响应面优化超声辅助提取香菇多糖的工艺研究

2014-01-09陆小雨王俐人王珊珊丁之恩

陆小雨,丁 昱,王俐人,王珊珊,郭 磊,丁之恩

安徽农业大学茶与食品科技学院,合肥 230036

Introduction

Mushroom,a kind of basidiomycetes in oyster mashroom family,is one of the edible and medicinal fungi[1].As an immune enhancer,lentinan has been widely studied since 1960 s,and it showed to have functions in anti-viral,anti-tumor,regulating,lowering blood glucose and anti-oxidant[2].

Although the extraction and purification technologies have made great progress in the past decades,the extraction rate of polysaccharides in mushrooms is still on the low side.Recently,the extraction of mushroom polysaccharide using hot water and alkaline solution is reported,but extraction using acid solution is rarely reported[3].The hot water extraction is extremely timingconsuming and energy-consuming.Besides that,the alkaline solution extraction does harm to the environment[4].Hence,in this study,diluted acid solution with ultrasonic assisted extraction was investigated for the extraction of lentinan.

Materials and Methods

Materials,reagents and instruments

Premium mushrooms,purchased from local supermarket.NaOH,HCl,95% ethanol,phenol and 98% H2SO4were all analytical reagents.ML204 electronic balance was from Mettle Toledo Instrument (Shanghai)Co.,Ltd;Golden Leaf rotary evaporator and SHZ circulating water pump were all from Shanghai Ya Rong Biochemical Instrument Factory;Electric-heated thermostatic water bath was from Shanghai Jing Hong experimental Equipment Co.,Ltd;CNC ultrasonic cleaning Instrument was from Kunshan Ultrasonic Instrument Co.,Ltd.

Methods

Extraction process of lentinan

Dried mushrooms (1.0 g)→grinding→petroleum ether reflux→weighing→adding extraction→ultrasonic processing→water bath extraction→centrifugal→extract→analyzed by the modified phenol-sulfuric acid method at 490 nm.

Determination of lentinan by phenol-sulfuric acid method

Method chosen

The phenol-sulfuric acid method was adopted to determine the content of lentinan.Under concentrate H2SO4environemnt,lentinan was first dehydrolyzed into monosaccharide and was then dewatered to form orange derivatives that showed a maximum absorption at 490 nm[5].

Preparation of phenol solution

100 g phenol was mixed with 0.1 g of aluminum sheet and 0.05 g of NaHCO3,and distilled water for distillation.The distillate was collected at 180 ℃.10 g of phenol was dissolved into 190 mL distilled water to form 5% phenol solution.

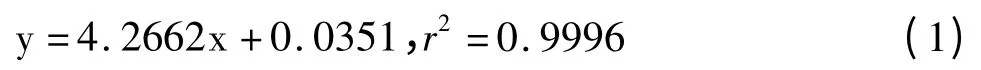

Standard curve

24.9mg of glucose reference substance was dissolved into 250 mL distilled water to form standard stock solution.5.0,10.0,15.0,20.0,25.0 mL of stock solution was added to 50 mL volumetric flasks and diluted to the volume with 0.2 mol/L NaOH to form a series of work solutions.1 mL of each diluted solution (1 mL 0.2 mol/L NaOH as control)was mixed with 0.3 mL 5% phenol solution respectively,and blended with 3mL concentrated sulfuric acid,keep 15 min before experiment.The absorbance values of the wok solutions were determined by UV spectrophotometer at 490 nm.The standard curve was as follows:

Content determination of lentinan

The extract of lentinan was dissolved in 100 mL distilled water and further diluted 50 times with 0.2 mol/L NaOH.1 mL of the diluted solution (1 mL 0.2 mol/L NaOH as control)was mixed with 0.3mL 5% phenol solution,and blended with 3mL concentrated sulfuric acid,keep 15 min before experiment,the absorbance values were determined by UV spectrophotometer at 490nm.The yield of lentinan was calculated using the following formula:

The yield of lentinan=[concentration of lentinan(mg/mL)× volume (mL)/Weight of raw materials

Experimental design and statistical analysis

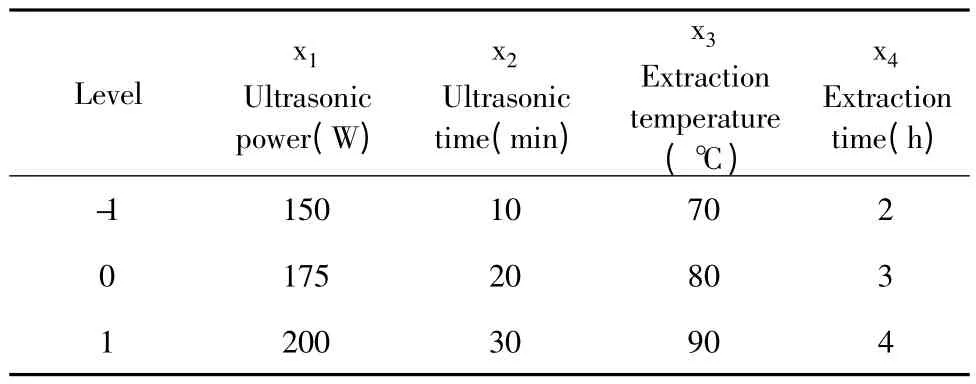

Response surface methodology was used to determine the influence of four independent variables (x1,ultrasonic power;x2,ultrasonic time;x3,extraction temperature;x4,extraction time)and the optimal extraction conditions of crude lentinan extract.A central composite design with the four independent variables and three levels was performed.The variables were coded according to the following equation:

Where xiwas the independent variable coded value;Xiwas the real value of an independent variable;was the real value of an independent variable at center point;△Xiwas the step change[6].Based on preliminary experiment results,the range of independent variables and their levels were presented in Table 1.

Table 1 Factors and levels of response surface analysis

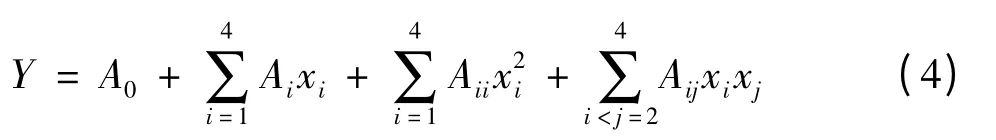

Data from CCD were analyzed by multiple regressions to fit the following quadratic polynomial model:

Where Y represented the response function;A0was the value for the fixed response at ventral point of experiments;Ai,Aiiand Aijwere coefficients estimated by the model;xi,xjwere levels of the independent variables.The analysis of variance table was generated,and the effect and regression coefficients of individual linear,quadratic and intercutting terms were determined.The regression coefficients were then used to make statistical calculation to generate three dimensional plots from the regression model[7].Design-Expert 8.0.6 software package was used to analyze the experimental data.The corresponding variables would be more significant if the absolute F-value becomes greater and the P-value becomes smaller.

Extraction yield of lentinan was used as the response value for the combination of the independent variables given in Table 2.

Table 1 Design and results of response surface analysis

Antioxidant activity of lentinan

Crystal violet method was chosen to reveal the antioxidant activity of lentinan.The reaction mixture consisted of 1 mL of 8.8 mmol/L H2O2,1 mL of 9 mmol/L Fe-SO4,1 mL of salicylic-ethanol,and 1 mL of different concentrations of lentinan samples.H2O2was lastly added to start the whole reaction.This reaction mixture was incubated at 37 ℃for 0.5 h.The absorbance of samples was measured at 510 nm against a blank of double distilled water.The mixture of 1 mL of 8.8 mmol/L H2O2,1 mL of 9 mmol/L FeSO4,1 mL of salicylic-ethanol,and 1 mL of double distilled water was determined as a background value.The scavenging effect was determined using the formula described by Ren[8].

Results and Discussion

Effect of ultrasonic power on extraction yield of lentinan

The effect of ultrasonic power on extraction yield of lentinan was shown in Fig.1.The ultrasonic power was set at 100,125,150,175,200 and 225 W while other extraction parameters were given as follows:ultrasonic time 40 min,extract 2 h in 80 ℃water bath.It can be found that the extraction yield increased as ultrasonic increased from 125 to 175 W,peaked at 175W,and then no longer increased when the ultrasonic power exceeded 175 W.

Effect of ultrasonic time on extraction yield of lentinan

Different ultrasonic time can significantly affect the extraction yield as shown in Fig.1.The ultrasonic time was set at 10,20,30,40,50 min while other extraction parameters were given as the follows:ultrasonic power 175 W,extract 2 h in 80 ℃water bath.It was found that the extraction yield of lentinan continued to increase evidently with the increasing ultrasonic time.But the extraction yield of lentinan was fallen down after the ultrasonic time exceeded 30 min.

Effect of extraction temperature on yield of lentinan

Fig.1 Effect of different extraction parameters on extraction yield of lentinan (ultrasonic power,W;ultrasonic time,min;extraction temperature,℃;extraction time,h)

In this experiment,the effects of different extraction temperature on the yield of lentinan were investigated,and the results were also shown in Fig.1.The other extraction conditions were fixed at ultrasonic power 175 W,ultrasonic time 40 min and with 2 h extraction time.As shown in Fig.1,the extraction yield of lentinan increased with the increasing of extraction temperature and reached the peak value when extraction temperature was 80 ℃.The extraction yield of lentinan no longer increased when the extraction temperature exceeded 80 ℃.

Effect of extraction time on yield of lentinan

Extraction time was another factor that would influence the extraction efficiency.A longer extraction time also presented a positive effect on the yield of lentinan.The effect of different time on extraction yield of lentinan was shown in Fig.1.When extraction yield was relatively rapid,and lentinan production reached a maximum at 3 h,and then no longer increased as the extraction proceeded.

Optimization of the extraction parameters of lentinan

Statistical analysis and model fitting

Table 2 showed the process variables and experimental data.The results of the model were summarized.The extraction yield ranged from 5.53% to 9.63%.The maximum value was found under the conditions of the ultrasonic power 175 W,ultrasonic time 20 min,and extraction temperature 80 ℃,extraction time 3 h.

The application of RSA offered,based on parameter estimates,an empirical relationship between the response variable (extraction yield of lentinan)and the testing variables under consideration.With applying multiple regression analysis on the experimental data,the response variable and the test variables were related by the following second-order polynomial equation:

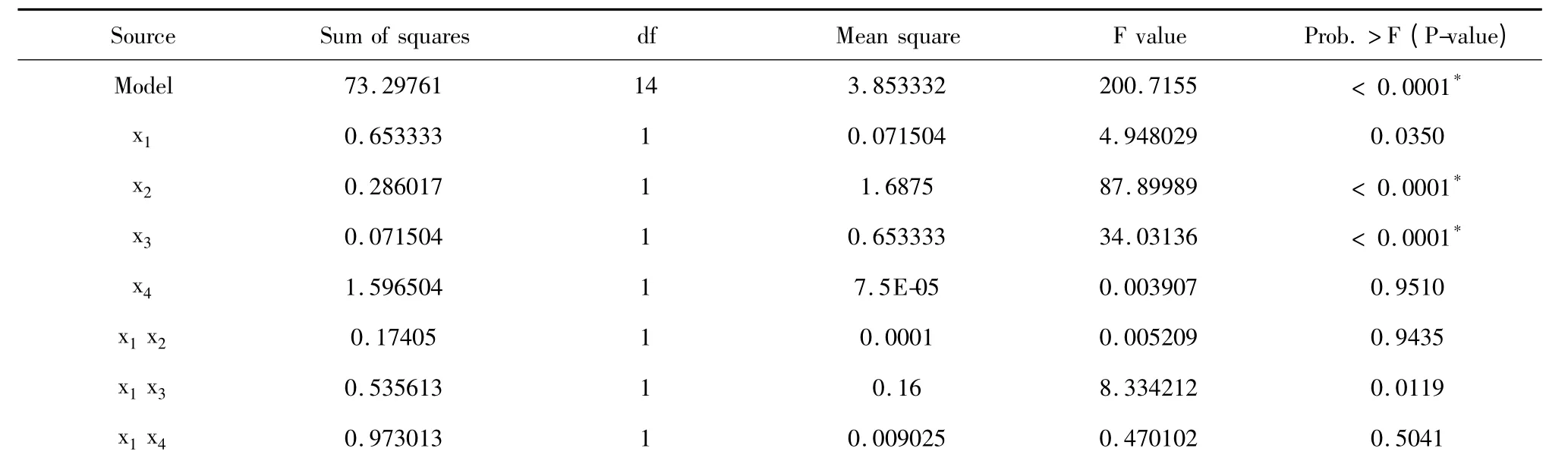

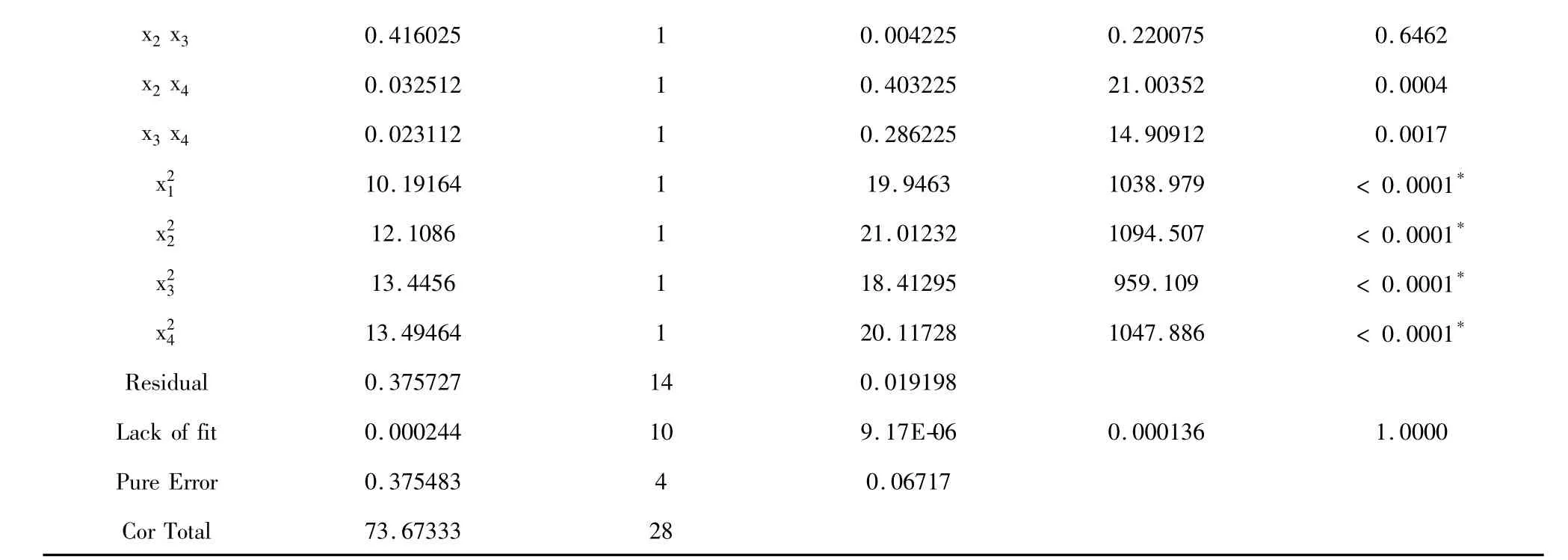

Table 3 ANOVA of response surface quadratic model

* means significant (values of“Prob.>F”<0.0001).

Statistical analysis of the model was performed in the form of analysis of ANOVA (Table 3),which was required to test the significant and adequacy of the model.The determination coefficient (R2=0.9950)was showed by ANOVA of the quadratic regression model.The P-value was used as a tool to check the significance of each coefficient,which in turn can indicate the pattern of the interactions between the variables.The smaller the P-value was,the more significant the corresponding coefficient was.It can be seen from this table that the linear coefficients (x2,x3),a quadratic term coefficientwere highly significant,with very small P-values (P <0.0001).The correlation measure for testing the goodness-of-fit of the regression equation was the adjusted determination coefficient(adjusted R2=0.9901).The value of adjusted R2was reasonably close to 1,indicated a high degree of correlation between the observed and predicted value.A very low value of coefficient of the variation (C.V.%=2.07)clearly indicated a very high degree of precision and a good deal of reliability of the experimental values.The full model filled Eq.(2)was made three-dimensional surface plots and contour plots to predict the relationships between the independent variables and dependent variables.

Interpretation of response surface model

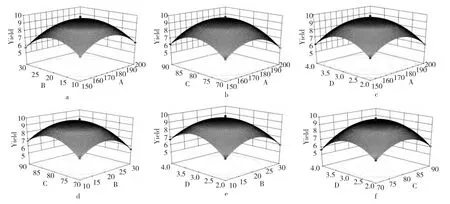

The three-dimension surface plots were drawn to illustrate the main and interactive effects of the independent variable on the dependent one.These graphs were obtained by fixing two variables at coded zero levels while varying the remaining two variables (lentinan yield).As Fig.2a shown,both ultrasonic power (x1)and ultrasonic time (x2)exerted a quadratic effect on lentinan production.Extraction yield of lentinan increased with increasing of ultrasonic power from 100 to 175 W,ultrasonic time from 5 to 20 min,but beyond 20 min,the extraction yield of lentinan decreased with the increasing extraction time as well as extraction power.Effect of ultrasonic power (x1)and extraction temperature (x3)on lentinan yield was presented in Fig.2b.The results revealed that the increase in ultrasonic power and extraction temperature extracted higher amount of lentinan.Fig.2c depicted the influence of ultrasonic power (x1)and extraction time (x4)when the ultrasonic power and extraction temperature were constant,the lentinan yield increased with the extraction time increased,when extraction time was over 3 h,the lentinan yield decreased as the extraction time rose.Fig.2d showed the 3-D plot at varying ultrasonic time (x2)and extraction temperature (x3).It can be seen as a quadratic effect for both ultrasonic time and extraction temperature.Fig.2e showed the 3-D plot at varying ultrasonic time (x2)and extraction time (x4).From the figures,it can be concluded that extraction yield of lentinan increased with increase of ultrasonic time from 5 to 20 min,and extraction yield of lentinan was found to increase rapidly with increase of extraction temperature from 60 to 80 ℃,then decreased from 80 to 100 ℃.The 3-D response surface plots based on independent variables extraction temperature (x3)and extraction time (x4)were shown in Fig.2f.It indicated that the maximum extraction yield of lentinan can be achieved when extraction temperature and extraction time was at the threshold level of 80 ℃and 3 h,respectively.

Fig.2 Response surface plots showing the effect of the ultrasonic power,ultrasonic time,extraction temperature,extraction time on the response yield (%)

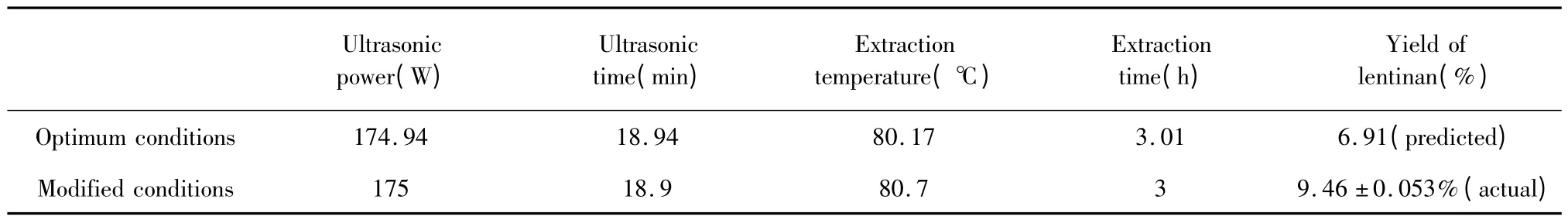

Verification of predicted model

The verification experiment was conducted under the optimized conditions obtained from the above study.The maximum predicted yield and experimental yield of lentinan were given in Table 4.To ensure the predicted result was not biased toward the practical value,experimental rechecking was performed by using these modified optimal conditions:ultrasonic power of 175W,ultrasonic time of 18.9min,extraction temperature of 80.7 ℃,extraction time of 3 h.A mean value of 9.46±0.053% was gained,obtained from actual experiments.It demonstrated the validation of the RSM model,indicating that the model was adequate for the extraction process.

Table 4 Predicted and experimental values of the responses at theoretical optimal and modified conditions

Unlike the previous reports,the raw materials were applied for the ultrasonic treatment and water bath simultaneously,which was clearly critical for improving the extract efficiency.The importance of this processing method was exemplified by Wang[9](the extraction yield of lentinan was 8.27%,which was higher than the previous reports).In addition,a dilute acid solution was used as the extractant,which substituted traditional distilled water,increased the degree of lentinan dissolution to a certain extent.

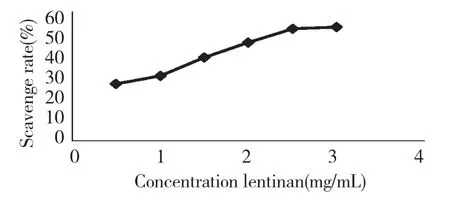

Antioxidant activity of lentinan

The experimental results showed that lentinan have good ability to scavenge ·OH,and the ability was proved to be concentration-dependent.As the concentration of lentinan increased,the rate of scavenging ·OH increased.When the concentration of lentinan was 3 mg/mL,the scavenging rate was determined to be 52.1%.

Fig.3 ·OH scavenging rates of lentinan

Conclusions

The extraction conditions of lentinan were successfully optimized with a statistical method based on the response surface methodology.The four investigated variables,namely ultrasonic power,ultrasonic time,extraction temperature and extraction time,all showed a positive influence on extraction yield of lentinan.The results showed that the optimal extraction conditions for the process were in 174.94 W of ultrasonic power,ultrasonic time 18.94 min,in 80.71 ℃extract 3.01 h,the highest extraction field reached at 9.61%.Compared with the traditional extraction methods,ultrasonic-assisted extraction using dilute acid solution was proved to be more efficient,time-saving,energy-saving.

It provided a useful reference for the extraction,development and utilization of polysaccharides from natural resources.

1 Borchers AT,Stern JS,Hackman RM,et al.Mushrooms,tumors and immunity.Proc Soc Exp Biol Med,1999,221:281-293.

2 Gu MExtraction,purification and structure elucidation of LT1,polysaccharides from lentinan eddoes.Wuhan:Huazhong University of Science and Technology,PhD.2009

3 Ma CQ,Xia R,Peng Y,et al.A study of methods for extraction of lentinan and amino acids from the foot body of Lentinus Edodes.Med Herald,2003,22:372-374.

4 Chepuruoim N.Influence of ultrasound on decrease sealer formation during evaporation of sugar solution.Pistchevaya Technol,1998,40:654-658.

5 Hromadkova Z,Ebringerova A,Valachovic P.Ultrasound-assisted extraction of water-soluble polysaccharides from the roots of Valerian.Ultrason Sonochem,2002,9:37-44.

6 Vázquez G,Freire MS,Santos J,et al.Optimization of polyphenols extraction from chestnut shell by response surface methodology.Waste Biomass Valor,2010,1:219-225.

7 Liu J,Miao S,Wen X,et al.Optimization of polysaccharides(ABP)extraction from the fruiting bodies of Agaricus blazei Murill using response surface methodology (RSM).Carbohyd Polym,2009,78:704-709.

8 Ren JY,Zhao MM,Shi J,et al.Purification and characteristics of antioxidant peptides from grass carp muscle hydrolysates by consecutive chromatography.Food Chem,2008,108:727-736.

9 Wang JY,Du FH,Chen TT,et al.Study on extracting of lentinan by ultrasonic wave.Food Ferment Tech,2010,47(3):96-99.