Wetting-drying effect on the strength and microstructure of cementphosphogypsum stabilized soils

2024-03-25LinglingZngXiBinJixingWngToZhng

Lingling Zng,Xi Bin,Jixing Wng,To Zhng

a College of Civil Engineering, Zhejiang University of Technology, Hanzhou, 310014, China

b Key Laboratory of Ministry of Education for Geomechanics and Embankment Engineering, Hohai University, Nanjing, 210098, China

c State Key Laboratory for Geomechanics and Deep Underground Engineering, China University of Mining and Technology, Xuzhou, 221116, China

d Jiangsu Water Source Company Ltd.of the Eastern Route of the South-to-North Water Diversion Project, Nanjing, 210000, China

e Power China Zhongnan Engineering Corporation Limited, Changsha, 410027, China

Keywords: Wetting-drying Phosphogypsum Microstructure Durability

ABSTRACT Phosphogypsum has often been used as an effective and environmentally friendly binder for partial replacement of cement,improving the engineering properties of slurries with high water content.However,the influence of phosphogypsum on the physicomechnical properties of stabilized soil subjected to wetting-drying cycles is not well understood to date.In this study,the effect of phosphogypsum on the durability of stabilized soil was studied by conducting a series of laboratory experiments,illustrating the changes in mass loss,pH value and unconfined compressive strength (qu) with wettingdrying cycles.The test results showed that the presence of phosphogypsum significantly restrained the mass loss in the early stage (lower than the 4th cycle),which in turn led to a higher qu of stabilized soil than that without phosphogypsum.After the 4th cycle,a sudden increase in mass loss was observed for stabilized soil with phosphogypsum,resulting in a significant drop in qu to a value lower than those without phosphogypsum at the 6th cycle.In addition,the qu of stabilized soils correlated well with the measured soil pH irrespective of phosphogypsum content for all wetting-drying tests.According to the microstructure observation via scanning electron microscope(SEM)and X-ray diffraction(XRD)tests,the mechanisms relating the sudden loss of qu for the stabilized soils with phosphogypsum after the 4th wetting-drying cycle are summarized as follows: (i) the disappearance of ettringite weakening the cementation bonding effect,(ii)the generation of a larger extent of microcrack,and(iii)a lower pH value,in comparison with the stabilized soil without phosphogypsum.

1.Introduction

A massive amount of solid waste is generated each year during industrial activities and urbanization in China.Bulk solid wastes in China refer to as solid wastes with production of more than 100 million tons per year in a single category,including industrial byproduct gypsum,coal gangue,fly ash,tailings,smelting slag,construction waste,and crop straw.However,the reutilization rate of these bulk solid wastes was approximately 55%,lower than that of developed countries (Implementation Plan,2022).As a result,there is a stockpiling amount of 60 billion tons of solid waste in China (Implementation Plan,2022).The disposal of these large amounts of solid wastes caused severe environmental problems and social tensions for the long-term occupation of land.Hence,it is of great importance to reuse these solid wastes as raw materials.

On one hand,urban excavated soil has emerged as an important proportion of urban construction waste due to underground space development and dredging projects.It is recommended to improve the mechanical properties of these local soils using chemical treatment with additional binders such as lime and cement to reuse excavated soil as construction materials,filling materials and other products(Yi et al.,2015,2018;Bian et al.,2016,2021a,b;Lang et al.,2021;Li et al.,2022a;Li and Yi,2022b).Usually,the chemical binder lime or cement is widely implemented with the benefits of easy accessibility and effectiveness in improving engineering properties.However,it should be emphasized that the production process of cement and lime may consume large amounts of natural raw materials and generate large quantities of carbon dioxide(Yi et al.,2015;Du et al.,2016).

On the other hand,many studies have suggested that industrial byproducts,such as carbide slag,fly ash,and phosphogypsum,can be used as additional binders with cement or lime to enhance the mechanical properties of cement-stabilized soil (Zhang and Tao,2008;Choobbasti and Kutanaei,2017;Yoobanpot et al.,2020;Zhang et al.,2020;Zeng et al.,2015,2017,2020;Cai et al.,2021;Bian et al.,2022a,2022b;Wu et al.,2022).Thus,it is encouraged to use industrial byproducts as partial replacements of cement or lime for stabilization of the urban excavated soils.This will not only consume the large storage of bulk industrial wastes but also cut carbon dioxide emissions by reducing the usage of cement or lime.

Zeng et al.(2021) proposed a method to use phosphogypsum combined with cement to improve the unconfined compressive strength (qu) of soils with high water contents.From laboratory experimental results,it was confirmed that phosphogypsum showed good engineering performance by increasing the unconfined compressive strength and stiffness of stabilized soils.This is mainly attributable to further chemical reaction between phosphogypsum and calcium (aluminate) silicate hydrate (C(A)SH),creating cementation material(ettringite) that would enhance the cementation bonding effect.It should be noted that there is a threshold value of phosphogypsum corresponding to the maximum strength.Several studies have also implemented phosphogypsum with cement or other slags to produce filling materials,showing good engineering properties(Chen et al.,2018;Calderón-Morales et al.,2021;Liu et al.,2022).Nevertheless,to reuse stabilized soil with phosphogypsum in real projects,the durability of stabilized soil subjected to cyclic wetting-drying cycles is of great concern (Walker,1995;Kamei et al.,2013;Wang et al.,2013;Du et al.,2016,2020;Yi et al.,2018;Zhang et al.,2020;Sadeghian et al.,2022).However,research has been rarely conducted on the effect of phosphogypsum on the durability performance of stabilized soil subjected to wetting-drying due to seasonally wet-dry cycle environments.

This study investigated the effect of phosphogypsum on the durability of stabilized soils with high water content.The variations in physiochemical behavior relating to mass loss,pH value,and water content with phosphogypsum content were proposed.The change in unconfined compressive strength with phosphogypsum content under different wetting-drying stages was obtained.Finally,the mechanism of phosphogypsum on the durability of stabilized soil was discussed by understanding the role of phosphogypsum on the alteration of mineralogical and microstructure at different wetting-drying cycles via X-ray diffraction (XRD) and scanning electron microscope (SEM) tests.

2.Materials and methods

2.1.Materials

The dredged soil was obtained from a lake dredging project,with a natural water content of 110%-170%.The particle size distribution of this soil consists of sand content(>0.074 mm)of 10.4%,silt content (0.074-0.005 mm) of 68%,and clay content(<0.005 mm)of 21.6%.The liquid and plastic limits were measuring 109.8% and 42.7%,respectively,with a plastic index of 67.1 (ASTM D4318-17,2017).The specific density of the soil particles was 2.72.The loss of ignition (LOI) of sediment samples was used to quantify the organic matter contents (ASTM D2974-20,2020).The LOI of the dredged soil is 15.88%,which can be classified as organic soil.

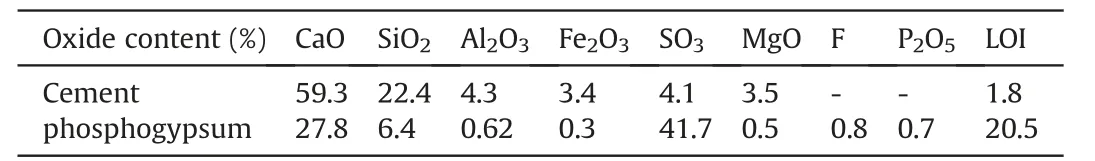

Ordinary Portland cement(42.5R/N)was used in this study,with a burn-off rate of 1.21%,which is in accordance with the national regulation on the burn-off of ordinary Portland cement(<5%).The phosphogypsum was obtained from a phosphogypsum landfill in Luhe District,Nanjing,China,with a burn loss of 3.87%.Their chemical compositions are shown in Table 1 (Zeng et al.,2021).

Table 1 Oxides composition of ordinary Portland cement and phosphogypsum (after Zeng et al.,2021).

2.2.Sample preparation

The air-dried soils were first crushed and passed through a 2-mm sieve.Then,the predetermined water was mixed with dry soil to obtain the slurry with two initial water contents corresponding to 1.25-1.5 times liquid limit.Afterwards,the slurry was thoroughly mixed with the cement powder for 10 min using an electronic mixer.Three cement contents(100 kg/m3,125 kg/m3and 150 kg/m3)and three phosphogypsum contents(0 kg/m3,40 kg/m3and 60 kg/m3) were implemented,where the cement content of 100 kg/m3represented 100 kg cement added into 1 m3slurry.The obtained homogeneous cement-phosphogypsum paste was transformed into a container 39.1 mm in diameter and 80 mm in height.The air bubbles were carefully removed by vibrating the container.The prepared sample inside the container was cured under standard conditions(temperature of(20 ± 2)°C and relative humidity of 95%)for 1 d.Afterwards,the sample was demolded and cured for 28 d to conduct wetting-drying tests.For each test,three specimens were used,with the average value as the final data.The mass loss(Mloss)is defined as the change in mass to the original mass of the specimen at a given number of wetting-drying cycles:

wherem0is the initial mass of specimen,andmiis the mass of specimen at theith wetting-drying cycle.The cumulative mass loss(CMloss) summarizes the mass loss at each cycle:

whereMlossiis the mass loss afterith wetting-drying cycle.

2.3.Experimental method

The wetting-drying tests were performed as the drying stage and the wetting stage(ASTM D4843-88,2016).For the drying stage,the specimens were oven-heated at 60°C for 24 h.For the wetting stage,the oven-heated specimens were first cooled at room temperature for 1 h to obtain an equilibrium specimen temperature.Afterwards,the specimen was soaked inside a water tank at a water temperature of 20°C for 23 h.Each sample was subjected to 12 wetting-drying cycles.Note that some specimens lacked integrity after the 10th cycle.Hence,the confined compression strength was measured until the 10th cycle,while the specimen was subjected to the 12th cycle to measure the change in physical properties such as water content and LOI.The specimen was weighed and photographed after each cycle.

The unconfined compression tests (UCTs) were conducted for specimen after each cycle.The strain rate was set as 1 mm/min.After the UCTs,the damaged specimen blocks were collected forwater content and pH value tests.The water content of specimen at each cycle was determined by oven at 105°C for 24 h.The pH value was determined with a procedure of 20 g of dry soil mixed at a ratio of 1:5 (soil: distilled water by weight),stirred for 5 min with a Magnetics JB-3 constant temperature timer,placed a Magnetics PHS-25 pH meter into the pore solution and waited for the screen to stabilize before taking a reading.

XRD analysis and SEM test were conducted on the sample after the UCT to explore the mineralogy and microstructure of the samples.Prior to testing,the 1 cm3specimen was first freeze-dried using liquid nitrogen and a freeze dryer.A Rigaku D/Max-2500 Xray diffractometer and a NOVA NanoSEM 230 were used to perform the XRD and SEM tests,respectively.

3.Results

3.1.Variation in mass loss

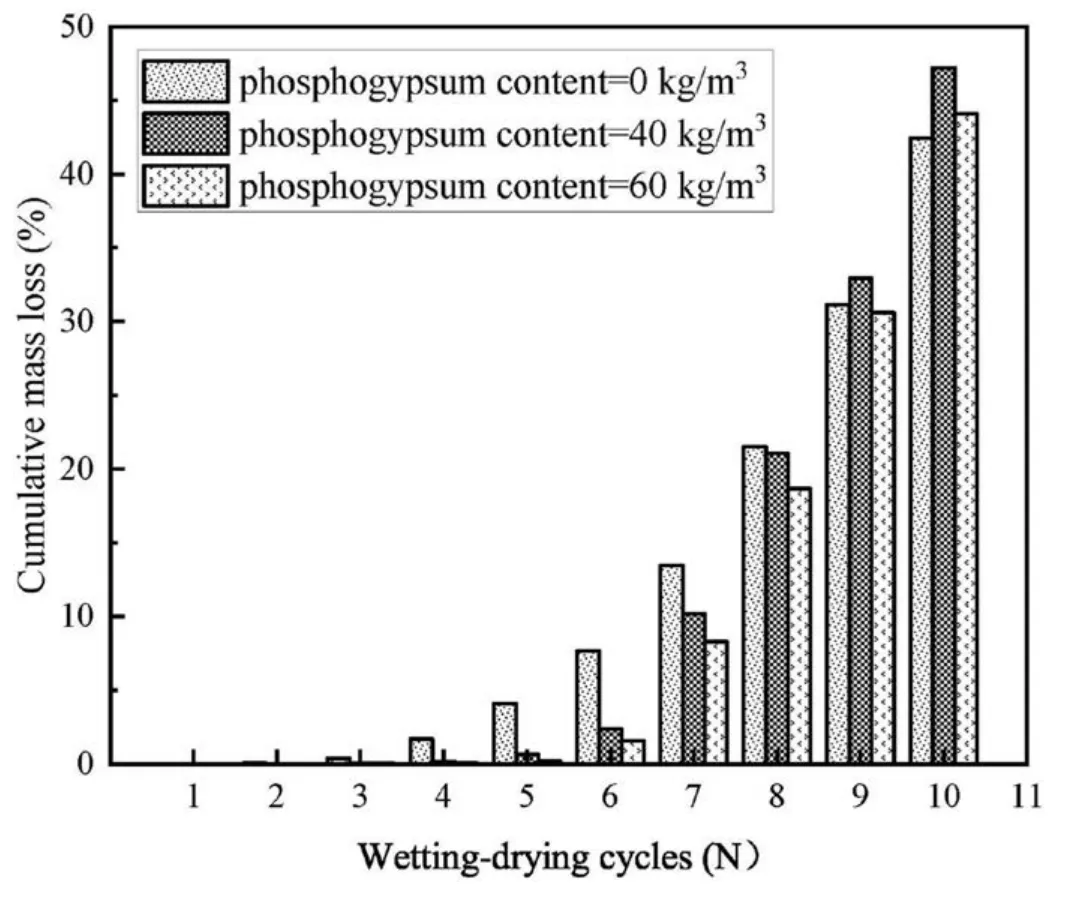

Fig.1 depicts the effect of phosphogypsum content on the cumulative mass loss after different numbers of wetting-drying cycles.The variation in cumulative mass loss (CMloss) for all specimens increased slightly with increase in the number of wetting-drying cycles up to 4 or 6 cycles,followed by a sharp rise with further cycles.This sudden increase inCMlossis due to the breakage of cementation bonds formed by cementation materials,such as calcium (aluminate) silicate hydrate (C(A)SH) and ettringite.The cementation material tended to exfoliate and dissolve with progressive wetting-drying cycles,destroying the cementation bonding in the specimen.To a certain extent,the microfractures around the specimen significantly developed,eventually damaging the integrity of the specimen.

Fig.1.Effect of phosphogypsum content on the cumulative mass loss.

When the number of wetting-drying cycles was lower than the 6,phosphogypsum showed a significant role in the reduction ofCMlossat the same number of wetting-drying cycles.For instance,at the 4th cycle,CMlosssignificantly decreased with increase in the phosphogypsum content.This observation indicated that when the specimen remains intact,the resistance to the wetting-drying impact can be significantly improved by adding phosphogypsum into stabilized soil.However,while the integrity of the specimen showed a high level of destruction after the 4th cycle,the increase rate ofCMlossshowed a significant rise in the presence of phosphogypsum.From the 6th to 10th cycle,the value of mass loss increased by 34.9%at phosphogypsum content of 0 kg/m3,44.8%at 40 kg/m3phosphogypsum content and 42.6% at phosphogypsum content of 60 kg/m3.This sudden increase in mass loss may result from the higher degree of brittleness for the stabilized soil with phosphogypsum.

Fig.2 shows the effect of cement content and initial water content onCMloss,respectively.w0andwLrepresents the initial water content and liquid limit,respectively.It is clear thatCMlossat a given number of wetting-drying cycles decreased with increasing cement content.This is because a stronger cementation bond was formed for specimens with higher cement content,resulting in a higher resistance to wetting-drying cycles.In contrast,CMlossshowed an increasing trend with initial water content,due to a lower cementation bonding effect at higher initial water content.

Fig.2.Effect of cement content and initial water content on the cumulative mass loss.

3.2.Variation in water content

Fig.3 presents the influence of phosphogypsum content on water content at different wetting-drying cycles.For the stabilized soil without phosphogypsum,a decrease in water content with increase in the number of wetting-drying cycles was observed due to the consumption of additional water from the pozzolanic reaction with increasing curing time.This behavior is consistent with previous findings (Bian et al.,2022a).

Fig.3.Effect of phosphogypsum content on water content.

For the stabilized soils with phosphogypsum,the change in water content with wetting-drying cycles showed a fluctuating pattern,with a slight decrease in water content up to the 4th cycle,followed by a significant rise to the 8th cycle,and then a slight decrease with more cycles.The first decrease in water content corresponded to the consumption of water with further pozzolanic reaction (Kamei et al.,2013).A higher level of pozzolanic reaction occurred in the presence of phosphogypsum at the same curing times,resulting in a lower degree of pozzolanic reaction after the wetting-drying cycle and thus a lower degree of water content reduction compared to that without phosphogypsum.After the 4th cycle,the increase in water content was mainly due to the large extent of microfractures extending into the specimen,and some part with unreacted phosphogypsum gradually absorbed water during the wet process,leading to an increase in water content.This increasing trend vanished gradually when the unreacted phosphogypsum was consumed.

3.3.Variations in qu

Fig.4 shows the variation inquwith wetting-drying cycles at different phosphogypsum contents.Without wetting-drying cycle,quincreased with increasing phosphogypsum content.This is mainly due to the enhancement of bonding strength with an increase in ettringite relating to the pozzolanic reaction between C(A)SH and phosphogypsum.The adequate swelling potential and bridge effect of ettringite resulted in an increase inqu,as proposed by Zeng et al.(2021).However,it should also be mentioned that when phosphogypsum content exceeded an optimal value,qushowed a further decreasing tendency with increase in the phosphogypsum content.Hence,the phosphogypsum content of 40 kg/m3or 60 kg/m3in this study did not exceed the optimal content for the used soil.

Fig.4.Variation in qu with wetting-drying cycles at different phosphogypsum contents.

For the stabilized soil without phosphogypsum,an increase inquwith the wetting-drying cycles up to the 4th cycle was observed,followed by a further reduction inqu.After the 12th cycle,qudecreased by 63%.The increase inquwith the number of wettingdrying cycles at the early stage was also reported in Kamei et al.(2013) and Bian et al.(2022b).As the number of wetting-drying cycles increased,the debonding effect due to the suction change of the specimen led to an increase in microfractures,resulting in a further decrease inqu.

As phosphogypsum was introduced into the stabilized soils,it was evident thatqudecreased monotonously during the wettingdrying test.This is mainly attributable to the chemical reaction between C(A)SH and phosphogypsum that occurred in the first 28-d curing,with less pozzolanic reaction at further curing times.Hence,when wetting-drying started,thequof stabilized soil with phosphogypsum rapidly decreased due to the loss of bonding structure.Within the first 6 cycles,qushowed an increasing order with increasing phosphogypsum content at a given number of wetting-drying cycle.This suggests that the durability of stabilized soil was enhanced by phosphogypsum at this stage.In contrast,qushowed a decreasing order with phosphogypsum content after the 6th cycle.At this stage,the decrease rate ofqufor stabilized soil with phosphogypsum was significantly higher than that without phosphogypsum.Accordingly,the difference betweenquamong different phosphogypsum contents gradually disappeared,reaching a lowerquwith a higher phosphogypsum content.This suggests that the enhancement of durability in the presence of phosphogypsum vanishes gradually after the 6th cycle.

Fig.5 depicts the effect of cement content and initial water content onqu.Similar to the variation inCMloss,quincreased with increase in the cement content and with decrease in the initial water content.This is attributable to a stronger cementation bonding with a higher cement content and a weaker cementation bonding with a higher initial water content.

Fig.5.Variation in qu with wetting-drying cycles at different cement content and initial water contents.

3.4.Variations in organic matter of leachate with wetting-drying cycle

Fig.6 shows the effect of phosphogypsum content on the value of LOI with wetting-drying cycles.It can be observed that the value of LOI decreased with the increase in wetting-drying cycles,accompanied by the exfoliation and dissolution of cementation materials.

Fig.6.Effect of phosphogypsum content on loss of ignition.

Without wetting-drying cycle,the LOI of stabilized soil with different phosphogypsum contents showed little difference.Once wetting-drying started,the LOI increased with increasing phosphogypsum content at a given cycle.For example,the LOI increased from 10.1% at phosphogypsum content of 0 kg/m3to 10.6% at phosphogypsum content of 40 kg/m3and 11.6%at phosphogypsum content of 60 kg/m3at the 8th cycle.This indicates that a lower value of organic matter was leached from the stabilized soil with phosphogypsum during the wetting-drying cycle in comparison with those without phosphogypsum.This behavior emphasized that the presence of phosphogypsum effectively stabilized the organic matter in the slurry,showing good environmental performance against the wetting-drying process.

3.5.Variations in pH value

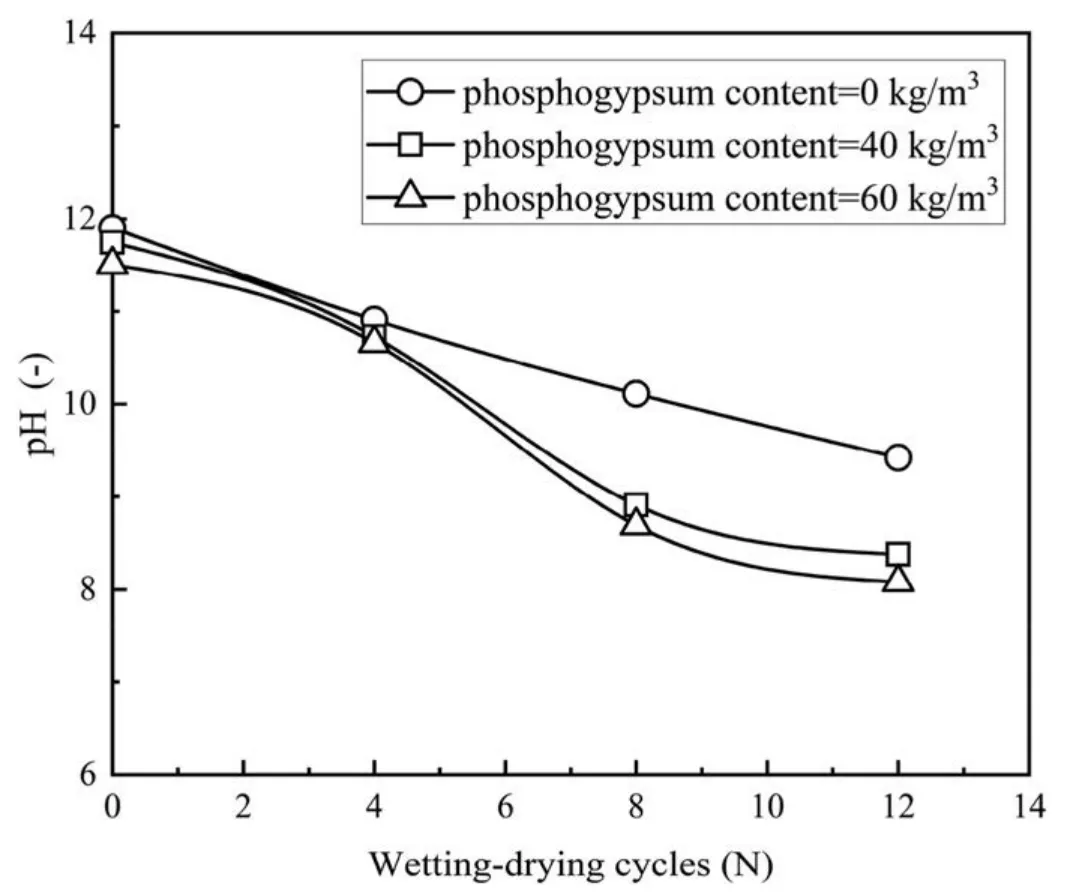

Fig.7 plots the effect of the phosphogypsum content on the pH value after different numbers of wetting-drying cycles.Similar to previous studies,the pH value for stabilized soils gradually decreased with the increase in the number of wetting-drying cycles for two main reasons: (1) the dissolution of alkaline substances from stabilized soils subjected to the wetting cycle,and (2) the consumption of OH-due to further pozzolanic reactions with increasing curing times (Chrysochoou et al.,2010).

Fig.7.Effect of phosphogypsm content on pH.

Prior to the wetting-drying tests,a lower pH value for the stabilized soil with a higher phosphogypsum content was observed,with a difference of approximately 0.4 between 0 kg/m3and 60 kg/m3of phosphogypsum content.This lower pH value is mainly due to the chemical reaction between phosphogypsum and hydration products consuming hydroxyl ions (OH-) (Zeng et al.,2021).After the 4th cycle,the difference in pH value among the three phosphogypsum contents almost remained unchanged.Exceeding the 4th cycle,a large drop in pH value was observed for the stabilized soil with phosphogypsum,with a larger difference of 1.4 between 0 kg/m3and 60 kg/m3of phosphogypsum content at the 8th cycle.This large drop in pH value after the 4th cycle is consistent with the decrease inqufor stabilized soil with phosphogypsum,as shown in Fig.4.

4.Discussion

To illustrate the effect of phosphogypsum on the durability of stabilized soil,the strength improvement factor (SIF) is adopted(Bordoloi et al.,2018):

wherequ(phosphogypsumcontent=0)is thequfor stabilized soil without phosphogypsum.

Fig.8 shows the variation in SIF with phosphogypsum content at different numbers of wetting-drying cycles.There are two regimes considering the variation of SIF value:

Fig.8.Variation of strength increment factor with phosphogypsm content.

(1) When the number of wetting-drying cycle was lower than 4,the value of SIF increased with increase in the phosphogypsum content.At 0 cycles,the value of SIF is 4 at phosphogypsum content of 60 kg/m3,implying thatquwas approximately 4 times that of soil without phosphogypsum.At the 4th cycle,the value of SIF decreased to 1.2-1.5,still showing a higherquthan those without phosphogypsum.Hence,a good resistance to wetting-drying occasions with the presence of phosphogypsum was observed at this stage;and

(2) When the number of wetting-drying cycle exceeding 4,the value of SIF for stabilized soil with phosphogypsum is lower than 1,corresponding to a strength lower than that without phosphogypsum.At this stage,the rapid decrease inquis observed in stabilized soil with phosphogypsum,leading to a reduction in the durability-enhancing effect of phosphogypsum.

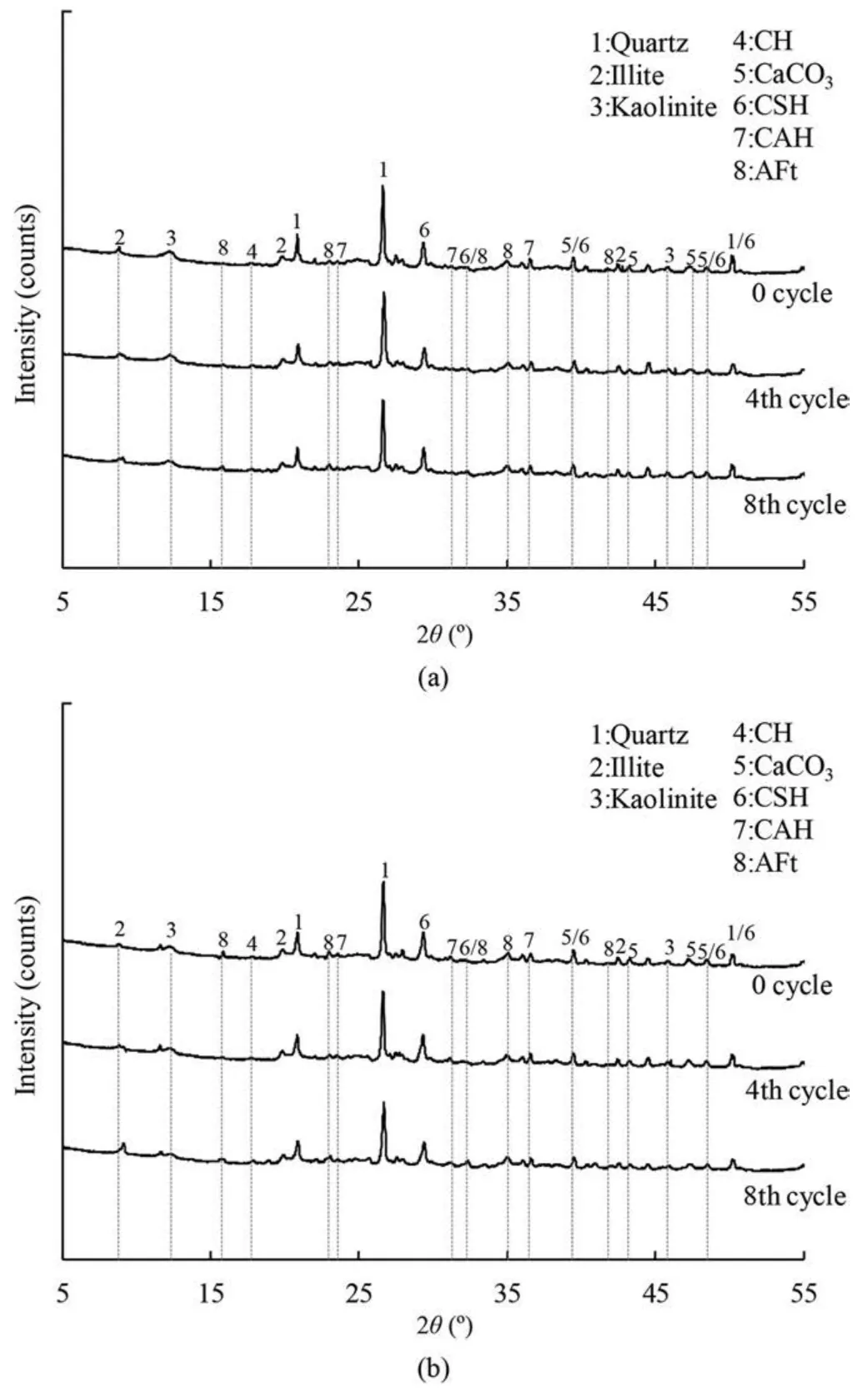

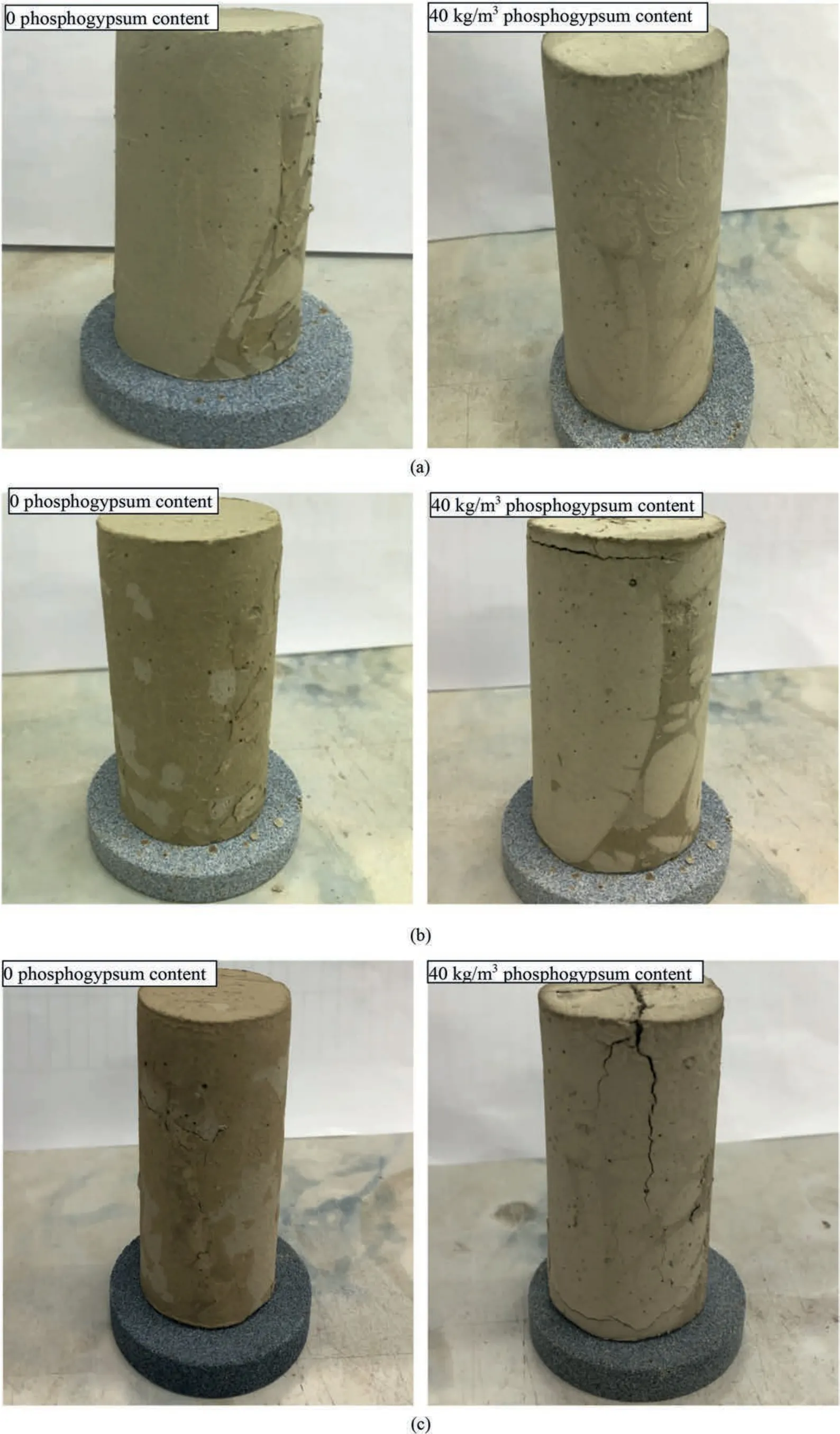

4.1.Disappearance of ettringite after the 4th cycle

Fig.9 illustrates the XRD patterns of the stabilized soil with and without phosphogypsum.As expected,the main hydration products for stabilized soil with phosphogypsum can be identified as calcium(aluminate)silicate hydrate(CSH peaks at 3.04,2.77,1.87 Å,CAH peaks at 7.65,3.77,2.86 Å),and ettringite(peaks at 3.87,2.56,2.16 Å),which is consistent with previous studies(Zeng et al.,2021;Bian et al.,2022a).The relative intensity of hydration products at the three main peaks is summarized in Table 2.Note that the value of the intensity of cementitious materials can be calculated by summarizing the intensity of the three main peaks mentioned above for CSH,CAH and ettringite through the XRD results for different stabilized soils.It should be emphasized that the semiquantitative analysis in this study only provides the relative amount of main cementitious materials,rather than the absolute quantities.

Fig.9.X-ray diffraction patterns of stabilized soil at different wetting-drying cycle:(a)Without phosphogypsum;and (b) phosphogypsum content of 40 kg/m3.

Table 2 Relative intensity of hydration products.

For the stabilized soil without phosphogypsum,C(A)SH was identified as the main cementation material,which was primarily contributed to the strength gain of stabilized soil.Table 2 shows that the intensity of C(A)SH decreased with an increase in the number of wetting-drying cycles,leading to a decrease in cementation bonding and thus a reduction inquwith an increase in the number of wetting-drying cycles (see Fig.4).

For the stabilized soil with phosphogypsum,the presence of ettringite was observed in the XRD results,similar to previous finding(Zeng et al.,2021).The formation of ettringite in stabilized soil with a high water content showed both a bridge effect on the soil-cement matrix and compaction of the pore space due to natural swelling (Calderón-Morales et al.,2021;Zeng et al.,2021).Hence,the bridge effect of ettringite led to a higher strength in the early curing stage for stabilized soil with phosphogypsum.As the wetting-drying cycles continue,the intensity of C(A)SH and ettringite decreases rapidly,as shown in Table 2.From the 4th to 8th cycle,the ettringite intensity almost vanished,especially for the peak at 15.784°.In other words,the disappearance of ettringite after the 4th cycle resulted in a larger extent of degradation of cementation bonding around the soil matrix,leading to a sudden drop inqufor the stabilized soil with phosphogypsum.As a result,qufor stabilized soil with phosphogypsum is lower than those without phosphogypsum after the 8th cycle,as shown in Fig.4.

4.2.Larger extent of micro-crack generation after 4th cycle

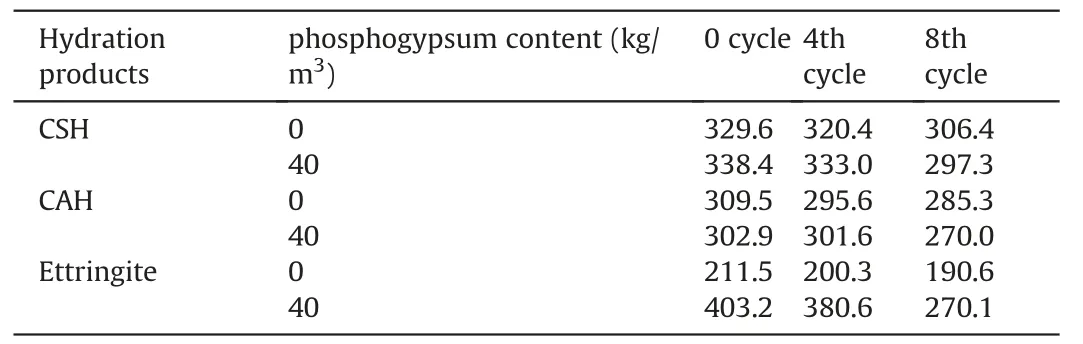

Photos of specimen at the 1st,4th and 8th cycles are shown in Fig.10.Cracks and flaking clearly developed due to the continuous wetting-drying process for the stabilized soils,irrespective of phosphogypsum content.As a result,qudecreased with the degradation of specimen integrity during the wetting-drying test.

Fig.10.Photos of stabilized soil at different wetting-drying cycles: (a) After 1st wetting-drying cycle;(b) after 4th wetting-drying cycle;and (c) after 8th wetting-drying cycle.

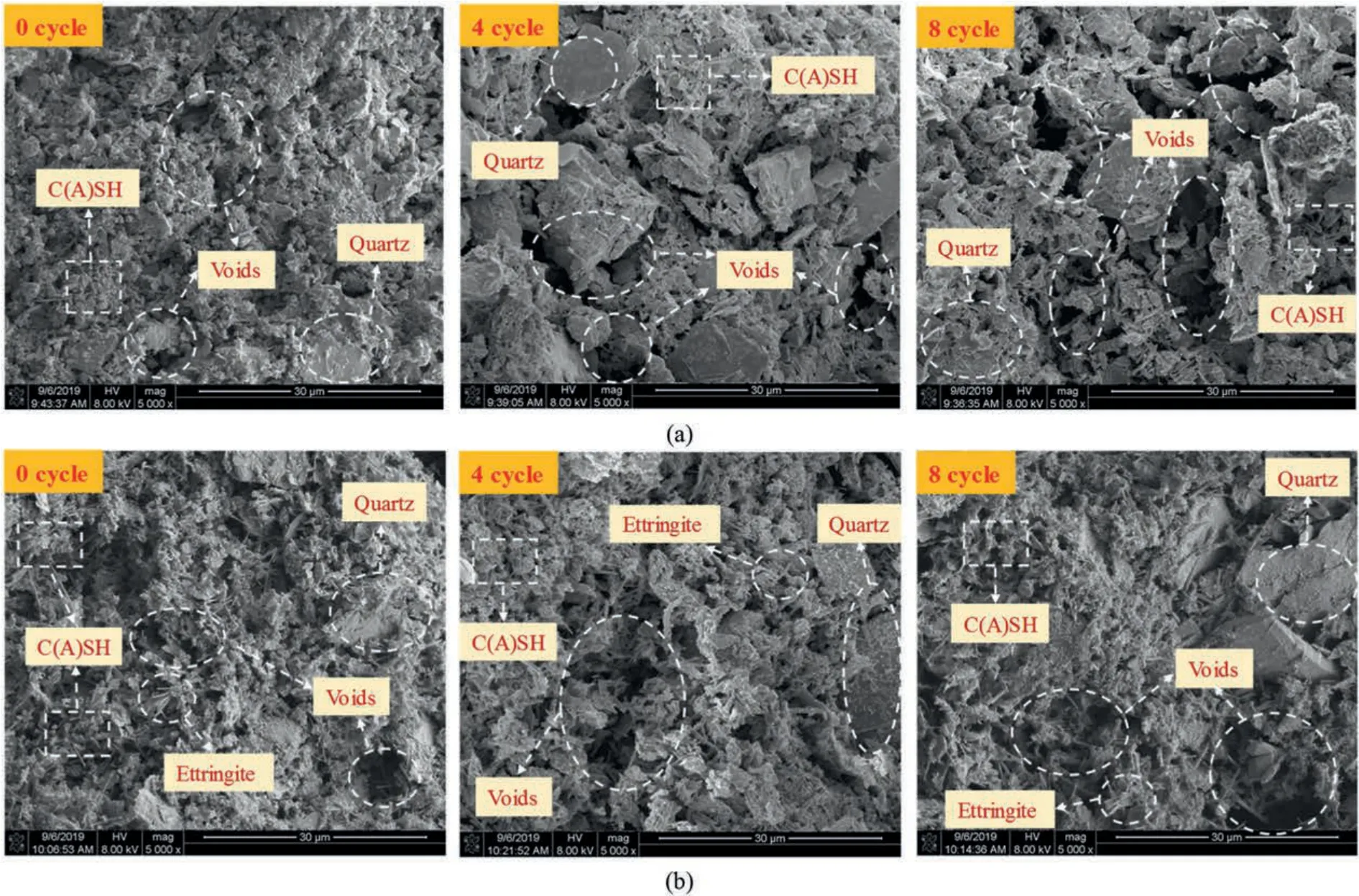

Regarding the change in the evolution of cracks with phosphogypsum content,it appears that up to the 4th cycle,the extent of cracks and flaking showed little difference with the change in phosphogypsum content.After the 8th cycle,a larger fracture penetrating through the specimen for stabilized soil at phosphogypsum content of 40 kg/m3was observed,compared with the specimen without phosphogypsum.This behavior corresponded to a rapid loss of integrity of the specimen for stabilized soil with phosphogypsum at this stage (Bian et al.,2022b).Once the cracks extended into specimen to a certain level,small blocks started to spall off from the surface of the specimen in the presence of phosphogypsum.Therefore,a greater loss ofquis expected for stabilized soil with phosphogypsum,as shown in Fig.4.Moreover,the SEM micrographs of stabilized soil at different wetting-drying cycles are presented in Fig.11.The hydration products C(A)SH and ettringite can be clearly identified for stabilized soils with different phosphogypsum contents.This is consistent with the XRD analysis,as shown in Fig.9.

Fig.11.SEM microscope of stabilized soil at different wetting-drying cycle: (a) Without phosphogypsum;and (b) phosphogypsum content of 40 kg/m3.

When no wetting-drying cycle occurred,the C(A)SH fabric was found to coat the clay cluster and fill the pore space of the stabilized soil,which formed a cementation bond to provide strength.As phosphogypsum was added into the stabilized soil,needle-like ettringite crystals were clearly observed,which improved the soil fabric by bridging the clay particles and C(A)SH,eventually leading to a higherquin comparison with the stabilized soil without phosphogypsum.

Up to the 4th cycle,a greater amount of micropores in the stabilized soil with phosphogypsum was observed,compared to those without phosphogypsum.This is consistent with the reduction of ettringite,as shown in Fig.9.After the 8th cycle,the formation of ettringite was almost invisible from SEM micrographs for stabilized soil with phosphogypsum.Thus,the degradation of cementation bonding with the wetting-drying cycle for the stabilized soil with phosphogypsum is greater,especially up to the 8th cycle.In other words,a greater amount of voids (microfractures)was induced by the wetting-drying process especially after the 8th cycle for stabilized soil with phosphogypsum,leading to extensive cracks distributed on the specimen surface as shown in Fig.12.As a result,the loss ofquinduced by the wetting-drying cycle was more notable for the stabilized soil with phosphogypsum after the 4th cycle.

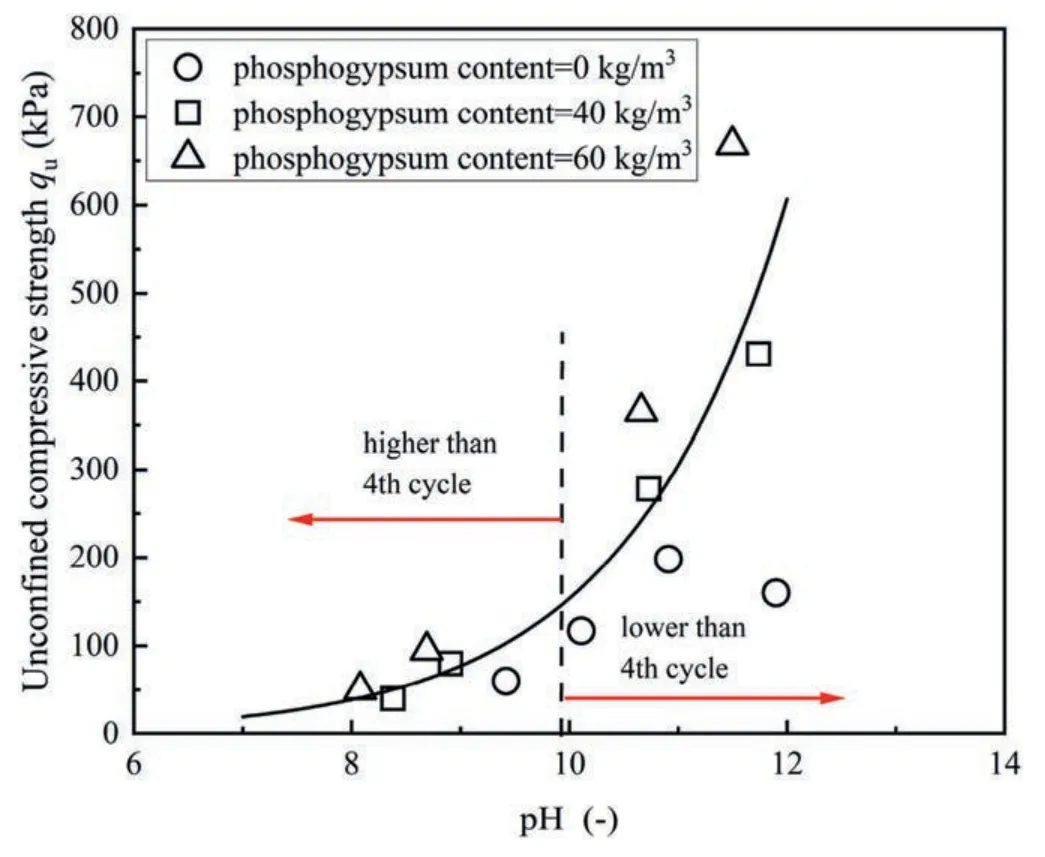

Fig.12.Relationship between soil pH and qu.

4.3.Lower pH value after 4th cycle

Fig.12 depicts the variation inquwith the pH value of stabilized soils at different wetting-drying cycles.It seems that a power relation between pH value andqucan be obtained for all the stabilized soil with or without phosphogypsum.In other words,qudecreased with decreasing pH value.

When the pH is higher than 10,corresponding to a wettingdrying cycle less than 4,it seems that thequof stabilized soil with phosphogypsum is higher than that without phosphogypsum for a given cycle.In contrast,while the pH decreased to below 10 after the 4th cycle,thequof stabilized soil with phosphogypsum was lower than that without phosphogypsum.This behavior is mainly attributable to the destruction of C(A)SH gel and the degradation of ettringite when the pH value is lower than 10.8(Chrysochoou et al.,2010;Du et al.,2016).As shown in Fig.7,the pH value of stabilized soil with phosphogypsum rapidly decreases to a value lower than 10 and is also lower than that of stabilized soil without phosphogypsum.As a result,the main cementation products(C(A)SH and ettringite)significantly decayed,leading to a larger extent of destruction of the cementation bond,as shown by XRD and SEM tests(see Figs.9 and 11).Therefore,the greater level of destruction of the cementation bond will result in a lowerquafter the 4th cycle when the pH value is lower than 10 for stabilized soil with phosphogypsum,as shown in Fig.4.It should be emphasized that the effect of a low pH value on the reduction ofqumight not be significant for the case of a pH value for stabilized soil higher than 10.

It should be emphasized that adequate phosphogypsum can enhance thequof stabilized soil with a high water content,as proposed by Zeng et al.(2021).The role of phosphogypsum on durability showed a complex manner,with a higherquupon lower than the 4th cycle,and a sudden drop inquwas noted when exceeding the 4th cycle in comparison with that without phosphogypsum.Hence,further studies to improve the durability of phosphogypsum-stabilized soil after longer wetting-drying occasions are recommended.

5.Conclusions

The effect of phosphogypsum on the durability of stabilized soil was studied by conducting a series of experimental tests on physical properties,pH value and unconfined compressive strength exposed to wetting-drying cycles.Microstructure observations were conducted using XRD and SEM tests to understand the role of phosphogypsum on fabric alteration of stabilized soil under wetting-drying cycles.The main conclusions can be drawn as follows:

(1) Phosphogypsum significantly restrains the mass loss for stabilized soil up to the 4th wetting-drying cycle.Afterwards,a higher mass loss is observed for the stabilized soil with phosphogypsum compared to those without phosphogypsum.The mass loss decreases with increasing cement content and decreasing initial water content.

(2) With increase in the phosphogypsum,a decrease in organic matter content leaching from the stabilized soil is observed at a given number of wetting-drying cycles.This behavior emphasizes that the presence of phosphogypsum effectively stabilizes the organic matter in stabilized soil,showing good environmental performance against the wetting-drying process.

(3) When the number of wetting-drying cycle is lower than the 4,the presence of phosphogypsum enhances the unconfined compressive strength of stabilized soil.At the 4th cycle,thequof stabilized soil with is 1.2-1.5 times those without phosphogypsum,confirming a good improvement in the durability with phosphogypsum.

(4) Once exceeding the 4th cycle,the stabilized soil with phosphogypsum displays a lower unconfined compressive strength than that without phosphogypsum.This phenomenon is mainly attributable to the absence of ettringite,a larger extent of microcracks generation,and a lower pH value for stabilized soil in the presence of phosphogypsum.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China(Grant Nos.52178328 and 52178361),the Fundamental Research Funds for the Open-end Research Fund of State Key Laboratory for Geomechanics and Deep Underground Engineering (Grant No.SKLGDUEK2114).

杂志排行

Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Limit load and failure mechanisms of a vertical Hoek-Brown rock slope

- Limit state analysis of rigid retaining structures against seismically induced passive failure in heterogeneous soils

- Bearing capacity of circular footings on multi-layered sand-waste tire shreds reinforced with geogrids

- Experimental investigation on the permeability of gap-graded soil due to horizontal suffusion considering boundary effect

- Damage constitutive model of lunar soil simulant geopolymer under impact loading

- A novel relationship between elastic modulus and void ratio associated with principal stress for coral calcareous sand