Drying Characteristics and Quality of Yacon (Smallanthus sonchifolius) during Heat Pump Drying

2014-01-18SHIQilongZHENGYaqinZHAOYa

SHI Qi-long, ZHENG Ya-qin, ZHAO Ya

(School of Agricultural Engineering and Food Science, Shandong University of Technology, Zibo 255049, China)

Drying Characteristics and Quality of Yacon (Smallanthus sonchifolius) during Heat Pump Drying

SHI Qi-long, ZHENG Ya-qin, ZHAO Ya

(School of Agricultural Engineering and Food Science, Shandong University of Technology, Zibo 255049, China)

The effects of sample thickness, surface load, drying temperature, air velocity and evaporator bypass air ratio (BAR) on the drying characteristics and quality of yacon during heat pump drying (HPD) were investigated. Experimental results showed that higher thickness and surface load resulted in lower drying rate (DR). DR increased with increasing drying temperature and air velocity. Most DR curves displayed both long time falling rate period and relatively short time constant rate period while only falling rate period existed in some DR curves. Thickness of 2-4 mm, surface load of 1-2 kg/m2, drying temperature of 25-35 ℃ and air velocity of 1.5-2.0 m/s were preferred by considering specific moisture evaporation rate (SMER), total color difference (ΔE), shrinkage ratio (SR) and rehydration ratio (RR). However, BAR had little influence on the HPD process of yacon.

heat pump drying; yacon; drying characteristics; quality

Yacon (Smallanthus sonchifolius) originated in the Andes Mountains are rich in essential amino acids, minerals (calcium, zinc and ferrum) and soluble carbohydrates such as fructose, glucose, sucrose and fructooligosaccharides (FOS) or inulin[1-2]. There is a particularly abundant source of FOS, which is considered as prebiotic, in yacon. FOS have beneficial effect on humans, such as having a low caloric value, reducing blood lipid and glucose levels, improving the intestinal balance of the microflora, preventing and controllin g constipation[3-4]. However, FOS is hydrolyzed rapidly after harvest which affects functional characteristics of yacon. Meanwhile, browning and decay are the common phenomena during postharvest storage and transportation which restrict sustainable development of yacon industry and result in tremendous postharvest economic loss[2]. Moreover, since the yacon is a seasonal plant, it is imperative to apply advanced equipment and technology, such as drying, to preserve it and make it available for processing throughout the whole year[1].

Reis et al.[5-6]studied the drying kinetics of yacon slices during vacuum drying and evaluated the effect of drying temperature, slice thickness and citric acid concentration in the enzymatic inhibition solution on the fractal dimension, rehydration ratio and color of yacon slices. Dryingtemperature was found to negatively affect the fractal dimension and slice thickness was found to negatively affect the rehydration ratio. Scher et al.[1]studied the hot air drying behavior of yacon tubes with and without steam blanching. The results indicated that the loss in moisture content and water activity were quicker when higher temperature was used for drying and blanching samples. However, hydrolysis of the FOS was found higher for blanching and elevated temperature samples. Conventional convective drying have a number of disadvantages causing poor quality and product contamination[7]. The critical factor for loss of quality is the high temperature of the drying process. Therefore, decreasing the drying temperature will have enormous potential for improving the quality of dried products[8]. Moreover, drying is an energy-intensive process. With shortage and rising cost of fuel, saving energy has seemed to be especially important. Therefore, a drying system that has both high efficient energy utilization and excellent product quality is desired. Heat pump drying (HPD) has been developed to satisfy all the requirements. As an alternative drying technique, HPD can improve energy efficiency and independently control the drying operation parameters, especially be suitable for temperature sensitive products[9-10]. It has been used in agricultural and marine products, such as apple[11], cocoa beans[12], herbs[13], hawthorn cake[14], cheese[15], Cantonesestyle meat[16]and fish[17–18]. However, little information is available on the drying characteristics of yacon drying by HPD. Therefore, the objective of this study was to investigate the effects of various heat pump operating conditions, such as sample thickness, surface load, drying air temperature, air velocity and bypass air ratio (BAR) on its drying characteristics, quality of dried products including total color difference (ΔE), shrinkage ratio (SR) and rehydration ratio (RR) and energy attributes (specific moisture evaporation rate, SMER).

1 Materials and Methods

1.1 Sample preparation

The fresh yacon tubers were purchased from a fruit wholesale market in Zibo, China. Before the experiment, yacon tubers were rinsed in fresh water, peeled and cut in cylinders with a certain thickness, then immediately immersed in 0.5 % sodium sulfite solution for 5-10 minutes. Finally the yacon were dra ined off on a stainless steel mesh screen, and then gently wiped with tissue paper to remove excess water.

1.2 Drying procedures

Heat pump drying process was performed in a laboratory scale heat pump dryer (Model 1HP-5, Haike Biotechnology Co. Ltd., Qingdao, China). The system was equipped with transducers to measure weight, temperature, and relative humidity (RH). A digital anemometer (Model AR826, Qingdao Intelli Instruments Co. Ltd., Qingdao, China) was used to measure the air velocity. An XSL circulation measurement device (Beijing Kunlun Haian Co., Beijing, China) was used for data acquisition and control in association with a desktop PC.

A certain weight of yacon was spread thinly on the tray. Periodic on-line weighing was performed per minute throughout the drying experiments. Drying was terminated until no further change in weight was observed.

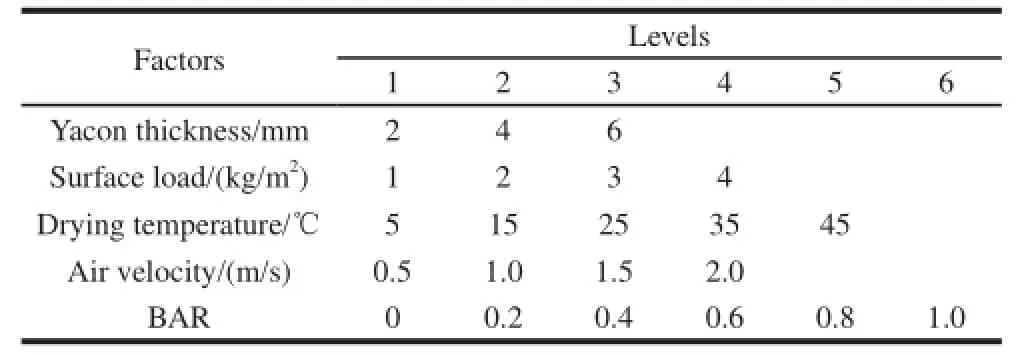

1.3 Experimental design

The effects of various operating parameters on the drying characteristics were investigated. Table 1 lists the factors and levels of the experimental runs covered in the present work. Drying experiments were repeated twice.

Table 1 Factors and levels of experimental runs

1.3.1 Effect of sample thickness

The effect of sample thickness on the drying characteristics and quality of yacon was investigated at drying temperature of 25 ℃ and air velocity of 1.5 m/s and surface load of 1 kg/m2. Thickness of 2, 4, 6 mm with initial moisture contents of 10.27, 9.12, 9.68 kg/kg (dry basis, the same as follows) respectively, were used.

1.3.2 Effect of surface load

The effect of surface load on the drying characteristics and quality of yacon was investigated at sample thickness of 4 mm, drying temperature of 25 ℃ and air velocity of 1.5 m/s. The initial moisture contents of yacon were 9.12, 9.68, 11.15, 9.82 kg/kg for the various runs at surface loads of 1, 2, 3, 4 kg/m2, respectively.

1.3.3 Effect of drying temperature

The effect of drying temperature on the drying characteristics and quality of yacon was investigated at sample thickness of 4 mm, surface load of 1 kg/m2and airvelocity of 1.5 m/s. The initial moisture contents of 10.75, 11.18, 9.12, 9.20, 10.36 kg/kg were determined before drying at 5, 15, 25, 35, 45 ℃, respectively.

1.3.4 Effect of air velocity

The effect of air velocity on the drying characteristics and quality of yacon was investigated at sample thickness of 4 mm, surface load of 1 kg/m2and drying temperature of 25 ℃. The experiments were conducted with air velocities of 0.5, 1.0, 1.5, 2.0 m/s with initial moisture contents of 11.56, 10.89, 9.12, 9.57 kg/kg, respectively.

1.3.5 Effect of evaporator bypass air ratio (BAR)

BAR is defined as the ratio of bypass air to the total air (mass basis) in the system. The effect of BAR on the drying characteristics and quality of yacon was investigated at sample thickness of 4 mm, surface load of 1 kg/ m2, drying temperature of 25 ℃ and air velocity of 1.5 m/s. The initial moisture contents of yacon were 9.62, 10.22, 9.92, 9.12, 9.56, 11.38 kg/kg for drying at BAR equaling 0, 0.2, 0.4, 0.6, 0.8 and 1.0, respectively.

1.4 Experimental indexes

1.4.1 Moisture content

Moisture contents were determined according to Association of Official Analytical Chemists (AOAC) methods[19]. Three replicates were measured, and the average was recorded as the moisture content of the sample.

1.4.2 Drying rate

Drying rate is calculated according to the following formula:

where DR is drying rate/(kg/(kg·h)); Mdis moisture content/(kg/kg); Md,iis moisture content at time ti/(kg/kg); Md,i+1is moisture content at vtime ti+1/(kg/kg).

1.4.3 Specific moisture evaporation rate

A performance indicator that is commonly used to define the performance of HPD was the specific moisture evaporation rate (SMER)[9]. SMER was defined as follows.

Energy input to the dryer was recorded by an electricity meter installed with heat pump dryer. The total electricity quantities consumed during yacon HPD were subsequently recorded.

1.4.4 Total colour difference

The colour values of each sample were measured using a color difference meter (Model HP-2132, Shanghai Han Spectrum Photoelectric Technology Co. Ltd., Shanghai, China). The changes in individual colour parameters were calculated as follows:

Colour parameter L is lightness; a is redness, -a is greenness; b is yellowness, -b is blueness. The subscript ‘0’refers to the initial colour parameters of each product at the beginning of drying experiment. For each drying experiment colour measurements were taken randomly on nine yacon slices before and after HPD. Each treatment was performed twice.

The total colour difference (ΔE) was then determined using the following equation[16]:

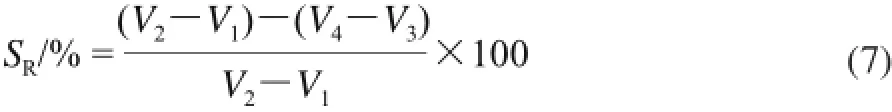

1.4.5 Shrinkage ratio

There is a change in volume of sample, called shrinkage, as it loses water to the drying medium. The solid replacement method was used to evaluate the shrinkage ratio (SR) of yacon during HPD. It is expressed as a percentage of the sample volume as compared with its original volume[2].

Where V1and V3are the volume of quartz sand before and after drying, respectively; V2and V4are the total volume of quartz sand and samples before and after drying, respectively. The average value of SRof samples in triplicate was recorded.

1.4.6 Rehydration ratio

Rehydration capacity is expressed using rehydration ratio (RR), which is defined as the ratio of weight of rehydrated sample (mR/g) to the weight of dried sample (mD/g).

Dried samples were immersed in distilled water at (45±1) ℃, taken out at 1h, and eliminated the superficial water. The evolution of the sample weight was recorded. All the treatments were carried out in triplicate.

1.5 Data analysis

Statistical analysis was performed using one-way ANOVA and mean comparison using Tukey’s test at 95% confidence level. The statistical software used was Origin (Version 7.5).

2 Results and Analysis

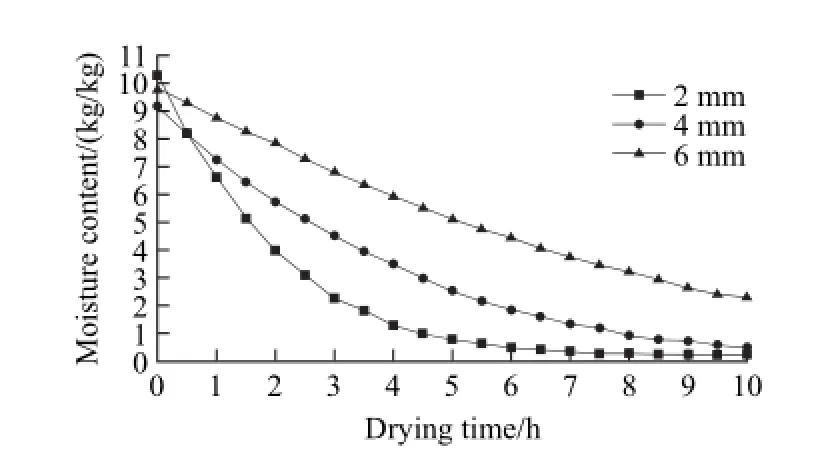

2.1 Effect of sample thickness

The variations of moisture content (dry basis, the same as follows) with the drying time are presented in Fig.1. Generally, moisture content decreased to a constant value with increasing drying time. Meanwhile, the required drying time increased as the thickness increased. Final moisture contents of 0.14, 0.19, 0.27 kg/kg were achieved after drying time of 13, 16, 27 h for the runs of thickness at 2, 4, 6 mm, respectively (data not presented). Longer time is needed to achieve the recommended moisture content of 0.11 kg/kg for yacon thickness of 6 mm.

Fig.1 Effect of sample thickness on drying curves of yacon using HPD

Fig.2 shows the drying rate against moisture content for thickness of 2, 4, 6 mm. Clearly, drying rate increased with decrease in thickness. Two transitory constant drying rate periods were emerged in the curve of 6 mm, each of which was followed by a falling rate period. The curve of 4 mm has an approximate constant period. However, there was no constant period in the curve of 2 mm, which has only a falling drying rate period. The yacon texture is incredibly fragile and puff and 2 mm thickness is quite thin, which accelerates the surface unsaturated and the internal moisture movement controlling the drying rate, and may result in this phenomenon.

Fig.2 Effect of sample thickness on drying rate of yacon using HPD

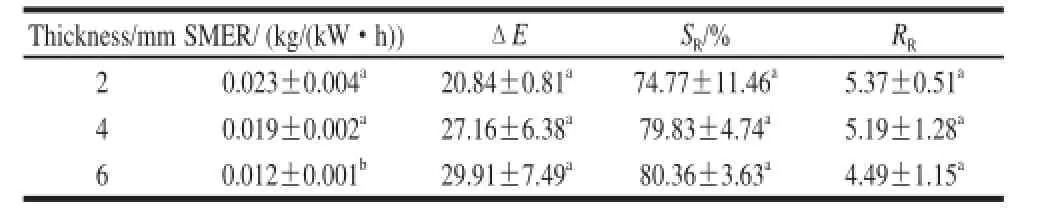

The effect of thickness on the index of SMER, ΔE, SRand RRis shown in Table 2. It can be seen that no significant differences (P>0.05) were found for the runs of thickness of 2, 4, 6 mm except SMER. SMER decreased as thickness increased. Thickness of 2, 4 mm has significantly (P<0.05) higher SMER than that of 6 mm. Overall consideration, 2―4 mm can be chosen in the next experiment.

Table 2 Effect of sample thickness on SME

Table 2 Effect of sample thickness on SME

Note: Different letters in the same column mean signifi cantly different (P< 0.05). The same as follows.

Thickness/mm SMER/ (kg/(kW·h)) ΔE SR/% RR2 0.023±0.004a 20.84±0.81a 74.77±11.46a 5.37±0.51a4 0.019±0.002a 27.16±6.38a 79.83±4.74a 5.19±1.28a6 0.012±0.001b 29.91±7.49a 80.36±3.63a 4.49±1.15a

2.2 Effect of surface load

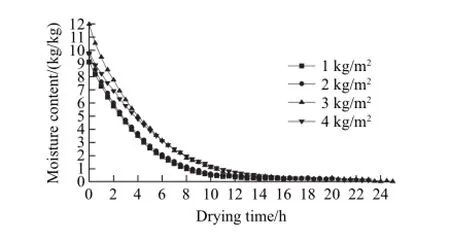

The variations of moisture content against the drying time are illustrated in Fig. 3. As drying time increased, the moisture content decreased to a certain value. The less surface load, the faster the moisture content decreased during the same drying time. Final moisture contents of 0.19, 0.19, 0.19, 0.15 kg/kg were achieved after drying time of 16, 19.5, 25, 26 h for the runs of surface load of 1, 2, 3, 4 kg/m2, respectively, which is quite close to the recommended moisture content of 0.11 kg/kg.

Fig.3 Effect of surface load on drying curves of yacon using HPD

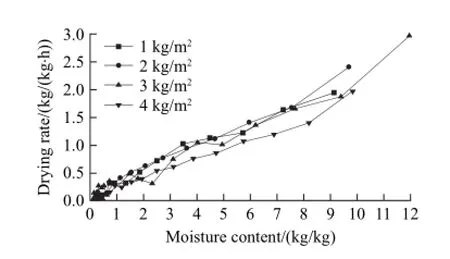

Fig.4 Effect of surface load on drying rate of yacon using HPD

Fig. 4 exhibits the relationships between drying rate and moisture content. All the curves present dominating falling rate trend during the whole drying process. Moreover, at the beginning of drying period the falling tendency was more notable. Although the curve of 3 kg/m2has more fluctuation than others, which may be caused by random error, the wholedevelopments have no significant differences. Several authors have found similar drying behaviour for cocoa beans and horse mackerel[12,15]. According to the drying mechanism, the whole drying rate was controlled by the rate of internal moisture migration. This can be used to explain why the drying processes show no constant rate periods.

The analysis results in Table 3 indicated that no significant differences (P>0.05) existed according to the ΔE, SRand RRwith different surface load except SMER. SMER increased with increasing surface load (P<0.05). Synthetically considering, 1―2 kg/m2can be used in the subsequent further experiment.

Table 3 Effect of surface loading on SMER,ΔE,SRa ndRR

2.3 Effect of drying temperature

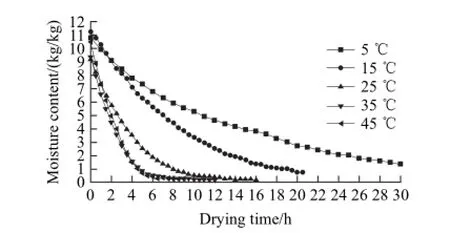

Fig.5 Effect of drying air temperature on drying curves of yacon using HPD

Fig. 5 shows the variations of moisture content with drying time for drying temperatures of 5, 15, 25, 35, 45 ℃. Higher drying temperature resulted in lower moisture content and reduced the drying time. Moisture content was comparable at drying temperatures of 35, 45 ℃. Final moisture contents of 0.42, 0.36, 0.19, 0.18, 0.24 kg/kg were achieved for the drying temperatures of 5, 15, 25, 35, 45 ℃ after drying time of 56, 25.5, 16, 10.9, 8.75 h, respectively (some data not presented). The variations of drying rate as a function of moisture content for drying temperatures of 5, 15, 25, 35, 45 ℃with constant air velocity of 1.5 m/s have been reported by Shi Qilong et al.[20]. DR decreased continuously with drying time and increased sharply with drying temperature. Generally, the overall drying process occurred in the falling rate period, which implies that the drying rate is controlled by internal diffusion phenomenon according to the mass transfer controlling process.

The effect of drying temperature on the index of SMER is shown in Fig.6. As can be seen, SMER increased with an increase in drying temperature (P<0.05). The treatments of 35, 45 ℃ have higher SMER than those at 5, 15, 25 ℃(P<0.05). However, no significant differences (P>0.05) were observed between 35 ℃ and 45 ℃. The effect of drying temperature on the index of ΔE, SRand RRhas been studied and no significant differences (P>0.05) were existed between drying temperatures[20]. Overall considering, 25-35 ℃ can be selected in further experiments.

Fig.6 Effect of drying temperature on SMER of HPD system

2.4 Effect of drying air velocity

Fig.7 Effect of air velocity on drying curves of yacon using HPD

Fig.7 reveals the variations of moisture content against drying time under different air velocities. Obviously, the elevated flow rates enhanced the rate of evaporation from the yacon due to the heat and mass transfer coefficients increased with the air velocity. The curves of 1.5 m/s and 2.0 m/s showed almost the same tendency. Final moisture contents of 0.28, 0.22, 0.19, 0.22 kg/kg were achieved with drying time of 18.5, 20.25, 16, 17.5 h for air velocities of 0.5, 1.0, 1.5, 2.0 m/s, respectively. The variations of drying rate as a function of moisture content for air velocities at 0.5, 1.0, 1.5, 2.0 m/s with constant drying temperature of 25 ℃ have been reported by Shi Qilong et al.[20], in which DR decreased continuously with drying time and increased with increasing air velocity, and DR for yacon dried at velocities of 0.5, 1.0 m/s were lower than those of 1.5, 2.0 m/s. As expected, all the curves present dominating falling rate period during the entire drying process, which indicates that internal diffusionis the most likely physical mechanism governing the moisture movement in the yacon slice during heat pump drying.

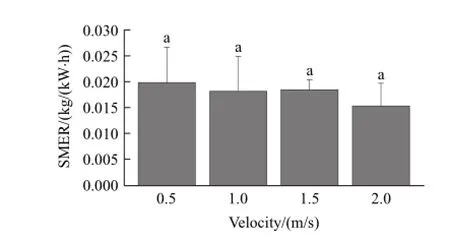

The effect of air velocity on the index of SMER is shown in Fig. 8. As can be seen, SMER decreased with increasing air velocity. However, no significant differences (P>0.05) existed between treatments. The effect of air velocity on the index of ΔE, SRand RRhas been investigated and no significant differences (P>0.05) were existed between treatments[20]. Overall considering, 1.5-2.0 m/s is suitable for yacon heat pump drying.

Fig. 8 Effect of air velocity on SMER of HPD system

2.5 Effect of evaporator BAR

Fig. 9 and 10 describe the effect of BAR on the drying process. Fig.9 presents typical drying curves, in which all the treatments showed nearly the same trend. In Fig.10, the drying rate curves also showed the same tendency, which after a falling period existed a transient constant drying rate period followed by a falling period. It seems that BAR has little influence on the drying process, and the results in Table 4 confirmed this. There were no significant differences (P>0.05) between treatments of BAR for SMER, ΔE, SR, and RR.

Fig.9 Effect of BAR on drying curves of yacon using HPD

Fig.10 Effect of BAR on drying rate of yacon using HPD

Table 4 Effect of BAR on SMER,

Table 4 Effect of BAR on SMER,

BAR SMER/(kg/(kW·h)) ΔE SR/% RR0.0 0.017±0.002a 28.60±1.41a 75.87±4.20a 5.76±0.22a0.2 0.020±0.001a 26.13±0.04a 78.68±2.90a 6.32±1.06a0.4 0.020±0.002a 24.55±6.67a 82.29±6.47a 7.19±0.79a0.6 0.019±0.002a 27.16±6.38a 79.83±4.64a 5.19±1.28a0.8 0.020±0.002a 27.57±0.39a 77.35±9.52a 6.38±0.64a1.0 0.020±0.002a 26.20±1.37a 85.30±0.64a 6.28±0.35a

3 Conclusions

The heat pump drying characteristics of yacon were influenced by thickness, surface load, drying temperature and air velocity. The required drying time increased as the thickness and surface load increased or the drying temperature and air velocity decreased. Lower thickness and surface load, and higher drying temperature and air velocity can yield high drying rate. Most heat pump drying rate curves of yacon displayed both long time falling rate period and a relatively short time constant rate period, while some curves existed only falling rate period. Considering SMER, ΔE, SRand RR, the optimum parameter range of yacon drying by HPD were thickness 2-4 mm, surface load 1-2 kg/m2, drying temperature 25-35 ℃ and air velocity 1.5-2.0 m/s. The drying characteristics and optimum parameter range of yacon during HPD will provide valuable information for the industrialization of yacon drying by HPD and for hybrid drying of HPD with other drying technology.

Referenncceess::

[1] SCHER C F, RIOS A D O, NOREÑA C P Z. Hot air drying of yacon (Smallanthus sonchifolius) and its effect on sugar concentrations[J]. International Journal of Food Science and Technology, 2009, 44(11): 2169-2175.

[2] SHI Qilong, ZHAO Ya, ZHENG Yaqin. Drying of yacon by hot air and microwave combination[J]. Food Science, 2011, 32(12):150-155.

[3] GENTA S, CABRERA W, HABIB N, et al. Yacon syrup: beneficial effects on obesity and insulin resistance in humans[J]. Clinical Nutrition, 2009, 28(2): 182-187.

[4] OJANSIVU I, FERREIRA C L, SALMINEN S. Yacon, a new source of prebiotic oligosaccharides with a history of safe use. Trends in Food Science and Technology, 2011, 22(1): 40-46.

[5] REIS F R, LENZI M K, MASSON M L. Effect of vacuum drying conditions on the quality of yacon (Smallanthus sonchifolius) slices: process optimization toward color quality[J]. Journal of Food Processing and Preservation, 2012, 36(1): 67-73.

[6] REIS F R, LENZI M K, BOLZÓN DE MUNIZ G I, et al. Vacuum drying characteristics of yacon (Smallanthus sonchifolius) and the effect of process conditions on fractal dimension and rehydration capacity[J]. Drying Technology, 2012, 30(1): 13-19.

[7] SAGAR V R, SURESH KUMAR P. Recent advances in drying and dehydration of fruits and vegetables: a review[J]. Journal of Food Science and Technology, 2010, 47(1): 15-26.

[8] NINDO C I, SUN T, WANG S W, et al. Evaluation of drying technologies for retention of physical quality and antioxidants in asparagus (Asparagus officinalis L.)[J]. LWT-Food Science and Technology, 2003, 36(5): 507-516.

[9] CHUA K J, CHOU S K, YANG W M. Advances in heat pump systems: a review[J]. Applied Energy, 2010, 87(12): 3611-3624.

[10] COLAK N, HEPBASLI A. A review of heat pump drying:Part 1-Systems, models and studies[J]. Energy Conversion and Management, 2009, 50(9): 2180-2186.

[11] GABAS A L, BERNARDI M, TELIS-ROMERO J, et al. Application of heat pump in drying of apple cylinders[C]// Proceedings of the 14th International Drying Symposium (IDS 2004), São Paulo, Brazil, August 22-25, 2004. São Paul: IDS 2004.

[12] HII C L, LAW C L, SUZANNAH S. Drying kinetics of the individual layer of cocoa beans during heat pump drying[J]. Journal of Food Engineering, 2012, 108(2): 276-282.

[13] FATOUH M, METWALLY M N, HELALI A B, et al. Herbs drying using a heat pump drier[J]. Energy Conversion and Management, 2006, 47(15/16): 2629-2643.

[14] WANG D C, ZHANG G, HAN Y P, et al. Feasibility analysis of heat pump dryer to dry hawthorn cake[J]. Energy Conversion and Management, 2011, 52(8/9): 2919-2924.

[15] CASTELL-PALOU Á, SIMAL S. Heat pump drying kinetics of a pressed type cheese[J]. LWT-Food Science and Technology, 2011, 44(2): 489-494.

[16] ZHANG Xuejiao, XIAO Gengsheng, TANG Daobang, et al. Mathematical modeling of thin layer heat pump drying of Cantonesestyle meat[J]. Food Science, 2013, 34(5): 100-104.

[17] SHI Qilong, XUE Changhu, ZHAO Ya, et al. Drying characteristics of horse mackerel (Trachurus japonicus) dried in a heat pump dehumidifier[J]. Journal of Food Engineering, 2008, 84(1): 12-20.

[18] GUAN Zhiqiang, ZHENG Lijing, LI Min, et al. Combined application of heat pump and microwave to dry tilapia fillets[J]. Food Science, 2012, 33(22): 58-62.

[19] Association of Official Analytical Chemists. Official methods of analysis[M]. Arlington V A: Association of Official Analytical Chemists, 2000.

[20] SHI Qilong, ZHENG Yaqin, ZHAO Ya. Mathematical modeling on thin-layer heat pump drying of yacon (Smallanthus sonchifolius) slices[J]. Energy Conversion and Management, 2013, 71: 208-216.

雪莲果热泵干燥特性及品质研究

石启龙,郑亚琴,赵 亚

(山东理工大学农业工程与食品科学学院,山东 淄博 255049)

研究雪莲果样品厚度、装料量、干燥温度、风速和旁通比对雪莲果热泵干燥特性及质量变化的影响。结果表明:雪莲果干燥速率随着样品厚度和装料量的增加而降低,随着干燥温度和风速的升高而增加。雪莲果热泵干燥过程绝大部分以降速干燥为主伴随相对较短时间的恒速干燥,而有些干燥速率曲线只存在降速干燥阶段。综合考虑单位能耗除湿率、色泽差异、收缩率、复水比,雪莲果热泵干燥最适参数范围:样品厚度2~4 mm、装料量1~2 kg/m2、干燥温度25~35℃、风速1.5~2.0 m/s。而旁通比对雪莲果热泵干燥进程影响不显著。

热泵干燥;雪莲果;干燥特性;质量

TS255.42

A

1002-6630(2014)03-0016-07

2013-03-26

国家自然科学基金项目(31171708);山东理工大学青年教师发展支持计划资助项目(110033)

石启龙(1974—),男,副教授,博士,研究方向为果蔬与水产品加工及贮藏工程。 E-mail:qilongshi@sdut.edu.cn

10.7506/spkx1002-6630-201403004