Dynamic compressive property and failure behavior of extruded Mg-Gd-Y alloy under high temperatures and high strain rates

2015-02-16*

*

School of Materials Science and Engineering,Shenyang University of Technology,Shenyang 110870,China

Dynamic compressive property and failure behavior of extruded Mg-Gd-Y alloy under high temperatures and high strain rates

Jin-cheng Yu*,Zheng Liu,Yang Dong,Zhi Wang

School of Materials Science and Engineering,Shenyang University of Technology,Shenyang 110870,China

For the purpose of investigating the dynamic deformational behavior and failure mechanisms of magnesium under high strain rates,the Split Hopkinson Pressure Bar(SHPB)was used for investigating dynamic mechanical properties of extruded Mg-Gd-Y Magnesium alloy at ambient temperature(300 K),200°C(473 K)and 300°C(573 K)temperature.The samples after compression were analyzed by scanning electron microscope(SEM)and metallographic microscope.Dynamic mechanical properties,crack performance and plastic deformation mechanism of extruded Mg-Gd-Y Magnesium alloy along the extrusion direction(ED)were discussed.The results show that,extruded Mg-Gd-Y Magnesium alloy has the largest dynamic compressive strength which is 535 MPa at ambient temperature(300 K)and strain rate of 2826 s-1.When temperature increases,dynamic compressive strength decreases,while ductility increases.The dynamic compression fracture mechanism of extruded Mg-Gd-Y Magnesium alloy is multi-crack propagation and intergranular quasi-cleavage fracture at both ambient temperature and high temperature.The dynamic compressive deformation mechanism of extruded Mg-Gd-Y Magnesium alloy is a combination of twinning,slipping and dynamic recrystallization at both ambient temperature and high temperature.

Extruded Mg-Gd-Y magnesium alloy;Split Hopkinson Pressure Bar;Dynamic compressive property;Failure behavior;High strain rates;High temperature

1.Introduction

Magnesium alloys are the lowest density of the metal structure material which have been widely applied to the automotive feld due to the advantages of high specifc strength,high specifc stiffness,good damping and machinability[1,2].In recent years,magnesium alloys used at the temperature above 200°C are all magnesium rare-earth.Mg-Gd-Yalloy system has become as one of the high strength cast and wrought magnesium systems[3].However,there have been small amount of studies highlighting the dynamic mechanical property of magnesium rare-earth and it is a limitation to use magnesium rare-earth complying with the actual usage.

JI Wet al.[4]found that,the shear bands in Mg-Gd-Yalloy during the course of ballistic were white under the optical microscope.The white bands were only formed in the stable plastic penetration stage.During the high temperature SHPB compression,signifcant plastic deformation bands were only formed when T=735 K.ZHANG F et al.[5]found that,Mg-Gd-Y alloy showed a brittle cleavage fracture characteristics. They found ASBs in the specifc location were phase transition bands.Strain rates affected the fracture mechanism by improving the thermal softening effect of Mg-Gd-Y alloy.

In the author's laboratory,the dynamic compressive properties and microstructure evolution of extruded Mg-Gd-Yalloy at ambient temperature along ED,TD and ND directions werestudied[6,7].Dynamic mechanical properties of extruded Mg-Gd-Y alloy do not exhibit strong anisotropy and along ED direction are relatively optimal.Microstructures of extruded Mg-Gd-Y Magnesium alloy along ED,TD and ND compression directions are sensitive to strain rates.When strain rate reaches 2500 s-1,the adiabatic shear band(ASB)begins to form.

In this paper,Split Hopkinson Pressure Bar apparatus (SHPB)with heating apparatus[8]was used to research the dynamic compressive property of extruded Mg-Gd-Y Magnesium alloy along ED direction.The failure mechanism and deformation behavior of extruded Mg-Gd-Y Magnesium alloy were discussed at high strain rates and high temperatures.The fracture surfaces were analyzed by SEM and the microstructures were observed using the optical microscopy.

2.Material and specimens

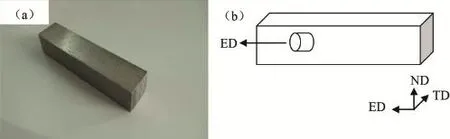

Extruded Mg-Gd-Y magnesium alloy(EW75M)as provided by Beijing General Research Institute for Non-ferrous Metals,which nominal compositions are listed in Table 1. The extrusion ratio is 20 and the extrusion temperature is 400°C.Researchers from Beijing General Research Institute for Non-ferrous Metals found that the strength and ductility of Mg-Gd-Y alloy were greatly improved with the increase of extrusion ratio[9].Specimens of dynamic compression were cut from the Mg-Gd-Y magnesium extrusion(Fig.1(a))along ED direction as shown in Fig.1(b)and the size of specimen was φ8 mm×6 mm.

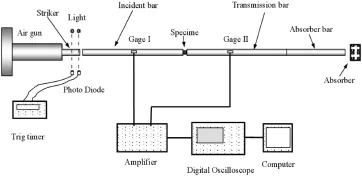

Split Hopkinson Pressure Bar(SHPB)was used under differentstrain ratesatambienttemperature(300 K), 200°C(473 K)and 300°C(573 K)temperature.The details of experimental device and methods can be found in papers [10-12].SHPB system is shown in Fig.2.The fractures were observed by SEM and microstructures of section perpendicular to loading direction,microstructures of section parallel with loading direction and microstructure of diagonal section wereobserved in broken specimensby metallographic microscope.

Table 1Nominal compositions of extruded Mg-Gd-Y alloy(mass fraction,%).

3.Results and discussion

3.1.Dynamic compressive properties

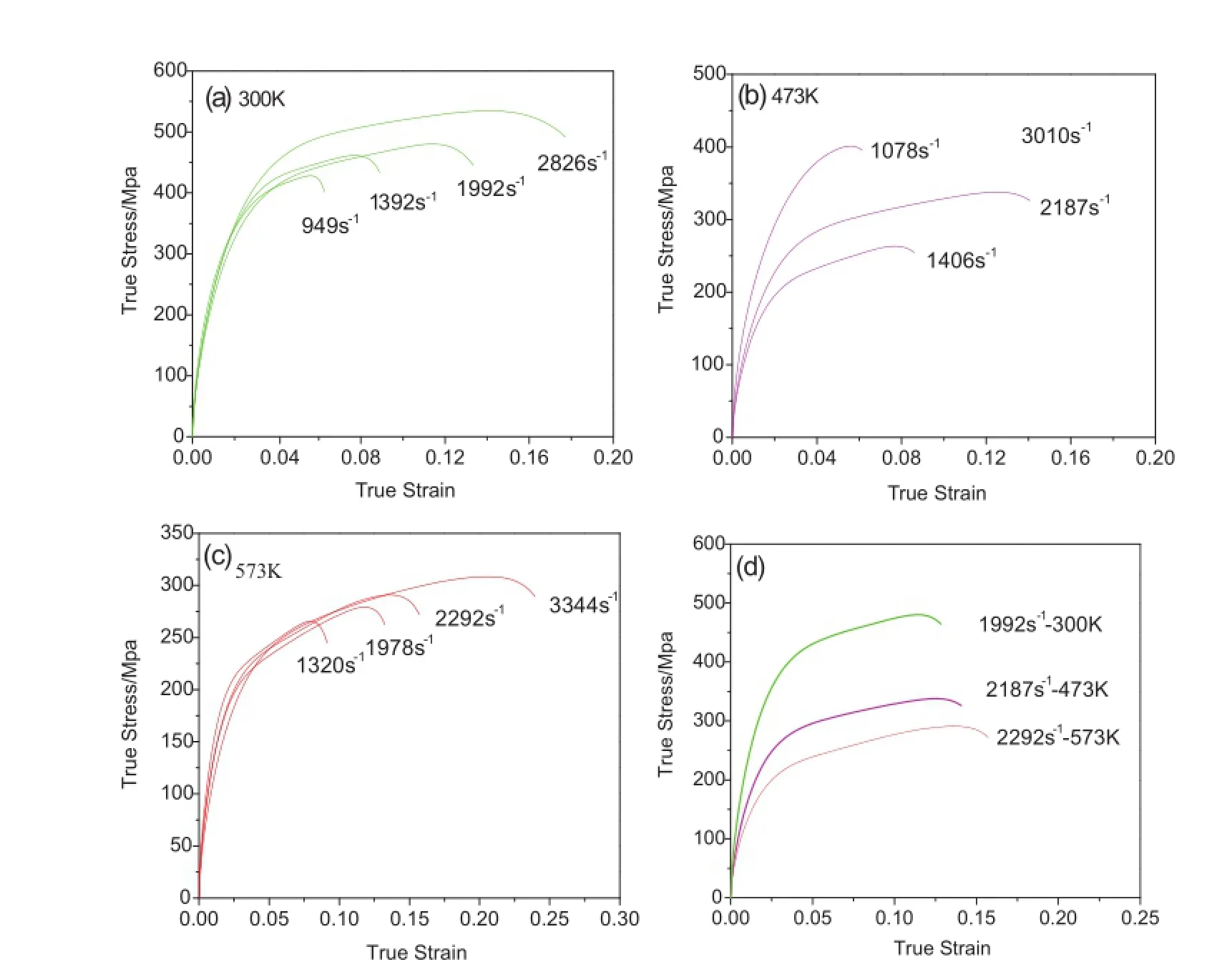

The dynamic compressive true stress-true strain curves of extruded Mg-Gd-Y magnesium alloy at different temperatures are shown in Fig.3.Fig.3(a)shows the true stress-true strain curves of extruded Mg-Gd-Y Magnesium alloy at ambient temperature(300 K)and the strain rates from 949 s-1to 2826 s-1.It can be found that extruded Mg-Gd-Y magnesium alloy yields continuously,and has a clearly positive strain rate effect with increasing strain rates.When strain rate comes to 2826 s-1,the specimen cracks.Dynamic compressive strength of extruded Mg-Gd-Y magnesium alloy is 535 MPa and strain to failure is 15%at ambient temperature(300 K).Fig.3(b) shows the true stress-true strain curves of extruded Mg-Gd-Y magnesium alloy at 200°C(473 K)and the strain rates from 1078 s-1to 3010 s-1.It can be seen that the curves frstly fall down and then rise up with increased strain rates at a higher temperature 200°C(473 K).It is because there is a competition between temperature and strain rate.High temperatures cause a soften effect while high strain rates cause a harden effect.At strain rates of 1406 s-1and 2187 s-1,the soften effect plays a leading role,thus the curves fall down.But the specimens are not broken.When strain rate comes to 3010 s-1,the specimen cracks.Dynamic compressive strength of extruded Mg-Gd-Y magnesium alloy at 200°C(473 K)is 434 MPa and strain to failure is 10%.Fig.3(c)shows the true stress-true strain curves of extruded Mg-Gd-Y magnesium alloy at 300°C(573 K)and the strain rates from 1320 s-1to 3344 s-1.It can be found that extruded Mg-Gd-Y magnesium alloy yields continuously,and has a clearly positive strain rate effect with increasing strain rates either at 300°C(573 K).When strain rate comes to 3344 s-1,the specimen cracks.Dynamic compressive strength of extruded Mg-Gd-Y magnesium alloy is only 308 MPa but strain to failure is 20%at 300°C(573 K).

Fig.1.(a)Photograph of extruded Mg-Gd-Y alloy;(b)dynamic compressive specimen.

Fig.2.Schematic view of SHPB system.

Fig.3(c)shows the true stress-true strain curves of extruded Mg-Gd-Y magnesium alloy at 300°C(573 K)and at the strain rates from 1320 s-1to 3344 s-1.It can be found that at 300°C(573 K)extruded Mg-Gd-Y magnesium alloy yields continuously,and has a clearly positive strain rate effect with increased strain rates.When strain rate comes to 3344 s-1,the specimen cracks.Dynamic compressive strength of extruded Mg-Gd-Y magnesium alloy at 300°C(573 K)is only 308 MPa but strain to failure is 20%.Above all,at ambient temperature (300 K)and the strain rate of 2826 s-1,extruded Mg-Gd-Y Magnesium alloy has the largest dynamic compressive strength which is 535 MPa.Fig.3(d)shows the comparison of the dynamic compressive true stress-true strain curves at similar strain rate atambienttemperature (300 K), 200°C(473 K)and 300°C(573 K)temperature.It can be found thatwhen temperature increases,the dynamic compressive strength of extruded Mg-Gd-Y magnesium alloy decreases,while the ductility increases.Extruded Mg-Gd-Y magnesium alloy hasthelargestdynamiccompressive strength at ambient temperature(300 K)and the strain rate of 2826 s-1.Temperature affects the strength and ductility of extruded Mg-Gd-Y magnesium alloy underdynamic compression.

Fig.3.Dynamic compressive true stress-true strain curves of Mg-Gd-Y magnesium alloy:(a)300 K;(b)473 K;(c)573 K;(d)comparison at similar strain rate of three temperatures.

3.2.Observation of fracture surfaces

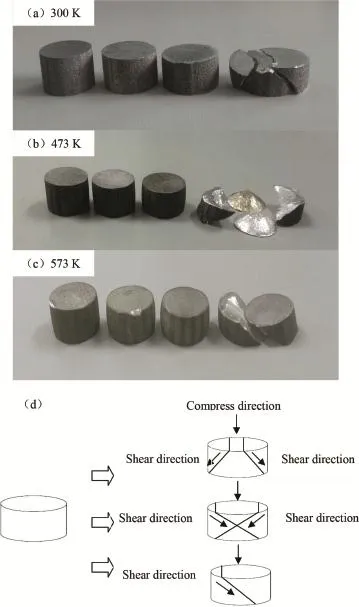

Fig.4 shows the dynamic compressive fractures of extruded Mg-Gd-Y magnesium alloy at different temperatures.It can be seen in Fig.4(a)-(c)that the specimens gradually deform with increased strain rates and eventually fail.When specimens break up,the fractures are along certain directions.Fig.4(d)indicates the approximate fracture mode. According to the law of Schmid,45°direction is the direction of maximal orientation factor when specimen is dynamic compressed.The shearstressisthe maximum along 45°direction.Thus when the specimen is compressed under high strains,main cracks appear along two 45°shear directions.In Fig.4(a)and(b)there are two 45°direction main cracks and Fig.4(c)there is only one 45°direction main crack. The amount of main crack depends on experimental conditions and specimens themselves.When shear stress increases with increasing strain rates,main cracks propagate and make the specimen broken in the end.

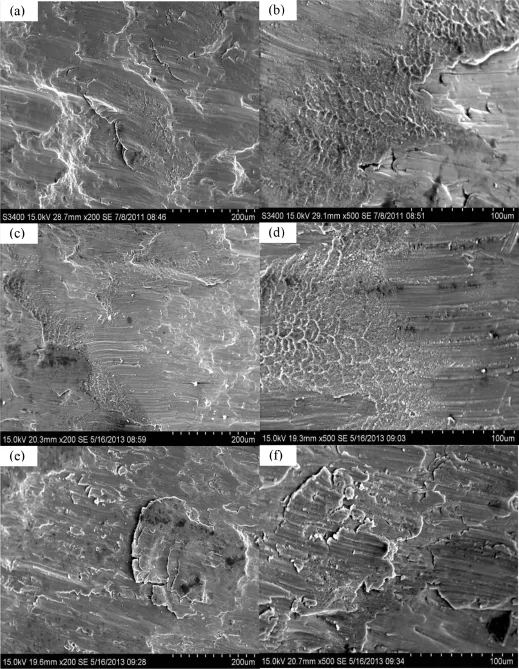

Fig.5 shows the SEM graphs of dynamic compressive fractures of extruded Mg-Gd-Y magnesium alloy at different temperatures.It is observed that there are a lot of steps on the gentle fracture section.Some small secondary cracks and a great deal of winding torn edges(in Fig.5(a),(c)and(e))are observed along the steps(in Fig.5(a)).There are fat tongueshaped pattern on the steps(in Fig.5(a),(e)and(f)).These results show that plastic deformation happens in localizedplace and cracks perform along certain crystallographic plane. Thus,the fracture performances of extruded Mg-Gd-Y magnesium alloy under dynamic compressive are all quasicleavage fracture at high temperatures and the type of fracture mechanism is not sensitive to temperatures.

Fig.4.(a)Photograph of specimens after dynamic compression:(a)300 K;(b) 473 K;(c)573 K;(d)force diagram of the broken specimens.

Furthermore,some melting areas are found along the crack in Fig.5(b)-(d).HUANG H et al.[13]in the compressive broken specimen of AZ31 under the strain rate of 2300 s-1and LIU T M et al.[14]in AZ31 in compressive test all found the special melting areas.It is due to under high strain rate the transient temperature is over the melting point when most plastic deformation work produces heat and adiabatic heating happens.In Taylor impact test of Ti-6Al-4V alloy,REN Y [15]thinks that these serious melting regions can be observed on the upper side of the smooth and smeared surface,which illustrates that a signifcant melting of the original shear area material takes place prior to shear fracture of the specimen. The melting areas are also proofs of thermal softening effect in localized place.

3.3.Microstructure observation

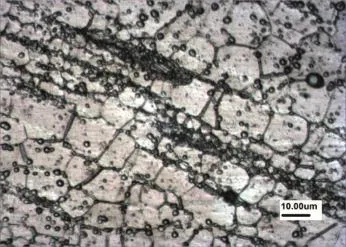

Fig.6 shows the original microstructures of section perpendicular to loading direction along ED direction.Original microstructure of extruded Mg-Gd-Y magnesium alloy along ED direction is typical extrusion state microstructure. There are a great amount of uniform equiaxed big-sized grains.The size is about 10 μm.A small amount of smallsized recrystallization grains which lie between the big-sized grains can be seen in black striped area.In additional,no twins are observed in both of the big and small grain sizes.

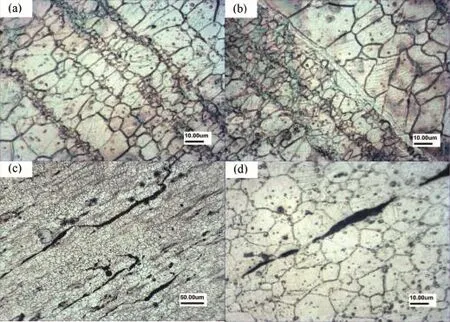

Fig.7 shows the compressive microstructures of extruded Mg-Gd-Y magnesium alloy along ED direction at 300 K under strain rate of 2826 s-1.Fig.7(a)is the microstructure of section perpendicular to loading direction.It can be observed that twinning happens in only several grains which are both big size grains and small size grains.Original recrystallized grains become more and grow up and the recrystallization bands become wide and continuous in a row.Fig.7(b)is the microstructure of section parallel with loading direction.The results show that a continuous white band appears and its average width is 3 μm.The white band is parallel with the band of recrystal grains and separates equiaxed grains from recrystal grains.Fig.7(c)and(d)show the microstructures of diagonal section after dynamic compression.There are many paralleled cracks in the broken specimen.It indicates that the dynamic failure mechanism of magnesium is muti-crack propagation mechanism and cracks extend along the grain boundary.

Fig.8 shows the compressive microstructures of extruded Mg-Gd-Y magnesium alloy along ED direction at 473 K under strain rate of 3010 s-1.Fig.8(a)is the microstructure of section perpendicular to loading direction.It can be observed that twinning happens in only several grains which are both big size grains and small size grains.

It indicates that twinning is a kind of dynamic compressive deformation mechanisms of extruded Mg-Gd-Y magnesium alloy at both ambient temperature and high temperature.The other deformation mechanism is slip.The higher strain rate is, the more percentage of slip is.This is because magnesium alloys have less slip systems at room temperature[16]and it causes a strong stress concentration near the grain boundaries. The strong stress concentration can improve the formation of twins and coordinate the plastic deformation.When strain rates and temperatures increase,cross slip and non-basal slip can start although the critical shear stress decreases which twinning needs.The amount of starting slip is increasing so that the stress concentration is weakened and it is against the formation of twins.As a result,twinning makes less contribution to the plastic deformation at high strain rates.On the contrary non-basal slip which has thermal activation characteristics can play important role during the release of stress concentration and the coordination of plastic deformation.In addition,during the plastic deformation twinning will choose to appear in advantageously oriented grains.It explains that twinning happens in only several grains which orientations are advantaged.Original recrystallized grains become more andgrow up and the recrystallization bands become wide and continuous in a row.Fig.8(b)is the microstructure of section parallel with loading direction.There is a continuous white band and twinning appears in it.The average width of the white band is 3 μm.The white band is parallel with the band of recrystal grains and separates equiaxed grains from recrystal grains.Fig.8(c)shows the microstructure of diagonal section after dynamic compression.Original recrystallization bands become more and original grains are broken into small grains after dynamic compression.In summary,the dynamic compressive deformation mechanism of extruded Mg-Gd-Y magnesium alloy under high stain rate compression is a combination of twinning, slipping and dynamic recrystallization.

Fig.5.SEM graphs of Mg-Gd-Y magnesium alloy under dynamic compression:(a)and(b)300 K;(c)and(d)473 K;(e)and(f)573 K.

Fig.6.Original microstructure of extruded Mg-Gd-Y magnesium alloy along ED direction.

Fig.7.Microstructures of extruded Mg-Gd-Y magnesium alloy at 300 K under strain rate of 2826 s-1:(a)microstructure of section perpendicular to loading direction;(b)microstructure of section parallel with loading direction;(c)and(d)microstructure of diagonal section.

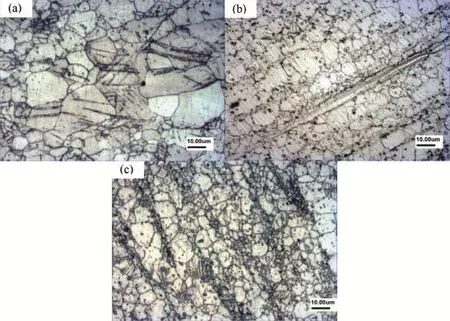

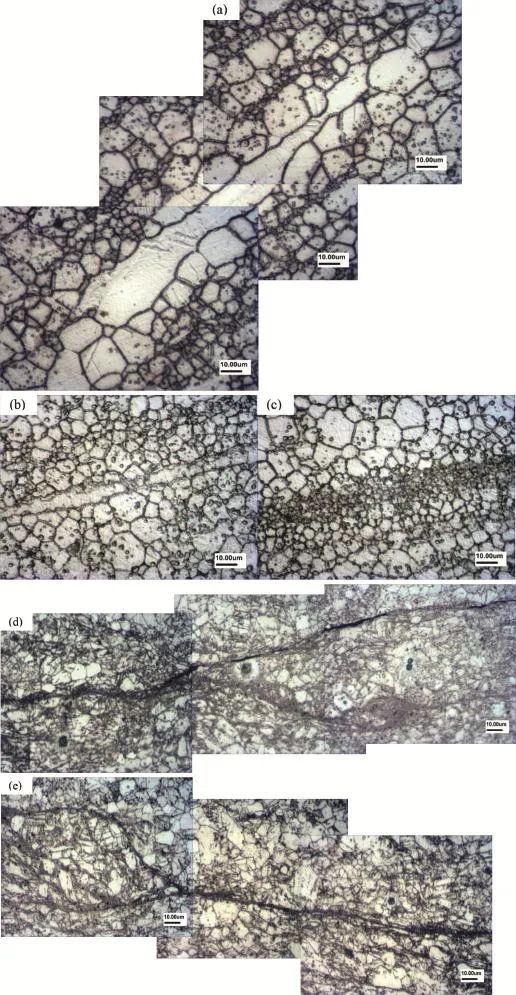

Fig.9 shows the compressive microstructures of extruded Mg-Gd-Y magnesium alloy along ED direction at 573 K under strain rate of 3344 s-1.Fig.9(a)is the microstructure of section perpendicular to loading direction.It can be observed that there are some abnormal big grains in the microstructure. This is because under high strain rates,the whole deformation is in a very short time and a large part(about 90%)of plastic work turns into heat.Heat concentration leads several grains growing up abnormally by grain boundary migration to absorb adjacent grains.The big grains decrease the material strength. It indicates that adiabatic temperature rising causes the thermal softening[17].Fig.9(b)and(c)are the microstructure of section parallel with loading direction.The results show that a continuous white band appears and parallel with the band of recrystal grains.In other area,recrystallized grains become more and grow up and the recrystallization bands become wide.Ion[18]thought that magnesium alloys can be easily dynamically recrystallized:(1)There are fewer slip systems of magnesium alloys and piling up of dislocationshappens easily so that dislocation density can meet the standard for dynamic recrystallization;(2)Magnesium and its alloys have lower stacking fault energy and extended dislocation is hard to strand.Therefore,it is diffcult to slip and climb,.and dynamically recover slowly but improve recrystallization;(3)Magnesium alloys have higher speed of the grain boundary diffusion and the dislocation energy piled up on the subgrain boundaries can be absorbed by the boundaries which can speed up the dynamic recrystallization.The grains of dynamic recrystallization are relevant not only to the size of deformation degree,but also to the temperature of deformation and strain rate.Higher the temperature is,more suffcient dynamic recrystallization is and more homogeneous microstructure is.

Fig.8.Microstructures of extruded Mg-Gd-Y magnesium alloy at 473 K under strain rate of 3010 s-1:(a)microstructure of section perpendicular to loading direction;(b)microstructure of section parallel with loading direction;(c)microstructure of diagonal section.

Fig.9.Microstructures of extruded Mg-Gd-Y magnesium alloy at 573 K under strain rate of 3344 s-1:(a)microstructure of section perpendicular to loading direction;(b)and(c)microstructure of section parallel with loading direction;(d)and(e)microstructure of diagonal section.

Fig.9(d)shows the microstructures of diagonal section after dynamic compression.It is shown that there are many broken grain boundaries bands in the specimen where the small cracks appear and grow up,as shown in Fig.9(d).When the strain rate and temperature increase,the grain boundaries become weak and then broken into bands at last.And the cracks choose the least resistance way to grow up,as seen in Fig.9(e).The process of crack propagation is also the process of impact energy attenuation.Thus,it is indicates that the dynamic failure mechanism of magnesium is intergranular muti-crack propagation mechanism and cracks extend along the grain boundary.

4.Conclusions

1)At ambient temperature(300 K)and the strain rate of 2826 s-1,extruded Mg-Gd-Y magnesium alloy has the largest dynamic compressive strength which is 535 MPa. When temperature increases,dynamic compressive strength of extruded Mg-Gd-Y magnesium alloy decreases,while ductility of extruded Mg-Gd-Y Magnesium alloy increases.

2)The dynamic compression fracture mechanismsof extruded Mg-Gd-Y magnesium alloy at both ambient temperature and high temperature are multi-crack propagation and intergranular quasi-cleavage fracture.

3)The dynamic compressive deformation mechanisms of extruded Mg-Gd-Y magnesium alloy at both ambient temperature and high temperature are a combination of twinning,slipping and dynamic recrystallization.

Acknowledgments

The authors would like to acknowledge the fnancial support from the National Key Basic Research Program(973 Program),Project(2013CB632205).

[1]Z.Liu,Y.Wang,Z.G.Wang,F.Wang,Z.Y.Shen,Chin.J.Material Res. 14(5)(2000)449-456.

[2]L.H.Chen,H.J.Zhao,Z.Liu,Z.Y.Shen,Y.Y.Nie,Foundry(10)(1999) 45-50.

[3]Y.J.Wu,W.J.Ding,L.M.Peng,X.Q.Zeng,D.L.Lin,Mater.China 30(2) (2011)1-9.

[4]W.Ji,Y.F.Fan,J.Chen,G.L.Qiao,Rare Metal Mater.Eng.38(4)(2009) 599-602.

[5]F.Zhang,C.W.Tan,X.D.Yu,H.L.Ma,F.C.Wang,H.N.Cai,Chin.J. Rare Metals 35(5)(2011)662-666.

[6]P.L.Mao,J.C.Yu,Z.Liu,Y.Dong,T.Xi,Chin.J.Nonferrous Metals 23 (4)(2013)889-897.

[7]P.L.Mao,J.C.Yu,Z.Liu,Y.Dong,J.Magnesium Alloys(1)(2013) 64-75.

[8]S.S.Hu,Ordnance Material Sci.Eng.(11)(1991)40-47.

[9]Y.J.Liu,K.Zhang,X.G.Li,M.L.Ma,H.Z.Wang,L.Q.He,Chin.J. Nonferrous Metals 20(9)(2010)1692-1697.

[10]S.W.Park,M.Zhou,Exp.Mech.39(4)(1999)287-294.

[11]L.Song,S.S.Hu,Explos.Shock Waves 25(4)(2005)368-373.

[12]B.Song,L.Song,S.S.Hu,Explos.Shock Waves 18(2)(1998)167-171.

[13]H.Huang,W.G.Huang,J.Mater.Eng.(11)(2009)51-54.

[14]T.M.Liu,L.W.Lu,Y.Liu,A study on the deformation and fracture behaviors of Mg alloy[EB/OL],2011/12/20.http://www.paper.edu.cn.

[15]Y.Ren,C.W.Tan,J.Zhang,F.C.Wang,Trans.Nonferrous Metals Soc. China 21(2011)223-235.

[16]P.L.Mao,Z.Liu,C.Y.Wang,X.Jing,F.Wang,Q.Y.Guo,J.Sun,Chin.J. Nonferrous Metals 19(5)(2009)817-820.

[17]Y.Yang,X.L.Cheng,Chin.J.Nonferrous Metals 12(3)(2002)402-407.

[18]S.E.Ion,F.J.Humphreys,S.H.White,Acta Metall.30(1982) 1909-1919.

Received 19 May 2014;revised 10 December 2014;accepted 20 April 2015

Available online 15 May 2015

*Corresponding author.Tel./fax:+86 0 24 25496166.

E-mail address:yujincheng062@sina.com(J.-c.Yu).

Peer review under responsibility of National Engineering Research Center for Magnesium Alloys of China,Chongqing University.

http://dx.doi.org/10.1016/j.jma.2015.04.003.

2213-9567/Copyright 2015,National Engineering Research Center for Magnesium Alloys of China,Chongqing University.Production and hosting by Elsevier B.V.All rights reserved.

Copyright 2015,National Engineering Research Center for Magnesium Alloys of China,Chongqing University.Production and hosting by Elsevier B.V.All rights reserved.

杂志排行

Journal of Magnesium and Alloys的其它文章

- Infuence of rolling parameters on dynamically recrystallized microstructures in AZ31 magnesium alloy sheets

- Effect of temperature on the mechanical abnormity of the quasicrystal reinforced Mg-4%Li-6%Zn-1.2%Y alloy

- Improving the corrosion resistance of AZ91D magnesium alloy through reinforcement with titanium carbides and borides

- Effects of Ti addition on the microstructure and mechanical properties of Mg-Zn-Zr-Ca alloys

- Phase stability,elastic properties and electronic structures of Mg-Y intermetallics from frst-principles calculations

- A comparative corrosion behavior of Mg,AZ31 and AZ91 alloys in 3.5% NaCl solution