生物质基环保型聚氨酯的制备与应用研究进展

2022-12-21谢利徐玥阳刘晓慧齐悦悦陈明欣郭禹彤周星

谢利,徐玥阳,刘晓慧,齐悦悦,陈明欣,郭禹彤,周星

生物质基环保型聚氨酯的制备与应用研究进展

谢利,徐玥阳,刘晓慧,齐悦悦,陈明欣,郭禹彤,周星

(西安理工大学 印刷包装与数字媒体学院,西安 710048)

从利用生物质资源制备环保型聚氨酯树脂的角度揭示聚氨酯的结构调控机制及性能影响因素,为植物油基聚氨酯及其印刷包装材料提供多种有效的制备途径,为印刷包装材料提供丰富的原料。通过对比不同种类的植物油制备不同聚氨酯原料,综述包括蓖麻油、大豆油、葵花籽油、亚麻子油等油脂,以及木质素、腰果酚等制备生物质基多元醇、异氰酸酯作为扩链剂的二元醇原料。详细讨论了生物质转化为活性原料用于合成环保型聚氨酯,并介绍了主要的机理和方法,认为环氧开环法仍是植物油转化为多元醇的主要途径。利用生物质资源及其废弃物制备环保型聚氨酯是未来绿色聚氨酯类产品的最有效途径,在绿色化学和纳米科技的推动下,植物油基的绿色、高性能的环保型聚氨酯能成为印刷油墨、包装胶黏剂及涂层的关键原料,具有广阔的应用前景。

水性聚氨酯;生物质;油墨

水性聚氨酯(Waterborne Polyurethane,WPU)是由分散在水中的聚氨酯(Polyurethane,PU)分子链卷曲形成的纳米颗粒组成的重要材料,水分散液一般呈现为乳白色液体,偶尔表现出轻微的蓝色或红色光[1]。WPU产品形式主要有纤维涂料、替代基材黏合剂、油墨黏合剂、金属底漆、嵌缝材料、涂料添加剂、消泡剂、缔合增稠剂、颜料浆和纺织染料等,广泛应用于运输、建筑、工业、机械、电子设备、家具、服装、纺织、印刷和包装、食品加工、生物医学等领域[2-8]。聚氨酯由低聚物多元醇(二醇)、多异氰酸酯(二异氰酸酯)、扩链剂和其他添加剂通过逐步聚合或乳液聚合合成。PU的主要原料都来自石油,容易被石油资源危机、世界政治及环境污染等问题所影响。同时,由于聚合物链的缓慢扩散特性,在保持机械强度的同时制造出具有优异愈合能力的PU具有较大的挑战性,尤其在合成具有高韧性、快速自愈能力和抗菌性能的功能性及高耐性的PU材料方面具有更大的需求[9]。因此,为了保障广泛应用的PU产品有充足的原料来源,且提升其综合性能,有必要对WPU原料进行开发研究。其中,生物质作为来源广泛的可再生自然资源,成本相对较低、容易获得且能大量生产,可避免石化资源造成的限制[10]。植物油很早就被用于印刷油墨的生产,将植物油进行深度开发进而制备综合性能良好的WPU;不同的植物油已经被用于制备酯交换产物,即二醇,可以作为合成PU的原料或其改性原料的前驱体,具备成本低的优势,且结构中存在的长脂肪酸链,可赋予涂层以优异的柔韧性和光泽,能有效为印刷包装油墨,涂料及胶黏剂等材料提供绿色、丰富的原料[11-13]。

1 水性聚合物分散液的性能

为了理解和制备WPU分散体,首先应了解水性聚合物的特性。众所周知,水性聚合物的聚集状态通常是热力学不稳定的,表明它是分散体而不是溶液。由于分散聚合物颗粒的内表面积较大,相分离和凝固会受到明显阻碍,因此通常需要添加稳定剂。颗粒团聚的驱动力来自于减少内表面所获得的能量。最后,在水相中产生微相分离的聚合物链段以形成具备自支撑性或者非自支撑性的聚合物颗粒。通常,具有高稳定性的聚合物分散体因其优异的综合性能而备受关注。这可以通过提供离子基团来实现,例如通过二羟甲基丙酸(Dihydroxymethylpropionic Acid,DMPA)将离子基团并入聚氨酯链,或在乳液中使用阴离子或阳离子表面活性剂以获得高稳定性的WPU[14-15],因此,制备WPU或者其他水性聚合物,原料的结构及性能特点成为了关键因素。

2 植物油基聚氨酯

2.1 植物油基原料种类及其在聚氨酯中的应用

植物油基PU被誉为PU工业最重要的技术创新之一[16]。根据是否采用异氰酸酯作为原料,PU可分为异氰酸酯型PU(Isocyanate Polyurethanes,IPU)和非异氰酸酯型PU(Non-Isocyanate Polyurethanes,NIPU)。在IPU中,植物油基原料可以用于制备低聚物多元醇、扩链剂二元醇、异氰酸酯等;在NIPU中,植物油基PU可以通过含有环碳酸酯键的植物油基主体和脂肪族或脂环伯胺反应得到[17],因此,植物油基原料在PU中有巨大的应用价值,后文将详细介绍不同种类的植物油基原料的制备原理及性能。

2.2 植物油基多元醇

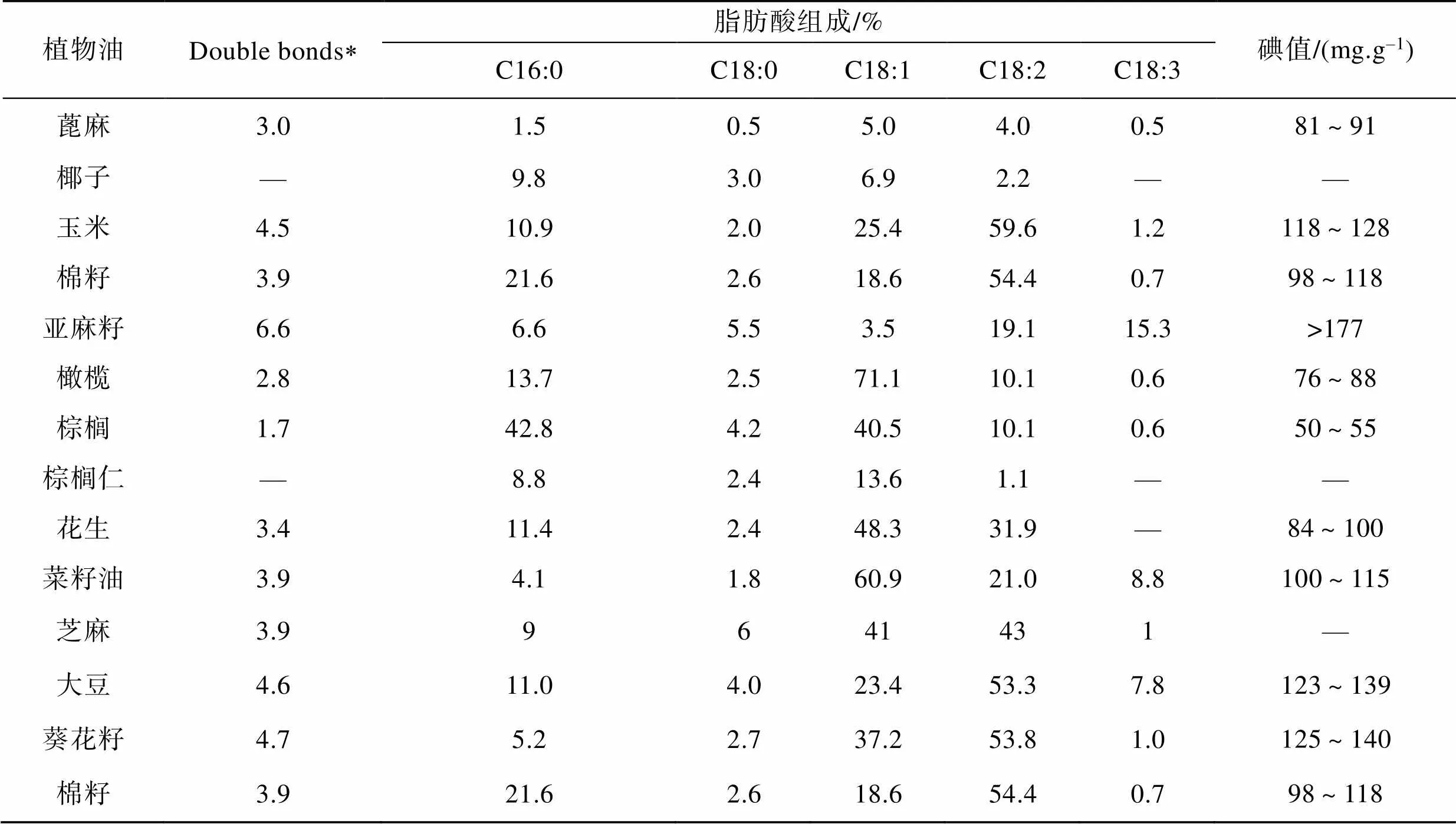

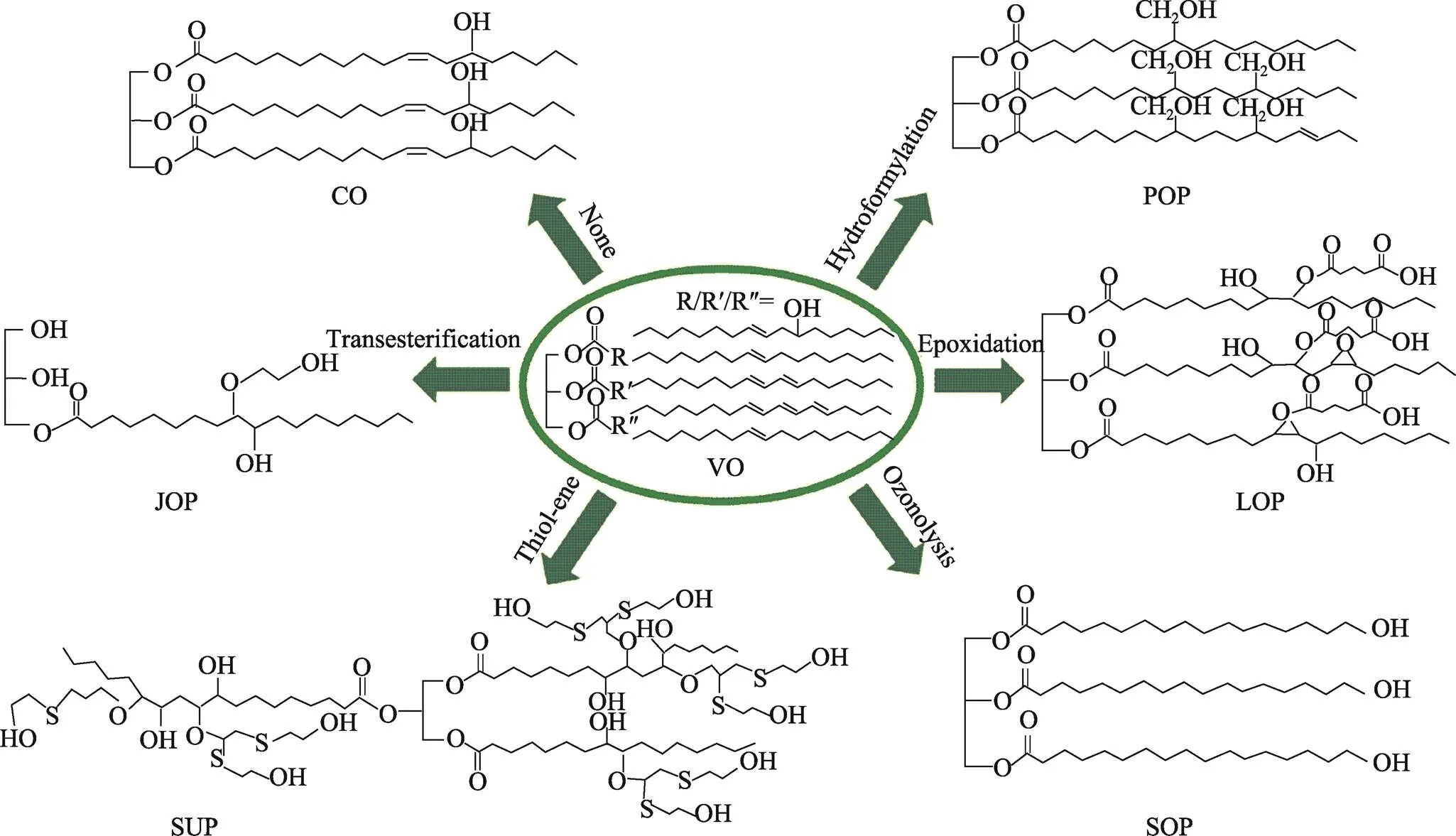

来自不同植物(大豆、棕榈、油菜籽等)的植物油由于其丰富的可再生资源,固有的生物降解性和低廉的价格,已成为WPU行业最有前途和吸引力的原料。植物油的化学成分是甘油三酯和3种不同组成的长链脂肪酸,反应性取决于碳–碳双键(C=C)和酯活性位点[18]。此外,一些植物油可以直接用作具有反应活性的天然羟基多元醇。但有些油中没有羟基,需要通过对双键和酯基等活性基团的改性将羟基引入分子结构中。主要方法是通过植物油(甘油与C6至C22碳原子脂肪酸的甘油酯)中的天然甘油三酯的水解[19]。普通植物油的脂肪酸组成和不饱和度是区分植物油的主要指标,见表1[12]。除蓖麻油外,由于缺乏化学反应活性羟基,其他植物油很难直接用于制备WPU。植物油甘油三酯中的C=C键和酯键允许引入此类基团与异氰酸酯反应。值得注意的是,相当多的大于2.5个C=C键的甘油三酯倾向于满足反应(表1)。PU分散体中使用的主要植物油(蓖麻油、大豆油、葵花油、亚麻籽油、麻疯树油和棕榈油)见图1。

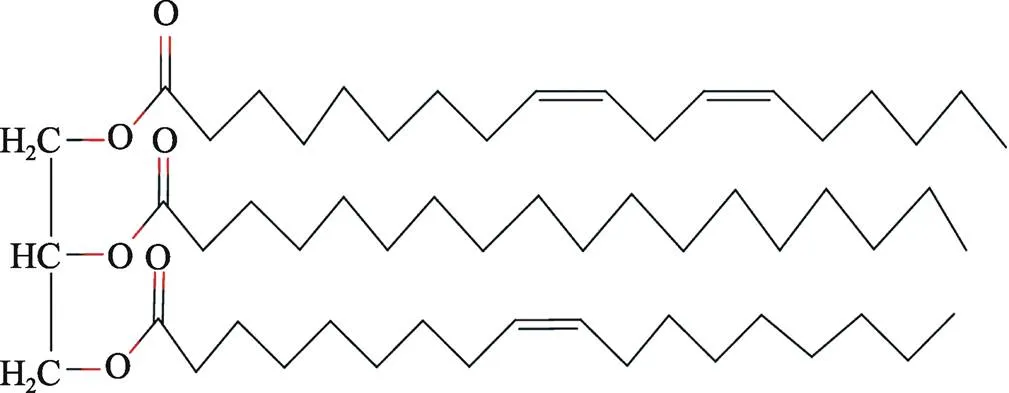

蓖麻油是一种脂肪酸甘油酯,化学结构见图2,可以直接与异氰酸酯反应,形成天然植物油多元醇形式的PU[20]。由于蓖麻油链上羟基的均匀分布,使得合成的WPU具有较大的交联度、较高的力学性能和热稳定性从而可以直接用于制备PU黏合剂、涂料、泡沫塑料,也可改性使用。Dang等[21]采用蓖麻油制备的阴离子WPU,将蓖麻油作为软链段添加聚合物链中,显著改变了薄膜的力学性能和柔韧性。此外,通过向醇解和酯交换反应中添加低分子多元醇,如乙二醇、甘油、季戊四醇等,可生成具有不同羟基值和分子量的蓖麻油衍生物多元醇。相较于橄榄油、大豆油和葵花籽油等其他植物油,蓖麻油具有显著优势。蓖麻油约90%的成分是蓖麻油酸,每12个碳上有一个羟基,第9和第10个碳之间有一个碳碳双键(如图2)。本体聚合过程中通过单点方法制备的蓖麻油基聚氨酯弹性体[22-24],然而,所得的弹性体不溶于常见的有机溶剂,从而有毒的催化剂和未反应的原料不能轻易从交联弹性体中去除。蓖麻油的羟基官能度平均为2.7,导致聚合过程中形成聚合物结构的三维网络,从而赋予聚合物以更高的黏弹性[25-26]。

表1 常见植物油的不饱和度和组成[12]

Tab.1 Degree of unsaturation and composition of common vegetable oils[12]

注:*表示每个甘油三酯的C=C双键数目。

图1 聚氨酯分散体中主要使用的植物油的分子结构[2]

图2 蓖麻油化学结构[18]

大多数植物油,如大豆、向日葵、亚麻子、桐油、麻疯树油和棕榈油中都没有化学反应活性羟基,因此,需要对C=C键反应位点进行化学修饰引入羟基。它们通常是通过双键的环氧化,然后环氧化物与乙醇开环而得到的,这可能会产生具备化学反应活性的二级羟基[27]。当前主要有5种合成路线,分别是环氧化环氧乙烷开环反应、硫醇烯反应、氢甲酰化加氢、臭氧分解和酯交换跨酰胺反应[10,18-19,28-39]。

大豆油是一种多不饱和或亚油酸,极易受到油脂氧化型油脂的影响,但大豆油不含天然羟基。同时,由于改性后大豆油基多元醇的多官能团,在合成PU时容易出现高交联和凝胶化。它优选于PU泡沫和弹性体,但不适用于WPU分散体。降低羟基官能度是调整多元醇可用于制备WPU的有效途径[40],主要方法为通过环氧开环反应将大豆油转化为活性多元醇,通过环氧化和羟基化,大豆油的官能度为1~6,羟值为50~700 mg/g。Zhang等[41]以1,8–二氮杂二环戊烯–7–烯为催化剂,研究了环氧化大豆油和蓖麻油脂肪酸之间的开环反应动力学。结果表明,环氧树脂与羧基的开环反应活化能为72.2 kJ/mol,而以质子为催化剂的开环活化能为75.1kJ/mol,较高的能量可能归因于蓖麻油长碳链的空间位阻效应。Feng等[42]通过巯基烯与2–巯基乙醇反应制备大豆油基多元醇(见图3),并且由于初级羟基的存在,所得多元醇对二异氰酸酯具有较高的反应活性。此外,利用这种环氧化大豆油和戊二酸可以得到生物基乳化剂,可以取代传统石油基乳化剂[43]。

葵花籽油可用作多元醇、异氰酸酯和扩链剂制备PU。通过环氧化和环氧基的开环作用将羟基引入植物油的C=C键结构中,进而形成化学反应活性多元醇[44]。Omrani等[45]通过硫醇–炔反应从葵花籽油中合成了高一级羟基官能度多元醇,如图4所示,新型葵花籽油基多元醇由于具有高羟基官能度,可高度调节以生成具有广泛交联密度的PU热塑性塑料。这些生物基聚氨酯具有合理热稳定性,可用作透明膜。同样,高羟基多元醇在紫外线固化PU、聚酯合成等领域有着广泛的应用[46-47]。另外,Shendi等[48]提出了一种新的含羧酸基团的多元醇以取代价格昂贵的二羟基酸,该多元醇由葵花籽油经环氧化、开环和皂化反应制备而成,并作为亲水性扩链剂制备WPU。

亚麻籽油是从亚麻籽中提取的廉价可再生资源之一。最新研究表明,亚麻籽油基多元醇是通过甘油的酯交换反应合成的,然后用作扩链剂与二异氰酸酯合成WPU。Cheng等[49]介绍了通过酯交换法从亚麻籽油合成WPU,实验结果表明,显著提高WPU中的生物基含量,改善了其热性能和力学性能。同时,亚麻籽油基涂料对木材具有优异的附着力、耐用性和耐光性。此外,亚麻籽油被成功用作取代二羟甲基丙酸的亲水性扩链剂制备阴离子WPU。同时,将亚麻籽油环氧化,然后用乙二醇和盐酸开环,可皂化为多羟基脂肪酸[50]。

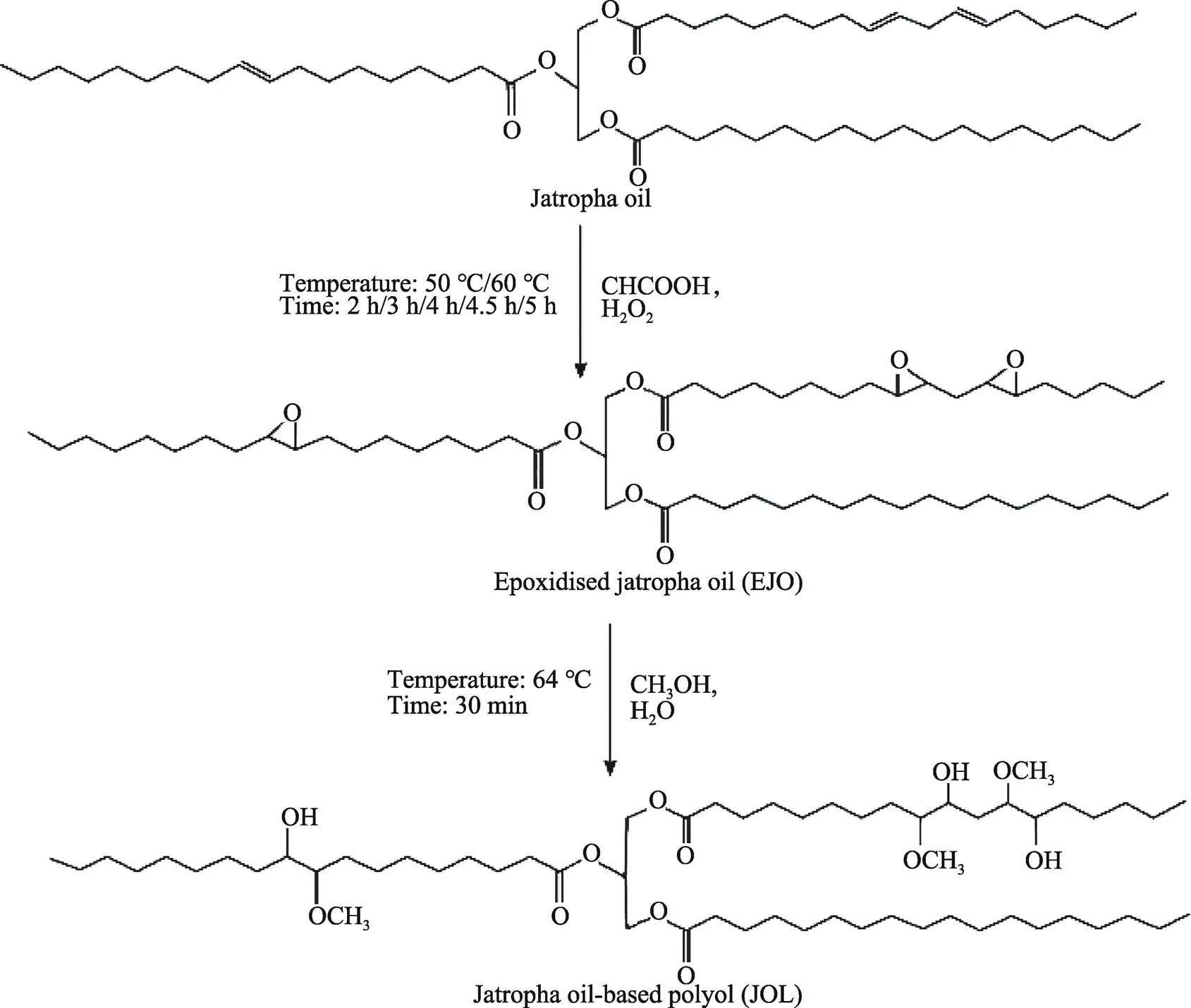

麻疯树油是从麻疯树种子中提取的,含有高浓度的佛波酯有毒成分,因此不能食用[51]。麻疯树油的含油量约为40%~60%,这对于提取具有良好的经济意义[52]。Saalah等[53]通过环氧化和环氧乙烷开环工艺从麻疯树油中制备了麻疯树油基多元醇,并研究了麻疯树油基WPU中硬段、羟基数和离子乳化剂含量对胶体稳定性和流变性能的影响,制备出来的聚氨酯分散体平均粒径较小,胶体具备良好的稳定性,见图5。

棕榈油由油棕制成,由甘油三酯和甘油三酸酯组成,化学结构见图6。为了制备PU,将羟基引入棕榈油骨架中制备具有反应活性多元醇较为关键,通过小分子多元醇的环氧化和酯交换是引入羟基制备棕榈油基多元醇的替代方法。Yeoh等[54-55]制备了棕榈油基聚酯多元醇,该多元醇由环氧化物棕榈油酸和戊二酸衍生而来,并与异佛尔酮二异氰酸酯反应生成脂肪族PU,无需再加入任何商用石化多元醇。

总而言之,以各种绿色天然植物资源为原料合成一系列植物油基多元醇,可以用作不同用途的聚氨酯产品中。植物油分子链上有酯基和不饱和碳碳双键等多种功能位点,易于转化为不同的功能单体,如二醇、多元醇和含羟基的聚合物,可用于合成聚氨酯,因此,它可以作为石油基聚合物的替代品,生产生物基聚氨酯的绿色前驱体。

图3 硫醇–烯光点击反应制备大豆油基多元醇[42]

图4 葵花籽油生物基超支化多元醇的合成途径[45]

Fig.4 Synthesis method of bio-based hyperbranched polyol from sunflower oil[45]

图5 通过环氧化和环氧乙烷开环法合成麻疯树油基多元醇[53]

图6 棕榈油化学结构

2.3 植物油基异氰酸酯

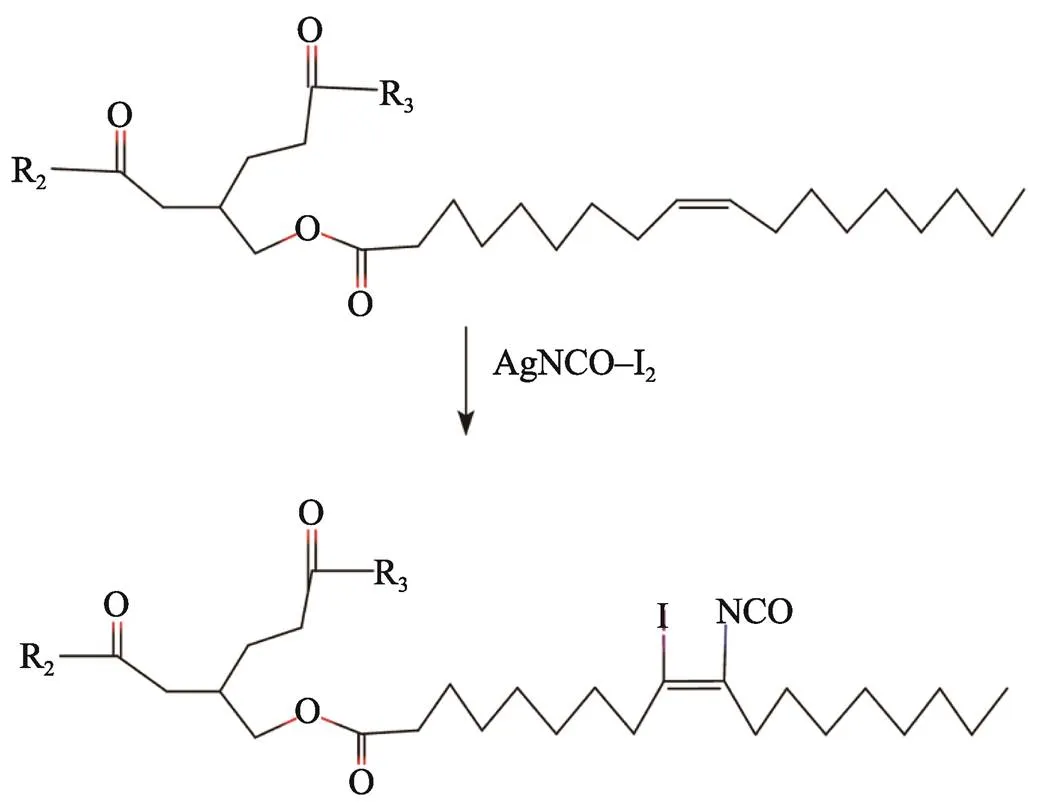

除了植物油基多元醇外,研究人员还致力于通过同时使用植物油来替代石油基异氰酸酯,从而实现异氰酸酯的绿色化。因为异氰酸酯具有高反应性和毒性,所以从植物油中合成适用于PU的二异氰酸酯仍然是一个巨大的挑战。据报道,汉高公司(Henkel Corporation Co)及通用磨坊公司(General Mills Co)提供了市场化的基于脂肪酸的二异氰酸酯,称为二聚二异氰酸盐[56]。大豆油有望通过异氰酸酯官能化合成二异氰酸酯,当前主要有2种策略,其中一种是使用N–溴代丁二酰亚胺在烯丙基位置溴化甘油三酯,然后与AgNCO反应生成含异氰酸酯的甘油三酸酯[57]。另一种是通过异氰酸酯碘和大豆油在室温下的反应,可进一步制备大豆油的异氰酸酯加合物,每甘油三酯含有3.1个异氰酸酯基团,见图7。这些异氰酸酯适合于制备WPU[23]。此外,油酸也有可能通过将二羧酸氧化后,通过复分解合成不饱和的,–二羧酸,进而可被用于制备新型长链不饱和二异氰酸酯[58]。

图7 含碘植物油基聚异氰酸酯的合成

3 其他生物质基低聚物多元醇

3.1 木质素多元醇

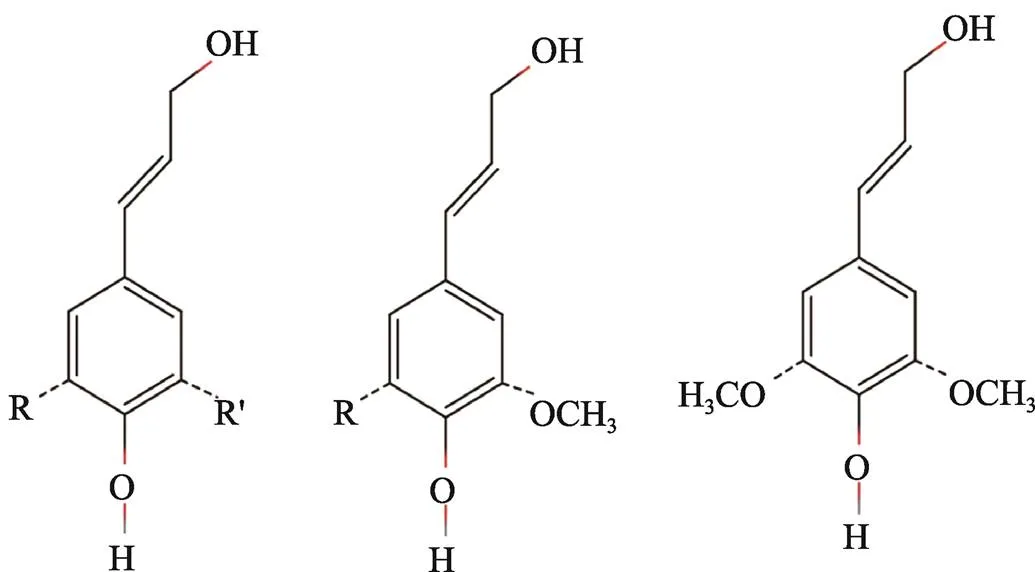

木质素来源于木材,是自然界中可再生且丰富的芳香族聚合物,它是由3种单体(松柏醇、对香豆醇和芥子醇)组成的交联网络结构化合物[59-60]。木质素的三维网络具备足够的强度和硬度,可直接混合到聚合物基质中,以获得抗菌、抗氧化、抗紫外线、阻燃等性能[61],在工业应用方面有巨大潜力。木质素的主要官能团有羟基、甲氧基、醚基、羰基和羧基[62]。如图8所示,这些活性基团为木质素的改性,引入新的化学活性位点提供了可能,例如,羟基功能化开发的多功能木质素共聚物,可作为PU的原料[63]。

图8 构成木质素的主要结构单元

由于羟基的存在,木质素可以直接与异氰酸酯作为多元醇前体反应,从而在较温和的条件下合成PU[64]。通过溶剂分馏预处理方法可以有效提取均质木质素馏分,以获得清晰的特征结构和较高的纯度[65-66]。Wang等[67]探索了以未改性软木硫酸盐木质素馏分作为初级羟基制备木质素基PU的方法。结果表明,木质素分子量的增加可以提高木质素基聚氨酯的硬度或变形抗力。利用木质素作为单一多元醇开发的聚氨酯材料通常很脆且硬[68],因此,可以对木质素进行化学改性以提高其反应性[69],例如,木质素的氧化作为一种提高醇羟基含量和木质素功能性的方法被广泛研究[70]。Ren等[71]研究了环氧氯丙烷改性木质素用于WPU的合成,并分析了木质素对粒径分布、热稳定性、力学性能以及耐水性的影响。

3.2 腰果壳液基多元醇

腰果壳液是从腰果中提取出来的,含有许多具有高度疏水性脂肪链的活性酚衍生物,如腰果酚、腰果醇、2–甲基腰果酚和苦味柠檬酸[70]。据报道,腰果壳液体通常用于环保型聚氨酯的开发,从腰果壳液中提取的一系列多元醇作为PU制备的组分[72]。含有特征性长不饱和脂肪族链的腰果酚也用作多元醇或者合成环保型PU,Wang等[73]通过硫醇基点击反应引入环氧化腰果酚多元醇,得到相对较高的羟值腰果酚(图9),在PU中具备潜在应用价值。

第二类工程包括封禁标牌、拦护设施、梯田、树盘、经济林、水土保持林、水土保持种草、谷坊等工程,这几类是传统水土保持工程,虽然尚未颁布专用的质量评定标准,但施工工艺成熟,控制项目和指标较清晰,因此应根据工程的具体施工工艺,制定合理的控制项目和指标,确定评定标准。并且在制定过程中,针对部分项目,可直接参考水利工程标准,尤其是在砌石工艺上采用较多,可直接参考规范中关于砌石的质量评定标准。对于林木和种草措施,可参考园林绿化的标准,并对其进行简化,符合生态清洁小流域治理工程的情况。

图9 腰果壳衍生的多元醇作为聚氨酯的可持续原料应用

3.3 植物秸秆多元醇

从纤维素中生产生物多醇一直是PU工业的常用方案。其中,农作物秸秆中含有丰富的纤维素,如大豆秸秆、油菜秸秆、小麦秸秆和玉米秸秆[74]。这些植物秸秆可以通过液化过程,由分解、酯化、缩聚等一系列反应,转化为液体生物多醇[75]。研究发现,将各种植物秸秆材料在不同溶剂中液化,生成多元醇,作为溶剂的液化产物是富含羟基的聚酯或聚醚多元醇,可与异氰酸酯反应生成PU,具备良好的综合性能[76]。Hu等[77]提出了利用粗甘油从大豆秸秆中提取高质量生物多醇用于合成PU。与传统的石油基PU相比,含有440~540 mg/g羟基的多元醇可制备性能良好的PU。Serrano等[78]研究了在甘油溶剂中通过液化反应制备麦草多元醇,并将其用于合成可生物降解的PU。

3.4 萜烯基多元醇

萜烯是从多种植物中提取的一类天然碳氢化合物,广泛分布于自然界,包括蒎烯、柠檬烯、匹罗卡酮、月桂烯、异罗卡烯、罗卡烯和法尼烯[79]。结构的多样性(即线性、环状或多环)和双键的存在使萜烯具有多功能和高反应性。近年来,在合成不同萜烯聚合物,特别是聚氨酯方面有了长足的进展[80]。

柠檬烯是从柑橘类水果中分离出来的廉价、可再生的原料,由2个不同的双键组成的单萜烯[81],由于这种特殊的结构,柠檬烯可以很容易地被改性为其他有价值的材料。通过环氧化或硫醇烯点击反应可以在其分子链上引入羟基,以获得多元醇,进而制备PU(图10a)[82-84]。Gupta等[82-85]报道了以柠檬烯为基础合成具有芳香结构的新型多元醇,并进一步用于制备PU。柠檬烯的双环氧化产物二氧化柠檬烯,是制备生物基聚碳酸酯或非异氰酸酯PU的关键前体,见图10b。

图10 柠檬烯制备PU的不同途径

3.5 松香基多元醇

松香主要由90%的松香酸组成,是松树树干分泌的一种脆性、透明的固体天然树脂,具有优异的绝缘性、黏附性和乳化性,能使聚合物具有较高的力学性能,广泛应用于材料、化学、医药和化妆品等领域[85]。由于松香分子结构中的共轭键和羧基等反应基团,通过加成、异构化、聚合、酯化等方式能得到不同的衍生物,因此,松香及其衍生物可被用作PU合成领域化学原料的替代品[86]。Liu等[87]研究了松香基环碳酸酯与胺成功制备松香基非异氰酸酯PU涂料。通过对松香上的共轭双键和羧基进行改性,可得到松香基二醇扩链剂,将其引入PU硬段结构中,得到生物基PU。Xu等[88-89]报道,从松香酸中提取的富马罗哌酸的聚酯多元醇可成功地用于合成一系列新型松香基WPU,更有助于提升WPU的力学性能、热稳定性和耐水性。

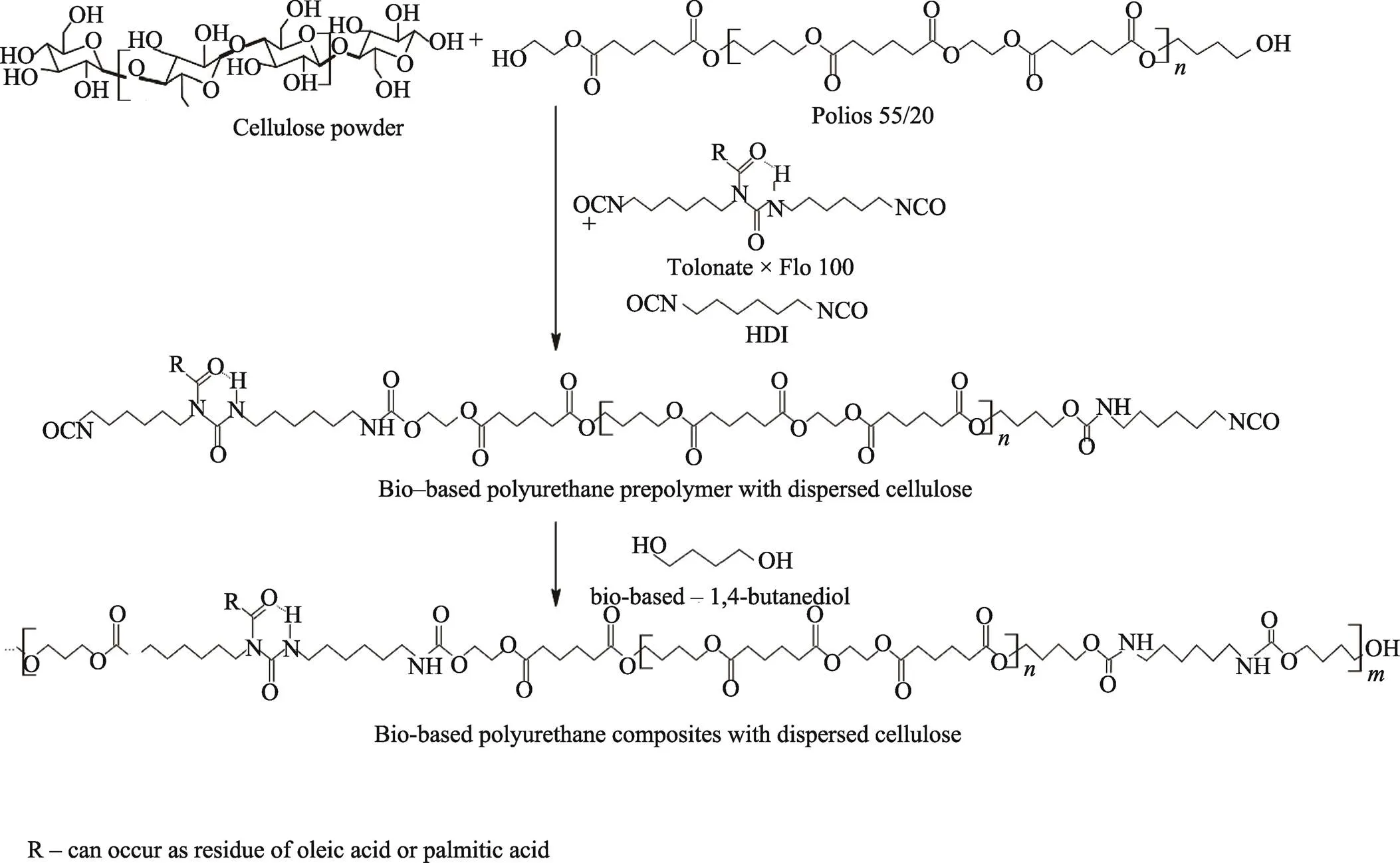

3.6 纤维素

纤维素由线性和长链葡萄糖组成,是目前最丰富的天然聚合物。由于存在大量羟基,从而与其他聚合物的氢键功能引入化学活性位点提供了可能[90-91]。纤维素种类可参照其微观形态分为纤维素纤维(微米级和纳米级)、纤维素纳米晶体(Cellulose Nanocrystals, CNC)和细菌纤维素(Bacterial Cellulose, BC)[92-93],由于具有优异的生物降解性、力学性能以及可再生性都被用于WPU的改性[94-96]。在PU合成过程中,纤维素在分子水平溶解上存在难题,较难获得用于聚合均匀的纤维素溶液,因此,不同的纤维素产品主要用作改性PU的填料是提高PU性能的有效途径[97-99]。

Głowinska等[100]研究了纤维素粉末参与生物基聚氨酯复合材料的合成,其中取代基R可以作为油酸或棕榈酸的残基出现,见图11。纤维素纳米纤维(Cellulose Nanofibers, CNF)可以分别通过化学接枝和物理共混工艺引入WPU。研究表明,氢键与PU链形成化学键用于化学接枝,对提高PU的物理共混性能起着关键作用。由于纤维素的不溶性,化学结构无明显变化,PU和通过CNF改性的PU热稳定性相似。值得注意的是,CNF显著提高了聚氨酯的抗拉强度(约41.8 MPa,高出纯聚氨酯约26.3 MPa)[101]。

由于纳米级氢键与PU链的相互作用,CNC表现出具有高结晶度的棒状纳米形态,基于它良好的热性能和力学性能,它可能是最具吸引力的纳米级生物质。在笔者之前的工作已经通过使用废纸中的CNC来增强WPU来证明了这一点[102-103]。CNC还可进一步改性以赋予WPU的新特性,包括导电性[104]、耐水性[105]和抗菌性能等[106]。此外,CNC还可与一氧化钒(Vanadium Oxide, VO)混合改性WPU,以呈现高硬度和兼容性、弹性恢复和黏附性等多功能特性[107]。

BC是一种来自细菌菌株的独特纤维素产品。在医学、食品和组织工程领域发挥着重要作用。由于存在强的链间氢键,其呈现出具有显著力学性能的3D纳米纤维网络。独特的结构和性能为将BC用作水凝胶治疗伤口提供了可能[108]。Urbina等[109]制备了具有形状记忆特性的凝胶状半透明BC/WPU复合膜,被认为是生物医学产品的最佳候选产品。形状记忆性能由温度调节,形状恢复率可达(92.8±6.3)%。

图11 生物基聚氨酯复合材料的制备[100]

4 水性聚氨酯基印刷包装材料及发展

WPU以其优异的综合性能而备受重视,越来越多的应用于印刷包装领域,尤其在印刷油墨、涂层、包装胶黏剂等产品中。在康师傅面碗表面印刷包装中,大部分胶黏剂及上光油采用WPU系列产品。WPU及其改性树脂也常用于镭射镀铝膜转移用背涂涂料中,在高精度防伪印刷包装中被广泛应用。

WPU因其广泛可调的软段与硬段交替结构,具备良好的弹性及机械强度,用于制备油墨时能赋予油墨良好的黏度、稳定性、细度等性能,同时使墨膜具备优异的粘弹性、耐刮擦性、光泽度等,在环保型油墨制造领域备受关注。俞胡斐等[110]将WPU 1 426/聚乙二醇400(质量比为2∶3)混合树脂为油墨连结料,制备水性变色油墨,发现当溶剂、连结料、去离子水三者质量分数分别为54.9%、17.4%、27.7%时,油墨样品印刷效果良好且变色效果最为显著。李海徽等[111]使用聚丙二醇(Polypropylene Glycol,PPG)为低聚物多元醇,以DMPA为亲水性扩链剂合成一系列醇溶性PU。发现随着PPG分子量的逐渐增大,油墨的黏度,细度和稳态剪切黏度先增大后减小,当PPG相对分子质量为1 500时,所合成PU制备的油墨综合性能最佳,在油墨黏度为880 MPa·s,细度为5 μm,析油率为5%,附着力为93%,初干性为84 mm/s,光泽度为37时,印刷适性良好,油墨在15 s的结构回复率为94.47%,触变性良好。

综上,将PU作为油墨连结料制备水性环保型油墨,具备较好的应用前景[112]。将植物油用于制备新型环保型WPU,有望取代现有的溶剂型聚合物连结料体系。事实上,植物油基油墨是出现最早的油墨之一,在世界工业化进程中,虽然因为印刷速度需求植物油基油墨逐渐被取代,但是新世纪以来石油资源危机、环境保护等问题日益严重,从而使得植物油基PU连结料及其油墨研究与植物油在涂料和印刷油墨中的应用中受到更广泛关注。Roy等[113]制备了植物油甲酯基“绿色”胶印油墨,评估了油墨的流变特性,并与使用石油基溶剂的标准印刷油墨进行了比较。得出酯类印刷油墨的性能与矿物油类产品相当,酯基油墨相较于矿物油基,其产品粘性、稳定性和光泽度更为优越。

在包装胶黏剂领域,WPU因分子链含有大量的氨基甲酸酯基团、脲键、醚键等,容易与不同基材表面产生多种相互作用,因而对多种基材黏结力良好,而且WPU中的亲水性羧基盐、羟基等活性基团在特定条件下容易形成交联,为进一步提升WPU胶黏剂粘结性能提供可能。2020年,日本东洋油墨集团的成员Toyochem公司推出Cyabine系列聚氨酯压敏胶,通过采用植物来源的原料制备环保型PU包装胶黏剂,且具备可生物降解性。Chen等[114]设计含有氨基磺酸基团(NH2SO3H)的桐油基PU预聚物制备WPU环保胶黏剂,180°T型剥离强度实验结果表明该胶黏剂的胶黏强度可达1.799 N,表现出优良的黏合性和力学性能。

在涂层领域,PU以其优异的力学性能和光泽度而成为上光油等保护印刷包装涂层的关键材料之一,尤其是紫外光(Ultraviolet,UV)固化环保型聚氨酯涂层,在木器、纸张、塑料、金属及玻璃等包装材料领域具备巨大的潜在应用价值。通常采用丙烯酸类的功能单体与PU预聚体进行接枝共聚,制备分子链段上含有C=C键的活性功能丙烯酸单体–聚氨酯共聚物,与光引发剂在分散相中混合均匀后作为涂料使用。在UV光照下,光引发剂产生的活性自由基引发C=C双键发生自由基聚合,进而促进PU产生交联,形成综合性能优异的涂层[115]。

5 结语

传统的PU工业及下游印刷包装材料严重依赖石油资源。随着人们对废物回收和环境污染问题的日益关注,直接导致了工业生产中可持续PU的可再生和生物降解资源的使用。文中系统地介绍了利用生物质资源合成WPU分散体作为可持续材料的最新研究进展。近年来,生物质基PU在印刷、包装、形状记忆聚合物等领域的材料功能化应用得到了进一步的探索。这些生物质中,特别是植物油和纤维素在过去十年中受到了广泛关注,为日益增长的环境和能源问题提供了有效解决方案。值得一提的是,生物基WPU仍然存在许多问题需要未来的更多研究。

1)植物油向多元醇(或二元醇、异氰酸酯)的转化效率相对有限。最常用的方法可能是环氧化物开环法,这可能会降低产品的纯度。

2)尽管设计了植物油基异氰酸酯,但非异氰酸酯WPU仍然需要扩大原料来源。

3)基于植物油基单体构建具有可控结构的WPU链段仍是研究焦点,尤其是采用活性聚合方法来扩大这些生物基聚合物的应用。

总而言之,基于生物基单体的环保型WPU应大规模设计和开发,进一步扩大生物质基原料来源范围,并实现规模化生产,以满足日益增长的功能化和智能化聚合物技术的需求。

[1] ZHOU Xing, et al. Protean Morphology of Waterborne Polyurethane Dispersion: An Overview of Nanoparticles from Sphere to Irregular Elongated Shape[J]. Progress in Organic Coatings, 2020, 146: 105742.

[2] ZHOU Xing, ZHANG Xin, PU Meng-yuan, et al. Bio-Based Polyurethane Aqueous Dispersions[J]. Physical Sciences Reviews, 2021, 20200075.

[3] ZHOU Xing, FANG Chang-qing, CHEN Jing, et al. Correlation of Raw Materials and Waterborne Polyurethane Properties by Sequence Similarity Analysis[J]. Journal of Materials Science & Technology, 2016, 32(7): 687-694.

[4] ZHOU Xing, FANG Chang-qing, LEI Wan-qing, et al. Thermal and Crystalline Properties of Waterborne Polyurethane by in Situ Water Reaction Process and the Potential Application as Biomaterial[J]. Progress in Organic Coatings, 2017, 104: 1-10.

[5] ZHOU Xing, FANG Chang-qing, LEI Wan-qing, et al. The Morphology and Structure of Natural Clays from Yangtze River and Their Interactions with Polyurethane Elastomer[J]. Composites Part A: Applied Science and Manufacturing, 2017, 96: 46-56.

[6] ZHOU Xing, SU Jian, WANG Chen-xi, et al. Design, Preparation and Measurement of Protein/CNTS Hybrids: A Concise Review[J]. Journal of Materials Science & Technology, 2020, 46: 74-87.

[7] ZHOU Xing, DENG Jing-rui, FANG Chang-qing, et al. Preparation and Characterization of Lysozyme@carbon Nanotubes/Waterborne Polyurethane Composite and the Potential Application in Printing Inks[J]. Progress in Organic Coatings, 2020, 142: 105600.

[8] ZHANG Chao-qun, GARRISON T F, MADBOULY S A, et al. Recent Advances in Vegetable Oil-Based Polymers and Their Composites[J]. Progress in Polymer Science, 2017, 71: 91-143.

[9] DUAN Ning, SUN Zhe, REN Yong-yuan, et al. Imidazolium-Based Ionic Polyurethanes with High Toughness, Tunable Healing Efficiency and Antibacterial Activities[J]. Polymer Chemistry, 2020, 11(4): 867-875.

[10] DESROCHES M, ESCOUVOIS M, AUVERGNE R. From Vegetable Oils to Polyurethanes: Synthetic Routes to Polyols and Main Industrial Products[J]. Polymer Reviews, 2012, 52(1): 38-79.

[11] KHANDERAY J C, GITE V V. Vegetable Oil-Based Polyurethane Coatings: Recent Developments in India[J]. Green Materials, 2017, 5(3): 1-14.

[12] SHI Meng-qing, YANG Jin, WANG Xi-wen. Preparation Castor Oil-Modified High Bio-Based Waterborne Polyurethane and Its Application[J]. Journal of Polymer Research, 2021, 28(9): 351.

[13] DENG Heng-hui, XIE Fei, SHI He-bo, et al. UV Resistance, Anticorrosion and High Toughness Bio-Based Waterborne Polyurethane Enabled by a Sorbitan Monooleate[J]. Chemical Engineering Journal, 2022, 446: 137124.

[14] ZHANG Yi, LIU Bo-yang, HUANG Kai-xi, et al. Eco-Friendly Castor Oil-Based Delivery System with Sustained Pesticide Release and Enhanced Retention[J]. ACS Applied Materials & Interfaces, 2020, 12(33): 37607-37618.

[15] ZHANG Yi, ZHANG Wen-bo, WANG Xiao, et al. Waterborne Polyurethanes from Castor Oil-Based Polyols for next Generation of Environmentally-Friendly Hair-Styling Agents[J]. Progress in Organic Coatings, 2020, 142: 105588.

[16] ZHAO Mei-he, WANG Ya-qi, LIU Ling-xiao, et al. Green Coatings from Renewable Modified Bentonite and Vegetable Oil Based Polyurethane for Slow Release Fertilizers[J]. Polymer Composites, 2018, 39(12): 4355-4363.

[17] 何鑫, 吴桂英, 闫云君. 植物油基平台化合物及高分子材料研究进展[J]. 生物工程学报, 2017, 33(5): 701-719.

HE Xin, WU Gui-ying, YAN Yun-jun. Advances in Platform Compounds and Polymers from Vegetable Oils[J]. Chinese Journal of Biotechnology, 2017, 33(5): 701-719.

[18] PETROVIC Z S, GUO A, ZHANG Wei, et al.. Structure and Properties of Polyurethanes Based on Halogenated and Nonhalogenated Soy-Polyols[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2000, 38(22): 4062-4069.

[19] GUO A, CHO Y, PETROVIC Z S, et al. Structure and Properties of Halogenated and Nonhalogenated Soy-Based Polyols[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2000, 38(21): 3900-3910.

[20] HORMAIZTEGUI M E V, ARANGUREN M I, MUCCI V L, et al. Synthesis and Characterization of a Waterborne Polyurethane Made from Castor Oil and Tartaric Acid[J]. European Polymer Journal, 2018, 102: 151-160.

[21] DANG L N, SINH L H, MINNA M, et al. Synthesis and Characterization of Castor Oil-Segmented Thermoplastic Polyurethane with Controlled Mechanical Properties[J]. European Polymer Journal, 2016, 81: 129-137.

[22] HABLOT E, ZHENG Dan, BOUQUEY M, et al. Polyurethanes Based on Castor Oil: Kinetics, Chemical, Mechanical and Thermal Properties[J]. Macromolecular Materials and Engineering, 2008, 293(11): 922-929.

[23] CAYLI G, KUSEFOGLU S. A Simple One-Step Synthesis and Polymerization of Plant Oil Triglyceride Iodo Isocyanates[J]. Journal of Applied Polymer Science, 2010, 116(4): 2433–2440.

[24] STIRNA U, LAZDIŅA B, VILSONE D, et al. Structure and Properties of the Polyurethane and Polyurethane Foam Synthesized from Castor Oil Polyols[J]. Journal of Cellular Plastics, 2012, 48(6): 476-488.

[25] YEGANEH H, MEHDIZADEH M R. Synthesis and Properties of Isocyanate Curable Millable Polyurethane Elastomers Based on Castor Oil as a Renewable Resource Polyol[J]. European Polymer Journal, 2004, 40(6): 1233-1238.

[26] CORCUERA M A, RUEDA L, D’ARLAS B F, et al. Microstructure and Properties of Polyurethanes Derived from Castor Oil[C]// 2nd International Conference on Biodegradable Polymers and Sustainable Composites, Alicante, SPAIN, 2010, 95(11): 2175-2184.

[27] PALASKAR D V, BOYER A, CLOUTET E, et al. Original Diols from Sunflower and Ricin Oils: Synthesis, Characterization, and Use as Polyurethane Building Blocks[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2012, 50(9): 1766-1782.

[28] NARAYAN R, GRAIVER D, FARMINER K W, et al. Novel Modified Fatty Acid Esters and Method of Preparation Thereof: US, 20100084603[P]. 2010-04-08.

[29] SHARMA V, KUNDU P P. Condensation Polymers from Natural Oils[J]. Progress in Polymer Science, 2008, 33(12): 1199-1215.

[30] BEHR A, FIENE M, BUß C, et al. Hydroaminomethylation of Fatty Acids with Primary and Secondary Amines-A New Route to Interesting Surfactant Substrates[J]. European Journal of Lipid Science and Technology, 2000, 102(7): 467-471.

[31] BANTCHEV G B, KENAR J A, BIRESAW G, et al. Free Radical Addition of Butanethiol to Vegetable Oil Double Bonds[J]. Journal of Agricultural and Food Chemistry, 2009, 57(4): 1282-1290.

[32] KOENIG N H, SWERN D. Organic Sulfur Derivatives. I. Addition of Mercaptoacetic Acid to Long-Chain Monounsaturated Compounds[J]. Journal of the American Chemical Society, 1957, 79(2): 362-365.

[33] LAROCK R C, DONG Xiao-yang, CHUNG S, et al. Preparation of Conjugated Soybean Oil and other Natural Oils and Fatty Acids by Homogeneous Transition Metal Catalysis[J]. Journal of the American Oil Chemists' Society, 2001, 78(5): 447-453.

[34] GUNSTONE F D. Chemical Reactions of Fatty Acids with Special Reference to the Carboxyl Group[J]. European Journal of Lipid Science and Technology, 2001, 103(5): 307-314.

[35] ZLATANIC A, PETROVIC Z S. Structure and Properties of Triolein-Based Polyurethane Networks[J]. Biomacromolecules, 2002, 3(5): 1048-1056.

[36] LYON C K, GARRETT V H, FRANKEL E N, et al. Rigid Urethane Foams from Hydroxymethylated Castor Oil, Safflower Oil, Oleic Safflower Oil, and Polyol Esters of Castor Acids[J]. Journal of the American Oil Chemists Society, 1974, 51(8): 331-334.

[37] PETROVIĆ Z S, GUO A, JAVNI I, et al. Polyurethane Networks from Polyols Obtained by Hydroformylation of Soybean Oil[J]. Polymer International, 2008, 57(2): 275-281.

[38] LI Zhen-rong, ZHAO Yu-hua, YAN Shi-run, et al. Catalytic Synthesis of Carbonated Soybean Oil[J]. Catalysis Letters, 2008, 123(3): 246-251.

[39] PARZUCHOWSKI P G, JURCZYK-KOWALSKA M, RYSZKOWSKA J, et al. Epoxy Resin Modified with Soybean Oil Containing Cyclic Carbonate Groups[J]. Journal of Applied Polymer Science, 2006, 102(3): 2904-2914.

[40] LU Yong-shang, LAROCK R C. Soybean-Oil-Based Waterborne Polyurethane Dispersions: Effects of Polyol Functionality and Hard Segment Content on Properties[J]. Biomacromolecules, 2008, 9(11): 3332-3340.

[41] ZHANG Chao-qun, LI Yu-zhan, CHEN Ru-qi, et al. Polyurethanes from Solvent-Free Vegetable Oil-Based Polyols[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(10): 2465-2476.

[42] FENG Ye-chang, LIANG Hai-yan, YANG Zi-ming, et al. A Solvent-Free and Scalable Method to Prepare Soybean-Oil-Based Polyols by Thiol-Ene Photo-Click Reaction and Biobased Polyurethanes Therefrom[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(8): 7365-7373.

[43] LIU Ling-xiao, LU Jing-yi, ZHANG Yi, et al. Thermosetting Polyurethanes Prepared with the Aid of a Fully Bio-Based Emulsifier with High Bio-Content, High Solid Content, and Superior Mechanical Properties[J]. Green Chemistry, 2019, 21(3): 526-537.

[44] BABANEJAD N, FARHADIAN A, OMRANI I, et al. Design, Characterization and in Vitro Evaluation of Novel Amphiphilic Block Sunflower Oil-Based Polyol Nanocarrier as a Potential Delivery System: Raloxifene-Hydrochloride as a Model[J]. Materials Science and Engineering: C, 2017, 78: 59-68.

[45] OMRANI I, FARHADIAN A, BABANEJAD N, et al. Synthesis of Novel High Primary Hydroxyl Functionality Polyol from Sunflower Oil Using Thiol-Yne Reaction and Their Application in Polyurethane Coating[J]. European Polymer Journal, 2016, 82: 220-231.

[46] HAJIRAHIMKHAN S, XU C C, RAGOGNA P J, et al. Ultraviolet Curable Coatings of Modified Lignin[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(11): 14685-14694.

[47] HOJABRI L, KONG Xiao-hua, NARINE S S, et al. Fatty Acid-Derived Diisocyanate and Biobased Polyurethane Produced from Vegetable Oil: Synthesis, Polymerization, and Characterization[J]. Biomacromolecules, 2009, 10(4): 884-891.

[48] SHENDI H K, OMRANI I, AHMADI A, et al. Synthesis and Characterization of a Novel Internal Emulsifier Derived from Sunflower Oil for the Preparation of Waterborne Polyurethane and Their Application in Coatings[J]. Progress in Organic Coatings, 2017, 105: 303-309.

[49] CHENG Zhao, LI Quan-tao, YAN Zheng, et al. Design and Synthesis of Novel Aminosiloxane Crosslinked Linseed Oil-Based Waterborne Polyurethane Composites and Its Physicochemical Properties[J]. Progress in Organic Coatings, 2019, 127: 194-201.

[50] CHEN Ru-qi, ZHANG Chao-qun, KESSLER M R, et al. Anionic Waterborne Polyurethane Dispersion from a Bio-Based Ionic Segment[J]. RSC Advances, 2014, 4(67): 35476-35483.

[51] KUMAR A, SHARMA S. An Evaluation of Multipurpose Oil Seed Crop for Industrial Uses (L.): A Review[J]. Industrial Crops and Products, 2008, 28(1): 1-10.

[52] LING Chai-kai, AUNG M M, RAYUNG M, et al. Performance of Ionic Transport Properties in Vegetable Oil-Based Polyurethane Acrylate Gel Polymer Electrolyte[J]. ACS Omega, 2019, 4(2): 2554-2564.

[53] SAALAH S, ABDULLAH L C, AUNG M M, et al. Physicochemical Properties of Jatropha Oil-Based Polyol Produced by a Two Steps Method[J]. Molecules, 2017, 22(4): 551.

[54] TANAKA R, HIROSE S, HATAKEYAMA H, et al. Preparation and Characterization of Polyurethane Foams Using a Palm Oil-Based Polyol[J]. Bioresource Technology, 2008, 99(9): 3810-3816.

[55] SITTINUN A, PISITSAK P, MANUSPIYA H, et al. Utilization of Palm Olein-Based Polyol for Polyurethane Foam Sponge Synthesis: Potential as a Sorbent Material[J]. Journal of Polymers and the Environment, 2020, 28(12): 3181-3191.

[56] LLIGADAS G, RONDA J C, GALIA M, et al. Plant Oils as Platform Chemicals for Polyurethane Synthesis: Current State-of-the-Art[J]. Biomacromolecules, 2010, 11(11): 2825-2835.

[57] CAYLI G, KUSEFOGLU S. Biobased Polyisocyanates from Plant Oil Triglycerides: Synthesis, Polymerization, and Characterization[J]. Journal of Applied Polymer Science, 2008, 109(5): 2948-2955.

[58] HOJABRI L, KONG Xiao-hua, NARINE S S, et al. Novel Long Chain Unsaturated Diisocyanate from Fatty Acid: Synthesis, Characterization, and Application in Bio-Based Polyurethane[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2010, 48(15): 3302-3310.

[59] ZAKZESKI J, BRUIJNINCX P C A, JONGERIUS A L, et al. The Catalytic Valorization of Lignin for the Production of Renewable Chemicals[J]. Chemical Reviews, 2010, 110(6): 3552-3599.

[60] MA Xiao-zhen, CHEN Jing, ZHU Jin, et al. Lignin-Based Polyurethane: Recent Advances and Future Perspectives[J]. Macromolecular Rapid Communications, 2021, 42(3): e2000492.

[61] LIU Li-na, QIAN Meng-bo, SONG Ping-an, et al. Fabrication of Green Lignin-Based Flame Retardants for Enhancing the Thermal and Fire Retardancy Properties of Polypropylene/Wood Composites[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(4): 2422-2431.

[62] BERNARDINI J, CINELLI P, ANGUILLESI I, et al. Flexible Polyurethane Foams Green Production Employing Lignin or Oxypropylated Lignin[J]. European Polymer Journal, 2015, 64: 147-156.

[63] CINELLI P, ANGUILLESI I, LAZZERI A, et al. Green Synthesis of Flexible Polyurethane Foams from Liquefied Lignin[J]. European Polymer Journal, 2013, 49(6): 1174-1184.

[64] CHERADAME H, DETOISIEN M, GANDINI A, et al. Polyurethane from Kraft Lignin[J]. British Polymer Journal, 1989, 21(3): 269-275.

[65] LI Hui, LIANG Yuan, LI Peng-cheng, et al. Conversion of Biomass Lignin to High-Value Polyurethane: A Review[J]. Journal of Bioresources and Bioproducts, 2020, 5(3): 163-179.

[66] GRIFFINI G, PASSONI V, SURIANO R, et al. Polyurethane Coatings Based on Chemically Unmodified Fractionated Lignin[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(6): 1145-1154.

[67] WANG Yun-yan, WYMAN C E, CAI C M, et al. Lignin-Based Polyurethanes from Unmodified Kraft Lignin Fractionated by Sequential Precipitation[J]. ACS Applied Polymer Materials, 2019, 1(7): 1672-1679.

[68] ZHANG Yan, LIAO Jian-jun, FANG Xiang-chen, et al. Renewable High-Performance Polyurethane Bioplastics Derived from Lignin-Poly(ε-Caprolactone)[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(5): 4276-4284.

[69] LAURICHESSE S, AVEROUS L. Chemical Modification of Lignins: Towards Biobased Polymers[J]. Progress in Polymer Science, 2014, 39(7): 1266-1290.

[70] GHOSH T, KARAK N. Cashew Nut Shell Liquid Terminated Self-Healable Polyurethane as an Effective Anticorrosive Coating with Biodegradable Attribute[J]. Progress in Organic Coatings, 2020, 139: 105472.

[71] REN Long-fang, ZHAO Yong-xia, QIANG Tao-tao, et al. Synthesis of a Biobased Waterborne Polyurethane with Epichlorohydrin-Modified Lignin[J]. Journal of Dispersion Science and Technology, 2019, 40(10): 1499-1506.

[72] KATHALEWAR M, SABNIS A. Preparation of Novel CNSL-Based Urethane Polyol via Nonisocyanate Route: Curing with Melamine-Formaldehyde Resin and Structure-Property Relationship[J]. Journal of Applied Polymer Science, 2015, 132(5): 41391.

[73] WANG Hao-ran, ZHOU Qi-xin. Synthesis of Cardanol-Based Polyols via Thiol-Ene/Thiol-Epoxy Dual Click-Reactions and Thermosetting Polyurethanes Therefrom[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(9): 12088-12095.

[74] ZHANG Jing-miao, HORI N, TAKEMURA A, et al. Thermal and Time Regularities during Oilseed Rape Straw Liquefaction Process to Produce Bio-Polyol[J]. Journal of Cleaner Production, 2020, 277: 124015.

[75] D’SOUZA J, YAN Ning. Producing Bark-Based Polyols through Liquefaction: Effect of Liquefaction Temperature[J]. ACS Sustainable Chemistry & Engineering, 2013, 1(5): 534-540.

[76] YE Li-yi, ZHANG Jing-miao, Zhao Jie, et al. Liquefaction of Bamboo Shoot Shell for the Production of Polyols[J]. Bioresource Technology, 2014, 153: 147-153.

[77] HU Sheng-jun, WAN Cai-xia, LI Ye-bo, et al. Production and Characterization of Biopolyols and Polyurethane Foams from Crude Glycerol Based Liquefaction of Soybean Straw[J]. Bioresource Technology, 2012, 103(1): 227-233.

[78] SERRANO L, RINCÓN E, GARCÍA A, et al. Bio-Degradable Polyurethane Foams Produced by Liquefied Polyol from Wheat Straw Biomass[J]. Polymers, 2020, 12(11): 2646.

[79] MONICA F D, KLEIJ A W. From Terpenes to Sustainable and Functional Polymers[J]. Polymer Chemistry, 2020, 11(32): 5109-5127.

[80] LIU Gui-feng, WU Guo-min, JIN Can, et al. Preparation and Antimicrobial Activity of Terpene-Based Polyurethane Coatings with Carbamate Group-Containing Quaternary Ammonium Salts[J]. Progress in Organic Coatings, 2015, 80: 150-155.

[81] FIRDAUS M, MEIER M A R. Renewable Polyamides and Polyurethanes Derived from Limonene[J]. Green Chemistry, 2013, 15(2): 370-380.

[82] GUPTA R K, IONESCU M, RADOJCIC D, et al. Novel Renewable Polyols Based on Limonene for Rigid Polyurethane Foams[J]. Journal of Polymers and the Environment, 2014, 22(3): 304-309.

[83] BHR M, BITTO A, ROLF M, et al. Cyclic Limonene Dicarbonate as a New Monomer for Non-Isocyanate Oligo- and Polyurethanes (NIPU) Based Upon Terpenes[J]. Green Chemistry, 2012, 14(5): 1447-1454.

[84] WU Guo-min, KONG Zhen-wu, CHEN Jian, et al. Preparation and Properties of Waterborne Polyurethane/Epoxy Resin Composite Coating from Anionic Terpene-Based Polyol Dispersion[J]. Progress in Organic Coatings, 2014, 77(2): 315-321.

[85] WILBON P A, CHU Fu-xiang, TANG Chuan-bing. Progress in Renewable Polymers from Natural Terpenes, Terpenoids, and Rosin[J]. Macromolecular Rapid Communications, 2013, 34(1): 8-37.

[86] HSIEH C C, CHEN Yi-chun. Synthesis of Bio-Based Polyurethane Foam Modified with Rosin Using an Environmentally-Friendly Process[J]. Journal of Cleaner Production, 2020, 276: 124203.

[87] LIU Gui-feng, WU Guo-ming, CHEN Jian, et al. Synthesis, Modification and Properties of Rosin-Based Non-Isocyanate Polyurethanes Coatings[J]. Progress in Organic Coatings, 2016, 101: 461-467.

[88] XU Xu, SONG Zhan-qian, SHANG Shi-bin, et al. Synthesis and Properties of Novel Rosin-Based Water-Borne Polyurethane[J]. Polymer International, 2011, 60(10): 1521-1526.

[89] ZHANG Li-sheng, JIANG Yan-hua, XIONG Zhu, et al. Highly Recoverable Rosin-Based Shape Memory Polyurethanes[J]. Journal of Materials Chemistry A, 2013, 1(10): 3263-3267.

[90] AKERHOLM M, HINTERSTOISSER B, SALMEN L. Characterization of the Crystalline Structure of Cellulose Using Static and Dynamic FT-IR Spectroscopy[J]. Carbohydrate Research, 2004, 339(3): 569-578.

[91] SIRO I, PLACKETT D. Microfibrillated Cellulose and New Nanocomposite Materials: A Review[J]. Cellulose, 2010, 17(3): 459-494.

[92] STANZIONE M, OLIVIERO M, COCCA M, et al. Tuning of Polyurethane Foam Mechanical and Thermal Properties Using Ball-Milled Cellulose[J]. Carbohydrate Polymers, 2020, 231: 115772.

[93] KLEMM D, KRAMER F, MORITZ S, et al. Nanocelluloses: A New Family of Nature-Based Materials[J]. Angewandte Chemie International Edition, 2011, 50(24): 5438-5466.

[94] LEE K Y, AITOMAKI Y, BERGLUND L A, et al. On the Use of Nanocellulose as Reinforcement in Polymer Matrix Composites[J]. Composites Science and Technology, 2014, 105: 15-27.

[95] AZEREDO H M C, ROSA M F, MATTOSO L H C. Nanocellulose in Bio-Based Food Packaging Applications[J]. Industrial Crops and Products, 2017, 97: 664-671.

[96] JORFI M, FOSTER E J. Recent Advances in Nanocellulose for Biomedical Applications[J]. Journal of Applied Polymer Science, 2015, 132(14): 41719.

[97] CHEN Ren-de, HUANG Chi-feng, HSU S H. Composites of Waterborne Polyurethane and Cellulose Nanofibers for 3D Printing and Bioapplications[J]. Carbohydrate Polymers, 2019, 212: 75-88.

[98] DUTTA G K, KARAK N. Waste Brewed Tea Leaf Derived Cellulose Nanofiber Reinforced Fully Bio-Based Waterborne Polyester Nanocomposite as an Environmentally Benign Material[J]. RSC Advances, 2019, 9(36): 20829-20840.

[99] CHOI S M, LEE M W, SHIN E J. One-Pot Processing of Regenerated Cellulose Nanoparticles/Waterborne Polyurethane Nanocomposite for Eco-Friendly Polyurethane Matrix[J]. Polymers, 2019, 11(2): 356.

[100] GLOWINSKA E, KASPRZYK P, DATTA J. Segmented Bio-Based Polyurethane Composites Containing Powdered Cellulose Obtained from Novel Bio-Based Diisocyanate Mixtures[J].Wood Science and Technology, 2021, 55(6): 1673-1691.

[101] KONG Ling-long, XU Dan-dan, HE Zai-xin, et al. Nanocellulose-Reinforced Polyurethane for Waterborne Wood Coating[J]. Molecules (Basel, Switzerland), 2019, 24(17): 3151.

[102] ZHOU Xing, ZHANG Xin, WANG Dong, et al. Preparation and Characterization of Waterborne Polyurethane/Cellulose Nanocrystal Composite Membrane from Recycling Waste Paper[J]. Journal of Renewable Materials, 2020, 8(6): 631-645.

[103] LEI Wan-qing, ZHOU Xing, FANG Chang-qing, et al. Eco-Friendly Waterborne Polyurethane Reinforced with Cellulose Nanocrystal from Office Waste Paper by Two Different Methods[J]. Carbohydrate Polymers, 2019, 209: 299-309.

[104] ZHANG Shuai-di, SUN Kang, LIU Hu, et al. Enhanced Piezoresistive Performance of Conductive WPU/CNT Composite Foam through Incorporating Brittle Cellulose Nanocrystal[J]. Chemical Engineering Journal, 2020, 387: 124045.

[105] ZHANG Ping-bo, LU Ya-dong, FAN Ming-ming, et al. Modified Cellulose Nanocrystals Enhancement to Mechanical Properties and Water Resistance of Vegetable Oil-Based Waterborne Polyurethane[J]. Journal of Applied Polymer Science, 2019, 136(47): 48228.

[106] CHENG Liang-song, REN Shao-bo, LU Xiao-ning. Application of Eco-Friendly Waterborne Polyurethane Composite Coating Incorporated with Nano Cellulose Crystalline and Silver Nano Particles on Wood Antibacterial Board[J]. Polymers, 2020, 12(2): 407.

[107] HORMAIZTEGUI M E V, DAGA B, ARANGUREN M I, et al. Bio-Based Waterborne Polyurethanes Reinforced with Cellulose Nanocrystals as Coating Films[J]. Progress in Organic Coatings, 2020, 144: 105649.

[108] HU Wei-li, CHEN Shi-yan, YANG Jing-xuan, et al. Functionalized Bacterial Cellulose Derivatives and Nanocomposites[J]. Carbohydrate Polymers, 2014, 101: 1043-1060.

[109] URBINA L, ALONSO-VARONa A, SARALEGI A, et al. Hybrid and Biocompatible Cellulose/Polyurethane Nanocomposites with Water-Activated Shape Memory Properties[J]. Carbohydrate Polymers, 2019, 216: 86-96.

[110] 俞胡斐, 钱静. 不可逆变色油墨的配方设计及其制备[J]. 包装工程, 2022, 43(7): 125-131.

YU Hu-fei, QIAN Jing. Formulation Design and Preparation of Irreversible Color-Changing Ink[J]. Packaging Engineering, 2022, 43(7): 125-131.

[111] 李海徽, 花文东, 贺蓬辉, 等. 聚丙二醇分子量对聚氨酯在油墨中应用性能的影响[J]. 包装工程, 2021, 42(19): 35-41.

LI Hai-hui, HUA Wen-dong, HE Peng-hui, et al. Influence of Polyol Molecular Weight on the Application Performance of Polyurethane in Ink[J]. Packaging Engineering, 2021, 42(19): 35-41.

[112] 张明光, 张明亮, 李效玉, 等. 亲水单体质量比对阴/非离子型水性聚氨酯及其油墨性能的影响[J]. 数字印刷, 2020(4): 59-67.

ZHANG Ming-guang, ZHANG Ming-liang, LI Xiao-yu, et al. Effect of the Mass Ratios of Hydrophilic Monomers on the Properties of Anionic/Nonionic Waterborne Polyurethane and the Corresponding Ink[J]. Digital Printing, 2020(4): 59-67.

[113] ROY A S, BHATTACHARJEE M, MONDAL R, et al. Development of Mineral Oil Free Offset Printing Ink Using Vegetable Oil Esters[J]. Journal of Oleo Science, 2007, 56(12): 623-628.

[114] CHEN Zhu-zuan, MAN Li-min, LIU Ju, et al. Vegetable Oil-Based Waterborne Polyurethane as Eco-Binders for Sulfur Cathodes in Lithium-Sulfur Batteries[J]. Macromolecular Rapid Communications, 2021, 42(19): e2100342.

[115] AGNOL L D, DIAS F T G, ORNAGHI H L. UV-Curable Waterborne Polyurethane Coatings: A State-of-the-Art and Recent Advances Review[J]. Progress in Organic Coatings, 2021, 154: 106156.

Preparation and Application Research of Biomass-based Environmental-friendly Polyurethane

XIE Li, XU Yue-yang, LIU Xiao-hui, QI Yue-yue, CHEN Ming-xin,GUO Yu-tong, ZHOU Xing

(Faculty of Printing Packaging Engineering and Digital Media Technology, Xi'an University of Technology, Xi'an 710048, China)

The work aims to reveal the structural regulation mechanism and affecting factors of polyurethane from the perspective of preparing environmental-friendly polyurethane resin with biomass resources, so as to provide a variety of effective preparation methods for vegetable oil-based polyurethane and its printing and packaging materials and abundant raw materials for printing and packaging materials. Different raw materials of polyurethane were prepared by different kinds of vegetable oil. The oil such as castor oil, soybean oil, sunflower oil, linseed oil and lignin, cardanol, etc. were used to prepare biomass-based polyols, isocyanates, and diol raw materials as chain extenders. The conversion of biomass into active raw materials for the synthesis of environmental-friendly polyurethane was reviewed in depth and the major mechanism and approach were also introduced. It was considered that the epoxy ring-opening method was still the most common way to convert polyols from vegetable oil. The use of biomass resources and its waste to produce environmental-friendly polyurethane is the most effective way to prepare green polyurethane products in the future. Driven by green chemistry and nanotechnology, vegetable oil-based green and high-performance environmental-friendly polyurethane can become the key raw materials of printing ink, packaging adhesive, and coating, and has vast application potential.

waterborne polyurethane (WPU); biomass; printing ink

TQ323

A

1001-3563(2022)23-0049-14

10.19554/j.cnki.1001-3563.2022.23.007

2022−10−16

中国博士后科学基金(2019M663785);陕西省重点研发计划社发领域一般项目(2022SF–168);西安市科技计划(21XJZZ0045);西安市碑林区应用技术研发类项目(GX2247,GX2232)

谢利(1968—),女,硕士,副教授,主要研究方向为包装结构与工艺、智能包装。

周星(1989—),男,博士,副教授,主要研究方向为印刷包装功能材料及其资源化。

责任编辑:曾钰婵