白山黑水浴火而生

2023-12-25王仁亮

王仁亮

在中国陶瓷发展史中,于冰天雪地中孕育而生的黑龙江陶瓷独具一格。黑龙江陶瓷的起源可追溯到7 000—13 000 年前。在悠长的发展进程中,新开流文化、渤海文化、金源文化等,都伴随有特色鲜明的陶瓷文化。其中,距今900 多年的金源文化期的“上京窑”最具代表性。

Heilongjiang ceramics, originating and developingin the icy and snowy region of northeastern China,holds a distinctive charm in the history of Chineseceramics. Across the ages, various cultures such asXinkailiu, Bohai, and Jinyuan, dating back to 7,000 to13,000 years ago, have each contributed their uniqueceramic traditions. Among these, the Shangjingceramics, stemming from the Jinyuan culture over 900years ago, stands as the most representative.

“上京窯”瓷器选用黑龙江省高岭土制作泥坯,融合了肃慎文化、渤海文化、金源文化中的典型文化符号与黑龙江的“冰雪文化”元素,在传承中不断创新。“上京窑” 瓷器以兴安落叶松为燃料,经过连续78 小时的高温烧制,研发形成兼具金色、冰色之地域特色的“上京金瓷”“上京冰瓷”等陶瓷品类。

Blending the essence of Sushen, Bohai, and Jinyuancultures with the signature “ice and snow” elements ofHeilongjiang, the Shangjing ceramics strikes a delicatebalance between tradition and innovation. It employslocally sourced kaolin for the clay and Xing’an larchbranches as fuel. te tring process takes a continuous78 hours, producing ceramic items boasting uniqueregional traits with fascinating gold and icy hues, suchas the “Shangjing Gold Ceramics” and the “ShangjingIce Ceramics”.

“上京窑”瓷器采取无釉裸烧工艺,将泥坯在不施釉的状态下直接装入窑内进行烧制。瓷器表面所形成的釉层,均为经过上千度高温、连续几天几夜烧制自然窑变而成,每件作品均独一无二。其窑变形成原理为:松木燃烧后所形成的木灰随着火焰飘落在窑内的土坯上,当窑温超过千度时,木灰开始融化,灰中的矿物质成分与瓷坯中的硅、铁等成分在高温状态下发生物理和化学反应,形成釉层;因窑内高温导致的不同程度的氧化、还原,釉面肌理变化多样、色彩层次丰富。正所谓“入窑一色,出窑万彩”,每一种变化均仰赖天工,非人为可及。

An unglazed tring technique is adopted, wherethe clay is directly loaded into the kiln without theapplication of artificial glaze. As the firing processtakes place at temperatures surpassing 1,000°C(around 1,832°F) for several days, a natural glazelayer forms on the surface of the items, giving adistinctive artistic touch to each piece.Here is an explanation of how the kiln changeprocess takes place: the wood ash falls onto theclay pieces inside the kiln and starts to melt oncethe temperature reaches over 1,000°C. The mineralcomponents in the ash will then physically andchemically interact with the silicon, iron, andother components in the clay body under hightemperatureconditions, and result in a natural glazelayer. Varying levels of oxidization and reductiongive birth to a diverse range of patterns and a myriadof color hues. tis phenomenon is oten described as“one shade before, and a million ater”, highlightingthe wonder of nature’s artistry, unmatched by humanendeavors.

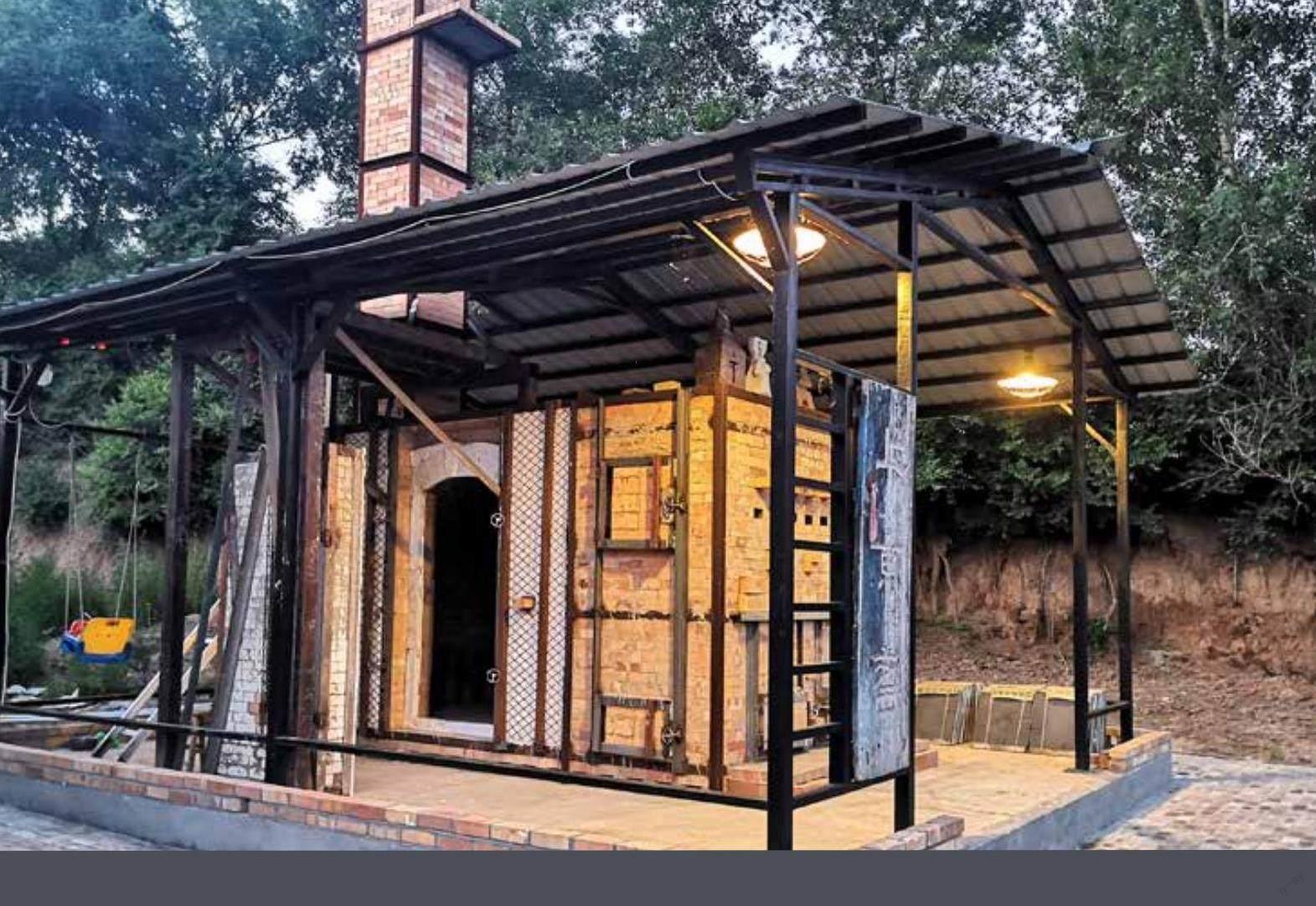

“上京窑”的窑炉是笔者团队自主研发建设的国内最大的寒地倒焰型柴窑。目前每年烧制两窑,半年为一个周期。其中,泥坯制作阶段为五个月,烧窑阶段一个月。因器物大小不同,每窑烧制陶瓷的数量在1 300 至3 000 件不等。

Our R&D team independently designed anddeveloped the largest low-temperature-region, crossdraft,wood-fired kiln in China for the production ofShangjing ceramics. Currently, two kiln firings takeplace every year, with each cycle lasting six months(tve months of clay body production and one monthof kiln tring). Each tring will produce 1,300 to 3,000pieces of Shangjing ceramics, depending on theproduct size.

柴烧瓷器的制作是一个艰苦而又快乐的过程。无论是在零上30℃的酷暑之中,还是在零下30℃的严寒之中,近一个月的艰苦劳作,在最终窑门打开的一瞬间,都凝结为收获的喜悦。

It is a rewarding journey filled with challengesand joy. As the kiln door opens, revealing the finalproducts, whether it is amid scorching summer daysof over 30°C or freezing winter days of —30°C, nearly a month of hardworking transform into a sense ofdelightful satisfaction.

每一窑瓷器的烧制均需经历装窑、烧窑、开窑三个阶段。

te production process can be divided into threemain stages: loading, tring, and unloading.

装窑是整个烧制阶段中最重要的环节,有“装窑如绣花”的比喻。受不同气温的影响,装窑时间一般为3—10 天,春秋用时较短、冬夏用时较长。装窑是将制作好的泥坯粘好支钉后一件件装入窑内,需要根据泥坯在窑内的摆放位置,安排窑内的走势。

Loading, the most crucial step in the productionprocess, is often described to be “as delicate asembroidering a flowery pattern”. It takes about threedays in spring and autumn and can take up to ten daysin summer and winter, as temperature has a majorimpact on the process. During this stage, artisansinstall the supporting stilts under the raw clay bodiesand arrange them in the kiln according to a carefullydesigned layout based on the specitc positioning of theitems.

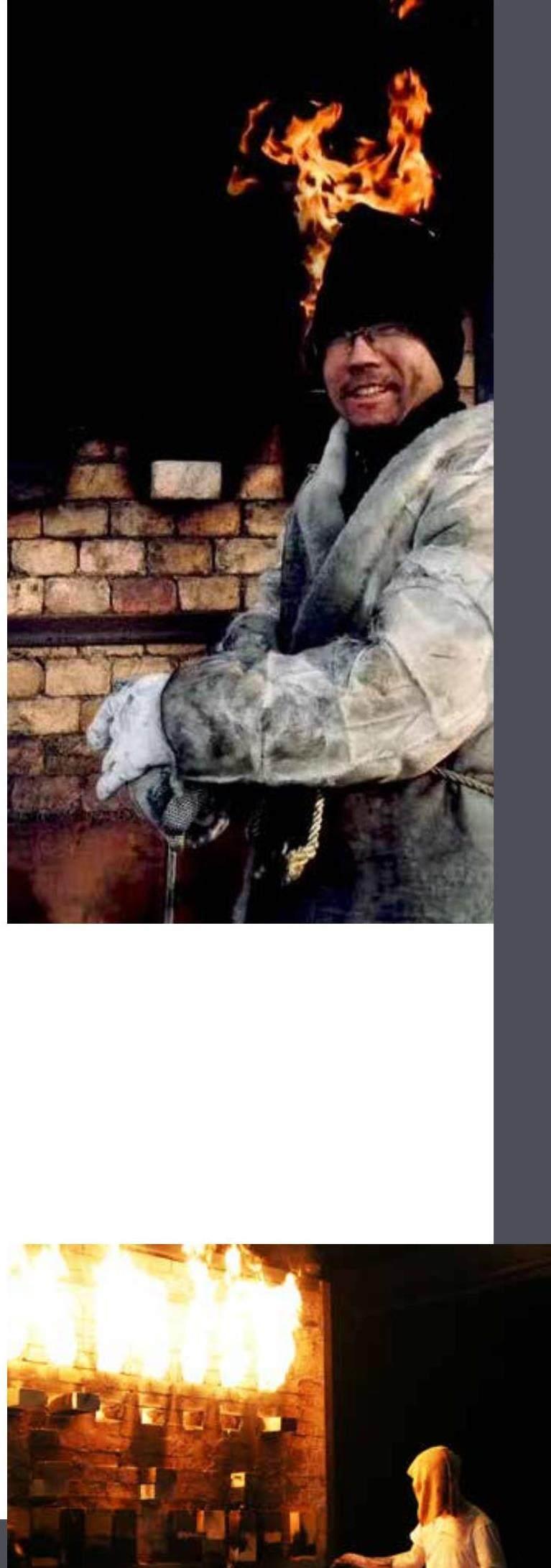

装窑完成后便封窑门,进入烧窑阶段。按照传统习惯,点火前须“拜窑神”。满满的仪式感,表达的是制瓷人对自然的敬畏与对文化的热爱。仪式结束,开始生火烧窑。从窑火点燃开始,制瓷人就要经历至少78 小时不眠不休、艰苦的“热烈劳作”。劈柴、投柴、观测等持续性劳动,伴随着上千度的高温、40m3 的木柴消耗量,一直持续至停火封窑。烧窑结束后7—8 天,窑体自然冷却。

Once the kiln is loaded, the door is sealed, and thefiring stage begins. In line with tradition, a worshipritual is held to honor the kiln god before ignition,a gesture of respect for nature and a celebrationof local culture. With the ceremony completed, acontinuous and laborious journey of at least 78 hoursof high-temperature firing starts, during whichceramic artisans split wood, add fuel, and monitorthe temperature day and night. tis stage requires theburning of approximately 40m3 of larch branches attemperatures exceeding 1,000°C. Subsequently, theartisans patiently wait for another seven or eight daysas the kiln gradually cools down after the fire isstopped.

待窯温自然降至外界温度时,最振奋人心的开窑时刻到来了。伴随着忐忑而又期待的复杂心情,制瓷人开启窑门,迎接大自然的馈赠。当窑门被缓缓开启的一刹那,火与土交融后的神秘面纱被逐渐揭开,这场由金、木、水、火、土合奏“大地共鸣曲”共同铸造的陶瓷生命正式面世。

ten, the most exhilarating moment arrives as thekiln reaches the ambient temperature. With a blendof anxious anticipation, the artisans unseal the doorto reap the rewards of their labor from nature. As thedoor opens, mystery unveils and a fascinating sightunfolds before people’s eyes — marvelous creationscrated from the Five Elements in traditional Chinesephilosophy: metal, wood, water, tre, and earth.

據统计,因柴烧工艺的特殊性,目前上京窑每窑作品成品率为60%—70%,其中,精品率约为30%,极品率约为10%,窑宝典藏级约为1%,每件精品级别以上的陶瓷作品均为难得的艺术佳作。

Due to the intricate anddemanding techniques requiredin the firing process, the currentsuccess rate is approximately 60%to 70% for each firing. Amongthem, around 30% are tne pieces,10% are exceptional pieces, and arare 1% are treasure pieces. Eachceramic product above the fineproductlevel is considered a trulyrare and exquisite masterpiece.

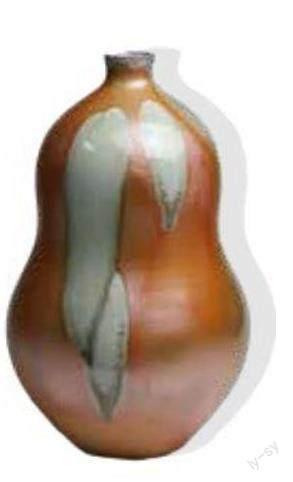

有别于传统瓷器青、白、黑、红、花色系,金色系陶瓷为上京窑独创。自然窑变而成的釉色在黄色与橘红色之间变化,极品近于黄金的色彩与光泽,数量稀少,是一方土木的绝美融合。上京金瓷的“金”,一方面指的是金色瓷器的色泽,另一方面寓意黑龙江金源文化的一脉相承。

In contrast to traditionalceramics, which often exhibithues of blue, white, black, red,or polychrome, the ShangjingGold Ceramics stands out withits unique golden brilliance. Theglaze, transformed naturally in thekiln, boasts a wide range of shadesfrom yellow to orange-red, whilethe exceptional pieces showcase aglaze with color and luster akin toprecious gold. tese rare artworkstruly demonstrate the mysticalsynergy between the earth andwood of this region. The name,Shangjing Gold Ceramics, nicelydescribes the golden glow of theproducts and simultaneously payshomage to the enduring legacy ofthe local Jinyuan Culture (literallymeaning the “Gold Source”Culture).

除了金瓷,上京冰瓷也极具地域特色,其自然窑变而成的釉色晶莹通透、开片精美。冰瓷的“冰”同样有着双重寓意,既指自然窑变形成的冰色釉,也象征着黑龙江独特的冰雪文化。

The Shangjing Ice Ceramics isanother local treasure, distinguishedby the glaze’s exquisite crystalclearand translucent quality andadorned with delicate crackles, bothgifted by the natural kiln changeprocess. The name “Ice Ceramics”also carries a dual signitcance, as itnot only captures the ice-like huesof the glaze but also embodies theessence of the unique ice and snowculture of Heilongjiang Province.

经检测,上京窑瓷器在盛装酒、水时会有钙、锌、钾、钠、铁五种对人体有益的微量元素析出,可改善水质,品茶、饮酒味道更加醇厚。2019 年,由中国工艺美术协会组织编撰的大型茶器具工具书《中华茶器具通鉴》的《茶器具古今名家名器精鉴》一卷中介绍了笔者和笔者团队制作的上京金瓷,这也是黑龙江省内唯一入编的陶瓷艺术品类。

Experiments have revealedthat when Shangjing ceramicsare used to contain wine orwater, they release beneficialmicroelements including calcium,zinc, potassium, sodium, andiron, which not only improvewater quality but also give aricher taste to the beverages. In2019, the “Renowned Artistsand Exquisite Wares” section of, an encyclopedicreference book compiled bythe China Ar t s and Craf t sAssociation, features my profileand introduces the ShangjingGold Ceramics of our team. It isthe only ceramic product fromHeilongjiang Province to beincluded in this book.

未来,上京窑将会继续依托“金源文化”“冰雪文化”等黑龙江特色文化,不断创新,创作出更多造型设计新颖、独具特色的陶瓷种类,将黑龙江的特色陶瓷文化发扬光大,不断传承下去。

In the future, the Shangjing Ceramics will continue todig into the rich local culture and pursue innovation. Ourgoal is to design and craft a more diverse range of noveland distinctive ceramic works, contributing to the furthercontinuation and promotion of Heilongjiang’s unique,cherished ceramics heritage.