碳纤维复合材料漏斗车的机械性能仿真分析

2023-05-30王一奇杜俊锋张新奇高航

王一奇 杜俊锋 张新奇 高航

摘 要 本文借鑒GLASSHOPPER公司推出的漏斗车建立了碳纤维复合材料漏斗车结构模型,借助有限元仿真软件ABAQUS对漏斗车结构进行性能的仿真分析,其中包括静力学分析和动力学分析。根据《铁道车辆强度设计及试验鉴定规范》对所建立的碳纤维复合材料漏斗车模型分别进行了静强度、静刚度、模态的研究,分析和评价了漏斗车结构的整体和局部性能,并给出了改进意见。

关键词 碳纤维复合材料;铁路运输;漏斗车;性能分析与评价

ABSTRACT In this paper,the structural model of carbon fiber reinforced composite hopper car is established based on the hopper car launched by GLASSHOPPER company,the performance of the hopper car structure is simulated and analyzed with the help of finite element simulation software ABAQUS,including static analysis and dynamic analysis. According to the “Code for Strength Design and Test Appraisal of Railway Vehicles”,the static strength,static stiffness and modal of the carbon fiber reinforced composite hopper car model established were studied respectively,and the overall and local performance of the hopper car structure was analyzed and evaluated. Improvement suggestions are given.

KEYWORDS carbon fiber reinforced composites; railway transportation; hopper car; performance analysis and evaluation

1 Introduction

Carbon fiber reinforced composites have high stiffness, strength and strong mechanical properties, as well as a variety of comprehensive properties such as high strength, high modulus, low density and corrosion resistance[1-3], and can meet multiple design indexes of rail transit vehicles, such as vibration and noise reduction, collision energy absorption, fatigue resistance, environmental corrosion resistance, etc.[4,5]. Therefore, the application of carbon fiber reinforced composites in rail transit has become a trend to realize the lightweight of hopper car body and improve the vehicle transportation capacity. Compared with the hopper car with steel structure of the same model, the weight of the hopper car with glass fiber structure launched by GLASSHOPPER company is reduced by 4536kg, which greatly reduces the energy loss caused by the body weight and significantly reduces the transportation cost[6].

Static analysis is usually used to evaluate the safety and reliability of car body structure, and the simulation results have certain guiding significance for the research and development of hopper car body structure, and provide a basis for car body performance analysis and structural optimization. Li[7] used the discrete element method to analyze the lateral pressure on the car body, the distribution of pressure field and velocity field in the car body. Composites are different from traditional metal materials. Due to their anisotropic characteristics, the simulation analysis and experimental verification of composites are more complicated. Wang[8] used carbon fiber reinforced composites to optimize the free size and paving sequence of the cab hood of metro vehicles. Jeon[9] studied a DFPRP bogie frame applied to subway train, tested the stress and deflection in the connection area of cross beam and side beam, and evaluated the safety of the structure. Kim[10,11] tested the fatigue strength of the bogie according to the bogie for railway vehicles - General rules for design (JIS E4207-1992), and carried out finite element simulation combined with Tsai-Wu failure criterion. The results show that the fatigue life of the frame is long and the durability is good. Wang[12] designed and calculated the structural strength and natural frequency of carbon fiber head cover of urban rail vehicles, which can meet the use requirements. Dovhaniuk[13] verified the possibility of unloading three different types of hoppers on the car dumper through the finite element analysis of the stress-strain of the car body when unloading on the VRS-134M car dumper, and the calculation model has high accuracy.

Of course, the strength check of large-scale structures such as hopper car wall is the premise of the service performance of the car body structure, but the connection area, corner bending area and bottom unloading bottom door in the car body structure are also the focus of performance analysis. Wan[14] proposed a research method that can ensure that the bottom door of railway carriage with self-unloading coal hopper can realize the specified mechanical action accurately, timely and coordinately. Xie[15] predicted the fatigue life of the closing weld of the car body based on the equivalent structural stress method, and proposed the structural improvement of the gondola car through the characteristics of the structural stress distribution of the weld.

In the research of hopper car body structure optimization, many scholars adopt the method of local lightweight to make the hopper car meet the overall performance, meet the use requirements and the concept of energy conservation and emission reduction at the same time. Al-Sukhon[16] considered the honeycomb sandwich panel in the low load area, and realized the weight reduction and emission reduction capacity of the hopper car through iterative optimization calculation. Ruhmann[6] discussed the main advantages of designing and manufacturing covered hopper cars with composite materials for railway industry, and summarized the selection of materials, such as reinforcement, resin and adhesive, as well as the process used in the construction of two cars. Li[17] optimized the laying of a subway cars front cover based on the composite material optimization technology.

At present, there is little research on the overall structure simulation of carbon fiber reinforced composite railway transport hopper car. Therefore, combined with the relevant finite element analysis theory, this paper realizes a complete set of research processes such as model establishment, performance analysis and evaluation.

2 Structural dimensions of hopper car

The main structure of the hopper car is composed of the car body, the bottom door opening and closing structure, the braking device and the bogie. This paper mainly analyzes and studies the body wall structure of the hopper car.

The design of carbon fiber reinforced composite hopper car mainly refers to the glass fiber hopper car structure of model GLASSHOPPER II launched by GLASSHOPPER company[6], which has passed all the tests required by the American Railway Association. Therefore, it has great reference significance for the structural design of hopper car used in this study. The car body structure is mainly composed of side wall, head wall, head wall support and stiffener. Each composite sandwich panel constituting the wall is mainly composed of two layers of carbon fiber laminates and its internal I-shaped carbon fiber beam structure. At the same time, the I-shaped beams are filled with CASCEL foam for vibration and noise reduction. This type of foam is produced by Zhejiang Zhongke Hengtai new materials Co., Ltd. the CASCEL-RS used is designed and developed to meet the vacuum assisted injection and resin transfer molding process. The adhesive force between the foam core material and the skin material can be optimally balanced, and the weight of components can be effectively reduced. The structure and size details of the carbon fiber reinforced composite hopper car designed in this study are shown in Figure 1. The designed hopper car shall meet the requirements of 100t load and freight transportation. According to TB/T1335-1996 code for strength design and test appraisal of railway vehicles, the construction speed of the freight car shall not be greater than 120km/h. The specific dimensional parameters and performance parameters of the hopper car are shown in Table 1.

3 Establishment of simulation model

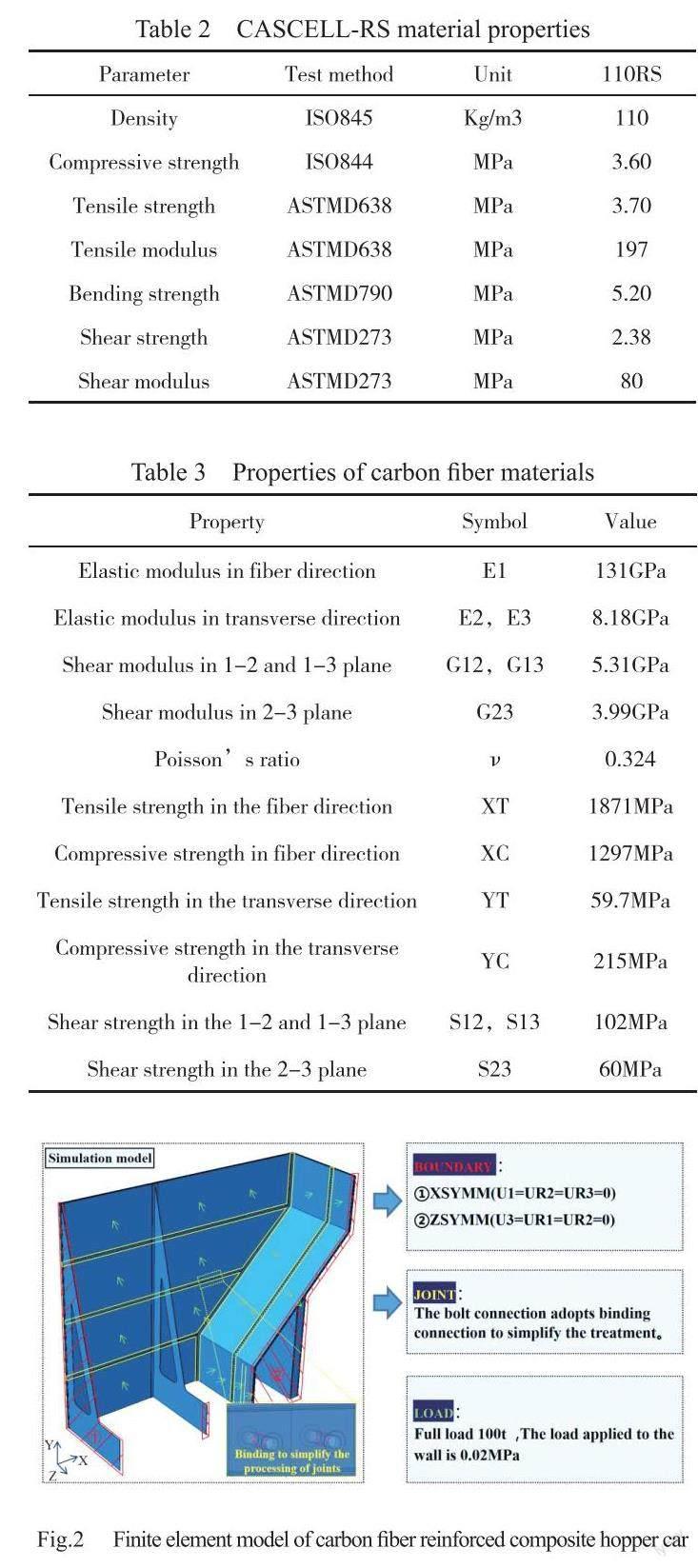

In this study, the commercial software ABAQUS CAE 2016 is used for finite element analysis, and the three-dimensional solid modeling is adopted. The boundary conditions, load, contact and other settings in the simulation are shown in Figure 2. The mechanical elastic material properties of laminates are input by lamina. Table 3 shows the material parameters input in the finite element. The selection corresponding to the grid properties of laminates is continuous shell element, and the number of grids in the thickness direction is 1. The material property parameters of CASCELL-110RS used are shown in Table 2.

Because the hopper car body designed in this study is a symmetrical structure, in order to improve the simulation efficiency, the model is symmetrically 1/4 of the original structure along its symmetry axis. In addition, the sandwich plates constituting the head wall and side wall are connected by bolts. In this study, the bearing performance of the overall structure of the hopper car is checked and analyzed, so the stress of the connection part is not considered. Through the binding treatment of the bolt hole, the complexity of the structure is greatly simplified and the risk of non convergence caused by bolt contact is reduced.

Based on TB/T1335-1996 standard, the side pressure of bulk granular goods acts on the vertical side/head wall. When only the side wall pressure is considered, the pressure per unit area is calculated according to formula (1):

where, is the pressure per unit area of the side wall, is the bulk density of bulk cargo, H is the actual loading height of bulk cargo,is the ratio of the vertical acceleration of the head wall at the height of the gravity center of the heavy-duty hopper car body to the gravity acceleration (generally 0.7), is the ratio of the longitudinal acceleration of the head wall at the center height of the heavy-duty hopper car body to the gravitational acceleration (generally 0.4), is the natural slope angle of bulk cargo.

In this study, the design target load of the dump truck is 100t and the trunk volume is about 100m3. Therefore, according to TB/T1335 standard, the side pressure of bulk goods is about 0.01MPa and the safety factor is 2.0. Therefore, the load applied to the side wall and head wall in the finite element analysis is 0.02MPa. In the research, the static strength, static stiffness and modal vibration mode of the hopper car will be analyzed under the full load state, and the improvement suggestions will be put forward.

4 Results and discussion

4.1 Static strength analysis of car body

Overall stress view - as shown in Figure 3 (a), the stress is mainly concentrated on the stiffeners connecting the two side walls in the hopper car body and the corner of the head wall. Because the left and right spans of the side walls are large and supported by three stiffeners, under the full load state of the hopper car, the side wall of the car body structure bears most of the lateral pressure, and the stiffeners on the outside bear more stress from above the side wall. It can be seen from table 4 that the maximum stress of the car body is less than the strength limit of the material, so the structural design of the carbon fiber reinforced composite hopper car can meet the use requirements. According to GB/T699-1999, the tensile strength of 45 steel is 600MPa and the yield strength is 355MPa. Therefore, the stiffener of 45 steel is slightly insufficient in its structural requirements.

As shown in Figure 3 (b), the stress borne by the side wall is mainly distributed on the side wall-plate 1 and the side wall-plate 2. These two laminated plates have a large span and a relatively large bearing area, and the stress is the largest at the connection between them and the stiffener 2. In addition, the stress at the connection between the side wall and the head wall is also large. The above problems can be solved by increasing the area of the connection area and increasing the number of side wall support structures.

As can be seen from Figure 3 (c), the maximum stress of the head wall is mainly at the bending part of the head wall, which is the area where stress concentration is easy to occur. The head wall support structure is a structural component to improve the stiffness of the head wall and the main structure to share the stress of the head wall. As shown in Figure 3 (d), the maximum stress occurs at the position where the head wall, side wall and head wall support are connected and intersected. The connection structure is complex and prone to stress concentration.

Figures 3 (e) and (f) respectively show the stress diagrams of the sandwich structure of the composite laminated plates of the side wall and the head wall. The sandwich structure in the laminated plate is the main structure to increase its bearing capacity and stiffness, and the stress is mainly borne by the I-beam stiffener. The CASCELL foam filled in the sandwich structure hardly plays the role of bearing the load. Figure 3 (f) shows that the stress is mainly concentrated at the connection part between the side wall and the stiffener, and close to the lower part of the side wall, which is caused by its own structural characteristics. Different from the overall stress diagram of the side wall in Figure 3 (b), the sandwich structure of the side wall is formed by bonding the stiffener structure with I-beam, which is not a continuous whole. Therefore, the stress has no continuity, so the stress is mainly concentrated at the connection position between the side wall and the stiffener. At the same time, the side wall-plate 1 near the upper part has a large span and weak rigidity, so it is subjected to greater stress.

Extracting the stresses on the individual path of the connected composite laminate in the side and end walls plots Figure 4 and Figure 5. It can be seen from Figure 4 that the stress of the side wall-plate 1 and side wall-plate 2 of the hopper car is mainly concentrated on both sides of the laminated plate and the connection part with the stiffener 2 during the loading process of goods. This is due to the hopper cars funnel shape, that is, the upper size gradually narrows to the lower side. As shown in Figure 5, the peak stress of the head wall plate occurs at these two bending parts, and the plate in the center of the head wall bears more load.

4.2 Static stiffness analysis of car body

Through the evaluation and analysis of the structural stiffness of the hopper car body, the overall stiffness performance, service performance and service life of the car body can be improved. The deflection calculation formula is shown in formula (3).

where, W is the maximum deflection in the beam span, L is the length of the beam, E is the elastic modulus of the material, I is the cross-sectional moment of inertia of the material.

As shown in Figure 6 (a), when the vehicle is full of goods, the maximum displacement in the hopper car body structure occurs on the side wall-plate 1. This is due to the funnel-shaped hopper car body, the side wall-plate 1 has a large span and poor rigidity, which is prone to side bending. As shown in Figure 6 (b), consistent with the above analysis structure, the maximum displacement in the side wall structure occurs at the side wall-plate 1 and plate 2 with large span and poor stiffness. As shown in Figure 6 (c), in the head wall structure, the maximum displacement occurs at the upper and lower sides of the head wall. Because these two parts have no structural support, the stiffness is relatively poor. As shown in Figure 6 (d), the overall displacement of the head wall support structure is slightly biased towards the middle of the structure.

In order to judge whether each component in the hopper car structure meets the stiffness evaluation requirements of the car body, the deflection span ratios of side wall-plate 1, plate 2, plate 3, plate 4, head wall-plate 1, plate 2 and head wall support are calculated respectively, which are calculated from the maximum vertical deformation and maximum span of the corresponding structure, the results are shown in Table 5. It can be seen from TB/T1335 standard that the recommended value of the evaluation standard for the deflection span ratio of freight car body is ≤ 1/1500. From the deflection span ratio calculated by each part of hopper car body in Table 5, it can be seen that side wall-plate 1, side wall-plate 2, head wall-plate 1 and head wall-plate 2 can not meet the allowable requirements in the specification. Therefore, in order to improve the structural stiffness of the side wall, we can increase the thickness of the side wall or increase the number of side wall stiffeners; The method to improve the structural stiffness of the head wall can be by increasing the thickness of the head wall or increasing the structural support in the area with large deformation of the head wall.

4.3 Modal analysis of car body

During the actual operation of freight cars, due to the increased vibration caused by the irregularity of some lines and the increase of vehicle speed, the frequency domain of random disturbance will be widened under the action of dynamic load, and the vertical and horizontal vibration acceleration of vehicles will increase[18,19]. By analyzing the natural frequency and vibration mode of the car body structure, we can master the dynamic characteristics of the car body, investigate the vibration characteristics of the structural system through modal analysis, and judge the rationality of the stiffness of the car body structure, so as to provide a basis for the improvement and optimization design of the car body structure.

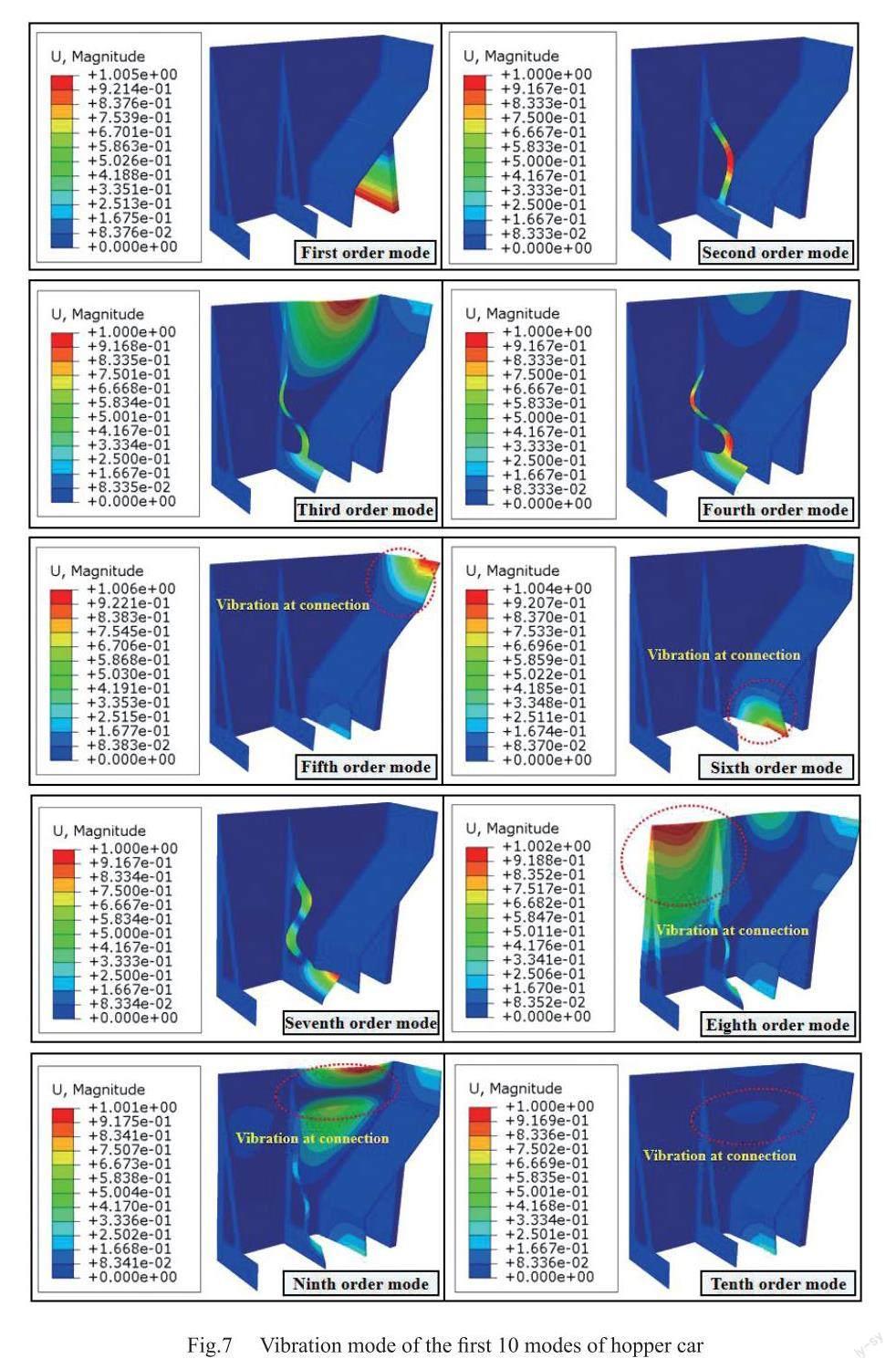

The car body is mainly composed of plate and beam bolt connection, and its structure may have local vibration and avoid resonance should be considered. In order to avoid the harmful effect of vibration coupling, the international railway union stipulates that in order to avoid the harm of resonance and local vibration, the first-order vertical bending modal frequency of the car body in servicing state should be higher than 10Hz, which is also stipulated in the code for high powered vehicles and dynamic performance[20]. The first ten modes of the car body are calculated and extracted by Lanczos method, and the modal information is obtained, as shown in Table 6.

As shown in Figure 7, according to the modal simulation analysis results of the first ten steps, the vibration mode of the car body mainly occurs in the side wall and outer stiffener, which indicates that the side wall and outer stiffener in the carbon fiber reinforced composite funnel car body model established in this simulation are weaker than other parts. In addition, according to the modal analysis results of the first two orders, the first-order and second-order frequencies are less than the specified vertical bending vibration frequency-10Hz, and the vibration modes corresponding to the first-order and second-order modes are the vibration of the end plate support and the bending of the outer stiffener respectively.

In Figure 7, the vibration modes corresponding to each of the first ten modes. In the figure, almost all the stiffener structures of the hopper car vibrate. Therefore, for the side wall support stiffener of the carbon fiber reinforced composite hopper car designed in the study, its size and thickness should be increased accordingly, or materials with higher strength should be selected. In the third to tenth order modal vibration modes, it can be found from the figure that almost all the vibration of the wall of the dump truck occurs at the bolt connection of the wall panel, especially in the ninth and tenth order modal vibration modes, and the obvious vibration mainly occurs at the bolt connection area above the side wall. In the 5th and 6th order modal shapes, it is found that obvious vibration occurs on the uppermost and lowermost sides of the connection between head wall-plate 1 and plate 2, respectively. For the structure of bolt connection, a reasonable connection and assembly process should be put forward.

5 Conclusion

In the carbon fiber reinforced composite hopper car model established in this study, the I-beam structure in the wall structure improves the strength and stiffness of the wall and reduces the mass of the structure. The built-in filled polymer material plays a role in reducing vibration and noise effect. The performance of the carbon fiber reinforced composite hopper car is analyzed and studied from the statics and dynamics perspectives, which can basically meet the requirements of use.

When the hopper car is fully loaded, the stress on the head wall is relatively high, and in order to facilitate the unloading of goods, the head wall designed in the shape of funnel is prone to stress concentration in the bending area. Therefore, more supporting structures are needed in this part to improve the overall bearing capacity of the head wall.

The wall of the hopper car is a laminated plate with sandwich structure, and the composite I-beam in it bears the main stress of the structure.

The left and right ends of side wall-plate 1 and side wall-plate 2 of hopper car have large spans and poor stiffness. In addition, due to the lack of supporting structure above and below each connecting plate of the head wall, it is the part with the worst stiffness in the structure.

In the first ten modal results of the dynamic analysis of the car body, the first two modes of the car body are slightly less than the specified vertical bending vibration frequency. The vibration modes of each order are mainly manifested in the obvious vibration behavior at the connection part of the hopper car body.

Acknowledgement

This research was supported by the National Natural Science Foundation of China (NSFC) [grant number 51605076] and the Fundamental Research Funds for the Central Universities [grant number DUT21LAB108]. The authors would like to acknowledge the above financial supports.

References

[1] Barile C,Casavola C,De Cillis F. Mechanical comparison of new composite materials for aerospace applications[J].Composites Part B-Engineering ,2019,162:122-128.

[2] Li MG,Zhang LJ. Application status and development trends of composites for rail transit equipment[J]. China Textile Leader,2020(07): 20-24.

[3] Camanho P.P.,Matthews F.L.. A progressive damage model for mechanically fastened joints in composite laminates[J].Journal of Composite Materials,1999,33(24):2248-2280

[4] Vallons K,Behaeghe A,Lomov SV,Verpoest I. Impact and post-impact properties of a carbon fibre non-crimp fabric and a twill weave composite[J]. Composites Part A-Applied Science and Manufacturing,2010,41:1019-1026.

[5] Johnston J,Mirza O,Kemp M,Gates T. Flexural behaviour of alternate transom using composite fibre pultruded sections[J]. Engineering Failure Analysis,2018,94:47-68.

[6] Ruhmann DC. The design,fabrication and testing of the glasshopper prototype covered hopper rail cars[J]. Composite Structures,1994,27:207-213.

[7] Li B,Fang Y. Simulation of the Coal Hopper Vehicle Loading and Unloading Process. Computer Simulation. 2014;31:190-4.

[8] Wang WB,Ji WY,Zhang DD. Stepwise optimization design of metro train cab hood made of carbon fiber composite material[J]. Urban Mass Transit,2018,21(11):27-31.

[9] Jeon KW,Shin KB,Kim JS. A study on fatigue life and strength of a GFRP composite bogie frame for urban subway trains. 11th International Conference on the Mechanical Behavior of Materials (ICM),2011[C]. Como,ITALY,2011.

[10] Kim JS,Shin KB,Yoon HJ,Lee WG. Durability evaluation of a composite bogie frame with bow-shaped side beams[J]. Journal of Mechanical Science and Technology,2012,26:531-536.

[11] Kim JS. Fatigue assessment of tilting bogie frame for Korean tilting train: Analysis and static tests[J]. Engineering Failure Analysis, 2006,13:1326-1337.

[12] Wang YG,Li DF,Liu S. Study of lightweight cab structure for urban rail transit vehicles[J]. Railway Locomotive and Motor Car, 2013(11): 5-7.

[13] Dovhaniuk S,Kalashnyk V,Reidemeister A,Shykunov O. Investigation of possibility of hopper cars unloading on the car dumper VRS-134M. 2nd International Scientific and Practical Conference on Energy-Optimal Technologies,Logistic and Safety on Transport 2019[C]. Lviv,UKRAINE 2019.

[14] Wan C,Liu Y,Li X. The Determination and Simulation for the Dead Zone of Opening/Closing Mechanism in the Bottom Door of the Railway Freight Cars. 2nd International Conference on Manufacturing Science and Engineering,2011[C]. Guilin,PEOPLES R CHINA 2011.

[15] Xie SM,Zhou XK,Li XW. Fatigue life prediction for weld line in heavy freight carbody based on ASME standard[J]. Chinese Journal of Computational Mechanics,2012,29(01): 129-134.

[16] Al-Sukhon A,ElSayed MSA. Design optimization of hopper cars employing functionally graded honeycomb sandwich panels[J]. Proceedings of the Institution of Mechanical Engineers Part F-Journal of Rail and Rapid Transit,2021,0:1-16

[17] Li YH,Wen X,Wang J. Optimization design of the overlay of composite material subway car head cover[J]. Modern Manufacturing Engineering,2019(09): 87-93.

[18] Li LD,Li WQ,Zhang Q. Modal test and simulation research on carbodies of C80 gondola cars[J]. Rolling Stock, 2019,57(11): 5-7.

[19] Zhang QC,Dai YD,Yu YB. Vibration control of unloaded fast-heavy haul freight train based on vibration transmission characteristic[J]. Journal of Tianjin University(Science and Technology),2018,51(09):903-911.

[20] Wang T. Study on the first step mode of locomotive carbody[J]. Electric Drive for Locomotives,2003(06): 24-26.