Driving Force Model for Non-pneumatic Elastic Wheel

2016-09-14LiBoZhaoYouqunZangLiguoBeiShaoyiFuHongxunZhangLanchun

Li Bo,Zhao Youqun,Zang Liguo,Bei Shaoyi,Fu Hongxun,Zhang Lanchun

1.College of Energy and Power Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China;2.School of Automotive and Traffic Engineering,Jiangsu University of Technology,Changzhou 213001,P.R.China(Received 24December 2014;revised 15May 2015;accepted 6June 2015)

Driving Force Model for Non-pneumatic Elastic Wheel

Li Bo1,2,Zhao Youqun1*,Zang Liguo1,Bei Shaoyi2,Fu Hongxun1,Zhang Lanchun2

1.College of Energy and Power Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China;

2.School of Automotive and Traffic Engineering,Jiangsu University of Technology,Changzhou 213001,P.R.China

(Received 24December 2014;revised 15May 2015;accepted 6June 2015)

In order to obtain good driving performance,a driving force model is presented for non-pneumatic elastic wheel.Brush model of pneumatic tyres is introduced and the deformations of elastic supports and tread are also taken into account.The longitudinal slip rate is redefined.The grounding pressure distribution of elastic wheels is analyzed and corrected according to speed,temperature and stiffness.Then rolling resistance equation is developed.Finally,simulation is conducted by software CarSim,and the results show that the estimated values are consistent with simulation values,especially at low longitudinal slip rate.The research can help to optimize design of non-pneumatic elastic wheel.

driving force;non-pneumatic elastic wheel;brush model;rolling resistance

0 Introduction

Motions of a vehicle depend on the interaction between tyres and ground,so a reasonable tyre model is a key for vehicle dynamic simulation.Tyre model is the basis for the developments of vehicle dynamics control systems and tyre sensors.Driving force is always an important indicator of tyre mechanical properties,which directly affects vehicle dynamic properties and passing abilities.Early researchers have developed a variety of physical models,theoretical models and semi-empirical models to analyze dynamic performances of pneumatic tyres[1-5].Gim et al.[2]proposed pure-slip tire model and combined a slip tire model of the brush theory and 3-D spring tire model.Gordon[3]elaborated the tire longitudinal force on slip rate based on brush theory.″Magic Formula″,obtained through fair enough experiments by Pacejka[4]was a semi-empirical tire model.However,theoretical models hold complex forms and low computational efficiency. Semi-empirical models require many experimental data and computations with large amounts of parameters.Physical models are easier to understand and requires less parameters,so its computation cost is small.

Many scholars have focused on a non-pneumatic elastic wheels[6-9].Jagadish[6]proposed a computational investigation of contact pressure for a non-pnemautic wheel with a metamaterial shear band.Bezgam[7]designed and analyzed the alternating spoke pair concepts for a non-pneumatic tire with reduced vibration at high speed rolling.Thyagaraja et al.[8]optimized the shear beam of a non-pneumatic wheel for low rolling resistance.Compared with pneumatic tyres,nonpneumatic elastic wheels utilize longitudinal force model of non-pneumatic elastic wheels,and longitudinal slip rate was redefined by considering the vertical and the longitudinal deformations of treads and elastic supports.The contact pressure distribution function defined by Rhyne and Cron[9]was corrected and the rolling resistance equation was established.To validate the model,a specific vehicle and condition were chosen inCarSim.The results showed that the theoretical model agreeed well with simulation data,especially at low longitudinal slip rates.

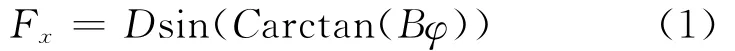

1 Magic Formula

The″Magic Formula″,proposed by Pacejka,has been widely used in tyre simulations[4].It is a semi-empirical formula from large volumes of measurement data of longitudinal force,lateral force and aligning torque.By entering vertical load,slip rate and roll angle,the formula can be used to calculate force and torque.Longitudinal force calculation is

where

kis the slip rate and Fzthe vertical load.φ,D,C,B,E,a1,a2,a3,a4,a5,a6,a7,a8are some specific parameters.The semi-empirical model needs large amounts of data,but the characteristic data of non-pneumatic elastic wheel are incomplete. Therefore,a relatively simple physical model,namely brush model,was selected to solve the problem.

2 Driving Force Model

2.1 Brush model of longitudinal force

We chose Tweel by Michelin(as shown in Fig.1),a typical non-pneumatic elastic wheel[10],composed of tread,elastic support and rigid wheel hub.

Fig.1 Tweel structure

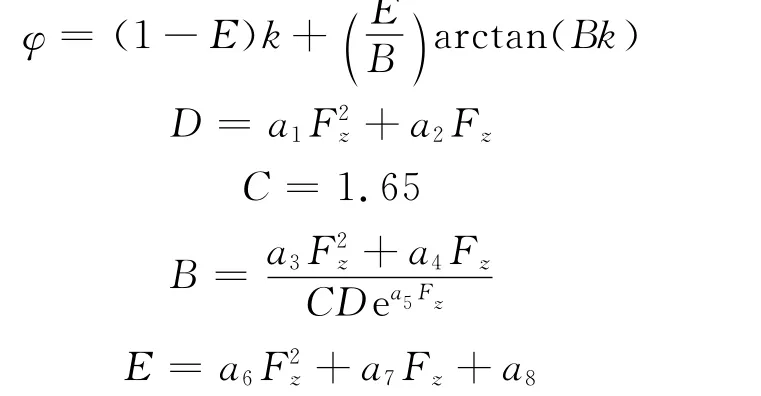

Elastic support is for damping,similar to inner tube of pneumatic wheel.Tweel is simplified according to brush model[11],as shown in Figs.2,3.At the loaded state,the tread and elastic support are deformed longitudinally and laterally under ground forces(See Fig.2).The involved parametres include rigid hub angular velocity w,wheel longitudinal sliding speed vlx,longitudinal force fx,lateral force fy,wheel hub diameter r,effective thickness of elastic support and tread with the vertical load h.

Fig.2 Deformation of wheel

Fig.3 Deformation situation of wheel grounding based on brush model

The wheel deformation in contact with ground is shown in Fig.3.The longitudinal length of contact area is 2a,and the breakpoint coordinate of slip area and adhesion area is xs.As the role of longitudinal and lateral forces,in longitudinal direction,bristles deformations areΔx(x)andΔy(x).Then longitudinal force fxand lateral force fyare solved.

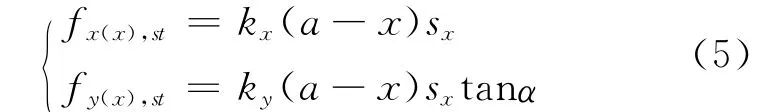

Bristles deformation analysis in adhesion area is

whereΔx(x),stis the bristles longitudinal deformation in adhesion area,Δy(x),stthe bristles lateraldeformation in adhesion areathe time from bristles entering contact area to the point x,the relatively longitudinal speed of birstles top and bottom.Assume wheel longitudinal slip rate is

Longitudinal stress and lateral stress are

where fx(x),stis the longitudinal stress in adhesion area,fy(x),stthe lateral stress in adhesion area,kxthe longitudinal stiffness,and kythe lateral stiffness.Similarly,the deformation in slip area is

Longitudinal stress and lateral stress are

whereΔx(x),slis the bristles longitudinal deformation in slip area,Δx(x),slthe bristles lateral deformation in slip area,fx(x),slthe longitudinal stress in adhesion area,fy(x),slthe lateral stress in adhesion area,θthe angle between wheel resultant force in contact with ground and the axis x, and tanθ=,μthe ground friction coeffi-cient,and q(x)the pressure distribution function in contact area.

Suppose that in the cut-off point xsof slip area and adhesion area,absolute value of the stress vector in Eqs.(5),(7)is equal.

Therefore

Therefore,the longitudinal force Fxcan be solved as follows by integration within the entire contact area with ground.

where bis the wheel width and Fzthe wheel vertical load.

2.2 Rolling resistance analysis

2.2.1 Grounding pressure distribution of nonpneumatic elastic wheel

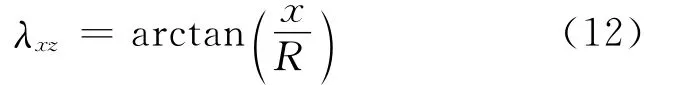

According to the elasticity theory,in Fig.4,the shear deformation occurs under static load. The shear strainλxzcan be given as

Fig.4 Length of a shear beam deformed to a flat surface

Using x=Rθand R=r+hin Fig.4,the shear strain becomes

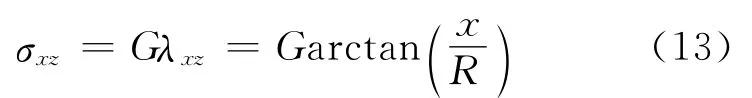

Assuming the composite shear modulus is G,the shear stress can be shown as

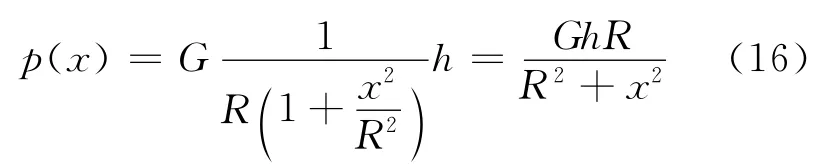

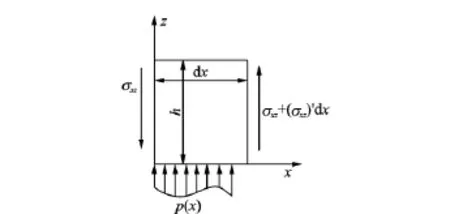

Consider the vertical stress distribution of an infinitesimal length of the wheel outer ring,as shown in Fig.5,and assume that the contact pressure is p(x)and the stress distribution coordinate system is the same as that in Fig.4.Then summing the forces in the z direction yields

As the shear stress from Eq.(13),Eq.(15)becomes

Fig.5 Vertical stress distribution of an infinitesimal length of the wheel outer ring

Obviously,this pressure distribution does not lead to rolling resistance,because in the contact area,contact pressures are symmetric. Therefore,we need to amend Eq.(16)and then establish the following equation

where kpis the pressure distribution coefficient,related to the wheel speed,temperature,longitudinal stiffness and ground stiffness.

2.2.2 Rolling resistance of non-pneumatic elastic wheel

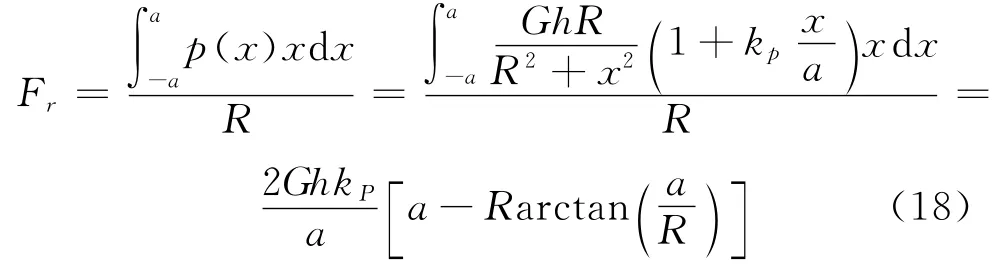

According to Eq.(17),rolling resistance function Frcan be obtained by p(x)integration in the contact patch.

where ais the longitudinal length of wheel contact patch.

2.3 Driving force model of non-pneumatic elastic wheel

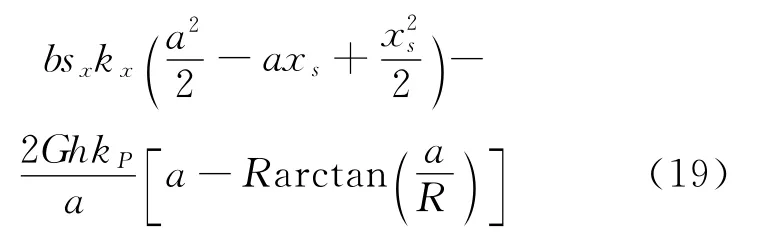

From Eqs.(10),(18),we can obtain

where Fdriis the wheel driving force and Fxthe wheel longitudinal force,as shown in Fig.6.

Fig.6 Rolling resistance

3 Experiment Verification by Car-Sim

CarSim is designed for vehicle dynamics simulation,and CarSim models run 3—6times faster than the real-time.It can simulate responses of the vehicle to the driver,road conditions and aerodynamics inputs.And it is usually used to predict and simulate handling stability,braking performance,riding comfort,dynamic property and economy,as well as in the development of modern automotive control systems.CarSim can define the test environment and procedures conveniently,and give detailed definition of the vehicle characteristic parameters and properties.

The vehicle″E-Class,SUV:High CG″,and″Full Throttle Acceleration(6spd.)″were chosen,and the specific parameters are lised in Table 1,where cz,treand cz,supare the tread vertical stiffness and the elastic support vertical stiffness,respectively,czis the wheel vertical stiffness,and their relationship is

Table1 Parameter in carsim

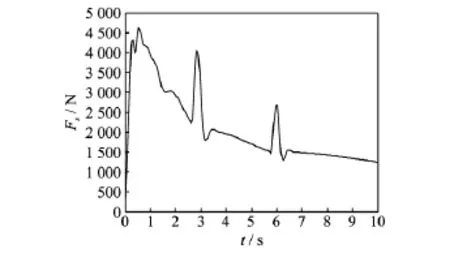

Simulation results of the rolling resistance Fr,longitudinal force Fx,vertical force Fzand vehicle velocity are shown in Fig.7—10.Simulation and theoretical analysis results of driving force Fdriwith slip rate ranging from 0to 0.6are shown in Fig.11.When slip rate ranged from 0to 0.27,the error between them is small(less than 4%).When slip rate ranged from 0.27to 0.6,the error increases.This is because in large longitudinal slip rates,the elastic support longitudinal deformation reaches the limit,and the tread is squeezed into the rigid wheel hub,and the longitudinal stiffness and vertical stiffness of the wheel change dramatically in the geometric nonlinearity.

Fig.7 Rolling resistance

Fig.8 Longitudinal force

Fig.9 Vertical force

Fig.10 Vehicle velocity

Fig.11 Theoretical and simulation model at different slip rates

4 Conclusions

(1)Brush model is introduced into the driving force analysis of the non-pneumatic elastic wheel.Ground-wheel interaction model is founded based on the structural characteristics of nonpneumatic elastic wheel.In the modeling process,with a full consideration of elastic wheel deformation,the effective thickness of elastic support and tread is involved for slip rate as a variable.

(2)According to the pressure distribution characteristics of the non-pneumatic elastic wheel under vertical loads,considering external conditions,including temperature,stiffness and speed,the pressure distribution coefficient is set and the wheel longitudinal rolling resistance function is established.

(3)Specific parameters of the non-pneumatic elastic wheel are discovered for simulating and validating the theoretical model by CarSim.The results shows a good fit,especially at low longitudinal slip rate.

Acknowledgements

This work was supported by the Major Exploration Project of the General Armaments Department of China(NHA13002),the Funding of Jiangsu Innovation Program for Graduate Education,the Fundamental Research Funds for the Central Universities of China(CXLX13_145),Jiangsu Province″333Project″Training Funded Project(BRA2015365),and the National Natural Science Foundation of Youth Fund Project(51305175,61503163).

References:

[1] CLOVER C L,BERNARD J E.Longitudinal tire dynamics[J].Vehicle System Dynamics,1998,29(4):231-260.

[2] KIM S,NIKRAVESH P E,GIM G.A two-dimensional tire model on uneven roads for vehicle dynamic simulation 1[J].Vehicle System Dynamics,2008,46(10):913-930.

[3] PACEJKA H.Tyre and vehicle dynamics[M].Burlington:Elsevier,2005:75-84.

[4] PACEJKA H B,BESSELINK I J M.Magic formula tyre model with transient properties[J].Vehicle System Dynamics,1997,27(S1):234-249.

[5] LIN Fen.Vehicle state and parameter estimation based on dual unscented particle filter algorithm[J]. Transactions of Nanjing University of Aeronautics & Astronautics,2014,31(5):568-575.

[6] JAGADISH R.A computational investigation of contact pressure for a non-pnemautic wheel with a metamaterial shear band[D].Clemson:Clemson University,2010:20-50.

[7] BEZGAM S.Design and analysis of alternating spoke pair concepts for a non-pneumatic tire with reduced vibration at high speed rolling[D].Clemson:Clemson University,2009:15-47.

[8] THYAGARAJA N,SHANKAR P,FADEL G,et al.Optimizing the shear beam of a non-pneumatic wheel for low rolling resistance[C]∥ASME 2011International Design Engineering Technical Conferences and Computers and Information in Engineering Conference.Washington,DC:American Society of Mechanical Engineers,2011:33-42.

[9] RHYNE T B,CRON S M.Development of a nonpneumatic wheel[J].Tire Science and Technology, 2006,34(3):150-169.

[10]Akshay Narasimhan.A computational method for analysis of material properties of a non-pneumatic tire and effects on static load-deflection,vibration,and energy loss from impact rolling over obstacles[D]. Clemson:Clemson University,2010:24-57.

[11]SVENDENIUS J,G FVERT M.A semi-empirical dynamic tire model for combined-slip forces[J].Vehicle System Dynamics,2006,44(2):189-208.

Dr.Li Bo is currently a lecturer in College of Vehicle and Traffic Engineering,at Jiangsu University of Technology. He received his first degree in Yantai University and Ph.D. degree in Nanjing University of Aeronautics &Astronautics.His research interest is tyre dynamic.

Dr.Zhao Youqunis currently aprofessor in College of energy and power,at Nanjing University of Aeronautics & Astronautics.He received his first degree and Ph.D.degree in Jilin University.His research interest is vehicle dynamic.

Dr.Zang Liguo is currently a lecturer at Nanjing Institute of Technology.He received his first degree in Shandong U-niversity of Technology and Ph.D.degree in Nanjing University of Aeronautics &Astronautics.His research interest is tyre dynamic.

Dr.Bei Shaoyi is currently aprofessor in College of Vehicle and Traffic Engineering,at Jiangsu University of Technology.He received his first degree and Ph.D.degree in Jiangsu University.His research interests are vehicle system dynamic and control.

Mr.Fu Hongxunis a Ph.D.candidate in College of Energy and Power,at Nanjing University of Aeronautics and Astronautics.He received his first degree in Shandong University of Technology.His research interest is vehicle system dynamic.

Dr.Zhang Lanchun is an associate professor in College of Vehicle and Traffic Engineering,at Jiangsu University of Technology.He received his first degree in Yantai University and Ph.D.degree in Nanjing University of Technology and Engineering.His research interest is vehicle transimission control.

(Executive Editor:Xu Chengting)

U463.3 Document code:A Article ID:1005-1120(2016)02-0231-06

*Corresponding author,E-mail address:yqzhao@nuaa.edu.cn.

How to cite this article:Li Bo,Zhao Youqun,Zang Liguo,et al.Driving force model for non-pneumatic elastic wheel[J]. Trans.Nanjing Univ.Aero.Astro.,2016,33(2):231-236.

http://dx.doi.org/10.16356/j.1005-1120.2016.02.231

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Forces and Stresses During Friction Stir Joining of 2024Aluminum Alloy

- Occupant Restraint System Simulation and Optimization Based on TESW

- Green Aircraft Taxiing Strategy Based on Multi-scenario Joint Optimization

- Multi-objective Optimization Design of Vented Cylindrical Airbag Cushioning System for Unmanned Aerial Vehicle

- Modeling and Sliding Mode Control with Boundary Layer for Unmanned Coaxial Rotor Ducted Fan Helicopter

- Parameter Optimization of Nose Landing Gear Considering Both Take-off and Landing Performance of Catapult Take-off Carrier-Based Aircraft