Recent Progress of Commercially Available Biosensors in China and Their Applications in Fermentation Processes

2014-07-02ChenYanFengDongBiChunyuanZhuSirongandShiJianguo

Chen Yan , Feng Dong Bi Chun-yuan Zhu Si-rong and Shi Jian-guo*

1 Biology Institute of Shandong Academy of Sciences, Key Laboratory for Biosensors of Shandong Province, Jinan 250014, China

2 Institute of Oceanology, Chinese Academy of Science, Qingdao 266071, Shandong, China

Introduction

In fermentation industries, process safety and product quality are two important issues of interest. Process monitoring is a widely adopted tool for process safety and quality enhancement. An optimized process leads to streamlined performance, reduction in running and material costs and improvements in quality con-trol.The effective monitoring of the fermentation process is necessary to develop, optimize and maintain biological reactors at the maximum eff i ciency (Kumar,2011). However, due to the complex nature of fermentation process, the use of the traditional analytical techniques is often hindered by the need for expensive instrumentation, experienced operators and complex sample purification and separation before analyses.Biosensors can have several advantages over traditional analytical techniques when they come to process monitoring and control. From a general point of the view, a biosensor is a "compact analytical device sensitive 'recognition' element integrated or associated with a physio-chemical transducer" (Turner, 2000).Biosensors can be used to monitor the presence of product, either biomass, enzyme, or antibody, or of a by-product of the process as an indirect measure of process conditions, which could make monitoring and control in the fermentation industry accurate and reproducible. Since the first biosensor, an enzymebased glucose sensor, was developed by Clark and Lyons at the New York Academy of Sciences Symposium in 1962, the biosensor field has grown enormously (Clark and Lyons, 1962). Most notable of the commercially available biosensors today is probably the range of the biosensors sold by the Yellow Springs Instrument Company (YSI), and their glucose biosensor was successfully launched commercially in 1975. This was the first of many biosensor-based laboratory analyzers to be built by companies around the world. YSI followed this in 1982 with a whole blood lactate analyzer. Since then,these products have become the gold standard for clinical diagnostic work in hospitals and laboratories.Nowadays, several kinds of YSI life sciences products,YSI 1500, YSI 2300, YSI 2700, YSI 2900, YSI 5300,YSI 7100, and YSI 8500 biochemistry analyzer, have been found around the globe in research institutions,hospitals and clinics, athletic training facilities, and biopharmaceutical companies. These products offer scientists, technicians, physicians, and clinicians precise, consistent data for life.

Biosensor in China started relatively late. The fi rst biosensor system applied in China, the Model 23-L Lactate Analyzer developed by the YSI Corporation,was introduced in the late 1980s. However, its high price limited its application in China. From then on,lots of the researchers did researches on the biosensor system (Jin et al., 1993; Sun et al., 1993; Wang and Deng, 1993; Hu and Leng, 1995; Hu, 1996; Liu et al.,1996; Kang et al., 1997; Liu et al., 1997; Liu et al.,1997; Qian et al., 1997; Ruan et al., 1997). The transition from laboratory achievement to the practical use of the biosensors is sometimes a complicated process. Although there are lots of laboratory achievements in China, few of them have been transformed into practical applications. So far only SBA-serial biosensors are widely used in fermentation process in China.

So, this review mainly focused on the development of SBA biosensor analyzers and their applications in fermentation including production of the starch sugar,ion exchange process, optimization of fermentation processing, quality control of fermentation products,and effective use of biomass waste. In addition, the recent studies on the on-line measurement and control system for the fermentation industries were also discussed.

Development of Serial SBA Biosensor Analyzers

One of the major driving force for the development of biosensors is fermentation monitoring and process control. In China, there are more than 6 000 companies working on traditional fermentation or the modern biotechnology, being involved in different industries, such as food, pharmacy, light manufacturing, environmental protection, and energy.Process monitoring during fermentation is widely applicable in the field of phyaramaceutical, food and beverages and wastewater treatment. Since, the ability to process monitor has direct relevance in improving performance, quality, productivity, and yield of the process, much attention has been focused on improving process monitoring tools. Biosensor may be a suitable tool for fermentation monitoring, due to their attractive features including relatively simple instrumentation, excellent selectivity, low prices,minimal sample preparation and easy automation of the measurements. Application of biosensor can provide insight into some of biochemical parameters and facilitate decision making. During the past 30 years, research and development institutions,universities, and various industrial sectors have developed biosensors, in which Biology Institute of Shandong Academy of Sciences is the only institute specializing in researches and applications of the industrial biosensors in China. The work in serial SBA biosensor began in 1983, and now more than 10 kinds of biosensors have been developed for measurement for substrates, products and intermediate metabolites.Comparing to the foreign similar products (YSI-serial products, Nova Biomedical products), SBA-serial biosensor analyzers have advantages such as small volume, simple and convenient operation, low cost, intime and cheap service.

Nowadays, several kinds of commercial SBA biosensors are available, which are able to detect bio-chemical parameters such as glucose, lactate, glutamate, lysine, ethanol, starch, dextrin, saccharose,lactose, saccharifying enzyme, pyruvic acid, and hypoxanthine. These biosensor analyzers have been listed in Fig. 1 (Feng, 2003).

Model SBA-30 lactate analyzer, a mono-electrode biosensor, is widely used in physical training and its consumers number more than 140 organizations.

Model SBA-50 monoelectrode biosensor is a new type of SBA-30, produced in 1995. It is more automated compared with SBA-30 and is used to detect lactate and also other substances as well, such as glucose, by replacing the immobilized-enzyme membrane and setting multiple parameters.

Model SBA-40 analyzer, a bielectrode analyzer,simultaneously analyzes any two of the following products: glutamate, glucose, or lactate. It has been used to control fermentation, saccharification, and recovery in more than 90% of the glutamate factories in China, each of which produces more than 10 000 tons of glutamate products.

Model SBA-60 on-line quadraelectrode biosensor analyzer system, authenticated by specialists in 1996,can be fitted out simultaneously with four kinds of biosensors. It is controlled by a computer, performs controlled dilution of samples, and can be connected to the fermenter or the biochemical reaction vessel to detect a substance on-line.

Model SBA-70 automatic analyzer based on FIA and auto-sampling system, can analyze glucose,L-lactate, pyruvic acid, hypoxanthine, and ethanol. It is especially suitable for the measurement of glucose and lactate simultaneously in whole blood or plasma.

Fig. 1 Prototypes of analyzers that have been developed

Model SBA-90 analyzer, terelectrode analyzer,simultaneously analyzes three products: glutamate,glucose, and lactate. The system operated in interactive mode with Chinese character menu, and more than 3 200 measurement results can be stored in a data collector for the future printout or computation. The status of the system is obtained from the computer display, including data collection, and parameter setting. We can also change the status of the system and display and print the previous records.

At present, these analyzers are widely used in enterprises in China, occupying more than 90% of the market in China. Among them, Model SBA-40 analyzers are used the most widely in biological industry, and now at present there are more than 4 000 users.

SBA Biosensor Analyzers Market

China has been a great biotechnological country in the world. In China, the demanded amount of biosensor is large and the market of it is vast. The biosensors market is categorized as a growth market with applications increasing with the development of each new biosensor. Biosensor developments have resulted in standardized equipment, standardized biomolecules,and standardized test processes for use in drug discovery, biodefense, environmental monitoring, process industries, and the development of an artificial nose for security applications, such as narcotics and explosive material detection (Scheller et al., 1991).Although YSI is the market leader in most countries in the world in providing biochemistry analyzers for process monitoring and control of nutrients and byproducts, SBA-serial biosensors with fast, accurate results and low cost occupy China market dominant position continuously. They hold more than 90%market share in China. The main vertical markets for SBA biosensors include research laboratories, clinical detection, physical fitness training, food analysis,environmental monitoring and industry control. Fig. 2 shows the percent of SBA biosensor users in 2013.From Fig. 2, we can see the applications of the biosensor analyzer for research laboratories and industry control dominate the market, accounting for 85%,followed by food analysis and physical fitness training, accounting for 8% and 3%, respectively. Clinical detection and environment monitoring only account for 3% and others account for 1%. The market of the biosensor is stabile, and research laboratories and industry control continue to dominate the market by 2020 and beyond. In biosensors for fermentation process applications, we expect a gradual shift from lab tests to on-line biosensors to ensure real-time analysis.

Fig. 2 Percent of SBA biosensor users in China in 2013

The sale volume of SBA biosensor analyzers in the last 24 years is shown in Fig. 3. From 1996 to 2000, there were about 400 biosensor analyzers,almost triple the number of the biosensor analyzer that appeared from 2000 to 2005. Because the explosion of biotechnology over 2 700 biosensor analyzers had been sold from 2006 to 2010, currently, there are more than 5 000 users, including academic institutions,enterprises, and other domains. Preliminary analyses indicated that the number of biosensor analyzers was steadily increasing. By 2015, the total number of biosensor analyzers is expected to reach 7 000 or so.

Fig. 3 Sale volume of biosensor analyzers in last 24 years

Applications of Single Biosensor Analyzers in Fermentation

SBA biosensor analyzers, as one of the products of the biotechnology industry, play an important role in developing and reforming traditional biotechnology in China. Benef i t of the application of the biosensors in biological industry has been obvious. For example,annual total productivity of amino acids in China is three million tons, which values about 40 billion Yuan. Biosensors are used in the process optimization,fed-batch control and down-stream process, resulting in a 10%-15% increase of the productivity, which accounts for about four billion Yuan increase value with exclusive of the environmental benefit. In the following, a number of the applications of the biosensor analyzer in relation to bioprocesses are overviewed. These examples clearly illustrate the potential of the biosensor analyzer in fermentation process.

Application in production of starch sugar

The determination and control of the glucose production in saccharification is very important. For several decades, saccharification has been controlled by the traditional Fehiing's method. However, this method is used to titrate the content of reducing sugar and its result cannot provide fully accurate information on the change of the glucose content. The glucose biosensor has many advantages and has attracted a lot of attention in saccharification. In recent years,the glucose biosensor used in glucose production has made significant progress. The percentage of the glucose in the glucose solution on a dry substrate is def i ned as DX value. DX value is always lower than DE value, and the specif i c ratio of DX to DE can be used to judge the fi nal quality of the glucose solution,in fact, which is equal to the reducing sugar value. The concept has been utilized fairly well in some factories equipped with the glucose biosensor. Zhoukou MSG Factory has successfully used glucose biosensors to control production in the saccharification and fermentation workshop, and they have developed the technique of increasing the quality of glucose solution and the fermentation level.

When fermentation factories use the bienzymatic method to produce glucose, the amount of glucoamylase added must be correctly controlled. So the enzyme activity must be tested to properly control the saccharif i cation process. After utilization in Wuxi Xingda Bioengineering Co., the largest enzymeproducng factory in China, the evaluation is as follows: SBA-50 biosensor analyzer needs only 3 min to determine the glucoamylase level, the regular iodometric method needs 60 min for the same task.

Application in ion exchange process

In ion exchange retrieval, detection of the change of biochemical composition is the key to increase the total product extraction rate. For example, in 1995, the extraction rate of the glutamate in 10 MSG enterprises in China ranged from 91.76% to 83.90% (according to a report in the Bulletin of Fermentational Science and Technology in February, 1996). This means that the extraction rate of the glutamate in ion exchange was very low, about 43.9%-55.9%. Much was wasted and lost. By using the glutamate biosensor,our group has conducted simulated experiments on the ion exchange retrieval of an isoelectric liquor supernatant of the glutamate. According to this simulated experiment, the retrieval rate in the test is about 90%. We increased the retrieval rate by more than 30%and reduced the loss caused by ineffective circulation in the ion-exchange process of the glutamate. The expenses of acid, alkali and environmental pollution are also reduced. Hao et al. (2008)used SBA biosensor analyzer to evaluate the adsorption capacity of ion-exchange resins for propionic acid, glucose and amino acids in vitamin (B12(VB12)fermentation broth.Results indicated that propionic acid was removed from the fermentation broth and the concentration of VB12increased from 9.1 mg · L-1to 13.1 mg · L-1, an increase of 44%.

Application in optimization of fermentation processing

Optimization of the operational procedures in bioprocessing either can concern state variables that should be kept under control at a predetermined setpoint or should follow the course of a preset trajectory,or discrete sequential actions. An optimized process leads to streamlined performance, reduction in running and material costs and improvements in quality control. Monitoring biomass or substrates or the inducer can provide insight into the feeding strategies for realizing better efficiency from the reactors.Most applications of SBA analyzer have concerned optimization of the composition of the growth and production culture media. Many examples can be found for production of the stains. Escherichia coli is produced when the substrate, glucose, is presented above certain concentrations. Accurate measurement of glucose concentration in E. coli fermentation is of great importance for achieving higher product concentration. Pan et al. (2011)studied the effects of carbon source feeding, nitrogen source feeding and feeding with pH control to obtain the optimal culture conditions. After culture 24 h under the optimal conditions, the cell dry weight concentration of E. coli increased by 104.7%. It is of great signif i cance for reducing the production cost of the preparing L-phenylalanine by enzyme method, enhancing the production eff i ciency of L-phenylalanine. Chai and Zhang (2011)applied SBA-40 analyzer to determine the optimal glucose for the growth of the strain LG-65 that has evoked considerable interest as a large-scale L-glutamine producer. Qin et al. (2011)used SBA biosensor analyzer to determine L-lactic acid and reducing sugar and optimization experiments to investigate the high L-lactic acid production strain of Lactobacillus casei. Under the control of the biosensor, the strain can accumulate L-lactic acid 188 g · L-1, sugar conversion efficiency more than 90% and the fermentation period less than 44 h. Jining MSG Factory using lactate biosensor to determine the lactate content in fermentation, established that the optimal lactate content in the glutamate fermentation process was 0-0.2%. At that point, the turnout of glucose-glutamate was the highest. Without proper operation, the highest content of the lactate in fermentation liquid was 4.0%, and the glutamate content was only 5.0%,which caused a great loss of the production. Under the control of a lactate biosensor, the production rate of the glutamate increases by 0.5%, thus increasing glutamate output by 6.0%.

Mathematical modeling of the bioprocess data has been discussed in biotechnology for the past 30 years. They could be applied for the calculation of the optimal feeding prof i les and other control strategies. In general, related parameters (such as concentration of substrate and product, temperature, pH, and dissolved oxygen)in fermentation are critical for establishing the mathematical model. The number of model parameters required, and the ease by which their values may be obtained, will influence the utility of mathematical models. Lack of suitable methods for parameter determination has proved to be a significant obstacle for establishing the optimal model. The development of new and more robust analytical techniques will lead to improved model, and deliver more precise estimate of important parameters, such as the growth rate and product formation rates. SBA series analyzers have injected a flow of fresh vitality into model establishment. For example, He et al. (2010)reported batch fermentation kinetic model of the glutathione producing by Saccharomyces cerevisiae. They monitored biomass, glutathione and glucose concentration to draw the profile of the bacth fermentation and establish the dynamic model of the cell growth,product formation and substrate consumption,respectively. Liang et al. (2013)used SBA biosensor analyzer to determine the residual glutamic acid and sugar content. With MATLAB software, they proposed the kinetic models for γ-polyglutamic acid and substrate consumption. The results showed that the models could provide a reasonable description for the batch fermentation. Zuo et al. (2013)used YPDF basic medium to simulate sugarcane juice to conduct ethanol fermentation at different sugar concentrations.Parameters of the fructose and glucose consumption process and ethanol production process were determined for curve fitting. Data suggested that lower sugar concentration could result in a lower discrepancy in fructose and glucose utilization.

Fermentation processes are commonly operated in fed-batch mode in order to prevent the accumulation of toxic substrates or products thus allowing the achievement of higher product concentrations. Fedbatch fermentation is superior to conventional fermentation when controlling concentrations of substrates affect the yield or productivity of the desired products. In industrial fed-batch cultivations,it is often necessary to control substrate concentrations at a low level to prevent the production of overflow metabolites and thus optimize the biomass yield.Biosensor monitoring in fermentation is increasingly preferred as it affects better control of substrate and product levels. In China, SBA biosensor analyzers,as the most popular commercial biosensor, have been developed to monitor the levels of substrate and product in fed-batch fermentation. For example,SBA-40C biosensor analyzer was used for monitoring the fed-batch feeding of the glucose and results showed that the optimal initial glucose concentration was 20 g · L-1and the fed-batch feeding strategy of adding 22, 24, 24, 24, 24, 22 g · L-1glucose at intervals of 3 h from 12 h to 27 h of fermentation resulted in the best effect (Pan et al., 2010). Sang et al. (2011)used SBA biosensor for determination of residual sugar in cephalosporin C (CPC)fermentation to control carbon source concentration and DO at adequate levels. Using this strategy, final CPC concentration and CPC yield reach 35.77 g · L-1and 13.3%, respectively. The major by-product, de-acetoxycephalosporin (DAOC)and DAOC/CPC were only 0.178 g · L-1and 0.5%. Likewise strategies on feeding depending upon the process states and key process variables can be adopted by monitoring.

Application in quality control of fermentation products

Fermentation processes are often sensitive to even slight changes of the conditions that may result in unacceptable end-product quality. One of the most promising ways of the developing rapid and relatively inexpensive methods for quality control in fermentation processes is the use of the biosensor systems. No matter which approach of the target product preparation is determined, one indispensable step should be taken into account for final isolation and purification of this product. This helps in reducing production of undesirable by-products like ammonia and lactate.Moreover, effective monitoring coupled with appropriate control strategy will facilitate increase of the production of desired product with high quality. Glucose,as the simplest form of sugar and the foundation of all the carbohydrates, is one of the main components in fermentation broth. Therefore, determination of such analytes (glucose, lactic acid, ethanol and glycerol)in the process of isolation and purification is very important. Using SBA biosensor analyzer to detect such analytes content in fermentation broth has the advantages of rapid response and high precision. For example, Sun et al. (2009)used glucose to product 2-keto-D-gluconic acid and applied membrane separation technology to extract fermentation product.In order to increase productivity and quality of the product, glucose concentration was monitored by SBA series biosensor analyzer in this process. In this case, the conversion rate of the glucose into 2-keto-D-gluconic acid was as high as 90%. Further monitoring enables generating early warning signals based on observed process deviations and devise appropriate control strategies. With these insights, it is possible to achieve high productivity e.g. by monitoring glucose and glutamine and maintaining the balance of these carbon and nitrogen sources, cell cultures can be run at optimal conditions. Wu et al. (2010)applied SBA biosensor analyzer for sensing residual sugar and studied the complexation extraction of succinic acid in simulated fermentation broth. Liquid ammonia in glutamate fermentation was a nitrogen source and pH conditioner and was added in feeding. In fermentation,ammonium ion might interfere with the determination and produce low data quality. Xing et al. (2011)proposed a pH feedback-controlled glucose feeding method to simplify the feeding method for glutamate fermentation. The linear relationship between the consumption amounts of ammonia and glucose was used as the ratio of the amount of ammonia and glucose in the feeding broth. Compared with the constant feeding method, the concentration of ammonia was controlled and the quality and productivity of glutamate was enhanced.

Application in effective use of biomass waste

Wet-milling is the common process used to produce corn starch with high quality and yield. Kernel steeping is the first and the most important step in the milling process, and is also a capital-intensive and time-consuming step because it involves grain soaking in weak solution of sulphurous acid at subgelatinisation temperatures (50-55℃)for 30-55 h.Reduced steep time decreases energy cost, increases plant capacity, and reduces the capital cost involved in constructing new wet-milling plants. A great number of the investigations have been approached to fi nd a steeping method that may decrease the time of this step. In order to solve the crucial problems of environmental pollution from high concentration of sulf i te and the long soaking cycle, our group explored a new technology to improve the soaking process.We employed biosensor analyzer to determine the contents of the reducing sugar, glucose and lactic acid in corn steep water and presented their variation rule.Under the optimum conditions, the soaking cycle was shortened by 42 h, and the amount of SO2was reduced by 0.1% (Feng et al., 2011).

Corn pericarp, a waste of industrial corn starch production, is mainly composed of carbohydrats including cellulose, hemicellucose, and residual starch.However, it used to be discarded or utilized as animal feed. Application of hydrolyzed corn pericarp in biology ferment will supply a kind of cheap biomass material for industrial fermentation. Determination of total sugar content and glucose content is very important for process optimization of corn pericarp hydrolysis. The biosensor detection method has less error and offers simpler operation, thus rapid detection of sugar can be achieved. For example,by using SBA biosensor analyzers to determine the glucose and xylose, Zhao et al. (2007)investigated the technologies in enzymatic hydrolysis of corncob,ethanol production from cellulosic hydrolysate,simultaneous saccharification and fermentation using a thermotolerant yeast strain and a recombinant yeast.By this technique, the simultaneous conversion of cellulose and hemicellulose to ethanol was realized,which was very meaningful in decreasing the ethanol production cost and increasing the productivity of the ethanol fermentation.

Application of On-line Measurement and Control System in Industrial Fermentation

The fermentative process is a complicated dynamic process with multiple key variables, most of which are difficult to be measured in real time. Furthermore,the response to changes in the process environment is less reproducible making the tasks of the process development, optimization and scale up difficult. Offline measurement though is useful, causes delay in process control and hence is generally used for the development of mathematical models and process development. On-line monitoring of the critical metabolites including substrate and product is desirable in order to facilitate rapid optimization and also to control a bioprocess. So, it is crucial to provide solutions to on-line sensing and optimization technique for bio-process to break down the bottleneck on the productivity of the fermentation.

In recent years, biosensor, due to its inherent specificity, simplicity and quick response, has also attracted increasing scientific interest in on-line monitoring of the fermentation process (Kumar et al.,2001; Akin et al., 2011; Kumar, 2011; Moeller et al.,2011; Bäcker et al., 2013; Mentana et al., 2013).Although the literature on various biosensors is extensive, examples of their use for on-line monitoring are rather limited. So far only Nova Bioprofile Flex and YSI 7100 MBS Multiparameter Bioanalytical System are widely used for on-line monitoring of the bioprocesses around the world (Fig. 4).

Fig. 4 Prototypes of on-line analyzing system that have been fully commercialized

With a well-established industry in fermentation,on-line monitoring of the fermentation processs has also gained wide attention in China. Recently,many efforts have been focused on the design and development of on-line analyzing system (Yang et al.,2003; Chen and Jin, 2011). Gao et al. (2012)developed the glucose on-line detection system for fermentation process. Glucose concentration was measured on-line in the coli fermentation process with the detection system, and the results exhibited the same variation trend as the commercial off-line SBA-40E biosensor analyzer. Though biosensor can be applied for measurement for substrates, products and intermediate metabolites, their use in bioreactors is scare owing to drift or fouling. In order to solve the problem of the contamination caused by a biosensor, we drained the sample from the fermenter and diluted it to the concentration range that could be detected by the biosensor. Nowadays, we have successfully developed SBA-60 on-line measurement and control system of the fermentation (Feng et al.,1998)(Fig. 5). This system consists of the three parts: (1)biosensors; (2)auto-samplers, which is used for sampling purposes and is installed outside the reactor; (3)a signal transmission lines and computing devices to implement the feed-back control. Compared with Nova Bioprofile Flex and YSI 7100 MBS, SBA-60 on-line analyzing system possesses strong anti-interference ability, which can be used directly in industrial environments. The application of SBA-60 on-line analyzing system is discussed below:

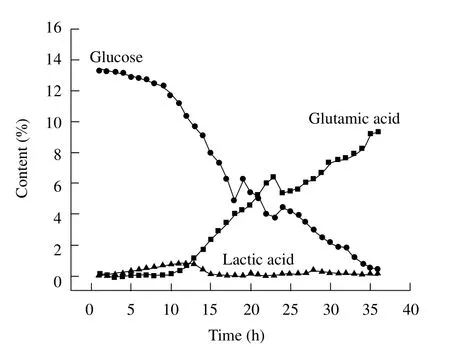

Simulating production with a small-scale fermenter parallels to a large scale fermenter to resolve production problems and explores new technological conditions. We used a small-scale fermenter together with SBA-60 on-line analyzing system and pH automatic analyzer to simulate a fermentation test. The total initial 6 000 mL of the fermentation liquor was put into the small-scale fermenter, the target product in fermentation was glutamate and the by-product was lactate. In the fermentation process, the amount of glucose decreased continuously and 1 075 mL of 30%glucose was added in the middle of the fermentation.At the end of the fermentation, 4 190 mL remained.The concentration of the glutamate, glucose, and lactate were 9.26%, 0.38% and 0.085%, respectively.The fermentation data are shown in Fig. 6.

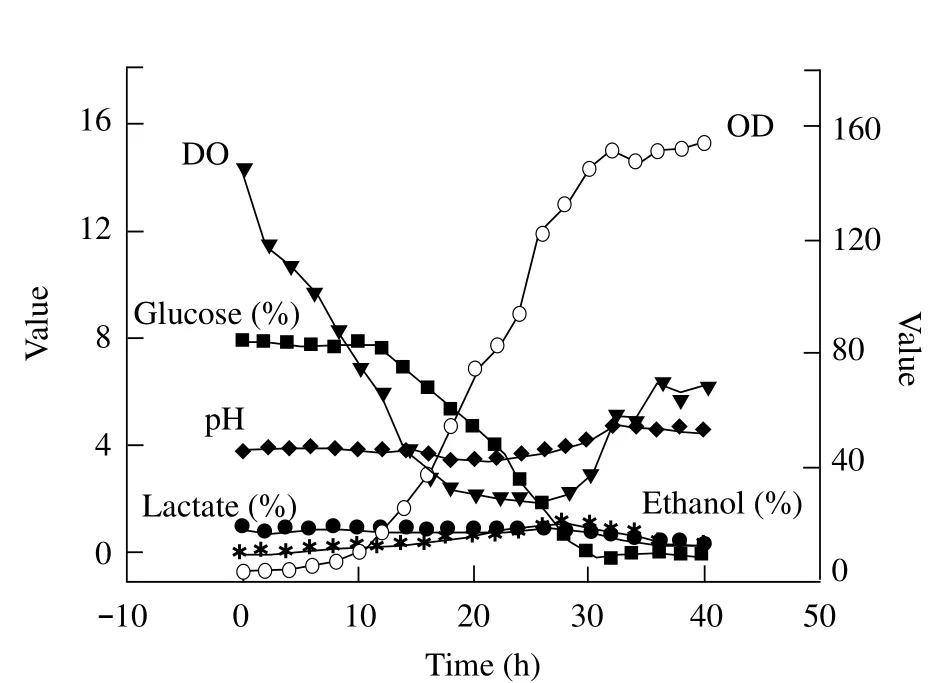

SBA-60 on-line analyzing system can be integrated to laboratory fermentors as well as industrial bioreactors with different biosensing configurations.Weifang Shengtai Pharmaceutical Co., Ltd., is the fi rst to apply this on-line measurement and control system in large-scale fermentation. They used a large-scale fermenter together with SBA-60 on-line analyzing system and pH automatic analyzer to keep oceanic red yeast fermentation in an optimal condition. In the fermentation process, the amount of the glucose decreased continuously and amount of the oceanic red yeast increased continuously. The dynamic change of biochemical substances in oceanic red yeast fermentation process are shown in Fig. 7. Under the control of this on-line system, the cost of red yeast was reduced, and the prof i ts increased. Calculated on eight tons fermentation tank, the production capacity of red yeast hyperchromic feed would increase by 120 kg. Calculated on the prices of 100/kg,increased sales income would be 12 000 Yuan. They also applied this on-line system in Saccharomyces boulardii fermentation process. Calculated on eight tons fermentation tank, the production capacity of Saccharomyces boulardii feed would increase by 80 kg. Calculated on the prices of 400/kg, increased sales income would be 32 000 Yuan. Applying this on-line system in yeast fermentation process optimization has increased the production and solved the pollution problems of by-product, which has considerable economic and social benef i ts.

Fig. 5 On-line measurement and control system for industrial fermentation process

Fig. 6 Dynamic change of biochemical substances in glutamic acid fermentation process

Fig. 7 Dynamic change of biochemical substances in oceanic red yeast fermentation

At present, on-line operation and control of fermentation is challenging. SBA-60 on-line analyzing system is continuously improved and the connection of a large-scale fermentation to biosensors still needs to be studied.

Conclusions and Prospects

China biological industry is growing fast and has been put into the national strategic emerging industries. This provides a good opportunity for biosensor development. Future research priorities are identified: first, developing multi-biosensors for simultaneous determination of multi-metabolites.The fermentation broth including raw substrates,fermentation products, microorganisms and its derivative components, chemical additives added to the fermentor, and gases such as oxygen and other metabolic gases, is a very complex soup or solution.The more (useful)measurements we can make the more likely are we to understand our bioprocesses.YSI's newest multiparameter bioanalytical system offers simultaneous multiparameter measurement for enhanced productivity. For example, YSI 7100 MBS offers multiparameter measurement of up to six distinct parameters at one time, but SBA-serial biosensors offer no more than four biochemistry parameters. In order to dominate Chinese industry biosensor market for a long time, we have sought to exploit multi-biosensors which can measure many metabolites simultaneously. Second, realizing online measurement and control of bioprocess by integration of the biosensors, chemical sensors and physical sensors. The complex dynamics of bioprocesses require automated tools for having a greater insight into the process in realtime. Indentification of phase states in brocesses and predicting the direction of the biosynthesis require knowledge of biochemical as well as physical and chemical variables. At present, we just realized the integration of SBA-60 biosensor with pH automatic analyzer. So the work need to be focused for integration of the biosensors, chemical sensors and physical sensors for bioprocess on-line measurement.Third, constructing intelligent bioprocess operation model by combination of the biosensors, IT and the internet of the things. With the intelligent bioprocess operation model, process development could be enhanced, quality control and safety of the bioreactor production be improved and process control be realized more eff i ciently.

Akin M, Prediger A, Yuksel M, et al. 2011. A new set up for multianalyte sensing: at-line bio-process monitoring. Biosen Bioelectron,26: 4532-4537.

Bäcker M, Rakowski D, Poghossian A, et al. 2013. Chip-based amperometric enzyme sensor system for monitoring of bioprocesses by fl ow-injection analysis. J Biotech, 163: 371-376.

Chai J K, Zhang W G. 2011. Breeding of L-glutamine high producing strain and its fermentation conditions. Chin J Bioproc Eng, 9:29-34.

Chen J, Jin Y L. 2011. Sensitive lactate determination based on acclimated mixed bacteria and palygorskite co-modified oxygen electrode. Bioelectrochem, 80: 151-154.

Clark L C, Lyons C. 1962. Electrode system for continuous monitoring in cardiovascular surgery. Ann NY Acad Sci, 102: 29-45.

Feng D R, Zhu S R, Zhou W L, et al. 1998. The design and study on model SBA-60 on-line quadra-electrode biosensor analyzer system.Shandong Sci, 11: 32-36.

Feng D R. 2003, Biosensors and their application in the People's Republic of China. Advances in Biosensors, 4: 289-313.

Feng W H, Zhou S M, Shi J G. 2011. The soaking technology of wet corn and its advances of research. J Shandong Insitute of Light Industry, 25: 29-31.

Gao X J, Liu G S, Cheng L, et al. 2012. Development of glucose on-line detection system for fermentation process. Chin J Anal Chem, 40:1945-1949.

Hao T, Li Q, Wang P, et al. 2008. Removal of propionic acid from fermentation broth by ion-exchange resins. J Beijing Univ Chem Tech, 35: 70-74.

He X X, Pan Y L, Jiang L. 2010. Batch fermentation kinetic model of glutathione producing by Saccharomyces cerevisiae. Food Sci Tech,35: 32-40.

Hu J. 1996. Reserch and development of biosensors in China. Sensor Mater, 8: 477-484.

Hu X Y, Leng ZZ. 1995. Characteristics of catechol response on the amperometric biosensor of polyphenol oxidase. Chin J Anal Chem,23: 416-418.

Jin L T, Ye J S, Fang Y Z. 1993. Pyruvate oxidase biosensor for the determination of GPT based on the glassy carbon electrode modif i ed with naf i on and methyl viologen. Chem J Chin Univ, 14:1210-1213.

Kang T F, Shen G L, Yu Y Q. 1997. Amperometric biosensor for glucose based on electropolymerized tetraaminophthalo-cyanatocobalt (II)and phenol fi lms. Anal Lett, 30: 647-662.

Kumar M A. 2011. Biosensors and automation for bioprocess monitoring and control. Lund University, Sweden. pp.11-29, 30-36.

Kumar M A, Thakur M S, Senthuran A, et al. 2001. An automated flow injection analysis system for on-line monitoring of glucose and L-lactate during lactic acid fermentation in a recycle bioreactor.World J Microb Biot, 17: 23-29.

Liang J Z, Wang F Q, Zhang L L. 2013. Establishment of a kinetic model for γ-polyglutamic acid with batch fermentation. Sci Tech Food Ind, 16: 174-177.

Liu B H, Hu R Q, Deng J Q. 1997. Studies on a potentiometric urea biosensor based on an ammonia electrode and urease, immobilized on a gamma-aluminum oxide matrix. Anal Chim Acta, 341: 161-169.

Liu H C, Zhang X H, Liu H Y, et al. 1996. Immobilization of glucose oxidase onto the blend membrane of poly (vinyl alcohol)and regenerated silk fibroin: morphology and application to glucose biosensor. J Biotechnol, 46: 131-138.

Liu H Y, Ying T L, Sun K, et al. 1997. Reagentless amperometric biosensors highly sensitive to hydrogen peroxide, glucose and lactose based on N-methyl phenazine methosulfate incorporated in a Naf i on fi lm as an electron transfer mediator between horseradish peroxidase and an electrode. Anal Chim Acta, 344: 187-199.

Mentana A, Palermo C, Nardiello D, et al. 2013. Simultaneous and ccurate real-time monitoring of glucose and ethanol in alcoholic drinks, must, and biomass by a dual-amperometric biosensor. J Agr Food Chem, 61: 61-68.

Moeller L, Grünberg M, Zehnsdorf A, et al. 2011. Repeated fed-batch fermentation using biosensor online control for citric acid production by Yarrowia lipolytica. J Biotech, 153: 133-137.

Pan Y L, He X X, Chen S. 2010. Fed-batch fermentation of glutathione.Food Sci, 31: 177-180.

Pan Z H, Gu W, Pan Y. 2011. Study on the effects of fed-batch culture method of Escherichia coli XD-12 fermentation. J Anhui Agri Sci,39: 14531-14533.

Qian J H, Liu Y C, Liu H Y, et al. 1997. Immobilization of horseradish peroxidase with a regenerated silk fibroin membrane and its application to a tetrathiafulvalene-mediating H2O2sensor. Biosens Bioelectron, 12: 1213-1218.

Qin H, Zhang W G, Ge, X Y, et al. 2011. Study on screening the high L-lactic acid production strain of Lactobacillus casei and its fermentation conditions. Sci Tech Food Ind, 32: 223-225.

Ruan C M, Yang F, Xu J S, et al. 1997. Immobilization of methylene blue using alpha-zirconium phosphate and its application within a reagentless amperometric hydrogen peroxide biosensor.Electroanalysis, 9: 1180-1184.

Sang M N, Yuan G Q, Li H F, et al. 2011. Cephalosporin C fermentation performance under different ammonium sulfate and soybean oil feeding strategies. Microbiology China, 38: 1321-1330.

Scheller F W, Hintsche R, Pfeiffer D, et al. 1991. Biosensors:fundamentals, applications and trends. Sens Actua B-Chem, B4:197-206.

Sun C Q, Zhang Y F, Gao Q, et al. 1993. Amperometric biosensors for glucose based on the carbon paste electrode modified by 1.1'-Dimethyferrocene and (C5H5)4B·N(CH3)4ion associate complex.Chin J Anal Chem, 21: 882-886.

Sun W J, Wei Z, Lin L, et al. 2009. Application of high concentration fermentation and membrane separation technology in the production of 2-keto-D-gluconic acid. Food Sci, 30: 244-246.

Turner A P. 2000. Biosensors-sense and sensitivity. Science, 290:1315-1317.

Wang Q, Deng J Q. 1993. Preparation of ginger tissue-based membrane electrode for L-ascorbic acid and its analytical application. Chin J Anal Chem, 21: 101-1021.

Wu H, Ren X Q, Jiang M, et al. 2010. Study on the complexation extraction of succinic acid fermentation broth. Food Fermentation Ind, 36: 1-5.

Xing Y, Zhang L Y, Cong W, et al. 2011. Application of a pH feedbackcontrolled substrate feeding method in glutamic acid fermentation.Chin J Biotech, 27: 1457-1463.

Yang H L, Lu X F, Wang L G, et al. 2003. The application of on-line micro-biosensors analyzer system on glutamic acid fermentation.China Condiment, 10: 16-20.

Zhao J, Chen M, Zhang J F, et al. 2007. Study on enzymatic hydrolysis of corncob for ethanol production. Chem Ind Forest Prod, 27: 7-10.

Zuo S, Wu S H, Zhang J, et al. 2013. Effect of sugar concentration on discrepany in fructose and glucose utilization during ethanol fermentation by Saccharomyces cerevisiae GJ2008. China Brewing,32: 25-29.

杂志排行

Journal of Northeast Agricultural University(English Edition)的其它文章

- Wheat Generation Adding in Xundian County of Yunnan Province in Summer

- Screening of Optimal Differentiation Medium to Lonicera edulis

- High-solid Anaerobic Co-digestion of Food Waste and Rice Straw for Biogas Production

- A Corpus-based Study on Collocation and Colligation of "Soil" in Agricultural English

- Microsatellite Analysis of Genetic Diversity Between Loach with Different Levels of Ploidy

- Rapid Non-destructive Detection for Molds Colony of Paddy Rice Based on Near Infrared Spectroscopy