Optimization of Solid-state Fermentation Conditions of Sophora japonica cv. jinhuai by Response Surface Methodology

2023-10-31MiaoYANGChaohaoGUQilingLIZhiqiangHUANGHaoLIUYanxiLAIZongyouCHENKaimeiZHU

Miao YANG, Chaohao GU, Qiling LI, Zhiqiang HUANG, Hao LIU, Yanxi LAI, Zongyou CHEN, Kaimei ZHU*

1. Guilin Medical University, Guilin 541004, China; 2. Guangxi Institute of Botany, Chinese Academy of Sciences, Guilin 541006, China

Abstract [Objectives] To optimize the solid-state fermentation process of Flos Sophorae Immaturus by Penicillium with Sophora japonica cv. jinhuai as raw material. [Methods] The fermentation conditions were optimized by single factor experiment and response surface methodology with quercetin content as the dependent variable. [Results] According to the established model, the optimal fermentation process of Flos Sophorae Immaturus was obtained as follows: temperature 29.97 ℃, time 6.88 d, rotation speed 180.86 rpm, inoculation amount 3.93 mL, and the expected content of quercetin was 34.805 3 mg/g. Based on this, the fermentation parameters were adjusted, and the actual content was 33.67 mg/g, which was close to the predicted value. [Conclusions] The optimization of fermentation process of Flos Sophorae Immaturus by response surface methodology provides a reference for the development and utilization of this medicinal material.

Key words Sophora japonica cv. Jinhuai, Quercetin, Penicillium, Fermentation process, Response surface methodology (RSM)

1 Introduction

The dried flower buds of the legumeSophorajaponicaL., commonly known as Flos Sophora Immaturus, are shaped like rice grains and mainly contain more than 10 flavonoids such as rutin and quercetin[1]. TheChinesePharmacopoeia(2015) shows that Flos Sophora Immaturus has the effects of cooling blood and stopping bleeding, clearing the liver and purging fire[2]. The main cultivars includeSophorajaponicaL.,Cassia surattensis Burm.f., andSophorajaponicacv. jinhuai. Among them,S.japonicacv. jinhuai is an excellent variety. Flos Sophora Immaturu fromS.japonicacv. jinhuai has the highest content of rutin, as high as 1-2 times of other varieties. Flos Sophora Immaturu fromS.japonicacv. jinhuai produced in Quanzhou of Guangxi has rutin content of 25%-28%, and the highest is up to 40%[3-4]. The source of quercetin can be hydrolyzed from rutin. Quercetin is a research hotspot in recent years. Quercetin has antioxidant, anti-Streptococcus mutans biofilm activity, anti-allergic, antiviral and anti-tumor effects[5-8]. It has great development space and application prospects in the medical and pharmaceutical industries. Therefore, it is necessary to optimize the preparation process of quercetin from Flos Sophora Immaturu fromS.japonicacv. jinhuai for both clinical application and pharmacy.

At present, the main methods to obtain quercetin are solvent extraction[9], ultrasound-assisted extraction[10], microwave-assisted extraction[11]and microbial fermentation[12-13]. Microbial fermentation refers to the conversion of active components of Chinese medicinal materials by enzymes produced during the growth and metabolism of bacteria in the fermentation process[14]. Studies have shown that after entering the intestinal tract, rutin, the active components of Flos Sophora Immaturu, is hydrolyzed into quercetin by microorganisms to exert its efficacy[15]. Taking Flos Sophora Immaturu fromS.japonicacv. jinhuai produced in northern Guangxi as the base material, the Penicillium was used for solid state fermentation, rutin in Flos Sophora Immaturu fromS.japonicacv. jinhuai was converted to quercetin. The fermentation process of Flos Sophora Immaturu fromS.japonicacv. jinhuai was optimized by the response surface methodology (RSM), in order to provide an idea for effective utilization of rutin in Flos Sophora Immaturu fromS.japonicacv. jinhuai.

2 Materials and methods

2.1 MaterialsThe medicinal material, collected from Quanzhou County of Guangxi, was identified by researcher Jiang Yunsheng from Guangxi Institute of Botany asSophorajaponicacv. jinhuai. Penicillium (isolated and screened by Pathogenic Microbiology Laboratory, School of Basic Medicine, Guilin Medical University); quercetin reference substance (China National Institute for Food and Drug Control, batch No.:100081, content 99.1%); methanol for chromatographic purity, water for ultrapure water; Czapek-Dox Medium (Shanghai Bioway Biotechnology Co., Ltd.); analytical balance (Shanghai Jingtian Electronic Instrument Factory); high-speed multifunctional pulverizer (Yongkang Boou Hardware Products Co., Ltd.); high performance liquid chromatograph (Shimadzu LC-20a, Shimadzu Enterprise Management Co., Ltd.); constant temperature oscillator (Shaoguan Taihong Medical Equipment Co., Ltd.).

2.2 Methods

2.2.1Preparation of seed solution. The strain was inoculated on Czapek-Dox Medium and cultured at 30 ℃ for 4-6 d. The spores were scraped off with sterile water to prepare the spore suspension. The spore suspension was placed in a conical flask containing 100 mL of seed liquid medium and cultured at 30 ℃ in a shaking incubator at 160 rpm for 72 h to obtain the seed solution.

2.2.2Solid-state fermentation culture. Dried and crushed the Flos Sophorae Immaturus (passing through a 100-mesh sieve), weighed 5 g of Flos Sophorae Immaturus powder, put it into a 250 mL conical flask, added a certain amount of inorganic salt Czapek-Dox Medium, and mixed well. Autoclaved at 121 ℃ for 30 min. Under the aseptic condition, a certain amount of seed solution was inoculated and then placed in a constant-temperature shaking incubator to be cultured for a certain time.

2.2.3 Determination of quercetin content(i) Chromatographic conditions. The column was InterSustain C18(4.6 mm×150 mm, 5 μm), the column temperature was 30 ℃, the flow rate was 1 mL/min, the detection wavelength was 365 nm, the injection volume was 20 μL, and the mobile phase was methanol-water (60:40). (ii) Plotting of quercetin content standard curve. Precisely weighed 5 mg of quercetin reference substance and added into a 50 mL volumetric flask, added chromatographic methanol to dissolve, fixed the volume to the scale line, and refrigerated at 4 ℃ for later use. Precisely weighed and fixed the volume with chromatographic methanol in accordance with the above chromatographic conditions. The results showed that the linear range of quercetin was 2-12 μg/mL and the regression equation wasY=173.74X-106.53,R2=0.999 7.

2.4 Response surface method optimization experiment

Four factors including fermentation temperature, fermentation time, shaker speed and inoculation amount were selected as independent variables, and the content of quercetin was selected as response value. According to the Box-Benhnken design principle, the response surface methodology with four factors and three levels was used to obtain the optimal fermentation process, which was repeated three times. The factor level design is shown in Table 1.

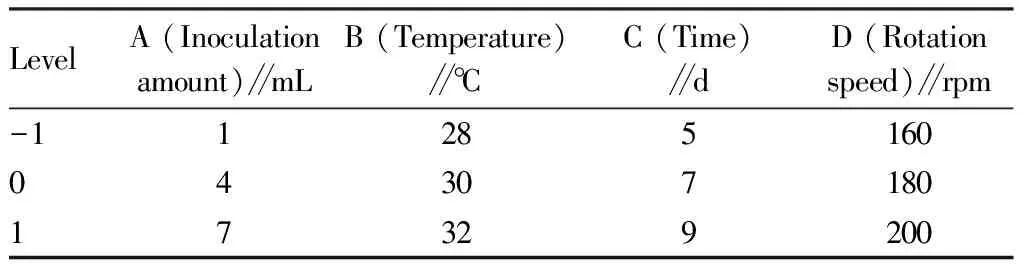

Table 1 Response surface factor levels

3 Results and analysis

3.1 Results of response surface

3.1.1Establishment and analysis of regression equation. Taking the fermentation temperature, time, rotation speed, and inoculation amount as main factors, the experiment was carried out according to BOX-Behnken Design principle. The experiment design and results are shown in Table 2.

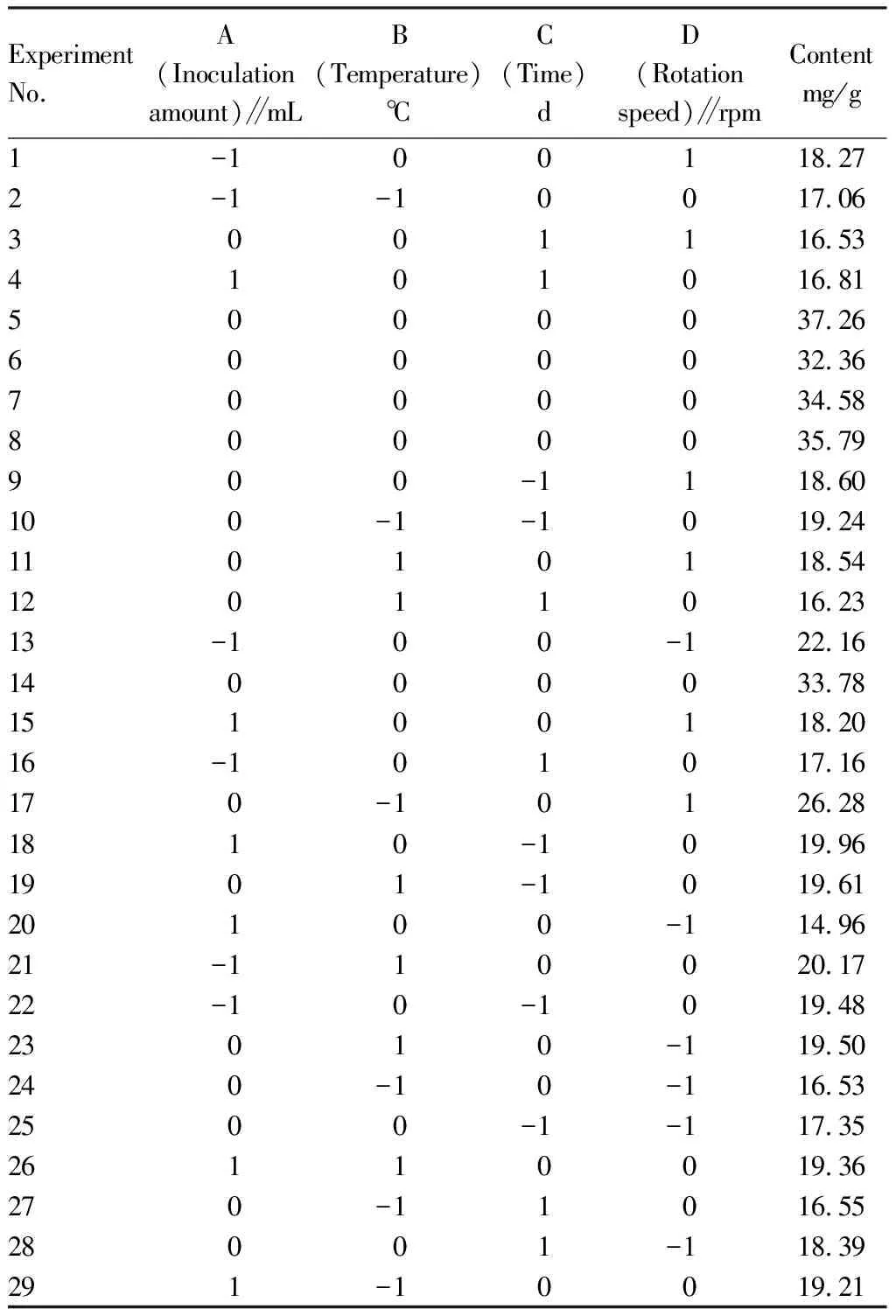

Table 2 Box-Behnken experiment design and results

With the aid of Design-Expert 8.0 software, the correlation equation of influencing factors can be obtained by quadratic regression analysis of the data in Table 2. The fitting equation of the model obtained by multiple regression fitting analysis is as follows:Y=34.75-0.48A-0.12B-1.05C+0.63D-0.74AB-0.21AC+1.78AD-0.17BC-2.68BD-0.78CD-8.12A2-7.43B2-8.98C2-7.80D2.

From Table 3, it can be seen that the regression equation was significant (P<0.000 1) and the lack of fit was not significant (P>0.05), indicating that the binomial equation in the test model was more in line with the actual fermentation situation, reflecting that the interaction of fermentation temperature, time, rotation speed and inoculation amount had a highly significant impact on the content of quercetin.

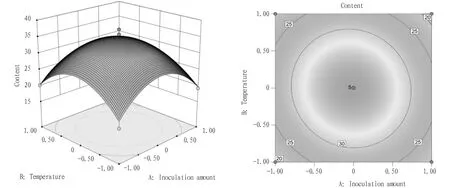

3.1.2Response surface interaction analysis. Fig.1 shows the effect of fermentation time 5 d, rotation speed 160 rpm, inoculation amount and temperature interaction on quercetin content. Fig.1 shows that when the fermentation temperature is constant, the content of quercetin first increases and then decreases with the increase in inoculation amount; when the inoculation amount is constant, the content of quercetin first increases and then decreases with the increase in fermentation temperature; the content of quercetin reaches the maximum when the fermentation temperature and inoculation amount is in the middle level.

Fig.1 Three-dimensional curved surface and contour of interaction between temperature and inoculation amount on quercetin content

Fig.2 shows the effect of fermentation temperature 30 ℃, rotation speed 160 rpm, inoculation amount and time on the content of quercetin. Fig.2 shows that when the fermentation time is constant, the content of quercetin first increases and then decreases with the increase in inoculation amount; when the inoculation amount is constant, the content of quercetin first increases and then decreases with the increase in fermentation time; The content of quercetin reaches the maximum when the fermentation time and inoculation amount is in the middle level.

Fig.2 Three-dimensional curved surface and contour of interaction between time and inoculation amount on quercetin content

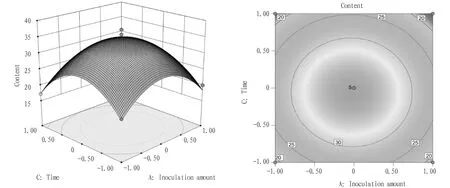

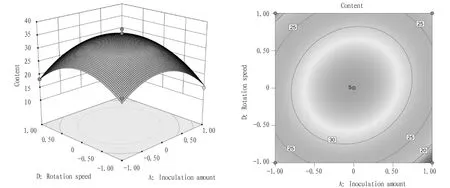

Fig.3 shows the effects of fermentation temperature 30 ℃, fermentation time 5 d, and the interaction of inoculation amount and rotation speed on the content of quercetin. It can be seen from Fig.3 that when the rotation speed is constant, the content of quercetin first increases and then decreases with the increase in inoculation amount; When the inoculation amount was constant, the content of quercetin increased first and then decreased with the increase in rotation speed, and the content of quercetin reaches the maximum when the inoculation amount and rotation speed is in the middle level.

Fig.3 Three-dimensional curved surface and contour of the interaction of rotation speed and inoculation amount on quercetin content

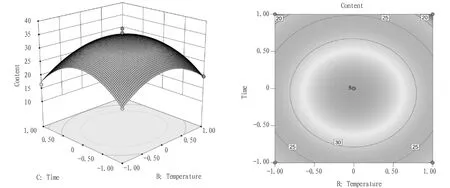

Fig.4 shows the effect of the interaction of fermentation time and fermentation temperature on the content of quercetin at inoculation amount of 4 mL, rotation speed of 160 rpm. Fig.4 shows that when the fermentation temperature is constant, the content of quercetin first increases and then decreases with the increase in fermentation temperature; when the fermentation temperature is constant, the content of quercetin first increases and then decreases with the increase in fermentation time; when the fermentation time and temperature are in the middle level, the content reaches the maximum.

Fig.4 Three-dimensional curved surface and contour of interaction of temperature and time on quercetin content

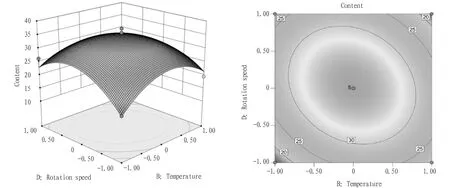

Fig.5 shows the effect of the interaction of rotation speed and fermentation temperature on the content of quercetin when the fermentation time is 5 d and the inoculation amount is 4 mL. Fig.5 shows that when the fermentation temperature is constant, the content of quercetin first increases and then decreases with the increase in the rotation speed; when the rotation speed is constant, the content of quercetin first increases and then decreases with the increase in the fermentation temperature; the content of quercetin reaches the maximum when the rotation speed and fermentation temperature are in the middle level.

Fig.5 Three-dimensional surface and contour of the interaction of rotation speed and temperature on quercetin content

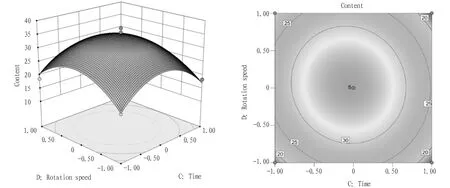

Fig.6 shows the effect of the interaction of rotation speed and fermentation time on the content of quercetin when the fermentation temperature is 30 ℃ and the inoculation amount is 4 mL. It can be seen from Fig.6 that when the fermentation time is constant, the content of quercetin increases first and then decreases with the increase in the rotation speed; when the rotation speed is constant, the content of quercetin increases first and then decreases with the increase in the fermentation time; when the rotation speed and fermentation time are at an intermediate level, the quercetine content reaches the maximum.

Fig.6 Three-dimensional surface and contour of the interaction between rotation speed and time on quercetin

3.2 Verification experimentAccording to Box-Behnken optimization test and regression model analysis, the optimum fermentation conditions of Flos Sophorae Immaturus were obtained as follows: inoculation amount was 3.93 mL, fermentation temperature was 29.97 ℃, fermentation time was 6.88 d, and rotation speed was 180.85 rpm. Under these optimized conditions, the content of quercetin was estimated to be 34.81 mg/g. Considering the practical operation, the fermentation parameters were adjusted to facilitate the experiment, and the optimal fermentation conditions were determined as follows: inoculation amount of 4 mL, fermentation temperature of 30 ℃, fermentation time of 7 d, and rotation speed of 180 rpm. The content of quercetin was 33.67 mg/g. The results were close to the predicted values, indicating the accuracy and reliability of the optimized solid-state fermentation conditions for the Flos Sophorae Immaturus fromS.japonicacv. jinhuai in northern Guangxi.

4 Discussion

The existing production of quercetin generally adopts a chemical two-step process to prepare the quercetin, and the rutin in Flos Sophorae Immaturus can be directly converted into the quercetin by microbial fermentation, and the solid-state fermentation has benefits of low requirement on equipment, low energy consumption and low pollution. The fermentation products do not need complex extraction and separation processes, which has practical value in further reducing production costs and environmental pollution. Microbial fermentation is an extremely complex biochemical reaction process. In the fermentation industry, its production level depends not only on the performance of the production strain itself, but also on the external environment such as fermentation conditions. Therefore, the optimization of fermentation medium plays an important role in improving the fermentation level[17]. In order to obtain the optimum fermentation process, we adopted the response surface methodology in this experiment. Compared with the traditional optimization method, the response surface methodology can optimize the optimal process through an intuitive and highly accurate mathematical model. We carried out polynomial fitting on the relationship between factors and results, and optimized the solid-state fermentation process of Flos Sophorae Immaturus by Penicillium withSophorajaponicacv. jinhuai as raw material. The optimum fermentation process is as follows: temperature 29.97 ℃, time 6.88 d, rotation speed 180.86 rpm, inoculation amount 3.93 mL. Under these conditions, the expected content of quercetin was 34.805 3 mg/g. The mathematical model established in this experiment is reliable and reasonable. It improves the work efficiency, and provides a reference for the further development of rutin in Flos Sophorae Immaturus to transform quercetin.

杂志排行

Medicinal Plant的其它文章

- Quality Control of Zhuang Medicine Xiaoyan Zhiyang Lotion

- Research Progress and Ideas on the Anti-liver Fibrosis Effect of Ethnic Medicine Plumbagin Based on microRNAs/TLR4/NF-κB and NLRP3 Inflammasome Activation

- Gastroprotective Effect of Alpinia zerumbet (Pers.) Burttet Smith on Ethanol-induced Gastric Ulcers in vivo and vitro

- Exploring the Mechanism of Blumea balsamifera (L.) DC in Preventing and Treating Alzheimer’s Disease Based on HPLC-ESI-HRMS and Network Pharmacology

- Observation on Therapeutic Effect of Erxian Decoction on Relieving Low Back Pain after PVP of PMOP-derived Vertebral Fracture

- Effects of Early-stage Phased Rehabilitation Training on Acute Respiratory Distress Syndrome: A Systematic Review and Meta-analysis