Damage Mechanism of Ultra-thin Asphalt Overlay (UTAO)based on Discrete Element Method

2024-04-11DUXiaoboGAOLiangRAOFaqiangLINHongweiZHANGHongchaoSUNMutianXUXiuchen

DU Xiaobo ,GAO Liang ,RAO Faqiang ,LIN Hongwei ,ZHANG Hongchao ,SUN Mutian ,XU Xiuchen

(1.Postdoctoral Station of Mechanical Engineering,Tongji University,Shanghai 201804,China;2.Guangzhou Daguang Expressway Co.,Ltd,Guangzhou 510075,China;3.Key Laboratory of Road and Traffic Engineering of Ministry of Education,Tongji University,Shanghai 201804,China)

Abstract: Aiming to analyze the damage mechanism of UTAO from the perspective of meso-mechanical mechanism using discrete element method (DEM),we conducted study of diseases problems of UTAO in several provinces in China,and found that aggregate spalling was one of the main disease types of UTAO.A discrete element model of UTAO pavement structure was constructed to explore the meso-mechanical mechanism of UTAO damage under the influence of layer thickness,gradation,and bonding modulus.The experimental results show that,as the thickness of UTAO decreasing,the maximum value and the mean value of the contact force between all aggregate particles gradually increase,which leads to aggregates more prone to spalling.Compared with OGFC-5 UTAO,AC-5 UTAO presents smaller maximum and average values of all contact forces,and the loading pressure in AC-5 UTAO is fully diffused in the lateral direction.In addition,the increment of pavement modulus strengthens the overall force of aggregate particles inside UTAO,resulting in aggregate particles peeling off more easily.The increase of bonding modulus changes the position where the maximum value of the tangential force appears,whereas has no effect on the normal force.

Key words: ultra-thin asphalt overlay;pavement distress;discrete element method;meso-mechanics;damage mechanism

1 Introduction

According to Statistical Bulletin on the Development of the Transportation Industry in 2020 issued by the Ministry of Transport of China,it was pointed out that,China’s highway maintenance mileage has reached 5.144 million kilometers,accounting for 99.0% of the total highway mileage by the end of 2020[1].Clearly,there faced heavy road maintenance work in China.Globally,developed countries,such as the United States,Japan,Europe,also have many roads that need to be maintained.Road pavement maintenance is generally divided into daily maintenance,corrective maintenance and preventive maintenance[2].The preventive maintenance was proposed in the United States in the early 1990s,which is a planned,cost-effective maintenance strategy for the existing road system[3,4].As an active maintenance strategy,preventive maintenance greatly reduces the cost of pavement maintenance projects and improves the life-cycle economic benefits of pavement construction,which has been paid more attention by the traffic maintenance departments of various countries.

At present,the commonly used preventive maintenance technologies include fog seal,slurry seal,micro-surfacing and thin overlay technology[5,6].Among them,Ultra-thin asphalt overlay (UTAO)originated in France in 1960s,and has been widely used in many countries around the world due to its excellent technical advantages[7].The full life cycle cost of UTAO has been comprehensively evaluated,demonstrated that UTAO has significant economic and social benefits in comparison with other maintenance techniques[8,9].Up to now,materials,road performances,and engineering applications of UTAO have been extensively studied.Liet alprepared highviscosity liquid asphalt by adding water-based epoxy resin emulsion and liquid carbon petroleum resin into SBS modified asphalt,and evaluated high and low temperature rheological properties and compatibility properties of high-viscosity liquid asphalt[10].A study conducted by Luoet alalso prepared two different high-viscosity modified asphalts[6].Based on this,the research on mineral gradation and mix ratio design of UTAO were carried out further,and a porous ultra-thin overlay (PUTO) technology was proposed.Moreover,the moisture sensitivity,high and low temperature performances and dynamic loading performance of PUTO were evaluated[11].High-toughness ultra-thin friction course (HUFC) was put forward by Yuet alfor the climatic characteristics of South China,which has been used in more than 100 engineering projects with its excellent noise reduction,anti-skidding and durability properties[12].Similarly,a kind of easy compaction and high-durability UTAO was propose to address the compaction and durability problem of UTAO and verified successfully in the test section[7].In addition,the durability of UTAO is also the focus of researchers.Huet alconcluded that OGFC-5 exhibited good moisture sensitivity and spalling resistance when the asphalt film thickness was increased to 14 μm and the dynamic viscosity was increased to 35000 Pa·s[13].However,a study showed that OGFC-5 UTAO had better spalling resistance and moisture sensitivity when the air void and asphalt film thickness were small.In contrast,UTAO showed better resistance to rutting,peeling,and fracture[14].It was suggested that the air void and asphalt film thickness should be determined in combination with road performance in OGFC-5 mix design.A study demonstrated that UTAO could effectively improve the high-temperature rutting resistance and low-temperature cracking resistance of asphalt pavement by evaluating the performance of the double-layer specimens combined with UTAO and AC-13[15].Texas has also formulated strict construction specifications and requirements for UTAO to ensure the successful UTAO projects[16].Besides,Labiet alstudied the rationality of evaluating the long-term effectiveness of UTAO by three different indicators:treatment life,average pavement condition increase,and area defined by performance curves[17].It is certain that the current research on UTAO has achieved many beneficial results,promoting the engineering application of UTAO.However,due to the thin layer thickness of UTAO,diseases frequently occur during service life.Although it has become an industry consensus that UTAO has prone to diseases,there is a lack of systematic disease investigations.What is more noteworthy is that the disease problems of UTAO are addressed from the perspective of material design at present,without considering the mechanical mechanism of UTO damage.

In the past few decades,relevant researches on the meso-mechanical response of asphalt mixture have made great progress due to the continuous progress of numerical simulation methods such as finite element method (FEM) and discrete element method (DEM).Compared with FEM,DEM is more suitable for studying the mechanical behavior of granular materials.The aggregates distribution,movement and damage process of asphalt mixture can be simulated accurately by DEM[18].Based on DEM,the influence of aggregate properties on the low temperature cracking of asphalt mixtures was investigated[19].Meanwhile,the pavement structure model can also be constructed by DEM to study the meso-mechanical response of pavement structure under traffic load[20].The load transmission during pavement structure is reflected by the form of force chain[21].Xuet alstudied the effect of temperature change of interlayer bonding layer on the mechanical response of asphalt pavement in different seasons through constructing DEM model of asphalt pavement structure[22].Similarly,the meso-mechanical response of the pavement structure was studied for semi-flexible pavement[23,24],graded gravel base asphalt pavement[25],and asphalt pavement overlay cement concrete slab under traffic load[26].A similar study analyzed the micromechanical properties of high-modulus asphalt concrete (HMAC) pavement structures under loading by DEM[27].Moreover,researchers have also studied the multi-scale mechanical responses of asphalt pavement structures under vibration loads[28],temperatureload interaction[29],and vehicle-road interaction[30].Obviously,many beneficial results have been made in the research on meso-mechanical response of different asphalt pavement structures using DEM,which provides a powerful means and experience for exploring the mechanical mechanism of UTAO disease.However,there are no meso-mechanical studies on UTAO pavement structures being reported until now.

In view of this,this paper aimed at summarizing the common disease forms through the investigation of UTAO disease.DEM was used to study the mesomechanical responses under different thickness,gradation type and surface modulus for further exploring the damage mechanism of UTAO.

2 UTAO disease investigation

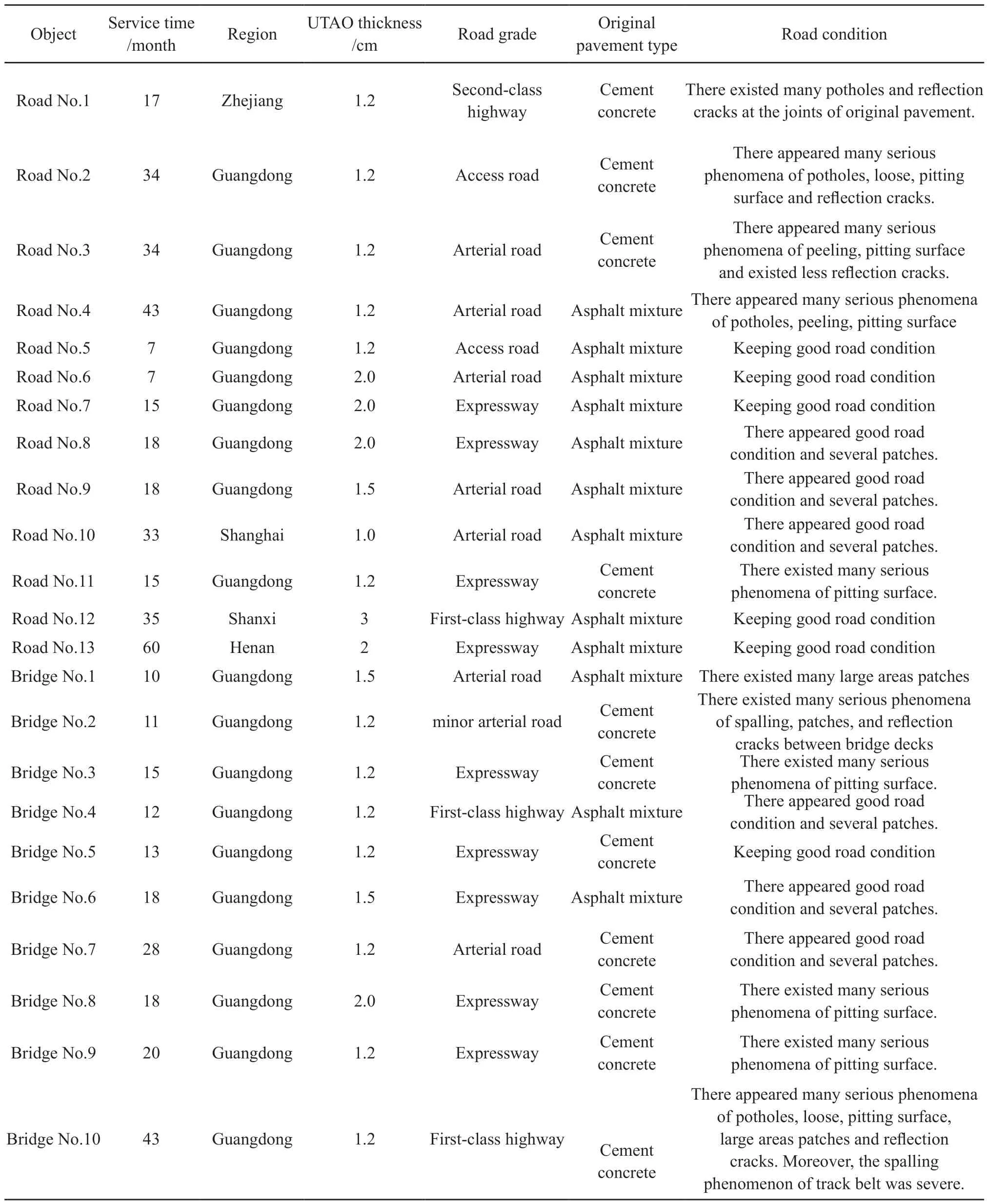

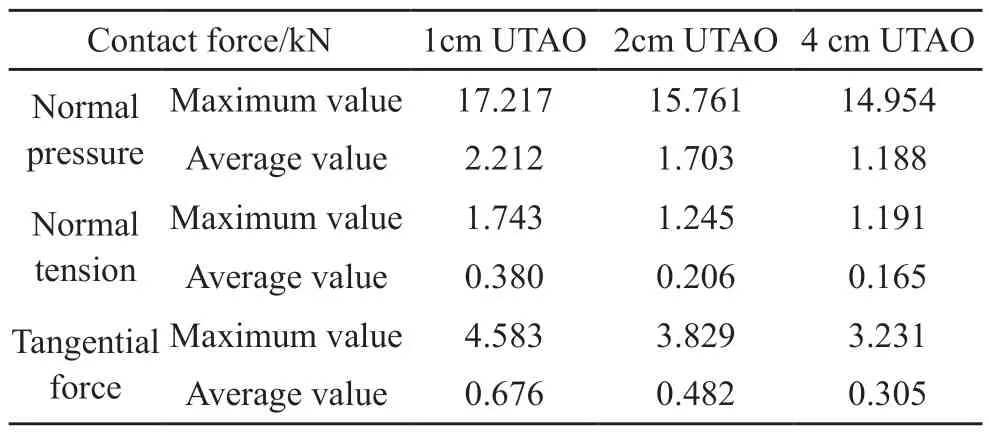

UTAO has been applied in many provinces and cities in China,such as Shanghai,Zhejiang,Guangdong,Guangxi,Fujian,Hebei,Sichuan.In order to make the survey broadly representative,several roads and highways are investigated,which included different grades of highways and urban roads.The mixture type used in UTAO was open-graded asphalt mixture with 4.75 mm nominal maximum aggregate size.And the thickness of UTAOs in this study ranged from 1 to 2 cm.Table 1 shows the results of UTAO distress investigation.

Table 1 Survey results of UTAO diseases[31]

Based on the survey results above mentioned,UTAO appeared diseases more easily in cement concrete pavement than in asphalt mixture pavement[32].Besides,From the point of view of service time,UTAO used for 10 to 43 months have various degrees of disease.The damage conditions became worse in UTAO over time.In general,the disease problems of UTAO were more related to the original pavement type and service time.

The main diseases of UTAO were summarized with referred to the classification of asphalt pavement diseases.The most common diseases of UTAO in cement concrete pavement were cracks,pitting surface and potholes.As for asphalt mixture pavement,there mainly existed many serious phenomena of pitting surface and potholes.The reflection crack of UTAO in cement concrete pavement mainly cause by some external factors of existing cracks in original pavement,cement concrete shrinkage or traffic load[26,33].Whereas,the phenomenon of pitting surface and potholes was mainly caused by internal factors of aggregates peeling within UTAO[4,14,34].Regardless of the original pavement is cement concrete or asphalt mixture pavement,aggregate peeling is the most common damage in many UTAO projects,especially occurring near the wheel track belt.Thus,it is necessary to explore the meso-mechanical response between aggregate particles within UTAO under traffic load,and to release the damage mechanism and influencing factors of aggregate peeling in UTAO.

3 DEM simulation

3.1 Micro parameters of UTAO model

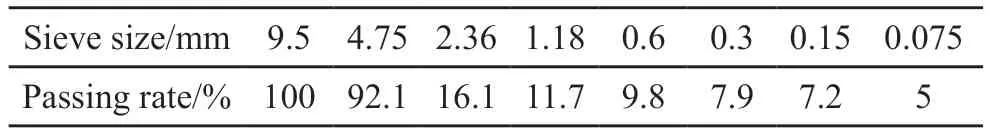

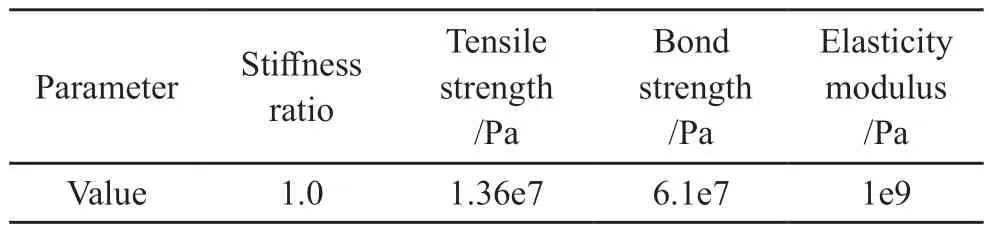

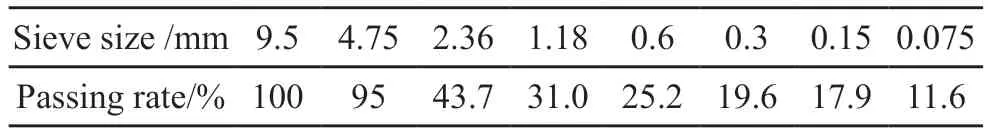

In this study,the micro parameters of UTAO pavement model were determined by a designed trialand-error method combining indoor and virtual indirect tensile tests.In the indoor indirect tensile test,OGFC-5 mixture was used for UTAO,which was designed of 18% air void.The aggregate gradation presents in Table 2.The asphalt used in the test was SBS high-viscosity asphalt,and the optimum asphalt dosage is 6%.The 0-3 and 3-5 mm aggregates were limestone aggregates and basalt aggregates respectively,and the ore powders were limestone ore powders.The fiber was basalt fiber,accounting for 0.3% of the total amount of the asphalt mixture.The technical properties of all materials met the requirements for China standard[35].The Indirect tensile test was carried out using 6 parallel standard Marshall specimens.The indoor Indirect tensile test results are shown in Table 4.

Table 2 OGFC-5 aggregate gradation

Table 3 The results of indirect tensile test in lab

Table 4 The micro-parameters of UTAO

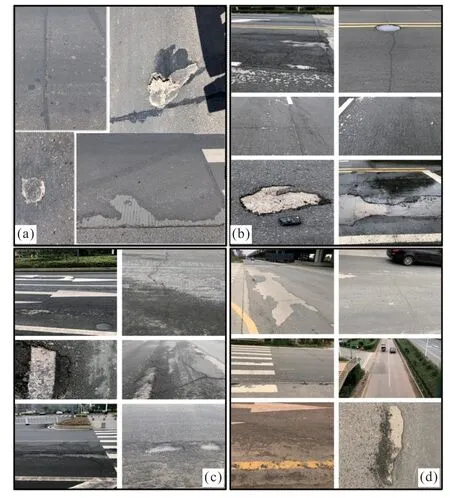

For the virtual indirect tensile test,the fine aggregate and asphalt mixture were defined as asphalt mortar.As can be seen in Table 2,there accounted for a low proportion of fine aggregate below 2.36 mm.Thus,particles larger than 2.36 mm were considered in the DEM model to balance the calculation efficiency[28].The parallel bond model was used to characterize the contact behavior of particles inside UTAO.

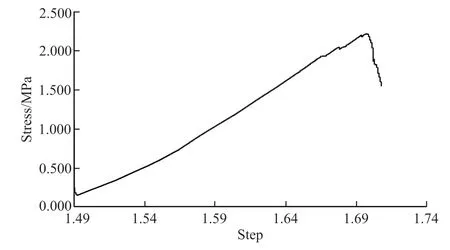

The virtual specimen model was generated by random generation,and was loaded by wall loading until it was destroyed,as shown in Fig.3.After adjusting micro model parameters of UTAO pavement one by one to fit the results of indoor indirect tensile test,the recommended final micro model parameters are shown in Table 4.Based on this,a virtual indirect tensile test was carried out.The curve of the stress changing with step is obtained in Fig.4.The indirect tensile strength in virtual test was 2.214 MPa more than 0.4% compared with indoor indirect tensile strength of 2.205 MPa.Therefore,the determined micro parameters were reasonable and feasible.

3.2 DEM model of asphalt pavement with UTAO

3.2.1 DEM model establishment

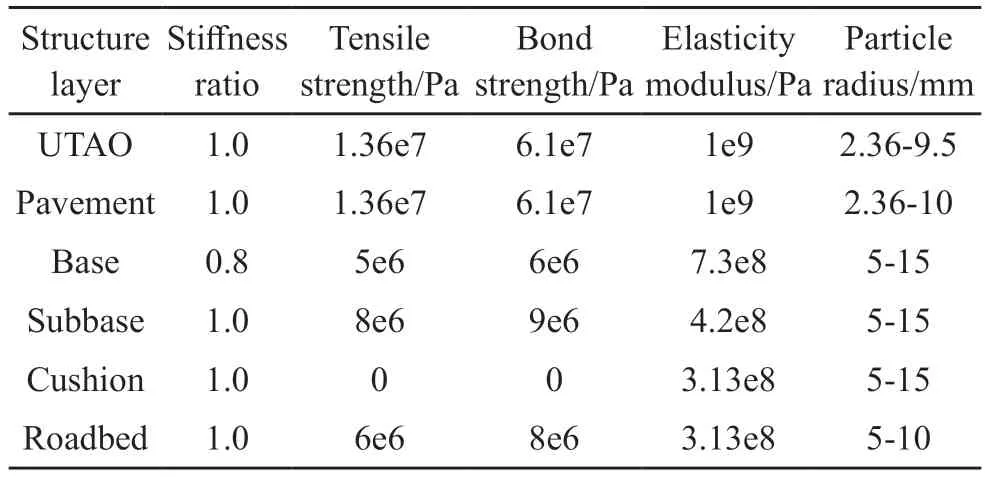

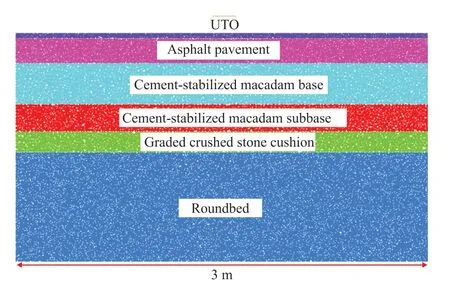

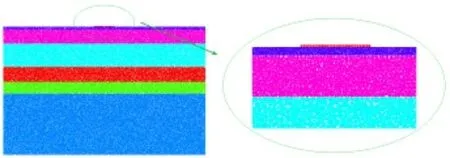

The common pavement structure of semi-rigid base asphalt pavement in China is selected to study the meso-mechanical response between aggregates of UTAO.The composition of pavement structure is shown in Fig.5.The micro model parameters of all pavement structure layers are listed in Table 5.As same to UTAO,the particle contact model of other structural layers was parallel bonding model.Considering that the object layer in this study is UTAO,the model parameters of other structural layers were adopted with reference to the existing research results[25,36].Based on this,the DEM model of asphalt pavement with UTAO was constructed,as shown in Fig.6.Notably,except for UTAO,the aggregate particles of other pavement structure layers were generated within the range of the maximum and minimum of setting sphere particle radius rather than according to specific gradation.

Table 5 The micro-parameters of the material in each pavement structure

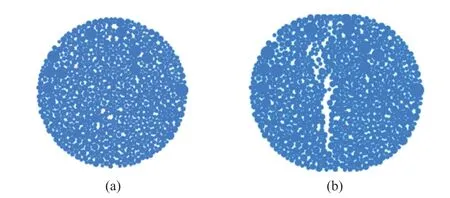

3.2.2 Load model establishment

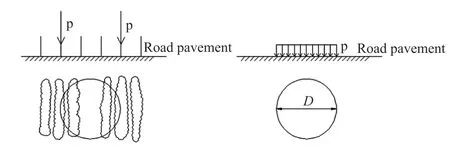

A single-axle load of 100 kN for a double wheel was used as the standard axle load,and the tire ground pressure is 0.7 MPa,as per to Chinses Specifications for Design of Highway Asphalt Pavement (JTG D50-2017)[37].The ground contact area of tires is usually simplified as a circle to calculate ground pressure,and the double wheels can be simplified as a single-circle load or a double-circle load according to the needs.In this study,the single-circle load form was adopted in Fig.7.And the load parameters are shown in Table 6.Then,the clump command was applied to simulate the single-circle load by giving a load of 50 kN and an action length of 30.2 cm.The loading model diagram is shown in Fig.8.

Table 6 Load parameter

4 Meso-mechanical response of UTAO based on DEM

4.1 Meso-mechanical response of UTAO with different thicknesses

4.1.1 Force chain

Fig.9 shows the force chain distribution of pavement structure under three UTAO thicknesses.The overall trend of force chain distribution of different UTAO thicknesses is basically the same,which spread downward in a trapezoidal shape.

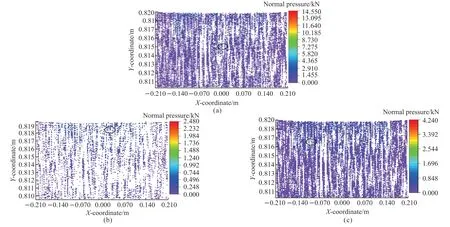

4.1.2 Maximum contact force

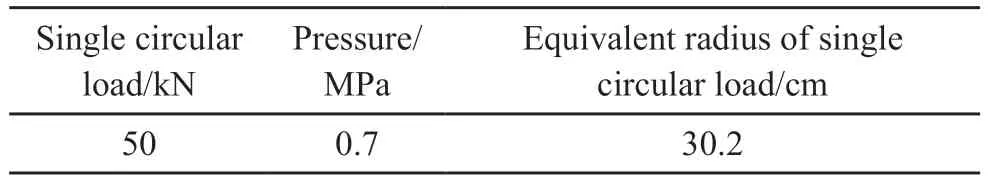

The contact force shown in Fig.9 are presented in Table 7.

Table 7 The contact forces of three thicknesses UTAO

The decrease in the UTAO thickness increases the maximum and mean values of contact normal pressure,contact normal tension,and contact tangential force.Aggregate exfoliation failure is usually tensile failure or shear failure.The decrease in the UTAO thickness strengthened tensile and tangential forces of particles,which is more prone to tensile or shear failure leading to particle exfoliation.

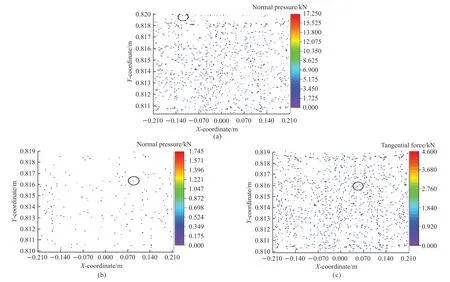

In addition,the heat maps of three types of contact force in UTAO are shown in Figs.10-12.The position of the black circle in the heat maps is the position of maximum contact force between the corresponding particles.In this regard,comparing Fig.10 to Fig.12,the maximum normal pressures of three different thicknesses UTAO were all located within 1 mm from the model surface,but far from the position of loading section.Besides,the maximum values of normal tension and tangential force were located within 4 mm from the model surface.Different from the location section of normal pressure,the maximum values of both were close to the position of loading section.This also explains why the phenomenon of aggregate exfoliation in UTAO is most serious near the wheel track.

Fig.1 Diseases of UTAO covering road pavement: (a)Road No.1;(b)Road No.2;(c)Road No.3;(d)Road No.4

Fig.2 Diseases of UTAO covering bridge deck: (a)Bridge No.1;(b)Bridge No.2;(c) Bridge No.3

Fig.3 Virtual indirect tensile test: (a) Indirect tensile test model;(b)Failure state of virtual specimen

Fig.4 The curve of stress change over time step

Fig.5 UTAO pavement structure

Fig.6 Discrete element model of UTAO pavement structure

Fig.7 Diagram of single circular load with two wheels

Fig.8 Loading model diagram

Fig.9 Force chain distribution of three thicknesses UTAO: (a) 1 cm;(b) 2 cm;(c) 4 cm

Fig.10 Thermal maps of three contact forces for 1 cm UTAO: (a) Normal pressure;(b) Normal tension;(c) Tangential force

Fig.11 Thermal maps of three contact forces for 2 cm UTAO: (a) Normal pressure;(b) Normal tension;(c) Tangential force

Fig.12 Thermal maps of three contact forces for 4 cm UTAO: (a) Normal pressure;(b) Normal tension;(c) Tangential force

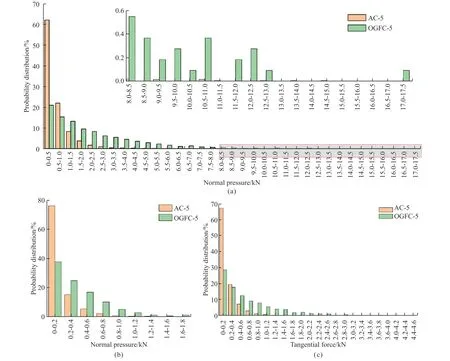

4.1.3 Probability distribution of contact force

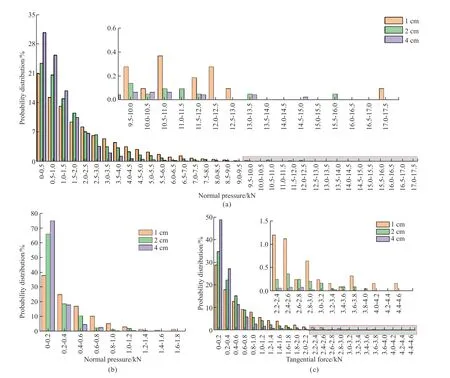

The value of contact force on particles of UTAO with three thicknesses was statistically analyzed and divided into several intervals.The probability distribution of force values is obtained,as shown in Fig.13.

Fig.13 Probability distribution of three contact force for different thicknesses UTAO: (a) Normal pressure;(b) Normal tension;(c) Tangential force

As can be seen from Fig.13(a),the normal pressure probability distribution of three thicknesses UTAO in all sections of 0-2.0 kN was sorted as 4 cm>2 cm>1 cm in descending order,whereas there sorted as 1 cm>2 cm>4 cm in the range larger than 2.0 kN.

In Fig.13(b),the normal tension of 4cm UTAO accounted for the largest proportion in all sections of 0-0.2 kN while the proportion of 1 cm UTAO was the smallest.As for probability distribution in sections over 2.0 kN,the order of three thicknesses UTAO is 1 cm>2 cm>4 cm.

Base on Fig.13(c),the tangential force of 4 cm UTAO accounted for the largest proportion in all sections of 0-0.4kN while the proportion of 1 cm UTAO was the smallest.The probability distribution order is 1 cm>2 cm>4 cm as the tangential force was over 0.4 kN.Obviously,three contact forces of 1 cm UTAO had a highest proportion in the large force range while 4 cm UTAO had highest proportion in the small force range.This is because the overall contact force of the upper area of UTAO decreased as the thickness of UTAO increased.Meanwhile,it can be seen in Fig.9 that greater UTAO thickness is conducive to increase the contact number of particles,which was beneficial to the transmission and dispersion of load.Therefore,the thickness increase of UTAO decreased the contact force between the particles and reduced aggregates exfoliation.

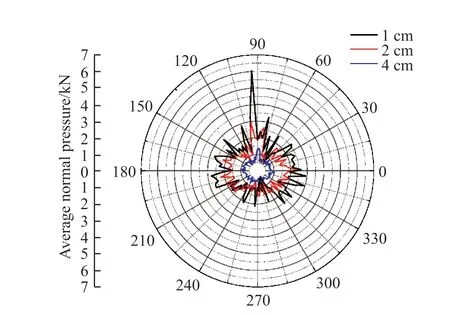

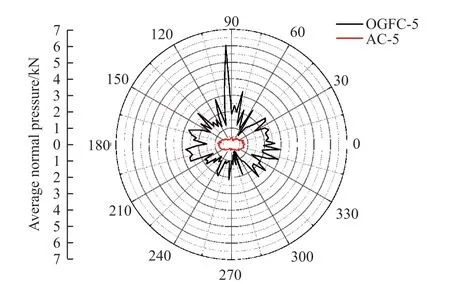

4.1.4 Angle distribution of contact normal force

Fig.14 shows angle distribution of normal contact force for UTAO with different thicknesses.The angle between the normal force and the horizontal direction was calculated by obtaining thex-direction andy-direction components of normal force,which was defined as of normal force with a range of 0-360°.Then,the angle ranging from 0 to 360° was divided into 90 intervals.The angle and magnitude of normal force within each interval were averaged and plotted in polar coordinates as the angle and radius coordinates,respectively.

Fig.14 Angle distribution of normal pressure for different thickness UTAO

From Fig.14,the normal forces of different UTAOs were distributed in the 0-360° direction,which indicated that the force chain diffusion was relatively scattered.The thickness of UTAO had little effect on the force chain diffusion.Meantime,the polar coordinate radius of different thicknesses UTAO in each interval was sorted as 1 cm>2 cm>4 cm in descending order.In addition,the angular distribution of contact normal force for three types of UTAO concentrated in the range of 75°-105°,indicating that the transmission direction of force chain mainly occurs in the vertical direction.This is consistent with the overall distribution direction of the force chain in Fig.9.

4.2 Meso-mechanical response of UTAO with different gradation

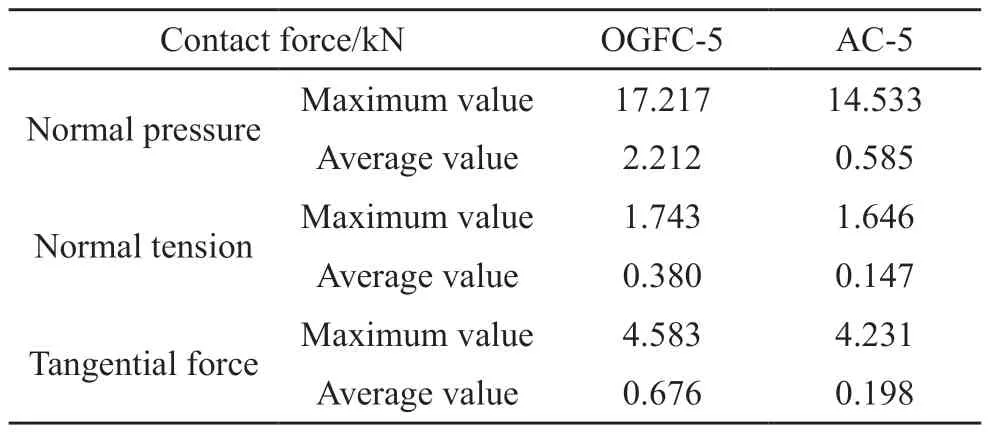

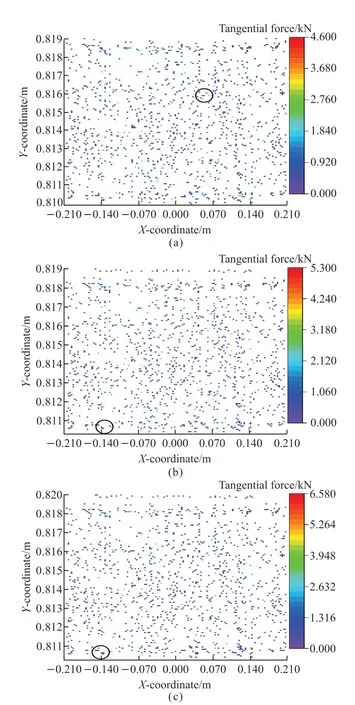

4.2.1 Maximum contact force

Table 8 shows contact force results of UTAO with different gradation.A discrete element model of AC-5 UTAO pavement structure was established to explore the effect of gradation on the meso-mechanical response in UTAO.The meso-parameters are shown in Table 5.Table 8 lists mineral gradation of AC-5 with a target void ratio of 4%.

Table 8 The contact forces of UTAO filled with different mineral gradations

Table 9 AC-5 aggregate gradation

It can be seen from Table 8 that the maximum and average values of normal pressure,normal tension and tangential force for AC-5 UTAO were smaller than those of OGFC-5.This is mainly because there are more small and medium-sized aggregates in AC-5 gradation,and lower air void than that of OGFC-5 gradation.According to statistical data of DEM model,the number of particles and contacts in the AC-5 model were 12,409 and 26,411 respectively,whereas there were only 695 particles and 1,294 contacts in the OGFC-5 model.Remarkably,the applied load in the AC-5 model was borne by more particles,resulting in less force per particle and contact.

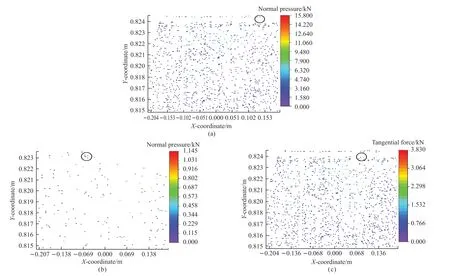

Three contact forces of AC-5 model are shown in Fig.15.The black circles in the figure exhibited the positions of maximum contact force.As like the results of OGFC-5 UTAO,the maximum values of all contact forces in AC-5 model were also distributed within 0.5mm of model surface,which is similar to the results of the OGFC-5 UTAO.However,most areas in heat map for three contact forces of AC-5 UTAO were purple,meaning that most of contact forces were small.

Fig.15 Thermal maps of three contact forces for AC-5 UTAO: (a) Normal pressure;(b) Normal tension;(c) Tangential force

4.2.2 Probability distribution of contact force

Fig.16 shows the probability distribution of contact force in UTAOs filled with two different gradations.Remarkably,the proportion of three contact forces in AC-5 UTAO was much higher than that in OGFC-5 UTAO in the range of small force values.As for AC-5 UTAO,the distribution proportion of normal pressure in 0-0.5 kN section,normal tension in 0-0.2 kN section and tangential force in 0-0.2 kN section all accounted for more than 60%.Compared with OGFC-5 UTAO,AC-5 UTAO presented a lower proportion of normal pressure in the range over 1.0 kN,normal tension in the range over 0.4 kN and tangential force in the range over 0.6 kN.This result was corresponded to the conclusions drawn from Fig.15.Most of three contact forces in AC-5 UTAO were smaller and the maximum values of three contact forces were also smaller than those of OGFC-5 UTAO.This is also the mechanical reason that AC-5 UTAO is less prone to aggregate spalling in comparison with OGFC-5 UTAO.

Fig.16 Probability distribution of three contact force for UTAO filled with different mineral gradations: (a) Normal pressure;(b) Normal tension;(c) Tangential force

4.2.3 Angle distribution of contact normal force

The angle distribution of normal contact force for AC-5 and OGFC-5 UTAO are exhibited in Fig.17.As same to OGFC-5 UTAO,the normal forces of AC-5 UTAO were distributed in the 0-360° direction.The force chain diffusion was relatively scattered.Notably,the polar radius of AC-5 UTAO was significantly smaller than that of the OGFC-5 UTAO.Moreover,the angle distribution of normal force for AC-5 UTAO was larger in the range of 330°-30° and 150°-210° than other ranges,indicating that the internal force chain of AC-5 UTAO fully diffused in the lateral direction.This is different from the fact that the force chain of OGFC-5 UTAO was concentrated in the vertical direction.

Fig.17 Angle distribution of normal pressure for UTAO filled with different mineral gradations

4.3 Meso-mechanical response of UTAO with different bond moduli of original pavement

4.3.1 Maximum contact force

The contact force results of OGFC-5 UTAO with different bond moduli of original pavement are shown in Table 10.In the study,the bonding modulus of original pavement was settled as 3e8,3e9,and 3e10,respectively.The micro model parameters are shown in Table 5.

Table 10 The contact forces for UTAO under three bond modulus of asphalt pavement

It can be seen from Table 10 that maximum and average values of normal pressure and contact tangential force strengthened with the bonding modulus of original pavement increasing.And maximum value of normal tension also increased,while the average value was slightly lower.Therefore,the increase of bonding modulus enhanced overall force of aggregates inside UTO,leading to more spalling of aggregates.

The heat maps of all contact forces t are shown in Fig.18-19.Obviously,most of the positions of normal tension and normal pressure have not changed,but only the force values have changed by comparing the heat maps of all contact forces under different bonding moduli.From Fig.18,most of color blocks in the heat map of normal pressure and normal tension overlap under the conditions of 3e8 and 3e10.Most importantly,the position of maximum values for two contact force did not change,indicating that the transmission of main force chain did not change significantly.However,as shown in Fig.19,the position of maximum tangential force transferred from the middle to bottom in UTAO.

Fig.18 Comparison of contact force thermograms for UTAO under two bond modulus 3e8 and 3e10 of asphalt pavement: (a) Normal pressure;(b) Normal tension

Fig.19 Thermal maps of tangential force for UTAO under three bond modulus of asphalt pavement: (a) 3e8;(b) 3e9;(c)3e10

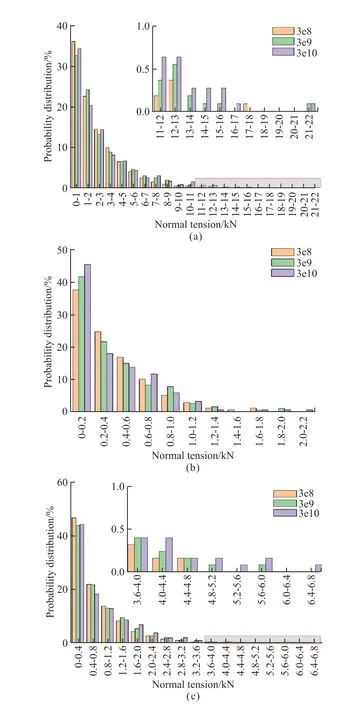

4.3.2 Probability distribution of contact force

Fig.20 shows the probability distribution of contact force in UTAO with different bond moduli of original pavement.As shown in Fig.20 (a),the normal pressure probability distribution of UTAO under different bonding modulus was sorted as 3e8>3e9>3e10 in 0-4.0 kN section,3e9>3e10>3e8 in 4-9 kN section and 3e10>3e9>3e8 in over 9 kN section in descending order,respectively.In addition,the probability distribution trend of tangential force in Fig.20(c) was close to the trend of normal pressure in Fig.20 (a).The results showed that the increase of bonding modulus of original pavement strengthened the normal pressure and tangential force of UTAO.

Fig.20 Probability distribution of three contact force for UTAO under three bond modulus of asphalt pavement: (a) normal pressure;(b) normal tension;(c) tangential force

From Fig.20(b),the order in range of 0-0.2 kN was 3e10>3e9>3e8.The proportion of normal tension in the small force range also enlarged as the bond modulus increased.However,there shown an irregular trend of the probability distribution of normal tension.

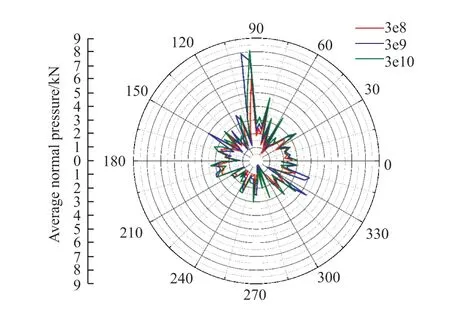

4.3.3 Angle distribution of contact normal force

The angle distribution of normal contact force under different bonding moduli is shown in Fig.21.The direction distribution trend of contact normal force under different bonding moduli was basically unchanged.In this regard,the increase of bonding modulus basically had no effect on the direction of contact normal,indicating that the transmission direction of force chain did not change.In general,the curves of 3e8 and 3e10 bonding modulus were respectively in the innermost and outermost layer,which meant that the normal contact force enlarged as the bonding modulus of original pavement increased.

Fig.21 Angle distribution of normal pressure for UTAO under three bond modulus of asphalt pavement

5 Conclusions

In this paper,an investigation about UTAO disease problem was carried out.A DEM model of UTAO pavement structure was established to explore influence of thickness,gradation and bonding modulus on meso-mechanics response of UTAO.The main conclusions are listed as follows:

a) Based on the field survey results of UTAO diseases in several provinces in China,the most common disease of UTAO was aggregate spalling.

b) As the thickness of UTAO decreases,the proportion in the large force range and overall values of all contact forces gradually enlarges,which resulting in aggregates spalling more easily because of tension or shear damage.The change of UTAO thickness had no effect on the diffusion direction of force chain.

c) Compared with OGFC-5 UTAO,the maximum and average values of all contact forces for AC-5 UTAO are smaller.All contact forces have a higher proportion in the small force range.In addition,the force chain in AC-5 UTAO was fully diffused in the lateral direction.

d) With the increase of the bonding modulus of original pavement,maximum and average value of normal pressure and tangential force strengthens.And maximum value of normal tension also increases,while the average value decreased slightly.Except for normal pressure and tangential force,the position of maximum tangential force transfers from the middle to bottom in UTAO.The increase of bonding modulus is bad for UTAO.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Fabrication of YAG: Ce3+ and YAG: Ce3+,Sc3+ Phosphors by Spark Plasma Sintering Technique

- Preparation of Modified UiO-66 Catalyst and Its Catalytic Performance for NH3-SCR Denitration

- Effect of Molecular Weight on Thermoelectric Performance of P3HT Analogues with 2-Propoxyethyl Side Chains

- Ultraviolet Photodetector based on Sr2Nb3O10 Perovskite Nanosheets

- Fabrication of Silane and Desulfurization Ash Composite Modified Polyurethane and Its Interfacial Binding Mechanism

- Bio-inspired Hydroxyapatite/Gelatin Transparent Nanocomposites