Strengthening effects of BFRP on reinforced concrete beams

2013-01-08HuangLihuaLiYujingWangYuefang

Huang Lihua Li Yujing Wang Yuefang

(School of Civil Engineering, Dalian University of Technology, Dalian 116023, China)

The fiber reinforced polymer (FRP) has been considered as a kind of highly efficient material for structural upgrading and retrofitting due to its lightweight, corrosion resistance, nonmagnetic property and easy constructability. The carbon fiber reinforced polymer (CFRP) and the glass fiber reinforced polymer (GFRP) have been extensively applied in the rehabilitation of deteriorated concrete structures since the 1970s, and their strengthening behaviors have been widely investigated in past decades[1-2]. In spite of the well demonstrated advantages of these strengthening methods, their drawbacks, such as high cost, low fireproofing, incompatibility of resins and substrate materials, and the strict requirements of strengthening surfaces and temperatures, are obvious. The strengthening performance of the basalt fiber reinforced polymer (BFRP) has drawn attention in recent years. The basalt fiber is made from melted basalt rocks formed by natural volcanic molten magma and has the properties of large strength-to-weight ratio and high durability[3-4]. BFRP costs less than other FRPs since the raw materials are rich in reserve, easily obtained and energy saving in production[5]. It is known that the strength of the basalt fiber is about 30% of the carbon fiber and 60% of the glass fiber, respectively. In addition, the basalt fiber has the advantages in terms of insulation and resistance to oxidation, abrasion, acid, alkali, and to low and high temperatures. It also has a unique property of short time resistance to high temperature over 1000℃ and it can be exposed to a temperature of 760℃ with only a 10% loss of strength[6], making itself an ideal strengthening material in thermal environments.

As its properties have been gradually understood, the BFRP is found to be more efficient in rehabilitation of concrete structures than the conventional FRPs[6-8]. Generally, the high tensile strengths of CFRP and GFRP cannot be completely used due to the frequent happenings of interfacial debonding for FRP strengthened beams. In this case, different ultimate tensile strengths of CFRP, GFRP and BFRP have little effect on the yielding strength of the strengthened beam. Furthermore, BFRP reinforcement possesses a higher ratio of performance-to-cost than other FRPs, which effectively reduces the budget of structural rehabilitation. The strengthening performance of the BFRP on reinforced concrete (RC) beams is experimentally investigated in this paper. The research indicates that the upgraded strength and the ductility of the strengthened beam with BFRP are both between those with CFRP and GFRP. Strengthening of two plies of BFRP on pre-cracked RC beams performs the most efficiently among the test specimens. Most of the failures of the strengthened beams with BFRP are caused by interfacial debonding induced by flexural cracks. Clamping of U-wraps along the strengthened beam is efficient in preventing debonding failure, but a lower ultimate strength of the beam is obtained than that with endpoint anchorage. The debonding strain of the BFRP can be predicted through the formulae presented in the guidelines, where all the formulae are based on CFRP, and a conservative estimation is obtained.

1 Experimental Program

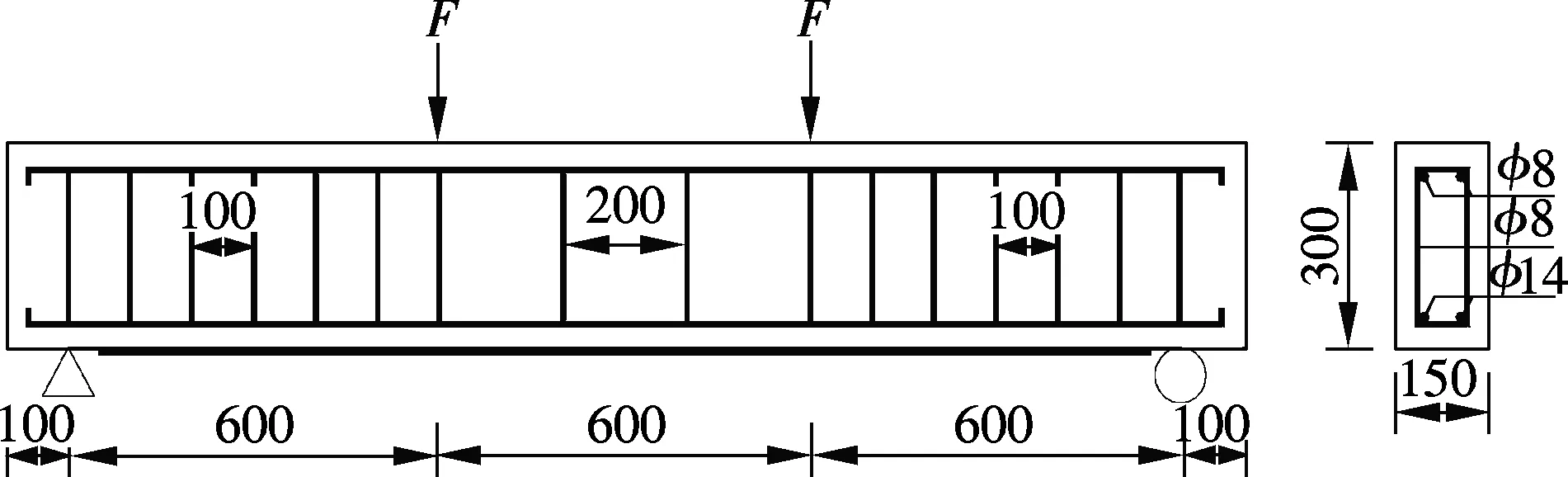

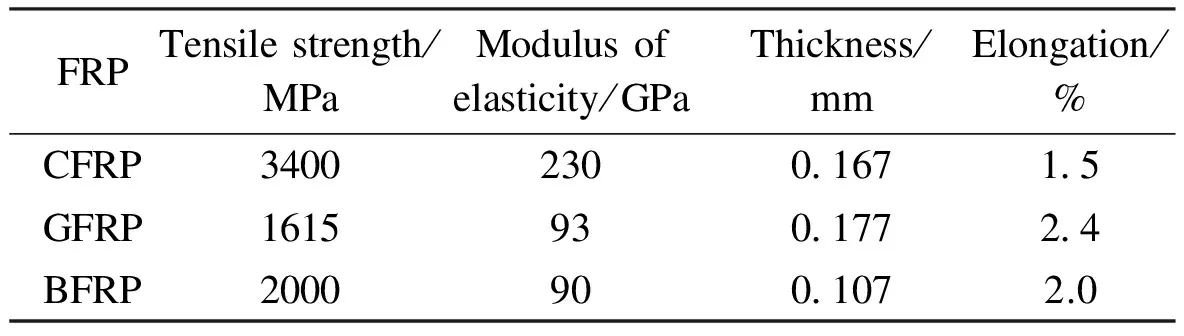

An experiment is carried out to investigate the contribution of the BFRP on the enhancement of the RC beam. A total of nine simply-supported 2 m long RC-beams are constructed. The profile of the specimen is shown in Fig.1. The longitudinal reinforcement consists of twoφ14 mm deformed steel bars with a yielding strength of 335MPa. The average compressive strength of the concrete is 26.8 MPa. RC beams externally bonded with one and two plies of BFRP, CFRP and GFRP have been tested. For understanding the interfacial bonding of the BFRP on the substrate, two schemes of transverse anchorages are set up: one along the beam and the other at the endpoint of the BFRP sheet. The mechanical properties of the FRPs used in the experiment are displayed in Tab.1. Araldite epoxy of XH180A and XH180B are laid between the FRPs and the concrete. Pre-cracked beams strengthened with the BFRP are also tested .

Fig.1 Profile of the specimen (unit:mm)

Tab.1 Material properties of FRPs used in the experiment

2 Experimental Results

The experiment is conducted by using a YAW-10000F hydraulic machine with an increasing load step of 5 kN. The cracking load of concretefcr, the yielding load of steel reinforcementfy, and the ultimate load of beamfuare recorded and presented in Tab.2. The ductility of each beam is measured by the deflection of the beam, the FRP strain and the strains of steel reinforcement and concrete. The yielding deflectionwy, the ultimate deflectionwuof each beam and the detailed strengthening schemes are also listed in Tab.2. For evaluating the enhancement of each FRP, the ratios of strength and ductility of the strengthened beam to those of the control beam, i.e.,ρsandρd, are calculated and shown in Tab.2.

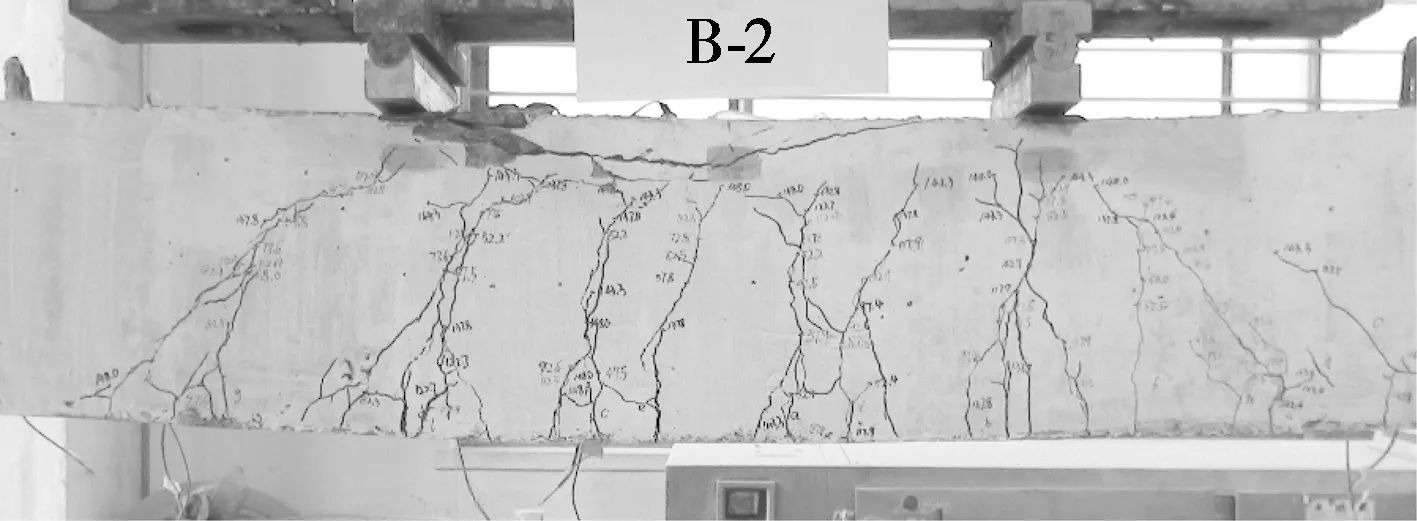

The failure mode is mainly governed by the yielding of the steel reinforcement, the crushing of the concrete and the debonding of FRP from the substrate. The propagation of cracks on the control beam is shown in Fig.2. The debonding failure shape and crack propagation of one of the strengthened beams are illustrated in Fig.3. It can be clearly seen that the pattern of concrete cracks is ameliorated by strengthening of the BFRP. There is little difference in inhibiting concrete cracking among the strengthened beams with the three FRPs. Although most failures of the strengthened beams are caused by debonding of FRP laminates induced by flexural cracks, abrupt fracture of strengthening laminates and U-wraps also occurs in the experiment.

Fig.2 Crack pattern of the control beam

Fig.3 Crack pattern of the strengthened beam

The experimental study shows that clamping of U-wraps along the whole beam cannot work more effectively in upgrading ultimate strength than that at endpoints. The compatibility of interfacial strain is restricted by close placement of U-wraps along the whole beam, leading to high strain concentration in BFRP laminates near concrete cracks and early brittle fracture of BFRP between two U-wraps, as shown in Fig.4.

Tab.2 Strengthening schemes and records of experimental data

Fig.4 U-wraps clamping along whole beam

3 Discussion

3.1 Upgrading performance of strengthened beams with BFRP

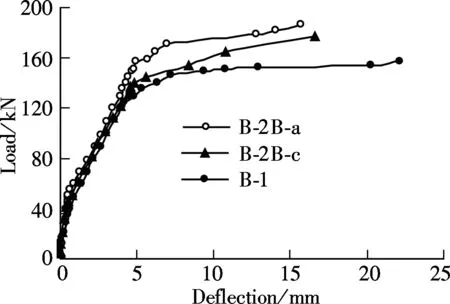

The effects of the BFRP layer number on the strengthened beam are investigated in the experiment. The results show that the strength and ductility of the strengthened beams are obviously improved with increasing the number of layers. Strengthening of two plies of the BFRP is more effective for upgrading the loading capacity of the strengthened beam than one ply of the BFRP, as shown in Fig.5. The yielding load, the ultimate load and the ductility of the beam strengthened with two plies of BFRP are increased by 18%, 17% and 22% compared with the control beam, respectively.

Fig.5 Beams with different plies of BFRP

To find the retrofitting performance of BFRP on pre-damaged beams, two beams are loaded by 80% of the loading capacity before being strengthened. For B-1B-b, the pre-damaged beam reinforced with one ply of BFRP, the ultimate load is little improved even though the cracking load is much higher than that of the control beam. As for B-2B-b, the pre-damaged beam reinforced with two plies of BFRP, the increments of the yielding load, the ultimate load and the ductility are 24%, 21% and 18%, respectively, as shown in Fig.6. The behavior of the BFRP strengthened beam is not affected by pre-damage, and the strengthening effects of the BFRP on the pre-damaged beam are more remarkable than those on the intact beam.

Interfacial debonding is the most common mode of failure in the experiment which restricts the strengthened beam to reach its ultimate loading capacity. For preventing the interfacial separation, many schemes of transverse anchorages have been studied in previous researches. Following the experimental results in Refs.[9-10], the reinforced beam B-2B-c is laterally anchored with U-wraps of 60 mm in width and 50 mm in space along the beam. It is found that clamping BFRP with close placement of U-wraps along the whole beam is less efficient than clamping at two endpoints with respect to upgrading ultimate strength, as shown in Fig.7. The ultimate strength and ductility of this scheme are increased by 13% and 23% compared with the control beam B-1, but 3% and 6% less than the beam B-2B-a of endpoint anchorages, respectively. Although interfacial debonding is avoided, the tensile stress of the BFRP is distributed unevenly in a longitudinal direction due to the constraints of the close placement of U-wraps. Consequently, the interfacial compatibility of strain cannot be realized, and local concentration of high strain is generated near flexural cracks of the concrete, which causes BFRP to partially rupture. Overall, the reinforcement of two plies of BFRP with endpoint anchorage is more effective in improving the performance of strengthened beams than that of other strengthening schemes.

Fig.6 Enhancement of pre-cracked beams

Fig.7 Effect of different anchorages

3.2 Comparative study of BFRP to CFRP and GFRP

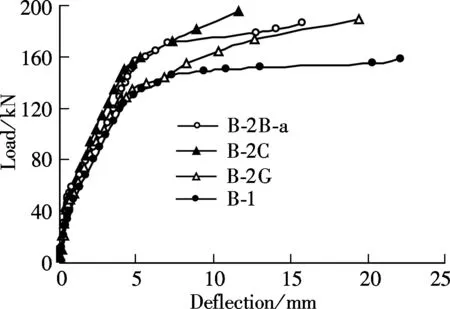

A comparative study is carried out to investigate the strengthening effects of RC beams enhanced with the BFRP, CFRP and GFRP. Cracking of concrete can be effectively inhibited by external bonding of the three FRPs. The similar failure of debonding occurs for each FRP strengthening. The improvement of the load capacity of beams bonded with two plies of FRPs is more noticeable than that with one ply. The cracking strengths of beams bonded with two layers of the three FRPs are almost the same. The yielding strength of the beam bonded with BFRP is 3% lower than that with CFRP, and 14% higher than that with GFRP. The contributions of BFRP, CFRP and GFRP to upgrading the strength of RC beams are 18%, 25% and 20%, respectively, as illustrated in Fig.8. It is concluded that the total performances of the strengthened beams bonded with the BFRP lie between those with the CFRP and the GFRP.

Fig.8 Reinforcement of various FRPs

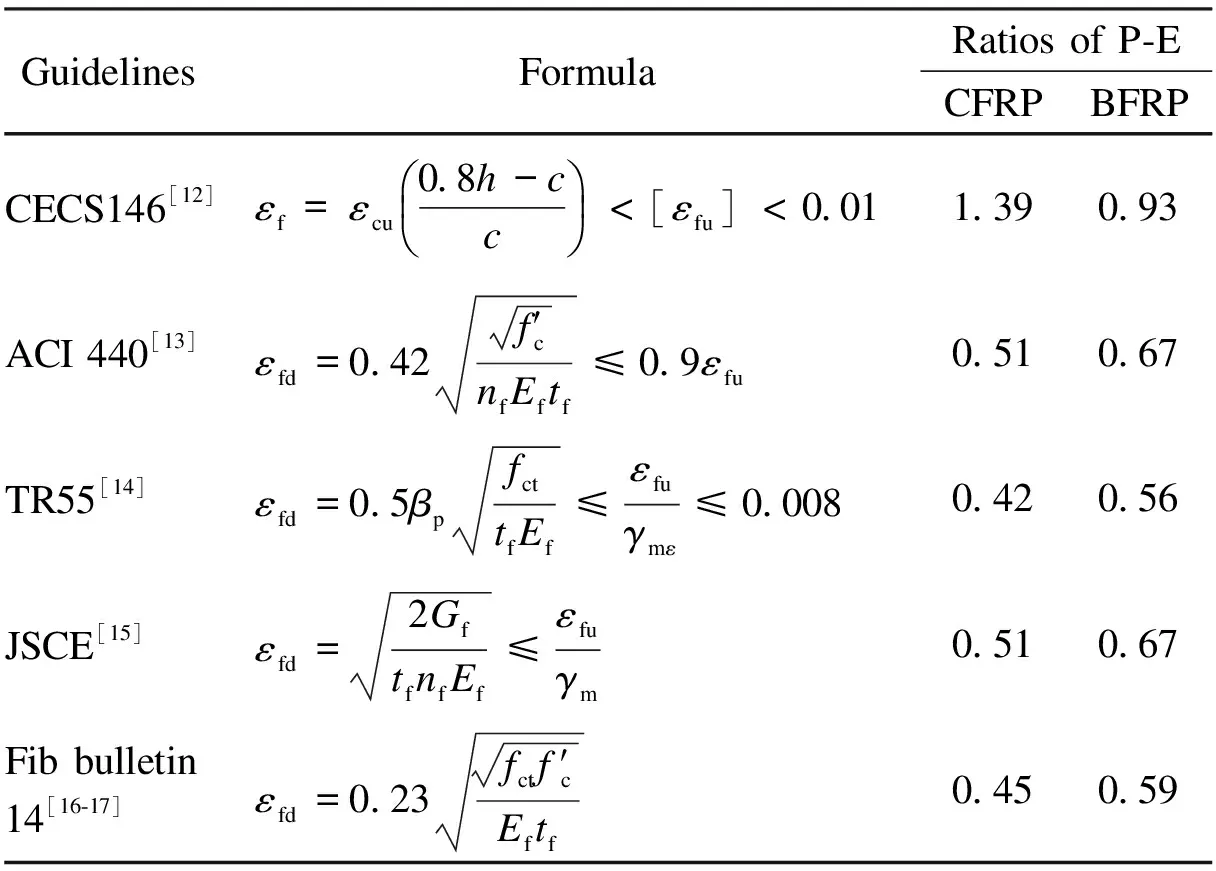

4 Predicted Debonding Strain of BFRP vs. Its Actual Value

Many models have been developed to predict the upgrading strength of RC beams externally bonded with CFRP since the 1990s[11]. The models that are used to compute debonding strain presented in the guidelines[12-17]are listed in Tab.3. All the models are based on laboratory and field data obtained from CFRP strengthening, and hence cannot be directly applied to other strengthening materials even though the same computational principles are adopted. To investigate the debonding strain of BFRP, the models in the guidelines are extended and the comparative results of predicted-to-experimental (P-E) debonding strains of CFRP and BFRP are summarized in the right two columns of Tab.3.

Tab.3 Models of predicted debonding strain and ratios of P-E

Conservative estimates about 50% of the actual values of debonding strains are obtained based on the formulae presented in the guidelines. The debonding strain determined by CECS146 is much greater than others since it assumes an ideal failure that the yielding of steel reinforcement, crushing of concrete and rupture of FRP occur at the same time. The ratio of the predicted-to-experimental values rises 10% when the formulae given by the guidelines are extended to determine the debonding strain of BFRP. That is to say, the predicted debonding strain accounts for about 60% of the actual values, and it is safe in the application of BFRP. Since the upgrading of the strengthened beam is affected by many factors including occurrences of uncertain failures, an unduly conservative estimation is needed throughout the design procedures.

5 Conclusion

BFRP can be applied in strengthening RC beams, whose overall performance lies between those of the CFRP and the GFRP. Cracking of concrete can be effectively inhibited by external bonding of BFRP. The upgrading strength and ductility of strengthened beams with two plies of the BFRP are more remarkable than those with one ply. Little difference is found for the intact beam and the pre-cracked beam strengthened with BFRP. Clamping BFRP near endpoints is more efficient than that along the whole beam with the upgrading ultimate load. The debonding strain of the BFRP can be predicted through the formulae presented in the guidelines, which gives a conservative estimation. Since the BFRP owns a higher ratio of performance to cost, eco-friendly quality and unique high temperature resistance than the CFRP and the GFRP, it can be a superior option as a strengthening material.

[1]Yao J. Research advance in FRP-strengthened RC structures [J].BulletinofScienceandTechnology, 2004,20(3):216-22.

[2]CRC Construction Innovation. Review of strengthening techniques using externally bonded fiber reinforced polymer composites [R]. Brisbane, Australia: CRC Construction Innovation, 2002.

[3]Xi R G, Li Z Y. Application prospect of basalt fiber [J].FiberComposites, 2003,17(3):17-20.

[4]Ouyang L J, Ding B, Lu Z D. BFRP and its application review in structural strengthening [J].FiberReinforcedPlastics/Composites, 2010,27(2):1-5. (in Chinese)

[5]Zhang X Y, Zou G P, Shen Z Q. Experimental research on continuous basalt fiber and basalt fibers reinforced polymers [C]//ProceedingsofSPIE—TheInternationalSocietyforOpticalEngineering. Nanjing, China, 2008: 73756C.

[6]Sim J S, Park C, Moon D Y. Characteristics of basalt fiber as a strengthening material for concrete structures [J].Composites,PartB:Engineering, 2005,36(6/7):504-512.

[7]Ludovico M D, Prota A, Manfredi G. Structural upgrade using basalt fibers for concrete externally bonding [J].JournalofCompositeforConstruction, 2010,14(5):541-552.

[8]Ouyang Y, Wang P, Li X. Experimental study on flexural RC beams strengthened with BFRP sheets [J].BuildingStructure, 2008,38(11):74-78. (in Chinese)

[9]Ye L P, Fang T Q, Yang Y X. Experimental research of flexural debonding performances about RC beams strengthened with CFRP sheets [J].BuildingStructure, 2003,33(2):61-65. (in Chinese)

[10]Choi H T, West J S, Soudki K A. Analysis of the flexural behavior of partially bonded FRP strengthened concrete beams [J].JournalofCompositesforConstruction, 2008,12(4):375-386.

[11]Saxena P, Toutanji H, Noumowe A. Failure analysis of FRP-strengthened RC beams [J].JournalofCompositesforConstruction, 2008,12(1): 2-14.

[12]China Construction Standardization Association. CECS146—2003 The technical specification for strengthening concrete structure with carbon fiber reinforced polymer laminates [S]. Beijing: China Planning Press, 2007. (in Chinese)

[13]ACI Committee. ACI440.2R Guide for the design and construction of externally bonded FRP systems for strengthening concrete structures [S]. Farmington Hills, USA: American Concrete Institute Committee, 2008.

[14]The Concrete Society. Technical Report No.55 Design guidance for strengthening concrete structures using fiber composite materials[R]. Berkshire: The Concrete Society, 2000.

[15]Japan Society of Civil Engineering. Recommendations for upgrading of concrete structures with use of continuous fiber sheets [S]. Tokyo, Japan: Japan Society of Civil Engineering, 2000.

[16]International Federation for Structural Concrete (fib). Bulletin No.14 Externally bonded FRP reinforcement for RC structures [R]. Lausanne, Switzerland: International Federation for Structural Concrete Technical Report, 2001.

[17]Chen J F, Teng J G. Anchorage strength models for FRP and steel plates bonded to concrete [J].JournalofStructuralEngineering, 2001,127(7):784-79

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Price and retailer’s service level decision in a supply chain under consumer returns

- Investigation on transformation process of trip mode choicefor planned special events

- Fuzzy traffic signal control with DNA evolutionary algorithm

- Alcohol dehydrogenase coexisted solid-state electrochemiluminescence biosensor for detection of p53 gene

- Adjacent vertex-distinguishing total colorings of ∨Kt

- Aggregating metasearch engine results based on maximal entropy OWA operator