新拌水泥浆体絮凝结构与流变行为及有效体积分数的关系

2014-11-25张力冉王栋民

张力冉,王栋民,潘 佳,李 娟,王 芳

(中国矿业大学(北京)化学与环境工程学院,混凝土与环境材料研究所,100083)

1 Introduction

Cement pastes(CP)are colloidal suspensions,in which the interaction of cement particles may lead to the formation of particular microstruc-tures,[1]i.e.the flocculent structures.[2]Concrete is essentially a mixture of CP and aggregates.The quality of concrete is much dependent on the rheological behavior of the fresh concrete.It is important to clarify the relationship between the rheo-logical behavior of CP with superplasticizer and the structural change governing the thixotropy and the breakdown of flocculent structure.

Recent work has mainly focused on various aspects for fresh CP,such as hydration,flowability,flowability retention,microstructure of hardened,mechanical properties and rheological behaviours.[3--11]As the basic building material,CP must have the preferable workability even after being transported for a long distance.Thus,fresh CP must possess an adequate flowability and its retention for a certain period to ensure the effective construction.Furthermore,the rheological properties of fresh CP also affect the strength and durability of hardened CP.In fresh CP,the addition of superplasticizer can affect the properties of CP,i.e.,thixotropy,[12--14]flocculability,[2,15--17]et al.Therefore,we could analyze the rheological performance and the flocs of fresh CP and concrete with superplasticizer via the measurement of the rheological properties.The results can characterize the com-patibility between the superplasticizer and cementitious materials,and optimize the design of concrete mixing proportion and the performance of chemistry additive in concrete.The rheological properties fresh CP play a decisive role in the production and construction of the concrete[15].

In this paper,the relationship between flocculent structure and rheological behavior/effective volume fraction of fresh cement paste with two types of superplasticizers at various water/cement ratios was investigated.The shear stress and viscosity at different shear rates for the fresh CP with superplasticizer was measured by a coaxial rotational rheometer.

2 Experimental

2.1 Materials and sample preparation

Portland cement P·I 42.5(GB 8076—2008)was supplied by from Lafarge Shui On Cement Co.,Ltd.,China.Table 1shows the composition of these materials.

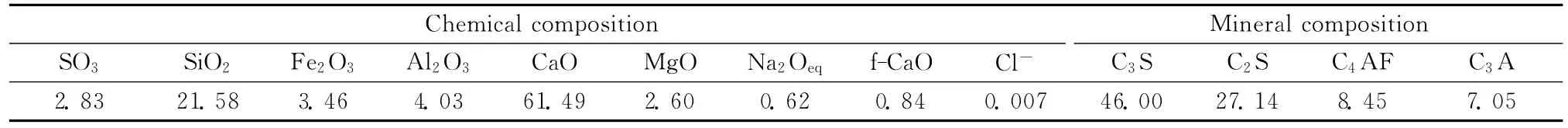

Table 1 Composition of Portland cement w/%

The superplasticizers used are a anionic poly-carboxylic ether(PCa)and a nonionic modified anionic poly-carboxylic ether(PCma).Table 2shows the characteristics of the superplasticizers.PCawas synthesized by aqueous free radical copolymerization ofα-methallyl-ω-methoxy poly(ethylene glycol)ether acrylic acid and sodiump-styrenesulfonate using methallyl sulfonic acid as a chain transfer agent.The molar ratios of the monomers were 1.00∶4.00∶0.02,and the number of ethylene oxide units in the side chain was 53.PCmawas synthesized by aqueous free radical copolymerization ofαmethallyl-ω-methoxy poly(ethylene glycol)ether,acrylic acid and styrene using methallyl sulfonic acid as a chain transfer agent.The molar ratios of the monomers were 1.00∶4.00∶0.03,and the number of ethylene oxide units in the side chain was 53.The dosage of each superplasticizer is 0.2%.

Table 2 Characteristics of superplasticizers used

2.2 Test methods

The rheological properties were measured at 25℃by a coaxial rotational NXS--11Arheometer.The fresh CP samples were prepared at water/cement(W/C)ratios of 0.25,0.30and 0.35,respectively.The samples with superplasticizers were used in B system(i.e.,the diameter of outer tube of 4cm,the diameter of inner tube of 3.17cm,and the tube height of 5cm).The flow curves were obtained,by increasing or decreasing shear rate steps.Each step lasted 30s,in order to reach a steady flow.

3 Results and discussion

3.1 Relationship between flocculent structure and rheological behavior

3.1.1 Relationship between the deformability of flocculent structures and rheological parameters The rheological properties of fresh CP can be described as the Bingham fluid model:

whereτis the shear stress(Pa),τ0is the yield stress(Pa),ηpis plasticity viscosity(Pa·s)and˙γis shear rate(s--1).

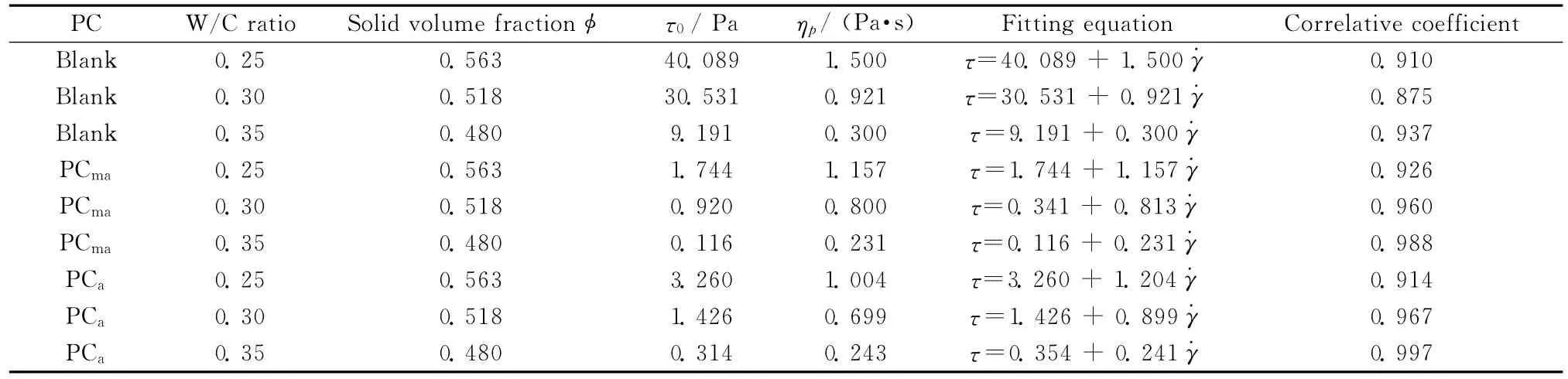

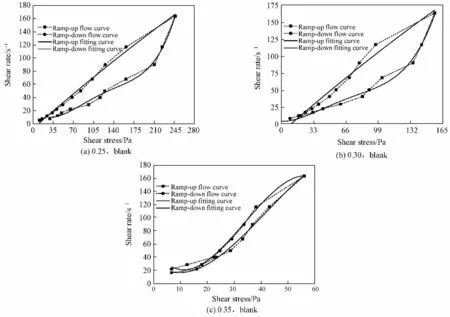

Figure 1shows the relationship between shear stress and shear rate.The shear stress changes linearly with shear rate at different W/C ratios.The shear rate vs shear stress were empirically fitted[19],Table 3shows the rheological parameters and the fitted results[i.e.,the yield stressτ0(the intercept of empirical formula)and plasticity viscosityηp(the slope of empirical formula)obtained in fresh CP with PCmaor PCaand blank sample at different W/C ratios].

Fig.1 Relationship between shear stress and shear rate at different W/C ratio

Table 3 Rheology parameters and fitted results of fresh CP with PCmaor PCaand blank sample

Fig.2 Flocculent structure of fresh cement paste[2,19]

Clearly,τ0of the CP without PC decreases from 40.089to 9.191Pa,when the W/C ratio increases from 0.25to 0.35,According to Wang[2,20],the flocculent structures are multi-level rather than single-level,and different types of superplasticizers break the flocculent structures in different levels(see Fig.2).Thusτ0can characterize the deformability of flocculent structures in different levels.This reflects that the lessτ0is,the more easily the deformation of paste will be.In Fig.1 and Table 3,theτ0of paste with PCais 3.260Pa at W/C ratio of 0.25,which is greater than that of PCma.The similar result occurs at different W/C ratios.It is indicated that fresh CP with PCmaappears deformation more easily than that of PC.This phenomenon could be since moderate styrene induced to PCmais used as so-called spacer molecules to adjust the conformational flexibility of the trunk chain,compared to PCa.

ηpresponses the internal friction force among suspension particles,liquid molecular and successive liquid phase under the condition that the breakage and recovery of the grid structure are in stable state in the laminar flow pastes.However,ηpis only apart of the internal friction forces and does not change with flowing speed grade.ηpcan be affected by some factors[21],such as solid volume fraction and the admixture in the paste.As shown in Table 3,ηpof the CP without PC increases gradually from 1.500to 0.300Pa·s with the increase of solid volume fraction from 0.480to 0.563.However,ηpof paste with PCmais greater than that of PCaat W/C ratio of 0.25and 0.3,ηpof paste with PCmais 0.231Pa·s at W/C ratio of 0.35,which is smaller than that of PCa.Thus,the influence of admixture onηpis inconsistent at different W/C ratios.In Fig.3,ηpis seldomly related toτ0,i.e.,ηpis seldomly related to the deformability of flocculent structure.

Fig.3 Variations in plastic viscosity with yield stress

3.1.2 Relationship between the broken degree of flocculent structure and the thixotropy Fresh CP is a kind of thixotropic fluid.The mobility of fresh CP increases temporarily due to the effect of external force.After a cement powder is mixed with water,the flocculent structures are formed due to the different binding forces among cement particles.The different external force could break the flocculent structures due to different binding force[2,20].There exists a certain broken degree of flocculent structures when external forces are determined.Based on the above analysis above,Nb,Nsand Nfcan be introduced at the same kind of cement and W/C ratios,where Nsrepresents the broken degree of flocculent structures due to the electrostatic repulsion and space steric effect of superplasticizer.Nfrepresents the broken degree of flocculent structures in fresh CP with PC due to the shear stress from rotation viscometer in this work,and Nbrepresents the broken degree of flocculent structures in the neat fresh CP due to the shear stress from rotation viscometer in this work,The following equation can be thus obtained:

The thixotropic loop obtained at different shear rates and time,and the area of thixotropic loop A can be used to evaluate the broken degree of flocculent structures by rotation viscometer,so we get:

By combining Eqs.(2)and(3),we can obtain:

where Abis the area of thixotropic loop of CP without PC due to the shear stress from rotation viscometer(Pa·s--1);Afis the area of thixotropic loop of CP with PC due to the shear stress from rotation viscometer(Pa·s--1),Asis the area of thixotropic loop of CP with PC due to the electrostatic repulsion and space steric effect of superplasticizer(Pa·s--1).

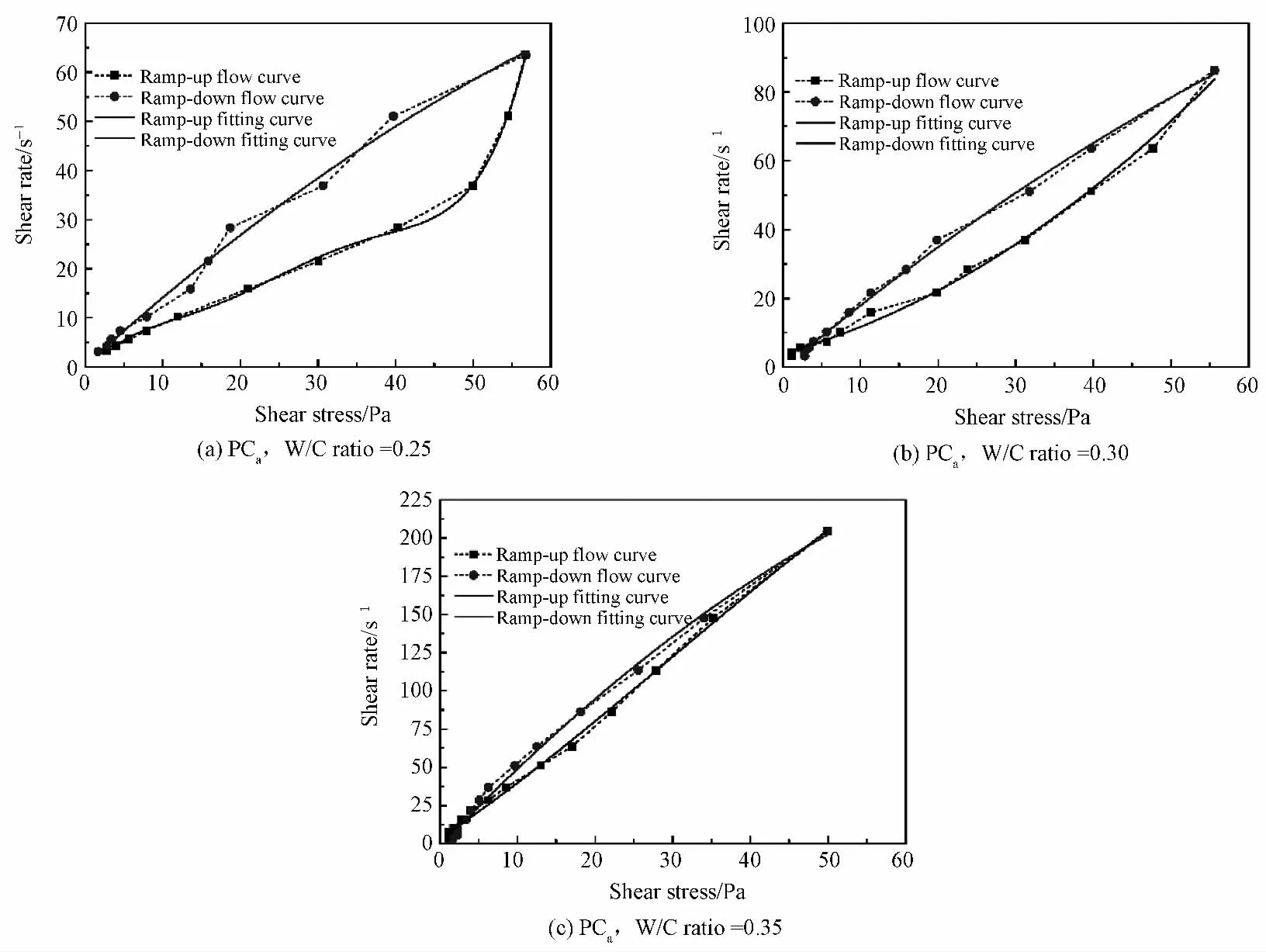

The effects of PCmaand PCaon the thixotropy of fresh CP and the broken degree of flocculent structures were also investigated.A polynomial equation was obtained based on the flow curves fitting.Aband Afwere obtained after integral subtraction.In Table.4,PCs and the shear stress from rotation viscometer both have a great effect on the thixotropy of fresh CP at different W/C ratios.In Table 4 and Fig.4--Fig.6,Abdecreases from 7 477.8to 507.1Pa·s--1with the increase of W/C ratios from 0.25to 0.35.The greater Abis,the higher broken degree of flocculent structures of neat fresh CP due to the shear stress from the rotation viscometer will be.For PCma,Asgradually decreases from 6 800.0to 175.3Pa·s--1with the increase of W/C ratios from 0.25to 0.35.At W/C ratios of 0.3,Asof fresh CP with PCmais 4 532.5Pa·s-1,which is greater than that of PCa,it is indicated that PCmahas a better dispersive effect on the breakage of the flocculent structures and the compatibility with CP rather than PCa.

Clearly,W/C ratio of cement and the type of superplasticizers boths have an effect on the value of As.In our previous study[22],the dosage of superplasticizer also has an effect on As.All of these parameters are related to value As.

Fig.4 Thixotropy of neat fresh CP at different W/C ratios

Fig.5 Influence of PCmaon fresh CP thixotropy at different W/C ratios

Fig.6 Influence of PCaon fresh CP thixotropy at different W/C ratios

Table 4 Area of thixotropic loop Aof fresh CP with PCmaor PCaand blank sample at different W/C ratios

According to Eq.(5),the broken degree of flocculent structures is greater at a greater As,while a limit value exist.The value of k and X both greater than 0,which are not confirmed and need to be further studied.However,these values are related to W/C ratio,the temperature,types and dosages of superplasticizer as well.

3.1.3 The relationship between de-flocculation/re-flocculation of flocculent structure and shearthinning/shear-thickening behavior.

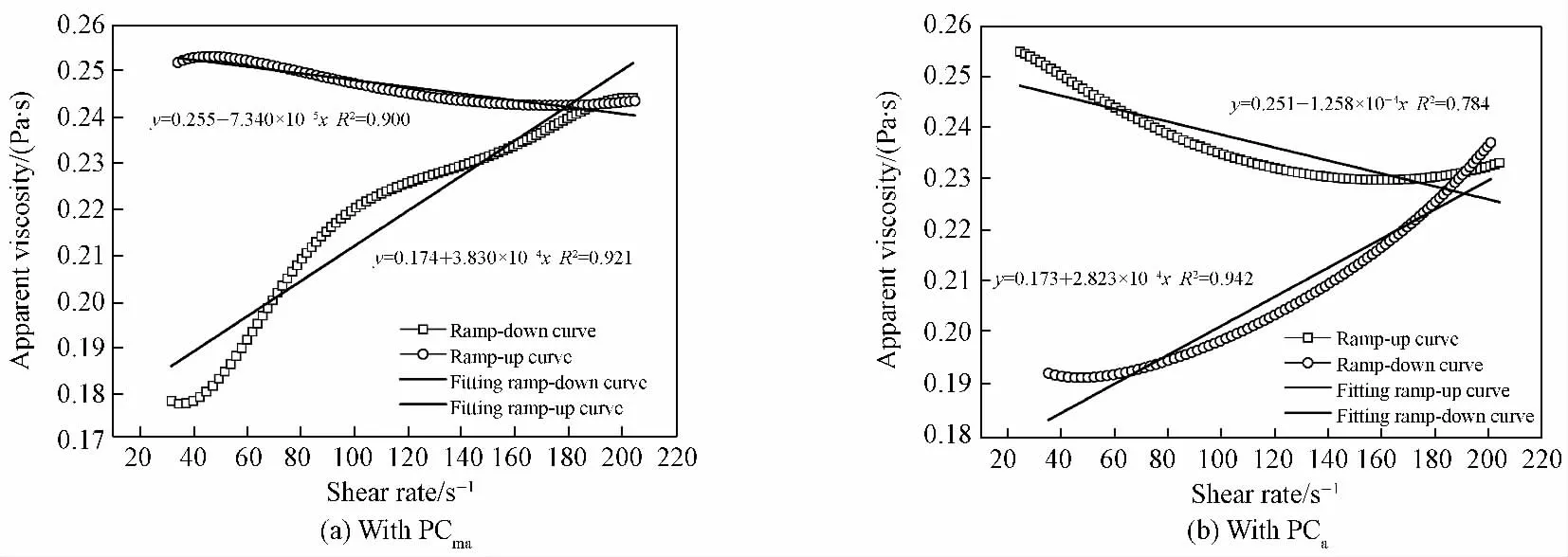

In general,ηaresponses the free solvent’s volume in suspension[23--24].Therefore,shear-thinning and shear-thickening behaviors should be due to the variation of free solvent’s volume,induced by the suspension particles distribution state during shearing.In Fig.7,ηadecreases when the shear rate increases.This behavior is shear-thinning.The decrease rate ofηarefers to the slope of rampup curves,as shown in Figs.7(a)and 7(b).If the shear rate was increases,the free solution volume of the paste increases,causing the deflocculation of the flocculent structures.The slope of ramp-up curve of CP with PCmais--7.340×10-7,which is smaller than that of PCa.CP with PCmashows a weaker shear-thinning behavior.This reflects that PCmahas a better dispersive ability on CP,compared to PCa.

Figure 7also shows the shear-thickening behaviors.The increased rate ofηarefers to the slope of ramp-down curves,as shown in Figs.7(a)and 7(b).The increased rate ofηaindicates that sthe free solution volume in the paste decrease as the shear rate increases,showing the re-flocculation of the dispersed flocculent structures.The slope of ramp-down curves of CP with PCmais 3.830,which is greater than that of PCa.This shows that PCmahas a greater effect on the reflocculation of dispersed flocculent structures,compared to PCa.

Fig.7 Variations in apparent viscosity with shear rate at W/C=0.35

3.2 Relationship between the average size and the effective volume fraction of flocculent structures

To the relationship between flocculent structures average size and effective volume fraction,based on flocculent structure.We adopt here the similar approach as proposed by Alice Chougnet,Mills and coauthors in a series of papers[26--28]to describe the non-Newtonian behaviour of flocculated suspensions under shear flow conditions.This approach is mainly based on the following considerations:the size of flocculent structures under shear flow conditions is obtained with a mean-field approximation and an effective volume fraction is considered in lieu of the actual volume fraction[10].Another rheological models have also been put forward by other authors over the last two decades[29--34].

Through the research of Alice Chougnet and coauthors[10]comes to the following conclusions:for cement suspensions,effective volume fractionφeff,the actual volume fractionφand shear stressτhad a the following relationship:

In fresh CP,the flocculent structures occupy the more random space than actual cement particles due to the flocculation of cement particles and cement hydration particles.As a result,the effective volume fraction of the flocculent structures is greater than the volume fraction of actual particles.The average size of the flocculent structures can be affected by its effective volume fraction.Figure 8shows the relationship between the effective volume fraction and the shear stress at differ-ent solid volume fractions of fresh CP with PCmaand PCa.It is seen that the effective volume fraction increases from 0.60to 0.72with the increase of actual solid phase volume fraction from 0.480to 0.562under shear stress of 30 Pa.At a greater volume fraction of actual particles,the greater average size of flocculent structures have a random distribution or accumulation,so the effective volume fraction is correlation to average size of the flocculent structures.The greater the effective volume fraction is,the greater the average size of flocculent structures will be.

Fig.8 Relationship between effective volume fractionφeffand shear stress at different solid volume fraction of cement paste with PCma/PCa

4 Conclusions

The effect of suerplasticizer on the rheological properties of fresh CP pastes with various W/C ratios was investigated.The following conclusions can be drawn based on the results obtained:

1)τ0could determine the deformation ability of the paste.At W/C ratio of 0.25,theτ0of paste with PCawas 3.260 Pa,which was greater than that of PCmaof 1.744Pa.The smallerτ0was,the easier the paste appears deformation would be.ηp was not correlated to the deformability of flocculent structures.

2)The variation of the broken degree of flocculent structures could cause the thixotropy.A greater Asgave a greater broken degree of the flocculent structure.Asof fresh CP with PCmawas 4 532.5 Pa·s--1,which was greater than that of showing had a better dispersive effect on the breaking ability of the flocculent structures and the compatibility with CP,compared to PCa.

3)For fresh CP with superplasticizer,a weaker shear-thinning behavior indicated a greater degree of deflocculaiton,while a stronger shear-thinning behavior showed a greater degree of reflocculation.

4)The average size of flocculent structure was concluded to its effective volume fraction.The greater the effective volume fraction was,the average size of flocculent structure would be.

[1]JARNY S,ROUSSEL N,RODES S,et al.Rheological behavior of cement pastes from MRI velocimetry[J].Cem Concr Res,2005,35(10):1873-1881.

[2]WANG D M,ZHANG L R,ZHANG W L,et al.Effects of superplasticizers on multi-level flocculation structure of fresh cement paste[J].J Build Mater(in Chinese),2012,15(6):755-759.

[3]COLLINS F,LAMBERT J,WEN H D.The influences of admixtures on the dispersion,workability,and strength of carbon nanotube-OPC paste mixtures[J].Cem Concr Compos,2012,34(2):201-207.

[4]STARK J.Recent advances in the field of cement hydration and microstructure analysis[J].Cem Concr Res,2011;44(7):666-678.

[5]THOMAS J J,BIERNACKI J J,BULLARD J W,et al.Modeling and simulation of cement hydration kinetics and microstructure development [J].Cem Concr Res,2011,41(12):1257-1278.

[6]BULLARD J W,JENNING H M,LIVINGSTON R A,et al.Mechanisms of cement hydration[J].Cem Concr Res,2011,41(12):53-62.

[7]LOTHENBACH B,SCRIVENER K,HOOTON R D.Supplementary cementitious materials [J].Cem Concr Res,2011,41(12):1244-1256.

[8]JUENGER M C G,WINNEFELD F,PROVIS J L,et al.Advances in alternative cementitious binders[J].Cem Concr Res,2011,41(12):1232-1243.

[9]MAHMOODZADEH F,CHIDIAC S E.Rheological models for predicting plastic viscosity and yield stress of fresh concrete[J].Cem Concr Res,2013,49(7):1-9.

[10]CHOUGNET A,PALERMO T,AUDIBERT A,et al.Rheological behaviour of cement and silica suspensions:Particle aggregation modeling [J].Cem Concr Res,2008,38(11):1297-1301.

[11]ZHANG Y R,KONG X M,HOU S S,et al.Study on the rheological properties of fresh cement asphalt paste[J].Cons Build Mater,2012,37(1):534-544.

[12]MUJUMDAR A,BERIS A N,METZNER A B.Transient phenomena in thixotropic systems[J].J.Non-Newtonian Fluid Mech,2002,102(2):157-178.

[13]ROUSSEL N.Steady and transient flow behavior of fresh cement pastes[J].Cem Concr Res,2005,35(9):1656-1664.

[14]ROUSSEL N.A thixotropy model for fresh fluid concretes:theory,validation and applications [J].Cem Concr Res,2006,36:1797-1806.

[15]WANG L J,TAN X Q,CAO M L.Study of Cement Flocculation[J].Concrete(in Chinese),2007(1):29-31.

[16]WALLEVIK J E,Rheological properties of cement paste:Thixotropic behavior and structural breakdown [J].Cem Concr Res,2009,39(1):14-29.

[17]MA K L,LONG G C,XIE Y J.Rheological properties of compound pastes with cement-fly ash-limestone powder[J].J Chin Ceram Soc,2013,41(5):582-587.

[18]PAPO A,PIANI L.Effect of various supeprlasticizers on the rheological properties of Portlnad cement pastes[J].Cem Concr Res,2004,34(11):2097-2101.

[19]MA K L,LONG G C,XIE Y J,et al.Rheological properties of compound pastes with cement-fly ash-limestone powder[J].J Chin Ceram Soc,2013,41(5):582-587.

[20]WANG D M,ZHANG L R,ZHANG W L,et al.Observation the multi-level flocculation structures of fresh cement paste by confocal laser scanning microscope[J].J Chin Electron Microsc Soc(in Chinese),2013,32(3):231-236.

[21]WANG Z M.The interface chemistry phenomena and rheological properties of“cement-water-superplaticizer”system(in Chinese,dissertation).Beijing:Beijing University of Technology,2006.

[22]ZHANG L R.Research and application of multi-level flocculation structures theoretical model of fresh cement paste(in Chinese,dissertation).Beijing:China University of Mining&Technology(Beijing),2012.

[23]FEYS D,VERHOEVEN R,SCHUTTER G D.Why is fresh self-compacting concrete shear thickening?[J].Cem Concr Res,2009,39(6):510-523.

[24]ROSQUOET F,ALEXIS A,KHELIDJ A,et al.Experimental study of cement grout:Rheological behavior and sedimentation[J].Cem Concr Res,2003,33(5):713-723.

[25]MILLS P.Non-Newtonian behaviour of flocculated suspensions[J].J Phys Lett,1985,46:301-309.

[26]MILLS P,SNABRE P.The fractal concept in the rheology of concentrated suspensions[J].Rheol Acta,1988,26:105-108.

[27]SNABRE P,MILLS P.Rheology of weakly flocculated suspensions of rigid particles[J].J Phys III,1997,6(12):1811-1834.

[28]SONNTAG R C,RUSSEL W B.Structure and breakup of flocs subjected to fluid stresses:II.Theroy[J].J Colloid Interf Sci,1987,115(2):378-389.

[29]PATEL P D,RUSSEL W B.A mean field theory for the rheology of phase separated or flocculated dispersions[J].Colloids Surf,1988,31:355-383.

[30]POTANIN A A.On the mechanism of aggregation in the shear flow of suspensions[J].J Colloid Interf Sci,1991,145(1):140-157.

[31]WESSEL R R,BALL R C.Fractal aggregates and gels in shear flow[J].Phys Rev,1992,46:3008-3011.

[32]POTANIN A A,ROOIJ R D,ENDE D V,et al.Microrheological modeling of weakly aggregated dispersions [J].J Chem Phys,1995,102:5845-5853.

[33]SNABRE P,HAIDER L,BOYNARD M.Ultrasound and light scattering from a suspension of reversible fractal clusters in shear flow[J].Eur Phys J,2000,1(1):41-53.