烧结NdFeB表面等离子喷涂Al防护涂层制备工艺及性能研究

2023-01-09张帅刘树峰鲁飞李慧刘小鱼

张帅,刘树峰,鲁飞,李慧,刘小鱼

烧结NdFeB表面等离子喷涂Al防护涂层制备工艺及性能研究

张帅,刘树峰,鲁飞,李慧,刘小鱼

(包头稀土研究院 白云鄂博稀土资源研究与综合利用国家重点实验室,内蒙古 包头 014030)

目的 采用大气等离子喷涂工艺在烧结NdFeB磁体表面制备Al防护涂层,实现NdFeB磁体防护强化。方法 通过不同喷涂工艺制备Al涂层,采用扫描电子显微镜观测涂层表面、截面形貌和堆积厚度,利用垂直拉拔法测试最佳工艺下涂层的结合强度。喷涂不同厚度Al防护涂层,采用电化学工作站和中性盐雾腐蚀试验研究涂层的耐腐蚀性能,利用脉冲磁场磁强计对比分析喷涂Al涂层厚度对磁体磁性能的影响。结果 喷涂电流从400 A提高至600 A,当喷涂电流为500 A时,涂层表面致密,无明显溅射堆垛和未熔颗粒;喷涂30次,涂层厚度达到40 μm,结合强度达15.5 MPa。等离子喷涂Al防护涂层对NdFeB基体构成牺牲阳极保护,不同厚度涂层的自腐蚀电位无明显差异,约为–1.1 V,自腐蚀电流密度相对NdFeB基体降低了2个数量级。随着涂层厚度的增加,Al防护涂层的耐腐蚀性能逐步提高,喷涂厚度的70mm的Al防护涂层耐中性盐雾腐蚀时间最高可达300 h以上。随着Al涂层厚度从0 μm增加至70 μm,磁体矫顽力略有提升,剩磁降低为原始样的2.0%~4.26%。结论 等离子喷涂技术可极大改善NdFeB磁体的耐腐蚀性能,为NdFeB防护的工业应用提供了新思路。

烧结NdFeB;等离子喷涂;Al防护涂层;抗腐蚀性能;磁性能

NdFeB永磁体具有体积小、质量轻和磁性能佳的优势,广泛应用于新能源、节能环保行业、通信、医疗和消费电子等领域[1-3]。在实际使用过程中,由于NdFeB磁体富钕相与主相之间的电位差较大,容易构成腐蚀原电池,造成磁体表面局部区域产生成分和结构破坏,进而影响磁体外形尺寸的完整性和磁学性能的稳定性,降低磁体实际使用寿命[4-6]。耐腐蚀性能差成为了NdFeB磁体在工业领域大规模应用的瓶颈。目前,提高NdFeB磁体耐腐蚀的通用做法有2类,一种是在磁体中添加合金元素,以提高晶界相的电势,进而改善磁体的耐蚀性,但该方法以损失磁体的磁性能为代价[7-8]。另一种是在磁体表面制备防护涂层,阻止腐蚀介质向内部渗透,通常的方法有电镀、化学镀、真空镀膜等[9-12]。其中电镀和化学镀存在镀液渗透和环境污染问题,急需寻找环保无污染的新工艺。

真空镀Al技术能够很好地避免电镀和化学镀工艺存在的不足,实施过程无原料外溢,无污染物排放,防护膜层附着力大,近年来在NdFeB磁体表面防护上的应用受到广泛关注。但该技术在推广应用方面存在以下几个方面问题:第一,由于柱状晶的生长特性,需要对涂层进行多层结构优化制备或进行磷酸盐、铬酸盐[15]表层钝化处理,改善柱状晶微孔缺陷,提升耐腐蚀性,增加了工艺复杂性,同时存在钝化液处理及排放问题;第二,真空镀膜的成膜速率不高,难以实现高质量防护涂层的快速制备;第三,该技术镀膜源高质量靶材价格昂贵,增加了磁体生产成本[13-14]。

开发无污染、高耐蚀、低成本、高效率的NdFeB防护涂层技术和工艺,并将其应用于工业生产是NdFeB行业的一个重要而急迫的课题。对比而言,喷涂法属于干法施镀,可以满足磁体表面防护涂层绿色、快速、低成本的制备要求,备受世人青睐。Ma等[16]通过冷喷涂方法在NdFeB基体表面制备了170 μm Al涂层,并对其腐蚀产物进行了分析。结果显示,喷涂Al涂层后,自腐蚀电流密度由4.361´10–6A/cm2降至1.350´10–6A/cm2。3.5% NaCl溶液浸泡360 h后,涂层表面形成了致密Al2O3膜层,对基体起到防护作用。Ma等[17]采用爆炸喷涂工艺在NdFeB表面制备了Al涂层,涂层孔隙率低至0.77%,厚度约为16 μm,中性盐雾腐蚀200 h后,表面未见明显锈斑。解伟等[18]通过等离子喷涂方式在NdFeB表面形成了EMAA树脂涂层,涂层结合力达23 MPa,中性盐雾腐蚀时间为300 h。可见喷涂法在制备NdFeB防护涂层方面具有极大应用优势。实际应用中,防护涂层及制备工艺对NdFeB磁体磁性能的影响也极为重要,如何在保证涂层耐蚀性的同时,减少对磁体磁性能的影响是涂层制备工艺能否工业化应用的关键所在。研究表明,涂层厚度及制备工艺对磁体磁性能的影响大不相同。Yu等[19]研究表明,NdFeB磁体表面12 µm的Zn-Cr涂层可使剩磁降低6%左右。Chen等[20]研究了化学镀Ni-P对磁体磁性能的影响,结果显示,磁体剩磁和矫顽力分别降低16%和24%。Mao等[21]对比分析了磁控溅射镀Al和电镀Ni/Cu/Ni对磁体磁性能的影响,结果表明,磁控溅射镀Al后,磁体矫顽力略有提升,剩磁轻微降低,而电镀Ni/Cu/Ni后,磁体剩磁和矫顽力分别降低1.0%和1.5%。然而,目前关于喷涂工艺制备防护涂层对磁体性能影响的研究鲜有报道,严重制约了喷涂工艺在NdFeB防护领域的应用推广。

本文采用等离子喷涂技术在NdFeB磁体表面制备了不同厚度的Al涂层,研究了涂层厚度对磁体耐腐蚀性能及磁性能的影响,以期为等离子喷涂Al涂层在磁体表面防护中的应用提供借鉴。

1 试验

1.1 NdFeB基体制备

以烧结NdFeB磁体为喷涂基体(牌号45M、45H和45SH,均产自包头稀土研究院),规格为30 mm× 20 mm×4 mm,且基体均处于退磁状态。喷涂前依次对NdFeB基体进行喷砂、超声清洗,去除基体表面油污、锈蚀、氧化皮等附着物,粗化、清洁化基体表面,确保基体粗化度和清洁度满足喷涂要求。

1.2 涂层制备

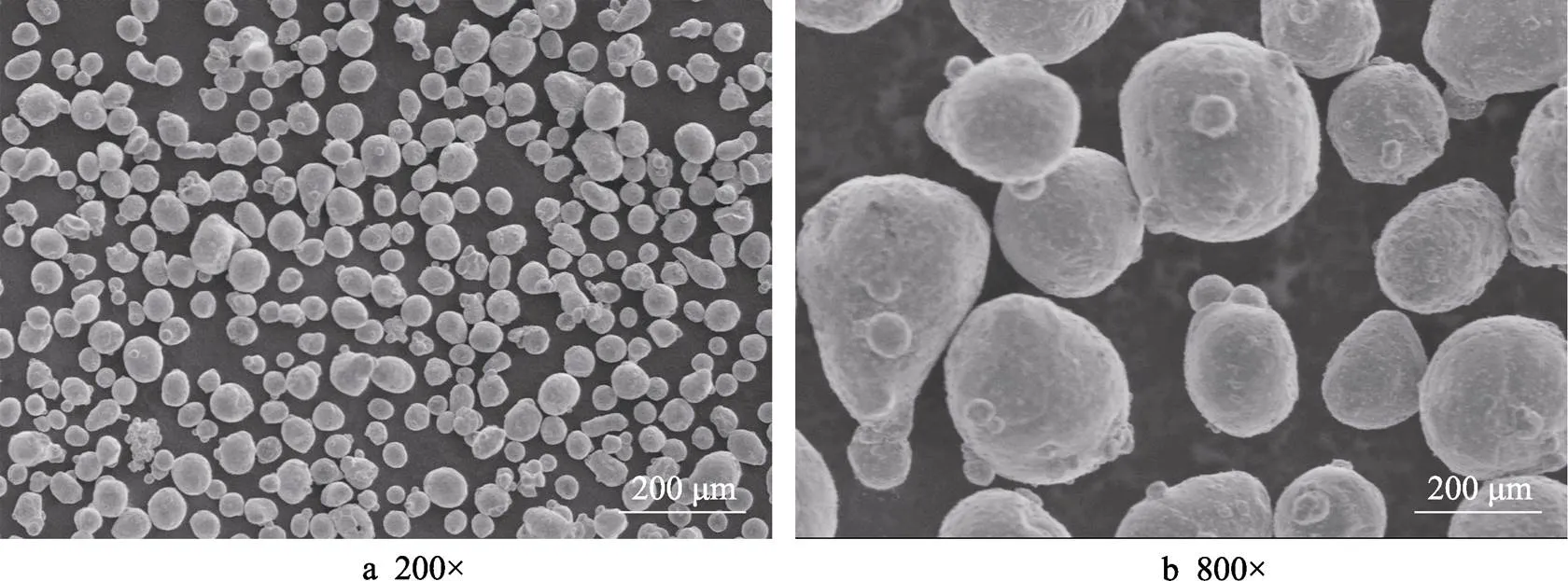

选用气雾化类球形Al粉作为喷涂粉体,铝粉纯度>99.9%,粉末粒度为20~40 μm,粉体形貌如图1所示。采用XM-80等离子喷涂设备在NdFeB基体表面喷涂Al防护涂层,具体喷涂工艺见表1,喷枪移动循环次数20次,制备Al防护涂层标记为Al-20。涂层厚度通过调整喷枪移动循环次数控制,将喷枪移动循环次数增加至30、40、50次,制备不同厚度Al防护涂层,涂层样品分别标记为Al-30、Al-40、Al-50。

1.3 测试分析

采用SIGMA500型场发射扫描电镜观察粉体及涂层表面、截面形貌,测量涂层厚度,并进行EDS线扫描。

采用垂直拉脱法(GB/T 5210—2006)测量Al涂层与烧结NdFeB基体间的结合强度。首先,用环氧树脂胶将涂层、基体分别与不锈钢对偶件粘接,后放置于烘箱50 ℃干燥固化3 h。然后,使用WDW3200万能力学试验机进行拉伸,根据涂层拉脱时临界载荷与拉脱面积,计算涂层与基体的结合强度。测试5次,取平均值,获得涂层与基体的结合强度。

采用Ivivum电化学工作站进行动电位极化测试。采用传统三电极体系,其中涂层为工作电极,有效测试面积为10 mm´10 mm,参比电极为饱和甘汞电极(SCE),对电极为铂片。腐蚀介质为3.5%NaCl溶液,测试温度为(25±3) ℃,扫描速度为1 mV/s。利用塔菲尔(Tafel)外推法对所测试的极化曲线进行拟合,确定自腐蚀电位(corr)和自腐蚀电流密度(corr)等腐蚀参数。

中性盐雾腐蚀试验(NSS)参考GB/T 34491—2017规定,采用YWX-750型中性盐雾喷雾试验箱,测试条件:连续喷雾,温度为(35±2)℃、5%±1%(质量分数)NaCl溶液,收集的盐雾沉降溶液pH为6.5~7.2,试样表面在盐雾箱中放置的倾斜角度为45°±5°。

选择45M、5H、45SH这3种牌号钕铁硼磁体进行不同厚度Al防护涂层的制备。采用Metis Instruments脉冲磁场磁强计分析不同牌号磁体等离子喷涂Al涂层前后磁体的能变化。

图1 等离子喷涂选用Al粉形貌

2 结果与讨论

2.1 工艺设计及形貌结构

涂层致密度和结合力的提高是制备优质防护涂层的关键技术。等离子喷涂涂层致密度和结合力的高低与喷涂过程中粉料熔融率及扁平化铺展凝固密切相关。喷涂粉料经等离子体火焰加热形成熔滴,熔滴在惰性气体(氩气或氮气)的加速下,高速喷射到工件表面,产生碰撞、变形、冷凝收缩,形成扁平化堆积涂层。

不同喷涂电流所制备的Al等离子喷涂防护涂层表面状态对比结果如图2所示,可见不同电流下涂层的表面状态差别明显。调节喷涂电流至400 A,保证其他喷涂工艺不变,涂层表面有明显未熔颗粒堆积(如图2a黄色箭头所示),颗粒粒径尺寸约为20 μm,满足喷涂用Al粉粒径分布。继续加大电流至450、500 A,等离子火焰中心温度提高,Al喷涂粉料基本熔融,涂层表面罕见未熔颗粒,如图2b、c所示。当喷涂电流为500 A,熔滴在惰性气体(氩气或氮气)加速下,高速喷射到工件表面,产生碰撞、变形、冷凝收缩,形成扁平化程度更好的堆积涂层。当提高喷涂电流至550、600 A,喷涂熔滴过熔,导致喷射到基体表面变形量过大,扁平化粒子边缘易飞溅,在粒子搭建处出现飞溅小颗粒聚集堆垛,如图2d、e箭头所示。这些飞溅小颗粒在随后的快速冷凝过程中,容易形成贯穿孔洞。相反地,若熔滴熔化不足,会造成熔滴变形量减小,形成未熔大颗粒。喷涂电流为500 A,熔融粒子变形量合适,扁平化冷凝粒子铺展充分,堆积状态良好,无小颗粒飞溅现象,涂层表面致密度和平整度高。综合考虑,后续制备不同喷涂次数Al防护涂层样品(Al-20、Al-30、Al-40、Al-50)的喷涂工艺选择500 A,其余工艺参数见表1。

不同喷涂次数Al防护涂层的截面形貌对比如图3所示。从图3中可以看出,随着喷涂次数的增加,涂层厚度逐渐增加。涂层内存在部分封闭孔隙,但未观察到贯穿到NdFeB基体的孔隙。不同喷涂次数Al涂层的EDS线扫结果如图4所示,扫描方式为沿涂层外部向NdFeB基体内部扫描。通过涂层截面SEM多次测量涂层厚度,并结合EDS扫描结果可知:喷涂次数20次时,涂层厚度约为20 µm;喷涂次数30次时,涂层厚度增至40 µm左右;继续增加喷涂次数达50次时,涂层厚度可达70 µm左右。

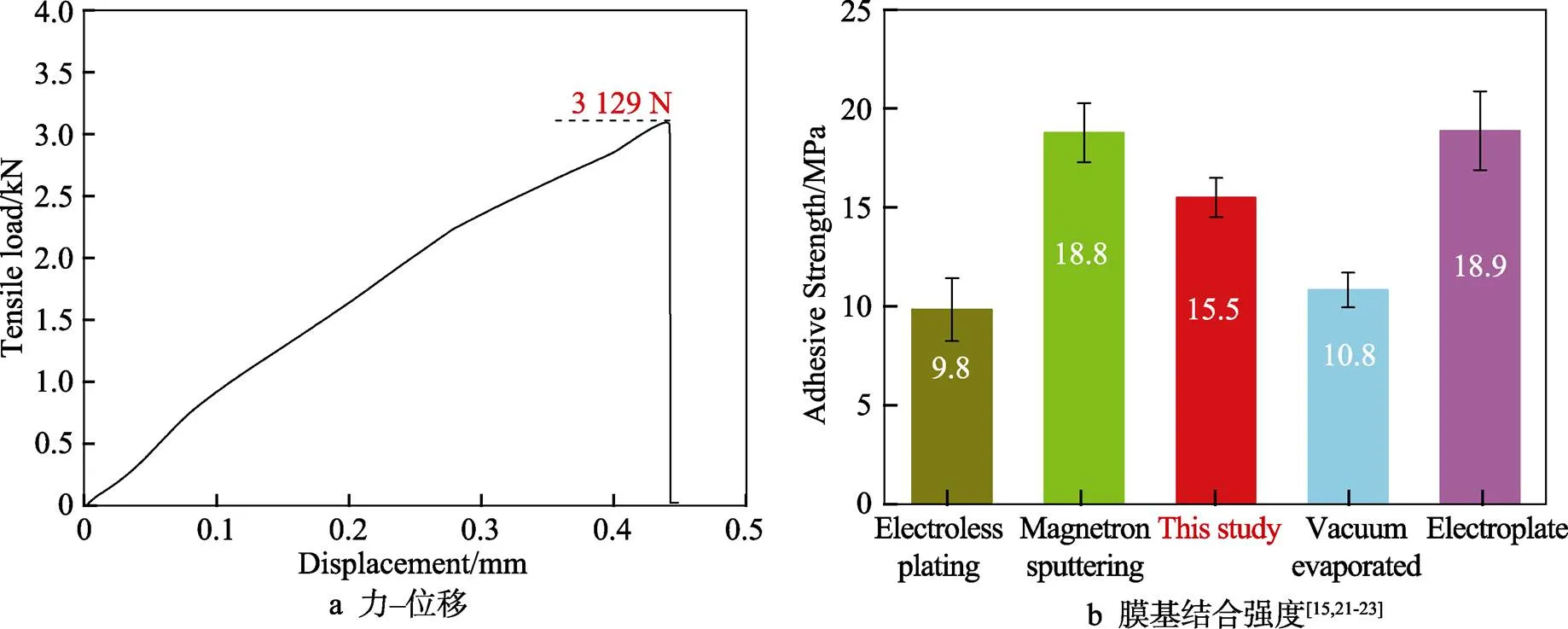

2.2 结合强度

Al-30涂层在拉伸试验过程中的力–位移曲线如图5所示。可以看出,在拉力达到3 129 N时,涂层发生了脱层。将涂层脱落的临界应力除以涂层脱落面积,计算得出Al 涂层与NdFeB基体的结合力可达15.5 MPa。进一步对不同工艺制备的Al防护涂层结合力进行对比,所列不同工艺均采用垂直拉拔法测试结合强度,结果如图5b所示。其中磁控溅射涂层厚度为7 μm,结合强度为18.8 MPa,测试机器为CMT5105;化学镀涂层材料为Ni-P,测试涂层平均厚度为5 μm,结合强度为9.8 MPa;真空蒸镀Al涂层厚13 μm,结合强度为10.8 MPa,测试仪器为WDW- 20;电镀Zn涂层厚度为4.3 μm,结合强度为18.9 MPa,测试仪器为WDW-20。采用等离子喷涂工艺制备40 μm厚的Al防护涂层,其结合强度高于真空蒸镀和化学镀的最佳结合强度,低于磁控溅射和电镀。

图2 不同喷涂电流Al涂层表面形貌对比

表1 等离子喷涂工艺参数

图3 不同喷涂次数Al防护涂层截面SEM形貌

图4 不同喷涂次数Al涂层截面的EDS 线扫

2.3 耐腐蚀性能

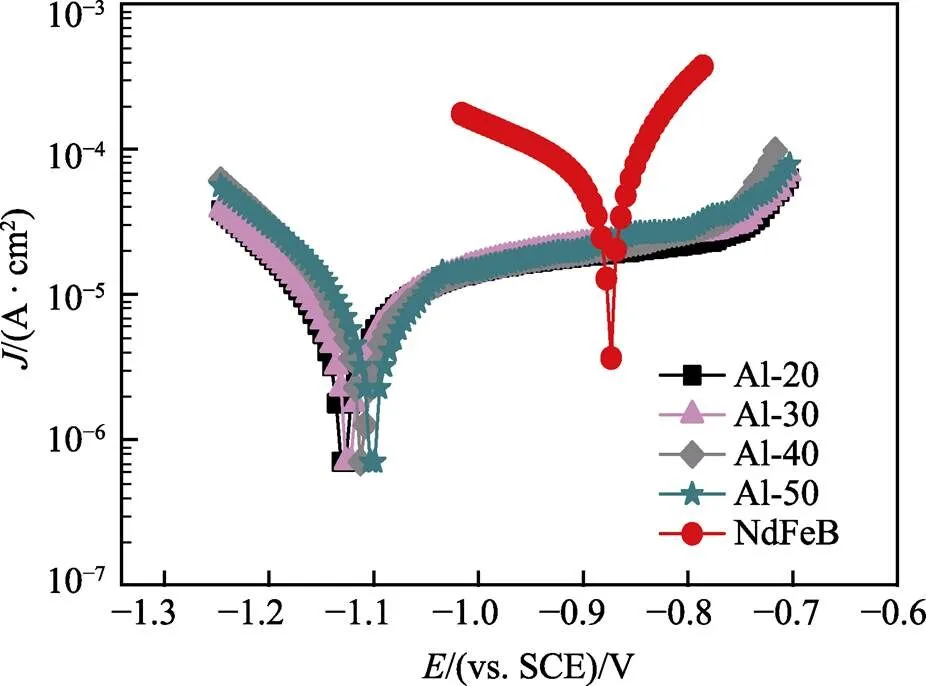

不同喷涂次数Al涂层和NdFeB基体的动电位极化曲线如图6所示。可以看出,NdFeB基体的阳极区主要表现为活性溶解特征。这是由于NdFeB为粉末冶金制备,表面存在大量孔隙,溶液中Cl–易进入孔隙,加快腐蚀进程。对比显示,喷涂Al涂层后,Al/NdFeB的阳极极化曲线在活性溶解反应前存在一明显钝化区,钝化区的出现与Al涂层表面形成的氧化膜有关。表明喷涂Al后,能够有效缓减NdFeB基体的腐蚀速率。

图5 拉脱法测试Al-30涂层结合力及与现有工艺对比

图6 不同喷涂次数Al涂层动电位极化曲线

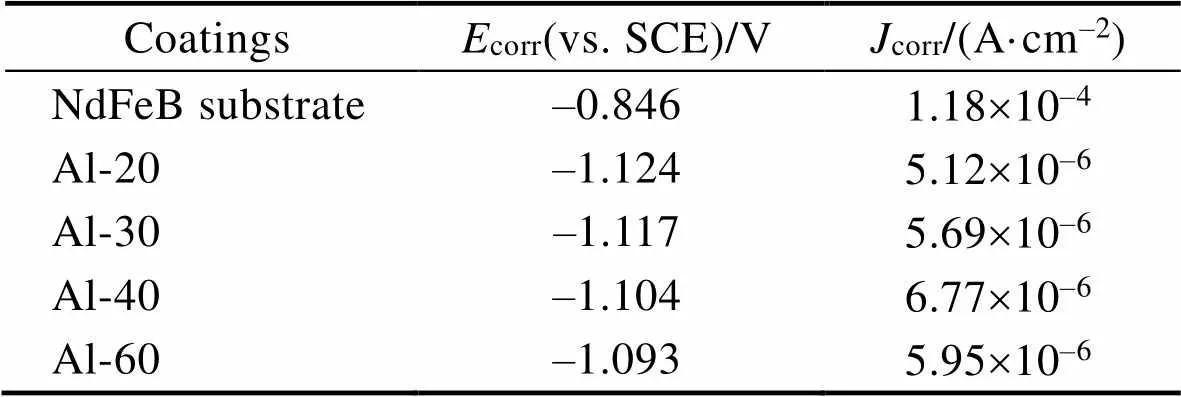

表2列出了利用Tafel外推法拟合确定的电化学腐蚀参数。对比显示,NdFeB基体的自腐蚀电位为–0.846 V,Al涂层的自腐蚀电位基本在–1.1 V左右,相对于NdFeB基体发生了负移。表明在电化学腐蚀环境中,Al喷涂涂层的腐蚀倾向性高,相对于NdFeB基体会作为阳极,对基体构成牺牲阳极保护。

腐蚀电位为热力学概念,只能说明腐蚀倾向性,而腐蚀电流密度为动力学概念,与腐蚀速率紧密相关。可以发现,Al涂层的自腐蚀电流密度降至5.12´10–6~6.77´10–6A/cm2,相对NdFeB基体(1.18´10–4A/cm2),降低了2个数量级。依据Faraday定律,对于同一基体而言,腐蚀速率与腐蚀电流密度成正比。可见Al喷涂防护层覆盖后,NdFeB磁体的腐蚀速率明显降低,表现出优异的耐腐蚀性能。Al涂层厚度对自腐蚀电位和自腐蚀电流密度的影响不大。

表2 NdFeB基体和Al涂层在3.5%NaCl溶液中的电化学腐蚀参数

为了进一步评价Al涂层的耐腐蚀性能,对比分析了不同喷涂次数Al防护涂层耐中性盐雾腐蚀结果,如图7所示。随着喷涂次数的增加,涂层厚度增加,耐盐雾腐蚀时间增加。喷涂次数为20次时,喷涂厚度较薄,盐雾腐蚀24 h后,涂层表面出现点蚀现象。喷涂次数增加至50次时,喷涂厚度为70 μm左右,耐盐雾腐蚀时间可达300 h以上。

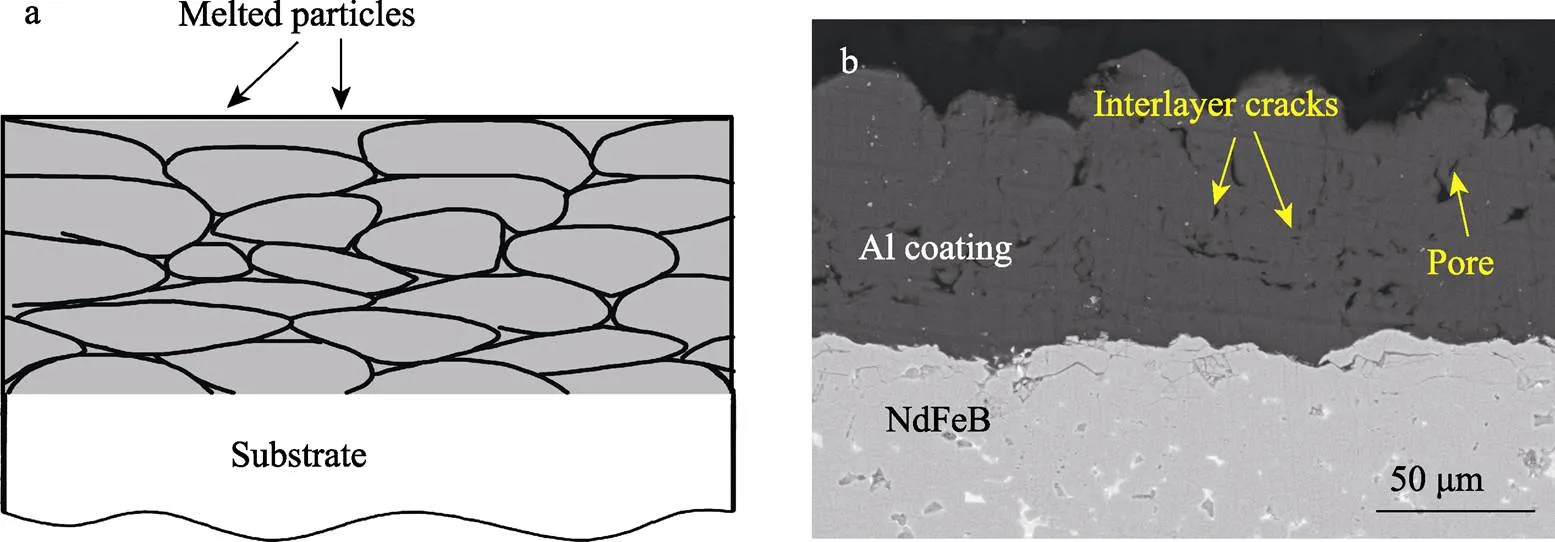

不同厚度Al喷涂防护层盐雾腐蚀结果差异可能与Al涂层表面堆积覆盖状态有关。如图8a所示,喷涂过程中,Al颗粒经等离子射流加热后,熔融粒子以层状结构堆积于烧结NdFeB表面,而层状堆积的熔融粒子之间易形成层间裂隙。同时,由于等离子喷涂工艺特性,不可避免地会出现未熔融或半熔融颗粒,造成涂层内出现微孔(如图8b黄箭头所示)。这些层间裂隙及微孔缺陷为腐蚀介质向NdFeB基体内部扩散提供了渗透通道,涂层厚度的增加有助于延长腐蚀介质渗透通道,进而延长腐蚀介质向NdFeB基体内部扩散时间,提升耐中性盐雾腐蚀能力。

图7 Al喷涂防护涂层中性盐雾腐蚀照片

图8 喷涂粒子堆积示意图(a)及Al涂层横截面SEM (b)

另外,研究表明[10,17],Al涂层在富Cl-环境中的腐蚀过程包括钝化膜Al(OH)3形成、溶解、再钝化过程,腐蚀反应过程如式(1)、(2)所示[24]:

Al(OH)+Cl–→Al(OH)–Cl(soluble)+OH–(2)

在腐蚀初始阶段,Al涂层表面发生点蚀,形成Al(OH)3钝化膜。继续增加腐蚀时间,喷涂表面吸附的Cl–和钝化膜Al(OH)3反应,生成可溶性氯化物,钝化膜破裂,在Al涂层上形成大而深的腐蚀孔洞,加剧腐蚀进程。此外,较薄的涂层(如Al-20)易产生贯穿至基体的层间间隙和孔洞,Cl–沿着这些缺陷可快速浸入并腐蚀基体。

不同工艺制备的Al/NdFeB腐蚀性能的对比结果见表3。采用等离子喷涂制备的Al涂层,其自腐蚀电流密度相对铸态Al高1个数量级,可能与铸态Al表面生成的氧化膜相对致密有关。喷涂防护层(Al)的耐盐雾腐蚀时间与电镀相当,明显高于物理气相沉积,但是其喷涂腐蚀电流密度却低于磁控溅射1个数量级。根据陈娥等[25]的研究分析,烧结NdFeB基体在制备及表面清洁化过程中表面粗糙不平整,磁控溅射镀Al厚度较低,且沉积速率较慢,这就导致镀层过薄,不能形成连续包覆层,从而产生空洞,腐蚀介质沿空洞渗入侵蚀基体。另外,物理气相沉积(磁控溅射或蒸镀)制备的Al涂层由于柱状晶生长特性,柱状晶间隙为腐蚀介质向NdFeB基体内部扩散提供了快速通道。

2.4 喷涂Al防护涂层对磁性能变化影响

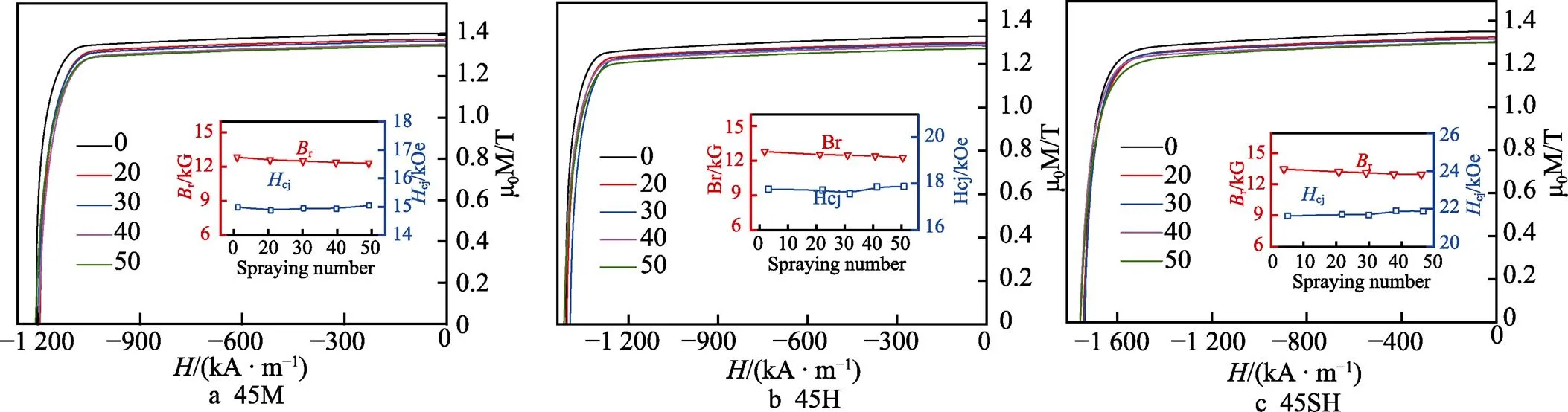

选择45M、45H、45SH等3种牌号NdFeB磁体进行等离子喷涂试验,测试结果如图9所示。随着喷涂次数的增加,3种牌号NdFeB磁体的矫顽力略有提升,分析原因可能是由于Al原子或者喷涂过程中的能量离子Ar+在磁畴中形成了钉扎效应,致使矫顽力提升[21,28],而且Al的磁导系数非常低,Al涂层在自然状态下不具有磁性,对NdFeB磁体磁性能的影响较小。其次,磁体的剩磁均呈降低趋势,45M、45H、45SH随着喷涂次数的增加,剩磁变化值均从2%增至约4%。剩磁的降低可能与等离子喷涂使磁体受热有关,不同喷涂次数导致受热时间不同,磁体内部组织结构发生变化,从而导致剩磁略微下降。具体喷涂对组织结构的热影响有待后续进一步深入研究。

不同工艺制备NdFeB防护涂层对磁体磁性能影响见表4。其中化学镀Ni-P对磁性能的影响最大,磁控溅射的影响最小。Ding等[21,29]研究了电镀工艺会降低磁体剩磁及矫顽力,镀膜材料及膜厚不同,影响程度也不一样。本文所做Al-20剩磁降低2.05%,矫顽力提高0.61%;Al-30剩磁降低2.97%,矫顽力提高0.4%。

表3 不同工艺制备Al / NdFeB耐腐蚀性能

图9 不同喷涂次数磁体磁性能变化

表4 不同工艺制备NdFeB防护层对磁性能的影响

3 结论

1)采用大气等离子喷涂工艺在烧结NdFeB磁体表面实现了Al防护涂层绿色、快速、低成本制备。

2)Al防护涂层对基体构成牺牲阳极保护,喷涂厚度的增加有助于改善涂层的耐腐蚀性能。

3)等离子喷涂Al防护涂层后,磁体矫顽力略有提升,剩磁影响值与电镀相当。

[1] GUTFLEISCH O, WILLARD M A, BRÜCK E, et al. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and more Energy Efficient[J]. Advanced Materials, 2011, 23(7): 821-842.

[2] 林松盛, 苏一凡, 宋可为, 等. 过渡层对钕铁硼表面蒸发镀铝涂层耐腐蚀性能的影响[J]. 表面技术, 2017, 46(12): 218-224.

LIN Song-sheng, SU Yi-fan, SONG Ke-wei, et al. Influence of Transition Layer on Corrosion Resistance of Evaporated Al Coating on NdFeB Magnets[J]. Surface Technology, 2017, 46(12): 218-224.

[3] 王静, 梁乐, 武梦艳, 等. 烧结NdFeB永磁体的晶界微细结构及性能研究进展[J]. 中国有色金属学报, 2014, 24(6): 1562-1577.

WANG Jing, LIANG Le, WU Meng-yan, et al. Research Progress on Grain Boundary Fine Microstructure and Magnetic Properties of Sintered NdFeB Magnet[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1562-1577.

[4] LI Zhi-jie, WANG Xiao-er, LI Jia-yang, et al. Effects of Mg Nanopowders Intergranular Addition on the Magnetic Properties and Corrosion Resistance of Sintered Nd-Fe-B[J]. Journal of Magnetism and Magnetic Materials, 2017, 442: 62-66.

[5] ZHOU Qiao-ying, LI Gang, LIU Zhang, et al. Influence of the Electroplating Pretreatment on Corrosion Mechanism of NdFeB Magnets[J]. Journal of Rare Earths, 2016, 34(2): 152-157.

[6] 许伟, 代明江, 胡芳. NdFeB永磁体表面磁控溅射铝防护镀层性能研究[J]. 表面技术, 2014, 43(1): 77-80.

XU Wei, DAI Ming-jiang, HU Fang. Corrosion Resistance of Aluminum Film on NdFeB Permanent Magnets by Magnetron Sputtering[J]. Surface Technology, 2014, 43(1): 77-80.

[7] BALA H, PAWLOWSKA G, SZYMURA S, et al. Corrosion Characteristics of Nd-Fe-B Sintered Magnets Containing Various Alloying Elements[J]. Journal of Magnetism and Magnetic Materials, 1990, 87(3): L255- L259.

[8] NI Jun-jie, ZHOU Shu-tai, JIA Zheng-feng, et al. Improvement of Corrosion Resistance in Nd-Fe-B Sintered Magnets by Intergranular Additions of Sn[J]. Journal of Alloys and Compounds, 2014, 588: 558-561.

[9] CAO Rui, ZHU Li-qun, LI Wei-ping, et al. The Effect of Alumina-Silica Sols on Electrodeposited Zinc Coatings for Sintered NdFeB[J]. Journal of Alloys and Compounds, 2017, 726: 95-106.

[10] MAO Shou-dong, YANG Heng-xiu, LI Ji-long, et al. Corrosion Properties of Aluminium Coatings Deposited on Sintered NdFeB by Ion-Beam-Assisted Deposition[J]. Applied Surface Science, 2011, 257(13): 5581-5585.

[11] REFFASS M, BERZIOU C, REBERE C, et al. Corrosion Behaviour of Magnetron-Sputtered Al1–x-Mnx Coatings in Neutral Saline Solution[J]. Corrosion Science, 2010, 52(11): 3615-3623.

[12] JIANG Wei, SHEN Li-da, WANG Kai, et al. Study on Ni-Ni(S)-Ni(P) Multilayer Coating by Friction-Assisted Jet Electroplating on Sintered NdFeB[J]. Journal of Alloys and Compounds, 2019, 787: 1089-1096.

[13] XIE Ting-ting, MAO Shou-dong, CHAO Yu, et al. Structure, Corrosion, and Hardness Properties of Ti/Al Multilayers Coated on NdFeB by Magnetron Sputtering[J]. Vacuum, 2012, 86(10): 1583-1588.

[14] CHEN Jing, YANG Hong-yi, XU Guang-qing, et al. Phosphating Passivation of Vacuum Evaporated Al/NdFeB Magnets Boosting High Anti-Corrosion Performances[J]. Surface and Coatings Technology, 2020, 399: 126115.

[15] ZHANG Peng-jie, LIU Jia-qin, XU Guang-qing, et al. Anticorrosive Property of Al Coatings on Sintered NdFeB Substrates via Plasma Assisted Physical Vapor Deposition Method[J]. Surface and Coatings Technology, 2015, 282: 86-93.

[16] MA Chun-chun, LIU Xiao-fang, ZHOU Chun-gen. Cold- Sprayed Al Coating for Corrosion Protection of Sintered NdFeB[J]. Journal of Thermal Spray Technology, 2014, 23(3): 456-462.

[17] MA Ji-zhao, LIU Xiao-fang, QU Wen-tao, et al. Corrosion Behavior of Detonation Gun Sprayed Al Coating on Sintered NFeB[J]. Journal of Thermal Spray Technology, 2015, 24(3): 394-400.

[18] 解伟, 肖震, 韩珩, 等. 钕铁硼的热喷涂涂层及其制备方法: CN105537075A[P]. 2018-12-21.

XIE Wei, XIAO Zhen, HAN Heng, et al. Neodymium- Iron-Boron Thermal-Spraying Coating and Preparation Method Thereof: CN105537075A[P]. 2018-12-21.

[19] YU Sheng-xue, CHEN Lin. Preparation Technology and Performances of Zn-Cr Coating on Sintered NdFeB Permanent Magnet[J]. Journal of Rare Earths, 2006, 24(2): 223-226.

[20] CHEN Zhong, NG A, YI Jian-zhang, et al. Multi-Layered Electroless Ni-P Coatings on Powder-Sintered Nd-Fe-B Permanent Magnet[J]. Journal of Magnetism and Magnetic Materials, 2006, 302(1): 216-222.

[21] MAO Shou-dong, YANG Heng-xiu, LI Jin-long, et al. The Properties of Aluminium Coating on Sintered NdFeB by DC Magnetron Sputtering[J]. Vacuum, 2011, 85(7): 772-775.

[22] WANG Yao, DENG Yu-zhou, MA Yuan-tai, et al. Improving Adhesion of Electroless Ni-P Coating on Sintered NdFeB Magnet[J]. Surface and Coatings Technology, 2011, 206(6): 1203-1210.

[23] ZHANG Peng-jie, XU Guang-qing, LIU Jia-qing, et al. Effect of Pretreating Technologies on the Adhesive Strength and Anticorrosion Property of Zn Coated NdFeB Specimens[J]. Applied Surface Science, 2016, 363: 499- 506.

[24] NGUYEN T H. The Chemical Nature of Aluminum Corrosion[J]. Journal of The Electrochemical Society, 1982, 129(1):27.

[25] CHEN E, PENG Kun, YANG Wu-lin, et al. Effects of Al Coating on Corrosion Resistance of Sintered NdFeB Magnet[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2864-2869.

[26] 陈静, 凌国平. 钕铁硼在AlCl3-EMIC离子液体中电沉积铝层的耐腐蚀性能[J]. 材料保护, 2011, 44(11): 1-4.

CHEN Jing, LING Guo-ping. Corrosion Resistance of Electrodeposited Aluminum Coating on NdFeB Magnet from AlCl3-EMIC Ionic Liquid[J]. Materials Protection, 2011, 44(11): 1-4.

[27] ZHANG Yan-yan, ZHENG Da-jiang, SONG Guang-ling, et al. Effect of Vacuum Degree on Adhesion Strength and Corrosion Resistance of Magnetron Sputtered Aluminum Coating on NdFeB Magnet[J]. Materials and Corrosion, 2019, 70(7): 1230-1241.

[28] XU J L, XIAO Q F, MEI D D, et al. Preparation and Characterization of Amorphous SiO2Coatings Deposited by Mirco-Arc Oxidation on Sintered NdFeB Permanent Magnets[J]. Journal of Magnetism and Magnetic Materials, 2017, 426: 361-368.

[29] DING Jing-jing, XU Ba-jin, LING Guo-ping. Al-Mn Coating Electrodeposited from Ionic Liquid on NdFeB Magnet with High Hardness and Corrosion Resistance[J]. Applied Surface Science, 2014, 305: 309-313.

Preparation Technology and Properties of Al Protective Coatings on the Surface of Sintered NdFeB Magnet Via Plasma Spray

,,,,

(State Key Laboratory of Baiyunobo Rare Earth Resource Researches and Comprehensive Utilization, Baotou Research Institute of Rare Earths, Inner Mongolia Baotou 014030, China)

The air plasma spraying process is a novel surface protective technology on sintered NdFeB, which have a quantity of advantage on preparation process, corrosion resistance and other properties. There are some researches had been reported about cold spraying and part of hot spraying technology applied on surface protective. Although the air plasma spraying have been mentioned seldom, it can greatly improve the corrosion resistance of NdFeB magnets and can provide new ideas for industrial applications in NdFeB protection. The work aims to prepare Al protective coatings on the surface of sintered NdFeB magnets by atmospheric plasma spraying technology, so as to strengthen the protection of NdFeB magnets by plasma spraying technology.

In this work, sintered NdFeB magnets with dimensions of 30 mm×20 mm×4 mm were degreased, dried in air, and then grit-blasted prior to deposition. All specimens were in the state of demagnetization. Pure aluminum powders (>99.9%) were divided into 20-40 μm, and then were applied to spray onto the NdFeB substrate. As a result, with the spraying current increased from 400 A to 600 A, through observing the surface and cross-section morphology with SEM (SIGMA500), the best spraying current was 500 A, under which the surface of coating was dense without obvious sputtering stacking and unmelted particles. Finally the sprayed current was 500 A, the carrier gas flow rate was 1 800 L/h, the powder feed rate was 0.1 r/min, the distance was 150 mm. Under this process parameter, with the spraying number increased from 20 to 50 times, the thickness of coating had increased; when the spraying number reached to 30 times, the average thickness was up to 40 μm and the adhesive strength was over 15.5 MPa.

Then, the corrosion resistance of coatings with different thickness were tested through electrochemical workstation (Ivivum) and salt spray test (YWX-750), and magnetic properties were tested with impulse magnetic field magnetometer (Metis Instruments). The Al coating was a sacrificial anode to protect the substrate and the self-corrosion voltage was about –1.1 V vs saturated calomel electrode, which had no apparently influence in thickness of Al coating. The self-corrosion current was smaller two orders of magnitude after deposition of Al coating on the NdFeB matrix, which decreased from 1.18´10–4A/cm2to 5.12´10–6–6.77´10–6A/cm2; as the thickness of Al coatings increased, the corrosion resistance of Al coatings was increased, and that of coatings as thick as 70 μm was over 300 h. With the thickness of coating increased from 0 to 70 μm, the coercivity of the magnet was slightly increased and the residual magnetism was decreased from 2.0% to 4.26% of the original sample. Plasma spraying coating with excellent performance in adhesion, corrosion resistance and preparation process were used to prepare Al protective coatings and achieve the great protection to NdFeB magnet. The sprayed Al coating is a sacrificial anode to protect the substrate and have almost no damage to magnet properties.

sintered NdFeB; plasma spray; Al protective coating; anticorrosion properties; magnetic properties

TG174

A

1001-3660(2022)12-0208-09

10.16490/j.cnki.issn.1001-3660.2022.12.021

2021–10–22;

2022–02–17

2021-10-22;

2022-02-17

内蒙古自然基金(2020MS05015);内蒙古科技兴蒙重点专项(XM2020BT01)

Natural Science Foundation of Inner Mongolia (2020MS05015); The Key Program for Science and Technology Prospering Inner Mongolia (XM2020BT01)

张帅(1994—),男,硕士,工程师,主要研究方向为表面工程。

ZHANG Shuai (1994-), Male, Master, Engineer, Research focus: surface engineering.

鲁飞(1986—),男,硕士,高级工程师,主要研究方向为功能材料。

LU Fei (1986-), Male, Master, Senior engineer, Postgraduate, Research focus: functional materials.

张帅, 刘树峰, 鲁飞, 等. 烧结NdFeB表面等离子喷涂Al防护涂层制备工艺及性能研究[J]. 表面技术, 2022, 51(12): 208-216.

ZHANG Shuai, LIU Shu-feng, LU Fei, et al. Preparation Technology and Properties of Al Protective Coatings on the Surface of Sintered NdFeB Magnet Via Plasma Spray[J]. Surface Technology, 2022, 51(12): 208-216.

责任编辑:刘世忠