Analysis of Micro-scale Flame Structure of AP/HTPB Base Bleed Propellant Combustion

2013-07-25RuiYEYonggangYUYongjieCAO

Rui YE*,Yong-gang YU,Yong-jie CAO

Analysis of Micro-scale Flame Structure of AP/HTPB Base Bleed Propellant Combustion

Rui YE*,Yong-gang YU,Yong-jie CAO

School of Energy and Power Engineering,Nanjing University of Science and Technology,Nanjing 210094,China Received 2 September 2013;revised 20 November 2013;accepted 25 November 2013 Available online 12 December 2013

A complex multiple fl ame structure is formed during the combustion of AP/HTPB base bleed propellant.The AP monopropellant fl ame is concentrated in a thin zone above the burning surface of AP crystal to maintain self-sustained decomposition.Due to the low temperature near the burning surface,the diffusion between the decomposition products of AP and the pyrolysis products of HTPB occurs,and a partly pre-mixed diffusion fl ame structure-leading edge fl ame(LEF)is formed.The effects of pressure,chemical reaction rate and AP particle size on diffusion fl ame structure in the range from 20 atm to 100 atm are discussed.The Peclet number increases from 6.64 at 20 atm to 21.91 at 100 atm when AP particle size is 140 μm.The high temperature zone is blown away from the burning surface because the convective transport rate increases with the increase in Peclet number.The chemical reaction rate is enhanced and the diffusion mixing is inhibited as Damkohler number increases.The chemical heat release is more concentrated and the chemical reaction zone becomes narrow when Damkohler number changes from 330 at 20 atm to 4700 at 100 atm.When AP particle diameter is decreased to 60 μm,the diffusion time scale is reduced due to the reduced diffusion length scale.So the diffusion mixing is enhanced and a more pre-mixed fl ame is formed.The burning rate increases because the more pre-mixed heat release increases the heat feedback to the HTPB binder.

CopyrightⒸ2013,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

AP/HTPB;Base bleed charge;Flame structure;Peclet number;Damkohler number

1.Introduction

Theammoniumperchlorate/hydroxyl-terminatedpolybutadiene(AP/HTPB)base bleed propellant has been used in extended range projectile to improve its f i ring range.But its shortcoming is that the f i ring range dispersion is bigger than that of traditional projectile.The main feature of AP/HTPB propellant is that the AP particles with different granularities are embedded in a HTPB polymer matrix.The study of AP/ HTPB base bleed propellant mainly focused on second ignition stability and second ignition consistency[1-4]. However,a few studies have been dedicated to combustion fl ame structure.When AP/HTPB propellant burns,the physical inhomogeneity and the complex physiochemical processes of condensed phase and gas phase may result in its combustion mechanism being different from that of homogeneous propellant to form a multiple fl ame structure[5].The fl ame structure and combustion characteristics depend on propellant composition,AP particle size,pressure and additives.In 1986, Price et al.[6]obtained a basic fl ame structure of AP/HTPB propellant by examining the extinguished surface of sandwich structure(AP/HTPB/AP)via rapid depressurization.With the development of technology,it’s possible to directly observe the fl ame structure using ultraviolet emission and transmission imaging technology.The experimental works in Refs.[7-9] provide data for theoretical modeling.

This paper attempts to characterize the micro fl ame structure and discuss the effects of pressure,chemical reaction rateand AP particle size on the combustion of AP/HTPB base bleed propellant based on Peclet(Pe)number and Damkohler (Da)number.

2.Physical model

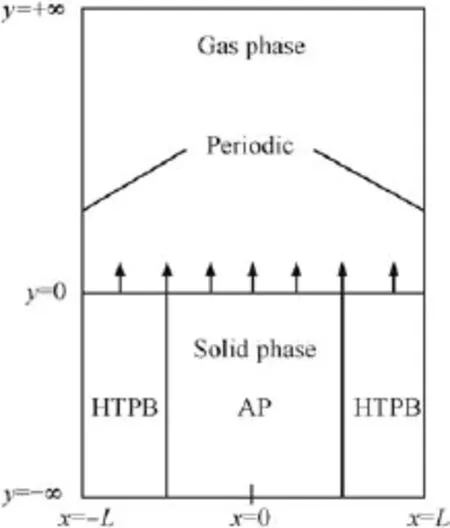

A two-dimensional sandwich combustion model of AP/ HTPB base bleed propellant is shown in Fig.1.To simplify the model,some assumptions are made as follows:

1)Only AP oxidizer and HTPB binder are considered in the solid phase,and they are treated as two independent ingredients with constant thermophysical properties.

2)The condensed phase reaction is regarded as surface reaction and simplif i ed as interfacial endothermic reaction, and only the thermal conduction effect is considered in the solid phase.

3)The gas phase is regarded as ideal gas and the Lewis number of all the ingredients is 1,the specif i c heat cgis constant and the thermal conductivity varies with temperature only.

4)Arrhenius law is introduced to characterize the thermal decomposition of solid phase,and BDP model is introduced to describe the gas phase reaction.

5)The prof i le of the burning surface is not considered here,and the coupled burning surface is regarded as a plane.

Fig.1.Sandwich combustion model of AP/HTPB base bleed charge.

3.Mathematical model

3.1.Gas phase governing equations

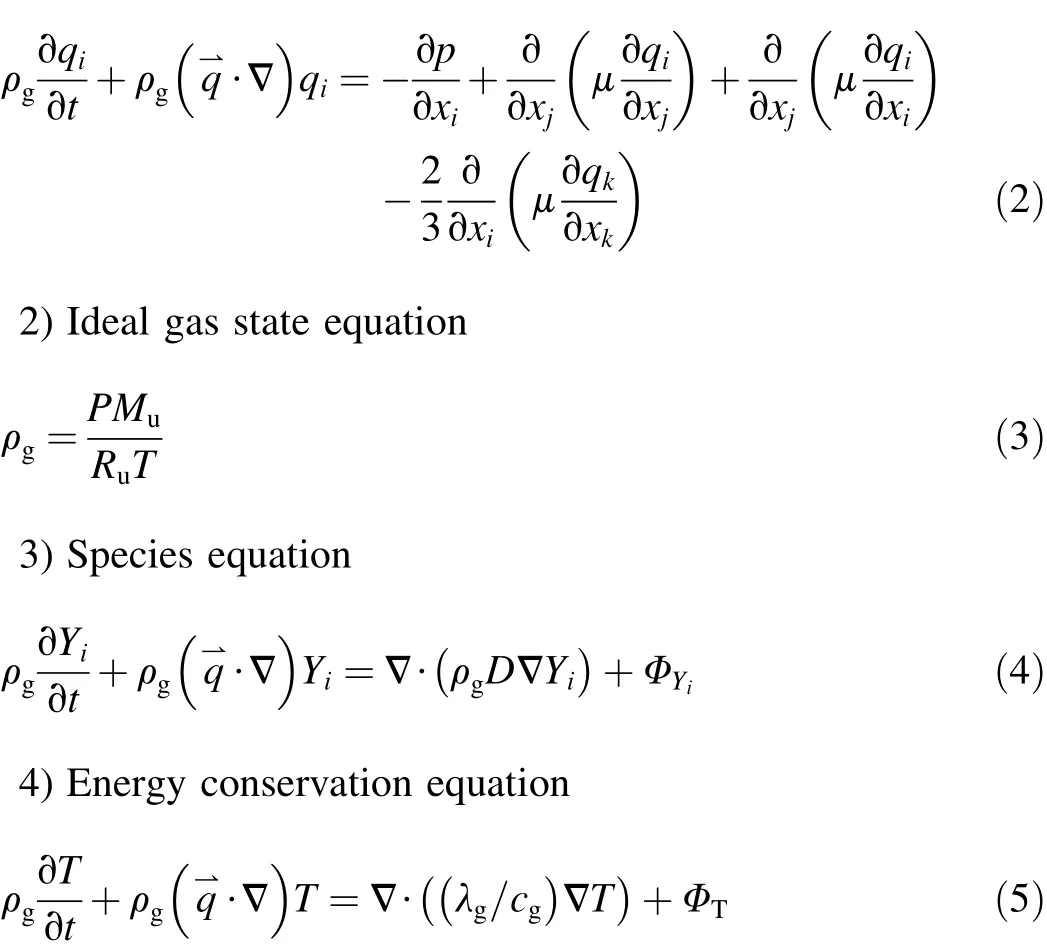

The gas phase governing equations include:

1)Navier-Stokes equation

where q⇀=(q1,q2)=(u,v)is the velocity vector;xi=(x1,x2)=(x,y)is the coordinate direction;ρg,μ,cgand Muare the gas density,viscosity,specif i c heat and molecular molar weight, respectively;Yiis the mass fraction of species;ΦYiand ΦTare the species and energy source,respectively.

However,the thermal conductivity coeff i cient,λg,of gas phase changes with temperature given by Ref.[10].λgis given by

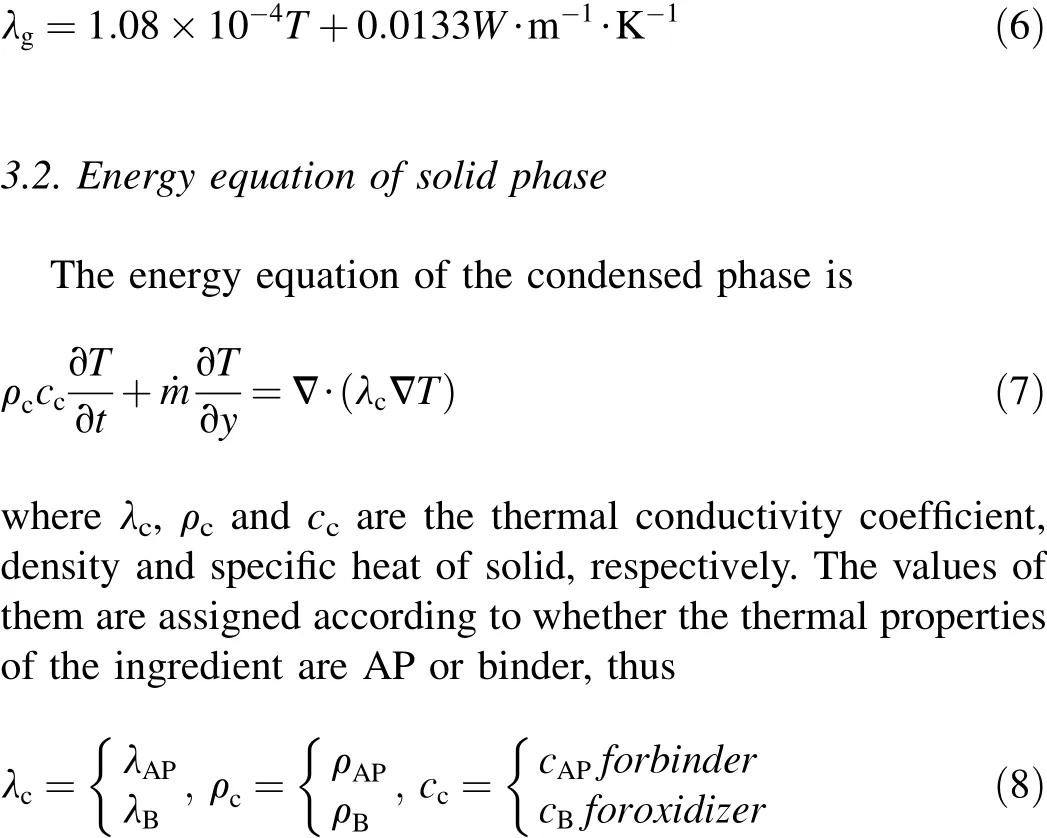

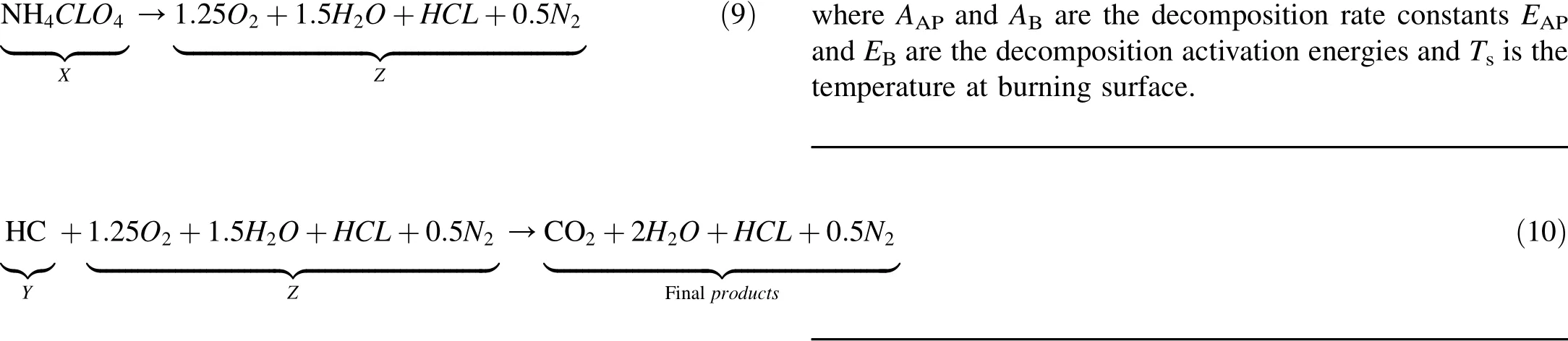

3.3.Gas phase chemical reaction mechanism

The detailed elementary chemistry of the gas phase is complex and still not well understood.The basic concept of modeling approach adopted is to use the simpli fi ed method to capture the two main features of AP/HTPB base bleed propellant combustion,AP monopropellant fl ame and diffusion fl ame.So a two-step global chemistry based on BDP model is used to characterize the gas phase reaction[11].From the equations above,NH4CLO4can be regarded as oxidizer X,the decomposition products,such as O2,H2O,HCL and N2can be regarded as oxidative intermediate product Z, and the pyrolysis product HC of binder can be regarded as fuel Y.So the gas phase chemical reaction process can be simplif i ed to

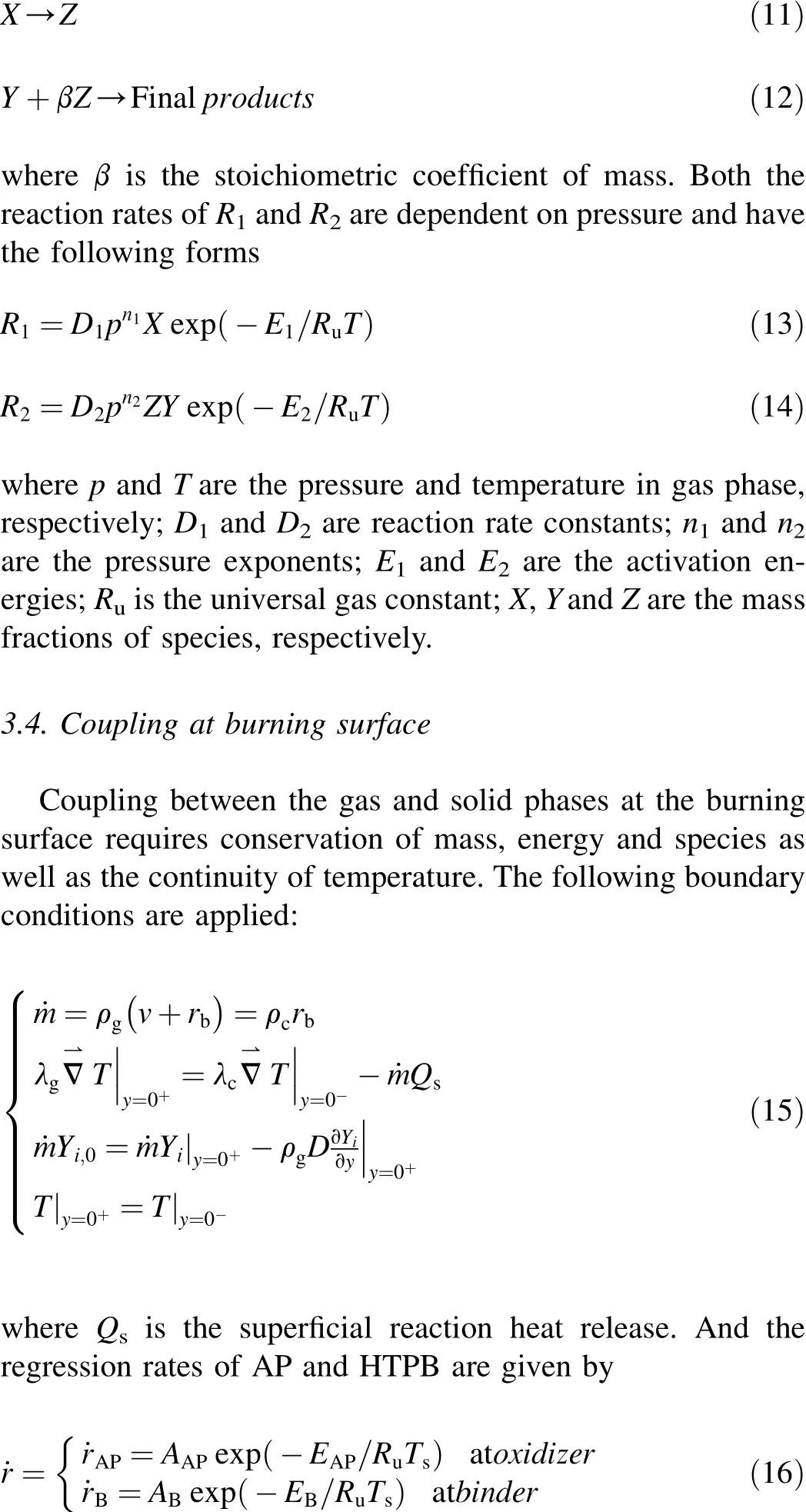

3.5.Boundary conditions

The periodic sandwich combustion model is shown in Fig.1.Here only periodic half width L is considered for simplifying.L is def i ned as follows

where α is the mass fraction of AP.α is 0.8 here.The burning surface is located at y=0 with reference frame f i xed on the burning surface.The heights of the gas and solid phases are 500 μm.The temperature of the solid far-f i eld boundary is taken as room temperature(300 K).For far-f i eld boundary condition of the gas phase,the gradients of both temperature and species along y direction are taken as zero.For the symmetric boundary,all the gradients of parameters along x direction are taken as zero.

4.Results and discussion

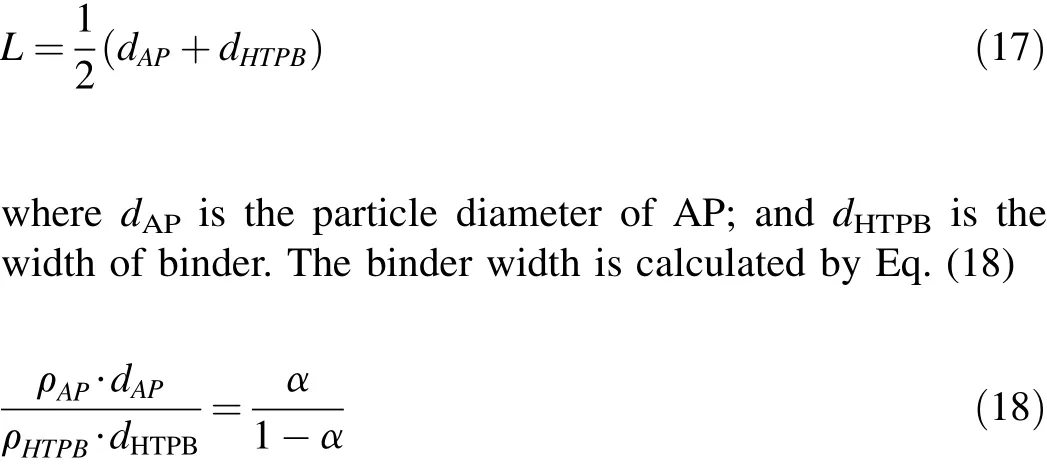

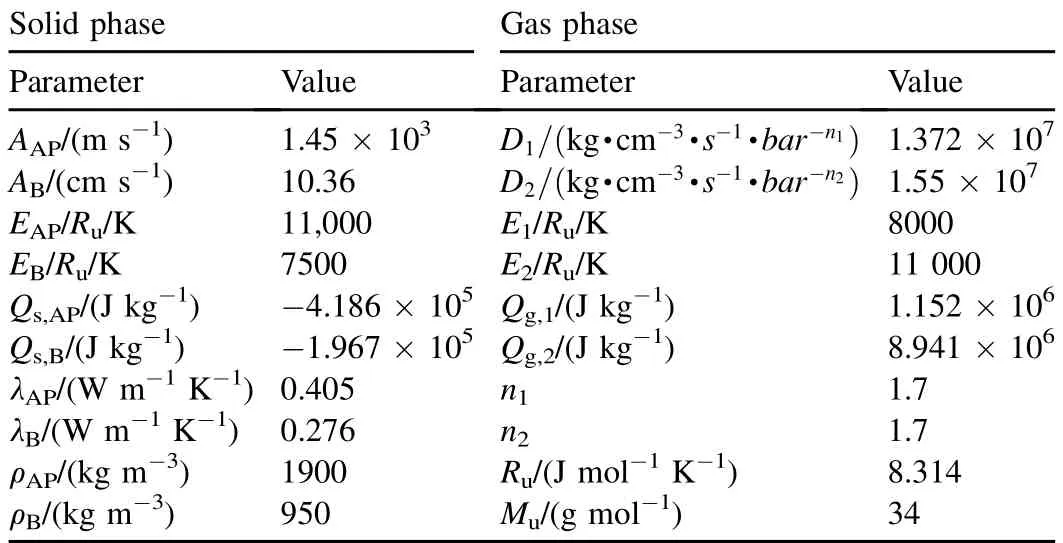

The chemical kinetics and thermophysical properties are obtained from Ref.[12],as listed in Table 1.

Table 1Parameter values in numerical solutions.

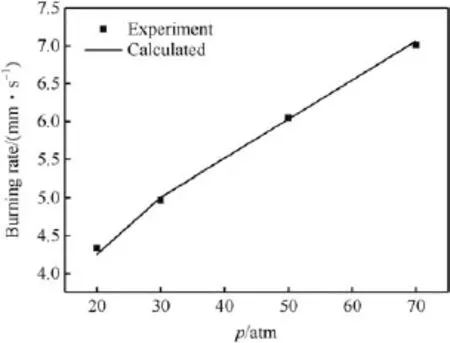

In order to validate the model,the calculated burning rate is compared with experimental data in Ref.[13]with AP mass fraction of 80%and AP particles diameter of 110 μm in the range of 20 atm-70 atm.Good agreement is achieved,as shown in Fig.2.

Fig.2.Burning rate varies with pressure for dAP=110 μm.

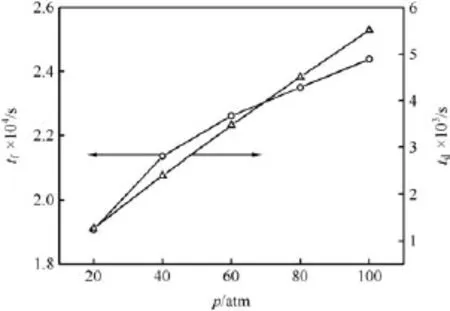

Fig.3 shows the basic fl ame structure of AP/HTPB base bleed propellant when AP particle size is 140 μm at 40 atm. The fl ame structure is characterized in terms of volumetric heat release.Fig.3(a)shows AP monopropellant fl ame.It should be noted that the AP monopropellant fl ame is distributed laterally in a relative thin sheet2over AP solid.The heat fl ux from gas to solid is 3707.6 W/cmat the cente2r line of AP particle.However,the heat fl ux is 3659.5 W/cmwhen pure AP is burnt at 40 atm.This implies that AP monopropellant fl ame just maintains self-sustained combustion.Fig.3(b) shows the diffusion fl ame between the decomposition products of AP and the pyrolysis products of HTPB.The diffusion fl ame is concentrated above AP/HTPB interface,but more over AP particle.Fig.3(c)shows the total fl ame structure. Therefore,it can be concluded that the diffusion fl ame controls the combustion of AP/HTPB.

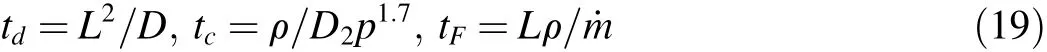

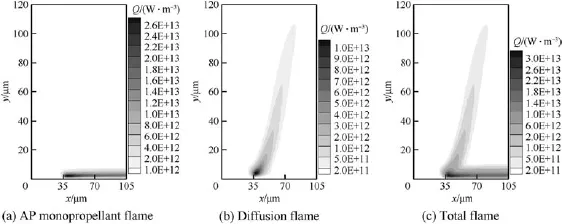

Three time scales,namely diffusion time scale,chemical reaction time scale and fl ow residence time scale,are introduced to analyze the effects of pressure,reaction rate and AP particle size on the combustion characteristics of AP/HTPB base bleed propellant.They are de fi ned by Eq.(19)

Here,another two non-dimensional parameters,namely Pe number and Da number,are introduced to characterize the relative magnitudes of the three time scales.Pe number represents the ratio of convective transport rate to diffusive transport rate,which is mostly related to burning rate and AP particle size.Da number represents the ratio of chemical reaction to diffusive transport rate,which is mostly related to pressure and AP particle size.They are estimated by the following expressions.

Fig.4.Correlations of diffusion time scale and f l ow residence time scale with pressure

Fig.3.Flame structure of AP/HTPB base bleed charge(p=40 atm,dAP=140 μm).

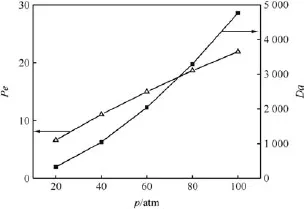

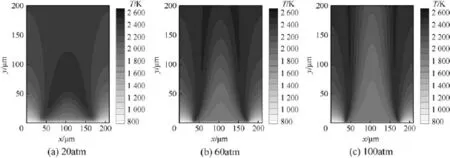

Fig.4 shows that the diffusion time scale and f l ow residence time scale vary with pressure when AP particle diameter is 140 μm.The diffusion time scale and f l ow residence time scale are 10-3s and 10-4s,respectively.Fig.5 shows that the Pe number changes from 6.64 at 20 atm to 21.91 at 100 atm. The convective transport effect is enhanced and the diffusion between AP decomposition products and HTPB pyrolysis products is relatively restrained with the increase in Pe number.The energy transfer due to diffusion is lower than the energy transfer due to convection.Therefore,a high temperature zone with sharp rim penetrates upstream and stays for a few microns above AP/HTPB interface,but for more long overAP side.A trailing diffusion f l ame followed the sharp high temperature zone above AP solid is blown away from the burning surface,as shown in Fig.6.The high temperature zone with sharp rim moves close to the burning surface from about 25 μm at 20 atm to about 3 μm at 100 atm.

It can be also seen from Fig.5 that the chemical reaction time scale is much smaller than the diffusion time scale.Da increases from 330 at 20 atm to 4700 at 100 atm.The value of Da approximately increases with p1.7dependence.However, the reaction time scale rapidly decreases with p1.7dependence.The smaller the chemical reaction time scale is,the faster the chemical reaction is.So the heat release kernel gets close to the burning surface.Also,with the increase in Da number,the diffusion transport rate is relatively limited.The fast chemical reaction rate makes it relatively diff i cult to mix between AP decomposition products and HTPB pyrolysis products.In other words,the chemical reaction initiates as soon as the species mix.Therefore,the reaction zone along the downstream direction becomes thin and narrow,as shown in Fig.7.

Fig.5.Correlations of Pe number and Da number with pressure.

Fig.6.Temperature distribution(K)of gas phase(dAP=140 μm).

Fig.7.Diffusion f l ame structures at different pressures(dAP=140 μm).

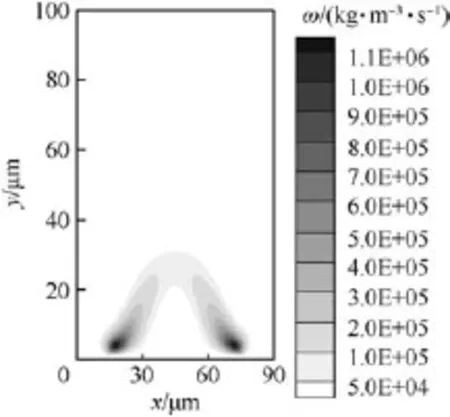

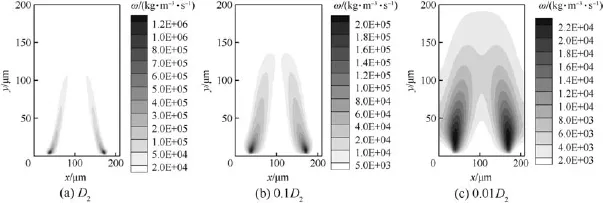

The heat release kernel is about 6 μm far from the burning surface when AP particle diameter is 140 μm at 20 atm.It works as a f l ame holder followed by a trailing diffusion f l ame. Price et al.[6]calls the structure as leading edge f l ame(LEF). The typical structure is shown in Fig.8.When the AP decomposition products and HTPB pyrolysis products leave the burning surface,the temperature of gas phase is lower than the initiation temperature of diffusion reaction.Low temperature means low Da number,and the diffusion mixing process is enhanced.There is a pre-mixed zone before the diffusion ignition temperature is reached.The temperature of the premixed zone raises as the pre-mixed species approaches the diffusion f l ame.Once the temperature of the pre-mixed species reaches the ignition temperature of diffusion f l ame,the chemical reaction initiates with rapid heat release.In the process,a pre-mixed diffusion f l ame structure,LEF,is formed.It can be seen that the diffusion f l ame is inf l uenced by both the reaction time scale and diffusion time scale.In order to further study this phenomenon,a calculation was madewith the pre-exponential factor reduced by 10 and 100 times. So the chemical reaction time scale is reduced to 0.1 and 0.01 of origin value,respectively.Fig.9 shows the reaction rate distribution of different pre-exponential factors at 40 atm.It can be seen from Fig.9 that the heat release kernel move far away from the burning surface at maximum heat release rate decreased by about 0.1 and 0.01 of its original value.The separate diffusion f l ame gets gradually merges when 0.01D2is used.The order of magnitude of Da is about 1 when the preexponential factor is 0.01D2.In this condition,the diffusion transport rate is relatively high,and the total chemical reaction is similar to pre-mixed combustion.It’s obvious that the gas phase reaction will be totally pre-mixing reaction and LEF structure will be vanished if a much smaller reaction rate constant is used.This implies that LEF is depended on the reaction rate.In addition,unlike the Burke-Schuman f l ame sheet model with inf i nite Da number(Da→∞),the chemical reaction between the decomposition products of oxidizer and binder occurs in a wider zone.Therefore,the existence of LEF is largely dependent on Da number,and also is largely dependent on chemical reaction rate.

Fig.8.AP composite propellant f l ame with LEF structure.

Fig.10 shows the diffusion reaction rate distribution when AP particle diameter is 60 μm at 40 atm.The diffusion time scale tdis reduced as the diffusion length scale decreases and so is the Da number.The diffusion mixing between the oxidizer and fuel species is much stronger than that of 140 μm AP diameter.It can be shown by comparing Fig.10 with Fig.9(a)that the two diffusion reaction layers merge together above AP solid when a smaller AP particle is used,which indicates a more pre-mixed f l ame.

Fig.10.Diffusion f l ame structure(p=40 atm and dAP=140 μm).

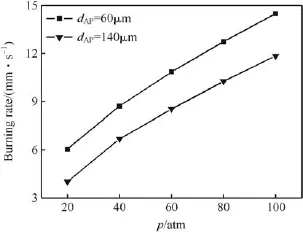

Fig.11 shows that the burning rate of AP particles of different diameters varies with pressure at 20 atm-100 atm. When a smaller AP particle is used,the diffusion length scale is decreased and a more pre-mixed diffusion f l ame is formed. The heat f l ux from the gas to the solid is more uniform,and hence the solid binder gets more heat feedback.The burning rate increases as AP particle size decreases.This feature indicates the ability of f i ne AP to adjust the burning rate.So in the real composite formulations,a different granularity gradation of AP particles is usually used to maintain the burning rate-pressure relationship.

Fig.11.Burning rate versus pressure for different AP particle diameters.

Fig.9.Diffusion reaction rate(p=40 atm,dAP=140 μm).

5.Conclusions

A numerical model has been established to study the combustion characteristics of AP/HTPB base bleed propellant. The f l ame structure is investigated,and the effects of pressure, chemical reaction rate and AP particle diameters on the combustion characteristics are discussed based on Peclet(Pe) number and Damkohler(Da)number.

a)When AP/HTPB base bleed propellant is bunt,AP monopropellant f l ame is concentrated in a thin layer above AP solid to maintain self-sustaining decomposition.The combustion characteristics are controlled by thediffusionf l ame.

b)The existence of LEF is largely dependent on Da number, and also is largely dependent on chemical reaction rate. When AP particle diameter is 140 μm and the pressure changes from 20 atm to 100 atm,Da number increases with simple p1.7dependence.The diffusion between AP decomposition products and HTPB pyrolysis products is suppressed.The LEF structure with more concentrated heat release gets close to the burning surface and the trailing diffusion f l ame reaction zone gets narrow.

c)The diffusion time scale decreases due to the decrease in

diffusion length scale.When a smaller AP particle is used, a more pre-mixed diffusion f l ame is formed.The heat f l ux from the gas to the solid is more uniform,and hence the solid binder gets more heat feedback.So the burning rate of 60 μm-diameter AP particle is higher than that of 140 μm-diameter AP particle.

Acknowledgments

The authors gratefully acknowledge the f i nancial support provided by the National Natural Science Foundation of China (No.51176076).

[1]Zhang YQ,Zhao ZH.Igniting progress of base bleed unit inf l uencing on range dispersion of bleed projectile.J Ball 1994;1:53-6[in Chinese].

[2]Pan GP,Yi Li,Zhang YQ.Ignition test for base bleed grain consisting AP/HTPB.Chin J Energ Mater 2001;9(2):8-10[in Chinese].

[3]Wang J,Ma HW,Zhang YQ.Ignition and combustion study for base bleed grain.J Projectile,Rockets,Missiles and Guidance 2004;24(2): 40-3[in Chinese].

[4]Lu CY,Zhou YH,Yu YG.Combustion of composite base bleed charge under rapid depressurization.Chin J Energ Mater 2007;15(6):587-91 [in Chinese].

[5]BecksteadMW,DerrRL,PriceCF.Amodelofcomposite solid-propellant combustion based on multiple f l ames.AIAA J 1970; 8(12):2200-7.

[6]Price EW,Sambamurthi JK,Sigman RK,Panyam RR.Combustion of ammoniumperchloratepolymersandwiches.CombustFlame 1986;63(63):381-413.

[7]Chropening BT,Kontt GM,Brewster MQ.Flame structure and burning rate of ammonium perchlorate/hydroxy-terminated polybutadiene propellant sandwiches.Proc Combust Inst 2000;28(1):847-53.

[8]Ramakrishna PA,Paul PJ,Mukunda HS,Sohn CH.Combustion of sandwichpropellantatlowpressures.ProcCombustInst 2005;30(30):2097-104.

[9]Fitzgerald RP,Brewster MQ.AP/HTPB laminate propellant f l ame structure:fuel-lean intrinsic instability.Proc Combust Inst 2007;31(31): 2071-8.

[10]Jackson TL,Buckmaster J.Heterogeneous propellant combustion.AIAA J 2002;40(3):1122-30.

[11]Knott MG,Brewster QM.Modeling the combustion of propellant sandwiches.Combust Sci Technol 2002;174(4):61-90.

[12]Xu Z,Jackson TL,Buckmaster J.A numerical study of periodic sandwich propellants with oxygenated binders.Combust Theor Model 2003;7(2):435-48.

[13]Makoto K.Burning characteristics and thermochemical behavior of AP/ HTPB composite propellant using coarse and f i ne AP particles.Propell, Explos,Pyrot 2011;36(1):57-64.

*Corresponding author.

E-mail address:yearutch@163.com(R.YE).

Peer review under responsibility of China Ordnance Society.

Production and hosting by Elsevier

2214-9147/$-see front matter CopyrightⒸ2013,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.dt.2013.12.001

杂志排行

Defence Technology的其它文章

- Effect of Hardfacing Consumables on Ballistic Performance of Q&T Steel Joints

- Numerical Research on The Stability of Launching Devices During Firing

- Contact Force Distribution and Static Load-carrying Capacity of Large Size Double Row Four-point Contact Ball Bearing

- Study on Random Initiation Phenomenon for Sympathetic Detonation of Explosive

- Rough Sets Probabilistic Data Association Algorithm and its Application in Multi-target Tracking

- Experimental Research on the Propagation Process of Continuous Rotating Detonation Wave