Formation of adiabatic shearing band for high-strength Ti-5553 alloy:A dramatic thermoplastic microstructural evolution

2022-11-28DongyngQinYinggngMioYulongLi

Dong-yng Qin ,Ying-gng Mio ,Yu-long Li

a School of Aeronautics,Northwestern Polytechnical University,Xi"an,710072,China

b School of Civil Aviation,Northwestern Polytechnical University,Xi"an,710072,China

Keywords:Titanium alloys Armor High loading rate Adiabatic shearing band Dynamic phase transformation

ABSTRACT By using split Hopkinson pressure bar,optical microscopy and electronic microscopy,we investigate the influence of initial microstructures on the adiabatic shear behavior of high-strength Ti-5Al-5V-5Mo-3Cr(Ti-5553)alloy with lamellar microstructure and bimodal microstructure.Lamellar alloy tends to form adiabatic shearing band(ASB)at low compression strain,while bimodal alloy is considerably ASBresistant.Comparing with the initial microstructure of Ti-5553 alloy,we find that the microstructure of the ASB changes dramatically.Adiabatic shear of lamellar Ti-5553 alloy not only results in the formation of recrystallized β nano-grains within the ASB,but also leads to the chemical redistribution of the alloying elements such as Al,V,Cr and Mo.As a result,the alloying elements distribute evenly in the ASB.In contrast,the dramatic adiabatic shear of bimodal alloy might give rise to the complete lamination of the globular primary α grain and the equiaxial prior β grain,which is accompanied by the dynamic recrystallization of α lamellae and β lamellae.As a result,ASB of bimodal alloy is composed of α/β nano multilayers.Chemical redistribution does not occur in ASB of bimodal alloy.Bimodal Ti-5553 alloy should be a promising candidate for high performance armors with high mass efficiency due to the processes high dynamic flow stress and excellent ASB-resistance.

1.Introduction

Advanced material with high ballistic performances is important to the design of the light weight armor system[1].Owing to the good strength-ductility combination,outstanding formability and excellent corrosion resistant,titanium alloys are widely used various structural armor applications.Ti-6Al-4V(Ti-64)alloy,which covers approximate 50% of the whole worldwide titanium production,is the most common titanium alloy for armors[2-7].Microstructures Ti-64 alloy could be classified into equiaxial,lamellar and bimodal[8,9].Deformation,damage and failure of Ti-64 alloy armor exhibits the following characters in ballistic test.First,in the vicinity of the crater a great number of adiabatic shearing bands(ASB)could be found in the shearing region of the Ti-64 armor with equiaxial,lamellar and bimodal microstructure[8-11].Second,the ballistic performance of Ti-64 alloy armor is directly related to the distribution and the density of ASB in the shearing region.The distribution of ASB for lamellar Ti-64 alloy armor is network-shaped,and the density of ASB is extremely high[8-11].However,it is reported that the distribution of ASB is along the shearing direction of the armor and that the density of ASB is lower in equiaxial and bimodal armor[8-11].As a result,the mass efficiency of the equiaxial and bimodal Ti-64 armor are considerable higher than that of lamellar alloy armor.

In addition of Ti-64 titanium alloy,many investigations have also been conducted on other class of Ti-alloy such as Ti-5Al-3Cr-2Fe (Ti-5322) alloy,Ti-5Al-2Sn-4Zr-4Mo-2Cr-1Fe (β-CEZ) alloy,Ti-6Al-3Nb-2Zr-1Mo(Ti-6321)alloy,Ti-6Al-8Mo-4Cr(Ti-684)alloy and Ti-5Al-5V-5Mo-3Cr(Ti-5553)alloy etc for potential ballistic applications[12-17].Recently,Ti-5553 alloy has attracted the researchers’attention of Ti-community,because the alloy has been reported to have high strength to weight ratio,improved hardenability and excellent dynamic mechanical properties[18-23].Microstructures of high-strength Ti-5553 alloy are lamellar and bimodal.Lamellar Ti-5553 alloy consists of coarse lamellar units,while bimodal Ti-5553 alloy is composed of globular primary α particles and fine lamellar units.Bartus investigated the ballistic performance of high-strength Ti-5553 armor and found thatV50limited velocity against 0.5 calorie fragment-simulating projectile of bimodal armor is 25.9% higher than that of lamellar armor[16].Furthermore,Wang et al.reported that damage and failure of Ti-5553 armor is also strongly related to the formation of ASB[17].

Owing to the coupling of the high strain-rate shearing and the dramatic temperature rise caused by the thermo-mechanical conversion,the adiabatic shear of titanium alloys might bring in the earthshaking microstructure evolution within ASB,which is strongly affected by the initial microstructure[3,8-11].The influence of initial microstructure on the microstructure for ASB of Ti-5553 alloy should be one of the most important bridges between the microstructure of the parent alloy and the ballistic performance of the alloy armor.Although the ballistic performance and failure mechanism of Ti-5553 alloy have been investigated,little work is devoted to the adiabatic shear behavior of Ti-5553 alloy,which is the parent material of Ti-5553 alloy armor.In this paper,the microstructures within the ASB of Ti-5553 alloy with lamellar microstructure and bimodal microstructures are examined.The aim of this study is to establish the link between the initial microstructure and the ballistic performance of Ti-5553 alloy armor and to explore the unknown microstructure for the ASB of the relatively new high-strength Ti-alloy for light-weight armors.

2.Material and methods

Chemical composition of Ti-5553 alloy ingot was Ti-5.3Al-4.9V-4.9Mo-3.0Cr(wt.%),and the β-transus temperature of the ingot was 845°C.The ingot was processed to a Φ 75 mm bar after the β-field forging and the multi-axial α+β forging.The bar with the dimension of 300 mm×Φ 75 mm bar was extruded to a Φ 25 mm bar at 780°C.Rod bars with the dimension of Φ 25 mm×80 mm were cut from the extruded-bar for heattreatments.The solution and the ageing were carried out in preheated Nabertherm N 7/H annealing furnace.After the heattreatment the rod bar was water quenched(WQ)to room temperature.The solution-ageing strategy of lamellar alloy was 900°C×1 h WQ+620°C×8 h WQ,while the strategy of bimodal alloy was 800°C×3 h WQ+620°C×8 h WQ.Specimens with the dimension of Φ 10 mm×10 mm were cut from the heat-treated bars for metallographic examination.The metallographic specimens were prepared by the route including mechanical grinding,polishing and etching within the Kroll"s reagent(3%HF-4%HNO3-93%H2O)for 5 s.ZEISS-Stemi2000c optical microscopy(OM)and ZEISS Supra-55 scanning electron microscopy(SEM)were used to observe the microstructure of the alloys.

Quasi-static tensile test was carried out on Instron-5895 testing machine,following the GB/T 228.1-2010 standard.The gauge for the tensile specimen was Φ 3 mm×15 mm.The dimension of the dynamic compression specimen was Φ 5 mm×4 mm,and the high direction of the specimen is parallel to the extrusion direction.The dynamic compression test was conducted on Φ 19 mm split Hopkinson pressure bar(SHPB).

Ruptured specimens were cut in half in the compression direction,mounted into resin and finally prepared into metallographic specimens.The microstructure of ASB were observed by ZEISS-Stemi2000c OM and ZEISS Supra-55 SEM.FEI Helios 600 focused ion beam(FIB)SEM was used to machine the transmission election microscope(TEM)sample containing ASB from the metallographic specimen.The dimension of rectangle TEM foil is approximate 10 μm in width and 20 μm in length,and the length direction of the TEM sample is perpendicular to the shearing direction of ASB.FEI Themis Z probe-corrected TEM was used to characterize the microstructure of ASB.Chemical composition of the ASB region was measured by energy dispersive spectrometer(EDS)equipped in the TEM.

3.Results

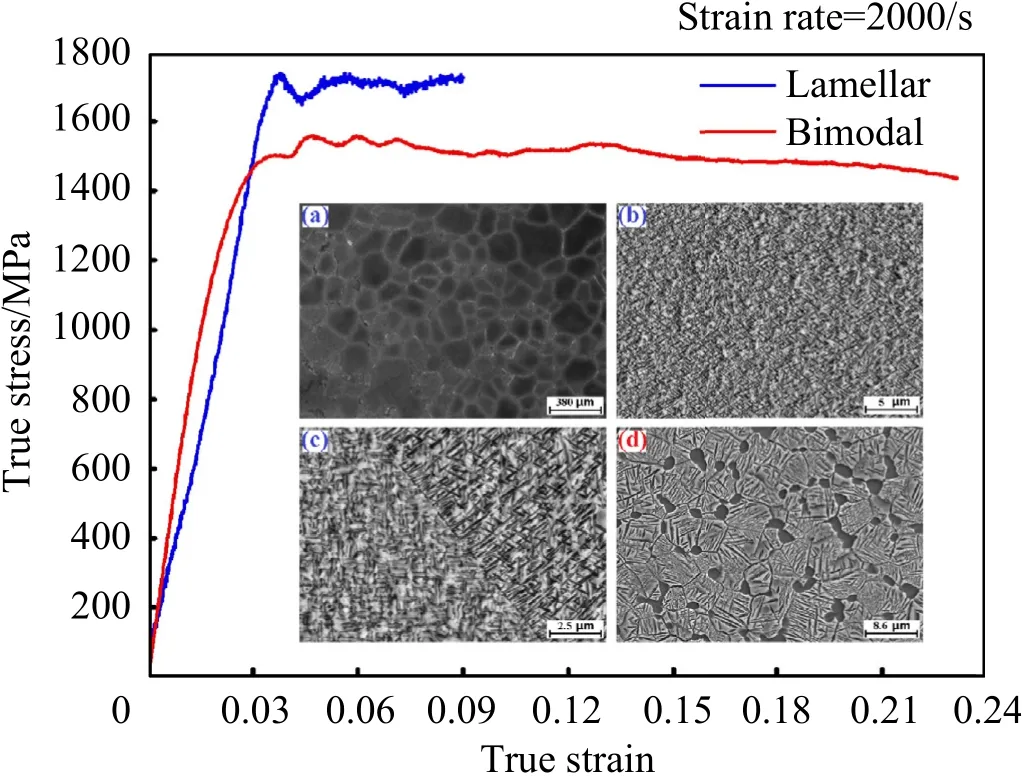

The yield strength(σ0.2)of lamellar Ti-5553 alloy is 1280 MPa,while σ0.2of bimodal alloy is 1200 MPa.Fig.1 shows the dynamic compressive stress-strain curves of Ti-5553 alloys.Lamellar alloy processes high yield strength,high flow stress and low failure strain.In contrast,bimodal alloy exhibits receivable combination of strength and ductility.Although yield strength of bimodal alloy is 12.5% lower than that of lamellar alloy,failure strain of bimodal alloy is almost 2 times higher than that of lamellar alloy.The insertion(a)of Fig.1 shows the low-magnification optical micrograph of lamellar Ti-5553 alloy.The prior β grain of lamellar Ti-5553 alloy is coarser than 100 μm.The insertion Fig.1(b)shows the secondary electron image(SEI)recorded inside the prior β grain.Ultra-fine intragranular α precipitations distribute evenly inside the prior β grain.The insertion Fig.1(c)shows the SEI recorded in the grain boundary region of the prior β grain.The straight grain boundary α precipitation and the α side-plate could be observed.Insertion Fig.1(d)illustrates the SEI of bimodal Ti-5553 alloy.β phase exhibits a bright contrast,while α phase exhibits a dark contrast.Bimodal alloy consists of the fine prior β grain which is less than 10 μm,the globular primary α particle that is distributed evenly on the grain boundary prior β grains,the intragranular α precipitation and the α side-plate.

Fig.1.Dynamic compressive stress-strain curves and initial microstructure of Ti-5553 alloy.(a)Optical micrograph of lamellar Ti-5553 alloy,the bright region is the grain boundary of prior β grains.(b)SEM micrograph recorded inside prior β grains of lamellar Ti-5553 alloy.(c)SEM micrograph recorded on the grain boundary region of prior β grains for lamellar alloy.(d)SEM micrograph of bimodal Ti-5553 alloy.

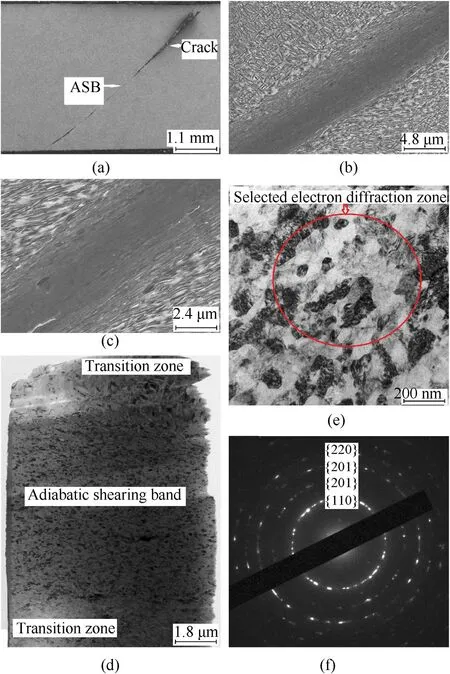

Fig.2.Microstructure for the ASB of lamellar Ti-5553 alloy.(a)SEM macrograph of the ruptured specimen.(b)SEM micrograph recorded in the region containing the ASB and the transition zone.(c)High-magnification SEM micrograph of the ASB.(d)TEM micrograph for the whole ASB specimen that is machined by FIB.(e)Bright field TEM image recorded in the central region of the ASB.(f)Selected electronic diffraction from the red circle region of Fig.2(e),the electronic diffraction rings of{110}β,{200}β,{221}β,and{220}β are marked.

Fig.2(a)shows the low-magnification SEI of the ruptured lamellar Ti-5553 alloy.The ASB and the long crack that propagates in the adiabatic shearing direction could be found.Fig.2(b)and Fig.2(c)are the high-magnification micrographs that contain the ASB and the transition zone.The ASB exhibits a dark grey contrast,and the thickness of the ASB is 5 μm.In the transition zone the length direction for most of the intragranular α precipitations has turned to the adiabatic shearing direction.Fig.2(d)shows the TEM micrograph for the whole specimen machined by FIB.The ASB consists of ultra-fine grains,and the microstructural of the ASB is homogeneous.Fig.2(e)illustrates the bright-field TEM micrograph in the central region of the ASB.The diameter of the globular grains is less than 100 nm,and the length of the short-rod grains is less than 200 nm.Fig.2(f)shows the selected electronic diffraction of the red circle region in Fig.2(e).It is surprising that the electronicdiffraction rings(or pattern)of α phase could not be detected any more and only the electronic-diffraction rings of β phase could be recorded.These electronic-diffraction rings should be{110}β,{200}β,{221}β,and{220}β,becaused12:d22:d32:d42=2:4:6:8,wheredis the diameter of the electronic-diffraction ring.Our data indicate that the ASB of lamellar Ti-5553 alloy consists of nano-scale β grain and that the α→β transformation occurs during the adiabatic shearing of lamellar Ti-5553 alloy.

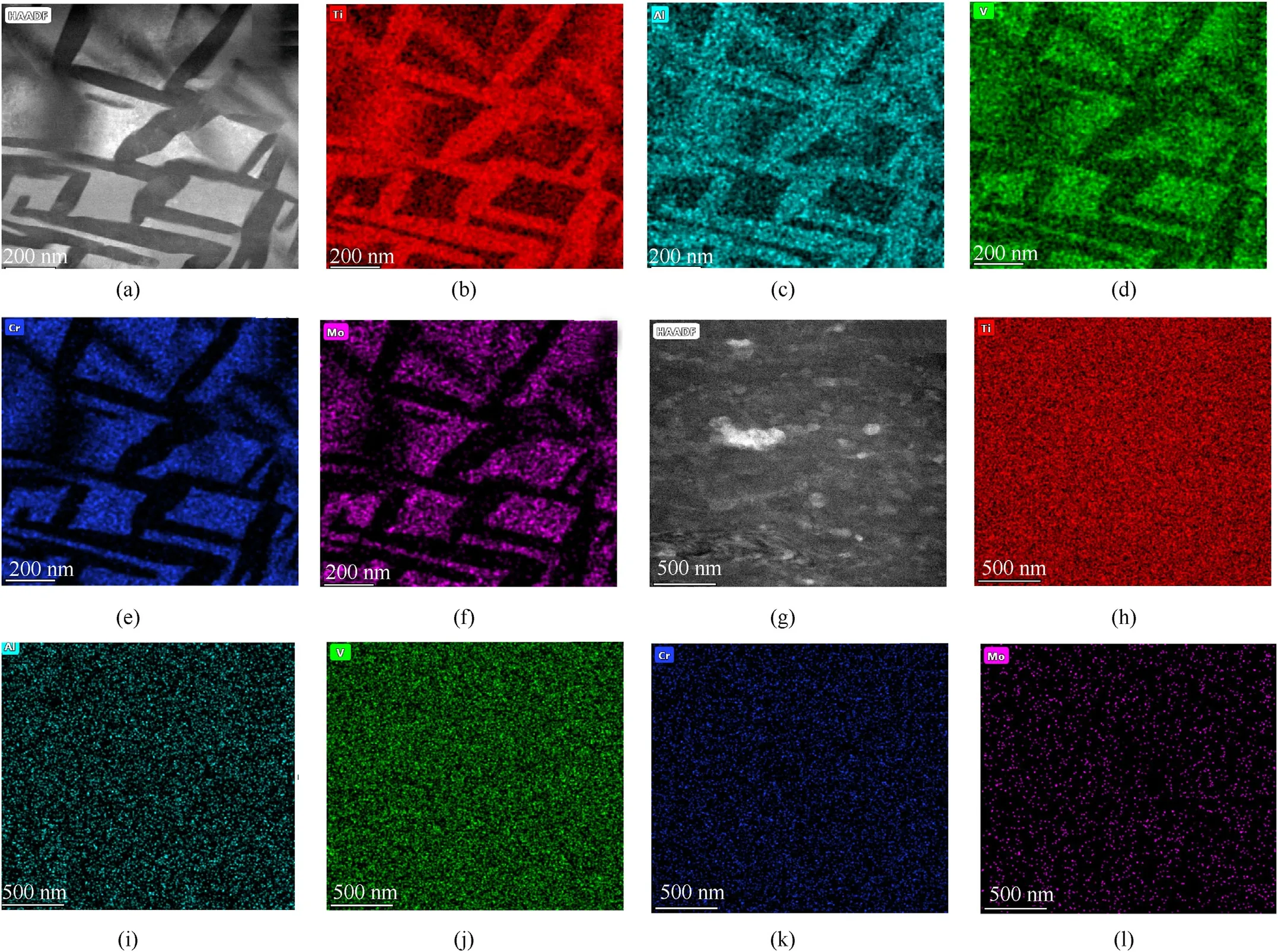

Fig.3.Composition redistribution for the ASB of lamellar Ti-5553 alloy.(a)STEM-HAADF micrograph of the transition zone for lamellar Ti-5553 alloy.(b)EDS mapping of Ti in the transition zone.(c)EDS mapping of Al in the transition zone.(d)EDS mapping of V in the transition zone.(e)EDS mapping of Cr in the transition zone.(f)EDS mapping of Mo in the transition zone.(g)STEM-HAADF micrograph of the ASB for lamellar Ti-5553 alloy.(h)EDS mapping of Ti in the ASB.(i)EDS mapping of Al in the ASB.(j)EDS mapping of V in the ASB.(k)EDS mapping of Cr in the ASB.(l)EDS mapping of Mo in the ASB.

Fig.3(a)shows the STEM-HAADF image of the transition zone,and Fig.3(b)-Fig.3(f)illustrate the EDS-mappings that are recorded in the same position of Fig.3(a)α phase is enriched with αstabilizer Al,while β phase is enriched with β-stabilizers such as V,Cr and Mo.Fig.3(g)shows the STEM-HAADF image of the ASB,and Fig.3(h)-Fig.3(l)display the EDS-mappings that are recorded in the same position of Fig.3(g).These EDS data imply that the alloying elements distribute evenly in the ASB of lamellar Ti-5553 alloy.Combining with the results of Fig.2,we conclude that the adiabatic shearing of lamellar Ti-5553 alloy could not only lead to the dynamic α→β phase transformation but also result in the compositional redistribution in a transient duration.

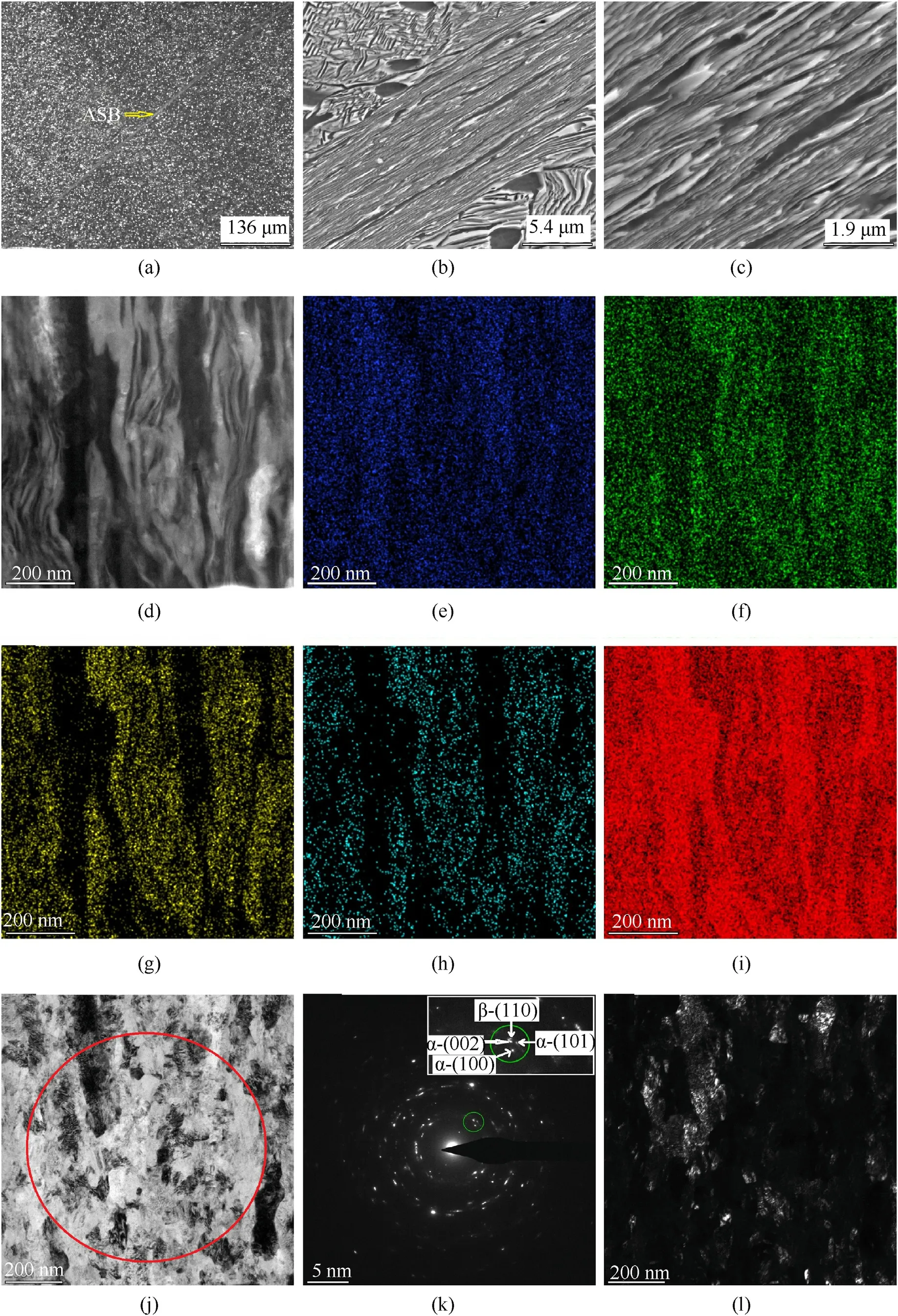

Fig.4(a)shows the optical micrograph for the ASB of bimodal Ti-5553 alloy.The ASB exhibits a dark grey contrast,and the angle between the adiabatic shearing direction and the compression direction is 45°.Fig.4(b)shows the SEI record in the region containing a section of ASB and the transition zone.The thickness of the ASB is approximate 10 μm,which is thicker than that of lamellar alloy.Comparing with the initial microstructure of bimodal Ti-5553 alloy,we find that equiaxial prior β grains,globular primary α phase,grain boundary α precipitation,intragranular α precipitations and α side-plate disappear in the ASB.Instead,the ASB processes a laminated microstructure.In the transition zone bimodal Ti-5553 alloy is severely sheared.Equiaxial prior β grains are distorted,and intragranular α precipitation,grain boundary α precipitation and α side-plate are bent.Fig.4(c)shows the highmagnification SEI in the central region of the ASB.As discussed in Fig.1(d),β phase and α phase exhibit bright contrast and dark contrast respectively in the SEI of the bimodal Ti-5553 alloy.Therefore,the bright layers should be the sheared β phase,and the dark layers should be the sheared α phase.The formation of the thick dark layers should be caused by the dramatic shearing of the globular primary α phase,while the formation of the thin dark layers should originate from the dramatic shearing of the intragranular α precipitation,the grain boundary α precipitation and the α side-plate,because the globular primary α particle is coarser than the three kinds of plate-like α precipitations.

Fig.4.Microstructure and composition for the ASB of bimodal Ti-5553 alloy.(a)Optical macrograph for the ASB containing the ASB and the transition zone.(b)SEM micrograph containing the ASB and the transition zone.(c)High-magnification SEM micrograph of the ASB.(d)STEM-HAADF micrograph recorded in the central region of the ASB.(e)EDS mapping of Al in the ASB.(f)EDS mapping of V in the ASB.(g)EDS mapping of Cr in the ASB.(h)EDS mapping of Mo in the ASB.(i)EDS mapping of Ti in the ASB.The position of these EDS mapping is the same as that of the STEM-HAADF micrograph.(j)Bright field TEM micrograph for the ASB.The position of the micrograph is the same as that of the STEMHAADF micrograph.(k)Selected electronic diffraction pattern from the circle region of Fig.4(j).The insertion is the enlargement of the green circle region.One diffraction pattern of{100}α,two diffraction patterns of{002}α,one diffraction pattern of{110}β and one diffraction pattern of{100}α are marked respectively.(l)Dark field TEM micrograph for the ASB,which is taken by using the diffraction patterns in the green circle region of Fig.4(j).

Fig.4(d)shows the STEM-HAADF image taken in the central region of the ASB.The dark layers of should be enriched with Al,while the bright layers should be enriched with Cr,Mo and V.Fig.3(e)-Fig.3(i)display the EDS mappings that are recorded in the same position of Fig.4(d).The distribution of the alloying elements is in reasonable agreement with the contrast of the STEM-HAADF image.Combining with the EDS results,we conclude that the bright layers of STEM-HAADF image and the dark layers of STEMHAADF image should be identified as β phase and α phase respectively.Coincidentally,the phase identification of STEMHAADF image is consistent with that of SEI.Fig.4(j)shows the bright-field micrograph that is recorded in the same position of Fig.4(d).Since the imaging principle of the bright-field micrograph is significantly different from that of STEM-HAADF micrograph,the bright-field image of the ASB is different form the STEM-HAADF micrograph.The dark layers and the bright layers disappeared,but nano-grains that are globular or rod-like could be observed.Fig.4(k)shows the electron diffraction pattern recorded from the circle region of Fig.4(j).The insertion is the enlargement of the green circle region,in which the diffraction patterns of(100)α,(002)α,(110)β and(101)α have been marked.The electronic diffraction data further confirms that the ASB of bimodal alloy is composed of α phase and the β phase.Fig.4(l)shows the dark field image that is recorded by using the five diffraction pattern within the green circle region for the insertion of Fig.4(k),in which nano grains could be observed.Our finding indicates that both the α layer and the β layer consist of nano grains and that the adiabatic shear of bimodal Ti-5553 alloy leads to the dynamic recrystallization of α phase and the dynamic recrystallization of β phase.

4.Discussion

4.1.ASB resistant of lamellar and bimodal Ti-5553 alloy

In the present work,we evaluate the adiabatic shear behaviors of two kinds of microstructures for Ti-5553 alloys.The compression strain at which the ASB initiates is higher than 0.2 for bimodal alloy,while lamellar alloy tends to form the ASB at extreme low compressive strain.These findings suggest that bimodal alloy is considerable resistant to the formation of ASB.Owing to the coarse prior β grains,lamellar alloy exhibits obvious strain localization during the plastic deformation[18,19].The compressive plastic strain only concentrates in the narrow deformation band of prior β grains and the grain boundary region of prior β grains[18].

Fig.5 shows the SEM micrograph recorded in the ASB region of bimodal Ti-5553 alloy.The ASB,the transition zone and the neighboring uniform compression region are found.The most striking feature of the transition zone is that it is hard to distinguish the boundary of the prior β grains because of the severe shearing.The width of the transition zone exceeds 500 μm,which is considerable wider than that of the lamellar alloy.In the uniform deformation region the primary α grains and the prior β grains deforms coordinately.The shearing band could not be found in the deformed prior β grains.It is possible that the ASB of bimodal alloy forms in the center of the transition zone in the final stage of the dynamic compression.Consequently,the excellent uniform deformation ability and the formation of wide transition region lead to the superior ASB resistance of bimodal Ti-5553 alloy.

4.2.Novel microstructures within the ASB of Ti-5553 alloy

Two kinds of novel microstructures for ASB are found in the ASB of Ti-5553 alloy.The ASB of lamellar Ti-5553 alloy is composed of ultra-fine β grains,in which the alloying elements distribute evenly.The ASB of lamellar alloy should be the transformed shearing band(TSB)[24,25].In contrast,the ASB of bimodal Ti-5553 consists of recrystallized α/β nano-multilayers whose thickness direction is perpendicular to the adiabatic shear direction.The ASB for bimodal alloy should be the deformed shearing band(DSB)[24-27].The laminated distribution of α phase and β phase indicates that bimodal Ti-5553 alloy process extraordinary shearing ability to accommodate the adiabatic shearing.

4.3.Temperature rise within the ASB of lamellar and bimodal alloy

The observation of the TSB formation of and the finding of the composition redistribution indicate that the temperature within the ASB of lamellar alloy might be higher than the β-transus temperature during the adiabatic shearing[28].However,temperature of the ASB for bimodal alloy should be lower than the β-transus temperature during the adiabatic shear.During the adiabatic shear of bimodal Ti-5553 alloy more plastic work is consumed by lamination of α phase,lamination of β phase,dynamic recrystallization of α phase and dynamic recrystallization of β phase[29].As a result,less cold-work is converted to heat.It is possible that the Taylor-Quinney coefficient of bimodal Ti-5553 alloy might be lower than that of lamellar Ti-5553 alloy[30].

4.4.Effects of adiabatic shear behavior on ballistic performance of Ti-5553 alloy armor

Bartus has pointed out that the ballistic performance of bimodal Ti-5553 alloy armor is much superior to that of lamellar Ti-5553 alloy armor.The outstanding ballistic performance of bimodal armor could be explained by the findings of the present work.First,bimodal Ti-5553 alloy is ASB resistant.It is reported that the failure of Ti-5553 alloy armor is dominated by the formation of ASB[17].Since we discover that the bimodal Ti-5553 alloy is considerable resistant to the formation of ASB in the present work,the ASB might tend to form at high shear strain in the shear region of bimodal armor.Second,bimodal Ti-5553 armor,with globular primary α grain and fine equiaxial prior β grain,processes extraordinary shearing ability to accommodate adiabatic shearing.Third,the thermal softening effect of bimodal Ti-5553 alloy armor,which is related to the ASB formation,might be relatively weaker,because the temperature rise within the ASB of bimodal alloy might be less dramatic than that of lamellar.In summary,the results presented in this work and data of Bartus suggest that bimodal Ti-5553 alloy should be a promising candidate for high performance armors with high mass efficiency.

5.Conclusions

In this paper,we investigate the influence of the initial microstructures on the dynamic compressive mechanical properties and the adiabatic shear behaviors of Ti-5553 alloy.The following conclusions could be drawn.

Dynamic α→β transformation,dynamic recrystallization and composition redistribution occur during the adiabatic shear of lamellar Ti-5553 alloy.

Fig.5.SEM micrograph for ASB,transition zone and neighboring uniform compression region of bimodal Ti-5553 alloy,the loading direction of the specimen is indexed by the black arrow.

The adiabatic shearing band of bimodal Ti-5553 alloy is composed of α/β nano-multilayers.α nano-layer and β nano-layer consist of the recrystallized α grain and recrystallized β grain.Highstrength bimodal Ti-5553 alloy should be a promising material for advanced armors.

Taylor-Quinney coefficient of bimodal Ti-5553 alloy will be investigated in further.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China(Grant No.11872317),Science Challenge Project(Grant No.TZ2018001)and the Fundamental Research Funds for the Central Universities(Grant No.3102019ZX001).

杂志排行

Defence Technology的其它文章

- Defence Technology

- The SSA-BP-based potential threat prediction for aerial target considering commander emotion

- Visual-simulation region proposal and generative adversarial network based ground military target recognition

- Preparation and characterization of HMX/NH2-GO composite with enhanced thermal safety and desensitization

- Interception probability simulation and analysis of salvo of two electromagnetic coil launched anti-torpedo torpedoes

- Damage behavior of the KKV direct hit against fluid-filled submunition payload