Experimental study on sand production and coupling response of silty hydrate reservoir with different contents of fine clay during depressurization

2023-08-30XiangyuFangDianhengYangFulongNingLinjieWangZhichaoLiuYanjiangYuWenweiXieHongfengLuYanlongLiMengXu

Xiangyu Fang ,Dianheng Yang ,Fulong Ning ,* ,Linjie Wang ,Zhichao Liu ,** ,Yanjiang Yu ,Wenwei Xie ,Hongfeng Lu ,Yanlong Li ,Meng Xu

a Faculty of Engineering,China University of Geosciences,Wuhan,430074,China

b Anhui Nuclear Exploration Technology Central Institute,Wuhu,241000,China

c National Center for International Research on Deep Earth Drilling and Resource Development,China University of Geosciences,Wuhan,430074,China

d MLR Key Laboratory of Marine Mineral Resources,Guangzhou Marine Geological Survey,Guangzhou,510075,China

e Laboratory for Marine Mineral Resources,Qingdao National Laboratory for Marine Science and Technology,Qingdao,266071,China

Keywords:Natural gas hydrate Clayey silt reservoir Clay content Depressurization Sand production Sand control

ABSTRACT To further understand the characteristics of clay and sand production(hereafter collectively referred to as sand production) and to provide optimization designs of sand control schemes are critical for gas production from clayey silt natural gas hydrate reservoirs in the South China Sea.Thus,gas-water-sand production behavoirs and coupling reservoir subsidence characteristics before,during,and after hydrate dissociation of the clayey silt hydrate reservoirs with different clay contents (5%,10%,15%,20%,25%,and 30%) have been studied through a self-developed experimental system.The results show that with the increase of clay content,the total mass of sand production first increases and then decreases,and it reaches maximum when the clayey content is 20%.The sand production is the lowest before hydrate dissociation and increases significantly during hydrate dissociation,which mainly occurs in the highspeed gas and water production stage at the beginning of hydrate dissociation.After hydrate dissociation,the sand production decreases significantly.During the whole depressurization process,the clay and free sand particles generally move to the sand outlet due to the fluid driving force and overlying stress extrusion.However,for conditions of high clay contents,those particles fail to pass through the sand control screen and gradually accumulate and block the screen by forming a mud cake,which greatly reduce the permeability of the screen and limite sand production as well as gas and water production.Our research lays a foundation for sand production prediction and sand control scheme selection during gas recovery from clayey silty hydrate reservoirs that greatly need to consider a balance between sand control and gas productivity.

1.Introduction

Natural gas hydrate (hereafter referred to as hydrate) is an icelike solid substance formed by water and gas under high pressure and low temperature conditions.In nature,hydrates are mainly distributed in marine sediments and high-latitude permafrost regions[1,2].The amount of hydrate resources estimated by the total amount of natural gas locked up in hydrates is approximately 2 × 1016m3,equivalent to twice the global carbon content of conventional fossil energy (coal,oil and natural gas);therefore,hydrate is regarded as a new,clean,alternative energy source for the future [3-5].More than 97% of hydrate resources are in the ocean [1],and the commercial exploitation of hydrates under the seafloor is an important topic in the field of energy research.China has conducted three hydrate production tests in the marine area and listed hydrates as the 173rd mineral in 2017 [6].

However,marine hydrate reservoirs are shallowly buried and mainly consist of weakly consolidated or underconsolidated clayey and sandy sediments.Hydrate phase transition and fluid flow during exploitation lead to dynamic coupling changes of mechanical properties,porosity,permeability and thermal properties,which lead to several geological engineering problems,such as sand production.Judging from the hydrate production test projects that have been carried out worldwide[7-20],sand production is an inevitable phenomenon during hydrate exploitation,creating a bottleneck that restricts the long-term safe,efficient,and controllable exploitation of hydrate [21-24].To solve this problem,it is necessary to understand the rules and mechanics of sand production.

Many scholars have previously studied the rules and mechanics of sand production[25-35]and appropriate sand control methods[36-38] during hydrate exploitation by laboratory experiments and numerical simulations.The preliminary results of these studies show that the source of sand is mainly fine particles in the hydrate reservoir,and the flow rate of the fluid,especially water flow rate,is the dominate factor in sand production.When the permeability of the reservoir is observed to decrease,the sand production caused by stress extrusion failure is enhanced.Hydrate saturation,hydrate decomposition rate,water production rate,and the formation and destruction of sand bridges all affect sand production behavior with stage characteristics.Selecting appropriate sand control methods is of vital importance for the sustainable exploitation of hydrate reservoirs.

The above studies mostly focus on sandy hydrate reservoirs,however,the target hydrate reservoirs in the South China Sea are usually comprised clayey silt deposits.Compared with sandy hydrate reservoirs,clayey silt hydrate reservoirs have a finer particle size and lower permeability,and the sand production problems,as well as the contradiction between sand control and productive economy,may be more prominent [39,40].In addition,sand production under different clay contents and different stages of hydrate decomposition remains understudied.Sand production,which are strongly coupled with fluid production and formation deformation in space and time evolutions,is urgent to clarify.

Therefore,this study focuses on sand production behaviors of silt hydrate reservoirs with different clay contents and interpretates experimental research on the temperature and pressure changes,gas and water production,formation settlement,and sand production characteristics that occur during the entire cycle of hydrate production before,during,and after the decompression process.This study can provide a reference and guide for the analysis of fluid-sand production and the optimization of sand control technology during the exploitation of clayey silty hydrate reservoirs.

2.Experimental method

2.1.Apparatus

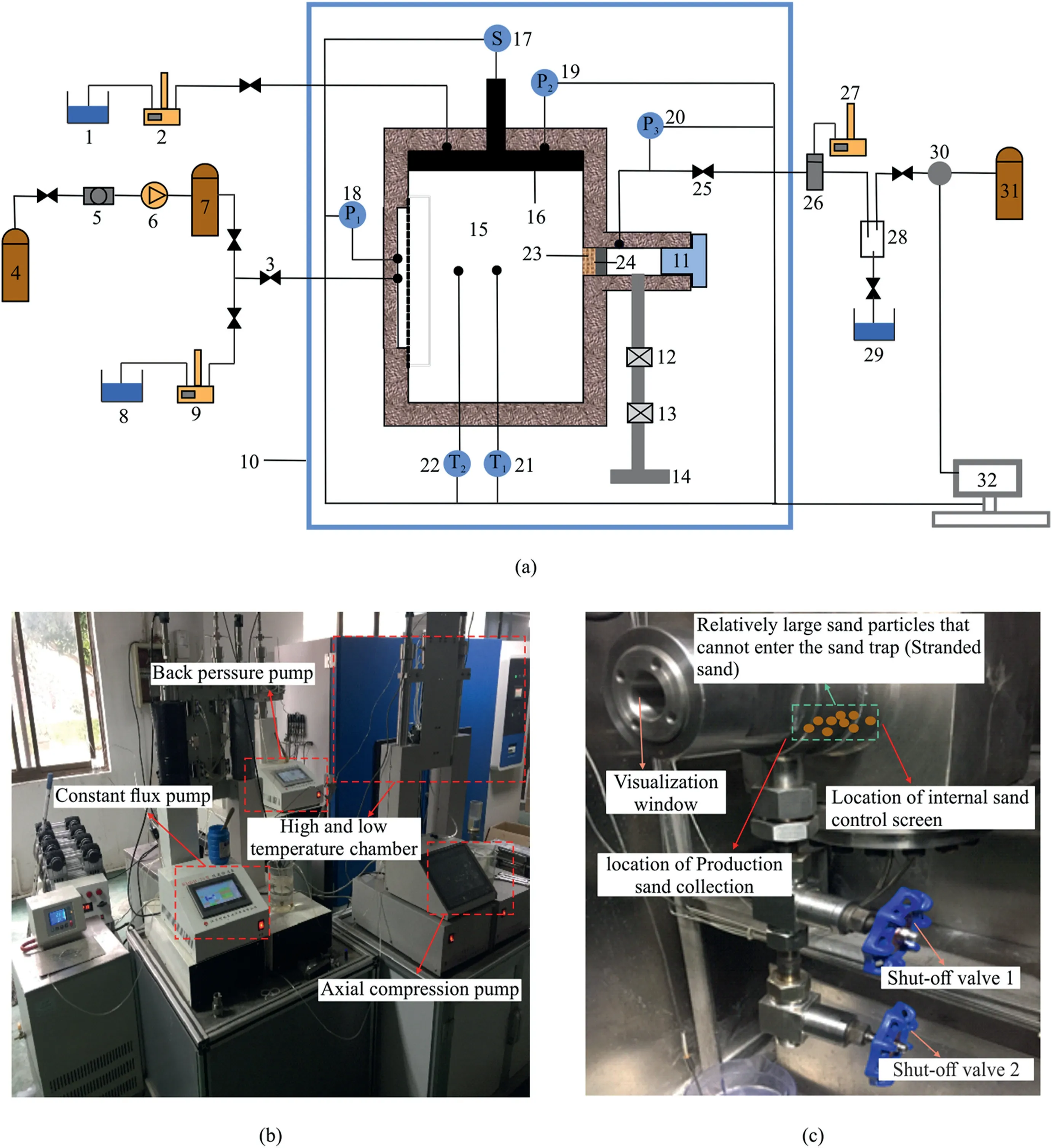

Fig.1 shows a self-developed sand production and control apparatus for gas hydrate-bearing sediments.The experimental apparatus consisted of a high-pressure reactor,temperaturecontrol subsystem,pressure-control subsystem,fluid-injection subsystem,gas-liquid-solid separation subsystem,and dataacquisition subsystem.Fang et al.[41] had introduced the parameters and functions of each part of this experimental device in detail.

Fig.1.(a) Schematic diagram of the experimental apparatus: 1.Distilled water tank;2.Axial compression pump;3.Inlet valve;4.Gas cylinder;5.Pressure regulating valve;6.Booster pump;7.Buffer tank;8.Constant temperature water tank;9.Constant flux pump;10.High and low temperature chamber;11.Visualization window;12.Shut-off valve 1;13.Shut-off valve 2;14.Sand collector;15.Reactor;16.Piston;17.Displacement sensor;18.Inlet pressure sensor;19.Axial pressure sensor;20.Outlet pressure sensor;21.Temperature sensors 1;22.Temperature sensors 2;23.Sand screen;24.Perforated supporting steel plate;25.Outlet valve;26.Back-pressure valve;27.Back-pressure pump;28.Gas-liquid separator;29.Water collecting bottle;30.Gas flow bottle;31.Gas collecting bottle;32.Computer.(b) Temperature,pressure and fluid injection subsystems.(c) Visualization window and outlet of high-pressure reactor.

2.2.Materials

The methane gas (purity ≥99.9%) used in the experiment was supplied by Jiangsu Hongren Special Gas Co.,Ltd.Quartz powder with a median particle size of 27.6 μm was purchased from Lianyungang Hongding Quartz Co.,Ltd.The simulated mud composition was approximately 2500 mesh montmorillonite and illite,provided by Hunyuan Junhong New Materials Co.,Ltd.Deionized water was prepared using an LD-DI-Micro-20 Liding deionized water machine from our laboratory.The clay content of 5%,10%,15%,20%,25% and 30% in silty sand hydrate reservoirs was adjusted by changing the mud content in the samples,and the mud was composed of montmorillonite and illite at a 1:1 mass ratio.Fig.2 presents the sample particle size distribution curve obtained using a laser particle size analyzer.According to the sand control criterion of Ding et al.[35],the size of the sand control screen was 3.8-4.2 times the median particle size of the formation sand.To better observe the behavior of sand production,the size of the sand control screen was appropriately expanded,and a sand screen of 80-mesh(approximately 180 μm)was used.In the experiment,a support plate with perforated hole diameter of 3 mm was used to support the sand screen and ensure its stability.

Fig.2.Grain size distribution of silty sand hydrate reservoirs with different clay contents.

The average hydrate saturation of clayey silt hydrate reservoirs is 13.7%-45.2%in the Shenhu Sea area of the South China Sea[19].Therefore,a 30% hydrate saturation was selected for this experiment and generated using quantitative deionized water.Hydrate saturation was calculated based on two basic assumptions: (1) all deionized water was converted into hydrate;and (2) the volume ratio of the water to hydrate was 1:0.87.This volume ratio was derived from hydrates in situ and other reference values used by researchers to test the mechanical properties of hydrate-bearing sediments [42],as follows:

whereVh(L) is the volume of hydrate andVw(L) is the volume of water.Therefore,hydrate saturation can be estimated according to the saturation of the pore water in the sample,as follows:

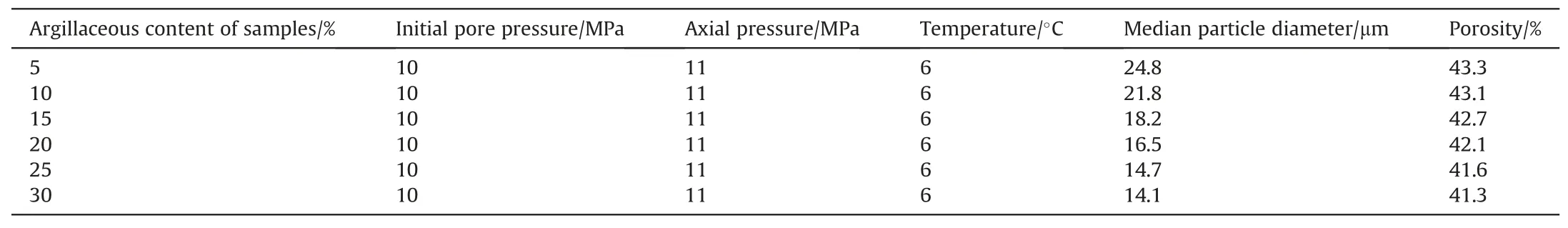

whereSh(%)is the saturation of hydrate,Sw(%)is the saturation of water,Vp(L)is the pore volume of the sample,Vs(L)is the volume of the sample,and Φ(%)is the porosity of the sample.The amount of deionized water needed in the experiment was estimated using Eq.(3).The porosity of the sample was measured using a mercury injection apparatus,and the clay content,median particle size,and porosity parameters of the sample are listed in Table 1.

2.3.Experimental procedure

The mixed skeleton particles were fully stirred with the quantitative deionized water at a specific proportion calculated using Eq.(3) and were stored for 24 h before being loaded into the reactor.Methane gas was continuously injected into the reactor to remove residual gas from the reactor.An axial pressure pump was used to apply an axial pressure of 11 MPa to the sample to simulate the overlying stress.The axial pressure was maintained at 11 MPa throughout the experiment.Subsequently,methane gas was injected into the reactor.When the inlet and outlet pressures reached 10 MPa,the CH4gas cylinder was closed,and the temperature of the high and low temperature chambers were set at 6°C to observe the formation of hydrate.Meanwhile,the buffer tank remained open to ensure an adequate supply of CH4.The increase in the temperature and drop in the inlet and outlet pressures indicated that hydrate formation had begun.When the pressure stopped decreasing and remained stable for more than 1 h,the hydrate growth was considered complete,and all deionized water in the sample was converted into hydrate.The hydrate distribution prepared by this method was mostly cemented [43].The backpressure valve was set at 10 MPa,and the outlet valve was opened.Deionized water at a temperature of 8°C was injected into the reactor through a constant flux pump at a flow rate of 6 mL/min.When the inlet and outlet pressures reached 10 MPa,the water injection was stopped.At this point,a sand-hydrate-watermethane gas system existed in the reactor.The backpressure valve was controlled by a backpressure pump to depressurize the reactor and simulate hydrate exploitation.The depressurization rate of the backpressure pump was set to 0.25 MPa/min,and the outlet pressure gradually dropped from 10 MPa to 0.1 MPa within 40 min.Then,the value remained stable at approximately 0.1 MPa.

During the depressurization process,methane gas was monitored in real time using a gas flow meter,and water was collected every 4 min.The mud and sand produced entered the sand collector through shut-off valves 1 and 2.When it was necessary to collect the mud and sand produced,shut-off valve 1 was opened,and the mud and sand particles entered the rigid tube between the two shut-off valves.After the system was left standing for a while,shut-off valve 1 was closed,shut-off valve 2 was opened,and the mud and sand particles entered the sand collector.Finally,shut-off valve 2 was closed,the sand collector was removed,and the mud and sand produced were dried and weighed.

In this experiment,the decrease in the temperature during depressurization indicated that the hydrate had begun to decompose.Hydrate decomposition ended when the temperature dropped to its lowest point[44].To study the sand production behavior before,during,and after hydrate decomposition,the first sand collection operation was carried out when the temperature began to decline,corresponding to the sand production conditions before hydrate decomposition.When the temperature dropped to its lowest point,the second sand collection operation was carried out,corresponding to the sand production conditions during hydrate decomposition.After depressurization,a third sand collection operation was carried out,corresponding to sand production conditions after hydrate decomposition.During this experiment,some of the produced sand had a relatively large particle size,passed through the sand control screen but could not enter the sand collector during water flow (Fig.1c).After the experiment was complete,the visual window was removed to collect the stranded sand,which is referred to as the fourth sand collection.The total amount of mud and sand produced was equal to the sum of the four sandcollecting operations.

3.Results

3.1.Characteristics of temperature and pressure responses

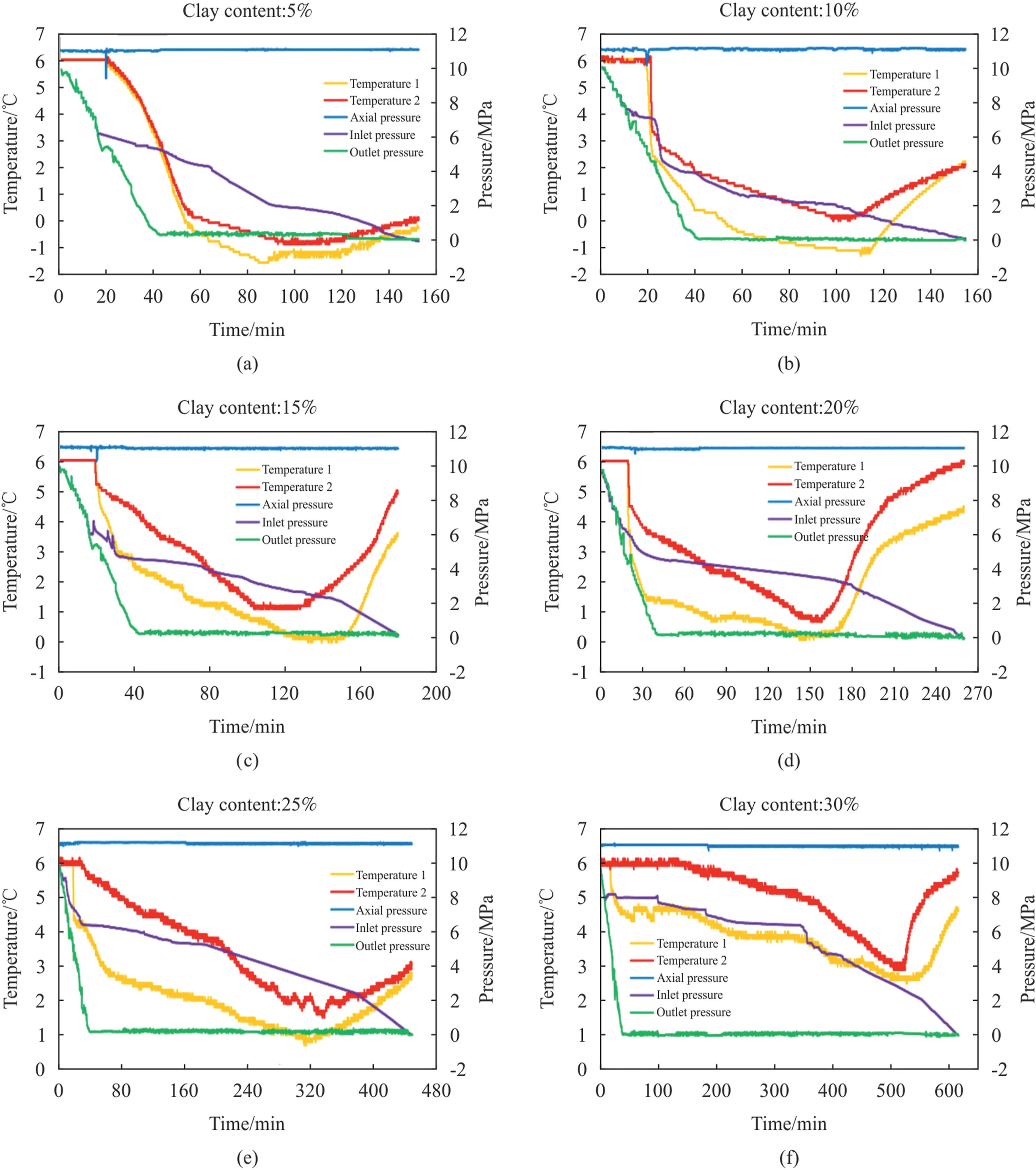

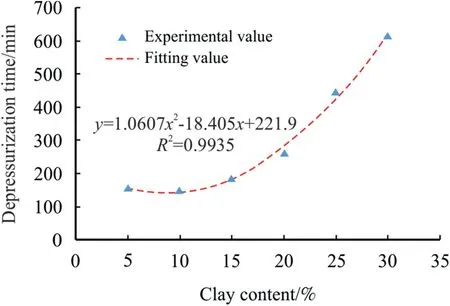

Fig.3 shows the variations in temperature,axial pressure,and inlet and outlet pressures during depressurization of the synthesized silty sand hydrate samples with different clay contents.When the clay content increased from 5% to 30%,the time required to release the inlet pressure to 0.1 MPa was 153,155,180,259,449 and 616 min,respectively.The relationship between the pressurereleasing time and clay content was found to be polynomial (see Fig.4).The higher the clay content,the more difficult the pressure transfer and the longer the pressure-releasing time.In the initial stage of depressurization,the effective stress of the reservoir changed very little,and the inlet pressure decreased simultaneously with the outlet pressure decreasing.During depressurization,a mud cake gradually formed at the screen mesh,resulting in poor permeability of the screen mesh.Meanwhile,the inlet pressure varied independently from the outlet pressure,and gradually and slowly decreased to 0.1 MPa.These phenomena indirectly indicate that the clay content has a significant influence on the formation permeability.The higher the clay content,the worse the reservoir permeability,and the slower the hydrate decomposition.

Fig.3.Responses of temperature and pressure changes of samples with different clay contents during depressurization.

Fig.4.Relationship between depressurization time and clay content of samples.

During depressurization before decomposition,there was no phase transition induced heat exchange caused in the reactor,and both temperatures 1 and 2 were maintained at approximately 6°C.As the depressurization process progressed,the hydrate began to decompose,and the temperature in the reactor rapidly dropped due to the endothermic reaction.The position of temperature 1 was closer to the outlet of the reactor (see Fig.1).Therefore,the decomposition rate of hydrate at the location of temperature 1 was faster and the decomposition degree was more severe than those values at the location of temperature 2.After hydrate decomposition completed,the temperature in the reactor no longer decreased,and due to the exchange of heat with the surroundings,temperatures 1 and 2 slowly increased to the surrounding temperature.During the entire process,the axial pressure was stable at 11 MPa.

When the clay content was 5%-15%,the axial pressure fluctuated downward for approximately 20 min.This fluctuation can be explained by the vast decomposition of hydrate at this time,which weakened the support and cementation effect of the hydrate and decreased the mechanical properties of reservoir [45].However,when the clay content was 20%-30% in the experiment,no axial pressure fluctuation was observed,which may be due to the high clay content,poor reservoir permeability,and slow hydrate decomposition.

3.2.Response characteristics of gas and water production and settlement

Fig.5 shows the variations in the instantaneous gas and water production and formation settlement during depressurization of silty hydrate-bearing samples with different clay contents.When the clay content was 5%,the instantaneous gas production presented a “parabolic” characteristic that with the depressurization process progressed,the instantaneous gas production increased and reached the peak value,and then began to decline at the end of the rapid hydrate decomposition.This behavior was mainly caused by the low clay content,which procuced slight blockage at the screen of sand control during the entire depressurization process,and relatively fast pressure transfer.When the clay content was 10%-30%,the fluidity of the sand control screen before hydrate decomposition was largely better than that at the later stage.The instantaneous water production was relatively large,and the instantaneous gas production fluctuated within the range of 0-2500 SCCM.This part of the produced gas was mainly residual free methane gas,which did not form hydrates in the reactor.Whenthe hydrate began to decompose,the hydrate dissipation and deficit effect and the increase in effective stress resulted in obvious fluctuations in the gas and water production.In the early stage,the effective stress compressive effect was not obvious,and the permeability enhancement effect by hydrate decomposition might have been dominant,resulting in the highest instantaneous water production and large instantaneous gas production,which is similar to the experimental phenomenon observed in Lu et al.[28].As pressure reduction continued,a mud cake was likely to form on the sand control screen,which reduced the permeability,and the instantaneous gas and water productions decreased.When the outlet pressure dropped to 0.1 MPa and before the hydrate was completely decomposed,the pressure drop in the reservoir mainly depended on the permeability of the sand control screen and sample.Therefore,instantaneous gas production was relatively stable and slowly decreased.At this stage,the instantaneous gas production and clay content approximately satisfied a relationship of negative exponential decline (Fig.6).After the hydrate was completely decomposed,sand and clay particles continued to accumulate around the sand control screen during depressurization.The instantaneous gas and water produced gradually decreased and eventually dropped to zero.

Table 1 Experimental sample parameters.

Fig.5.Responses of gas production,water production and settlement during the depressurization process of samples with different clay contents(I,II and III represent the stages before,during,and after hydrate decomposition,respectively).

Fig.6.Relationship between clay content and instantaneous gas production of samples (after the outlet pressure drops to 0.1 MPa and stabilizes).

In general,the higher the clay contents are,the more the clay minerals migrate to the outlet under the action of the fluid driving force and overburden stress extrusion.In addition,the more serious the screen blockage,the worse the permeability of the mud cake,and the lower the instantaneous gas and water production.Especially,when the clay content was 25%-30%,the instantaneous water production in the late stage of hydrate decomposition was only approximately 1-2 mL.

During depressurization,the amount of subsidence before decomposition of the hydrate was small,generally not more than 5 mm.When the hydrate began to decompose,the subsidence rate significantly increased.This may be due to the dissipation of solid hydrates and migration of water and gas.The mechanical properties of the reservoir deteriorated significantly [46],and the subsidence value was large over a short period of time when the sample was under the effect of overlying effective stress.Later,with continuous mining,the reservoir gradually“adapts”to the hydrate decomposition and flow effects under the gradually increasing effective overlying stress.The settlement slowed and eventually approached zero.Considering the size effect in the experiment,the reservoir would suffer the above subsidence response,but may not have such an obvious subsidence value in actual mining.

3.3.Response characteristics of sand production

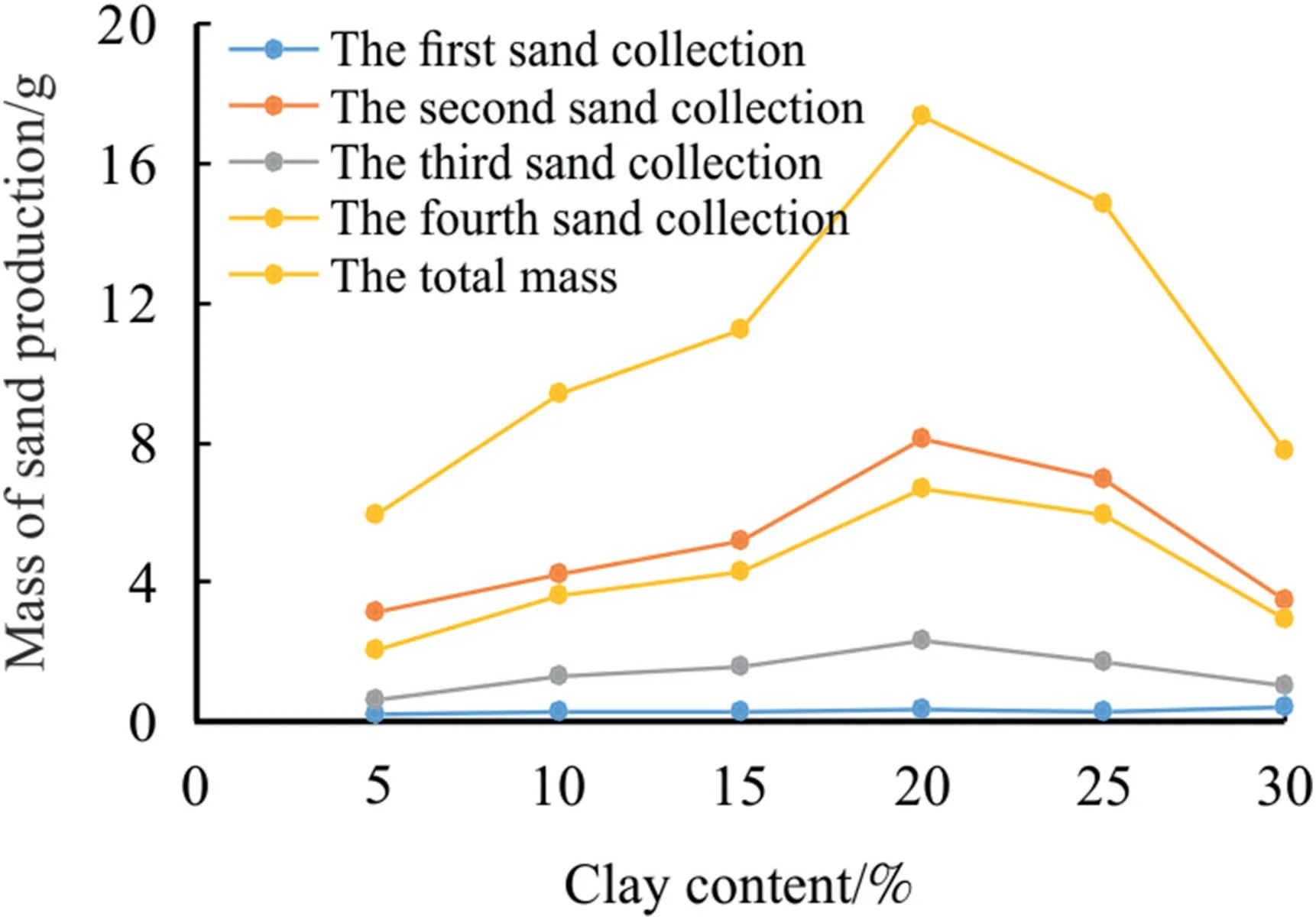

Fig.7 shows the four sand extractions of the hydrate-beairng samples with different clay contents during depressurization.The amount of sand produced during the first collection before hydrate decomposition was the smallest compared to those of other collection stages,and the amount of sand produced for each sample was less than 0.5 g.This part of the sand was mainly free particles produced by the erosion of pore water flow on the reservoir.The sand produced during the second,third,and fourth collections first increased and then decreased as the clay content increased above 20%.Thus,the highest total amount of sand produced also occurred when the clay content around 20%.

Fig.7.Relationship between sand production and clay content of samples.

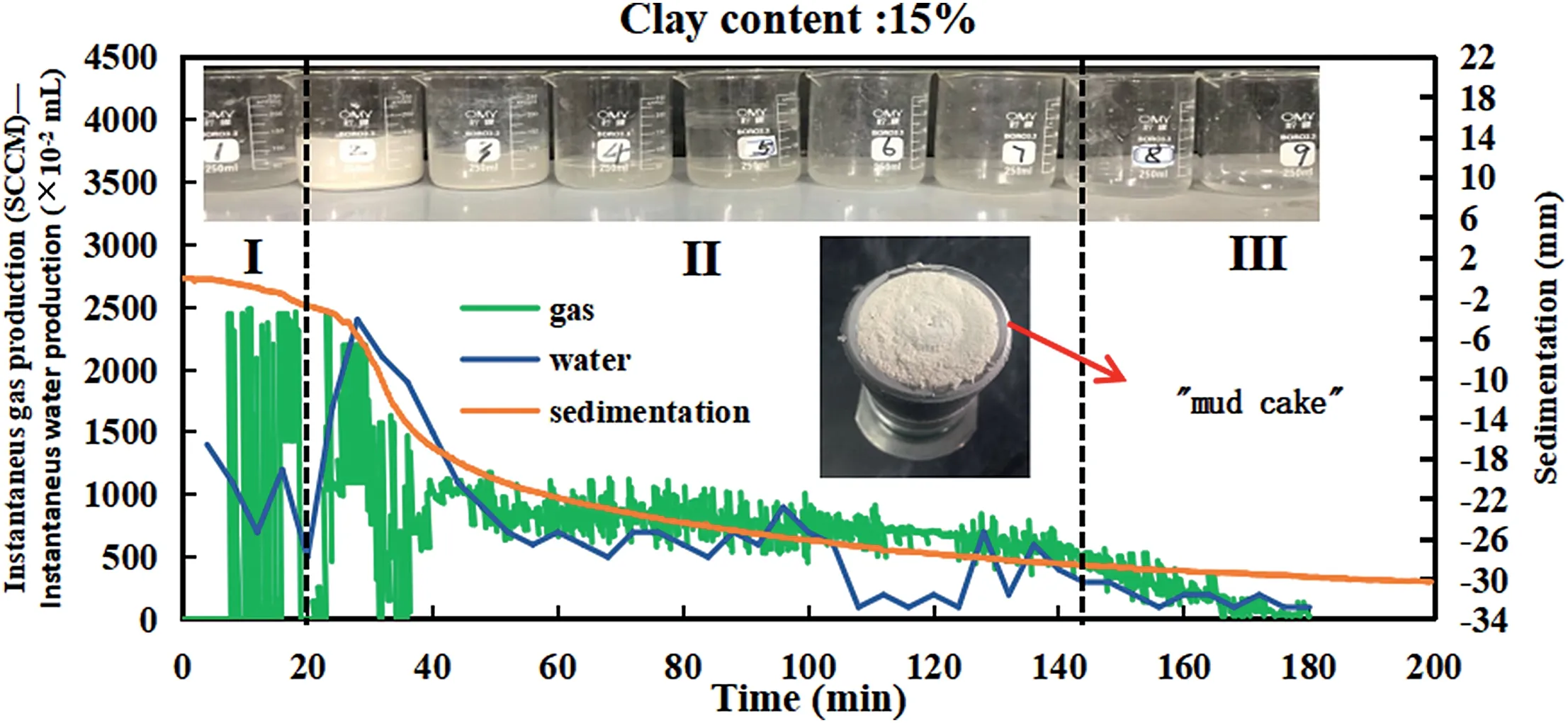

The variations in gas and water production,subsidence,and sand production during depressurization of other samples with different clay contents were similar.Fig.8 shows the overall changes in gas production,water production,subsidence,and sand production during depressurization when the clay content of sample was 15%,as well as a photo of the plugged sand control screen removed after the experiment and a sequence of the sand production collected during the experimental process.Before hydrate decomposition,the instantaneous gas and water productions were considerable,but the sand production was less due to the relatively intact sample.In the initial stage of hydrate decomposition,the instantaneous gas production and instantaneous water production were high,and there was no blockage at the screen;therefore,sand production was the largest.Later,a“mud cake” gradually formed on the screen,which was similar to the experimental phenomenon reported in Dong et al.[28,37].The formation of the “mud cake” limited sand and gas and water production,and the amount of sand produced gradually decreased.After hydrate decomposition,the amount of sand produced was small due to the sand retaining effect of the “mud cake” on the screen and the slow rate of water and gas production.

Fig.8.Gas production,water production,subsidence,and sand production during depressurization when the clay content was 15% (I,II and III represent the stage before,during and after hydrate decomposition,respectively).

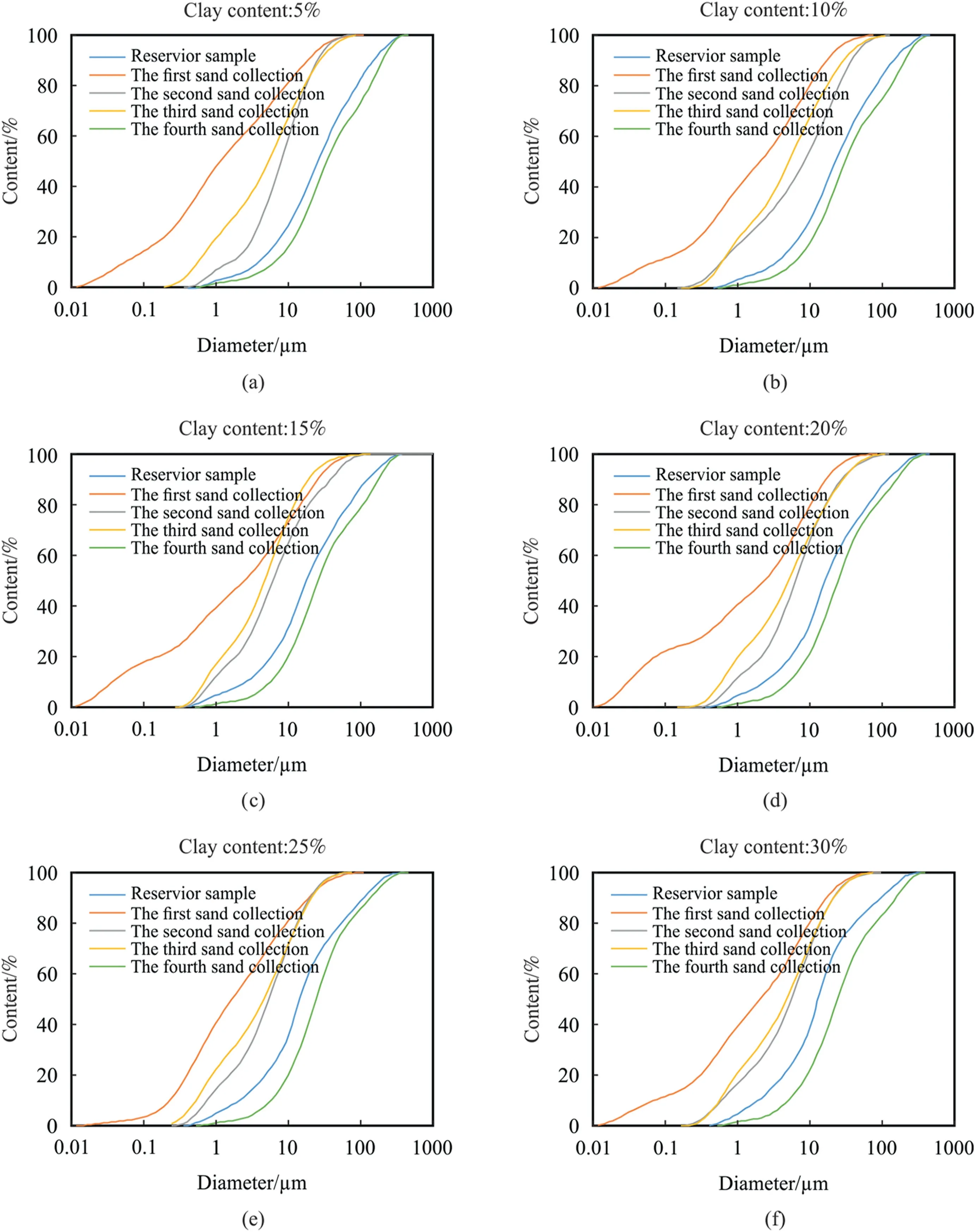

Fig.9 shows the particle size distributions of the four sand collections of samples with different clay contents.The median diameter of the first sand collection before hydrate decomposition was the smallest,at 1.15-2.55 μm.Those of the second and third sand collections were 5.55-8.24 μm and 4.59-5.29 μm,respectively.The particle size of sand production during decomposition(second sand collection)varied widely due to skeleon collapse and intense fluid flow.In addition,relatively fine particles of the third sand collection may be result from the weak fluid driving force.Based on the analysis of the sand production behaviors,combined with the observation of the visualization window and particle size distribution,the sand of fourth collection was most likely belonged to the initial stage of hydrate decomposition as its particle size varied at 23.9-34 μm.

Fig.9.Particle size distributions of the four sand collections of samples with different clay contents.

4.Discussion

4.1.Coupling behaviors among fluid-sand production,subsidence,and sand production

The sand production is closely related to fluid production and settlement behaviors (see Fig.8).Before depressurization,the hydrate reservoir was a weakly consolidated sand-water-hydrate-free gas system (Fig.10a).The sand and clay particles in the reservoir were in close contact due to the overlying stress.Part of the hydrate in reservoir supported and cemented the skeleton particles.In the depressurization stage before hydrate decomposition (Fig.10b),free gas and water were mainly produced.At this point,sand and clay did not accumulate on the sand screen,and the permeability was relatively good.Free gas and water can be produced during depressurization of outlet pressure.The sand and clay particles in the reservoir remained stable,and the movement of water had a denudation effect on the sand and clay particles.Several small particles were detached from the skeleton and became free to move[47];these particles migrated toward the sand outlet under the driving force of the fluid.In addition,the reservoir slowly subsided with the combined effect of sand production and effective stress increasing.

Fig.10.Mechanisms of gas production,water production,subsidence,and sand production of samples during different production stages:(a)initial state of reservoir;(b)the state before hydrate decomposition;(c)the initial state of hydrate decomposition;(d)the mid-late state of hydrate decomposition;(e)the state after hydrate decomposition;(f)the state of reservoir after depressurization.

When the hydrate began to decompose(Fig.10c),the supporting and cementation effects of the hydrate weakened,the stability of the reservoir was damaged,and the reservoir subsidence rate increased sharply under the overlying stress,resulting in many mobile free sand and clay particles [48,49].In addition,the reservoir permeability improved at the initial stage of hydrate decomposition,which migrated more free sand and clay particles to the sand outlet [29].However,during the above migration process,some of the clay particles failed to pass through the sand control screen,and the permeability of the sand control screen gradually decreased with continued clay particles plugging.Therefore,the initial stage of hydrate decomposition was the“high yield stage” of gas,water,and sand production.As the hydrate continuously decomposed(Fig.10d),an increasing number of sand and clay particles accumulated in the sand control screen,causing more serious blockage and gradually decreasing the permeability to the lowest value [50,51].Moreover,a layer of “mud cake” was gradually formed because of the existence of clay minerals,which furtherly limited sand,gas,and water production.In addition,the reservoir continued to settle under the effect of increasing overlying stress and sand production;however,the subsidence rate genrally decreased.

After hydrate decomposition(Fig.10e),no methane gas or water generated by hydrate decomposition was generated in the sample.Combined with the effect of the “mud cake” on the sand control screen,the instantaneous gas and water production rate as well as the sand production slowed.The subsidence rate of the reservoir corresponding slowed and became stable.After depressurization(Fig.10f),the reservoir was only composed of sand clay,and residual water,and the skeleton structure reached a new stable state under the compaction of the overlying stress.

4.2.Influence of clay content on sand production

As shown in Fig.11,fine particles were easy to migrate with the hydraulic force,which promoted sand production.However,the fine particles also preferred to form mud cakes that can limit sand production.Therefore,as the clay content increases,a higher sand production trend competed with the sand prevention trend.Fig.7 shows that there is a threshold for the influence of clay content on sand production,which was 20%under the simulated conditions of this experiment.When the clay content was 5%-20%,the rate of formation of low-permeability mud cake was relatively slow,and an increase in sand production caused by the increase in clay content dominated.When the clay content was 25%-30%,although a greater amount of sand was produced to migrate,but most of them were prevented by the mud cake,which leaded to a decreasement of sand production with the increase of clay content.

Fig.11.Mud cake formed on the sand control screen (orange represents sand particles,brown represents clay minerals).

During the field exploitation of silty sand hydrate reservoir,the approximate threshold of clay content can be determined using experimental simulations.Then,according to the clay content of different reservoirs,the characteristics of sand and gas and water production can be analyzed and evaluated.The appropriate completion and sand control methods based on the sand production characteristics of different production stages can be selected with the goal of moderate sand production and maximum productivity.

5.Conclusions

Based on the self-developed sand production and sand control system,we performed the experiments on sand production and coupling response of silty hydrate reservoir with different clay content.The conclusions were listed below.

(1) At the experimental scale,we find that the sand production,gas and water production,and subsidence of silty hydratebearing samples with different clay contents sharply increase when the hydrates begin to decompose.The sand production during hydrate decomposition is mainly concentrated at the initial stage of hydrate decomposition,and after that,the sand,gas,and water production and corresponding subsidence gradually decrease.

(2) During depressurization,sand and clay particles migrate to the sand outlet under the action of fluid flow.Some sand and clay particles accumulate and block the sand control screen,and gradually form a mud cake layer,which restricts sand production,gas production,and drainage.

(3) Under the experimental conditions,the sand production increases and then decreases as the clay content increases.Due to the promotion effect of clay particles and the sand prevention effect of mud cake,the amount of sand production reaches its peak value at the critical clay content of 20%.

Therefore,to achieve a balance between sand control and gas productivity,it is necessary to consider the relationship between the clay content and sand production,as well as the combined influence of clay content on gas production,water production,and reservoir settlement,and to select appropriate completion and sand control methods.In addition,the critical value of clay content may be also influenced by the hydrate saturation,reservoir temperature,and clay mineral types.Future research is needed to determine the influence of these factors on the critical value to better guide the gas production from silty sand hydrate reservoirs.

Declaration of competing interest

The manuscript is approved by all authors for publication.We authors confirm that no conflict of interest exits in the submission of this manuscript.The original work has not been published previously and is not under consideration for publication elsewhere,in whole or in part.

Acknowledgement

This work was supported by the National Key Research and Development Program of China (2018YFE0126400),the China Geological Survey Project (DD20190232),the Qingdao National Laboratory for Marine Science and Technology Open Fund(QNLM2016ORP0203),the Department of Natural Resources of Guangdong Province Project (GDNRC[2020]-047).

杂志排行

Petroleum的其它文章

- Super gas wet and gas wet rock surface: State of the art evaluation through contact angle analysis

- Petroleum system analysis-conjoined 3D-static reservoir modeling in a 3-way and 4-way dip closure setting: Insights into petroleum geology of fluvio-marine deposits at BED-2 Field (Western Desert,Egypt)

- Development and performance evaluation of a high temperature resistant,internal rigid,and external flexible plugging agent for waterbased drilling fluids

- Anti-drilling ability of Ziliujing conglomerate formation in Western Sichuan Basin of China

- Production optimization under waterflooding with long short-term memory and metaheuristic algorithm

- Investigation of replacing tracer flooding analysis by capacitance resistance model to estimate interwell connectivity