Experimental investigation on heat transfer characteristics of a new radiant floor system with phase change material

2015-03-01XiaYiZhangXiaosong

Xia Yi Zhang Xiaosong

(1 School of Energy and Environment, Southeast University, Nanjing 210096, China)(2 School of Energy and Mechanical Engineering, Nanjing Normal University, Nanjing 210046, China)

Experimental investigation on heat transfer characteristics of a new radiant floor system with phase change material

Xia Yi1,2Zhang Xiaosong1

(1School of Energy and Environment, Southeast University, Nanjing 210096, China)(2School of Energy and Mechanical Engineering, Nanjing Normal University, Nanjing 210046, China)

Abstract:In order to improve the heat transfer characteristics of the traditional phase change material(PCM) floor, a new double-layer radiant floor system with PCM is proposed, which can store thermal or cold energy in the off-peak period and use them in the peak period. An experimental setup was developed to study the heat transfer characteristics of the new system under both cooling and heating modes. The experimental results show that the double-layer radiant floor system with PCM can meet both the cold and thermal requirements of users. Moreover, with the same duration of the thermal energy storage process, the increase of water temperature supplied to the system can improve the heat transfer characteristics of the system but lead to the discomfort of users. On the other hand, if the air temperature at the end of the thermal energy storage process is the same under different conditions, the increase of supplied water temperature will decrease the thermal energy storage time and ensure the comfort of users.

Key words:energy-saving; radiant floor; phase change material; double-layer; heat transfer characteristics

Received 2015-07-24.

Biographies:Xia Yi(1980—), male, graduate; Zhang Xiaosong (corresponding author), male, doctor, professor, rachpe@seu.edu.cn.

Foundation items:The National Science and Technology Pillar Program during the 12th Five-Year Plan Period (No.2011BAJ03B14), the National Natural Science Foundation of China (No.51376044).

Citation:Xia Yi, Zhang Xiaosong. Experimental investigation on heat transfer characteristics of a new radiant floor system with phase change material[J].Journal of Southeast University (English Edition),2015,31(4):496-500.[doi:10.3969/j.issn.1003-7985.2015.04.011]

With the development of the social economy and the improvement of personal living standards, air-conditioning is widespread in the society. Among all air conditioning technologies, the radiant floor heating system has been widely used in many countries[1-3]. The radiant floor heating system is a low-temperature heating system, which can make efficient use of building space and requires no cleaning[4-6].

The radiant floor heating system combined with the phase change material(PCM)[7-11]can store thermal energy in the PCM by using valley electricity at night, and the difference between the peak and valley power load will be small. However, the system can only work in winter and should be left idle in summer. As a result, the maintenance consumption of the system will be improved and people need an additional refrigeration device to only work in summer, which will increase the initial cost and operational cost. In order to reduce the cost of the radiant floor heating system combined with PCM, Jin et al.[11]developed a new double-layer PCM floor, which can work for people in both winter and summer. The system is used to store thermal or cold energy during the off-peak period and release it during the peak period. Compared with the radiant floor without PCM, the energy released by the floor with PCM during the peak period will be increased by 41.1% and 37.9% during heating and cooling when the heat of fusion of the PCM is 150 kJ/kg.

In order to improve the heat transfer characteristics of the double-layer PCM floor, a new double-layer radiant floor system with PCM is proposed in this paper. In this system, the heat exchange pipes are directly placed in the thermal storage PCM and the cold storage phase PCM. In this paper, an experimental investigation on the heat transfer characteristics of the double-layer radiant floor system with PCM in both cooling and heating modes is reported. The energy storage performance and the energy release characteristics of the new system are analyzed.

1Double-Layer Radiant Floor System with PCM

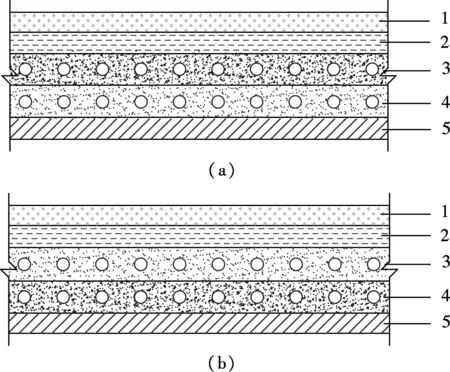

The structure of the new system is shown in Fig.1. The new system consists of the floor, leveling layer, thermal storage PCM, cold storage PCM, reflecting film, insulation layer, building, hot water pipe and cold water pipe. The hot water pipe is filled in the thermal storage PCM, and the cold water pipe is filled in the cold storage PCM. Under different climate conditions, the new system has two operational modes.

1.1 Cooling mode

In this operational mode, the new system uses cheap electric power at night to cool the water. The cold water flows into the cold water pipe and cools the cold storage PCM. In this way, the temperature of the cold storage PCM is decreased and the cold energy is stored. In the daytime, when people need a cool environment, the cold storage PCM will release the cold energy to cool the air in the building. As a result, the temperature of the building room will be maintained within the suitable range. In this 5—thermal storage layer; 6—cold storage layer; 7—reflecting film; 8—insulation; 9—building operational mode, the cold energy storage process occurs at night and the cold energy release process occurs in the daytime.

Fig.1 The structure of double-layer radiant floor with PCM

1.2 Heating mode

In this operational mode, the new system uses the cheap electric power at night to heat the water. The hot water flows into the hot water pipe and heats the thermal storage PCM. In this way, the temperature of the thermal storage PCM is improved and the thermal energy is stored. In the daytime, when people need a thermal environment, the thermal storage PCM will release the thermal energy to heat the air in the room. As a result, the temperature of the building room will be maintained within the suitable range. In this operational mode, the thermal energy storage process occurs at night and the heat release process occurs in the daytime.

The new system has many advantages. First, the new system can use cheap electric power at night to cool or heat water, and store the cold energy or thermal energy which should be used in the daytime. Thus, the cost of the system will be decreased. Secondly, the cold water pipe is filled in the cold storage PCM, and the hot water pipe is filled in the thermal storage PCM. Thus, the heat transfer resistance of the system will be decreased and the heat transfer efficiency of the system will be improved. Finally, the system can work in both summer and winter. As a result, the initial cost of the system will be decreased.

2Experimental Setup

2.1 Experimental material

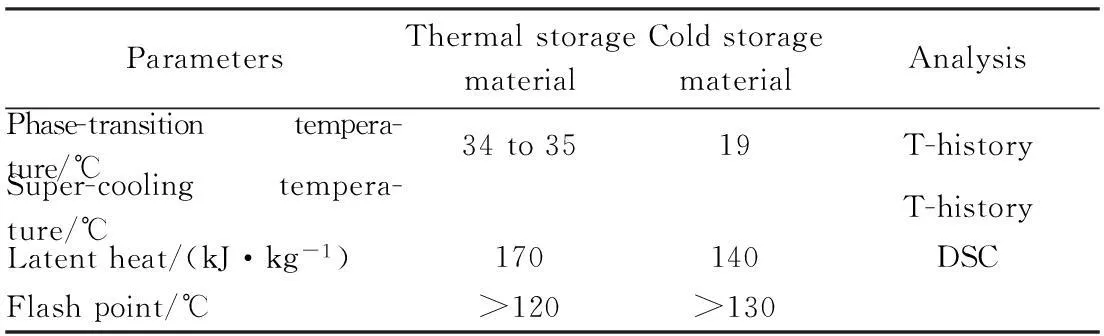

The phase change energy storage material in the experimental system is organic fatty acid. The specific parameters of the thermal and cold storage PCMs are shown in Tab.1.

Tab.1 Specific parameters of phase change materials

2.2 Experimental system

In the experiment, two different experimental rooms (room A and room B) were built to investigate the effects of different floor structures on the heat transfer characteristics of the double-layer radiant floor system with PCM. The two experimental rooms were built in a temperature and humidity control room. Therefore, the environmental temperature of the two experimental rooms can be controlled.

Comparing experimental room A with room B, only the places of the thermal and cold storage PCMs are different. In the experimental room A (see Fig.2(a)), the thermal storage PCM is placed below the cold storage PCM. In the experimental room B (see Fig.2(b)), the cold storage PCM is placed below the thermal storage PCM. In both experimental rooms A and B, the thickness of the floor is 10 mm, the thickness of the leveling layer is 30 mm, the thickness of the thermal storage PCM is 25 mm, and the thickness of the cold storage PCM is 30 mm.5—insulation

Fig.2 Floor structure.(a) Room A; (b) Room B

2.3 Measuring instruments

In the experiment, the temperatures of the thermal storage PCM, cold storage PCM, leveling layer, floor, air in the experimental room and air out of the experimental room are tested by T-type thermocouple with an accuracy of 0.1 ℃. The temperature readings are scanned and recorded into the computer by a data acquisition instrument (Agilent 13 970 A). The flow rate of hot water is tested by LC-WB micro flow meter with an accuracy of 0.1 L/h.

2.4 Experimental process

The applied flow rate of water in the experiment was 120 L/h. In the experiment, the double-layer radiant floor systems with PCM in both room A and room B were operated in the continuous operation mode. During the first 8 h, the double-layer radiant floor system with PCM was in the energy storage mode. In this mode, feed water was recycled from the constant temperature water bath. During the next 16 h, the double-layer radiant floor system with PCM was in the energy release mode. In this mode, there was no water flowing into the double-layer radiant floor system with PCM, and the energy in the energy storage PCM can be transferred to the air in the experimental rooms, both A and B.

3Results and Discussion

In the experiment, the heat transfer characteristics of the double-layer radiant floor system with PCM in both cooling and heating modes were investigated. The temperature fields of the double-layer radiant floor system with PCM in the two experimental rooms under different conditions were studied. The energy storage performance and energy release characteristics of the new system were also analyzed.

3.1 Cooling mode

In the experiment of the new double-layer radiant floor in cooling mode, the temperature of cold water was 15 ℃ and the temperature out of the two experimental rooms was 30 ℃.

The air temperature in different experimental rooms in cooling mode is shown in Fig.3. Fig.3 shows that in cooling mode, the air temperature in room B at the end of the cold energy storage process is higher than that in room A. However, the air temperature in room B at the end of the cold energy release process is close to that in room A. The temperature difference at the end of the cold energy release process is only less than 0.5 ℃. In room A, the air temperature is 26.5 ℃ at the end of the cold energy storage process, which is the same as that at the end of the cold energy release process. Under the same condition, room A has lower air temperature, but the air temperature change in room A is greater than that in room B. This indicates that the double-layer radiant floor system with PCM can meet the cold requirement of users. Therefore, in the cooling mode, the heat transfer performance of room A is a little better than that of room B.

The temperature of the cold storage PCM in different rooms is shown in Fig.4. It can be seen that the temperature of the cold storage PCM is the lowest at the end of

Fig.3 Air temperature in room A and B in cooling mode

the cold energy storage process of the two experimental rooms. In the cold energy release process, the temperature of the cold storage PCM is increased in the two rooms and the temperature of the cold storage PCM in room A is lower than that in room B.

Fig.4 Temperature of cold storage layer in different rooms in cooling mode

3.2 Heating mode

The experiments of the new system in the heating mode were carried out in three operational conditions. Under conditions 1, 2, 3, the temperatures of hot water were 40, 45, 52 ℃, respectively.

The air temperature in experimental room B and environmental temperature of room B under three conditions are shown in Fig.5. Fig.5 shows that the air in room B has the highest temperature under condition 3, which is 26 ℃ at the end of the the thermal storage process. The air in room B has the lowest temperature under condition 1, which is 17 ℃ at the end of the the thermal storage process. Different from the large temperature difference among three conditions at the end of the the thermal storage process, the temperature difference among three conditions at the end of the heat release process is 5 ℃. It indicates that with the same time of the thermal storage process, the increase of water temperature supplied to the double-layer radiant floor system with PCM will increase the air temperature variation during the heat release process. This can improve the heat transfer characteristics of the system but lead to the discomfort of users. On the other hand, if the air temperature at the end of the thermal storage process is the same under three conditions, the increase of supplied water temperature will decrease the time of the thermal storage process and ensure the comfort of users. Fig.5 also shows that since the air temperature in room B under condition 3 is much higher than those under the other two conditions, the environmental temperature of room B under condition 3 is higher than those under the other two conditions.

Fig.5 Air temperature in and out of room B under different conditions of heating mode

Air temperature in different experimental rooms and environmental temperature under condition 2 are shown in Fig.6. It is clear that under condition 2, air temperature in room B at the end of the thermal storage process is much higher than that in room A. However, air temperature in room B at the end of the heat release process is close to that in room A. Note that the temperature difference at the end of the heat release process is only 2 ℃. In room B, the air temperature is 20 ℃ at the end of the thermal storage process and 14 ℃ at the end of the heat release process. This indicates that under the same condition, room B has higher air temperature, but the air temperature change in room B is also larger than that in room A. Therefore, in the heating mode, the heat transfer characteristics of room B is much better than that of room A.

Fig.6 Air temperature in and out of room A and B under condition 2 of heating mode

As a result, considering both heating and cooling modes, the heat transfer characteristics of room B are better than those of room A.

The temperature of the thermal storage PCM in room B under different conditions is shown in Fig.7. Fig.7 shows that the thermal storage PCM in room B has the highest temperature under condition 3. This indicates that the temperature of the thermal storage PCM under condition 3 is much higher than that under the other two conditions at the end of the thermal storage process. However, the temperature of the thermal storage PCM under condition 3 is close to that under the other two conditions at the end of the heat release process.

Fig.7 Temperature of thermal storage layer in room B under different conditions

4Conclusion

In order to improve the heat transfer characteristics of the double-layer PCM floor, a new double-layer radiant floor system with PCM is proposed in this paper, which can store thermal or cold energy in the off-peak period and use them in the peak period. An experimental setup was developed to study the heat transfer characteristics of the double-layer radiant floor system with PCM in both cooling and heating modes.

The double-layer radiant floor system with PCM can meet both the cold and thermal requirements of users. Considering both heating and cooling modes, the heat transfer characteristics of room B are better than those of room A.

This indicates that with the same duration of thermal energy storage process, the increase of water temperature supplied to the system will increase air temperature variation during the heat release process, which can improve the heat transfer characteristics of the system but lead to the discomfort of users. On the other hand, if the air temperature at the end of the thermal energy storage process is the same under three conditions, the increase of supplied water temperature will decrease the thermal energy storage time and ensure the comfort of users.

References

[1]Jin X, Zhang X S, Luo Y J. A calculation method for the floor surface temperature in radiant floor system [J].EnergyandBuildings, 2010, 42(10): 1753-1758.

[2]Sattari S, Farhanieh B. A parametric study on radiant floor heating system performance [J].RenewableEnergy, 2006, 31(10): 1617-1626.

[3]Karabay H, Arici M, Sandik M. A numerical investigation of fluid flow and heat transfer inside a room for floor heating and wall heating systems [J].EnergyandBuildings, 2013, 67: 471-478.

[4]Fontana L. Thermal performance of radiant heating floors in furnished enclosed spaces [J].AppliedThermalEngineering, 2011, 31(10): 1547-1555.

[5]Maerefat M, Zolfaghari A, Omidvar A. On the conformity of floor heating systems with sleeping in the eastern-style beds; physiological responses and thermal comfort assessment [J].BuildingandEnvironment, 2012, 47:322-329.

[6]Jeon J, Jeong S G, Lee J H, et al. High thermal performance composite PCMs loading xGnP for application to building using radiant floor heating system [J].SolarEnergyMaterialsandSolarCells, 2012, 101: 51-56.

[7]Haurie L, Mazo J, Delgado M, et al. Fire behaviour of a mortar with different mass fractions of phase change material for use in radiant floor systems [J].EnergyandBuildings, 2014, 84:86-93.

[8]Zhou G B, He J. Thermal performance of a radiant floor heating system with different heat storage materials and heating pipes [J].AppliedEnergy, 2015, 138:648-660.

[9]Ansuini R, Larghetti R, Giretti A, et al. Radiant floors integrated with PCM for indoor temperature control [J].EnergyandBuildings, 2011, 43: 3019-3026.

[10]Mazo J, Delgado M, Marin J M, et al. Modeling a radiant floor system with phase change material (PCM) integrated into a building simulation tool: analysis of a case study of a floor heating system coupled to a heat pump [J].EnergyandBuildings, 2012, 47: 458-466.

[11]Jin X, Zhang X S. Thermal analysis of a double layer phase change material floor [J].AppliedThermalEngineering, 2011, 31(10): 1576-1581.

doi:10.3969/j.issn.1003-7985.2015.04.011

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Mitigation of inter-cell interference in visible light communication

- Modified particle swarm optimization-based antenna tiltangle adjusting scheme for LTE coverage optimization

- Distribution algorithm of entangled particles for wireless quantum communication mesh networks

- Kernel principal component analysis networkfor image classification

- CFD simulation of ammonia-based CO2 absorption in a spray column

- Simulation and performance analysis of organic Rankine cycle combined heat and power system