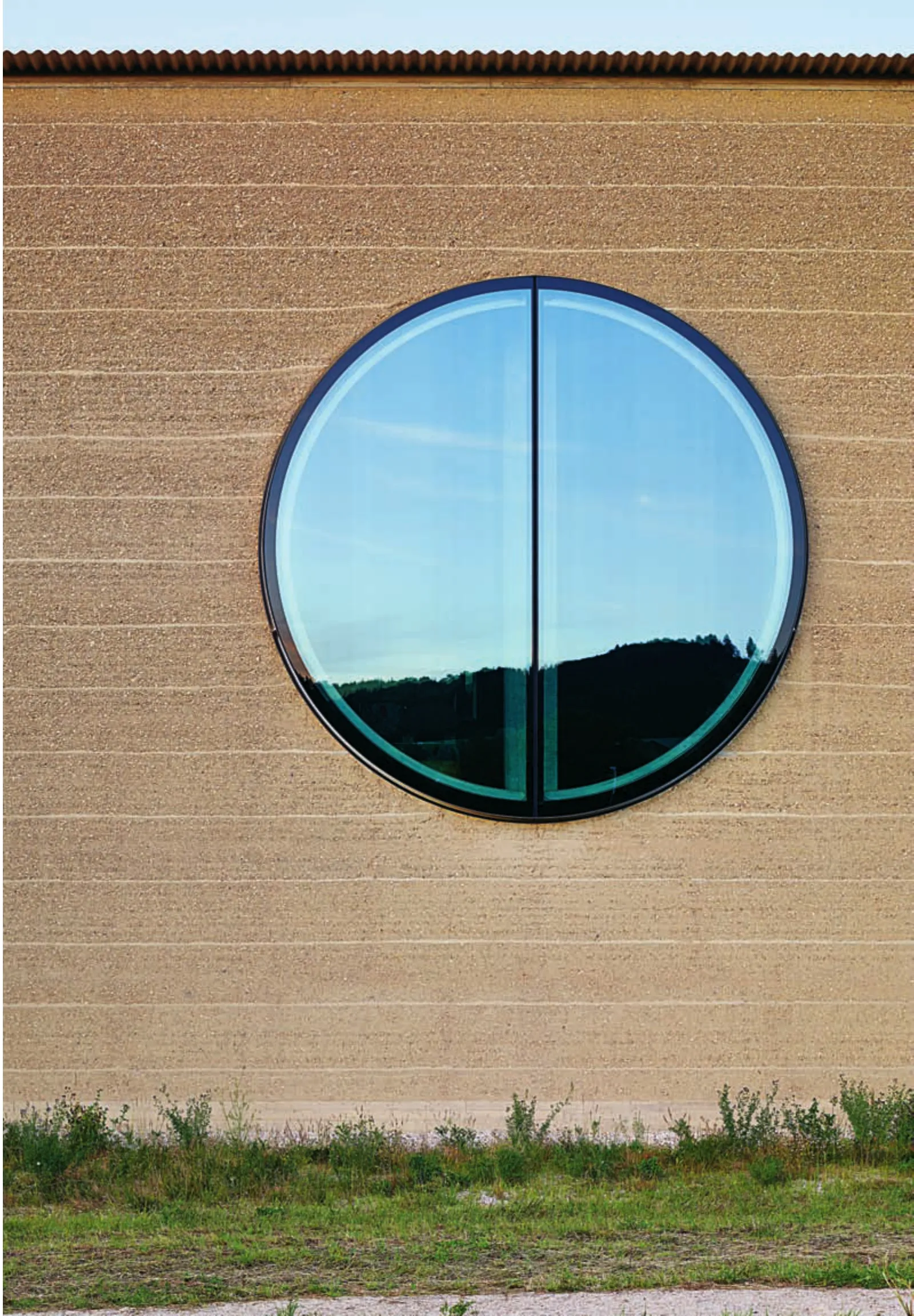

1 草药中心坐落在农业园中/The Kräuterzentrum is situated in a agricultural area

2 总平面/Site plan

建筑和景观

新的草药中心,像是一块奇特的砂砾,处在装点着传统工业建筑的田野中。它狭长的形式呼应着田间小径和篱笆,这样的景观是该区域长久以来最显著的特征。建筑的长度也反映了草药加工过程的多个步骤:从烘干、切割、搅拌到储藏。这座新的加工厂让利口乐公司得以将这些重要步骤纳入公司内部的生产线。

作为景观的建筑

草药中心基本都是用当地土壤建造的;它就像是景观的几何化片段,而激进的材料选择又强化了它的尺度和古朴效果。草药和土壤定义了这座功能明确、特征鲜明的厂房,追随着利口乐公司其他建筑的脚步:1987年的全自动仓储建筑;1993年位于米卢斯-布伦斯塔特的生产及装配建筑,采用丝网印刷立面;1999年位于劳芬的市场营销总部,采用了玻璃幕墙。这些建筑不仅凝聚着利口乐公司独特的企业哲学和对环境保护的投入,而且都对所在场所做出了杰出的贡献。

建筑立面上的货物入口和仓储部分都是整体性的,夯土墙在室内也可以看到。预制夯土构件是在附近的工厂用当地采石场及矿山中开采的原料制作的。当地开采的粘土、泥灰和其他材料混合在一起,夯实成砌块,然后再堆叠形成墙壁。由于土壤的可塑性,我们可以将缝隙重新润饰,使建筑获得统一而整体的形象。为了防止风雨的腐蚀,我们将一种由火山灰和石灰混合而成的火山土以1:8的比例调配入预制夯土构件。大幅圆形窗户为室内带来充足采光。立面是自承重的,与室内的承重混凝土框架相连。

能源和可持续性

能源和可持续性并不是简单的技术辅助而已,它们是建筑形式和项目核心特征的一部分。土壤作为一种可调节湿度的材料,对于能源使用和整体气候控制有着积极、可持续性的影响。屋顶上的光电板以及对附近生产车间冗余热量的使用,也能够改进草药中心的生态平衡。□(黄华青 译)

项目信息/Credits and Data

建筑设计/Architects: 赫尔佐格与德梅隆事务所/Herzog & de Meuron (Basel, Switzerland)

合伙人/Partners: Jacques Herzog, Pierre de Meuron, Stefan Marbach (责任合伙人/Partner in Charge)

客户/Client: 利口乐股份有限公司/Ricola AG (Laufen, Switzerland)

设计团队/Project Team: Michael Fischer (项目负责人/Project Director), Nina Renner (项目经理/Project Manager), Zdeněk Chmel, Wolfgang Hardt, Harald Schmidt, Hendrik Steinigeweg, Luca Ugolini, Freya Winkelmann

夯土团队/Project team rammed earth: Martin Rauch (项目负责人/Project Director), Thomas Honermann (项目经理/Project Manager), Hanno Burtscher (场地管理/Site Manager)

结构工程/Structural Engineer: Schnetzer Puskas (Basel, Switzerland)

建筑面积/Floor Area: 4800m²

夯土/Rammed Earth: 3060m², 2935t

建造周期/Construction Phase: 2012-2014

摄影/Photos: Benedikt Redmann (fig.1,3,6), Markus Bühler-Rasom (fig.8-11,14)线图/Plans: Herzog & de Meuron(Basel,Switzerland)

3 外景/Exterior view

4 平面/Floor plan

5 剖面/Section

6 每个立面均设有一个直径5.5m的圆形窗/Each facade has only one rounded window with a diameter of 5.5m

Architecture and Landscape

The new Kräuterzentrum (Herb Center) is situated like an erratic block in the midst of a landscape dotted with conventional industrial buildings. Its elongated shape echoes the pathways and the hedges that have long been a distinctive feature of this area. The length of the building also reflects the steps involved in the industrial processing of herbs, from drying and cutting to blending and storing. The new processing plant enables Ricola to integrate these important steps into the company's own in-house production.

Architecture as Landscape

The Kräuterzentrum is built largely out of locally sourced earth; it is like a geometrical segment of landscape with its dimensions and archaic effect heightened by the radical choice of material. Herbs and earth define the purpose-built, distinctive character of the center, following in the footsteps of Ricola's other buildings: the fully automated storage building of 1987, the packaging and distribution building of 1993 in Mulhouse-Brunstatt with its screen-print façade, and the glazed marketing headquarters of 1999 in Laufen. These buildings not only embody Ricola's exceptional philosophy and commitment to the environment, they each make a striking contribution to their locations.

The delivery entrance and warehouse sections of the herb center's façade are monolithic, with the loam walls visible in the interior as well. The prefabricated earth elements are manufactured in a nearby factory out of ingredients extracted from local quarries and mines. Clay, marl and material excavated on site are mixed and compacted in a formwork and then layered in blocks to build the walls. Thanks to the plasticity of the loam, the seams can be retouched, giving the overall structure a homogeneous appearance. To arrest erosion caused by wind and rain, a trass mortar achieved by mixing volcanic tuff (trass) with lime is compacted every 8 layers of earth directly in the formwork. Large round windows illuminate the rooms. The façade is self-supporting and simply linked to the concrete loadbearing structure of the interior.

Energy and Sustainability

Energy and sustainability are not simply treated as technical auxiliaries; they are built into the architecture and essential features of the project as a whole. Earth as a material that regulates humidity has a positive, sustainable effect on the use of energy and overall climate control. Photovoltaic modules on the roof and the use of waste heat from the production center nearby also contribute to improving the ecological balance of the Kräuterzentrum.□

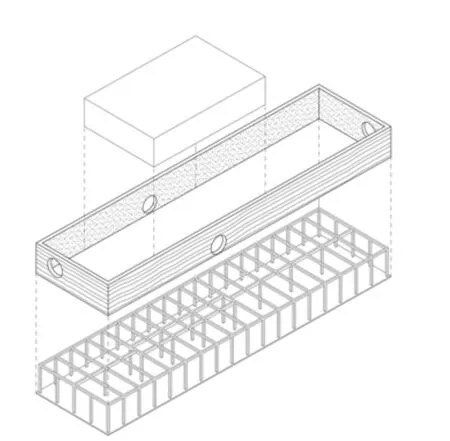

8 预制构件的生产线示意/Production line of the prefabricated rammed earth elements

9 现场安装/Installation on site

10.11 现场安装/Installation on site

12 窗口剖面/Section of window

13 构造细部/Structural features

评论

穆钧:手工化作业具有的高人力投入和精确性局限,是常规夯土技术实现工业化应用所面临的核心挑战。在此背景下,马丁·劳奇开创性地将传统夯土工艺引入现代预制墙体施工体系。在基地附近的临时工厂内,利用自行研发的自动化机具系统,可一次性高速且高质地夯筑近80m的夯土墙体,并根据在建筑中不同的位置需要,预埋构造并切割成相应长度和连接倒角的夯土单元。经过至少4 - 6周的阴干后,夯土单元即可运至施工现场,如其他类型的预制墙体一样,可自如地进行吊装砌筑,并与主体框架结构进行连接。利口乐草药中心所采用的预制化夯土技术,有效地规避了传统夯土在干燥收缩、施工效率、工艺精度等方面的相对不足,更从根本上颠覆了人们对于夯土应用局限性的传统认知。

李烨:这个项目具有里程碑式的意义。以这个项目为契机马丁设计了可以半自动配料夯筑的夯土机器人,几千年的夯土工艺从传统的人工夯土从此进入到半机械化时代。

整个建筑是混凝土框架结构,夯土在这里作为脱离结构框架并且自承重的表皮出现。为了节省高昂的人工费用和减少运输污染,马丁在项目地周边建了夯土工厂,利用机器人预制夯土模块,并设计了一体化的生产流程。最终夯土建筑呈现出令人赞叹的效果,使一个巨大的建筑物在广阔的田野中毫不突兀,安静自然的与环境融为一体。

14 内景/Interior view

Comments

MU Jun:Manual construction, due to its high input of human labor and low precision, is a critical challenge for industrialized application of conventional rammed-earth technology. In this regard, Martin Rauch ingeniously introduced traditional rammed-earth technique into the modern prefabricated wall construction system. In a temporary factory near the site, self-developed automated machine system can quickly build up high quality rammed-earth walls up to 80m in a single process. In addition, depending on the requirements of different locations of the building, tectonic elements can be embedded, and rammed-earth units can be cut into required lengths and connection chamfering. After at least 4-6 weeks of shaded drying, rammed-earth units will be shipped to the construction site, and, just like any other prefabricated walls, can be freely hoisted and laid up, then connected to the main structural framework. The prefabricated rammed-earth technology used in Ricola Kräuterzentrum has effectively avoided the shortcomings of traditional rammed earth with regard to drying and shrinkage, construction efficiency, and technique precision, which has fundamentally changed the conventional understanding of the application constraints of rammed earth. (Translated by SHANG Jin)

LI Ye:This project is a milestone of its kind. Taking this project as an opportunity, Martin designed a robot to automatically distribute the earth compound and semi-mechanically compact it. Thus rammed-earth techniques of traditional manual work for thousands of years have been replaced mostly by machines.

The structure of the building is concrete-frame. Rammed earth plays a role as self-supporting skin that is almost independent from the frames, just connected with some friction-fit brackets. In order to save expensive costs and reduce polluting transportation, Martin built a factory for rammed earth close to the project site. He used robotic production line to make pre-fabricated rammed earth modules, and also designed an integrated procedure including transportation and on-site assembly. The finished building had a very amazing effect - the massive construction appeared not in the least abrupt, but peacefully merged into the nature and the environment. (Translated by WANG Xinxin)

Ricola Kräuterzentrum (Herb Center), Laufen, Switzerland, 2014

Architects: Herzog & de Meuron