康普茶细菌纤维素的形成途径及其在废弃茶叶资源高效利用中的应用

2024-11-08徐晴晴聂晴刘助生郭青刘仲华蔡淑娴

摘要:废弃茶叶资源和夏秋茶用于生产康普茶和细菌纤维素,不仅有助于减少环境污染和资源浪费,还能开发高市场价值的产品。细菌纤维素作为一种高晶度、可再生的多糖,广泛应用于生物医疗、环保包装、纺织、新能源电池、护肤品等领域。综述了近年来细菌纤维素膜的应用研究,重点分析了不同发酵环境和茶叶种类对细菌纤维素膜品质的影响,证实了通过调整发酵参数可获得具有特定结晶结构的纤维素。进一步探讨了茶叶成分在菌膜形成中的作用,并提出了提高康普茶细菌纤维素膜产量和质量的新思路。文章强调了康普茶细菌纤维素膜的保健功效及其在可持续产品开发中的重要作用,并指出了进一步研究以促进其工业化应用的必要性。

关键词:康普茶细菌纤维素;废弃茶叶资源利用;生物可降解材料;膳食多糖

中图分类号:S571.1;TS272 文献标识码:A 文章编号:1000-369X(2024)05-707-11

Review on the Formation Pathway of Kombucha Bacterial Cellulose and Its Application in Efficient Utilization of Tea Waste

XU Qingqing1,3, NIE Qing1,3, LIU Zhusheng2*, GUO Qing1,3, LIU Zhonghua1,3, CAI Shuxian1,3*

1. National Research Center of Engineering and Technology for Utilization of Botanical Functional Ingredients, Changsha 410128, China;

2. Guangxi Research Institute of Tea Science, Guilin 541004, China;

3. Key Lab of Education Ministry of Hunan Agricultural University for Tea Science, Changsha 410128, China

Abstract: Tea waste and summer-autumn tea can be used to produce Kombucha and bacterial cellulose, helping to reduce environmental pollution and resource waste while developing high market value products. Bacterial cellulose, as a highly crystalline and sustainably renewable polysaccharide, has a wide range of potential applications in biomedicine, eco-friendly packaging, textiles, new energy batteries, skincare products, and other fields. This paper reviewed recent research on the applications of bacterial cellulose membranes, focusing on the effects of different fermentation environments and tea types on the quality of bacterial cellulose membranes. It confirmed that adjusting fermentation parameters can produce cellulose with specific crystalline structures. The paper also discussed the role of tea components in the formation of bacterial cellulose membranes and proposed new ideas for improving the yield and quality of Kombucha bacterial cellulose membranes. The health benefits of Kombucha bacterial cellulose membranes and their significant role in sustainable product development were emphasized. The paper highlighted the need for further research to promote their industrial application.

Keywords: Kombucha bacterial cellulose, tea waste utilization, biodegradable materials, dietary polysaccharide

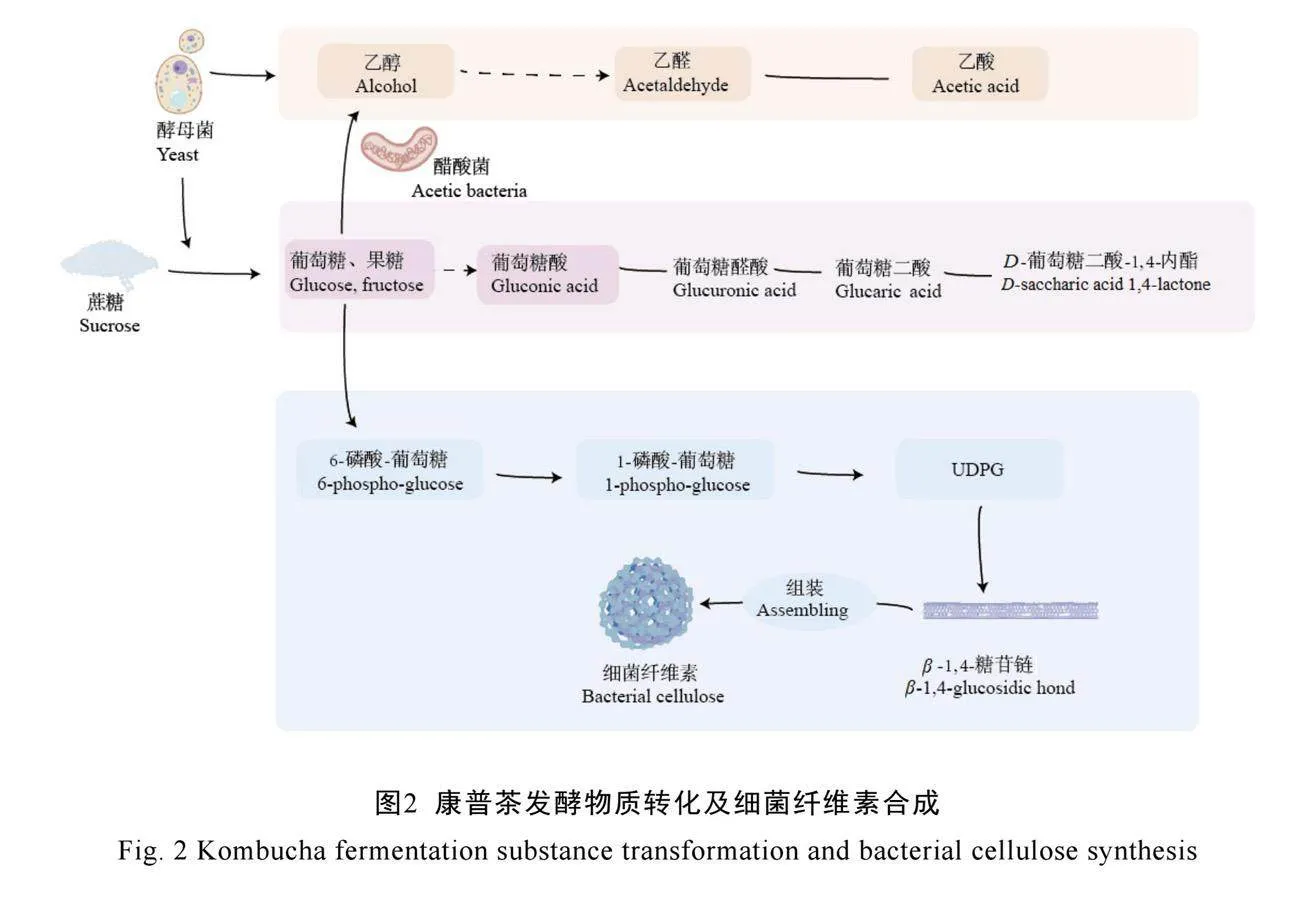

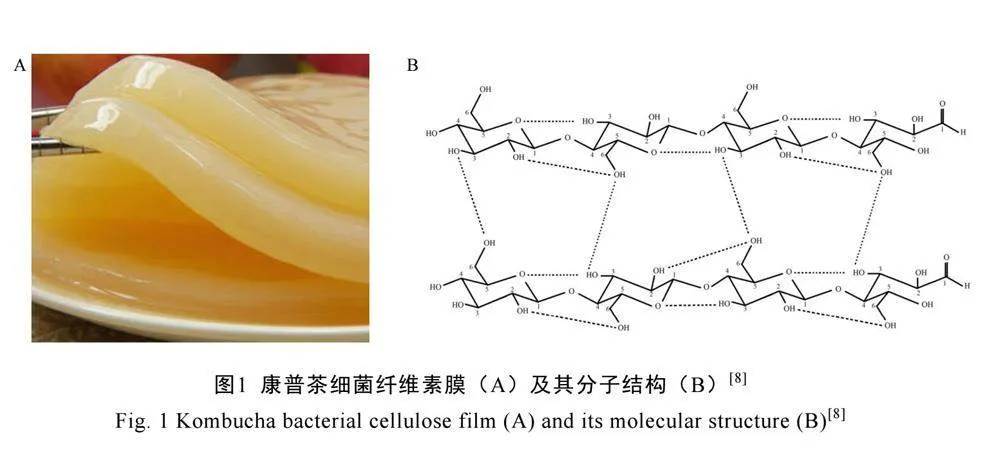

多糖是生物体常见的一类生物大分子,主要分为储能多糖和结构多糖。细菌纤维素(Bacterial cellulose,BC)是一种典型的结构多糖,是细菌细胞壁和生物膜的重要组成部分[1]。BC由葡萄糖单元通过β-1,4糖苷键连接而成,具有高晶度和可持续再生的特点(图1)[2]。农业副产品的焚烧和填埋处理方式常导致环境污染,而这些废料富含纤维素、果胶、酚类物质和类黄酮,具有广泛的应用潜力[3]。因此,开发这些副产品的可持续利用策略对工业应用具有重要意义。

康普茶(Kombucha)历史悠久,通常以红茶和绿茶为发酵基底,并加入蔗糖作为碳源[4]。在发酵过程中,酵母菌和醋酸菌共生,形成一种漂浮于液面的凝胶状BC膜[5]。研究显示,康普茶发酵法生产BC,不仅效益高且原料来源广泛,适合工业化大规模生产。这种方法不仅降低生产成本,还能创造高附加值产品,符合可持续生产和环保的要求[6-7]。

本文综述了茶叶废料和夏秋茶的利用、康普茶发酵方法的优化,以及不同茶类对BC膜质量的影响。同时探讨了BC作为膳食多糖在

生物医药、纺织、包装和电池等领域的应用前景。康普茶BC的开发不仅增加了康普茶的附加值,也为生物材料领域开辟了新的研究方向。随着科技进步和市场需求的增加,康普茶BC膜在未来将发挥越来越重要的作用。

1 康普茶BC膜

在康普茶的发酵过程中,通过酵母菌和醋酸菌等微生物的共生作用,会形成一层漂浮在液面上的凝胶状膜(图1A),其主要成分为BC。这种纤维素由纳米级的细小纤维组成,这些纤维相互缠绕,形成具有高比表面积和孔隙率的三维网络结构,其分子结构如图1B所示。康普茶发酵过程以茶水、蔗糖和特定菌种为基础进行培养,对原料的要求相对较低,且培养方法简单、操作方便。由于BC具有巨大的潜在商业价值和市场吸引力,采用康普茶发酵法生产BC成为一种成本效益高、原料来源广泛的生产方式,非常适合工业化大规模生产。这种方法不仅能够降低生产成本,还可以创造高附加值的产品,符合当前可持续生产和环保要求的工业趋势。

2 康普茶发酵形成BC膜的过程

在康普茶的发酵过程中,醋酸菌和酵母菌共生,形成一个相对稳定的微生物生态系统。酵母菌通过分泌转化酶将蔗糖分解成单糖和葡萄糖,并利用糖酵解途径产生乙醇;同时,醋酸菌将乙醇转化为乙酸,并将葡萄糖氧化,最终生成D-葡萄糖二酸-1,4-内酯(D-saccharic acid 1,4-lactone,DSL),这一系列反应形成了一个复杂的代谢链[9-10]。

此外,酵母菌产生的乙醇能刺激细菌纤维素合酶的活性,从而促进纤维素膜的生成。在发酵过程中,适当浓度的乙醇有助于纤维素膜的形成[11]。唐水佳等[12]研究表明,康普茶发酵生产的纤维素量是木葡糖酸醋杆菌的3倍以上,这得益于康普茶发酵体系中酵母菌、醋酸菌和乳酸菌之间高度共生的关系及其协同代谢作用,这些互动显著促进了纤维素的生产[13]。

纤维素的生物合成过程涉及多个酶的参与(图2)。首先,葡萄糖被转化为6-磷酸-葡萄糖,随后转化为1-磷酸-葡萄糖;在尿苷二磷酸葡萄糖(Uridine diphosphate glucose,UDPG)焦磷酸化酶的催化作用下,1-磷酸-葡萄糖形成UDPG分子,这是纤维素分子的前体。纤维素合酶随后作用于UDPG,促使更多的UDPG单元相互连接,迅速形成每秒约20万个单元的聚合物链,最终形成β-1,4葡聚糖链,并组装合成BC[14]。

3 康普茶产BC膜的菌株类型

张妍[2]研究发现,康普茶发酵初期酵母菌迅速繁殖,随着次级代谢产物的产生,促进纤维素的形成;随后酵母菌生长减缓,且大部分沉降于菌液底部,含量减少。因此,主要附着在菌膜中的葡萄糖杆菌属(Gluconobacter)成为纤维素的主要生产菌株。余瞻等[15]通过筛选和16 S rDNA测序,鉴定出木糖驹形氏杆菌(Komagataeibacter xylinus)为高产BC的优势菌种。此外,从绿茶康普茶发酵剂中分离到的新型驹形杆菌(Komagataeibacter rhaeticus)也显示出较高的BC生产潜力[16]。

微生物群落的组成对康普茶的发酵过程有显著影响。康普茶中的酵母菌种类差异较大,其对发酵过程的具体影响值得进一步研

究。吕橄等[17]研究发现,在发酵的前7 d,发酵液中原核生物多样性高于菌膜,但在发酵后期,发酵液中的多样性急剧下降,与菌膜的多样性趋于一致,主要菌群为驹形杆菌属(Komagataeibacter)。这表明特定细菌属在BC形成中的关键作用,对于优化康普茶发酵过程至关重要。

与康普茶分离菌株Komagataeibacter hansenii B22及参考菌株Komagataeibacter xylinus DSM 46604、Komagataeibacter hansenii DSM 5602相比,Komagataeibacter rhaeticus的纤维素产量显著提高[18]。驹形杆菌属菌株的酶活性促进UDPG的产生,能够形成高达20万个葡萄糖分子的聚合物链,通过β-1,4糖苷键聚合最终合成纤维素[19]。这些发现强调了选择合适微生物菌株在优化BC生产过程中的重要性。

4 发酵基质对BC形成的影响

4.1 碳源

糖是发酵基质中的主要碳源,最佳质量浓度为100 g·L-1,能显著提高纤维素的产量[20]。其中,蔗糖被认为是最佳的碳源,因为它可以被分解为葡萄糖和果糖,从而增加葡萄糖酸的产量,在一定pH范围内有利于纤维素膜的形成。其次,葡萄糖也是一种有效的碳源[21-22]。当蔗糖的质量分数达到5%时,BC的产量达到最高[23];而浓度过高可能产生抑制性物质,阻碍微生物的生长[24]。此外,葡萄糖作为碳源还会产生副产物葡萄糖酸,降低培养基pH值,从而影响BC的形成。

4.2 茶叶及其成分

茶叶作为氮源对微生物的生长及细胞构建至关重要,不同茶类对BC的产量和质量有显著影响。Ramirez等[25]研究发现,红茶发酵的康普茶在21 d后BC产量较多。此外,红茶康普茶中有较多的微生物,推测高微生物含量与优质纤维素的形成密切相关[16,26]。

研究表明,绿茶对BC产量的影响显著高于红茶;BC的质量与绿茶-红茶混合物负相关,但与单独的茶渣、绿茶和红茶呈正相关[21,27]。红茶发酵的康普茶产生的BC较厚且呈深黄棕色,结晶度较低;而绿茶发酵的康普茶产生的BC则更光滑透明,结晶度较高,表面结构也更均匀[23,25]。使用茶渣作为底物生产的BC产量较高,与单一菌株相比,混合培养或添加茶叶生产的BC质量更高、成本更低[24]。

为了寻找新的经济培养基用于工业化生产BC,许多研究尝试使用农业废弃物,如针叶副产物、咖啡渣、葡萄皮、茶渣等。利用茶叶废料发酵生产康普茶不仅能够减少环境问题,还对茶产业具有积极影响。研究表明,添加绿茶茶渣的康普茶总多酚和咖啡碱含量显著高于未添加茶渣的康普茶[28]。茶叶浓度对BC形成有重要影响。Balasubramanian等[21]研究显示,最佳茶叶添加量为10 g·L-1。添加过多茶叶会抑制微生物生长,导致菌膜质量不佳;添加过少则不利于菌膜形成[24,29]。不同茶类发酵康普茶的成分和微生物群落各异,这也会影响BC的产量和质量[30]。

茶叶中富含多酚类物质,其中具有多个芳香环的酚类化合物通常比只有1个芳香环的化合物与纤维素的结合力更强[31]。此外,中性的儿茶素显示出最强的纤维素吸附能力和结合亲和力[32]。在BC的生长过程中,位于顶部纤维下的中间层充满了细菌细胞,这些细胞被视为BC生长的活性剂。该区域利用被纤维包围的酵母代谢产物和自溶作用促进细菌的营养作用,从而使纤维素分子能够结合茶叶中的多酚类物质,抑制过多的多酚对细菌细胞膜的毒性,进一步促进BC的形成[33]。

综上所述,茶叶在BC的形成过程中发挥了多重作用,包括提供营养和促生长因子,以及调节发酵环境和影响微生物的生存。研究发现,康普茶中的茶叶富含矿物质和维生素,这些成分能促进微生物的生长和细胞结构的构建,加速发酵过程[34]。茶叶中的咖啡碱、茶叶碱和可可碱能够通过激活纤维素生成复合物,刺激细菌产生纤维素[35]。茶多酚的自发氧化能够使康普茶在发酵24 h后接近厌氧状态,加速酵母菌向发酵代谢转变,从而促进纤维素的形成[36]。红茶中的茶黄素、茶红素也能促进细菌产生纤维素[37]。随着茶叶浓度增加,BC生成量减少,这可能是因为茶多酚能够抵抗发酵过程中产生的有害氧化物质,从而保护醋酸菌免受氧化应激损伤[38]。

4.3 废弃茶叶资源在BC制备中的应用

废弃茶叶资源来自茶树修剪、茶叶生产以及日常冲泡。在特定的酸性条件下,乌龙茶茶渣可以高效生产具有热稳定性的微晶纤维素,产率达到86.7%[39]。按照采摘季节,茶叶可分为春茶、夏茶和秋茶,其中夏秋茶因苦涩味重、市场溢价能力弱、销量低,导致企业对其生产积极性较低[40]。

不同茶类的茶渣成分虽有一定差异,但总体上具备相似的营养成分。例如,茶渣中含有粗蛋白质、脂肪、灰分、水分、粗纤维、半纤维素、多酚和游离氨基酸等[41-42]。红茶废弃物和绿茶茶渣含有表儿茶素(EC)、表没食子儿茶素(EGC)、表没食子儿茶素没食子酸酯(EGCG)、表儿茶素没食子酸酯(ECG)、没食子儿茶素(GC)和没食子酸[43]。研究进一步表明,成熟叶片通常含有较高水平的EGC和EC,而幼嫩的叶片和芽则富含有ECG和EGCG,此外,成熟叶片中的咖啡碱含量低于幼嫩芽叶[44]。这些成分的差异可能会影响废弃茶叶资源在康普茶发酵过程中的作用和效果。

以上成分在康普茶发酵过程中对BC的形成起到了重要作用,有助于调节发酵环境的pH,促进细菌与酵母菌的共生培养,并抑制污染物的生长和腐败[45]。这些特性使得茶叶废弃物成为BC生产中的重要资源,为资源循环利用和可持续发展提供了新的途径。

5 BC膜的纯化方法及性能改进

5.1 纯化方法

纯化BC膜的过程包括去除细菌、清洗去除杂质或培养基成分,最后通过物理或化学方法改善其性能[46-47]。具体步骤如下:(1)去除附着细胞和杂质:将BC置于80 ℃的0.5 mol·L-1 NaOH溶液中处理120 min,去除附着细胞和杂质[48]。(2)洗涤和漂白:使用1.0 mol·L-1 NaOH在90 ℃下进行两次初始洗涤,然后用1.5% NaClO漂白2 h,可得到白度值高达(81.4±4.8)的BC[49]。(3)最终纯化:在室温下用5%的KOH溶液处理BC 14 h,以进一步纯化[23]。经过纯化处理,BC的Iα和Iβ纤维素的结晶度从37%提高到87%,并且经过喷雾干燥处理的BC表现出更高的热稳定性[50]。

5.2 性能改进

不同的处理方法可以显著改善BC的理化性能,目前已在以下几个方面开展了研究和应用:(1)增强机械性能:Knöller等[51]利用钛(IV)双(乳酸铵)二氢氧化物(Ti-BALDH)处理BC,通过增强交联改善BC机械性能,使其更适用于纺织业。(2)调整结晶度和尺寸:Hamed等[45]研究发现,通过γ辐照处理,可以根据不同的剂量调整BC的结晶度和尺寸,从而优化其结构特性。(3)提高柔韧性和抗氧化性:BC中添加适量甘油可以形成柔韧性强且具有良好抗氧化性的聚合物水凝胶,使其适用于食品包装材料[52-53]。(4)改善断裂伸长率和阻隔性能:在BC中掺入8%的茶多酚和壳聚糖,可以有效提高其断裂伸长率、接触角和水汽阻隔性能[54]。(5)提高强度和延伸率:在康普茶中添加蛋白胨作为氮源能够提升BC的强度和延伸率[55]。(6)增强硬度和抗氧化活性:将BC浸入聚甲基丙烯酸甲酯(Polymethyl methacrylate,PMMA)基质中,形成的PMMA-BC复合材料具有更高的硬度[56],而将BC颗粒掺入马来酸化亚麻籽油(Maleinized linseed oil,MLO)-聚乳酸(PLA)中则能增强其抗氧化活性[57]。(7)提高吸附能力:利用超声波法和氧化石墨烯的羧基可以显著提高BC对Pb(II)的吸附能力[58]。(8)改善光吸收性能:制备壳聚糖BC材料的涂层可以有效改善其在UV-Vis范围内的光吸收性能[59]。

此外,开发机器学习预测模型来识别影响康普茶生产BC的关键工艺参数,通过发酵性能分析进行预测建模,可以最大限度地提高产量并降低试错成本[60]。这些研究成果展示了各种改进方法对BC性能的不同影响,为BC在实际应用中的优化提供了重要参考。

6 BC的功效及应用

6.1 作为膳食多糖的保健功效

BC作为可食用膳食纤维,不仅具有与天然纤维素相似的益处,还能降低患糖尿病、肥胖症、心血管疾病的风险[61-62]。毒理学评估表明,BC对小鼠无生殖毒性、无胚胎毒性、无致畸作用,也无炎症反应[63-65]。1992年,美国食品和药物管理局(FDA)将BC认定为“公认安全”(GRAS)[66]。BC的多功能性和可降解性使其在烘焙食品、甜点、零食和饮料中得到广泛应用,并因其与植物纤维素的相似结构,常被用作高纤维膳食补充剂和素食者的肉类替代品[67]。

研究表明,BC和植物纤维素的摄入能显著促进粪便中脂肪、胆固醇和胆汁酸的排出,降低血清甘油三酯、总胆固醇、低密度脂蛋白水平[66]。BC降低血脂和胆固醇的效果优于植物纤维素,这可能与其膳食纤维的特性有关[68-69]。BC与魔芋葡甘露聚糖的混合物能改善高脂饮食诱导的小鼠的高胰岛素血症和高血糖,并调节脂质相关的细胞因子和炎症因子,显著提高小鼠肠道菌群的丰度和多样性,从而预防肥胖并调节脂肪酸代谢[70]。

BC可以增加地芬诺酯(Diphenoxylate)诱发的便秘大鼠上皮细胞的黏液和肌肉厚度,减少水通道蛋白的表达,并削弱ATP酶活性,从而缓解便秘[71]。BC的三维网络结构能结合淀粉颗粒和葡萄糖分子,降低食糜中的葡萄糖浓度,从而延缓餐后血糖水平的升高[72]。此外,BC还被用作复杂细胞壁膳食纤维发酵的模型系统,通过进行体外发酵比较,确定影响粪便细菌发酵速率和最终产物的因素[73]。

6.2 在多领域中的应用

BC是一种丰富且可再生资源,在生物医药、纺织和包装等领域展现出广阔的应用前景。BC具有纳米级纤维的三维网状结构,其化学结构与植物纤维素相似,但不含木质素、半纤维素、果胶等杂质,且不需要繁杂的化学处理,因此在物质化学性能上更为优越[14,74]。由于BC的纤维直径为植物纤维素的1/1 000~

1/100,是一种纳米纤维材料[75],在生产上具有很大的优势。

BC具备亲水性、高力学性能、高纯度及高结晶度等特性,被广泛认为是一种环保且无污染的材料。BC显著的抗菌性使其能够有效保护伤口、促进愈合并防止感染,因此被广泛应用于皮肤移植、重度烧伤、面部脱皮、手术缝合等多种皮肤损伤治疗[76-77]。作为可生物降解的材料,BC可用于各种包装材料中,保持蔬菜和水果的营养成分及新鲜度,延长食品的保质期[78]。此外,BC还可作为保护益生菌的基质,提高益生菌在胃肠道中的生存能力[79]。

BC具有还原金属离子的能力,使其能将膜内金属离子还原成均匀分散的金属粒子,这有助于解决碳纳米管在聚合物中的团聚和分散问题[80]。在造纸工业中,BC能提升纸张的物理性能,改善其附着性和均匀吸墨性[81]。

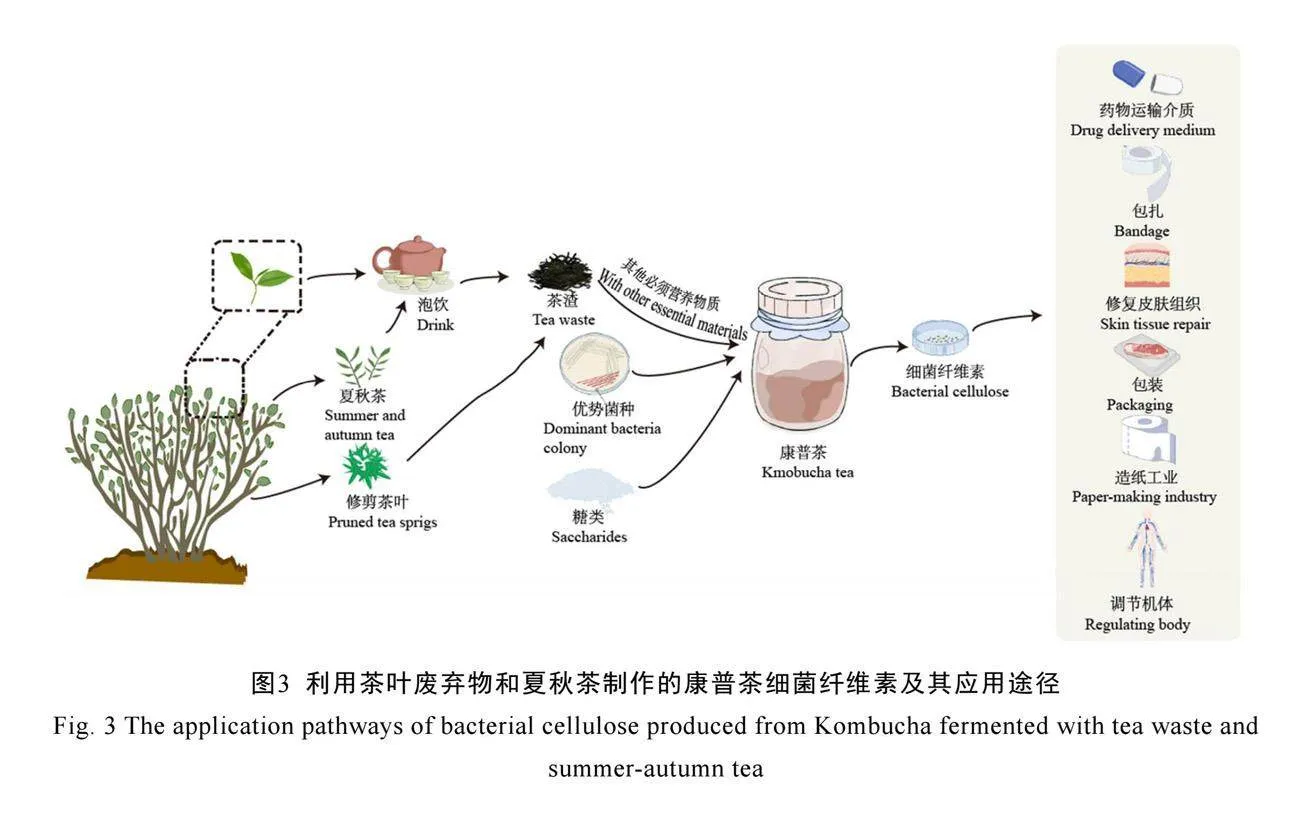

以茶叶废弃资源和夏秋茶为底物进行康普茶发酵产生的BC膜在多个领域具有应用前景(图3)。例如,由BC制成的包装袋不仅能保留食品的物理和营养性质,还可生物降解,从而有效缓解白色污染问题[82]。通过生产高附加值的BC膜,不仅有助于茶产业的发展和转型,还能提高资源利用率,实现绿色可持续化生产。

7 总结与展望

发酵基质对BC的形成有着显著的影响。废弃茶叶资源和夏秋茶中的多酚类、咖啡碱等

物质在康普茶发酵形成BC的过程中发挥重要作用,如调节发酵液的pH、抑制葡萄糖醛酸的形成等。保留茶渣发酵还能增加BC的产量和质量。在工业化生产中,通过调节碳源、茶叶类型、发酵时间和温度等因素,可获得高产的BC。

BC在包装领域的应用已经得到广泛研究。在食品包装中,BC可以减少分解为纳米纤维的能量,从而受到关注,但仍需寻找更有效的方法生产具有最佳特性的BC。在消化或食品加工过程中,由BC负载的不稳定功能因子能改善其功能特性。为了BC能在食品工业中有更广泛的应用,需要对BC进行更多的改性研究。

BC的产量和生产成本是其在食品工业中应用的主要制约因素。我们的研究揭示了康普茶中存在高产BC的菌种,并发现通过茶渣发酵法可以显著提高康普茶菌膜的产量[28]。因此,利用康普茶生产BC的方法对于降低生产成本、提高产量以及简化生产流程具有重要意义。尽管夏秋茶产量高于春茶,但因其品质较差、经济价值较低而被大量废弃,造成资源浪费。将夏秋茶及其加工过程产生的废渣用于生产康普茶中的BC,可能是一种提高夏秋茶利用效益和实现BC规模化生产的有效方法。

此外,使用低成本的糖蜜和茶渣作为康普茶生物膜所需的碳源和氮源,不仅能降低生产成本,还能实现资源的循环利用。目前的研究主要集中在微生物形态和可培养性,以及BC作为替代材料的潜力等方面,针对康普茶中的茶叶成分对BC形成的具体作用机制仍然较少涉及。未来的研究需要明确BC的作用机制,优化生产工艺,探索通过添加特定茶叶成分提高BC产量的方法,实现BC在各个领域的广泛应用。

参考文献

[1] Liu Y, Li X, Shi L, et al. Analysis of polysaccharide structure involves separating homologous polysaccharides, drawing elution curve, measuring purity and molecular weight of polysaccharide in segmented homologous polysaccharide group, determining structure, glycosidic bonds and functional groups of each polysaccharide: CN117990732-A [P]. 2024-05-07[2024-06-19].

[2] 张妍. 红茶菌发酵产细菌纤维素工艺及其性能研究[D]. 哈尔滨: 哈尔滨商业大学, 2013.

Zhang Y. Study on the process and characterization of bacterial cellulose producted by Kombucha [D]. Harbin: Harbin University of Commerce, 2013.

[3] Görgüç A, Gençdag E, Yilmaz F M. Bioactive peptides derived from plant origin by-products: biological activities and techno-functional utilizations in food developments: a review [J]. Food Research International, 2020, 136: 109504. doi: 10.1016/j.foodres.2020.109504.

[4] Wang B Y, Rutherfurd-Markwick K, Zhang X X, et al. Kombucha: production and microbiological research [J]. Foods, 2022, 11(21): 3456. doi: 10.3390/foods11213456.

[5] 蒋立文. 红茶菌优势微生物的分离、鉴定及抗菌机理的研究[D]. 长沙: 湖南农业大学, 2007.

Jiang L W. Studies on isolation and identification of predominant microbes from Kombucha and their anti-microbes mechanism [D]. Changsha: Hunan Agricultural University, 2007.

[6] Behera B, Laavanya D, Balasubramanian P. Techno-economic feasibility assessment of bacterial cellulose biofilm production during the Kombucha fermentation process [J]. Bioresource Technology, 2022, 346: 126659. doi: 10.1016/j.biortech.2021.126659.

[7] Devanthi P V P, Kho K, Nurdiansyah R, et al. Do Kombucha symbiotic cultures of bacteria and yeast affect bacterial cellulose yield in molasses? [J]. Journal of Fungi, 2021, 7(9): 705. doi: 10.3390/jof7090705.

[8] Esa F, Tasirin S M, Rahman N A. Overview of bacterial cellulose production and application [J]. Agriculture and Agricultural Science Procedia, 2014, 2: 113-119.

[9] Dufresne C, Farnworth E. Tea, Kombucha, and health: a review [J]. Food Research International, 2000, 33(6) : 409-421.

[10] 吴薇, 盖宝川, 籍保平. 红茶菌菌种主要代谢产物的试验研究[J]. 食品科学, 2004, 25(12): 147-151.

Wu W, Gai B C, Ji B P. D-glucaric acid and other metabolites in Kombucha [J]. Food Science, 2004, 25(12): 147-151.

[11] Villarreal-Soto S A, Beaufort S, Bouajila J, et al. Understanding Kombucha tea fermentation: a review [J]. Journal of Food Science, 2018, 83(3): 580-588.

[12] 唐水佳, 杨雪霞, 洪枫. 红茶菌制备细菌纤维素的研究[J]. 纤维素科学与技术, 2012, 20(2): 40-45.

Tang S J, Yang X X, Hong F. Production of bacterial cellulose by Kombucha [J]. Journal of Cellulose Science and Technology, 2012, 20(2): 40-45.

[13] Savary O, Mounier J, Thierry A, et al. Tailor-made microbial consortium for Kombucha fermentation: microbiota-induced biochemical changes and biofilm formation [J]. Food Research International, 2021, 147: 110549. doi: 10.1016/j.foodres.2021.110549.

[14] Laavanya D, Shirkole S, Balasubramanian P. Current challenges, applications and future perspectives of SCOBY cellulose of Kombucha fermentation [J]. Journal of Cleaner Production, 2021, 295: 126454. doi: 10.1016/j.jclepro.2021.126454.

[15] 余瞻, 赵福权, 徐成龙, 等. 红茶菌中细菌纤维素产生菌的筛选、鉴定及其发酵动力学模型构建[J]. 食品与发酵工业, 2021, 47(6): 92-98.

Yu Z, Zhao F Q, Xu C L, et al. Screening, identification of bacterial cellulose producing bacteria and establishment of fermentation kinetics [J]. Food and Fermentation Industries, 2021, 47(6): 92-98.

[16] Chakravorty S, Bhattacharya S, Chatzinotas A, et al. Kombucha tea fermentation: microbial and biochemical dynamics [J]. International Journal of Food Microbiology, 2016, 220: 63-72.

[17] 吕橄, 赵文韬, 龚建萍, 等. 细菌纤维素在食品工业中的应用研究进展[J]. 现代食品, 2021(16): 23-28.

Lü K, Zhao W T, Gong J P, et al. Research progress on the application of bacterial cellulose in food industry [J]. Modern Food, 2021(16): 23-28.

[18] Semjonovs P, Ruklisha M, Paegle L, et al. Cellulose synthesis by Komagataeibacter rhaeticus strain P1463 isolated from Kombucha [J]. Applied Microbiology and Biotechnology, 2017, 101(3): 1003-1012.

[19] Emiljanowicz K E, Malinowska-Panczyk E. Kombucha from alternative raw materials: the review [J]. Critical Reviews in Food Science and Nutrition, 2020, 60(19): 3185-3194.

[20] AlKalifawi I, Hassan A A. Factors influence on the yield of bacterial cellulose of Kombucha (Khubdat Humza) [J]. Baghdad Science Journal, 2014, 11(3): 1420-1428.

[21] Balasubramanian P, Praharaj P T. Principal component analysis revealed the key influencing factors of kombucha bacterial cellulose yield and productivity [J]. Bioresource Technology Reports, 2023, 23: 101539. doi: 10.1016/j.biteb.2023.101539.

[22] Neera, Ramana K V, Batra H V. Occurrence of Cellulose-Producing Gluconacetobacter spp. in Fruit Samples and Kombucha tea, and production of the biopolymer [J]. Applied Biochemistry and Biotechnology, 2015, 176(4): 1162-1173.

[23] Yim S M, Song J E, Kim H R. Production and characterization of bacterial cellulose fabrics by nitrogen sources of tea and carbon sources of sugar [J]. Process Biochemistry, 2017, 59: 26-36.

[24] Sharma C, Bhardwaj N K. Biotransformation of fermented black tea into bacterial nanocellulose via symbiotic interplay of microorganisms [J]. International Journal of Biological Macromolecules, 2019, 132: 166-177.

[25] Ramirez Tapias Y A, Di Monte M V, Peltzer M A, et al. Bacterial cellulose films production by Kombucha symbiotic community cultured on different herbal infusions [J]. Food Chemistry, 2022, 372: 131346. doi:10.1016/j.foodchem.2021.131346.

[26] Mahmoud F, Haines D, Al-Ozairi E, et al. Effect of black tea consumption on intracellular cytokines, regulatory T cells and metabolic biomarkers in type 2 diabetes patients [J]. Phytotherapy Research, 2016, 30(3): 454-462.

[27] Gargey I A, Indira D, Jayabalan R, et al. Optimization of etherification reactions for recycling of tea fungal biomass waste into Carboxymethylcellulose [M]//Drück H, Pillai R G, Tharian M G, et al. Green buildings and sustainable engineering. Singapore: Springer Singapore, 2019.

[28] Zhou D D, Saimaiti A, Luo M, et al. Fermentation with tea residues enhances antioxidant activities and polyphenol contents in Kombucha beverages [J]. Antioxidants, 2022, 11(1): 115. doi: 10.3390/antiox11010155.

[29] 李昊燃. 红茶菌中细菌纤维素产生菌的筛选鉴定及发酵条件优化[D]. 开封: 河南大学, 2016.

Li H R. Screening and identification of a strain producing bacterial cellolose from Kombucha and purification of fermentation process [D]. Kaifeng: Henan University, 2016.

[30] 蒋立文, 刘德华, 廖卢燕, 等. 红茶菌发酵过程中主要化学成分变化的研究[J]. 食品科学, 2007, 28(3): 238-240.

Jiang L W, Liu D H, Liao L Y, et al. Study on changes in major components during tea fungus fermentation [J]. Food Science, 2007, 28(3): 238-240.

[31] Tang H R, Covington A D, Hancock R A. Structure-activity relationships in the hydrophobic interactions of polyphenols with cellulose and collagen [J]. Biopolymers, 2003, 70(3): 403-413.

[32] Phan A D T, Netzel G, Wang D, et al. Binding of dietary polyphenols to cellulose: structural and nutritional aspects [J]. Food Chemistry, 2015, 171: 388-396.

[33] Tran T, Grandvalet C, Winckler P, et al. Shedding light on the formation and structure of Kombucha biofilm using two-photon fluorescence microscopy [J]. Frontiers in Microbiology, 2021, 12: 725379. doi: 10.3389/fmicb.2021.725379.

[34] 张慧霞. 红茶菌微生物的分离及其代谢的初步研究[D]. 福州: 福建师范大学, 2019.

Zhang H X. Isolation and metabolism of Kombucha microorganisms [D]. Fuzhou: Fujian Normal University, 2019.

[35] Balentine D A, Wiseman S A, Bouwens L C M. The chemistry of tea flavonoids [J]. Critical Reviews in Food Science and Nutrition, 1997, 37(8): 693-704.

[36] Tran T, Verdier F, Martin A, et al. Oxygen management during kombucha production: roles of the matrix, microbial activity, and process parameters [J]. Food Microbiology, 2022, 105: 104024. doi: 10.1016/j.fm.2022.104024.

[37] Fontana J D, Franco V C, Desouza S J, et al. Nature of plant stimulators in the production of Acetobacter xylinum (tea fungus) biofilm used in skin therapy [J]. Applied Biochemistry and Biotechnology, 1991, 28: 341-351.

[38] Serra D O, Mika F, Richter A M, et al. The green tea polyphenol EGCG inhibits E. coli biofilm formation by impairing amyloid curli fibre assembly and downregulating the biofilm regulator CsgD via the σE-dependent sRNA RybB [J]. Molecular Microbiology, 2016, 101(1): 136-151.

[39] Zhao T, Chen Z Z, Lin X R, et al. Preparation and characterization of microcrystalline cellulose (MCC) from tea waste [J]. Carbohydrate Polymers, 2018, 184: 164-170.

[40] 王奕, 杨娟, 杨海滨, 等. 基于实地与网络调查的夏秋茶产业发展现状及建议[J]. 南方农业, 2023, 17(13): 194-199.

Wang Y, Yang J, Yang H B, et al. Development status and suggestions of summer and autumn tea industry based on offline and online surveys [J]. South China Agriculture, 2023, 17(13): 194-199.

[41] Zheng Q M, Han C Y, Zhong Y M, et al. Effects of dietary supplementation with green tea waste on growth, digestive enzyme and lipid metabolism of juvenile hybrid tilapia, Oreochromis niloticus×O. aureus [J]. Fish Physiology and Biochemistry, 2017, 43(2) : 361-371.

[42] Sudheer B A, Ramakrishna C, Raju S, et al. Evaluation of tea waste or tea residue, orange peels and pigeon pea pods for proximate composition, fodder quality and digestibility parameters [J]. The Pharma Innovation Journal, 2022, 11(11): 1441-1445.

[43] Balcı-Torun F, Özdemir K S, Mavuş R, et al. Determination of cream formation conditions and its composition during production of concentrated tea extract from black tea manufacturing wastes [J]. The Journal of Food, 2021, 46(2): 339-350.

[44] Ho K K H Y, Haufe T C, Ferruzzi M G, et al. Production and polyphenolic composition of tea [J]. Nutrition Today, 2018, 53(6): 268-278.

[45] Hamed D A, Maghrawy H H, Abdel Kareem H. Biosynthesis of bacterial cellulose nanofibrils in black tea media by a symbiotic culture of bacteria and yeast isolated from commercial kombucha beverage [J]. World Journal of Microbiology and Biotechnology, 2022, 39(2): 48. doi: 10.1007/s11274-022-03485-0.

[46] Hussain Z, Sajjad W, Khan T, et al. Production of bacterial cellulose from industrial wastes: a review [J]. Cellulose, 2019, 26(5): 2895-2911.

[47] Hegde S, Bhadri G, Narsapur K, et al. Statistical optimization of medium components by response surface methodology for enhanced production of bacterial cellulose by Gluconacetobacter persimmonis [J]. Journal of Bioprocessing & Biotechniques, 2013, 4: 142. doi: 10.4172/2155-9821.1000142.

[48] Padmanabhan S K, Lamanna L, Friuli M, et al. Carboxymethylcellulose-based hydrogel obtained from bacterial cellulose [J]. Molecules, 2023, 28(2): 829. doi: 10.3390/molecules28020829.

[49] Amarasekara A S, Wang D, Grady T L. A comparison of kombucha SCOBY bacterial cellulose purification methods [J]. Discover Applied Sciences, 2020, 2: 240. doi: 10.1007/s42452-020-1982-2.

[50] Dima S O, Panaitescu D M, Orban C, et al. Bacterial nanocellulose from side-streams of Kombucha beverages production: preparation and physical-chemical properties [J]. Polymers, 2017, 9(8): 374. doi: 10.3390/polym9080374.

[51] Knöller A, Widenmeyer M, Bill J, et al. Fast-growing bacterial cellulose with outstanding mechanical properties via cross-linking by multivalent ions [J]. Materials, 2020, 13(12): 2838. doi: 10.3390/ma13122838.

[52] Tapias Y A R, Peltzer M A, Delgado J F, et al. Kombucha tea byproduct as source of novel materials: formulation and characterization of films [J]. Food and Bioprocess Technology, 2020, 13: 1166-1180.

[53] Kamiński K, Jarosz M, Grudzień J, et al. Hydrogel bacterial cellulose: a path to improved materials for new eco-friendly textiles [J]. Cellulose, 2020, 27: 5353-5365.

[54] Zhou X Y, Liu X L, Wang Q, et al. Antimicrobial and antioxidant films formed by bacterial cellulose, chitosan and tea polyphenol: shelf life extension of grass carp [J]. Food Packaging and Shelf Life, 2022, 33: 100866. doi: 10.1016/j.fpsl.2022.100866.

[55] Betlej I, Salerno-Kochan R, Krajewski K, et al. The influence of culture medium components on the physical and mechanical properties of cellulose synthesized by Kombucha microorganisms [J]. Bioresources, 2020, 15(2): 3125-3135.

[56] Oliver-Ortega H, Geng S, Espinach F X, et al. Bacterial cellulose network from Kombucha fermentation impregnated with emulsion-polymerized poly (methyl methacrylate) to form nanocomposite [J]. 2021, 13(4): 664. doi: 10.3390/polym13040664.

[57] Agüero A, Lascano D, Ivorra-Martinez J, et al. Use of bacterial cellulose obtained from kombucha fermentation in spent coffee grounds for active composites based on PLA and maleinized linseed oil [J]. Industrial Crops and Products, 2023, 202: 116971. doi: 10.1016/j.indcrop.2023.116971.

[58] Zhang X X, Xu J, Zhang Z J, et al. Pb(II) adsorption properties of a three-dimensional porous bacterial cellulose/graphene oxide composite hydrogel subjected to ultrasonic treatment [J]. Materials, 2024, 17(13): 3053. doi: 10.3390/ma17133053.

[59] Julia M M R, Rubí E R Q, Juan P H R, et al. Production and characterization of biocomposite films of bacterial cellulose from Kombucha and coated with chitosan [J]. Polymers, 2022, 14(17): 3632. doi: 10.3390/polym14173632.

[60] Priyadharshini T, Nageshwari K, Vimaladhasan S, et al. Machine learning prediction of SCOBY cellulose yield from Kombucha tea fermentation [J]. Bioresource Technology Reports, 2022, 18: 101027. doi: 10.1016/j.biteb.2022.101027.

[61] 张秀伶, 王稳航. 纳米纤维素研究及在食品工业中的应用前景[J]. 食品工业科技, 2016, 37(21): 377-382.

Zhang X L, Wang W H. Study on nano-cellulose and its application prospect in food industry [J]. Science and Technology of Food Industry, 2016, 37(21): 377-382.

[62] 张艳, 张丽薇, 张金叶, 等. 红茶菌类产品的研究进展[J]. 现代食品, 2017(20): 44-46.

Zhang Y, Zhang L W, Zhang J Y, et al. The research progress of Kombucha's products [J]. Modern Food, 2017(20): 44-46.

[63] Okiyama A, Yamanaka S, Takehisa F. Effect of bacterial cellulose on fecal excretion and transit time in rats [J]. Journal of Japanese Society of Nutrition and Food Science, 1993, 46(2): 155-159.

[64] Hagiwara A, Imai N, Sano M, et al. A 28-day oral toxicity study of fermentation-derived cellulose, produced by Acetobacter aceti subspecies xylinum [J]. The Journal of Toxicological Sciences, 2010, 35(3): 317-325.

[65] Xu C, Ma X, Chen S W, et al. Bacterial cellulose membranes used as artificial substitutes for dural defection in rabbits [J]. 2014, 15(6): 10855-10867.

[66] Chau C F, Yang P, Yu C M, et al. Investigation on the lipid- and cholesterol-lowering abilities of biocellulose [J]. Journal of Agricultural and Food Chemistry, 2008, 56(6): 2291-2295.

[67] Lin D H, Liu Z, Shen R, et al. Bacterial cellulose in food industry: current research and future prospects [J]. International Journal of Biological Macromolecules, 2020, 158: 1007-1019.

[68] Garcia-Diez F, Garcia-Mediavilla V, Bayon J E, et al. Pectin feeding influences fecal bile acid excretion, hepatic bile acid and cholesterol synthesis and serum cholesterol in rats [J]. Journal of Nutrition, 1996, 126: 1766-1771.

[69] Lairon D. Dietary fibres and dietary lipids [M]//McCleary B V, Prosky L. Advanced dietary fibre technology. Malden City: Blackwell Science Ltd., 2001.

[70] Zhai X C, Lin D H, Zhao Y, et al. Effects of dietary fiber supplementation on fatty acid metabolism and intestinal microbiota diversity in C57BL/6J mice fed with a high-fat diet [J]. Journal of Agricultural and Food Chemistry, 2018, 66(48): 12706-12718.

[71] Zhai X C, Lin D H, Zhao Y, et al. Bacterial cellulose relieves diphenoxylate-induced constipation in rats [J]. Journal of Agricultural and Food Chemistry, 2018, 66(16): 4106-4117.

[72] Zhang L L, Zhang W, Peng F B, et al. Effects of bacterial cellulose on glucose metabolism in an in vitro chyme model and its rheological evaluation [J]. International Journal of Food Science & Technology, 2021, 56(11): 6100-6112.

[73] Mikkelsen D, Gidley M J, Williams B A. In vitro fermentation of bacterial cellulose composites as model dietary fibers [J]. Journal of Agricultural and Food Chemistry, 2011, 59(8): 4025-4032.

[74] Avcioglu N H B M, Bilkay I S. Optimization and physicochemical characterization of enhanced microbial cellulose production with a new Kombucha consortium [J]. Process Biochemistry, 2021, 108: 61-67.

[75] 朱昌来, 李峰, 尤庆生, 等. 纳米细菌纤维素的制备及其超微结构镜观察[J]. 生物医学工程研究, 2008, 27(4): 287-290.

Zhu C L, Li F, You Q S, et al. Preparation of nanometer biomaterial bacterial cellulose and observation of its ultra-structure [J]. Journal of Biomedical Engineering Research, 2008, 27(4): 287-290.

[76] 胡晨, 唐义权. 细菌纤维素在眼科等医学领域的研究与展望[J]. 合成材料老化与应用, 2021, 50(5): 178-180.

Hu C, Tang Y Q. Research and prospect of bacterial cellulose in the field of ophthalmology [J]. Synthetic Materials Aging and Application, 2021, 50(5): 178-180.

[77] Czaja W, Krystynowicz A, Bielecki S, et al. Microbial cellulose: the natural power to heal wounds [J]. Biomaterials, 2006, 27(2): 145-151.

[78] Aduri P, Rao K A, Fatima A, et al. Study of biodegradable packaging material produced from scoby [J]. Research Journal of Life Sciences, Bioinformatics, Pharmaceutical and Chemical Sciences, 2019, 5(3): 389. doi: 10.26479/2019.0503.32.

[79] Khorasani A C, Shojaosadati S A. Bacterial nanocellulose-pectin bionanocomposites as prebiotics against drying and gastrointestinal condition [J]. International Journal of Biological Macromolecules, 2016, 83: 9-18.

[80] 蒋高鹏. 基于细菌纤维素的质子交换膜的制备、表征及其在燃料电池中的应用研究[D]. 上海: 东华大学, 2012.

Jiang G P. Preparation, characterization of proton exchange membranes based on bacterial cellulose and their application in fuel cells [D]. Shanghai: Donghua Univversity, 2012.

[81] 刘玉智, 李景超, 陈立宗, 等. 细菌纤维素在造纸行业中的研究与应用进展[J]. 山东化工, 2019, 48(22) : 55, 57.

Liu Y Z, Li J C, Chen L Z, et al. Research and application progress of bacterial cellulose in the field of papermaking [J]. Shandong Chemical Industry, 2019, 48(22): 55, 57.

[82] Aung T, Kim M J. A comprehensive review on kombucha biofilms: a promising candidate for sustainable food product development [J]. Trends in Food Science & Technology, 2024, 144: 104325. doi: 10.1016/j.tifs.2024.104325.