Simulation of VGT control based on charge oxygen concentration

2014-08-08ANXiaohui安晓辉ZHANGFujun张付军LIUBolan刘波澜CUITao崔涛

AN Xiao-hui(安晓辉), ZHANG Fu-jun(张付军), LIU Bo-lan(刘波澜), CUI Tao(崔涛)

(School of Mechanical Engineering, Beijing Institute of Technology, Beijing 100081, China)

Simulation of VGT control based on charge oxygen concentration

AN Xiao-hui(安晓辉), ZHANG Fu-jun(张付军), LIU Bo-lan(刘波澜), CUI Tao(崔涛)

(School of Mechanical Engineering, Beijing Institute of Technology, Beijing 100081, China)

A turbocharged diesel engine model was built with the GT-Power software, and experimentally verified. Then two different control variables for the control of the variable geometry turbocharger (VGT) were described, and their distinct effects on engine performance, i.e. NOxand soot emissions and fuel consumption, were simulated and compared on the basis of this model. The results showed that NOxemissions decreased obviously with the increase of exhaust gas recirculation (EGR) rate at constant boost pressure condition, but soot emissions and fuel consumption considerably increased. It was a good way to reduce NOxemissions without increasing fuel consumption and soot emissions when VGT was controlled to maintain the excess oxygen ratio unchanged as EGR rate increases.

diesel engine; exhaust gas recirculation (EGR); variable geometry turbocharger (VGT); engine control; oxygen concentration

Legislated emission limits for diesel engine are constantly reduced while there is a significant drive for good fuel economy at the same time. To meet the requirements, researchers across the world have been seeking more complex configurations like exhaust gas recirculation (EGR) systems and variable geometry turbochargers (VGT).

External exhaust gas recirculation is a well-known in-cylinder method to reduce NOxemissions, mainly because of the decreased flame temperature during combustion. However the inducted exhaust gas also reduces the oxygen content, which has a negative influence on soot emissions and fuel economy. To obtain good boost at all operation conditions and transient performance, variable geometry turbochargers are employed. In VGTs, an actuator adjusts the angle of guide vanes placed at the entrance of the turbine to guide the flow direction of the incoming exhaust gas. This allows large air flow rates and high efficiencies to be achieved at different pressure and temperature conditions, and makes engine get lower soot emissions and fuel consumption. Therefore EGR and VGT are often simultaneously equipped in modern direct injection (DI) diesel engine[1-2].

Since both EGR flow and turbine flow are driven by the exhaust gas, it is clear that there is a strong coupling between the two systems. Traditional control method ignores this coupling, and uses the VGT to control boost pressure and the EGR valve to control mass air flow or EGR rate[3-4]. This paper focuses on the selection of feedback variables for VGT. Two different control variables are compared to study their distinct effects on engine performance at various EGR rate using a GT-Power model.

1 Modeling

1.1 Description of the engine

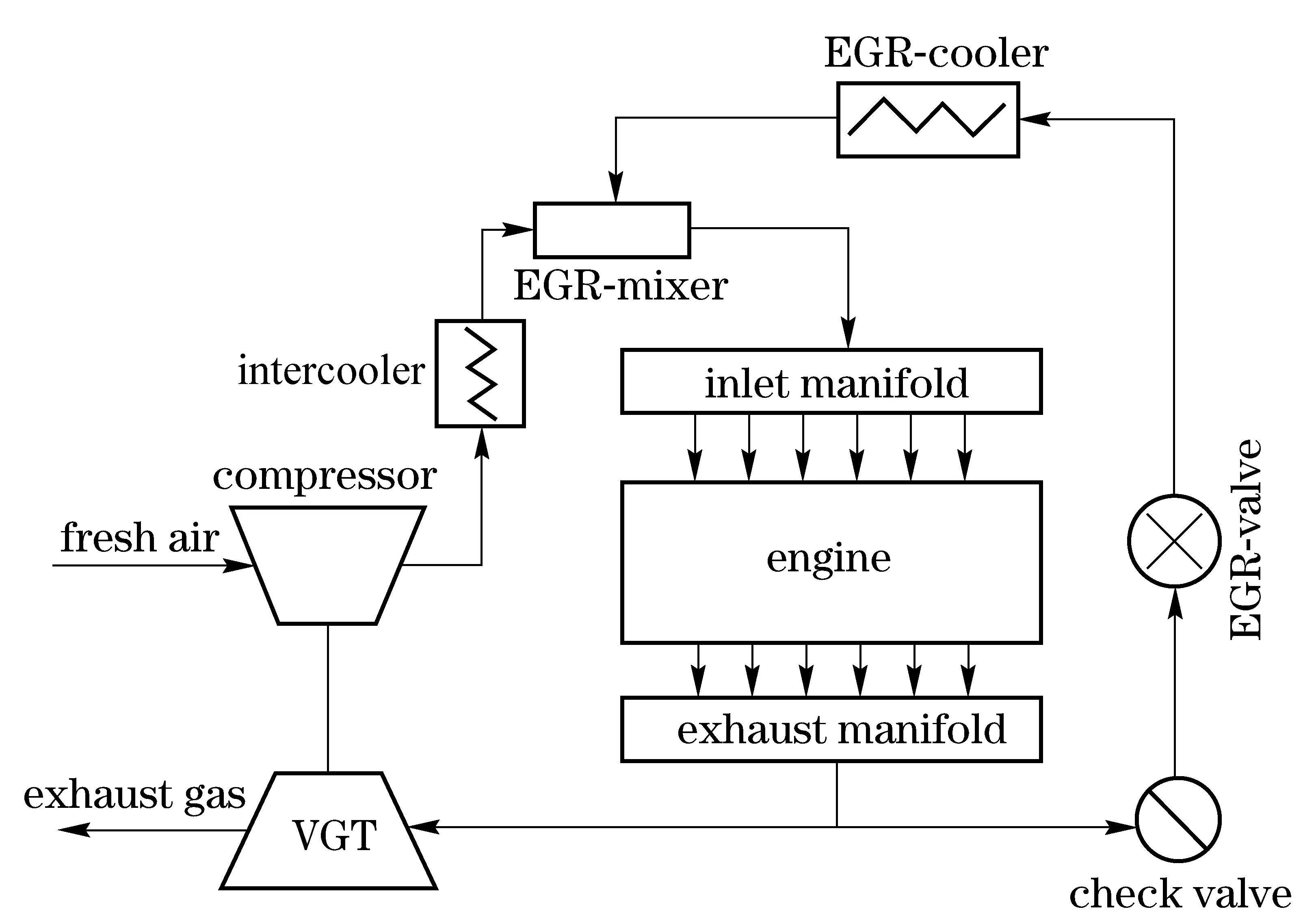

The engine used for the modeling is a water-cooled DI diesel engine, equipped with a cooled EGR circuit, a variable geometry turbine and an intercooler. Engine configuration is displayed in Fig.1. The EGR flow is inducted from the upstream of turbine to the downstream of the intercooler, called high-pressure EGR loop. Additionally check valves are used to prevent the backflow of the exhaust gas. Main specifications of the engine are given in Tab.1.

Fig.1 Engine configuration

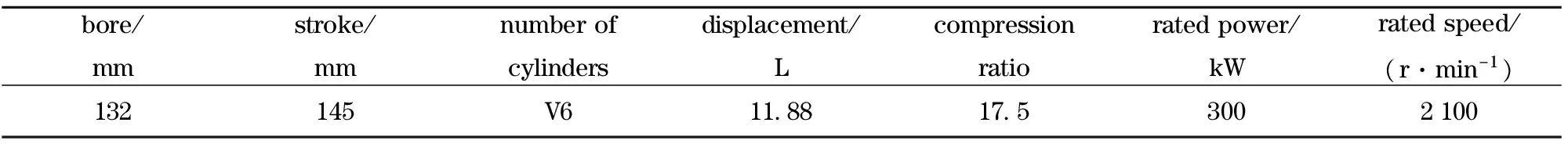

Tab.1 Specifications of the engine

1.2 Description of the model

GT-Power is a leading and one-dimensional engine simulation tool developed by the U.S. Gamma Technologies, Inc. It is suitable for analysis of a wide range of engine issues. A detailed engine mode is built with GT-Power.

The main purpose of the present work is not the building of a simulation model for DI heavy-duty diesel engines but its use to examine the effects of different control strategies for VGT on engine performance at various EGR rate. Therefore only the main theory of the model is given in this paper.

1.2.1 Combustion model

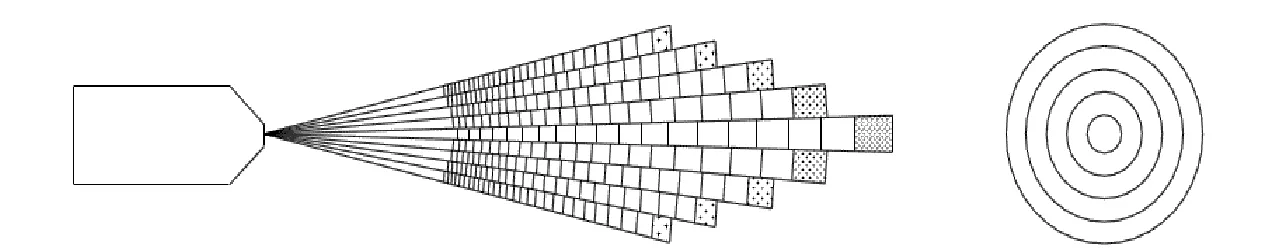

The combustion model used is a multi-zone phenomenological one where the fuel jet is divided into zones in the three dimensions: 5 radial zones and a maximum of 80 axial zones (see Fig.2).This description enables us to determine the distribution of thermal dynamic parameters inside the fuel jet that lead to the formation of pollutants and to examine the actual effect of EGR on pollutant emissions and engine performance.

Fig.2 Combustion model

1.2.2 NOxmodel

While nitric oxide (NO) and nitrogen dioxide (NO2) are usually grouped together as NOxemission, NO is the predominant oxide of nitrogen produced inside the engine cylinder. The NO emissions are calculated using the Extended Zeldovich mechanism as[5]

(1)

wherenNOis molar concentration of NO, the flame temperatureTis in Kelvin, the concentrations are in mol/cm3,CO2denotes chemical equilibrium concentration of oxygen, andCN2denotes chemical equilibrium concentration of nitrogen. It is obvious that high flame temperature and high oxygen concentrations result in high NO formation rates.

1.2.3 Soot model

In the present work a semi-empirical model is chosen to predict the rate of soot formation (namely Hiroyasu model). Soot is considered to form and oxidize inside each zone, so the net soot mass rate is given as[6]

(2)

Themassformationrateandthemassoxidationrateareestimatedas

(3)

(4)

wherethesubscriptfstandsforsootformation,thesubscriptoforoxidation;msis the mass of the net soot;msfis the mass of the formed soot;msois the mass of the oxidated soot;mfvis the mass of fuel vapor;Pcis the in-cylinder pressure,YO2is the oxygen molar fraction, andTis the flame temperature. The activation energies of soot formation and combustionEsfandEso, respectively, are 82 000 J/mol and 120 000 J/mol. The predicted soot concentrations are not particularly meaningful and just used to study the trends in the results.

Fig.3 shows the comparison between experimental and predicted maximum combustion pressure and brake torque at 1 300 r/min and 1 900 r/min respectively at different loads. As seen the model can predict the maximum pressure and brake torque accurately.

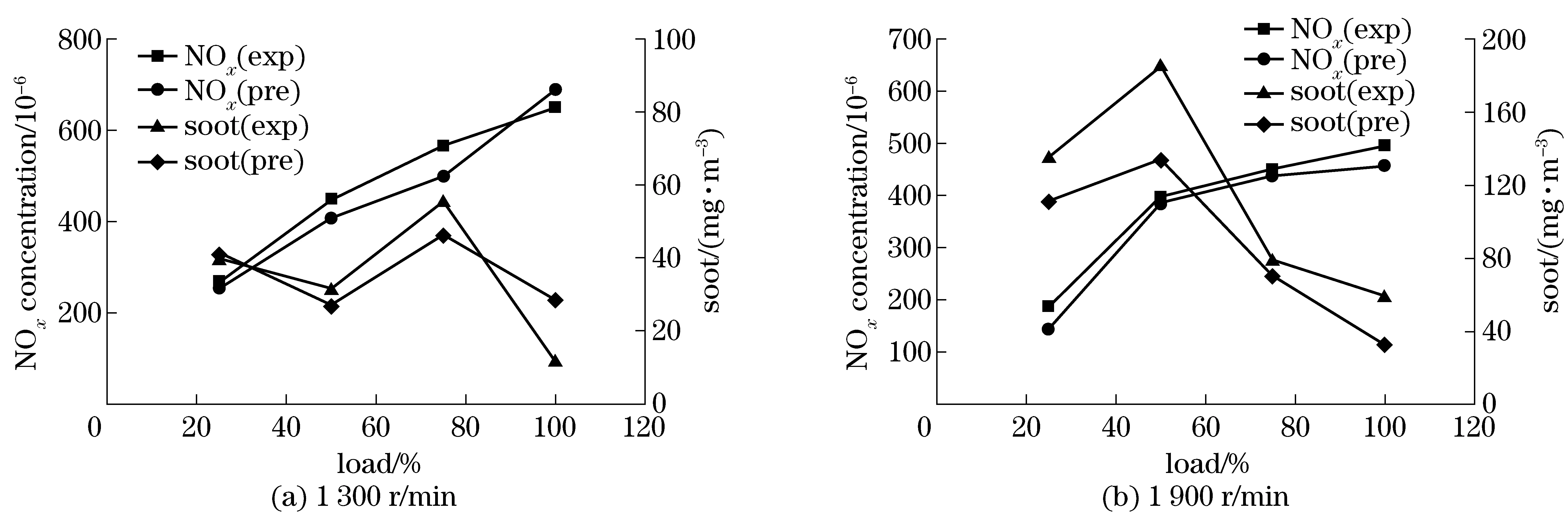

Fig.4 shows the comparison between experimental and predicted NOxand soot emissions vs. load at 1 300 r/min and 1 900 r/min. The NOxand soot are tested by MEXA-720NOxand AVL 415S Smoke Meter respectively. Particularly, it exhibits a satisfactory accuracy of the model in predicting NOxemissions. Comparing the measured and predicted values for soot we observe that the trend of soot formation with engine load is estimated well even though the difference, compared to NOx, is slightly higher.

The results given in Fig.3 and Fig.4 prove that model estimations are accurate enough for most of the engine operating conditions. Especially the model is useful to predict the trend of tailpipe emissions.

Fig.3 Predicted and experimental values of engine peak combustion pressure and torque for various loads

Fig.4 Predicted and experimental values of NOxand soot emissions vs. load without EGR

2 Simulation of different control variables

As is well known, EGR and VGT are effective technologies to solve economy and emissions issues in modern diesel engines. In this section, we use the EGR valve to control EGR rate, and the following control strategies of VGT are described, simulated and evaluated.

① The VGT is operated to maintain a constant boost pressure (p) at a fixed working condition, which means the gas mass introduced into the cylinder is almost unchanged. This is the traditional control method for VGT.

② The VGT is operated to increase boost pressure to keep the excess oxygen ratio (λo)constantatafixedworkingcondition.Thatmeanstheoxygenmassinductedintothecylinderisinvariable.Thespecificdefinitionoftheexcessoxygenratiois

(5)

whereminandmfare the mass of gas introduced into cylinders and the mass of fuel injected into cylinders respectively;Cinis the oxygen mass concentration of the intake charge gas;Cais the oxygen mass concentration of air, and αsisthestoichiometricair-fuelratio.

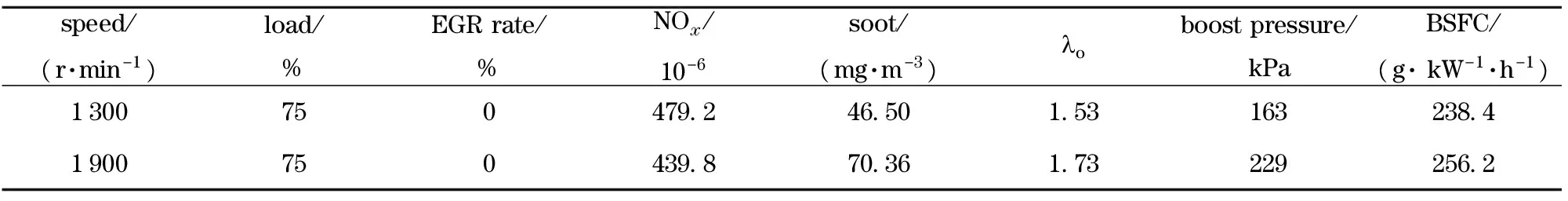

WefocusontwooperationpointstocarryonourresearchaslistedinTab.2.Themainpredicteddataarealsolisted.

Tab.2 Some main predicted data

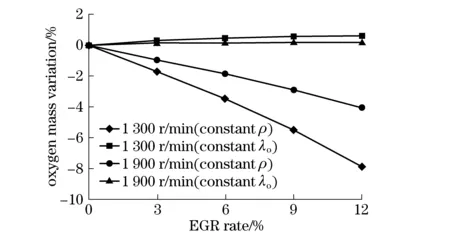

Fig.5 compares the effect of the two control strategies on NOxemission values as the EGR rate increases at two engine speeds of 1 300 r/min and 1 900 r/min at 75% load. It is observed that the increase of EGR rate at constant boost pressure leads to a serious reduction of NOxvalues. The reduction of NOxbased on percentage is similar for the two engine speeds examined.

When we maintain the excess oxygen ratio constant, a similar behavior is observed. The main difference is that the reduction percentage is slightly lower compared to constant boost pressure. The reason for this (shown as Fig.6) namely the slightly lower NOxreduction compared to the case of constant boost pressure, is the combined effect of the unchanged O2and the increased total gases inside the combustion chamber. Consequently, the mixing of oxygen and fuel is unchanged and the total heat capacity increases, resulting in the slightly lower NOxreduction[7].

Fig.5 Variation of NOxemissions vs. EGR rate for constant p and λo

Fig.6 Mass variation of oxygen inducted into cylinders vs. EGR rate for constant p and λo

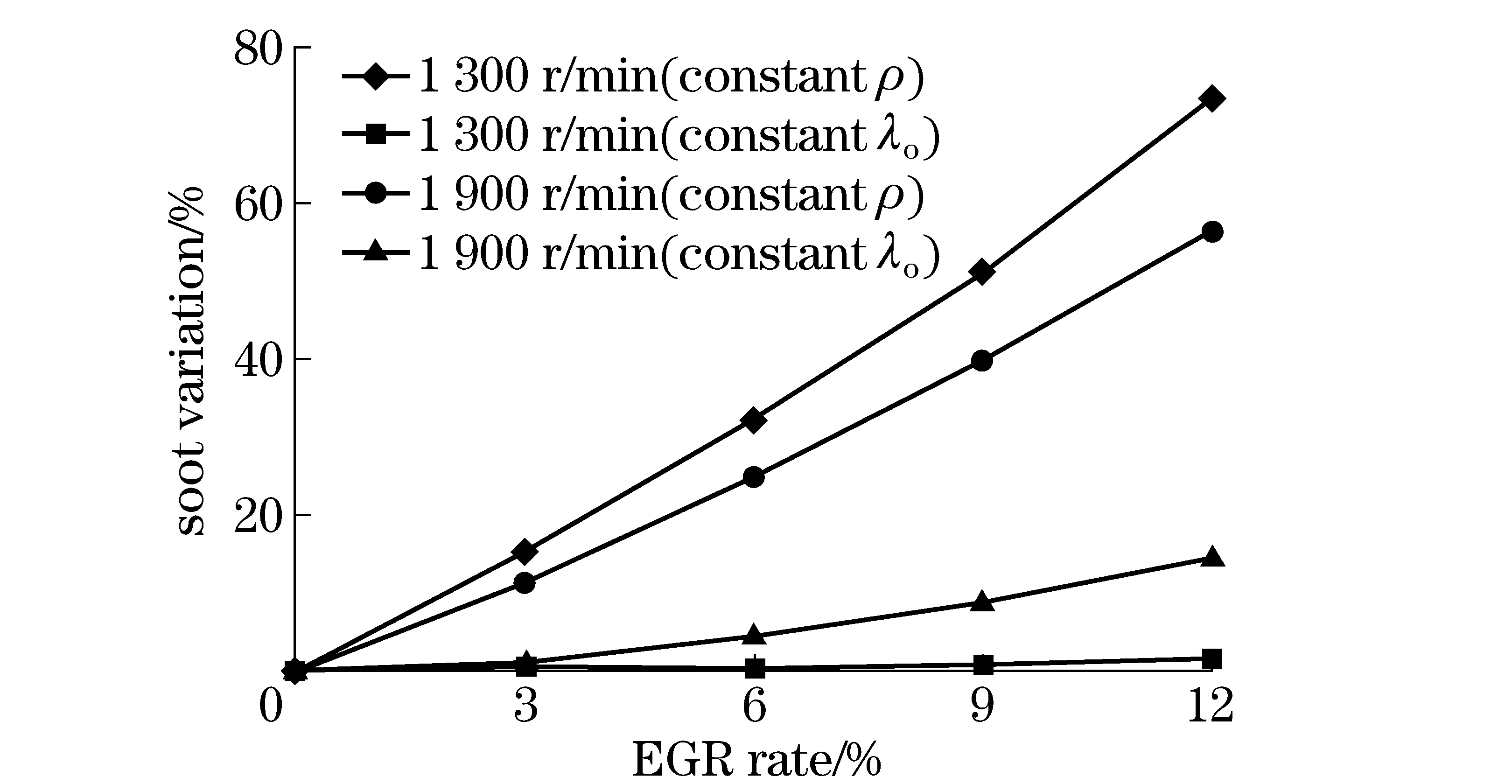

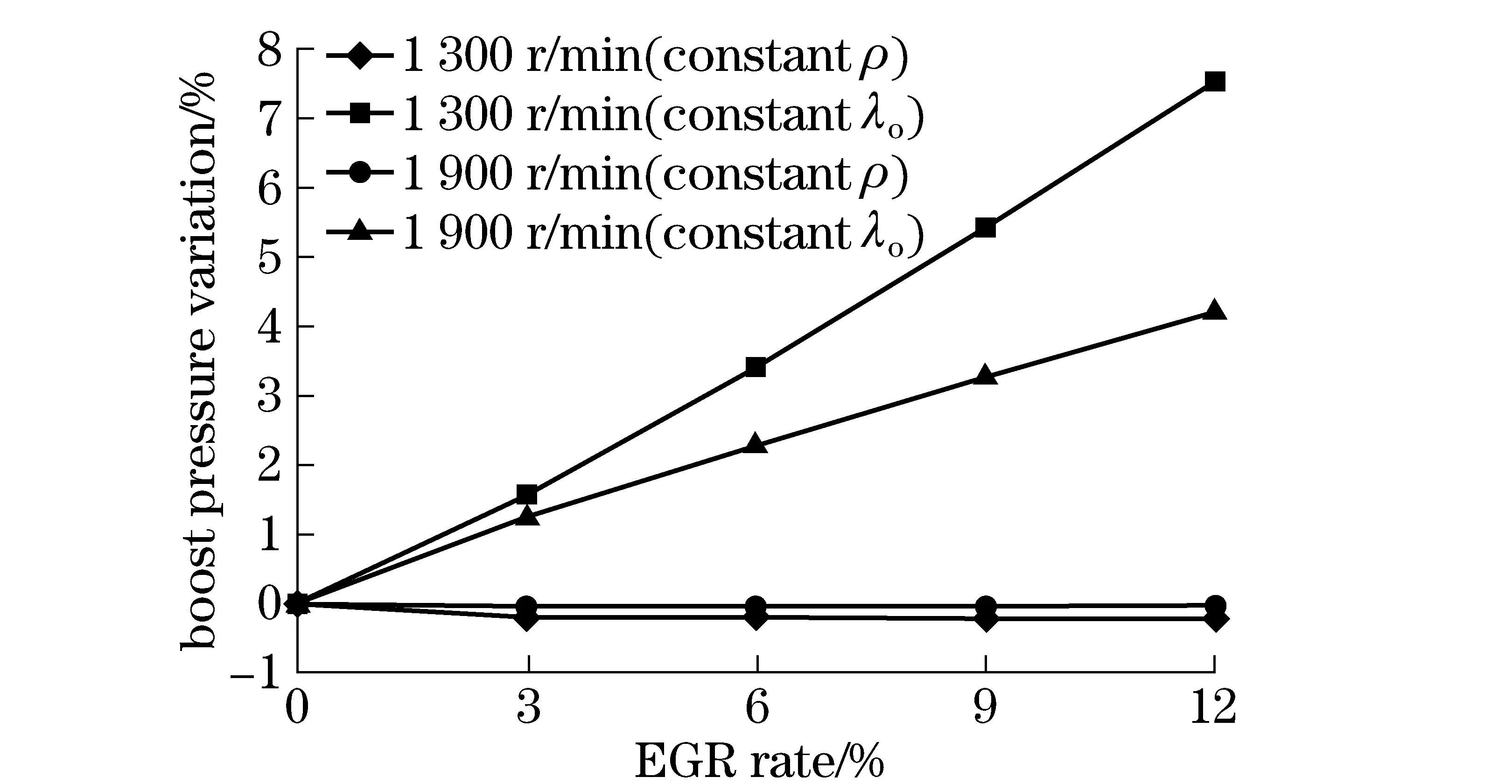

Fig.7 shows the corresponding results for soot emissions at the same simulated cases above with constant boost pressure and constant excess oxygen ratio. From the simulation results we can see soot emissions are considerably increased with the increase of EGR rate at constant boost pressure condition. The simulation results obtained are especially significant when using a constant excess oxygen ratio (by the increase of the boost pressure, see Fig.8). As seen in this case the relative increase of soot is extremely lower with the increase of EGR compared to constant boost pressure condition. The reason for the results is that the oxygen/fuel ratio inside the combustion chamber has a dominate effect on soot formation, a relation which has been clearly reported[8-9].

Fig.7 Variation of soot emissions vs. EGR rate for constant p and λo

Fig.8 Variation of boot pressure vs. EGR rate for constant p and λo

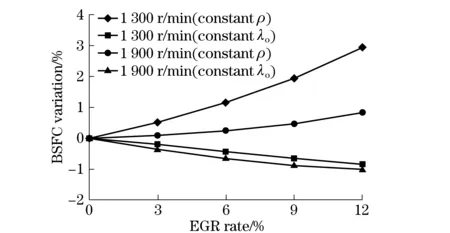

In Fig.9 it is given the simulation results of brake specific fuel consumption (BSFC) for constant boost pressure and excess oxygen ratio with the increase of EGR rate. As observed at constant boost pressure BSFC increases when increasing EGR percentage especially at high values of EGR. The main cause for decreasing brake thermal efficiency is attributed to decreased combustion work (i.e. indicated work), because of combustion deterioration due to lower combustion temperatures and smaller A/F ratio.

But when keeping the excess oxygen ratio constant we observe that BSFC decreases slightly as EGR increases due to the increased boost pressure. This behavior is the same at both of the simulated engine speeds. Thus maintaining the excess oxygen ratio unchanged overcomes the disadvantage caused by the use of EGR.

Fig.9 Variation of BSFC vs. EGR rate for constant p and λo

From the simulation above, we can see that it is a good way to inhibit deteriorations of soot emissions and BSFC by keeping the excess oxygen ratio constant when EGR rate increases. It only results in slightly lower NOxreduction, compared to the constant boost pressure condition. However, it should be noticed that VGT may not be able to increase boost pressure to keep excess oxygen ratio constant at higher EGR rate, because the increase of EGR may lead to an irremediable decrease of gas flow through the turbine.

3 Conclusions

The effects of the two VGT control variables on emissions and BSFC of the diesel engine with EGR were studied. Main conclusions are as follows:

① A simulation model was built with GT-Power software. The model is accurate enough for most of the engine operating conditions and is useful to predict the trend of tailpipe emissions.

② High reduction of NOxemissions can be obtained as the EGR rate increases when VGT is controlled to keep the boost pressure constant. But this is accompanied with an increase of soot emissions and BSFC.

③ It leads to a slightly lower reduction of NOxemissions rate at the constant excess oxygen ratio condition compared to the constant boost pressure condition as the increase of EGR. However this VGT control strategy inhibits the penalty of EGR on soot emission and BSFC. Further experimental investigations should be done to study and validate the effect of this control strategy on engine performance.

[1] Maiboom A, Tauzia X, Hetet J. Experimental study of various effects of exhaust gas recirculation (EGR) on combustion and emissions of an automotive direct injection diesel engine [J]. Energy, 2008, 33(1):22-34.

[2] Shi Xin, Ma Chaochen. Computation of the matching performance of diesel engine with variable geometryturbocharger [J].Journal of Beijing Institute of Technology, 2006, 15(4):379-383.

[3] Nieuwstadt M J, Kolmanovsky I V, Moraal P E. Coordinated EGR-VGT control for diesel engines: an experimental comparison, SAE paper 2000-01-0266 [R]. Detroit, USA: Society of Automotive Engineering, 2000.

[4] Stefanopoulou A G, Kolmanovsky I. Control of variable geometry turbocharged diesel engines for reduced emissions [J]. IEEE Transactions on Control Systems Technology, 2000, 8(4): 733-739.

[5] Heywood J B. Internal combustion engine fundamentals [M]. New York: McGraw-Hill, Inc., 1988:570-577.

[6] Arsie I, Pianese C, Sorrentino M. Effects of control parameters on performance and emissions of HSDI diesel engines [J]. Oil & Gas Science and Technology, 2007:62(4):457-469.

[7] Kouremenos D A, Hountalas D T. The effect of EGR on the performance and pollutant emissions of heavy duty diesel engines using constant and variable AFR, SAE paper 2001-01-0198[R]. Detroit, USA: Society of Automotive Engineering, 2001.

[8] Desantes J M, Arrègle J, Molina S. Influence of the EGR rate, oxygen concentration and equivalent fuel/air ratio on the combustion behavior and pollutant emissions of a heavy-duty diesel engine, SAE paper 2000-01-1813[R]. Detroit, USA: Society of Automotive Engineering, 2000.

[9] Ladommatos N, Abdelhalim S, Zhao H. The effects of exhaust gas recirculation on diesel combustion and emissions [J].International Journal of Engine Research, 2000, 1(1):107-126.

(Edited by Cai Jianying)

2013- 01- 26

Supported by Diesel Engine Development Program of MIIT (DEDP-1004); Natural Science Foundation of BIT(3030012211428)

TK 421.8 Document code: A Article ID: 1004- 0579(2014)02- 0172- 06

E-mail: liubolan@bit.edu.cn

猜你喜欢

杂志排行

Journal of Beijing Institute of Technology的其它文章

- Expert ranking method based on ListNet with multiple features

- Investigating fatigue behavior of gear components with the acoustic emission technique

- Contour tracking using weighted structure tensor based variational level set

- Consensus problem of multi-agent systems under arbitrary topology

- One-piece coal mine mobile refuge chamber with safety structure and less sealing risk based on FEA

- Three-dimension micro magnetic detector based on GMI effect