Effects of Moisture on Rheological Properties of PAV Aged Asphalt Binders

2013-07-31YuXinWeiJianmingLiuYunxinLuoYilinWangYingYinLong

Yu Xin; Wei Jianming; Liu Yunxin; Luo Yilin; Wang Ying; Yin Long

(1.College of Civil and Transportation Engineering, Hohai University, Nanjing 210098;

2. State Key Laboratory of Heavy Oil Processing, China University of Petroleum(East China), Qingdao 266580)

Effects of Moisture on Rheological Properties of PAV Aged Asphalt Binders

Yu Xin1; Wei Jianming2; Liu Yunxin1; Luo Yilin1; Wang Ying1; Yin Long1

(1.College of Civil and Transportation Engineering, Hohai University, Nanjing 210098;

2. State Key Laboratory of Heavy Oil Processing, China University of Petroleum(East China), Qingdao 266580)

1 Introduction

For the most coastal areas where the air is very humid, study on the effect of humidity on the performance of asphalt has its practical significance. However, limited research has been done to investigate the effect of humidity on rheological properties of asphalt. In this study, asphalt binders were aged in the pressure aging vessel (PAV) under different conditions of moisture and aging time. Then Dynamic Shear Rheometer (DSR) and Bending Beam Rheometer (BBR) measurements were conducted to obtain the parameters relating to the complex modulus, phase angle, failure temperature, and creep stiffness. It was found that the low temperature performance decreased as evidenced by the results of the creep stiffness. While there were no significant differences among conditioned binders based on complex modulusG* and phase angleδ, it was found that theδvalue increased when the humidity increased from 0% to 80%, and then theδvalue decreased when the humidity increased to 100%. In addition, the results of the failure temperature indicated that the humidity of 80% would be a critical point for the high temperature performance of the asphalt binders.

humidity; PAV aging; asphalt binders; rheological properties

It is well-known that the air in many coastal cities is very humid in China. Many studies have shown that the moist environment may inflict a big damage to the asphalt pavement. Since the effect of the moisture on the asphalt binders will play a significant role to the asphalt pavement, the study on effect of humidity on the behavior of asphalt has a practical significance.

In recent years, studies have been conducted to investigate the effect of moisture on the asphalt materials. Huang, et al. considered the factor of moisture in PAV and found out that the existence of moisture in PAV had a notable impact on the parameter ofG*/sinδ. They suggested to add moisture in the PAV test process to improve the accuracy in the simulation of asphalt service condition[1-3]. Huang’s study showed that moisture had no significant effect on the oxidation rate at atmospheric pressure. And the master curves of complex modulus and phase angle for dryaged and moist-aged asphalt binders fell right on the top of each other. Also it was identified that the aging in the presence of water (99% of relative humidity) at the pavement service temperature under atmospheric condition did not affect the rheological properties of asphalt binders[4]. Sun, et al.[5-9]investigated the effect of moisture on asphalt materials, and found that the water could dissolve a part of aged samples, which promoted the aging of the asphalt[8]. Lu, et al.[9]conducted the permanent deformation test of the asphalt mixture at 45 ℃ under moisture and dry–loading, and the results showed that the rutting depth was higher under wet condition than dry condition. Copeland[10]found out that the new types of flushing oil, internal loose materials, sinkage, rutting, etc., would emerge at the asphalt pavement under the influence of moisture.

It is known that previous studies mostly focused on the effect of water on the performance of asphalt mixtures[5-14]. Few studies have drawn the conclusion that the moisture could accelerate the aging of asphalt binder and reduce the service life of asphalt pavements[1-3]. In this study, rheological properties of asphalt after PAV aging in the presence of 0%, 80%, and 100% moisture, respectively,were studied to investigate the effect of moisture on the behavior of asphalt binders.

2 Experimental

2.1 Materials

Two types of asphalt binders, the un-modified asphalt binder and the SBS modified asphalt binder, were selected in this study. Table 1 shows the properties of the two asphalt binders.

Table 1 Properties of asphalt binders

2.2 Determination of the humidity condition

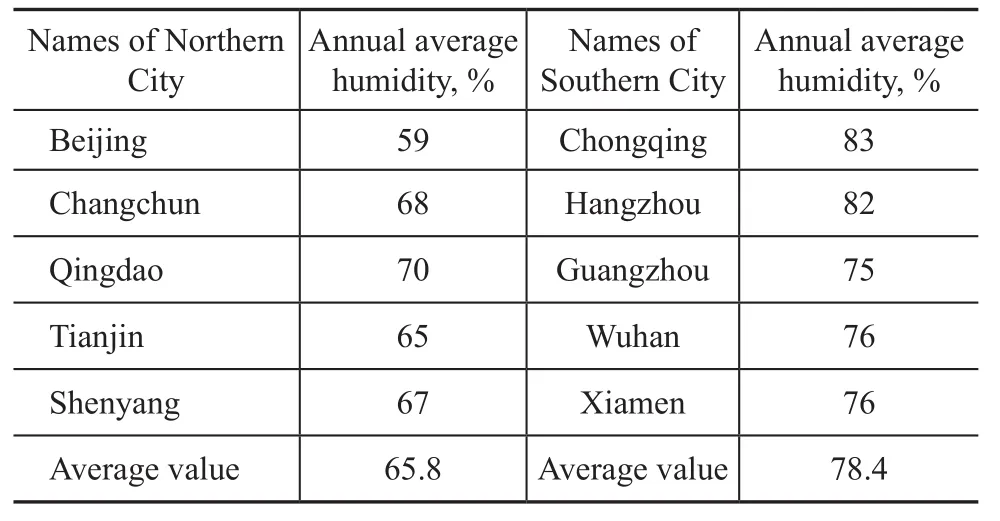

Table 2 shows the annual average humidity of the coastal cities in China in recent years[15].

Table 2 Annual average humidity of some typical cities in China

In order to compare the properties of the asphalt under various humidity conditions, the humidity conditions of 0%, 80% and 100% were selected in this study based on data depicted in Table 2.

2.3 Process of the sample preparation

Before the PAV test, a certain amount of water was added into the plate, and then the liquid water would be evaporated into water vapor in a short time and reach the required humidity value when PAV test started.

At a PAV temperature of 100 ℃, the related saturation vapor pressure (P0) will be 0.101 MPa. It is indicated that the pressure produced by water will be 0.101 MPa at the most in a limited volume. And the humidity can be calculated based on the definition of the relative humidity. Then the mass of liquid water can be calculated as follows:

in whichP—pressure (Pa), withP=80%×P0at a humidity of 80%;

V—volume (m3), withV=0.01 m3for the experimental device used;

n—amount of substance;

m—mass, g;

M—molecular weight,M=18;

R—gas constant,R=8.314; and

T—temperature measured,T=373 K.

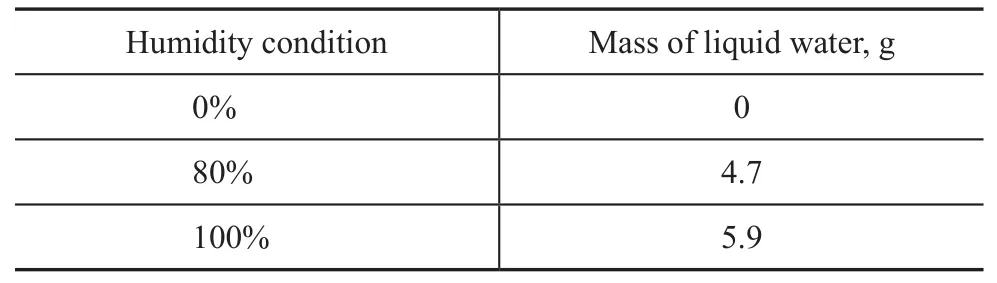

The calculated results are presented in Table 3.

Table 3 Mass of liquid water corresponding to two humidity conditions

Since it is generally accepted that the humidity may accelerate the aging process, two aging time of 15 hours and 20 hours were selected. The asphalt samples prepared by PAV in this study are shown in Table 4.

Table 4 Preparation of asphalt samples

Then, the DSR tests were conducted on all the samples to obtain the values of complex modulus and phase angle,and BBR measurements were carried out to investigate the creep stiffness and creep rate.

2.4 Test program

1) Dynamic Shear Rheometer (DSR) Test

A TA-AR1500EXmodel DSR was used to conduct frequency sweep experiments with various samples. The complex modulus (G*) and phase angle (δ) were collected. Then the master curves ofG*andδ, and the rut factor (G*/sinδ) were obtained to evaluate the viscoelastic properties of the asphalt samples. The testing temperature ranged from 25 ℃to 80 ℃, and the frequency was set from 0.1 Hz to 10 Hz and the strain control was 12%, while a diameter of 25 mm and a gap of 1 mm were used (at 25—80 ℃).

2) Bending Beam Rheometer (BBR) Test

Creep tests were performed according to the SHRP specification using the bending beam rheometer to evaluate the low temperature behavior of the binders at different temperatures (-12 ℃, -18 ℃, and -24 ℃). The creep stiffness (S) and creep rate (m) of the binders were determined from the bending stress and strain at a loading time of 60 s with the Surperpave design system[16].

2.5 Experimental procedure

The flow chart of the experimental procedure is presented in Figure 1.

Figure 1 Flow chart of the experimental program

3 Results and Discussion

3.1 Complex modulus and phase angle master curves

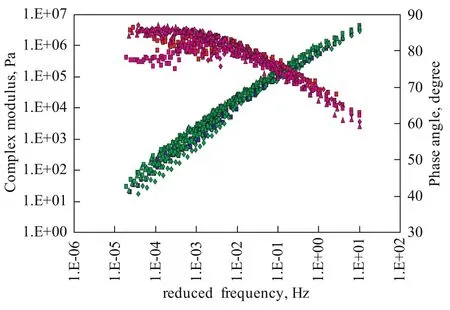

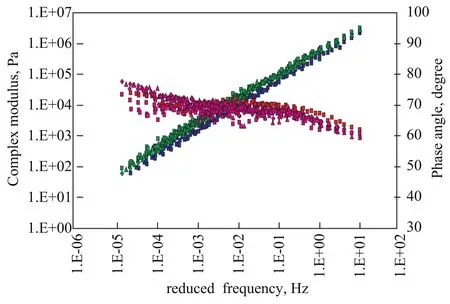

The conditioned binders, before and after being aged in PAV, were tested by DSR. According to the timetemperature superposition principle (TTSP), the complex modulus (G*) and phase angle (δ) master curves of these binders were constructed using the Sigmoidal model. The reduced frequency was calculated with a reference temperature of 25 ℃[17]. The master curves are shown in Figures 2-5. Generally, the decrease of phase angle indicates an increase of elastic response of the binder.

It can be seen from Figures 2 and 3 that there were no significant differences among these un-modified asphalt samples because aging mainly occurred in RTFOT[18-19], while the binders that were aged in PAV were not aged after RTFOT in this study. With regard to the effect of the humidity on the rheological properties of asphalt binders after being aged for 15 h, it can be concluded that the complex modulus (G*) showed a slight decrease when the humidity increased from 0% to 80%, and then a slight increase was identified when the humidity increased from 80% to 100%, especially at lower frequencies. However,the complex modulus (G*) of the SBS-modified asphalt decreased monotonously when the humidity increased from 0% to 100%, as shown in Figures 4 and 5.

Figure 2 G* and δ vs. frequency master curves of un-modified asphalt aged in PAV for 15 h

Figure 3 G* and δ vs. frequency master curves of un-modified asphalt aged in PAV for 20 h

It can be concluded from the data shown in Figures 4 and 5 that aging after PAV increased the complex shear modulusG*, and the differences among theG*values under different conditions of humidity and aging times were not obvious. Theδvalue increased when the humidity increased from 0% to 80%, and then theδvalue decreased when the humidity continued to increase from 80% to 100%, especially at higher frequencies. This phenomenon means that the elasticity of the asphalt binders was at the lowest level at a humidity of 80%.

Figure 4 G* and δ vs. frequency master curves of SBS modified asphalt aged in PAV for 15 h

Figure 5 G* and δ vs. frequency master curves of SBS modified asphalt aged in PAV for 20 h

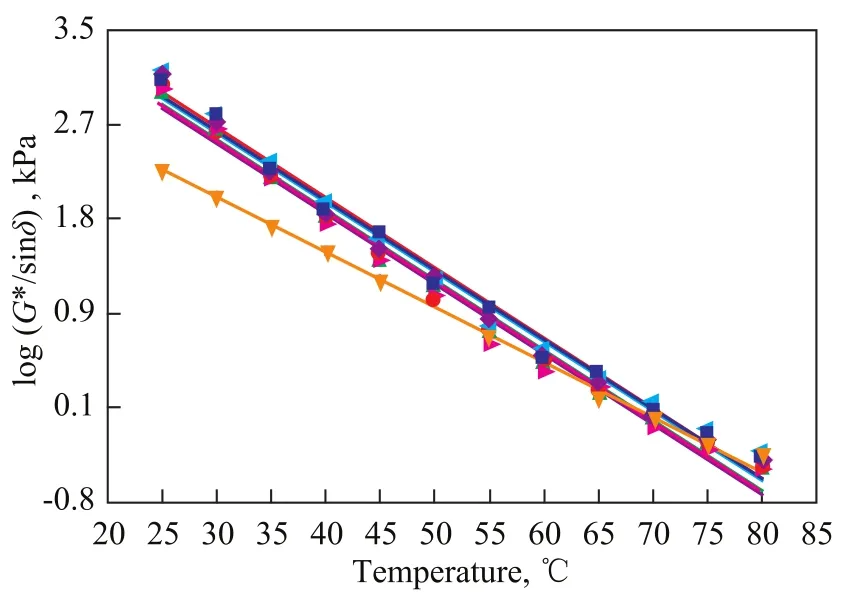

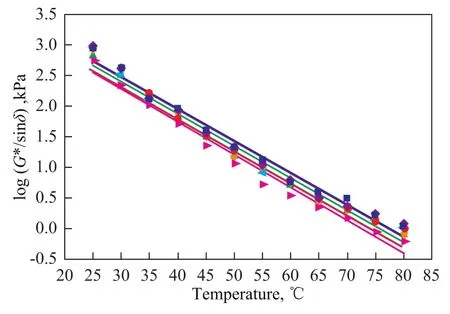

3.2 Failure temperature

Failure temperature used in the study is the temperature at which the binder fails at high temperature according to the SHRP specification[20]. By definition, the binder will fail when the parameter (G*/sinδ) of the conditioned binders obtained from DSR test is less than 1.0 kPa for original state, which is used in this study. Various prepared samples of binders were tested with DSR. The rutting factor (G*/sinδ) was measured at every 5 ℃ increment in the temperature range from 25 ℃ to 80 ℃. Thelogarithm of the rutting factor against the temperature is shown in Figures 6 and 7, respectively.

Figure 6 The logarithm of rut factor of un-modified asphalt with/without exposure in moisture

Figure 7 The logarithm of rut factor of SBS modified asphalt with/without exposure in moisture

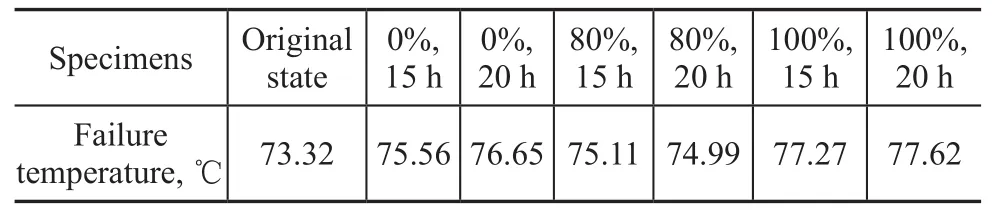

The failure temperatures of the rutting factor at 1.0 kPa were obtained by the linear regression models shown in Figures 6 and 7. And the test results are given in Tables 5 and 6.

Table 5 Failure temperature of un-modified asphalt

Table 6 Failure temperature of SBS modified asphalt

As shown in Tables 5 and 6, the failure temperatures of both un-modified asphalt and SBS modified asphalt slightly increase after PAV aging, which is consistent with the published results[21]. The failure temperatures of the asphalt binders decrease when the humidity is 80%, and then slightly increase when the humidity increases from 80% up to 100%. It is indicated that the high temperature properties of both asphalt binders would reach a minimum value when the humidity was 80%.

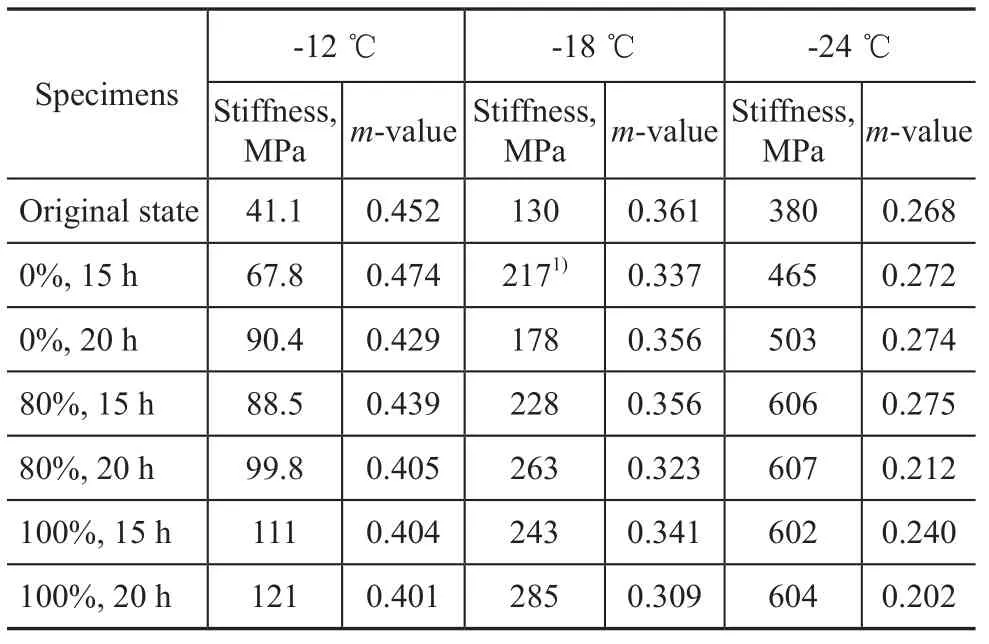

3.3 Creep stiffness and the m-value

The low temperature performance of various binders aged in PAV were evaluated by the BBR at different temperatures (-12 ℃, -18 ℃, and -24 ℃). The creep stiffness and creep rate (m-value) of asphalt samples are given in Tables 7 and 8, respectively.

Table 7 Creep stiffnessSandm-value after PAV treatment of un-modified asphalt

Table 8 Creep stiffnessSandm-value after PAV treatment of SBS modified asphalt

It can be noted from the data listed in Tables 7 and 8 that stiffness of the un-modified asphalt and the SBS modified asphalt was affected by humidity at different agingtime. By taking the aging time of 20 hours as an example, the maximum increase in the creep stiffness of the unmodified and SBS modified asphalt samples were 46.8% and 33.8% at -12 ℃, respectively, indicating that the low temperature properties of the specimen significantly decreased under the influence of humidity. Also, the SBS modified asphalt showed slightly superior resistance ability than the un-modified asphalt.

4 Conclusions and Recommendations

In this study, asphalt binders with moisture in PAV aging were tested in DSR and BBR on their complex modulus, phase angle master curves, failure temperature and stiffness. Based on these test results, several conclusions and recommendations can be drawn as follows:

With the same aging time, the results of the complex modulus, phase angle master curves and the failure temperature showed that moisture played a counteractive role on the aging of asphalt binders. In other words, it is indicated that the moisture reduced the high temperature performance of the asphalt binders aged in PAV. The humidity of 80% seems to be a turning point, which means that the high temperature property of the binders would reach a minimum value at a humidity of 80%. With the same humidity, the complex modulus slightly increased with the increase of aging time, which is a reasonable outcome.

The low temperature performance also decreased when the humidity increased as evidenced by the results of stiffness, which indicated that the humidity had a negative impact on the properties of asphalt binders.

The SBS modified asphalt exhibited superior resistance performance against the humidity than the un-modified asphalt. Thus, the SBS modified asphalt is recommended to be used in high humidity environments.

More research should be conducted to reduce the effect of humidity on the properties of asphalt as well as the asphalt mixtures.

Acknowledgements:This research is supported by the National Natural Science Fund Project of China (NSFC) (No.: 51278173) and the Natural Science Fund Project of Jiangsu Provincial Communications Department (No.: SBK201120606).

[1] Li Haijun, Huang Xiaoming, Wang Hongchang. Water aging of asphalt during its service life of pavements[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2005, 21(4): 75-78 (in Chinese)

[2] Ma T, Huang X, Mahmoud E, et al. Effect of moisture on the aging behavior of asphalt binder[J]. International Journal of Minerals, Metallurgy, and Materials, 2011, 18(4): 460-466

[3] Bian Fenglan, Zhao Yongli, Huang Xiaoming, et al. Experimental study of water aging on asphalt during service life of pavements[J]. Journal of Southeast University (English Edition), 2010, 26(4): 618-621

[4] Huang S C, Glaser R, Turner F. Impact of Water on Asphalt Aging[J]. Transportation Research Record: Journal of the Transportation Research Board, 2012, 2293(1): 63-72

[5] Liu Liping, Sun Lijun. Environment influence coefficients of field fatigue equations for asphalt pavements[J]. Journal of Tongji University (Natural Science), 2008, 36(2): 178-181 (in Chinese)

[6] Lu Zhenglan, Sun Lijun. Impact analysis of shear strength on the rutting performance of asphalt mixture[J]. Shanghai Highways, 2006 (3): 6-9 (in Chinese)

[7] Lu Zhenglan, Sun Lijun. Research on rutting prediction of asphalt pavement[J]. Journal of Tongji University (Natural Science), 2007, 35(11): 1476-1480 (in Chinese)

[8] Kang Aihong, Zhou Xin, Wu Meiping, et al. Aging of TOR asphalt rubber in combination of environmental factors[J]. Journal of Nanjing University of Science and Technology, 2012, 36(4): 724-728 (in Chinese)

[9] Lu Hewei, Zhang Hongchao, Sun Lijun. Permanent deformation analysis of asphalt mixture under moisture-loading coupled action[J]. Journal of Building Materials, 2012, 15(6): 788-792 (in Chinese)

[10] Copeland A R. Influence of moisture on bond strength of asphalt-aggregate systems[D]. Vanderbilt University, Civil Engineering, 2007

[11] Cheng D X, Little D N, Lytton R L, et al. Moisture damage evaluation of asphalt mixtures by considering both moisture diffusion and repeated-load conditions[J]. Transportation Research Record, 2003(1832): 42-49

[12] Caro S, Masad E, Bhasin A, et al. Moisture susceptibilityof asphalt mixtures, Part 1: mechanisms[J]. International Journal of Pavement Engineering, 2008, 9(2): 81-98

[13] Kringos N, Scarpas A, Copeland A, et al. Modelling of combined physical–mechanical moisture-induced damage in asphaltic mixes. Part 2: Moisture susceptibility parameters[J]. International Journal of Pavement Engineering, 2008, 9(2): 129-151

[14] Aschenbrener T. Evaluation of Hamburg wheel-tracking device to predict moisture damage in hot-mix asphalt[J]. Transportation Research Record, 1995 (1492): 193-201.

[15] Average annual temperature and humidity of major cities in the country[R//OL]. http://news.mechnet.com.cn/content/2010-02-03/72699.html

[16] Zhu Chunyang, Yang Yi, Liu Xuejian. Research on bending beam rheological properties of different label asphalt[J]. Journal of China & Foreign Highway, 2007 (4): 289-291 (in Chinese)

[17] Khattak M J, Khattab A, Rizvi H R, et al. The impact of carbon nano-fiber modification on asphalt binder rheology[J]. Construction and Building Materials, 2012, 30: 257-264

[18] Zhang Zhengqi, Liang Xiaoli, Li Ping. Evaluation method of asphalt aging properties [J]. Journal of Traffic and Transportation Engineering, 2005, 15(1):1-5 (in Chinese)

[19] Wang Peng, Zeng Fanqi, Guo Chengchao. Effects of aging way and aging time on the behaviors of asphalt [J]. Hunan Communication Science and Technology, 2006, 32(4): 7-18 (in Chinese)

[20] Shen J, Amirkhanian S. The influence of crumb rubber modifier (CRM) microstructures on the high temperature properties of CRM binders[J]. The International Journal of Pavement Engineering, 2005, 6(4): 265-271

[21] Tian Xiaoge, Zheng Jianlong. Zhang Qisen. Effect of aging on viscoelastic performance of asphalt binder [J]. Journal of Traffic and Transportation Engineering, 2004, 4(1): 3-6 (in Chinese)

Recieved date: 2013-06-09; Accepted date: 2013-06-28.

Dr. Yu Xin, Telephone: +86-13584097196; E-mail: hhu_yuxin@163.com.

杂志排行

中国炼油与石油化工的其它文章

- Study on the Synthesis and Properties of PET Using Hydrotalcite as Catalyst

- Kinetic Modeling of Methanol to Olefins (MTO) Process on SAPO-34 Catalyst

- CFD Simulation of Orifice Flow in Orifice-type Liquid Distributor

- Photocatalytic Denitrogenation over Modified Waste FCC Catalyst

- Experimental and Molecular Dynamics Simulations for Investigating the Effect of Fatty Acid and Its Derivatives on Low Sulfur Diesel Lubricity

- Study on Reactive Adsorption Desulfurization of Model Gasoline on Ni/ZnO-HY Adsorbent