电阻式柔性触觉传感器的研究与医养健康领域应用现状

2024-03-04殷霞张士进田明伟刘红

殷霞 张士进 田明伟 刘红

摘要:近年来,可穿戴智能系统的进步对柔性压力传感器提出迫切的需求。其中,电阻式柔性触觉传感器因其原理简单、易于加工、集成效率高等特点得到了迅速发展。但是,如何实现传感器在宽压力监测范围内,具有高灵敏度仍是研究者们要面临的挑战。为了解决上述问题,除了选择先进的功能材料和合适的衬底材料,优化传感器结构也是一个重要的研究方向。本文立足于传感器件的结构设计,分别介绍了一维的纤维/纱线传感器件,基于表面微结构、纳米结构构筑的二维平面传感器件及具有空间结构和高空隙的多维立体结构传感器件,通过以上结构设计实现了传感器件性能的提升,最后分析了其在医养健康领域的实际应用进展。

关键词:电阻式柔性触觉传感器;结构设计;医养健康;一维纤维/纱线传感器件;二维平面结构传感器件;多维立体结构传感器件;健康监测

中图分类号:TP212.3; TQ342.8

文献标志码:A

文章编号:10017003(2024)02007609

DOI:10.3969/j.issn.1001-7003.2024.02.009

收稿日期:20230914;

修回日期:20231220

作者简介:殷霞(2000),女,硕士研究生,研究方向为服装舒适性与功能服装。通信作者:刘红,讲师,lh1221@qdu.edu.cn。

触觉是人类感知和识别物体的重要方式,在没有触摸的情况下,人类将无法获得物体的基本特征。皮肤作为人体最大的器官,含有大量的神经传感器,赋予人们触觉感知能力,是人类感知外界环境中压力、温度、湿度及物体形状等物理信息最重要的途径。受人体皮肤的启发,仿生电子皮肤被开发并应用到人机交互、可穿戴医疗设备和智能机器人等各个领域。对于仿生电子皮肤而言,其最重要的部分是可以模仿人体的触觉传感器。

常见的柔性触觉传感器依据其传感机制可分为电容式、压电式、摩擦电式和电阻式,如图1所示。电容式传感器由两个平行电极和两电极之间的介电层组成,通过将压力刺激转化为电容信号进行传感,具有毫秒响应时间及出色的应变能力,但其灵敏度会随着器件尺寸的减小而降低。压电式传感器是基于外加应变引起的压电材料极化导致电势变化,具有固有频率高、性能稳定等特点,但由于压电材料产生的输出电压是脉冲信号,故其大多应用于测量动态压力,而不能稳定地测量静态信号。为了满足传感器自供电这一需求,基于摩擦电纳米发电机(TENG)研发的传感器近几年受关注较多。摩擦电传感器通过将人体在运动过程中产生的能量进行收集并保存在电容器中,从而实现自供电,但极易受外部静电感应产生信号干扰的特性,限制了其应用场景。而电阻式传感器因其工作原理简单、成本较低、信号采集方便等特性,成为了目前研究最多且应用最广泛的触觉传感器。

电阻式触觉传感器的工作原理主要基于压阻效应,当传感器受到外界施加的压力时,外部压力被转换为电阻信号,以此来完成电信号的输出。合理的结构设计,不仅可大幅度提升传感器的灵敏度及其他各项性能,而且还可以灵活地调整传感器的灵敏度和响应特性,以满足特定的应用需求。對传感层进行结构创新设计,改变导电材料间的接触电阻及导电弹性复合材料中的导电路径,是提高电阻式触觉传感器性能重要的研究方向。将柔性电阻式触觉传感器与可穿戴设备结合监测人体生理信号,如血压、心率、脉搏等,可为患者提供个性化康复方案。也可将纤维/纱线基柔性触觉传感器编织成床垫、坐垫等产品,实现身体不同部位的压力分布监测,可有效预防压疮生成,在医养健康领域具有重要意义。

本文综述了近年来电阻式柔性触觉传感器的最新进展。首先根据其结构设计分别介绍了在不同维度上的研究进展,包括一维纤维/纱线传感器件、二维平面结构传感器件、多维立体结构传感器件。随后分析了其在医养健康领域的实际应用进展。最后,讨论总结了电阻式柔性触觉传感器目前所面临的挑战。

1 电阻式柔性触觉传感器的结构设计

1.1 一维纤维/纱线基传感器件

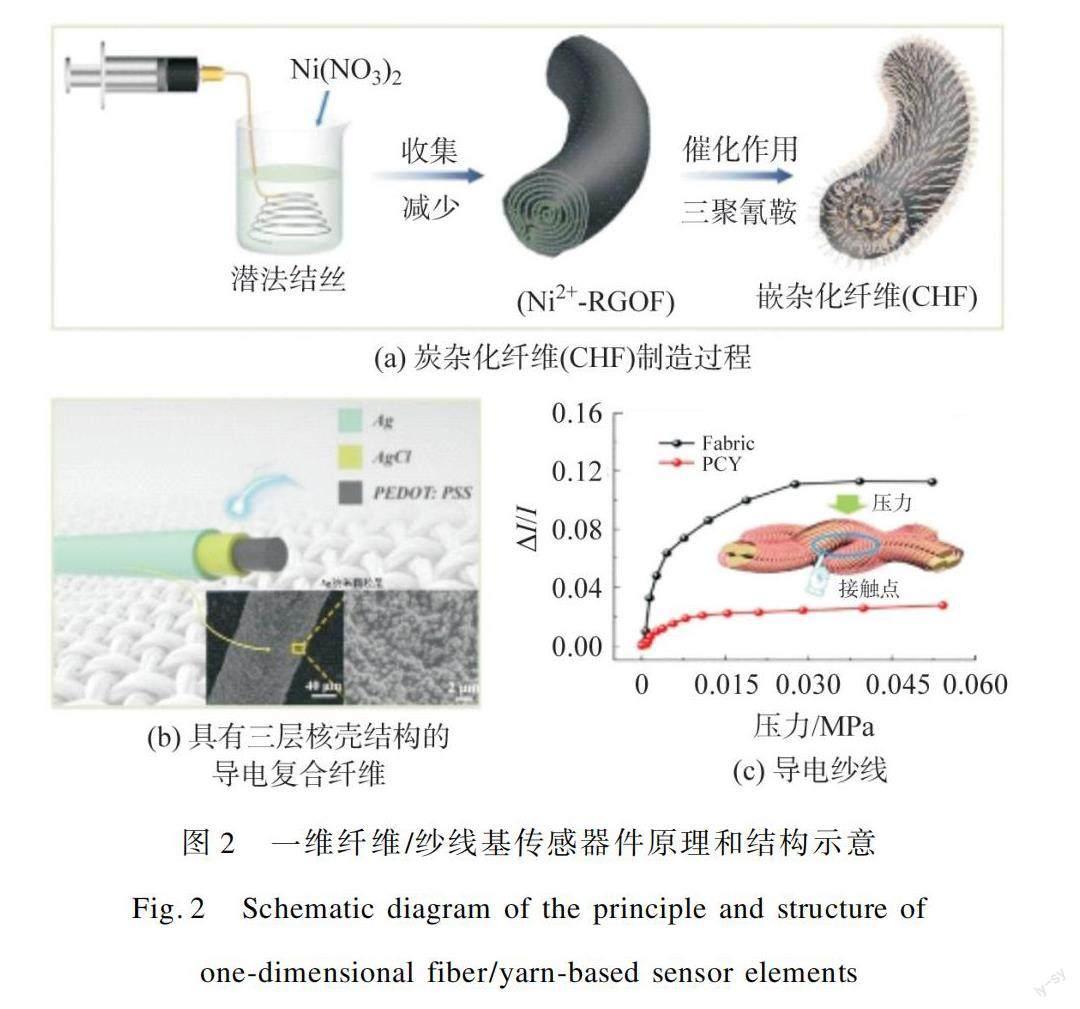

一维纤维/纱线结构因其柔软性、可编织性、形状适应性故具有优异的纺织加工性能,较多集成到纺织服装当中应用。大多数纤维/纱线通过采用湿法同轴、静电纺丝、对纤维/纱线进行特殊后处理(喷涂、浸渍、原位生长、化学气相沉积)的方法制备核壳结构。Hu等通过化学气相沉积(CVD)工艺制造以石墨烯纤维作为芯层,原位生长的碳纳米管分层作为壳层的碳杂化纤维(CHF),如图2(a)所示。具有核壳结构的纤维/纱线,纤维芯和外部的壳或包覆层可以相互作用,提高纤维材料的抗拉、抗压、抗弯等力学性能,也可以防止纤维芯受到外界环境的影响,同时可以根据需求调节其芯层或外壳的成分和厚度,从而使纤维材料可适应不同的应用领域和环境,且基于核壳结构的压阻式传感器件普遍具有较高的灵敏度和线性度。Zhong等通过湿法纺丝制备的芯层为镀银尼龙,壳层为表面具有微孔结构的碳纳米管(CNTs)/热塑性聚氨酯(TPU)的核壳压阻纱线,灵敏度高达84.5 N。利用同轴纺丝和后处理方法相结合的方式,可制备具有三层核壳结构的导电复合纤维。Wang等[将湿纺制备的已经具有核壳结构的纤维,又通过在纤维表层发生银镜反应,形成紧密堆叠的Ag纳米颗粒层,制备了具有三层核壳结构的导电复合纤维,如图2(b)所示。

除了通过同轴纺丝实现纤维的核壳结构,还可选择在纺纱的过程中将纤维加捻成特殊的纱线结构,如包芯纱、包缠纱等赋予纱线核壳结构。Ding等以柔性乳胶长丝为芯层,紧密缠绕包裹PET长丝为壳层,在PET长丝上沉积导电聚吡咯形成导电网络,且制备的导电纱线对应力非常敏感,如图2(c)所示。近年来,与核壳结构类似地使用弹性管状材料,如(弹性微管、中空橡胶管)对液态导电金属进行封存,制作导电纱线的方法受到较多关注。与传统的核壳结构纱线相比,该方法制作的导电纱线,具有高度可拉伸和耐水洗的优点。Yu等使用将液态金属合金共晶镓铟(eGaIn)沉积到弹性微管内制备的导电纱线编织的功能性织物,即使在洗衣机内经过了典型的洗涤循环,仍保持高功能性。

综上所述,现有的一维纤维/纱线传感器件主要基于核壳结构,其虽具有较高线性度,但传感器件的灵敏度和分辨率易受到纤维直径和长度的限制,在测量一些微小变化时可能精度不高。此外,纤维在使用过程中易疲劳和损伤,传感器的耐久性和稳定性受到影响。因此,在制作纤维/纱线传感器件的时候,可选择使用更加耐久和稳定的纤维材料,如碳纤维和聚合物纤维等。

1.2 二维平面结构传感器件

可穿戴电阻式应变传感器通常由绝缘的柔性聚合物基体和导电材料两部分构成,为了获得高性能的传感器,除了需要选择合适的弹性基板及导电性好的敏感材料外,在二维导电层上设计并构建精细的微观结构或纳米级几何形状,是提高传感器灵敏度较为有效的方法。目前已出现的较为常见的微观结构如棘突结构、微圆顶结构、微纳米棒状结构、微金字塔结构、空心球微结构、皱纹结构、互锁结构、微柱结构及各种仿生微结构,这些微结构可以为传感器两电极之间提供丰富的接触点,来提高传感器的性能。

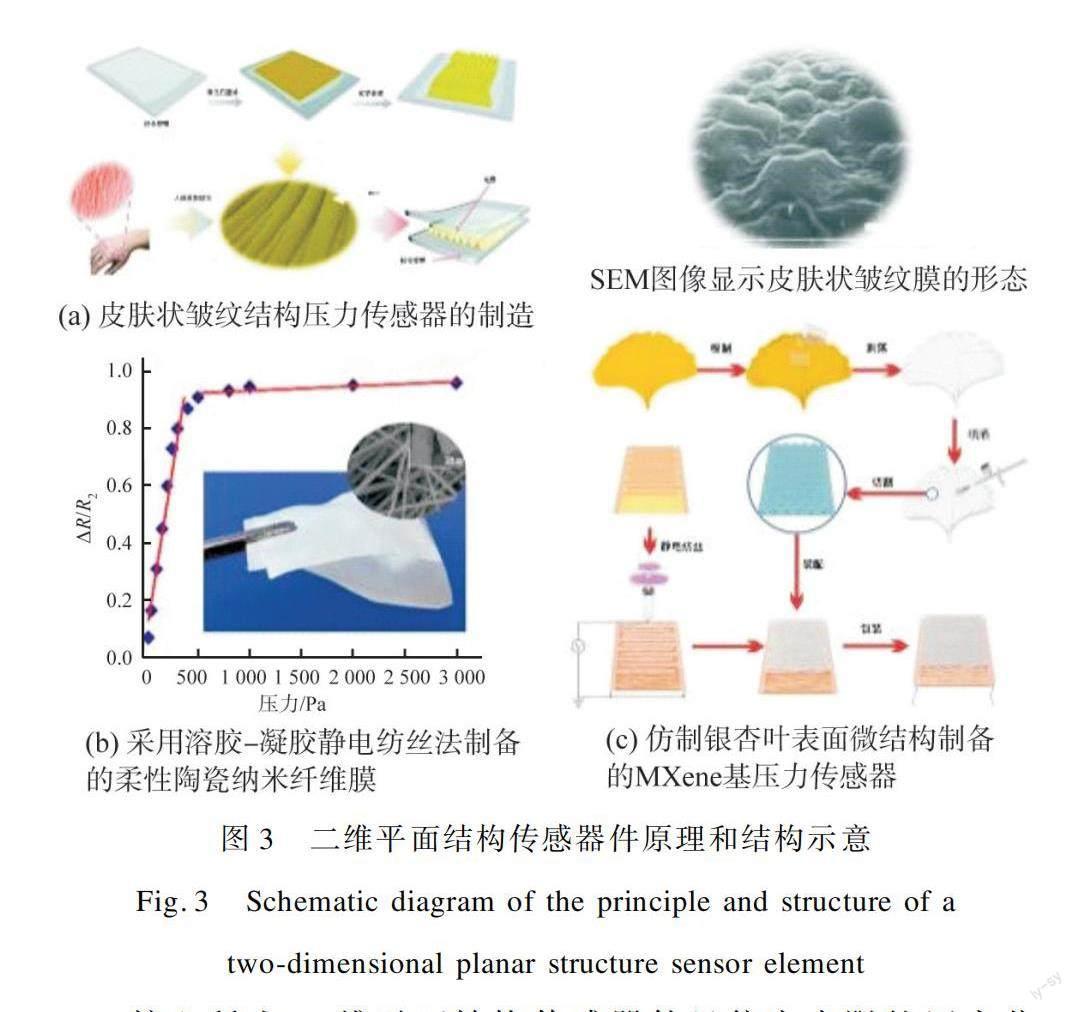

在这些微观结构中,因人类表皮的微观结构与砂纸表面具有相似的形貌,使用砂纸作为模板来制备的具有随机高度分布的棘突微结构,不仅可检测细微压力的极限且具有成本较低,制作工艺简单等优点。Sun等将石墨与聚二甲基硅氧烷(PDMS)的混合液倒在砂紙模板上,直接形成具有棘突结构的导电膜。皱纹结构的开发同样是仿制人类皮肤的一种微结构设计,类似于褶皱的结构为传感器提供了可拉伸性。Jia等通过梯度减少氧化石墨烯(rGO)形成具有皱纹结构的导电层,制备的传感器表现出出色的灵敏度,如图3(a)所示。为了设计出合理的微观结构,将特殊的生物/植物表面微结构进行仿制,是一种便捷且能有效提高传感器灵敏度的方法。Yan等通过仿制银杏叶表面微结构制备的MXene基压力传感器,灵敏度高达403.46 kPa,如图3(c)所示。除了选择在织物、薄膜、凝胶等柔性基体表面进行微观结构设计,还可采用静电纺丝喷涂的方法,由于纤维的交错排列,同样可以在传感层表面形成精细的多层网络微结构。Gao等用柔性锡(IV)掺杂的SrTiO,采用溶胶-凝胶静电纺丝法制备的柔性陶瓷纳米纤维膜,在小于400 Pa的低压范围下灵敏度可达2.24 kPa,且表现出优异的稳定性,如图3(b)所示。

综上所述,二维平面结构传感器件只能在有限的压力范围内具有高灵敏度,为了提高其应力监测范围,设计新型的织物表面微结构,增大阻值变化是有效的解决途径。同时在对织物进行导电处理时选择适合的导电材料,增加导电通道,通过改善导电材料的分散性可提高织物的导电性。

1.3 多维立体结构传感器件

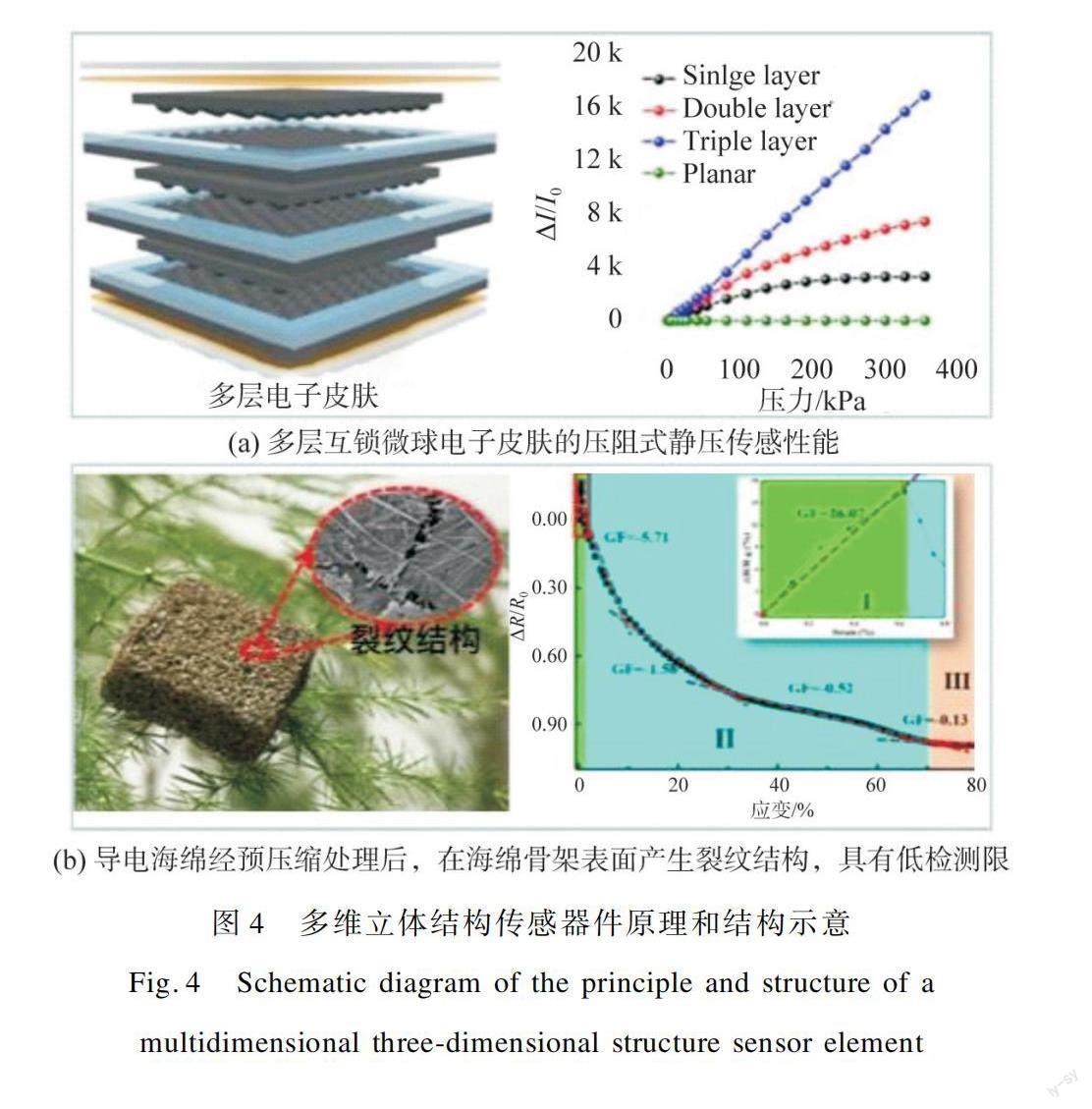

多维立体结构设计的电阻式压力传感器,得益于其空间结构存在高孔隙且基材具有良好的弹性,相邻多孔骨架之间的“接触效应”可产生大幅度的电阻变化,使其总能在宽线性范围内具有高灵敏度。常见的制备多维立体空间结构的策略主要包括多层微结构叠加、赋予三维(3D)多孔基材传感性能、导电“骨架”团聚三维结构。多层微结构构筑的立体结构可以很好地优化传感器线性传感范围,相较于单层微结构,使传感器能够在大的压力范围下保持高灵敏度。Lee等堆叠多层具有互锁微圆顶结构设计的传感层,如图4(a)所示。由于逐层之间的应力分布,使传感器在0.001 3~353 kPa的宽压力范围内可线性响应。直接赋予三维(3D)多孔基材传感性能的策略,避免了逐层组装的麻烦,具有低成本、可大规模制备等优点。常用的多孔基材主要包括泡沫、海绵、热塑性弹性体(TPE)等,这些材料具有丰富的3D网络结构,便于将导电材料涂覆到其弹性体骨架上。Zhang等 在海绵上浸渍碳纳米管(CNT),上下電极采用银浆涂覆作为导电层,制作了一款价格低廉且具有高性能和简单制造工艺的传感器。其中,将海绵经预压缩处理后在其骨架上获得裂纹结构的设计,对于弹性三维微孔压阻材料来说具有重要研究意义。Zhang等 将通过导电纤维素纳米纤维(CNF)、AgNWs制备的导电海绵经预压缩处理后,在海绵骨架表面产生裂纹结构,如图4(b)所示(根据压缩速率不同,裂纹产生的密度也会随之变化),基于小应变的“裂纹效应”,该传感器的检测限可低至0.2%。虽然基于聚合物材料的传感器具有高灵敏度和较大的工作压力范围,但聚合物材料普遍存在弹性回复性差、恢复滞后等问题,因此继续探索其他新型材料构筑3D结构是必要的。Chen等将水性MXene油墨和植物纤维通过物理发泡的方法来制作类似于海绵的三维结构,再对其通过组装、浸涂、封装后制备的压阻式传感器表现出的可压缩应变达60%。

综上所述,多维立体结构的传感器件主要存在弹性回复性差、制造难度较大等问题,弹性回复性差主要是由于传感器材料在反复压缩过程中发生塑性失真、疲劳等。其次传感器立体结构设计得不均匀,弹性变形后也很难回复到原有状态。在未来可以引入新的材料制备技术和制造工艺,如微纳米加工技术、3D打印等,以提高传感器的制造精度,从根本上改善传感器的回复性。

2 电阻式柔性触觉传感器在医养健康领域应用现状

2.1 临床医学及生命体征监测应用

随着医疗技术和条件的快速发展,多样化的传感器作为可穿戴医疗设备的重要组成部分,已经应用于各个方面。其中,电阻式柔性触觉传感器对微小应力变化非常敏感,可以检测到细微的触摸和压力信息,对临床应用兴起的机器人辅助微创手术的发展具有重要意义。Aubeeluck等将多壁碳纳米管(MWCNTs)和热塑性聚氨酯(TPU)复合材料制备的油墨进行丝网印刷得到柔性薄膜,再将具有微结构的叉指电极薄膜进行多层叠加后进行封装,设计和制造了一种9 mm的超薄柔性电阻触觉传感器,用于机器人辅助微创手术中磁性微夹持器手术工具,提高了手术的安全性。

生命体征是人体基本身体机能的测量值,用于评估人体的身体健康状况。而传感器是各类探知生命体征智能端口的核心元器件,是采集生命体征信息、构建数字化管理平台、实现健康风险科学预警的重要途径。电阻式柔性触觉传感器通过模仿皮肤的传感特性制备的电子皮肤可有效地克服传统医疗设备笨重、繁琐等缺陷,实现对人体体征信息的全方位监测。Chao等将MXene油墨丝网印刷到丝素纳米纤维膜上制备的MXene/蛋白质的电阻式压力传感器组装的电子皮肤具有良好的生物相容性,通过电阻变化检测人类的脉冲波型,来评估佩戴者的心血管状况及判断是否存在血管老化和动脉僵硬等问题,如图5(a)所示。Li等通过将壳聚糖和MXene交替涂覆到PU海绵骨架上制备的传感器能有效检测许多非接触运动,可以隔着塑料面罩检测呼吸和说话,并进行语音识别,在未来临床医学监测方面具有巨大的潜力,如图5(b)所示。此外,针对当代年轻人的生活需求及生活方式的转变,将传感器集成在腕带、手表、护膝等可穿戴设备中,更易于在日常生活运动中对心率进行监测。Gao等演示了一种具有微流体膜片的压力传感器,分别将传感器嵌入聚二甲基硅氧烷(PDMS)腕带和PDMS手套,在触摸或握住物体时,根据阻值变化可提供手的全面触觉反馈。佩戴该传感手腕进行运动,可实时测量运动者脉搏变化,进行心率监测。

2.2 居家健康监测及康复治疗应用

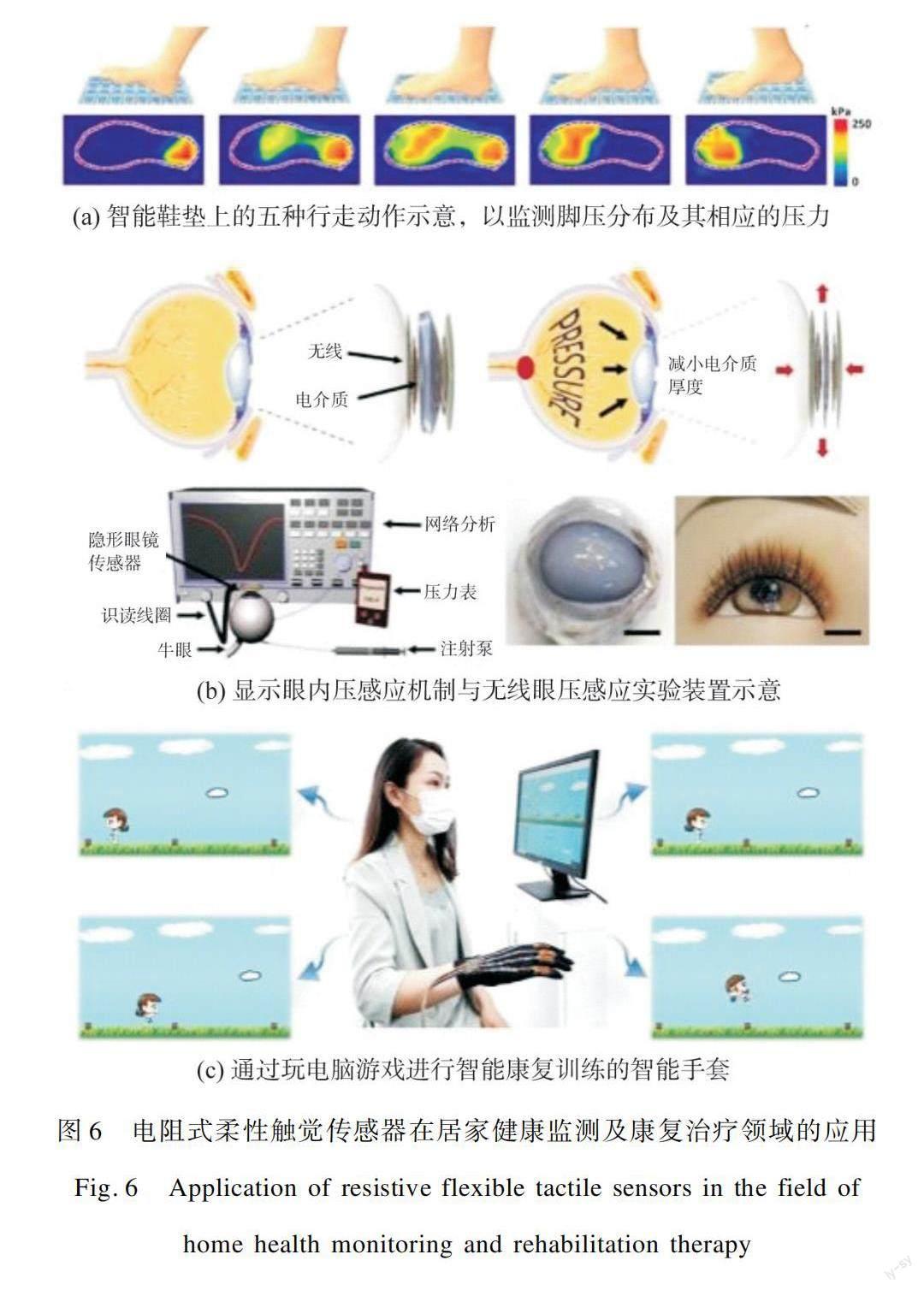

居家健康监测可以有效地进行个人健康管理及中老年疾病预防,不仅能提高治疗效果,而且还可节省公共医疗资源。对于老年人和慢性病患者而言,居家健康监测设备可提供长期的照护支持。足底压力监测对损伤预防、运动生物力学具有重要意义。Lee等通过传感器阵列制作的智能鞋垫,可以清楚地监测行走过程中的高脚压分布,如图6(a)所示。对于一些老年人的步态监测,某些区域的异常步态和过度的脚压可能与很多疾病相关,如糖尿病足溃疡、帕金森病患者的特征性步态模式,监测老年人的步态模式和姿势可以对这些疾病进行早期诊断。Kim等以隐形眼镜为基板,设计了一款可以监测眼内压的透明和可拉伸的多功能隐形眼镜传感器,如图6(b)所示。用于无线监测佩戴者的葡萄糖和眼内压,不仅适用于糖尿病患者,还可以帮助青年佩戴者评估眼睛健康,如青光眼筛查、视力保护等。Hu等使用制备的碳杂化纤维(CHF)组装的光纤传感器,将其安装在腰椎和颈椎上,可捕获各种生理信号,时实精确记录坐姿信号,当坐姿不规范时,基于该传感器的警告系统会发出警示,帮助指导纠正坐姿,改善不良的生活方式。此外,通过与触觉显示器相结合,实现人机交互,将日常监测数据可视化,对康复治疗具有重要意义。Zhong等将传感器固定在纺织手套的指关节区域,并且基于该传感器建立人机界面,如图6(c)所示。佩戴患者根据电脑提示做出指定手势,开发了一个智能康复训练平台,以有趣和具有挑战性的方式帮助患者训练和提高手指关节技能,在康复医疗、外骨骼机械手甚至工业制造方面显示出潜在的应用前景。

3 结 论

电阻式柔性触觉传感器因其原理简单、成本较低等特点,在柔性可穿戴领域中具有显著优势。本文综述了近年来电阻式柔性触觉传感器结构设计在不同维度上的最新进展,结果表明:不论是一维纤维/纱线基传感器件、二维平面结构设计传感器件,还是多维立体传感器件,都需要对其结构进行创新设计,才能够在原有的基础上,实现传感性能大幅度提升。在已确定传感器件的形状和尺寸要求下,构筑“微结构”增大两电极间的接触点/空隙是提升传感器灵敏度较为有效的策略。同时,除了注重其结构设计,还可以围绕材料的选择进行创新。此外,虽然电阻式柔性传感器虽已经在柔性电子、医疗监测、人机交互等各个领域都有了较大的进展,但目前同样存在一些方向需要突破。

1)柔性电阻式触觉传感器在长时间使用或复杂环境中可能会受到损坏或性能下降的影响。为了提高稳定性和可靠性,需要改进材料的耐久性和稳定性,解决电阻元件的老化问题,并增强传感器的保护措施。2)根据使用者的需求对传感器进行功能设计,整合其他传感器模块,如温度、湿度等,提供更广泛的应用领域。3)在进行传感器设计和制造时,考虑成本效益和生产难度,开发低成本且可批量生产的传感器是未来的发展重点。

参考文献:

[1]CASTELLANOSG M, CONZALEZ M C, RUBIO G B, et al. A Cognitive Psychological Approach to Identify the Significant of the Role of Visual Sense in Haptic Sense[C]. Wuhan: International Conference on Biometrics and Kansei Engineering (ICBAKE), 2013.

[2]WANG C, LIU C, SHANG F, et al. Tactile sensing technology in bionic skin: A review[J]. Biosensors and Bioelectronics, 2023(220): 114882.

[3]王康. 基于MXene的高性能柔性触觉传感器[D]. 长春: 吉林大学, 2021.

WANG Kang. High Performance Flexible Tactile Sensor Based on MXene[D]. Changchun: Jilin University, 2021.

[4]CAO M, SU J, FAN S, et al. Wearable piezoresistive pressure sensors based on 3D graphene[J]. Chemical Engineering Journal, 2021(406): 126777.

[5]潘曉君, 鲍容容, 潘曹峰. 可穿戴柔性触觉传感器的研究进展[J]. 高等学校化学学报, 2021, 42(8): 2359-2373.

PAN X J, BAO R R, PAN C F. Research progress of flexible tactile sensors applied to wearable electronics[J]. Chemical Journal of Chinese Universities, 2021, 42(8): 2359-2373.

[6]ZHONG M J, ZHANG L, LIU X, et al. Wide linear range and highly sensitive flexible pressure sensor based on multistage sensing process for health monitoring and human-machine interfaces[J]. Chemical Engineering Journal, 2021(412): 128649.

[7]LI X P, LI Y, LI X, et al. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets[J]. Journal of Colloid and Interface Science, 2019(542): 54-62.

[8]LEE Y, PARK J, CHO S, et al. Flexible ferroelectric sensors with ultrahigh pressure sensitivity and linear response over exceptionally broad pressure range[J]. Acs Nano, 2018, 12(4): 4045-4054.

[9]LEE H J, YANG J C, CHOI J, et al. Hetero-dimensional 2D TiCT MXene and 1D graphene nanoribbon hybrids for machine learning-assisted pressure sensors[J]. Acs Nano, 2021, 15(6): 10347-10356.

[10]IQBAL S M A, MAHGOUB I, DU E, et al. Advances in healthcare wearable devices[J]. Npj Flexible Electronics, 2021, 5(1): 9.

[11]MENG K, XIAO X, WEI W, et al. Wearable pressure sensors for pulse wave monitoring[J]. Advanced Materials, 2022, 34(21): 2109357.

[12]HWANG J, KIM Y, YANG H, et al. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor[J]. Composites Part B: Engineering, 2021(211): 108607.

[13]BAI N, WANG L, WANG Q, et al. Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity[J]. Nature Communications, 2020(1): 209.

[14]BOUTRY C M, KAIZAWA Y, SCHROEDER B C, et al. A stretchable and biodegradable strain and pressure sensor for orthopaedic application[J]. Nature Electronics, 2018(1): 314-321.

[15]YANG Y, PAN H, XIE G, et al. Flexible piezoelectric pressure sensor based on polydopamine-modified BaTiO/PVDF composite film for human motion monitoring[J]. Sensors and Actuators A: Physical, 2020(301): 111789.

[16]CHEN Z, WANG Z, LI X, et al. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures[J]. Acs Nano, 2017, 11(5): 4507-4513.

[17]CAI Y W, ZHANG X N, WANG G G, et al. A flexible ultra-sensitive triboelectric tactile sensor of wrinkled PDMS/MXene composite films for E-skin[J]. Nano Energy, 2021(81): 105663.

[18]JIN T, SUN Z, LI L, et al. Triboelectric nanogenerator sensors for soft robotics aiming at digital twin applications[J]. Nature Communications, 2020(11): 5381.

[19]ZHU G, YANG W Q, ZHANG T, et al. Self-powered, ultrasensitive, flexible tactile sensors based on contact electrification[J]. Nano Letters, 2014, 14(6): 3208-3213.

[20]JIA J, HUANG G, DENG J, et al. Skin-inspired flexible and high-sensitivity pressure sensors based on rGO films with continuous-gradient wrinkles[J]. Nanoscale, 2019, 11(10): 4258-4266.

[21]CHENG Y, MA Y, LI L, et al. Bioinspired microspines for a high-performance spray TiCT MXene-based piezoresistive sensor[J]. Acs Nano, 2020, 14(2): 2145-2155.

[22]PAN L, CHORTOS A, YU G, et al. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film[J]. Nature Communications, 2014(5): 3002.

[23]PENG Y, YANG N, XU Q, et al. Recent advances in flexible tactile sensors for intelligent systems[J]. Sensors, 2021, 21(16): 5392.

[24]DING Y, XU T, ONYILAGHA O, et al. Recent advances in flexible and wearable pressure sensors based on piezoresistive 3D monolithic conductive sponges[J]. Acs Applied Materials & Interfaces, 2019, 11(7): 6685-6704.

[25]CHEN B, ZHANG L, LI H, et al. Skin-inspired flexible and high-performance MXene@ polydimethylsiloxane piezoresistive pressure sensor for human motion detection[J]. Journal of Colloid and Interface Science, 2022(617): 478-488.

[26]YAN J F, MA Y, JIA G, et al. Bionic MXene based hybrid film design for an ultrasensitive piezoresistive pressure sensor[J]. Chemical Engineering Journal, 2022, 431(4): 133458.

[27]佘明华, 徐瑞东, 韦继超, 等. 纺织基柔性触觉传感器及可穿戴应用进展[J]. 絲绸, 2023, 60(3): 60-72.

SHE M H, XU R D, WEI J C, et al. Textile-based flexible tactile sensors and wearable applications[J]. Journal of Silk, 2023, 60(3): 60-72.

[28]CHAO M Y, HE L, GONG M, et al. Breathable TiCT MXene/Protein nanocomposites for ultrasensitive medical pressure sensor with degradability in solvents[J]. Acs Nano, 2021, 15(6): 9746-9758.

[29]OH Y S, KIM J H, XIE Z, et al. Battery-free, wireless soft sensors for continuous multi-site measurements of pressure and temperature from patients at risk for pressure injuries[J]. Nature Communications, 2021, 12(1): 5008.

[30]CHO S, HAN H, PARK H, et al. Wireless, multimodal sensors for continuous measurement of pressure, temperature, and hydration of patients in wheelchair[J]. Npj Flexible Electronics, 2023, 7(1): 8.

[31]HAN J, XU C, ZHANG J, et al. Multifunctional coaxial energy fiber toward energy harvesting, storage, and utilization[J]. Acs Nano, 2021, 15(1): 1597-1607.

[32]YU R, ZHU C, WAN J, et al. Review of graphene-based textile strain sensors, with emphasis on structure activity relationship[J]. Polymers, 2021, 13(1): 151.

[33]XU L, JIAO X, SHI C, et al. Single-walled carbon nanotube/copper core-shell fibers with a high specific electrical conductivity[J]. Acs Nano, 2023, 17(10): 9245-9254.

[34]TANG Z, JIA S, WANG F, et al. Highly stretchable core-sheath fibers via wet-spinning for wearable strain sensors[J]. Acs Applied Materials & Interfaces, 2018, 10(7): 6624-6635.

[35]WU J, WANG M, DONG L, et al. A trimode thermoregulatory flexible fibrous membrane designed with hierarchical core-sheath fiber structure for wearable personal thermal management[J]. Acs Nano, 2022, 16(8): 12801-12812.

[36]LI P, GAO X, ZHAO B, et al. Multi-color tunable and white circularly polarized luminescent composite nanofibers electrospun from chiral helical polymer[J]. Advanced Fiber Materials, 2022, 4(6): 1632-1644.

[37]INNOCENT M T, ZHANG Z, CAO R, et al. Piezoresistive fibers with large working factors for strain sensing applications[J]. Acs Applied Materials & Interfaces, 2023, 15(1): 2277-2288.

[38]LIU Z, ZHENG Y, JIN L, et al. Highly breathable and stretchable strain sensors with insensitive response to pressure and bending[J]. Advanced Functional Materials, 2021, 31(14): 2007622.

[39]HU Y F, HUANG T, ZHANG H, et al. Ultrasensitive and wearable carbon hybrid fiber devices as robust intelligent sensors[J]. Acs Applied Materials & Interfaces, 2021, 13(20): 23905-23914.

[40]ZHONG W B, MING X, JIANG H, et al. Full-textile human motion detection systems integrated by facile weaving with hierarchical core-shell piezoresistive yarns[J]. Acs Applied Materials & Interfaces, 2021, 13(44): 52901-52911.

[41]ZHOU J, XU X, XIN Y, et al. Coaxial thermoplastic elastomer-wrapped carbon nanotube fibers for deformable and wearable strain sensors[J]. Advanced Functional Materials, 2018, 28(16): 1705591.

[42]WANG Y H, ZHU J, SHEN M, et al. Three-layer core-shell Ag/AgCl/PEDOT: PSS composite fibers via a one-step single-nozzle technique enabled skin-inspired tactile sensors[J]. Chemical Engineering Journal, 2022(442): 136270.

[43]DING X C, ZHONG W, JIANG H, et al. Highly accurate wearable piezoresistive sensors without tension disturbance based on weaved conductive yarn[J]. Acs Applied Materials & Interfaces, 2020, 12(31): 35638-35646.

[44]YU L T, YEO J C, SOON R H, et al. Highly stretchable, weavable, and washable piezoresistive microfiber sensors[J]. Acs Applied Materials & Interfaces, 2018, 10(15): 12773-12780.

[45]ZHANG J, WANG Y, ZHOU J, et al. Multi-functional STF-based yarn for human protection and wearable systems[J]. Chemical Engineering Journal, 2023, 453(2): 139869.

[46]LI W, JIN X, HAN X, et al. Synergy of porous structure and microstructure in piezoresistive material for high-performance and flexible pressure sensors[J]. Acs Applied Materials & Interfaces, 2021, 13(16): 19211-19220.

[47]YANG M, CHENG Y, YUE Y, et al. High-performance flexible pressure sensor with a self-healing function for tactile feedback[J]. Advanced Science, 2022, 9(20): 2200507.

[48]YAO B, YE Z, LOU X, et al. Wireless rehabilitation training sensor arrays made with hot screen-imprinted conductive hydrogels with a low percolation threshold[J]. Acs Applied Materials & Interfaces, 2022, 14(10): 12734-12747.

[49]CHEN D, LIU Z, LI Y, et al. Unsymmetrical alveolate PMMA/MWCNT film as a piezoresistive e-skin with four-dimensional resolution and application for detecting motion direction and airflow rate[J]. Acs Applied Materials & Interfaces, 2020, 12(27): 30896-30904.

[50]CHOONG C L, SHIM M B, LEE B S, et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array[J]. Advanced Materials, 2014, 26(21): 3451-3458.

[51]PARK H, JEONG Y R, YUN J, et al. Stretchable array of highly sensitive pressure sensors consisting of polyaniline nanofibers and au-coated polydimethylsiloxane micropillars[J]. Acs Nano, 2015, 9(10): 9974-9985.

[52]SHI J, WANG L, DAI Z, et al. Multiscale hierarchical design of a flexible piezoresistive pressure sensor with high sensitivity and wide linearity range[J]. Small, 2018, 14(27): 1800819.

[53]PANG Y, ZHANG K, YANG Z, et al. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity[J]. Acs Nano, 2018, 12(3): 2346-2354.

[54]SUN Q J, ZHUANG J, VENKATESH S, et al. Highly sensitive and ultrastable skin sensors for biopressure and bioforce measurements based on hierarchical microstructures[J]. Acs Applied Materials & Interfaces, 2018, 10(4): 4086-4094.

[55]ZHOU Y, ZHAO L, TAO W, et al. All-nanofiber network structure for ultrasensitive piezoresistive pressure sensors[J]. Acs Applied Materials & Interfaces, 2022, 14(17): 19949-19957.

[56]GAO X, ZHOU F, LI M, et al. Flexible stannum-doped SrTiO nanofiber membranes for highly sensitive and reliable piezoresistive pressure sensors[J]. Acs Applied Materials & Interfaces, 2021, 13(44): 52811-52821.

[57]XU J, ZHANG L, LAI X, et al. Wearable RGO/MXene piezoresistive pressure sensors with hierarchical microspines for detecting human motion[J]. Acs Applied Materials & Interfaces, 2022, 14(23): 27262-27273.

[58]PAN H, XIE G, PANG W, et al. Surface engineering of a 3D topological network for ultrasensitive piezoresistive pressure sensors[J]. Acs Applied Materials & Interfaces, 2020, 12(34): 38805-38812.

[59]JING M, ZHOU J, ZHANG P, et al. Porous AgNWs/Poly(vinylidene fluoride) composite-based flexible piezoresistive sensor with high sensitivity and wide pressure ranges[J]. Acs Applied Materials & Interfaces, 2022, 14(49): 55119-55129.

[60]LI L, BAO X, MENG J, et al. Sponge-hosting polyaniline array microstructures for piezoresistive sensors with a wide detection range and high sensitivity[J]. Acs Applied Materials & Interfaces, 2022, 14(26): 30228-30235.

[61]SENGUPTA D, PEI Y, KOTTAPALL A G P. Ultralightweight and 3D squeezable graphene-polydimethylsiloxane composite foams as piezoresistive sensors[J]. Acs Applied Materials & Interfaces, 2019, 11(38): 35201-35211.

[62]LIU Z, WAN K, ZHU T, et al. Superelastic, fatigue-resistant, and flame-retardant spongy conductor for human motion detection against a harsh high-temperature condition[J]. Acs Applied Materials & Interfaces, 2021, 13(6): 7580-7591.

[63]汪康, 何壯, 喻研. 柔性压阻式压力传感器的制备与性能优化[J]. 电子元件与材料, 2022, 41(8): 781-793.

WANG K, HE Z, YU Y. Preparation and performance optimization of flexible piezoresistive pressure senor[J]. Electronic Components and Materials, 2022, 41(8): 781-793.

[64]PANG Y, TIAN H, TAO L, et al. Flexible, highly sensitive, and wearable pressure and strain sensors with graphene porous network structure[J]. Acs Applied Materials & Interfaces, 2016, 8(40): 26458-26462.

[65]YUE Y, LIU N, LIU W, et al. 3D hybrid porous MXene-sponge network and its application in piezoresistive sensor[J]. Nano Energy, 2018(50): 79-87.

[66]YU R, XIA T, WU B, et al. Highly sensitive flexible piezoresistive sensor with 3D conductive network[J]. Acs Applied Materials & Interfaces, 2020, 12(31): 35291-35299.

[67]ZHANG H, LIU N, SHI Y, et al. Piezoresistive sensor with high elasticity based on 3D hybrid network of sponge@CNTs@AgNPs[J]. Acs Applied Materials & Interfaces, 2016, 8(34): 22374-22381.

[68]WU Y, LIU H, CHEN S, et al. Channel crack-designed gold@PU sponge for highly elastic piezoresistive sensor with excellent detectability[J]. Acs Applied Materials & Interfaces, 2017, 9(23): 20098-20105.

[69]ZHANG S D, LIU H, YANG S, et al. Ultrasensitive and highly compressible piezoresistive sensor based on polyurethane sponge coated with a cracked cellulose nanofibril/silver nanowire layer[J]. Acs Applied Materials & Interfaces, 2019, 11(11): 10922-10932.

[70]CHEN T J, LIU Z, ZHAO G, et al. Piezoresistive sensor containing lamellar MXene-plant fiber sponge obtained with aqueous MXene ink[J]. Acs Applied Materials & Interfaces, 2022, 14(45): 51361-51372.

[71]AUBEELUCK D A, FORBRIGGER C, TAROMSARI S M, et al. Screen-printed resistive tactile sensor for monitoring tissue interaction forces on a surgical magnetic microgripper[J]. Acs Applied Materials & Interfaces, 2023, 15(28): 34008-34022.

[72]GAO Y J, OTA H, SCHALER E W, et al. Wearable microfluidic diaphragm pressure sensor for health and tactile touch monitoring[J]. Advanced Materials, 2017, 29(39): 1701985.

[73]KIM J, KIM M, LEE M S, et al. Wearable smart sensor systems integrated on soft contact lenses for wireless ocular diagnostics[J]. Nature Communications, 2017(8): 14997.

Research on resistive flexible tactile sensors and their current applications in the field of

medical and health care

YIN Xia, ZHANG Shijin, TIAN Mingwei, LIU Hong

(College of Textile & Clothing, Qingdao University, Qingdao 266071, China)

Abstract:The working principle of resistive flexible tactile sensors is mainly based on the piezoresistive effect. When the sensor is subjected to external pressure, the external pressure is converted into a resistance signal, thereby generating an electrical output signal. In recent years, the advancement of wearable smart systems has created an urgent demand for flexible pressure sensors. Among them, resistive flexible tactile sensors have experienced rapid development due to their simple principle, ease of processing, and high integration efficiency. Although biomimetic electronic skins based on resistive flexible tactile sensors have been widely applied in various fields such as human-computer interaction, wearable medical devices, and smart robots, to obtain sensors with a wide pressure monitoring range and high sensitivity remains a challenge for researchers.

To address the aforementioned issues, in addition to selecting advanced functional materials and suitable substrate materials, optimizing sensor structure is also an important research direction. Rational structural design can not only significantly enhance the sensitivity and other performance parameters of the sensor but also flexibly adjust its sensitivity and response characteristics to meet specific application requirements. Currently, the structural design of resistive flexible tactile sensors can be divided into three dimensions: one-dimensional fiber/yarn-based sensor elements, two-dimensional planar structure sensor elements, and multi-dimensional three-dimensional structure sensor elements. Innovatively designing the sensor layers in different dimensions to change the contact resistance between conductive materials and the conduction paths in conductive elastic composites is currently an important research direction to improve the performance of resistive tactile sensors.

The existing structural design of one-dimensional fiber/yarn-based sensor elements is mainly based on the core-shell structure achieved through coaxial spinning. Although it exhibits high linearity, the sensitivity and resolution of the sensor elements are easily limited by the fiber diameter and length, resulting in lower accuracy in measuring micro changes. Additionally, fibers are prone to fatigue and damage during use, which affects the durability and stability of the sensor. Two-dimensional planar structure sensor elements are primarily designed and constructed with fine microstructures or nanoscale geometries on a two-dimensional conductive layer. Commonly used microstructures include protrusions, micro-domes, micro/nano-rod structures, micro-pyramid structures, hollow sphere microstructures, wrinkled structures, interlocking structures, micro-column structures, and various biomimetic microstructures. These microstructures provide abundant contact points between the two electrodes of the sensor, thereby improving the performance of the sensor. Specifically, resistive pressure sensors designed with multi-dimensional three-dimensional structures benefit from their high porosity and good elasticity of the substrate. The “contact effect” between adjacent porous frameworks can generate significant changes in resistance, enabling the sensor to have high sensitivity within a wide linear range. Common strategies for fabricating multi-dimensional spatial structure sensor elements include the stacking of multi-layer microstructures, endowing three-dimensional (3D) porous substrate with sensing performance, and aggregation of conductive “skeleton” in a three-dimensional structure. The multi-layer microstructure construction of three-dimensional structures optimizes the sensor’s linear sensing range, allowing it to maintain higher sensitivity over a wide pressure range compared to single-layer microstructures.

Resistive flexible tactile sensors are highly sensitive to micro changes in stress and can detect subtle touch and pressure information. By integrating resistive flexible tactile sensors with minimally invasive surgical devices, they have been applied in clinical robotic-assisted minimally invasive surgery, enhancing the safety of surgical procedures. Combining resistive flexible tactile sensors with wearable medical devices not only enables the monitoring of physiological signals such as blood pressure, heart rate, and pulse but also assists doctors in building digital management platforms. They can also be utilized in home health monitoring devices and rehabilitation treatment equipment to provide long-term care support and personalized treatment plans for patients, which is of significant importance in the field of medical and health care.

Resistive flexible tactile sensors have significant advantages in the field of flexible wearables due to their simple principle and low cost. In designing the sensor structure, constructing “microstructures” to increase the contact points/gaps between the two electrodes is an effective strategy for improving sensor sensitivity. In addition to focusing on structural design, innovation can also be driven by material selection. Furthermore, although resistive flexible sensors have made significant progress in various fields such as flexible electronics, medical monitoring and human-computer interaction, there is still a need to improve the durability and stability of materials, address aging issues in resistive elements, and enhance sensor protection measures. In designing and manufacturing sensors, considering cost-effectiveness and production difficulties, developing low-cost and mass-producible sensors will be a key focus for future development.

Key words:resistive flexible tactile sensor; structure design; medical and health care; one-dimensional fiber/yarn-based sensor elements; two-dimensional planar structure sensor elements; multi-dimensional three-dimensional structure sensor elements; health monitoring