Magnetic and microwave absorbing properties of M-type barium ferrite/graphene oxide composite microwave absorber

2015-03-01JingHongyangTangMengruHanYongdianXuLianyongLiMin

Jing Hongyang Tang Mengru Han Yongdian Xu Lianyong Li Min

(School of Materials Science and Engineering, Tianjin University, Tianjin 300072, China)(Tianjin Key Laboratory of Advanced Joining Technology, Tianjin 300072, China)

Magnetic and microwave absorbing properties of M-type barium ferrite/graphene oxide composite microwave absorber

Jing Hongyang Tang Mengru Han Yongdian Xu Lianyong Li Min

(School of Materials Science and Engineering, Tianjin University, Tianjin 300072, China)(Tianjin Key Laboratory of Advanced Joining Technology, Tianjin 300072, China)

Abstract:In order to improve the absorbing properties of M-type barium ferrite absorbing materials, M-type barium ferrite/graphene oxide composites with different graphene oxide contents were synthesized by the sol-gel auto-combustion method. X-ray diffraction (XRD), a scanning electronic microscopy (SEM), a physical properties measurement system (PPMS-9), and a vector network analyzer were used to analyze their structure, surface morphology, magnetic and absorbing properties, respectively. The results show that the absorbing band of the composite absorbing material is widened and the absorbing strength is increased compared with the pure M-type barium ferrite. The sample with the content of doped graphene oxide of 3% has the minimum reflectivity at 10 to 18 GHz frequencies. Hence, the doped graphene oxide effectively improves the absorbing properties of M-type barium ferrite.

Key words:M-type barium ferrite; graphene oxide; composite microwave absorber; magnetic property; microwave absorbing property

Received 2015-03-20.

Biography:Jing Hongyang (1966—), male, doctor, professor, hjing@tju.edu.cn.

Foundation item:The National Natural Science Foundation of China (No.51205282).

Citation:Jing Hongyang, Tang Mengru, Han Yongdian, et al.Magnetic and microwave absorbing properties of M-type barium ferrite/graphene oxide composite microwave absorber[J].Journal of Southeast University (English Edition),2015,31(4):511-515.[doi:10.3969/j.issn.1003-7985.2015.04.014]

The increase in electromagnetic pollution due to the rapid development of gigahertz (GHz) electronic systems and telecommunications has resulted in a growing interest in electromagnetic absorption technology[1-3]. An ideal electromagnetic wave absorber should exhibit a thin matching thickness, low density, broad bandwidth, and strong electromagnetic absorption[4-6]. Nanostructured ferrite-based materials have attracted considerable attention from scientists and technologists. M-type barium hexagonal ferrites (BaFe12O19), also named magnetoplumbite, are one absorption of the mostly used ferrites with applications in permanent magnets, high density magnetic recording media and millimeter wave devices due to their low cost, suitable saturation magnetization, good chemical stability, high resistivity, high magnetic coercivity, etc[7-8]. However, ferrites, as conventional absorbing materials, have some disadvantages, such as a narrow absorbing band, low efficiency, high density and quality, etc, thus restricting their applications to a certain extent[9-10]. Therefore, it is necessary to synthesize composite microwave absorbing materials for widening the microwave absorbing band, increasing the absorption intensity and decreasing the absorbers’ density.

To our best knowledge, much research on composite microwave absorbers has been reported. Zhan et al.[11] developed a simple, effective and reproducible solvothermal method for the self-assembly of magnetite nanoparticles along with carbon nanotunes (CNTs), which are believed to have potential applications in the microwave absorbing area. Ghasemi et al.[12] reported that the structural, magnetic, and reflection loss characteristics of barium ferrite/functionalized multi-walled carbon nanotube nanocomposites were evaluated. Wang et al.[13] also reported that SrFe12O19/multi-walled carbon nanotube composite exhibits good absorbing performance at a lower frequency (0 to 6 GHz) with good electromagnetic properties. Previous reports demonstrated that the composites of CNTs and magnetic materials would exhibit excellent microwave absorbing properties. Therefore, as a kind of new carbon material, graphene oxide may also be a potential microwave absorbing material similar to CNTs[14-16]. Wang et al.[17]found that the chemically reduced grapheme oxide shows enhanced microwave absorption compared with graphite and carbon nanotubes, and can be expected to display better absorption than high quality graphene, exhibiting a promising prospect as a microwave absorbing material. He et al.[18] demonstrated a simple and efficient chemical approach to prepare multifunctional nano sheets of grapheme/Fe3O4with scalable, cost-effective, highly reproducible, and well controllable properties.

However, so far there are few reports on the absorbing properties of ferrite/graphene oxide composites in the field of electromagnetic wave absorbers. In this paper, M-type barium ferrite/graphene oxide composite microwave absorbers are synthesized by the sol-gel auto-combustion method. Then, the effects of doping different amounts of graphene oxide (0%, 3%, 5%, 7%, 9%) into the composites on the crystal structure, surface morphology, magnetic and absorbing properties of composites are investigated.

1Experimental

1.1 Sample preparation

The M-type barium ferrite/graphene oxide composite microwave absorber was prepared by the sol-gel auto-combustion method. Ba(NO3)2and Fe(NO3)3were dissolved in deionized water with a molar ratio of 1∶12.Citric acid was used as a chelating agent to form the homogenous, steady and trans-parent sol solutions. The molar ratio of citric acid to metal nitrates was 2∶1. The graphene oxide was dissolved in alcoholic solution and then mixed homogenously for 1 h using an ultrasonic agitation machine. These three solutions were mixed and the pH value of the solution was adjusted to 7 by adding ammonia solution. The polyethylene glycol (PEG) was added to the mixed solution[19]. Then, the obtained solution was heated at 80 ℃ in a water bath for 4 h to form a sol. The obtained sol solutions were heated at 120 ℃ for 20 h for dehydration. During this process, the sol solutions firstly became viscous gels, and then gels were dried and finally a self-propagating combustion phenomenon was seen. When all the dry gels were completely burnt out, fluffy powders (called precursor powders) were obtained. The precursor powders were then fired at 850 ℃ for 3 h to obtain final prepared powders.

1.2 Experimental techniques

The phase structure of samples was examined by X-ray diffraction (XRD), which operates at 40 kV and uses Cu Kα radiation in the sweep range of 20° to 90°. Scanning electronic microscopy (SEM) examinations were performed using a Nova NanoSEM 430 under the accelerating voltage of 0.1 to 30 kV. The magnetic characteristics were measured with a physical properties measurement system (PPMS-9) at the external magnetic field of -2 to 2 T. The complex permeability and permittivity of the composite were measured in the frequency range of 1 to 18 GHz with an HP8722ES vector network analyzer. The sample thickness, test temperature, and environmental humidity are 2 mm, 0 ℃, 0%, respectively. The tangent of dialect, magnetic loss and the reflection loss curves were calculated and discussed.

2Results and Discussion

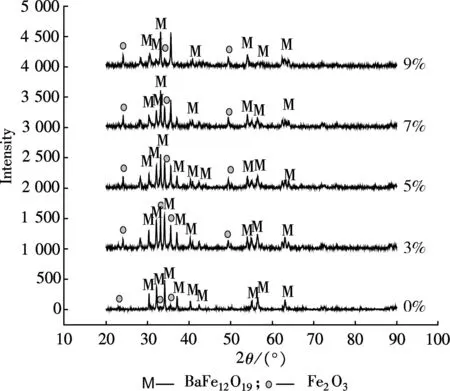

2.1 X-ray diffraction analysis

Fig.1 shows the XRD patterns of M-type barium ferrite/graphene oxide composite microwave absorber, in which the mass fraction of graphene oxide was 0%, 3%, 5%, 7%, 9%, respectively. M-type barium ferrite phase was found to co-exist with a small amount of Fe2O3phase in all samples. Compared with pure M-type barium ferrite, the M-type barium ferrite doped graphene oxide had more characteristic peaks and the impure phases had stronger intensity. Moreover, the main phase was BaFe12O19and the impure phase was Fe2O3in all the five samples. Therefore, the doped graphene oxide and the amount of doped graphene oxide do not change the kinds of phase structure of the composite absorbing materials, but to some extent, increase the impure phase’s intensity.

Fig.1 XRD patterns of M-type barium ferrite samples doped different contents of graphene oxide

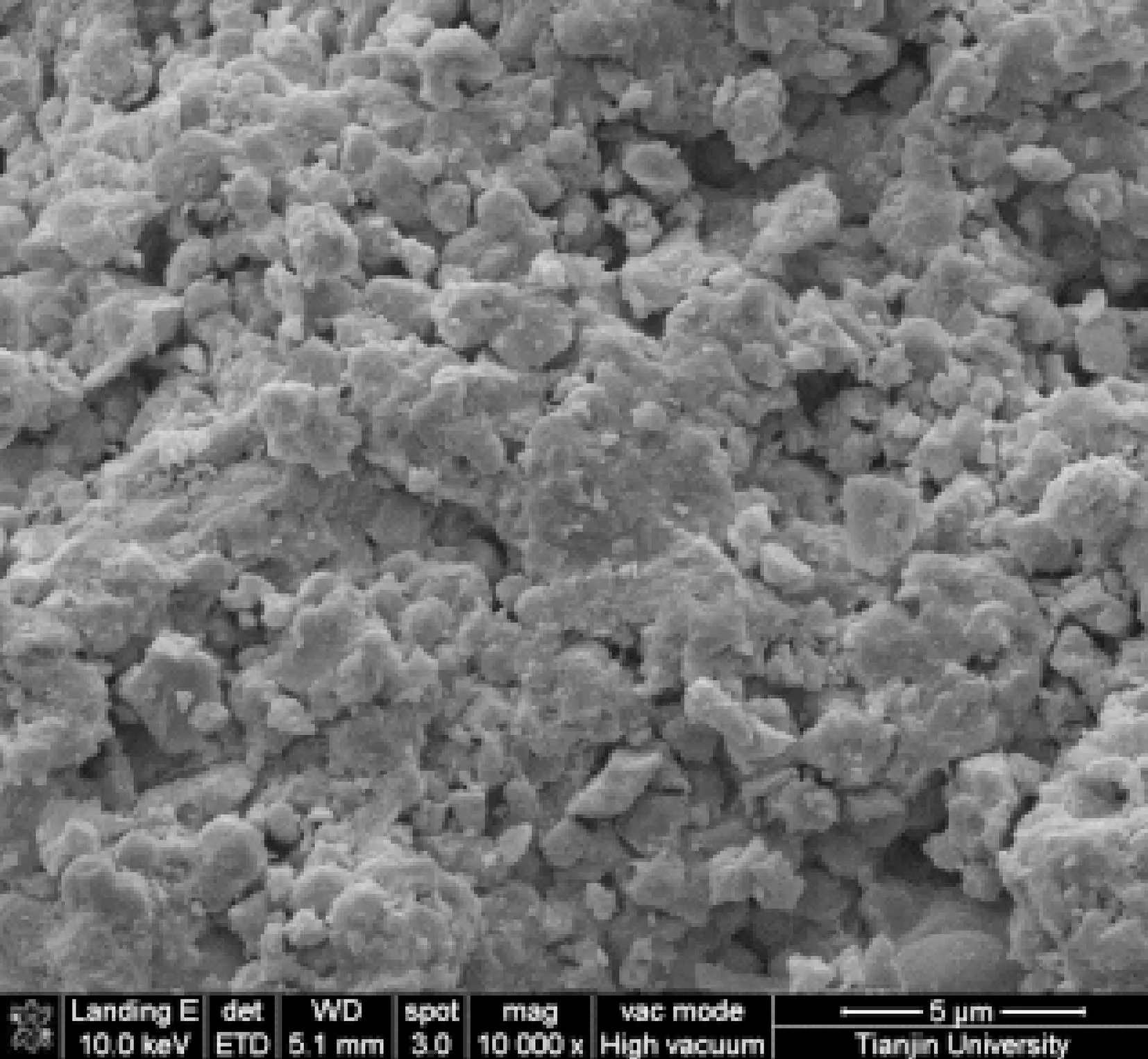

2.2 Morphology analysis

The SEM photographs of M-type barium ferrite/graphene oxide composite microwave absorber, in which the mass fraction of graphene oxide was 0%, 3%, 5%, 7%, 9%, respectively, are shown in Fig.2. It can be observed from Fig.2(a) that the microstructure of pure M-type barium ferrite was irregular flakes, substantially uniform in size and distribution. Although there was a certain degree of agglomeration, agglomeration was not very serious. Figs.2(b) to (e) shows that the microstructures of the composites retained a flake structure, substantially uniform in size and distribution, but the agglomeration phenomenon was more obvious and the sizes of particles were larger compared with Fig.2(a). For M-type barium ferrite doped with 3% grapheme oxide, the agglomeration phenomenon was the lightest and the size was the most uniform. It can be seen that the amount of doped graphene oxide does not change the flake morphology of the composite.

(a) (b)

(c) (d)

(e)Fig.2 SEM photographs of M-type barium ferrite samples doped different contents of graphene oxide. (a) 0%; (b) 3%; (c) 5%; (d) 7%; (e) 9%

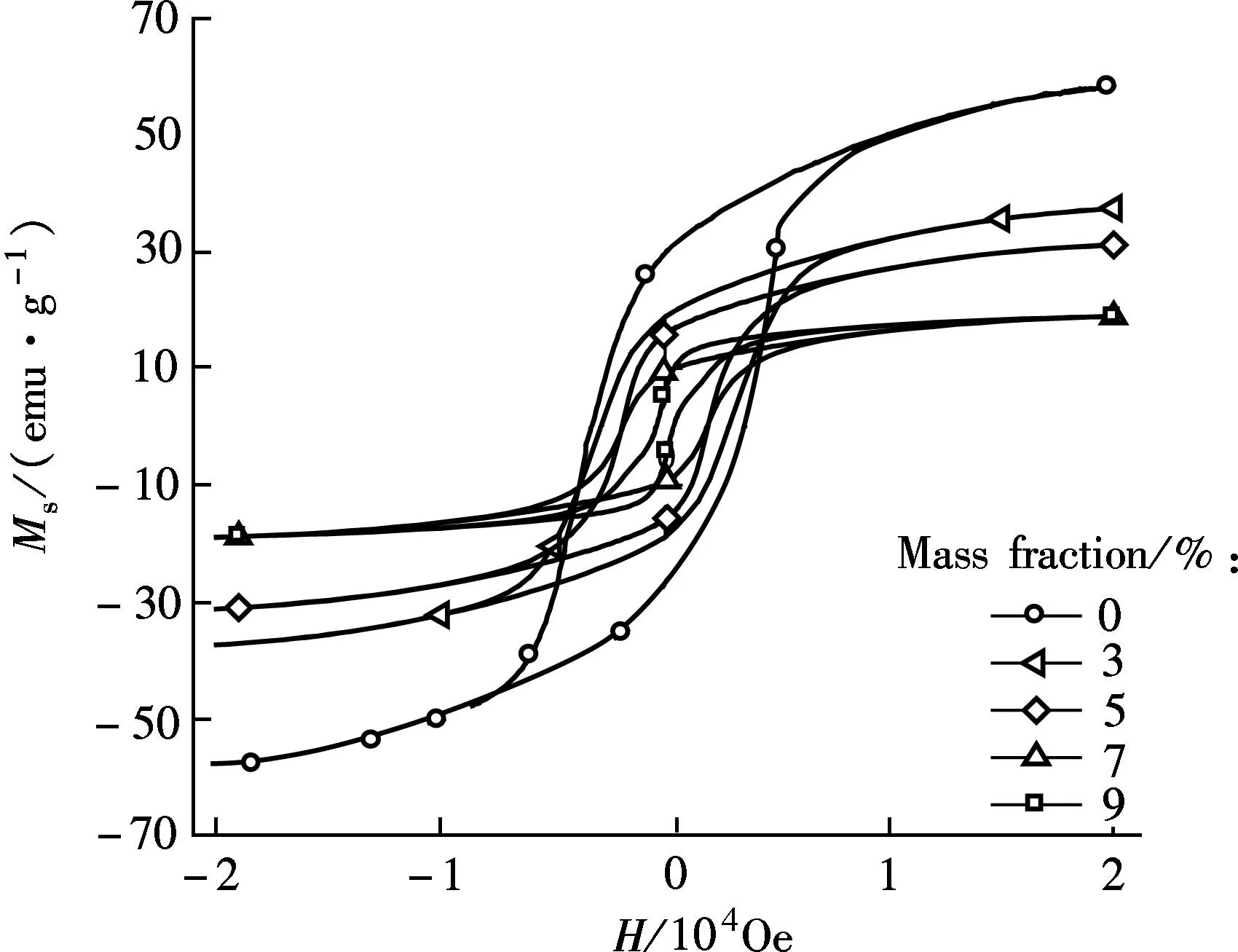

2.3 Magnetic property analysis

Fig.3 shows the hysteresis loops of M-type barium ferrite doped with different amounts of graphene oxide. Tab.1 shows the magnetic properties of M-type barium ferrite doped with different contents of graphene oxide. It is clearly shown that the saturation magnetization (Ms), residual magnetization (Mr) and coercive force (Hc) decreased compared with pure M-type barium ferrite. The decrease inMs,MrandHccould be most likely due to the existence of graphene oxide, which had no magnetism, reducing the magnetic moment. We can also see that the saturation magnetization, remnant magnetization and coercive force of all samples decreased with the increase in the mass fraction of doped graphene oxide; wherein the coercive force became gradually smaller, indicating that permeability was improved. For M-type barium ferrite doped with 3% grapheme oxide, the saturation magnetization, residual magnetization, and coercive force were 37.32 emu/g, 18.85 emu/g, 2 910 Oe, respectively, indicating that the magnetic property reached the best performance. According to the Stoner-Wohlfarth model,S=Mr/Msgradually deviated away from 0.5 with the increasing mass fraction of doped graphene oxide.

Fig.3 Hysteresis loops of M-type barium ferrite samples doped different contents of graphene oxide

Massfractionofgrapheneoxide/%Ms/(emu·g-1)ResidualmagnetizationMr/(emu·g-1)Hc/OeS=Mr/Ms058.0528.9733700.499337.3218.8529100.505531.2215.7720010.505719.929.4218230.473918.777.234540.385

2.4Analysis of electromagnetic parameters and wave absorbing property

Electromagnetic parameters (μ′,μ″,ε′,ε″) are the intrinsic features of absorbing materials. The dielectric loss tangent and magnetic loss tangent of the absorber medium are defined as tanδu(μ″/μ′) and tanδε(ε″/ε′), respectively. Figs.4 and 5 show the variations of dielectric loss tangent and magnetic loss tangent versus the frequency of M-type barium ferrite doped with different contents of graphene oxide.

Fig.4 Dielectric loss tangent of different composites

Fig.5 Magnetic loss tangent of different composites

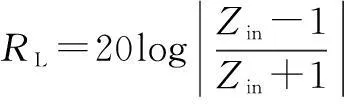

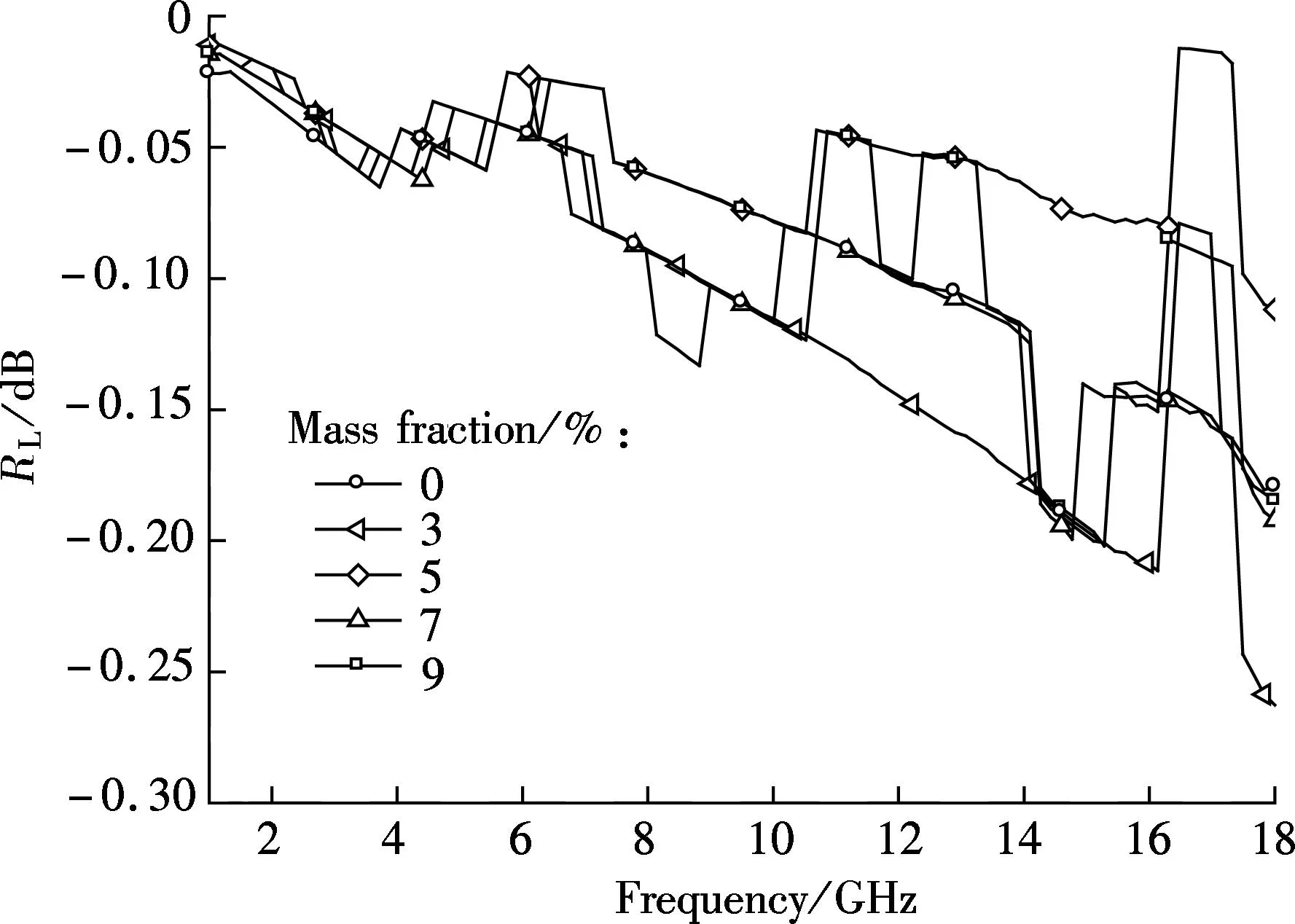

In this case, reflection loss depending on the loss tangent value can be evaluated by[20-21]

(1)

whereZinis the normalized input impedance.

(2)

whereurandεrare the relative permeability and permittivity, respectively, of the composite medium;cis the velocity of electromagnetic waves in free space;fis the frequency of microwaves;dis the thickness of the absorber.

According to these equations, using the specific parameters of the composite, the relationship between reflection loss and frequency of the composite of 2 mm and 2 cm thick are obtained and shown in Figs.6 and 7. From Fig.6, the microwave absorbing properties of the samples had consistent trends. The reflection loss value for the sample of 3% graphene oxide gradually decreased in the range of 7 to 16 GHz, and reached minimum (-0.23 dB). From Fig.7, the microwave absorbing properties of the samples also had consistent trends. There were two absorbing peaks which were in the range of 3 to 5 GHz and 11 to 13 GHz, respectively, reaching-1.5 and -3.2 dB. The reflection loss value for the sample of 3% graphene oxide reached minimum (-3.2 dB) at 12 GHz. On the whole,

Fig.6 Reflection loss of different composites in 2 mm thickness

Fig.7 Reflection loss of different composites in 2 cm thickness

the sample of 3% graphene oxide has the best absorbing properties among all the samples.

Compared Fig.7 with Fig.6, it is found that as the thickness of samples increases, absorbing peaks shift to the left and the absorbing performance is improved significantly. M-type barium ferrite/graphene oxide composite absorbing materials not only widen the microwave absorbing band, but also increase the absorption intensity compared with pure M-type barium ferrite. This is caused by the following reasons: 1) Graphene oxide has a special two-dimensional sheet structure, high electrical and thermal conductivity, large specific surface area, light weight, which are beneficial to the absorption and attenuation of electromagnetic waves. 2) Absorption of electromagnetic waves of ferrite materials and graphene oxide are based on magnetic loss and dielectric loss. This makes the ferrite/graphene oxide composite absorbing materials absorb electromagnetic waves using two absorption mechanics to improve their absorbing properties. 3) The reflection loss of ferrites generally occurs in the lower frequency range (<10 GHz), and the reflection loss of graphene oxide usually occurs in the high frequency range (>10 GHz), so the composite of two materials is also beneficial for widening the band absorption.

3Conclusion

M-type barium ferrite/graphene oxide composites have been synthesized using the sol-gel auto-combustion method. The doped graphene oxide did not change the kinds of phase structure and the flake morphology of M-type barium ferrite. Moreover, the magnetic properties of the composite absorbing material decreased with the increase in the amount of graphene oxide added. The absorbing band of the composite absorbing material is widened and the absorbing strength is increased compared with M-type barium ferrite, wherein the sample with the content of doped graphene oxide being 3% has the minimum reflectivity in 10 to 18 GHz frequencies, and at 12 GHz, its absorbing properties were increased by 20% compared with the M-type barium ferrite.

References

[1]Qi X S, Zhong W, Deng C Y, et al. Large-scale synthesis, electromagnetic and enhanced microwave absorption properties of low helicity carbon nanotubes/Fe nanoparticles hybrid [J].MaterialsLetters, 2013, 107(10):374-377.

[2]Zhao B, Wang Q L, Zhang C R. Fabrication and electromagnetic characteristics of microwave absorbers containing Li0.35Zn0.3Fe2.35O4 micro-belts and nickel-coated carbon fibers [J].JournalofMagnetism&MagneticMaterials, 2013, 345(8):249-254.

[3]Ge H L, Chen Q, Wang X Q, et al. The research progress of barium ferrite absorbing materials [J].JournalofChinaJiliangUniversity,2006,17(3):182-187. (in Chinese)

[4]Li Y, Zhao J L, Han J C, et al. New progress in the preparation process of ferrite powders [J].PowderMetallurgyTechnology, 2000, 18(1): 51-55. (in Chinese)

[5]Zhu W C, Zhang D S, Pan F. The preparation and the research of dispersion of Zn0.5Ni0.5Fe2O4nano powder materials [J].JournalofSoutheastUniversity:NaturalScienceEdition, 2003, 33(2):241-244. (in Chinese)

[6]Yang A, Chen Y J, Chen Z H, et al. Magnetic and atomic structure parameters of Sc-doped barium hexagonal ferrites [J].JournalofAppliedPhysics, 2008, 103(7): 07E511.

[7]Meshram M R, Agrawal N K, Sinha B, et al. Characterization of M-type barium hexagonal ferrite-based wide band microwave absorber [J].JournalofMagnetism&MagneticMaterials, 2004, 271(2-3):207-214.

[8]Ghasemi A, Liu X, Morisako A. Magnetic and microwave absorption properties of BaFe12-x(Mn0.5Cu0.5Zr)x/2O19synthesized by sol-gel processing [J].JournalofMagnetismandMagneticMaterials, 2007, 316(2): e105-e108.

[9]Huo J, Wang L, Yu H J. Polymeric nanocomposites for electromagnetic wave absorption [J].JournalofMaterialsScience, 2009, 44(15): 3917-3927.

[10]Bi C, Zhu M F, Zhang Q H, et al. Electromagnetic wave absorption properties of multi-walled carbon nanotubes decorated with La-doped BaTiO3nanocrystals synthesized by a solvothermal method [J].MaterialsChemistry&Physics, 2011, 126(3):596-601.

[11]Zhan Y Q, Zhao R, Lei Y J, et al. A novel carbon nanotubes/Fe3O4inorganic hybrid material: synthesis, characterization and microwave electromagnetic properties [J].JournalofMagnetismandMagneticMaterials, 2011, 323(7): 1006-1010.

[12]Ghasemi A, Shirsath S E, Liu X X, et al. Enhanced reflection loss characteristics of substituted barium ferrite/functionalized multi-walled carbon nanotube nanocomposites [J].JournalofAppliedPhysics, 2011, 109(7): 07A507.

[13]Wang W T, Li Q L, Chang C B. Effect of MWCNTs content on the magnetic and wave absorbing properties of ferrite-MWCNTs composites [J].SyntheticMetals, 2011, 161(1-2): 44-50.

[14]Compton O C, Nguyen S T. Graphene oxide, highly reduced graphene oxide, and graphene: versatile building blocks for carbon-based materials [J].Small, 2010, 6(6):711-723.

[15]Zhan Y Q, Meng F B, Lei Y J, et al. One-pot solvothermal synthesis of sandwich-like graphene nanosheets/Fe3O4hybrid material and its microwave electromagnetic properties [J].MaterialsLetters, 2011, 65(11): 1737-1740.

[16]Zhang X F, Dong X L, Huang H, et al. Microwave absorption properties of the carbon-coated nickel nanocapsules [J].AppliedPhysicsLetters, 2006, 89(5): 053115-01-053115-03.

[17]Wang C, Han X J, Xu P, et al. The electromagnetic property of chemically reduced graphene oxide and its application as microwave absorbing material [J].AppliedPhysicsLetters, 2011, 98(7):072906-01-072906-03.

[18]He H K, Gao C. Supraparamagnetic, conductive, and processable multifunctional graphene nanosheets coated with high-density Fe3O4nanoparticles [J].ACSAppliedMaterials&Interfaces, 2010, 2(11): 3201-3210.

[19]Jing H Y, Ding X, Li M, et al. Process optimization and magnetic properties of M-type barium ferrite [J].JournalofTianjinUniversity:ScienceandTechnology, 2014, 47(7): 641-646. (in Chinese)

[20]Che R, Peng L M, Duan X F, et al. Microwave absorption enhancement and complex permittivity and permeability of Fe encapsulated within carbon nanotubes [J].AdvancedMaterials, 2004, 16(5): 401-405.

[21]Xu P, Han X J, Wang C, et al. Synthesis of electromagnetic functionalized barium ferrite nanoparticles embedded in polypyrrole [J].TheJournalofPhysicalChemistryB, 2008, 112(10): 2775-2781.

doi:10.3969/j.issn.1003-7985.2015.04.014

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Mitigation of inter-cell interference in visible light communication

- Modified particle swarm optimization-based antenna tiltangle adjusting scheme for LTE coverage optimization

- Distribution algorithm of entangled particles for wireless quantum communication mesh networks

- Kernel principal component analysis networkfor image classification

- CFD simulation of ammonia-based CO2 absorption in a spray column

- Simulation and performance analysis of organic Rankine cycle combined heat and power system