食品接触材料中微塑料的释放及检测

2023-10-16姚晶晶韦存茜孙梦捷

姚晶晶,韦存茜,孙梦捷

食品接触材料中微塑料的释放及检测

姚晶晶,韦存茜,孙梦捷

(上海市质量监督检验技术研究院,上海 201114)

讨论微塑料从食品包装、餐具、厨具、加工机械等食品接触材料中的释放途径和检测技术,为食品接触材料中微塑料选择和组合多样化的分析方法提供建议,为食品接触材料中微塑料及相关有毒有害物质的监测研究提供依据。首先概述食品接触材料中微塑料的释放途径及影响因素,其次系统阐述食品接触材料中微塑料的分离富集技术,以及显微镜法、光散射法、光谱法和热裂解气相色谱质谱法等多种检测技术,针对不同技术的适用范围和特点进行比较和分析,并提出具有代表性的食品接触用材料中微塑料从样品处理到颗粒分析的框架和技术路线图,以识别微塑料的化学成分、形貌、丰度、尺寸及分布等特性。针对不同的样品和场景,有必要选择和组合多样化的技术,以达到最优的路径,同时标准化的分析方法和检测技术处理仍是食品接触材料中微塑料风险评估的一大挑战,还亟待提出更为规范的标准化操作流程和检测技术,以提高结果准确性。

食品接触材料;微塑料;释放;样品前处理;检测技术

微塑料(Microplastics,MPs)被认为是对环境至关重要的新兴污染物。研究者将直径小于5 mm的塑料颗粒定义为微塑料[1]。目前,微塑料没有国际公认的定义,对纳米塑料的尺寸分类仍然存在争议,在ISO/TR 21960—2020及一些研究中将纳米塑料尺寸范围定义为1~1 000 nm[2-4]。EFSA在2016年发布的报告中将微塑料定义为从0.1 μm到5 mm的塑料颗粒[5-6]。依据产生途径,微塑料可分为在人工生产过程中直接产生的原生微塑料和由塑料产品受到光照、外力、风化等物理化学作用破坏而形成的次生微塑料[7]。这些不同来源的塑料颗粒释放到环境中并最终可能通过水和空气进入食物链[7-11]。全球多个国家均报道了在饮料、啤酒、牛奶、蜂蜜、海产品、蔬菜肉类等食品中发现了微塑料,并证实了微塑料在人体粪便、血液、胎盘中等的存在[12-15]。

最近的一些研究发现,除了水源与空气,食品加工过程、储存过程、食用过程,甚至清洗过程中都有可能有微塑料的产生[7,16-20]。因此食品接触材料(Food Contact Materials,FCM)中微塑料释放的问题也日益引起人们广泛关注。例如奶瓶奶嘴、外卖餐具、烘焙模具、可折叠电热壶、水瓶、不粘锅、电饭煲中的密封圈等常用于高温高湿环境,在反复高温水热条件下易释放大量的微塑料[21-28]。欧盟食品和饲料类快速预警系统(Rapid Alert System for Food and Feed,RASFF)将塑料食品包装材料列为关注重点[29],并从2017年至2020年共通报食品、饲料以及食品相关产品中塑料颗粒、碎片等异物156例。然而,食品接触材料中微塑料释放的浓度普遍偏低,相关研究起步较晚,对其释放微塑料的分离富集及识别是一项挑战。

为了更好地理解食品接触材料中微塑料如何被释放和识别,笔者对食品接触材料中微塑料的释放途径、影响因素及其检测技术进行系统地阐述,并通过不同技术的比较,提出从样品处理到颗粒分析的整个路线图。

1 食品接触材料中微塑料的释放及其影响因素

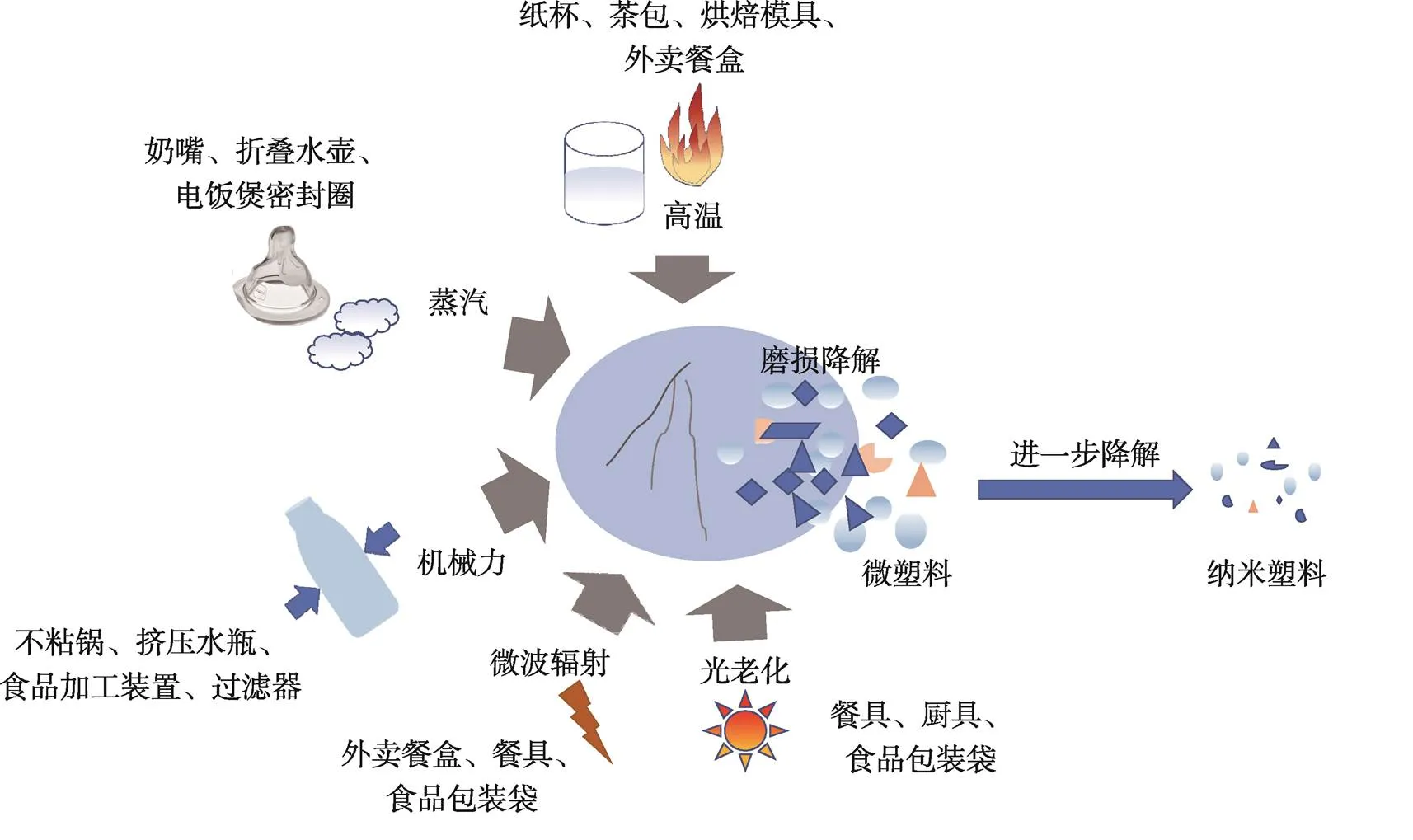

塑料由于来源丰富、价廉、可塑性强、力学性能好、物理化学稳定性好等优点,成为广泛应用的食品接触材料,包括聚乙烯(Polyethylene,PE)、聚丙烯(Polypropylene,PP)、聚苯乙烯(Polystyrene,PS)、聚氯乙烯(Polyvinyl Chloride,PVC)、聚对苯二甲酸乙二醇酯(Polyethylene Terephthalat,PET)、聚偏二氯乙烯(Polyvinylidene Chloride,PVDC)、聚碳酸酯(Polycarbonate,PC)等。在食品的运输和使用过程中,这些材料受到一定的物理、化学或生物作用(湿、热、光、机械力、微生物等),导致它们破碎成不同形状的微尺寸颗粒,即微塑料[30]。此外,降解过程不会停止,而是继续将微塑料降解为纳米尺寸的颗粒(纳米塑料)(图1)。

研究表明,温度、蒸汽、外部机械力、微波辐射及光老化是造成食品接触材料磨损、剥落并产生微塑料的主要原因。研究发现暴露在高温下(100 ℃)的灭菌的奶瓶,其聚丙烯的有序结构和无定型内部结构受到一定破坏,比未灭菌奶瓶释放更多的微塑料颗粒[27]。餐盒、茶袋及纸杯也具有相似的结果,温度的升高促进了塑料的磨损,增加了微塑料颗粒的释放[31-34]。Sobhani等[35]发现,在剪切、撕裂、切割或打开等食品包装时,会有0.46~250个颗粒/cm微塑料的释放。Du等[36]研究发现轻微机械力导致的食物或餐具与容器内表面的摩擦可导致微塑料的剥落和污染。Luo等[37]发现洗碗海绵在使用时,机械摩擦可导致尼龙和聚酯微塑料的脱落。Winkler等[38]评估了一次性矿泉水瓶在机械力作用下微塑料的释放情况,研究发现,聚对苯二甲酸乙二酯瓶颈和高密度聚乙烯帽是微塑料的主要来源,特别是在延长机械应力(开和关过程)的情况下。此外,在生产、运输或其他过程的磨损也会积累微塑料的释放,墨西哥对8个国际品牌的牛奶样本进行分析发现,热塑性砜类聚合物微塑料存在于所有的分析样本中,而它来源于牛奶加工过程中使用的薄膜过滤器的磨损[39]。矿泉水瓶在灌装过程中,高压和流体压力在瓶体上产生剪切应力,并最终产生刮擦力,也同样会释放微塑料[40-42]。

图1 食品接触材料中微塑料的释放

2 食品接触材料中微塑料的检测技术

2.1 食品接触材料中微塑料的分离富集

食品接触材料的样品主要来自食品包装、餐具厨具、食品加工机械等。不同类型的样品,前处理有所不同。对于矿泉水、饮料等食品包装样品,由于其有机物基质和复杂颗粒较少,可以直接采用过滤的方式将瓶中液体中的微塑料分离[43]。在一些情况下,为了研究特定条件下微塑料的产生会增加一些步骤,例如在研究机械作用对水瓶中微塑料释放的影响,采用多次开合瓶和挤压等预处理[38]。存在有机物复杂混合物(如矿物质、脂肪及蛋白质)时,需要先进行特定的预处理。例如一些研究采用螯合剂(乙二胺四乙酸)和表面活性剂(十二烷基磺酸钠)将钙和镁离子与螯合剂络合,溶解钙镁碳酸盐颗粒,以取得更好的样品均匀性和高通量的过滤效果。对富含脂肪和蛋白质等有机物的样品,研究中普遍使用酸碱消化(NaOH、KOH、HNO3和HCl)、氧化剂(H2O2和芬顿试剂)和酶这几种方法去除有机材料,减少微塑料鉴定过程中的干扰[44-45]。

对餐具、厨具等微塑料释放的研究,研究者们大多是先模拟真实使用的场景,例如将奶瓶在高温下进行灭菌[27],在纸杯和食品容器中注入合适温度的水[34,46],用洗碗海绵在盘子上反复摩擦[37]或改变样品储存条件[47],随后再将收集的溶液过滤分离。需要注意的是,由于食品接触材料释放的微塑料颗粒尺寸较小,对大多数样品需要进一步进行浓缩和富集。例如一些研究中利用超滤、微滤、纳滤、渗透、超速离心、旋转蒸发、冷冻干燥等方法来收集更小尺寸的塑料颗粒[30, 48-52]。此外,固相微萃取技术也被用于微塑料颗粒的提取中。Ouyang等[53]基于固相微萃取技术建立了一种袋装茶迁移过程中微塑料和初级芳香胺一体化富集预处理方法。这样一体化的样品预处理技术为食品安全样品中微塑料和有害分子的一步法测定提供了新的思路和技术。

2.2 食品接触材料中微塑料的分析方法

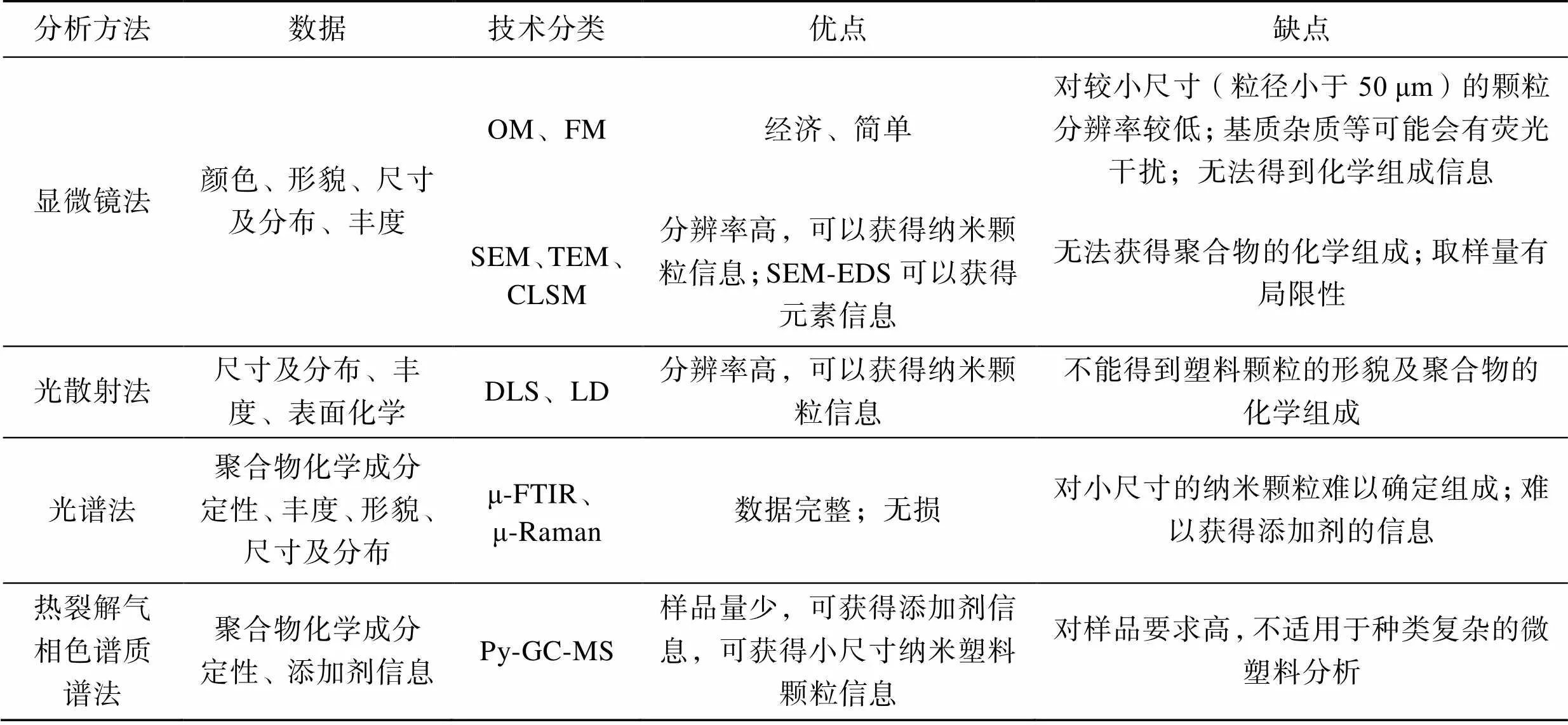

对食品接触材料中微塑料的分析主要是对微塑料的物理特性(尺寸、形貌)和化学特性(微塑料成分的定性和定量)进行表征(表1)。目前文献中使用的表征方法有显微镜法、光散射法、光谱法和热裂解气相色谱质谱法。

表1 食品接触材料中微塑料的分析方法及其特点

Tab.1 Analysis methods and characteristics of microplastics in food contact materials

2.2.1 显微镜法

显微镜是获得微塑料样品形态样品的有力手段。其中,光学显微镜(OM)、荧光显微镜(FM)、电子显微镜(SEM/TEM)和共焦激光显微镜(CLSM)是最常用的分析方法。

光学显微镜可以根据形状和颜色等颗粒形态特征识别微塑料。为了提高检测的效率,常将样品荧光染色后再结合荧光显微镜进行观察计数,可以更容易地对微塑料进行测定。这种方法也被用于聚酯水瓶、聚丙烯食品盒、聚苯乙烯盒、高密度聚乙烯袋、三聚氰胺碗等食品接触材料中微塑料的研究[47, 54-55]。然而这种测试方法对大体积的样品来说是耗时的,并且对粒径小于50 μm的颗粒是不合适的。此外,塑料颗粒的老化和透明颗粒使目视法具有更大的挑战性。因此,目前研究多是采用光谱与光学显微镜联用的方法,能更准确地识别微塑料。扫描电镜(SEM)可以提供微塑料的尺寸、形态等多种信息,高倍扫描电镜还可以观测到食品接触材上的裂缝、表面裂纹、凹槽等,有利于分析微塑料的产生和降解模式[34, 56-57]。另外,SEM与能谱仪(EDS)可以获得微塑料的元素组成,利于微塑料的溯源分析。Makhdoumi等[58]通过SEM-EDS发现聚乙烯微塑料从食品容器中释放到食用醋中,并且除C外,还具有O、Al、Na、Cl等元素,从而推测这些元素可能来自塑料添加剂或周围介质中。透射电子显微镜(TEM)由于经加速和聚集的电子束投射到非常薄的样品上,具有很高的分辨力,且能够提供颗粒内部而非表面的信息,也常用于纳米塑料的识别中[59-60]。另外,共焦激光显微镜(CLSM)在荧光显微镜成像的基础上加装了激光扫描装置,经常被用来研究荧光染色的纳米塑料粒子在生物体内的转移[59]。Stock等[61]使用了共焦荧光显微镜研究了不同粒径(1、4、10 μm)的球形荧光聚苯乙烯(PS)微塑料颗粒在胃肠道中的吸附和输运的情况。

显微镜的技术可以提供食品接触材料中微塑料颗粒的高分辨图像和多层次信息,但只能对样品特定区域进行测定,容易遗漏信息,导致结果偏差。此外,它们也不能提供微塑料化学成分更多的信息。

2.2.2 光散射法

光散射法是利用激光在微塑料的散射来获得颗粒的物理信息。动态光散射(DLS)可以通过悬浮液的激光束强度波动对1~3 mm内的颗粒进行测定。Oriekhova等[62]通过DLS测定了纳米塑料悬浮液,以了解这些纳米塑料颗粒表面电荷的变化。Deng等[32]将PE和PP食物容器在微波炉加热后,利用DLS分析了浸出液中200~800 nm内聚酯和聚丙烯的粒径分布,并用SEM图像加以佐证。激光衍射(LD)是另一种基于静态激光散射的技术,能够测定10 nm~10 mm内的颗粒,因此,可以同时表征多孔塑料、亚微米塑料[63]。Seghers等[64]指出由于DLS计算模型是基于球体的,激光衍射法高估了所有粒子的实际体积,并且来自基质、聚集体或灰层残留物的大颗粒污染物可能会掩盖实际的分析物。此外,DLS没有提供任何化学信息,无法区分形状相似但化学成分不同的颗粒。

2.2.3 光谱法

红外光谱和拉曼光谱由于非破坏性、高分辨率、低样品量测试的特点经常被应用于食品接触材料中微塑料的定性分析。值得注意的是,研究发现当PP、PE、PET、PS等包装材料老化降解,并产生微塑料释放到环境中时,其表面会发生一定的化学变化,明显改变了原始的光谱图,这为微塑料的成分鉴定带来困难。因此一些研究者建议将聚合物的老化光谱纳入数据库,以获得更准确的匹配效果[65]。由于食品接触材料在使用过程中释放微塑料的尺寸较小,目前的研究大多是将红外光谱技术与成像技术结合的方式。受限于红外的波长,显微红外(μ-FTIR)一般识别的最小尺寸为10~20 μm,可获得颗粒成分、丰度、形貌、尺寸及分布等多层次的信息[28, 60, 66]。

O-PTIR光热红外显微成像技术是一项快速简单的非接触式光学技术,其空间分辨率可以提高至几百纳米,可直观判断亚微米尺度下塑料表面的降解情况。Su等[26]利用O-PTIR发现硅橡胶奶嘴蒸汽消毒后的表面及清洗后的水中出现了大量聚二甲基硅氧烷弹性体和聚酰胺的微(纳米)塑料(尺寸为0.6~332 μm),并追踪了奶嘴在蒸气消毒不同时间后的老化降解过程,将塑料水解、氧化、刻蚀、颗粒迁移和脱落可视化表达。

显微拉曼(μ-Raman)是食品接触材料中微塑料检测的有力手段。其识别的最小极限尺寸为1 μm,可以识别塑料瓶、玻璃瓶、饮料纸盒等食品包装释放的小于20 μm的微塑料颗粒[41]。由于μ-Raman可以获取到波长600 cm−1以下的信息,更有利于鉴别出有机及无机的添加剂和涂料。但由于μ-Raman是通过物体表面的散射信号来确定物质成分,对尺寸较小的颗粒普遍信号较弱,很多研究中需要采用增强技术提高信号强度[67-68]。Luo等[22]采用拉曼成像来扫描不粘锅的表面,并收集光谱作为光谱矩阵,创建了一种新的混合算法来提取特氟龙微塑料,特别是纳米塑料的极弱信号,以表征和量化微塑料和纳米塑料。另外,值得注意的是,由于样品中某些有机成分也会产生荧光,可能会影响检测分析的准确性。可见,红外光谱与拉曼光谱在识别微塑料时,各具优势,将2种光谱结合使用会更有利于微塑料的准确识别。

2.2.4 热裂解气相色谱质谱法

热裂解气相色谱-质谱(py-GC-MS)是表征食品接触用材料中微塑料的一种有效技术。这种技术的一个主要优点是Py-GC-MS对微小质量的样品具有很高的灵敏性,有利于识别纳米塑料,并且在分析过程中可以同时表征聚合物本身和样品中存在的有机添加剂。Gerhard等[69]对7种不同的婴儿奶瓶中微塑料的释放进行了研究。结果发现与其他研究中光谱结果不同,Py-GC-MS证明了并无PP和PA微塑料检出,只有脂肪酸等从奶瓶中释放。这可能是在瓶体生产中经常用作脱模剂的脂肪酸酯等添加剂的迁移和沉淀的结果。迁移的添加剂可能导致微塑料颗粒的假阳性误差,这是聚合物在受热实验条件下需要考虑的关键问题。Kirstein等[70]比较了μ-FTIR成像和Py-GCMS 2种方法被应用于实际饮用水中微塑料的评估。2种方法都成功地测定了饮用水中低含量的微塑料颗粒。然而,μ-FTIR和Py-GCMS在MP含量总体较低的样品中发现了不同的聚合物类型。因此,Py-GC-MS和光谱技术在鉴定微塑料方面的互补性也得到研究者的证明。在一项研究中发现,相较于微衰减全反射傅里叶变换红外光谱,Py-GC-MS能够给出与添加剂相关的化学信息,但分析速度缓慢,且无法识别出某些合成纤维的成分[71]。由于大多数风险评估研究都与颗粒的大小、形状和数量有关,像FTIR成像这样的光谱技术是必不可少的,但对于建模、质量平衡研究及其监测,Py-GC/MS则是首选的方法。因此在工作流程中,应结合2种技术进行识别和量化[72]。

2.3 食品接触材料微塑料的检测方案

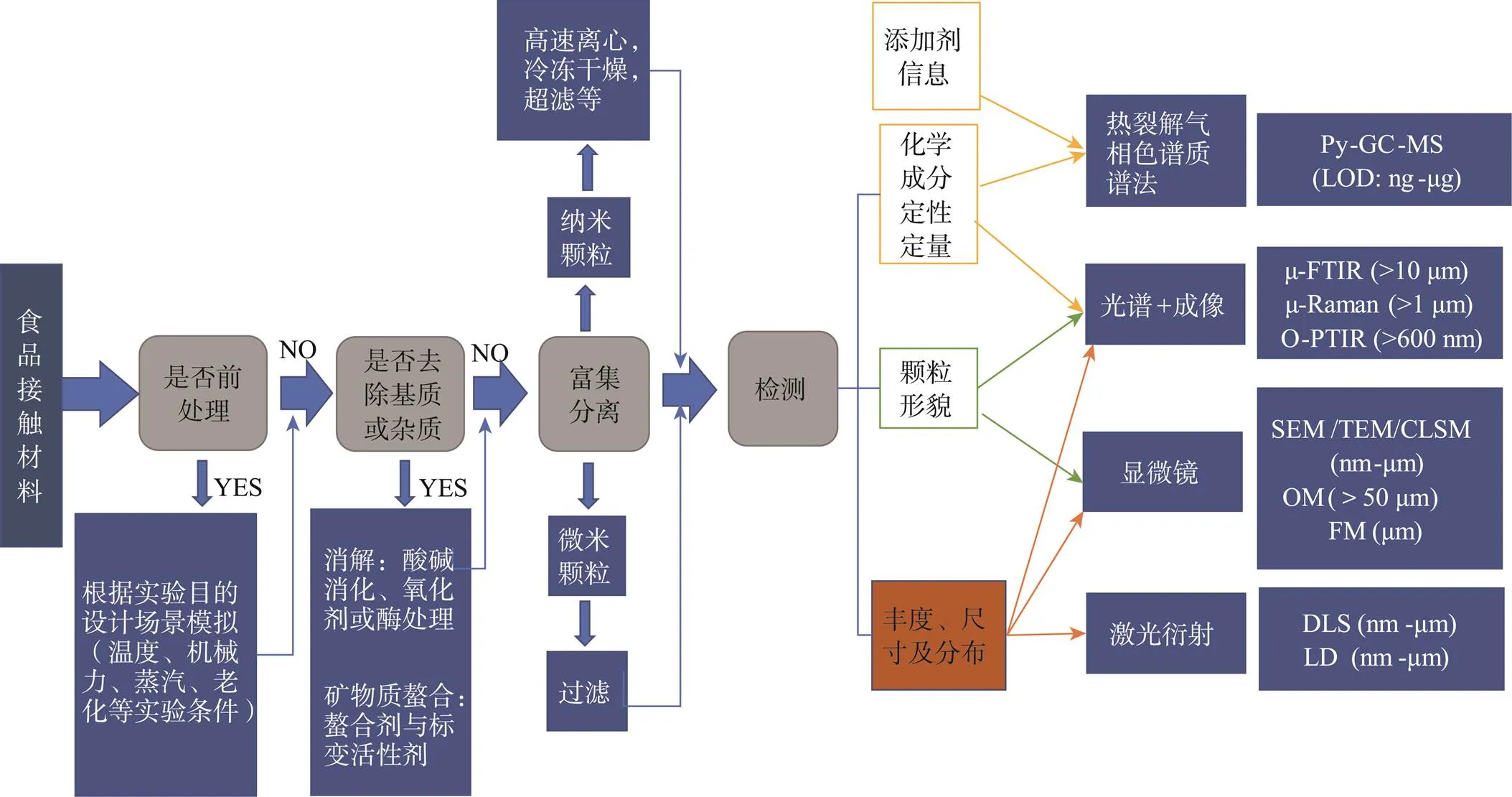

从以上总结来看,有多种技术方法用于识别来源于食品接触材料中微塑料的特性,并且它们各有优缺点,需要结合使用以获取最佳的实验结果。目前,由于缺乏统一的试样收集流程和检测方法,各种实验方案、数据采集和仪器的巨大差异也给结果的对比带来了困难。目前市场上日益增多的食品接触材料种类也增加了找到合适方法的挑战性。基于此,对目前文献中所出现的食品接触材料中微塑料的检测方法,提出了一个具有代表性的检测流程(图2),包括微塑料的分离富集及其定性和定量所采用的方法、设备和技术,为制定更适合食品接触材料中微塑料的检测方案提供依据。

如图2所示,针对不同的情况采用不同的技术路线。首先,需要根据采样的场景、研究目标以及样品的特性选择预处理(温度、蒸汽、机械力、老化等实验条件)或除去基质杂质(消化或矿物质螯合等)的实验步骤。随后,根据颗粒尺寸采取不同的分离富集方式。通过浓缩和分离过程后,对微塑料进行化学成分定性定量、颗粒形貌、丰度、尺寸及分布等检测分析,根据仪器的适用范围可选择最少且最优的组合方式。值得注意的是,需要避免各种来源(空气、实验服、仪器设备等)的二次污染。同时,在实验过程中需要空白实验确认在处理和分析过程中是否有其他污染。

图2 食品接触材料中微塑料的检测分析示例框架

3 结语

综上所述,概述了食品接触材料释放微塑料的影响因素,总结了微塑料的分离富集方法,并阐述了显微镜法、光散射法、光谱法及热裂解气相色谱质谱法等多种最新的分析技术。通过比较它们的适用范围和特点,提出了具有代表性的食品接触用材料中微塑料从样品处理到颗粒分析的框架和技术路线图。针对不同的样品特性、采样场景和研究目的,有必要选择和组合多样化的技术,以达到最优的路径。

目前来说,具有标准化的分析方法和检测技术处理仍是食品接触材料中微塑料风险评估的一大挑战,还亟待提出更为规范的标准化操作流程和检测技术,以提高结果准确性。另外,需要注意的是食品接触材料中微塑料尺寸普遍较小,而纳米塑料即使采用多种表征技术也难以被准确识别。因此纳米颗粒的分离富集、表征分析及其毒理学评估数据的进一步突破也是食品接触材料中微塑料风险评估的关键。同时,添加剂等化学物质的迁移也可能造成微塑料假阳的现象,此类化学物质在高温等条件下的迁移及其与微塑料的相互作用等研究也需要进一步得到关注。

[1] THOMPSON R C, OLSEN Y, MITCHELL R P, et al. Lost at Sea: Where is all the Plastic?[J]. Science, 2004, 304(5672): 838.

[2] GIGAULT J, TER HALLE A, BAUDRIMONT M, et al. Current Opinion: What is a Nanoplastic?[J]. Environmental Pollution, 2018, 235: 1030-1034.

[3] SCHWAFERTS C, NIESSNER R, ELSNER M, et al. Methods for the Analysis of Submicrometer- and Nanoplastic Particles in the Environment[J]. TrAC Trends in Analytical Chemistry, 2019, 112: 52-65.

[4] ISO/TR 21960: 2020: DS/CEN ISO/TR 21960, Plastics-Environmental Aspects-State of Knowledge and Methodologies[S].

[5] HOOGENBOOM L A P. Statement: Presence of Microplastics and Nanoplastics in Food, with Particular Focus on Seafood[J]Efsa Journal, 2016, 14(6): 04501.

[6] SHOPOVA S, SIEG H, BRAEUNING A, et al. Risk Assessment and Toxicological Research on Micro- and Nanoplastics after Oral Exposure via Food Products[J]. EFSA Journal European Food Safety Authority, 2020, 18: 181102.

[7] 胡佳玲, 张天龙, 陈杰, 等. 微塑料在食品中的来源及其检测技术研究进展[J]. 分析测试学报, 2021, 40(11): 1672-1680.

HU Jia-ling, ZHANG Tian-long, CHEN Jie, et al. Research Progresses on Source of Microplastics in Food and Their Identification Technology[J]. Journal of Instrumental Analysis, 2021, 40(11): 1672-1680.

[8] TOUSSAINT B, RAFFAEL B, ANGERS-LOUSTAU A, et al. Review of Micro- and Nanoplastic Contamination in the Food Chain[J]. Food Additives & Contaminants Part A, Chemistry, Analysis, Control, Exposure & Risk Assessment, 2019, 36(5): 639-673.

[9] OKEKE E S, OKOYE C O, ATAKPA E O, et al. Microplastics in Agroecosystems-Impacts on Ecosystem Functions and Food Chain[J]Resources Conservation and Recycling, 2022, 177: 105961.

[10] CVERENKAROVA K, VALACHOVICOVA M, MACKULAK T, et al. Microplastics in the Food Chain[J]Life-Basel, 2021, 11(12): 1349.

[11] MERCOGLIANO R, AVIO C G, REGOLI F, et al. Occurrence of Microplastics in Commercial Seafood under the Perspective of the Human Food Chain a Review[J]. Journal of Agricultural and Food Chemistry, 2020, 68(19): 5296-5301.

[12] YAN Ze-hua, LIU Ya-fei, ZHANG Ting, et al. Analysis of Microplastics in Human Feces Reveals a Correlation between Fecal Microplastics and Inflammatory Bowel Disease Status[J]. Environmental Science & Technology, 2022, 56(1): 414-421.

[13] ZHANG J J, WANG L, TRASANDE L, et al. Occurrence of Polyethylene Terephthalate and Polycarbonate Microplastics in Infant and Adult Feces[J]Environmental Science & Technology Letters, 2021, 8(11): 989-994.

[14] LESLIE H A, VAN VELZEN M J M, BRANDSMA S H, et al. Discovery and Quantification of Plastic Particle Pollution in Human Blood[J]. Environment International, 2022, 163: 107199.

[15] RAGUSA A, SVELATO A, SANTACROCE C, et al. Plasticenta: First Evidence of Microplastics in Human Placenta[J]. Environment International, 2021, 146: 106274.

[16] BAI C L, LIU L Y, HU Y B, et al. Microplastics: A Review of Analytical Methods, Occurrence and Characteristics in Food, and Potential Toxicities to Biota[J]Science of the Total Environment, 2022, 806: 150263.

[17] KWON J H, KIM J W, PHAM T D, et al. Microplastics in Food: A Review on Analytical Methods and Challenges[J]. International Journal of Environmental Research and Public Health, 2020, 17(18): 6710.

[18] BAI Cui-lan, LIU Liang-ying, GUO Jia-liang, et al. Microplastics in Take-out Food: Are we over Taking It?[J]. Environmental Research, 2022, 215: 114390.

[19] WEISSER J, BEER I, HUFNAGL B, et al. From the Well to the Bottle: Identifying Sources of Microplastics in Mineral Water[J]. Water, 2021, 13(6): 841.

[20] JIN Meng-ke, WANG Xue, REN Tao, et al. Microplastics Contamination in Food and Beverages: Direct Exposure to Humans[J]. Journal of Food Science, 2021, 86(7): 2816-2837.

[21] HE Ying-jie, QIN Yan, ZHANG Tie-li, et al. Migration of (Non-) Intentionally Added Substances and Microplastics from Microwavable Plastic Food Containers[J]. Journal of Hazardous Materials, 2021, 417: 126074.

[22] LUO Yun-long, GIBSON C T, CHUAH C, et al. Raman Imaging for the Identification of Teflon Microplastics and Nanoplastics Released from Non-Stick Cookware[J]. The Science of the Total Environment, 2022, 851: 158293.

[23] SCHWABL P. Microplastics in Hot Water[J]. Nature Food, 2020, 1(11): 671-672.

[24] SHI Y, LI D, XIAO L, et al. The Influence of Drinking Water Constituents on the Level of Microplastic Release from Plastic Kettles[J]Journal of Hazardous Materials, 2022, 425: 127997.

[25] KEDZIERSKI M, LECHAT B, SIRE O, et al. Microplastic Contamination of Packaged Meat: Occurrence and Associated Risks[J]. Food Packaging and Shelf Life, 2020, 24: 100489.

[26] SU Yu, HU Xi, TANG Hong-jie, et al. Steam Disinfection Releases Micro(Nano) Plastics from Silicone- Rubber Baby Teats as Examined by Optical Photothermal Infrared Microspectroscopy[J]. Nature Nanotechnology, 2022, 17(1): 76-85.

[27] LI D Z, SHI Y H, YANG L M, et al. Microplastic Release from the Degradation of Polypropylene Feeding Bottles During Infant Formula Preparation[J]Nature Food, 2020, 1(11): 746.

[28] ZHOU X J, WANG JREN J F. Analysis of Microplastics in Takeaway Food Containers in China Using FPA-FTIR Whole Filter Analysis[J]Molecules, 2022, 27(9): 2646.

[29] 寇筱雪, 黄华军, 蔡汶静, 等. 食品接触材料检测技术新进展[J]. 分析测试学报, 2022, 41(3): 409-417.

KOU Xiao-xue, HUANG Hua-jun, CAI Wen-jing, et al. New Progress on Detection Techniques for Food Contact Materials[J]. Journal of Instrumental Analysis, 2022, 41(3): 409-417.

[30] JADHAV E, SINGH SANKHLA M, BHAT R, et al. Microplastics from Food Packaging: An Overview of Human Consumption, Health Threats, and Alternative Solutions[J]. Environmental Nanotechnology Monitoring & Management, 2021, 16(1-4): 100608.

[31] LIU G Q, WANG J, WANG M J, et al. Disposable Plastic Materials Release Microplastics and Harmful Substances in Hot Water[J]Science of the Total Environment, 2022, 818: 151685.

[32] DENG Jing-yu, IBRAHIM M S, TAN Lang-yang, et al. Microplastics Released from Food Containers can Suppress Lysosomal Activity in Mouse Macrophages[J]. Journal of Hazardous Materials, 2022, 435: 128980.

[33] HERNANDEZ L M, XU E G, LARSSON H C E, et al. Plastic Teabags Release Billions of Microparticles and Nanoparticles into Tea[J]. Environmental Science & Technology, 2019, 53(21): 12300-12310.

[34] RANJAN V P, JOSEPH A, GOEL S. Microplastics and other Harmful Substances Released from Disposable Paper Cups into Hot Water[J]. Journal of Hazardous Materials, 2021, 404: 124118.

[35] SOBHANI Z, LEI Yong-jia, TANG You-hong, et al. Microplastics Generated when Opening Plastic Packaging[J]. Scientific Reports, 2020, 10(1): 4841.

[36] DU Fang-ni, CAI Hui-wen, ZHANG Qun, et al. Microplastics in Take-out Food Containers[J]. Journal of Hazardous Materials, 2020, 399: 122969.

[37] LUO Y L, QI F J, GIBSON C T, et al. Investigating Kitchen Sponge-Derived Microplastics and Nanoplastics with Raman Imaging and Multivariate Analysis[J]Science of the Total Environment, 2022, 824: 153963.

[38] WINKLER A, SANTO N, ORTENZI M A, et al. Does Mechanical Stress Cause Microplastic Release from Plastic Water Bottles?[J]. Water Research, 2019, 166: 115082.

[39] KUTRALAM-MUNIASAMY G, PÉREZ-GUEVARA F, ELIZALDE-MARTÍNEZ I, et al. Branded Milks - are they Immune from Microplastics Contamination?[J]. The Science of the Total Environment, 2020, 714: 136823.

[40] AMIN A. Occurrence of Microplastic Particles in the most Popular Iranian Bottled Mineral Water Brands and an Assessment of Human Exposure[J]. Journal of Water Process Engineering, 2021, 39: 1-8.

[41] SCHYMANSKI D, GOLDBECK C, HUMPF H U, et al. Analysis of Microplastics in Water by Micro-Raman Spectroscopy: Release of Plastic Particles from Different Packaging into Mineral Water[J]. Water Research, 2018, 129: 154-162.

[42] OßMANN B E, SARAU G, HOLTMANNSPÖTTER H, et al. Small-Sized Microplastics and Pigmented Particles in Bottled Mineral Water[J]. Water Research, 2018, 141: 307-316.

[43] SRIDHAR A, KANNAN D, KAPOOR A, et al. Extraction and Detection Methods of Microplastics in Food and Marine Systems: A Critical Review[J]. Chemosphere, 2022, 286: 131653.

[44] DIAZ-BASANTES M, CONESA J A, FULLANA A. Microplastics in Honey, Beer, Milk and Refreshments in Ecuador as Emerging Contaminants[J]. Sustainability, 2020, 12(14): 5514.

[45] AFRIN S, RAHMAN M M, HOSSAIN M N, et al. Are There Plastic Particles in My Sugar? A Pioneering Study on the Characterization of Microplastics in Commercial Sugars and Risk Assessment[J]The Science of the Total Environment, 2022, 837: 155849.

[46] GUAN Qing-fang, YANG H, ZHAO Y, et al. Microplastics Release from Victuals Packaging Materials during Daily Usage[J]. EcoMat, 2021, 3(3): 12107.

[47] HEE Y Y, WESTON K, SURATMAN S. The Effect of Storage Conditions and Washing on Microplastic Release from Food and Drink Containers[J]. SSRN Electronic Journal, 2021: 100826.

[48] KÄPPLER A, WINDRICH F, LÖDER M G J, et al. Identification of Microplastics by FTIR and Raman Microscopy: A Novel Silicon Filter Substrate Opens the Important Spectral Range below 1 300 cm‒1for FTIR Transmission Measurements[J]. Analytical and Bioanalytical Chemistry, 2015, 407(22): 6791-6801.

[49] HILDEBRANDT L, VOIGT N, ZIMMERMANN T, et al. Evaluation of Continuous Flow Centrifugation as an Alternative Technique to Sample Microplastic from Water Bodies[J]. Marine Environmental Research, 2019, 151: 104768.

[50] OßMANN B E, SARAU G, SCHMITT S W, et al. Development of an Optimal Filter Substrate for the Identification of Small Microplastic Particles in Food by Micro-Raman Spectroscopy[J]. Analytical and Bioanalytical Chemistry, 2017, 409(16): 4099-4109.

[51] LABORDA F, BOLEA E, CEPRIÁ G, et al. Detection, Characterization and Quantification of Inorganic Engineered Nanomaterials: A Review of Techniques and Methodological Approaches for the Analysis of Complex Samples[J]. Analytica Chimica Acta, 2016, 904: 10-32.

[52] LI P, KUMAR A, MA J, et al. Density Gradient Ultracentrifugation for Colloidal Nanostructures Separation and Investigation[J]Science Bulletin, 2018, 63(10): 645-662.

[53] OUYANG Xiao-yan, HU Yu-ling, LI Gong-ke. Integrated Sample-Pretreatment Strategy for Separation and Enrichment of Microplastics and Primary Aromatic Amines in the Migration of Teabag[J]. Journal of Separation Science, 2022, 45(4): 929-937.

[54] MASON S A, WELCH V G, NERATKO J. Synthetic Polymer Contamination in Bottled Water[J]. Frontiers in Chemistry, 2018, 6: 407.

[55] KANKANIGE D, BABEL S. Smaller-Sized Micro-Plastics (MPs) Contamination in Single-Use PET-Bottled Water in Thailand[J]. The Science of the Total Environment, 2020, 717: 137232.

[56] MARAZUELA M D, KLAIBER M, MORENO- GORDALIZA E, et al. Safety Assessment of Commercial Antimicrobial Food Packaging: Triclosan and Microplastics, A Closer Look[J]Food Packaging and Shelf Life, 2022, 31: 100780.

[57] FADARE O O, WAN Bin, GUO Liang-hong, et al. Microplastics from Consumer Plastic Food Containers: Are we Consuming It?[J]. Chemosphere, 2020, 253: 126787.

[58] MAKHDOUMI P, NAGHSHBANDI M, GHADERZADEH K, et al. Micro-Plastic Occurrence in Bottled Vinegar: Qualification, Quantification and Human Risk Exposure[J]Process Safety and Environmental Protection, 2021, 152: 404-413.

[59] WANG Qiang-qiang, BAI Jia-lei, NING Bao-an, et al. Effects of Bisphenol a and Nanoscale and Microscale Polystyrene Plastic Exposure on Particle Uptake and Toxicity in Human Caco-2 Cells[J]. Chemosphere, 2020, 254: 126788.

[60] SONG Ke, DING Run-run, SUN Cai-yun, et al. Microparticles and Microplastics Released from Daily Use of Plastic Feeding and Water Bottles and Plastic Injectors: Potential Risks to Infants and Children in China[J]. Environmental Science and Pollution Research International, 2021, 28(42): 59813-59820.

[61] STOCK V, BÖHMERT L, LISICKI E, et al. Uptake and Effects of Orally Ingested Polystyrene Microplastic Particles in Vitro and in Vivo[J]. Archives of Toxicology, 2019, 93(7): 1817-1833.

[62] ORIEKHOVA O, STOLL S. Heteroaggregation of Nanoplastic Particles in the Presence of Inorganic Colloids and Natural Organic Matter[J]. Environmental Science: Nano, 2018, 5(3): 792-799.

[63] XU R L. Light Scattering: A Review of Particle Characterization Applications[J]Particuology, 2015, 18: 11-21.

[64] SEGHERS J, STEFANIAK E A, LA SPINA R, et al. Preparation of a Reference Material for Microplastics in Water-Evaluation of Homogeneity[J]. Analytical and Bioanalytical Chemistry, 2022, 414(1): 385-397.

[65] FERNANDEZ-GONZALEZ V, ANDRADE-GARDA J M, LOPEZ-MAHIA P, et al. Impact of Weathering on the Chemical Identi Fication of Microplastics from Usual Packaging Polymers in the Marine Environment[J]Analytica Chimica Acta, 2021, 1142: 179-188.

[66] LUO X, WANG Z Q, YANG L, et al. A Review of Analytical Methods and Models Used in Atmospheric Microplastic Research[J]Science of the Total Environment, 2022, 828: 154487.

[67] KÄPPLER A, FISCHER D, OBERBECKMANN S, et al. Analysis of Environmental Microplastics by Vibrational Microspectroscopy: FTIR, Raman or Both?[J]. Analytical and Bioanalytical Chemistry, 2016, 408(29): 8377-8391.

[68] LIANG Z, CHU Y, GEN M, et al. Single-particle Raman Spectroscopy for Studying Physical and Chemical Processes of Atmospheric Particles[J]Atmospheric Chemistry and Physics, 2022, 22(5): 3017-3044.

[69] GERHARD M N, SCHYMANSKI D, EBNER I, et al. Can the Presence of Additives Result in False Positive Errors for Microplastics in Infant Feeding Bottles?[J]Food Additives and Contaminants Part a-Chemistry Analysis Control Exposure & Risk Assessment, 2022, 39(1): 185-197.

[70] KIRSTEIN I V, HENSEL F, GOMIERO A, et al. Drinking Plastics? - Quantification and Qualification of Microplastics in Drinking Water Distribution Systems by µFTIR and Py-GCMS[J]. Water Research, 2021, 188: 116519.

[71] PEÑALVER R, ARROYO-MANZANARES N, LÓPEZ- GARCÍA I, et al. An Overview of Microplastics Characterization by Thermal Analysis[J]. Chemosphere, 2020, 242: 125170.

[72] PRIMPKE S, FISCHER M, LORENZ C, et al. Comparison of Pyrolysis Gas Chromatography/Mass Spectrometry and Hyperspectral FTIR Imaging Spectroscopy for the Analysis of Microplastics[J]. Analytical and Bioanalytical Chemistry, 2020, 412(30): 8283-8298.

Release and Detection of Microplastics in Food Contact Materials

YAO Jing-jing, WEI Cun-qian, SUN Meng-jie

(Shanghai Institute of Quality Inspection and Technical Research, Shanghai 201114, China)

The work aims to discuss the release pathway and detection technology of microplastics from food packaging, tableware, kitchenware, processing machinery and other food contact materials, so as to provide suggestions for the selection of microplastics in food contact materials and analysis methods of diversified combinations, and provide basis for monitoring and research of microplastics and related toxic and harmful substances in food contact materials. The release pathways and affecting factors of microplastics in food contact materials were overviewed. The separation and enrichment technology of microplastics in food contact materials, as well as various detection technologies such as microscopy, light scattering, spectroscopy and pyrolysis gas chromatography-mass spectrometry were systematically expounded. The application scope and characteristics of different technologies were compared and analyzed, and the framework and technical pathway of representative microplastics in food contact materials from sample treatment to particle analysis were put forward to identify the chemical composition, morphology, abundance, size and distribution of microplastics. For different samples and scenarios, it is necessary to select and combine a variety of technologies to achieve the optimal path. At the same time, standardized analysis methods and detection technologies are still a big challenge for microplastics risk assessment in food contact materials. More standardized operating procedures and detection technologies are needed to improve the accuracy of results.

food contact materials; microplastic; release; sample pretreatment; identification technology

O657

A

1001-3563(2023)19-0033-09

10.19554/j.cnki.1001-3563.2023.19.005

2023-06-08

上海市2022年度“科技创新行动计划”启明星项目(扬帆专项)(22YF1444700);上海市质量监督检验技术研究院科技项目(KY-2021-16-QH);上海市科委研发公共服务平台项目(14DZ2293000)

责任编辑:曾钰婵