Availability function deployment of the CNC lathe based on multi factors

2015-09-17BingkunCHENGuangsiPANGGuixiangSHEN

Bing-kun CHEN,Guang-si PANG,Gui-xiang SHEN*

,Feng RONG1,Zhen-ke XI3

(1School of Mechanical Science and Engineering,Jilin University,Changchun 130025,China)

(2Dalian Huarui Heavy Industry Group Co.,Ltd.,Dalian 116035,China)

(3College of Earth Sciences,Jilin University,Changchun 130025,China)

1 Introduction

The CNC lathe industry of our country has rapid growth in recent years,but there is large gap between domestic CNC lathe and import CNC lathe in the dynamic availability of customer demand[1].

We study the tradition of the availability base on single factor study according to failure data,such as Failure Mode,Effects and Criticality Analysis[2-3],GO methods[4],FAT[5]and so on.We always ignored the interaction relations of failure[6],and more important is that we also ignored the analysis of the customer demand,which lead to the result of dynamic availability analysis is inaccuracy to the vulnerable spot of the CNC lathe.The improvement of availability will not satisfy the customer demand based on it.So comprehensive consideration multiple factors for the availability is a basis of the improvement work for the availability.

This paper will structure the dynamic house of availability,deploy the availability function,and determine the weight of subsystem comprehensive effect according to the thought of the QFD [7-9],then provides direction for the improvement work for the availability.This paper will achieve the user’s maximum satisfaction with the input at least work and improve the competitive power of product.

2 Structure the Dynamic Availability of the house based on the thought of QFD

The analysis of the CNC lathe availability is called Dynamic availability function development which has used the QFD thought,the model of the Dynamic A-vailability of the house as follow:

Fig.1 Structure Chart of DHOA

In the figure:① Demand index of availability,it is get from the complex information which has been arranged;② The weight of demand index,we determine the value of it according to the different degree of attention for different demand index;③Correlation matrix C,it show the influence relation between every subsystem and demand index;④The self-correlation matrix of subsystems F,it shows the influence relation among the every subsystem,correlation coefficient Fikshow that the influence of the subsystem i to k,correlation coefficient Fkiis the influence of the subsystem k to i;⑤The weight of availability comprehensive effect,it is the result of the final output.

According to the output of DHOA,We can arrange the key subsystems and clear the way to improve the availability.

3 Transform DHOA into Matrix-Form

Solving the DHOA is easy to get wrong because of it’s structure is too complex.If we change the DHOA to the matrix and calculate some matrix,we can solve this problem.

For example:There is n CNC lathe subsystem,and m demand index of availability.We can calculate it as follow:

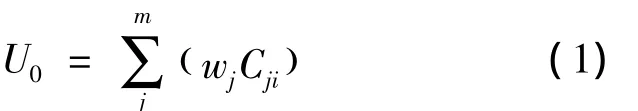

1)Only consider the correlation relation between demand index and subsystem,the effect weight U0of the No.i subsystem:

Where:wjis the weight of the No.j demand index of availability,j=1,2,…,m;Cjiis the score of the No.i subsystem to the No.j demand index,i=1,2,…,n.

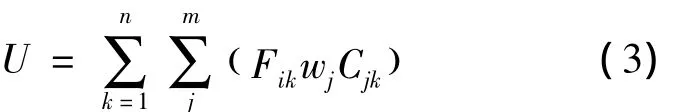

2)The comprehensive effect weigh U of the No.i subsystem after considering the self-correlation of subsystems.

Where:Fikis the score of correlation of the subsystem i to k.

In general,the degree of effect of subsystem to itself is defined 1,so Fii=1,and the formula(2)can be changed to:

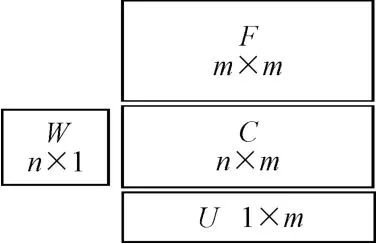

From the structure of formula(3),we can get an easy matrix to calculate which is changed from the DOHA,as shown in the Fig.2.

Fig.2 Matrix-Form of DHOA

According to the Fig.2,we can change the formula(1)and(3)into:

Where:F is the m×m order self-correlation matrix among every subsystems;W is the weight of demand index;C is the n×m order correlation matrix between demand index and subsystem;U is the comprehensive effect weight of subsystem.

4 Availability function deployment of a certain CNC lathe

4.1 Ensure the input information W and F

We arrange the demand index of availability according to the investigation of a certain CNC lathe customer:failure fate is W1;precision retaining ability is W2;fault diagnosis is W3;degree of repair difficulty is W4;comply with the man-machine engineering requires maintenance is W5;maintenance costs is W6;maintenance time is W7.And

W= [0.302,0.248,0.077,0.126,0.03,0.061,0.156]T

The major subsystems of a certain CNC lathe:E-E-lectrical system,T-Main drive system,F-Feed system,D-Hydraulic system,M-tool rest,S-Servo sys-tem,NC-Numerical control system,B-Base piece,WCooling system,K-Chip-removal system,L-Lubrication system.

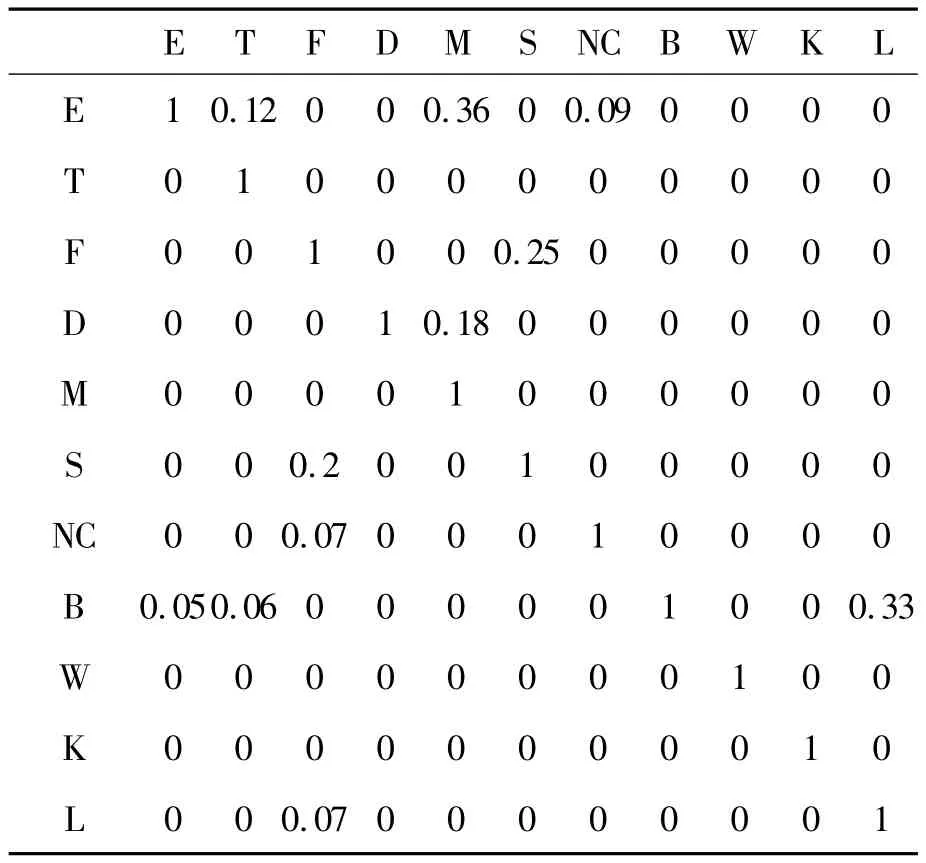

According to the analysis between independent failure and correlation failure we get self-correlation matrix F of subsystems based on pair-wise comparison,as shown in the Table 1.

Table 1 Correlation matrix of subsystem

In the above table,the row is initial failure subsystem,and the line is subsequent failure subsystem.

4.2 Structure correlation matrix C

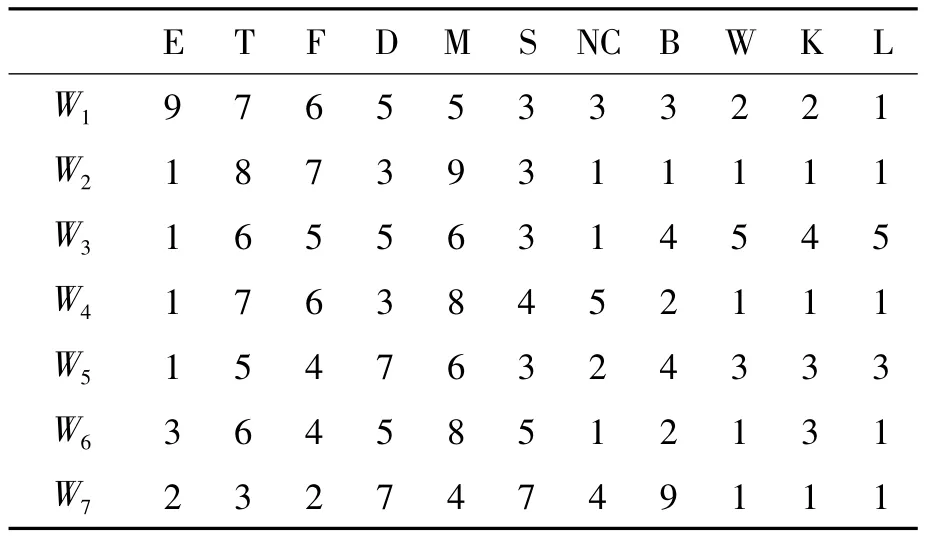

Frist,we determine the value of correlation coefficient,as shown in the Table 2.

Table 2 The value of correlation coefficient

We are directed against every demand index,combine characteristic of the subsystem,ensure value of every demand index,and then we structure the correlation matrix C according to the above table.

Table 3 Correlation matrix C

4.3 Calculate the output of matrix

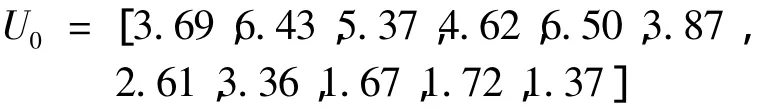

Take W and F into the formula(4),we can get the weight vector of the initial effect of subsystem.

The rank of U0:M>T>F>D>S>E>B>NC>K>W>L.

Take W,F and C into the formula(5),we can get the weight vector of the comprehensive effect of subsystem.

The rank of U:E>M>T>F>D>S>B>NC>L>K>W.

We can find from the result that:if we don’t consider the self-correlation of the subsystems,the effect of tool rest is the most serious.If we consider the correlation of the subsystem,the effect of Electrical system is the most serious.This is because that the electrical system is not only can cause itself failure,but also cause the main drive system,tool rest and numerical control system failure in a large part.So if we improve the electrical system,we will indirect improve the availability of correlation subsystems.This result is accordant to engineering practice.

5 Conclusions

This paper overall considerated the information of user demand,autocorrelation of subsystem and the correlation between subsystem and user demand,deploy the availability function according to the thought of the QFD.In addition,we translated the DHOA into the matrix-form for simplify the process of calculation.Though the mend,we can find the key subsystem fast and accuracy which response the customer demand.Based on it,this paper can achieve the customer’s maximum satisfaction and improve the market competitive power of product.

Acknowledgements

This paper is supported by National Natural Science Foundation of China(51275205).

[1]LI Xiangru.Development Status of Domestic CNC Machine Tools[J].Hunan Agricultural Machinery,2014,41(2):79-80.

[2]Kang Rui,Shi Rongde.FMECA technology and its application[M].Beijing:National Defense Industry Press,2006.

[3]NIU Yumei,HE Yuzhu,LI Jianhong,et al.The optimistic of RPN criticality analysis method in FMECA[C]//International Conference on Apperceiving Computer and Intelligent Analysis.Shanghai.2009:166-170.

[4]Shen Zhupei,Huang Yangrui.GO principle and Application[M].Beijing:Tsinghua Press,2004.

[5]Chen Limin.Fault tree analysis of CNC[J].Changzhou College of Information Technology,2007,6(3):13-15.

[6]SUN Yong,MA Lin,MATHEW J,et al.An analytical model for interactive failures[J].Reliability Engineering and System Safety,2006,91(5):495-504.

[7]Clausing D P,Pugh S.Enhanced QFD[J].Proceedings of the Design Productivity Conference,1991(1):15-25.

[8]Shao Jiajun.Quality Function Deployment[M].Beijing:Machinery Industry Press,2014.

[9]Raharjo H,Aarnout C.Brombacher T N.Goh and Bo Bergman.On Integrating Kano’s Model Dynamics into QFD for Multiple Product Design[J].Quality and Reliability Engineering International.2009,26:351-363.

杂志排行

机床与液压的其它文章

- Research on comprehensive index system about product quality monitoring

- Exploration on the calculating formula of main transmission chain structural formulas of machine tools

- Visualization study of the oscillating bubble near the elastic wall

- Study on electro-hydraulic load simulator based on flow compensation method

- Optimal design for amplifier of jet deflector servo valve

- Strict greedy design paradigm applied to the stochastic multi-armed bandit problem