The Current Situation of the Study on Twisted Tape Inserts in Pipe Exchangers

2014-07-30ChangzhongManChongWangandJinyuYao

Changzhong Man, Chong Wang and Jinyu Yao

Institute of Internal Combustion Engine, Dalian University of Technology, Dalian 116024, China

1 Introduction1

Insertion of twisted tapes into a tube provides a simple passive technique for enhancing the convective heat transfer by introducing swirls into the bulk flow and by disrupting the boundary layer at the tube surface due to repeated changes in the surface geometry. This means that these types of tapes induce turbulence and superimpose vortex motion(swirl flow) causing a thinner boundary layer and consequently resulting in a higher heat transfer coefficient and Nusselt number due to repeated changes in the twisted tape geometry. However, the pressure drop in the tube is higher for a higher friction factor. So an optimal design is needed to achieve the best heat transfer performance with less friction loss.

Twisted tapes can be classified in several categories (Liu and Sakr, 2013).

Typical twisted tapes:these tapes have a length equal to the length of the exchanger tube.

Varying length and width twisted tapes:these tapes have a shorter length than the exchanger tube, and a smaller width than the tube’s inside diameter, or different pitches.

Twisted tapes with alternate axis:the axis of the tapes alternate in a clockwise and counter-clockwise direction.

Twisted tapes with modification in the peripheral region:twisted tapes with cuts in the peripheral region.

Twisted tapes with modification on the surface:add wire nails or make the center wings on the surface of the tapes.

Multiple twisted tapes:more than one twisted tape is coupled and used in one heat exchanger tube.

Twisted tapes with a rod and varying spacer:twisted tapes with a rod and spacer are used to enhance the heat transfer.

Twisted tapes with wings:wings are attached to the twisted tapes to achieve more augmentation.

For the first six kinds of tapes, there is a more simple structure and they can be manufactured and installed more easily, so they fit the reforming of the traditional heat exchanger better. Hence this paper will focus more attention on these twisted tapes.

2 Twisted tape devices

2.1 Typical twisted tapes

2.1.1 Twisted tapes with full length

Research was carried out on the effects of twisted tape inserts on heat transfers in a tube (Noothonget al., 2006).The experimental data showed that the maximum Nusselt numbers for using twisted tapes had twisted ratios (y) of 5.0 and 7.0 which are 188% and 159%, respectively, higher than that for the plain tube. The friction factors were 3.37 and 2.94 times, fory=5.0 and 7.0 respectively in comparison with the plain tube. Another conclusion reached was that the heat transfer enhancement coefficient, Nusselt number and friction factor all increased with the decrease of the twist ratio.

Hanet al.(2012) studied the heat transfer and friction characteristics of the tube with the twisted tape inserts with different widths and twist ratios. The results showed that with the same width, a higher heat transfer efficiency and friction loss can be obtained with a lower twist ratio. Patil and Babu (2014a) also did research on the effects of twisted tape on a laminar flow in a square tube and compared the results with those of a circular tube. The results indicated that the friction factor and Nusselt number for a square duct were about 1.90 and 2.10 times respectively higher than those of a circular tube, which can be explained by the fact that the square duct offers a higher surface area than that of the circular tube and induces a higher degree of swirl.

2.1.2 Twisted tapes with varying length and width twisted tapes

In order to reduce excessive pressure drops and to save materials, reduced width or length twisted tapes were introduced by the researchers.

Al-Fahedet al.(1999) first studied the pressure drop and heat transfer characteristics of the tube with twisted tape inserts in a laminar flow. The results indicated that the effects of the width were directly related to the twist ratio.For the twist ratios of 3.6 and 5.4, the tight-fit tape gives higher values for the heat transfer than the loose-fit tape. Fory=7.1, the loose-fit tape geometry gives a higher value of heat transfer than the tight-fit one. Similar behavior is seen for the pressure drop data where the tight-fit tape for both they=3.6 and 5.4 twist ratios were higher than the loose-fit tape. For the twist ratio of 7.1, the behavior is different,where the loose-fit pressure drop data were higher. The loose-fit is recommended to be used in the design of the heat exchanger where low twist ratios and high pressure drop situations are expected since it is easier to install and remove for cleaning purposes. Otherwise, the tight-fit tape will give a better performance over the loose-fit tape.

Continued research was carried out by Saradaet al.(2010). The experimental data showed that the overall enhancement ratio of the tubes with full width twisted tape inserts is 1.62 for the full width of 26 mm and 1.39 for the reduced width of 22 mm twisted tape insert. However, 61%material savings could be obtained for the reduced width of 22 mm and performance is 1.32–1.39 times better as compared to the plain tube. So the authors suggested that from the consideration of enhanced heat transfer and savings in pumping power and in tape material cost, reduced-width tape inserts were seen to be more attractive for enhancing turbulent flow heat transfer in a horizontal circular tube.

Eiamsa-ardet al.(2009) compared the heat transfer efficiency of the twisted tapes with varying lengths in an experiment. The experimental data indicated that: 1)compared with the full-length tapes, the short-length tapes with the ratios (the length of tapes to the length of the tube)of 0.29, 0.43 and 0.57 perform 14%, 9.5%, 6.7% lower heat transfer values and 21%, 15.3%, 10.5% lower friction factor values, respectively; 2) the heat transfer enhancement coefficient of the tube with the short-length tape insert was lower than that of the full-length one; 3) the heat transfer enhancement coefficient is higher than the unity only for the full-length tape insert at a low Reynolds number, which can be explained by the fact that the twist ratio was too low.

Eiamsa-ardet al.(2012) introduced non-uniform twisted tapes, including twisted tapes with sequentially increasing twist ratios (SL), twisted tapes with sequentially decreasing twist ratios (LS), twisted tapes with repeatedly increasing-decreasing twist ratios (SL/SL), twisted tapes with repeatedly decreasing-increasing twist ratios (LS/LS),twisted tapes with intermittently increasing-decreasing twist ratios (SL→LS) and twisted tapes with intermittently decreasing-increasing twist ratios (LS→SL). The results showed that SL and LS generate swirl flows with monotonically increasing or decreasing swirling intensity,resulting in a lower Nusselt number as compared with the other four non-uniform twisted tapes. SL/SL and SL→LS give higher heat transfer enhancement coefficients than the other four non-uniform twisted tapes. Over the range investigated, SL/SL offered the maximum thermal performance factor of around 1.03. However, the heat transfer characteristics of SL/SL and LS/LS, SL→LS and LS→SL would be the same if the test section was lengthened. Patil and Babu (2014b) also performed an experimental study on the effects of increasing and decreasing order twisted tapes for a laminar flow in a square duct. The results showed that the heat transfer enhancement coefficient in the duct with an increasing order twisted tape was almost the same as that fitted with a decreasing order twisted tape, which can be explained by the fact that the increasing order twisted tape induced a strong swirl at the beginning and a weak swirl at the end of the test section and vice versa for the decreasing order twisted tape.

In a word, the full length twisted tape always has the best heat transfer enhancement efficiency; the effects of the width are directly related to the twist ratio; with the same twist ratio, the full width twisted tape has the best heat transfer enhancement coefficient while the reduced-width twisted tape can save pumping power and tape material cost.

2.2 Twisted tapes with an alternate axis

On the basis of the peripherally-cut twisted tape (PC)(Eiamsa-ardet al., 2010a), Seemawute and Eiamsa-ard(2010) introduced the peripherally-cut twisted tape with an alternate axis (PC-A). The obtained results showed that the heat transfer enhancement coefficients were varied between 0.86 and 1.25 for the PC-A, 0.88 and 1.11 for the PC, and 0.87 and 1.02 for the typical twisted tape. Comparatively,the tube with the PC-A provided about 5.3% and 7% higher mean heat transfer enhancement coefficients than the PC and typical twisted tape, respectively. The authors suggested that the geometry of the PC-A was more appropriate for practical use than the others from the viewpoint of energy as well as operating cost savings.

Eiamsa-ard and Promvonge (2010) carried out an experiment on the effects of the clockwise and counterclockwise twisted tape (C-CC). The results revealed that the C-CC twisted tapes provide a higher heat transfer enhancement coefficient and friction factor than those of the typical twisted one or the plain tube in the similar operating conditions. This can be explained by the fact that with C-CC twisted tape inserts the periodic change of the swirl direction and also the strong collision of the recombined streams behind the changing location lead to superior chaotic mixing and better heat transfer, as compared with the typical twisted tape. In addition, the C-CC tapes with a twist angle of 90°provide better heat transfer enhancement coefficients than those with twist angles of 30°and 60°.

It can be concluded from the experiments that the alternate axis can induce better heat transfer enhancement coefficients, especially when it is combined with peripheral cuts or other modifications. And the most effective twist angle is 90°.

2.3 Twisted tapes with modifications

2.3.1 Modification in the peripheral region

Many modifications can be done in the peripheral region of a twisted tape; hence researchers have carried out a lot of researches concerning this.

Murugesanet al. (2010a, 2011a, 2011b) investigated experimentally on the heat transfer and pressure drop characteristics in the tubes equipped with a square-cut twisted tape (SCT), trapezoidal-cut twisted tape (TCT) and v-cut twisted tape (VCT), respectively. In the study on the SCT twisted tapes, the mean Nusselt numbers for the tube equipped with the SCT twisted tapes with twist ratios of 2.0,4.4 and 6.0, were respectively 1.81, 1.60 and 1.40 times of those for the plain tube and 1.08, 1.067 and 1.055 times of those for the tube equipped with the typical twisted tape.The mean friction factors for the SCT with twist ratios of 2.0,4.4 and 6.0 were respectively, 3.81, 3.27 and 2.83 times of those for the plain tube and 1.09, 1.12 and 1.15 times of those for the tube with typical twisted tape inserts. Over the range of the Reynolds number considered, the heat transfer enhancement coefficients are around 1.02 to 1.27 in the tube equipped with SCT and 1.0 to 1.2 in the tube equipped with typical twisted tape (Murugesanet al., 2010a). Similar results were obtained in the investigations of the TCT and VCT. Over the same range of Reynolds numbers considered,the average heat transfer enhancement coefficients in the tube equipped with the typical tape were 1.15, 1.06 and 1.02 and in the tube equipped with TCT were 1.19, 1.07 and 1.03 respectively for the twist ratios of 2.0, 4.4 and 6.0(Murugesanet al., 2011a). With the use of VCT, heat transfer enhancement coefficients are in a range between 1.23–1.27, 1.15–1.11 and 1.11–1.07 respectively for the twist ratios of 2.0, 4.4 and 6.0, while the numbers for the use of the typical twisted tape are 1.18–1.16, 1.07–1.05 and 1.03–1.01. And the mean heat transfer enhancement coefficients for VCT withDR=0.43 andWR=0.34 are higher than those offered by the tape withDR=0.34 andWR=0.34,andDR=0.34 andWR=0.43 of around 1.65% and 2.05%respectively, which means the influence of the depth ratio is more dominant than that of the width ratio (Murugesanet al.,2011b). It can be seen from the aforementioned data that the heat transfer enhancement coefficients for all modifications are higher than one. This means the effect on heat transfer is more dominant than that on the friction factor. So they can be used in place of typical twisted tapes to reduce the size of heat exchangers.

Different from the other researchers, Saha (2011) carried out an experiment by using square and rectangular ducts with transverse ribs and twisted tapes with and without oblique teeth. The results indicated that, for all types of twisted tapes, both the friction factor and the Nusselt number of the tapes with oblique teeth were higher than those of the tapes without oblique teeth. Both the friction factor and the Nusselt number increase with the increase in the tooth’s horizontal length and tooth angle. Furthermore,the effect of the oblique teeth was more prominent on the friction than on the Nusselt number, because the hydrodynamic boundary layer is more affected than the thermal boundary layer.

Eiamsa-ardet al.(2010a) introduced a peripherally-cut twisted tape (PCT). The results revealed that the use of PCTs offered heat transfer enhancement coefficients in a range between 2.28 and 4.88 in the laminar region and around 0.88 and 1.29 in the turbulent region, which were higher than those for the plain tube with typical twisted tapes of 1.93 to 3.37 in the laminar region and 0.87–1.01 in the turbulent region. In addition, the Nusselt number,friction factor, as well as the heat transfer enhancement coefficient were found to be increased with the increasing tape depth ratio and decreasing tape width ratio, and the influence of the depth ratio was more dominant.

2.3.2 Modification in the surface

Eiamsa-ardet al.(2010b) combined the modification of the center wings with the alternate axis. The investigation included the twisted tape with the wing (WT) alone, the twisted tape with alternate axes (AT) alone and the twisted tape with the center wing and alternate axes (WAT). The results revealed that both the Nussel number and friction factor increased with the increase of the angle of attack. The mean values of the heat transfer and heat enhancement provided by WAT with an angle of 74°were respectively 7.8%, 4.9% and 24% higher than those of the tube with WT,AT and the typical twisted tape. This means the twisted tape with the wing and alternate axes is the most efficient.

Rahimiet al.(2010) carried out an experiment and CFD studies on heat transfer and friction factor characteristics in a tube fitted with modified twisted tapes, including a perforated twisted tape, notched twisted tape and jagged twisted tape. The results showed that all twisted tapes except for the jagged twisted tape not only had no positive effect on the heat transfer enhancement but also reduced its values.By using the jagged twisted tape, maximum increases of 31% and 22% was reduced in the Nusselt number and the heat transfer enhancement coefficient, respectively, as compared with those that used the typical ones.

Murugesanet al. (2010b) introduced a twisted tape with wire nails. The results indicated that the use of twisted tape with wire nails offered heat transfer enhancement coefficients in the range of 1.27–1.33, 1.12–1.16 and 1.06–1.11 respectively for twist ratios of 2.0, 4.4 and 6.0. At the higher Reynolds numbers, the offered heat transfer enhancement coefficients for twist ratios of 2.0, 4.4 and 6.0 respectively were 6.2%, 8.1% and 13.3% higher than the plain tube and 3.5%, 4.7% and 7% higher than the typical twisted tapes.

Leiet al. (2012) did numerical simulations to study the fluid flow and heat transfer characteristics of a tube with staggered twisted tapes with central holes. Compared with the tube equipped with the typical twisted tape, the tube equipped with staggered twisted tapes with central holes offered higher a Nusselt number and friction factor with the values of 34.1%–46.8% and 84%–92%, respectively. The computed results indicated that the tube with the staggered twisted tape offered much higher heat transfer enhancement coefficients than those with the typical twisted tape, which means that the integrated performance of the tube with modified twisted tapes was superior to that of the tube with the typical twisted tapes.

To balance the heat transfer and pressure drop, the perforated twisted tape (PTs) was proposed by Thianponget al.(2012). The data results showed that in the range studied,PTs consistently provide higher Nusselt numbers than the typical twisted tapes due to the extra fluid turbulence around the tube wall caused by the holes on the tapes. The Nusselt number increases with the decrease of the twisted ratio and pitch ratio of the tapes. For the range studied, the twisted tape with pitch ratios (s/W) of 0.4, 0.6 and 0.8 respectively enhance the heat transfer rate up to 77.5%, 53% and 48%over the plain tube. The Nusselt number also increases in a way with the increase of the perforation hole diameter. An average friction factor generated by PTs is found to be around 24% higher than that induced by typical twisted tapes. The friction factor increases with the decrease of the twisted ratio, pitch ratio and perforation hole diameter ratio.The results revealed that a smaller pitch ratio can offer higher heat transfer enhancement coefficients, which varied between 0.94–1.07, 0.91–1.05 and 0.9–1.03 fors/W=0.4, 0.6 and 0.8, respectively. A smaller perforation hole diameter ratio of 0.11 can provide higher heat transfer enhancement coefficients, which are 1.7%–2.1% and 0.8%–1.3% higher than those of 0.14 and 0.17, respectively. Bhuiyaet al.(2013a) also did experimental research on the thermohydraulic characteristics of a circular tube with perforated twisted tapes with four different porosities. The results demonstrated that the Nusselt number, friction factor and heat transfer enhancement coefficients obtained from the tube with the perforated twisted tape inserts were 340%,360% and 59% higher than those of the plain tube values,respectively and the heat transfer performance obtained for the tube with perforated twisted tape inserts of different porosities was found to be 28%–59% higher than those of the plain tube values.

Sahaet al. (2012) studied on the heat transfer characteristics of the laminar flow through a circular tube having wire coil inserts and fitted with center-cleared twisted tape. The results showed that both the Nusselt number and friction factor decrease with the increase of the center-clearance diameter initially. But forc=0.6, the Nusselt number significantly decreased while the friction factor did not decrease appreciably. Therefore,c>gt;0.4 was not recommended. The combined use of wire coil inserts and twisted tape offered a 15%–25% higher friction factor and a 45%–65% higher Nusselt number as compared with the separate case of wire coil inserts or twisted tape, so the center-cleared twisted tape (appropriate clearance value) in combination with wire coil inserts was recommended.

Eiamsa-ardet al. (2013a) introduced three kinds of twin delta wings twisted tape (TTW). All these three kinds of twisted tape offer a higher Nusselt number and friction factor than the typical twisted tape with the values of 103%,84.4%, 90.8%, and 56%, 46.6%, 51.4%, respectively. Both the Nusselt number and the friction factor increase with the decrease of the wing tip angle. The heat transfer enhancement coefficients provided by the twin delta-winged twisted tape in the counter flow arrangement (TTW-up),twin delta-winged twisted tape in the co-flow arrangement(TTW-down), and the opposite winged twisted tape (TTW-o)were increased with the decrease of the wing tip angle and the highest values were 1.26, 1.17, and 1.20, respectively.

2.4 Multiple twisted tapes

Eiamsa-ardet al. (2013b) conducted research on the heat transfer enhancement in a heat exchanger with a coupling twisted tapes insert (CTT). The comparison between the results of the co-CTTs, counter-CTTs and typical twisted tapes showed that, both the co-CTTs and counter-CTTs offered significantly higher Nusselt numbers, which were 69.9% and 85.5% higher than those of the plain tube. The Nusselt numbers in the tube equipped with the counter-CTTs were 5.3%–14.1% higher than those in the tube with the co-CTTs. The Counter-CTTs can induce a higher friction factor than the co-CTTs and typical twisted tapes. The results also revealed that the counter-CTTs offer higher heat transfer enhancement coefficients with numbers of 4.7% and 5.8% over the co-CTTs and the typical twisted tapes respectively. As a result, the counter-CTTs are recommended by the authors.

Based on the study regarding coupling twisted tapes,Bhuiyaet al. (2013b) carried out an experimental investigation of the influence of triple twisted tapes on thermal characteristics. According to the experimental results, the tube with the triple twisted tape inserts obtained 1.73 to 3.85 times a higher Nusselt number than those of the plain tube, and the values of the friction factor were 1.109 1 to 4.2. The results also showed that a smaller twist ratio led to a higher heat transfer enhancement coefficient and the enhancement efficiency in the tube fitted with triple twisted tape inserts was 1.10 to 1.44 times higher than the plain tube values at a constant blower power.

2.5 Other modified twisted tapes

Besides the aforementioned modified twisted tapes, there are other modified ones including regular space twisted tapes (Sahaet al., 2001), twisted tapes with alternate-axes and triangular, rectangular and trapezoidal wings(Wongchareea and Eiamsa-ard, 2011), dual twisted tapes(Eiamsa-ardet al., 2010c), perforated helical twisted tapes(Nananet al., 2014),etc. These modified twisted tapes have more complicated structures and are not easily manufactured and installed, which may ultimately induce more costs.Furthermore, they are not more efficient than other kinds of twisted tapes.

3 Correlations between the Nusselt number and friction factors

Based on these experimental data, correlations between the Nusselt number and friction factor were established by these researchers. All these correlations provided theoretical fundamentals for further study.

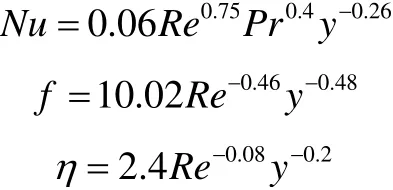

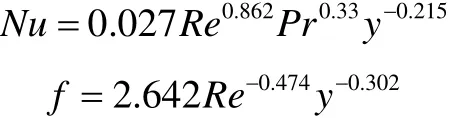

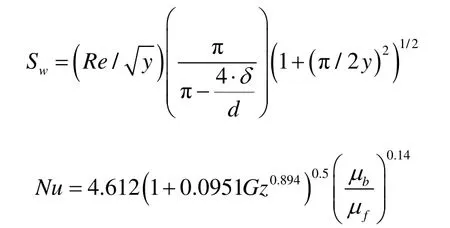

Correlations between the Nusselt number, friction factor and heat transfer enhancement coefficient (η) of the tube with a single twisted tape insert were established by Eiamsa-ardet al.(2010c). These are expressed as follows and can be used in different twisted ratios:

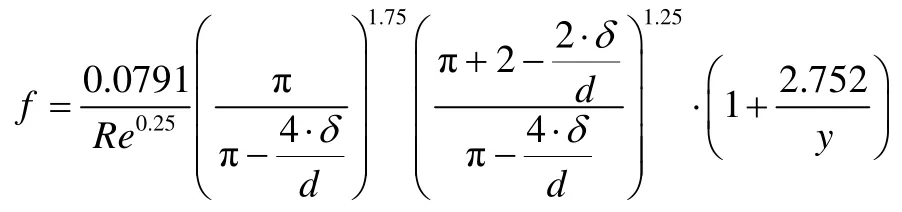

Murugesanet al. (2010b) also developed the following correlations between the Nusselt number and friction factor based on their experimental results:

These aforementioned correlations were developed from specific experimental conditions and thereby they are applicable to finite instances.

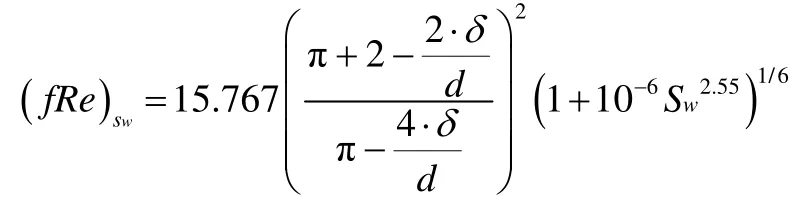

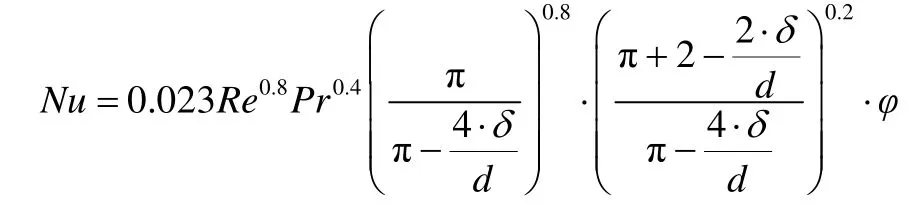

Manglik and Bergles (1993a, 1993b) established correlations between the Nusselt number and friction factor,at a uniform wall temperature or uniform heat flux conditions, which can be written as follows:

Laminar flow correlations:

whereSwis the swirl parameter, which can be defined as:

Turbulent flow correlations:

where

n=0.18 for liquid heating andn=0.30 for liquid cooling.m=0.45 for gas heating andm=0.15 for gas cooling.Dis inside diameter of test tube;δthickness of tape;Wwidth of tape;ReReynolds number;NuNusselt number;PrPrandtl number;GzGrzetz number;ffriction factor;ηheat transfer enhancement coefficient.

These correlations developed by Manglik and Bergles gave a rather wide performance envelope for typical conditions and were used in many researches to evaluate the deviation.

4 Conclusions

According to the above researches, we can summarize the conclusions as follows:

1) Twisted tapes, especially full length and tight-fit twisted tapes can enhance heat transfer effectively. For example, the use of twisted tape with the twist ratios of 5.0 and 7.0 can induce 188% and 159% higher Nusselt numbers respectively. But loose-fit twisted tapes can save materials prominently with little influence on heat transfer.

2) Different modifications can affect heat transfer and friction factor characteristics differently. The twisted tapes with a center wing and alternate axes can cause the highest heat transfer enhancement coefficient, which is 24% higher than the typical twisted tape.

3) Twisted tapes perform better in lowReconditions.Take PCTs for example, the use of PCTs offered heat transfer enhancement coefficients with the values of 2.28–4.88 in the laminar flow, but only 0.88–1.29 in the turbulent flow. But if the pressure drop is not concerned,twisted tapes are effective in both the laminar flow and in the turbulent flow.

4) Twisted tape performed better in the square tube. The study indicated that the friction factor and Nusselt number for a square duct were about 1.90 and 2.10 times higher than those in a circular tube in the laminar flow regions.

5) Twisted tapes also have negative effects that can cause higher pressure drops. To balance the heat transfer and friction factor, some researchers have conducted studies and have recommended modified twisted tapes, like perforated twisted tapes, which can result in a slightly higher heat transfer enhancement coefficient. Further studies should put emphasis on this issue.

6) Despite this, a lot of research has been done in the past several years, and it has been discovered that there is not a lot of practical applications for heat exchangers. Most heat exchangers are traditional ones now, especially in China.Twisted tapes have great potential and profound implications if they can be used in traditional heat exchangers.

Al-Fahed S, Chamra L, Chakroun W (1999). Pressure drop and heat transfer comparison for both microfin tube and twisted-tape inserts in laminar flow.Experimental Thermal and Fluid Science, 18, 323-333.

Bhuiya M, Chowdhury M, Saha M, Islam MT (2013a). Heat transfer and friction factor characteristics in turbulent flow through a tube fitted with perforated twisted tape inserts.International Communications in Heat and Mass Transfer, 46,49-57.

Bhuiya M, Chowdhury M, Shahabuddin M, Saha M, Memon LA(2013b). Thermal characteristics in a heat exchanger tube fitted with triple twisted tape inserts.International Communications in Heat and Mass Transfer, 48, 124-132.

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2009).Convective heat transfer in a circular tube with short-length twisted tape insert.International Communications in Heat and Mass Transfer, 36, 365-371.

Eiamsa-ard S, Promvonge P (2010). Performance assessment in a heat exchanger tube with alternate clockwise and counter-clockwise twisted tape inserts.International Journal of Heat Transfer and Mass Transfer, 53, 1364-1372.

Eiamsa-ard S, Seemawute P, Wongcharee K (2010a). Influences of peripherally-cut twisted tape insert on heat transfer and thermal performance characteristics in laminar and turbulent tube flows.Experimental Thermal and Fluid Science, 34, 711-719.

Eiamsa-ard S, Wongcharee K, Eiamsa-ard P, Thianpong C (2010b).Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of centre wings and alternate-axes.Experimental Thermal and Fluid Science, 34, 1151-1161.

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2010c).Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem.International Communications in Heat and Mass Transfer, 37, 39-46.

Eiamsa-ard S, Wongcharee K, Promvonge P (2012). Influence of nonuniform twisted tape on heat transfer enhancement characteristics.Chemical Engineering Communications, 199,1279-1297.

Eiamsa-ard S, Nuntadusit C, Promvonge P (2013a). Effect of twin delta-winged twisted-tape on thermal performance of heat exchanger tube.Heat Transfer Engineering, 34(15), 1278-1288.

Eiamsa-ard S, Nanan K, Thianpong C, Eiamas-ard P (2013b).Thermal performance evaluation of heat exchanger tubes equipped with coupling twisted tapes.Experimental Heat Transfer, 26, 413-430.

Han Jiguang, Wu Xin, Zhou Yi, Zhan Yue (2012). Experimental study on heat transfer and friction factor characteristics in a circular tube with twisted tape and coiled wire inserts.Journal of Engineering for Thermal Energy and Power, 27(4), 434-438.(in Chinese)

Lei Yonggang, Zhao Chenhong, Song Chongfang (2012).Enhancement of turbulent flow heat transfer in a tube with modified twisted tapes.Chemical Engineering Technology,35(12), 2133-2139.

Liu S, Sakr M (2013). A comprehensive review on passive heat transfer enhancements in pipe exchangers.Renewable and Sustainable Energy Reviews, 19, 64-81.

Manglik RM, Bergles AE (1993a). Heat transfer and pressure drop correlations for twisted-tape inserts in isothermal tubes: part I–laminar flows.Journal of Heat Transfer, 115, 881-888.

Manglik RM, Bergles AE (1993b). Heat transfer and pressure drop correlations for twisted-tape inserts in isothermal tubes: part II–laminar flows.Journal of Heat Transfer, 115, 890-896.

Murugesan P, Mayilsamy K, Suresh S (2010a). Turbulent heat transfer and pressure drop in tube fitted with square-cut twisted tape.Chinese Journal of Chemical Engineering, 18(4),609-617.

Murugesan P, Mayilsamy K, Suresh S (2010b). Heat transfer and friction factor studies in a circular tube fitted with twisted tape consisting of wire-nails.Chinese Journal of chemical Engineering, 18(6), 1038-1042.

Murugesan P, Mayilsamy K, Suresh S (2011a). Heat transfer in tubes fitted with trapezoidal-cut and plain twisted tape inserts.Chemical Engineering Communications, 198, 886-904.

Murugesan P, Mayilsamy K, Suresh S, Srinivasan PSS (2011b).Heat transfer and pressure drop characteristics in a circular tube fitted with and without V-cut twisted tape insert.International Communications in Heat and Mass Transfer, 38, 329-334.

Nanan K, Thianpong C, Promvonge P, Eiamsa-ard S (2014).Investigation of heat transfer enhancement by perforated helical twisted-tapes.Heat and Mass Transfer, 52, 106-112.

Noothong W, Eiamsaard S, Promvonge P (2006). Effect of twisted-tape inserts on heat transfer in a tube.The 2nd International Conference on Sustainable Energy and Environment, Bangkok, Thailand, 1-5.

Patil SV, Babu PVV (2014a). Laminar heat transfer augmentation through a square duct and circular tube fitted with twisted tapes.Experimental Heat Transfer, 27, 124-143.

Patil SV, Babu PVV (2014b). Heat transfer and pressure drop studies through a square duct fitted with increasing and decreasing order of twisted tape.Heat Transfer Engineering,35(14-15), 1380-1387.

Rahimi M, Shabaniana SR, Alsairafi AA (2010). Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts.Chemical Engineering and Processing, 48, 762-770.

Saha SK (2011). Thermohydraulics of turbulent flow through square and rectangular ducts with transverse ribs and twisted tapes with and without oblique teeth.Journal of Enhanced Heat Transfer, 18(4), 281-293.

Saha SK, Barman BK, Banerjee S (2012). Heat transfer enhancement of laminar flow through a circular tube having wire coil inserts and fitted with center-cleared twisted tape.Journal of Thermal Science and Engineering Application, 4,1-9.

Saha SK, Dutta A, Dhal SK (2001). Friction and heat transfer characteristics of laminar swirl flow through a circular tube fitted with regularly spaced twisted-tape elements.International Journal of Heat and Mass Transfer, 44, 4211-4223.

Sarada SN, Raju ASR, Radha KK, Sunder LS (2010). Enhancement of heat transfer using varying width twisted tape inserts.International Journal of Engineering, Science and Technology,2(6), 107-118.

Seemawute P, Eiamsa-ard S (2010). Thermohydraulics of turbulent flow through a round tube by a peripherally-cut twisted tape with an alternate axis.International Communications in Heat and Mass Transfer, 37, 652-659.

Thianpong C, Eiamsa-ard P, Eiamsa-ard S (2012). Heat transfer and thermal performance characteristics of heat exchanger tube fitted with perforated twisted-tapes.Heat Mass Transfer, 48,881-892.

Wongchareea K, Eiamsa-ard S (2011). Heat transfer enhancement by twisted tapes with alternate-axes and triangular, rectangular and trapezoidal wings.Chemical Engineering and Processing,50, 211-219.

杂志排行

Journal of Marine Science and Application的其它文章

- Optimization of Wigley Hull Form in order to Ensure the Objective Functions of the Seakeeping Performance

- Numerical Investigation on Two-dimensional Boundary Layer Flow with Transition

- Flow-induced Noise and Vibration Analysis of a Piping Elbow with/without a Guide Vane

- Developing a Computer Program for Detailed Study of Planing Hull’s Spray Based on Morabito’s Approach

- Experimental Research on Flash Boiling Spray of Dimethyl Ether

- Fast Prediction of Acoustic Radiation from a Hemi-capped Cylindrical Shell in Waveguide