Mechanical properties and surface characteristics of SiC fibers irradiated by swift heavy ions

2022-11-21LiQingZhangChongHongZhangChenChunHaoGuoDongHuZhengDongFengYongJianTangWenKunZhuJianYangLiQingHuang

Li-Qing Zhang• Chong-Hong Zhang• Chen-Chun Hao • Guo-Dong Hu •Zheng-Dong Feng • Yong-Jian Tang • Wen-Kun Zhu • Jian-Yang Li•Qing Huang

Abstract SiC fibers were irradiated by 414.4-MeV 112Sn27.3+ ions to different fluences (5.0 × 1012,6.0 × 1013, 1.6 × 1014, and 1.92 × 1015 ions/cm2).112Sn27.3+ deposited its energy mainly via electron energy loss and passed through the SiC fiber.Then,the mechanical properties and surface characteristics of fibers were studied using a specific single filament tensile test and field emission scanning electron microscopy. Results revealed that the carbon concentration on the fiber surface increased while the silicon concentration decreased. Moreover, the addition of oxygen was found to correlate with an increase in ion fluence.Meanwhile,the fiber surface morphology of the least fluence(5.0 × 1012 ions/cm2)irradiated specimen displayed no obvious changes and its diameter was slightly reduced. With successive increases of ion fluence, large grains/bubbles on the fiber surface first appeared and then disappeared,and the diameter of fibers evidently increased.Moreover,at the highest fluence(1.92 × 1015 Sn ions/cm2)irradiated specimen, some fibers were brittle fractured. As a result, the mean tensile strength and the average elastic modulus of the fibers generally decreased with respect to the ion fluence. The degradation mechanisms of mechanical properties of SiC fibers under irradiation are discussed in detail.

Keywords SiC fibers ∙Swift-heavy-ion irradiation ∙FESEM ∙Tensile test

1 Introduction

In contrast to ferritic steels, vanadium alloys, and monolithic ceramics [1, 2], Silicon carbide fiber-reinforced/silicon carbide matrix composites (SiCf/SiCm) possess superior physical and chemical characteristics,such as lower density, lower neutron-induced activation, lower neutron capture cross-section, higher temperature endurance, excellent creep resistance, and sufficient toughness for damage tolerance [3–6]. Therefore, they are primary candidate structural components for application in advanced nuclear energy systems, such as channel boxes and fuel cladding tubes in fission reactors, as well as first wall, breeder blanket, and flow channel inserts in future fusion reactors [7, 8]. SiC fibers that were prepared by the splitting decomposition of the polycarbosilane are promising reinforcements of SiCf/SiCmcompositions.Moreover, the performance of the SiCf/SiCmcompositions strongly depends on the high strength of the fiber components due to the consumption of load energy via fiber debonding and pull-out within the interfacial layer [9].However, the fiber’s mechanical stability is mainly determined by their microstructure changes when they work in irradiation environments[10,11].It has been reported that SiC fibers that were composed of near-stoichiometric,crystalline SiC, exhibited the least degradation after being irradiated with neutrons at high fluences [12, 13]. And the irradiation induced by neutron was reported to cause a ~10% shrinkage in the volume of SiC fibers due to the transformation from an amorphous state to crystallization of amorphous SiOC phase [14].

Besides the neutron, there are various energetic heavy ions in reactor systems. In fission reactors, various highenergy fission nuclides are produced from the chain fission of uranium (U-235). The kinetic energy of these fission fragments is up to several hundred MeV. While in fusion reactors, primary knock-on atoms (PKAs) are generated in materials due to neutron irradiation.The PKAs also carry a mean kinetic energy of several hundred keV. Due to the high energy, these fission fragments and PKAs deposit their energy mainly via electron energy loss in the materials. That is, this energy deposition process is mainly dominated by ionization and excitation of energetic ions along the incident path. SiC fibers are the backbone of SiCf/SiCmcompositions in the bearing capacity of the load.Their mechanical strength and stability are very important throughout the whole utilization process. Damage effects of SiC fibers induced by various swift heavy ions were studied extensively.Huguet-Garcia et al.[15]revealed that similar amorphization kinetics occur in 6H-SiC single crystal and Tyranno SA3 fibers, after 4-MeV Au ion irradiation at high fluences. Chun-Yu Ho et al. [16] displayed that larger voids and edge dislocations were induced by 7-MeV Si ion in SiC fiber-reinforced composites at high temperatures, leading to a degradation in strength. Meanwhile, they [16] also showed that vacancy loops were produced in 3C-SiC single crystal at the same irradiation conditions. Chaaˆbane et al. [17] found that after 12-MeV Au-ion irradiation,a disordered/distorted state in fibers and a longitudinal shrinkage of the fibers were observed due to the irradiation. An investigation carried out by A. Jankowiak et al. [18] showed that 92-MeV Xe-ion induces a significant local structure modification in Tyranno SA3 SiC fiber at about 25 ± 5 °C room temperatures, accompanied by a gradual increase of longitudinal strain.

Moreover, the energetic heavy ion is an alternative tool for tailoring microstructures and properties of multiphase materials. Atta et al. [19, 20] reported that surface characteristics of methylcellulose/polyaniline and silver-coated flexible PDMS polymeric films were modified by low energy oxygen and argon irradiation, respectively. Abdelhamied et al. [21, 22] reported variations in the structures and properties of the PVA/PANI/Ag nanocomposite film and the influence of silver nanoparticles on dielectric properties of flexible PVA/PANI polymer composite films under oxygen irradiation. Abdeltwab et al. [23] displayed modifications on high-density polyethylene and polyethylene terephthalate caused by the plasma. Chaitali Gavade et al. [24] revealed microstructures and properties of Ag/polymethyl methacrylate nanocomposites induced by swift heavy ion irradiation. SiC fiber is also a multiphase material. It is composed of the β-SiC, free carbon,and amorphous SiCxOyphase [25]. Carbonizations,decompositions, as well as oxidations maybe occur under energetic ion irradiations. Therefore, it is necessary to obtain an adequate understanding of the microstructure and the mechanical properties of SiC fibers under irradiation with swift heavy ion.

In this investigation, we study the changes in surface features and mechanical properties of SiC fibers by a field emission scanning electron microscopy (FE-SEM) and a specific electron single filament tensile test,after they were irradiated by 414.4-MeV112Sn27.3+ions to different fluences. Our aim is to understand the mechanical retention and the fracture mechanisms of SiC fibers irradiated by swift heavy ions and to forecast the performance of SiCf/SiCmcompositions under irradiation environments.

The novelty of the work lies in using energetic112Sn27.3+to perform the irradiation experiment and probe its damage mechanisms to SiC fiber materials. In fission reactors, the chain fission of U-235 produces a large number of high-energy fission nuclides with mass numbers between 72 and 161. The energetic112Sn27.3+is one of the main fission products of U-235. Our goal is to provide important reference data for SiCf/SiCmcompositions to be used widely in advanced nuclear energy systems, especially in fission reactors.

2 Experiment

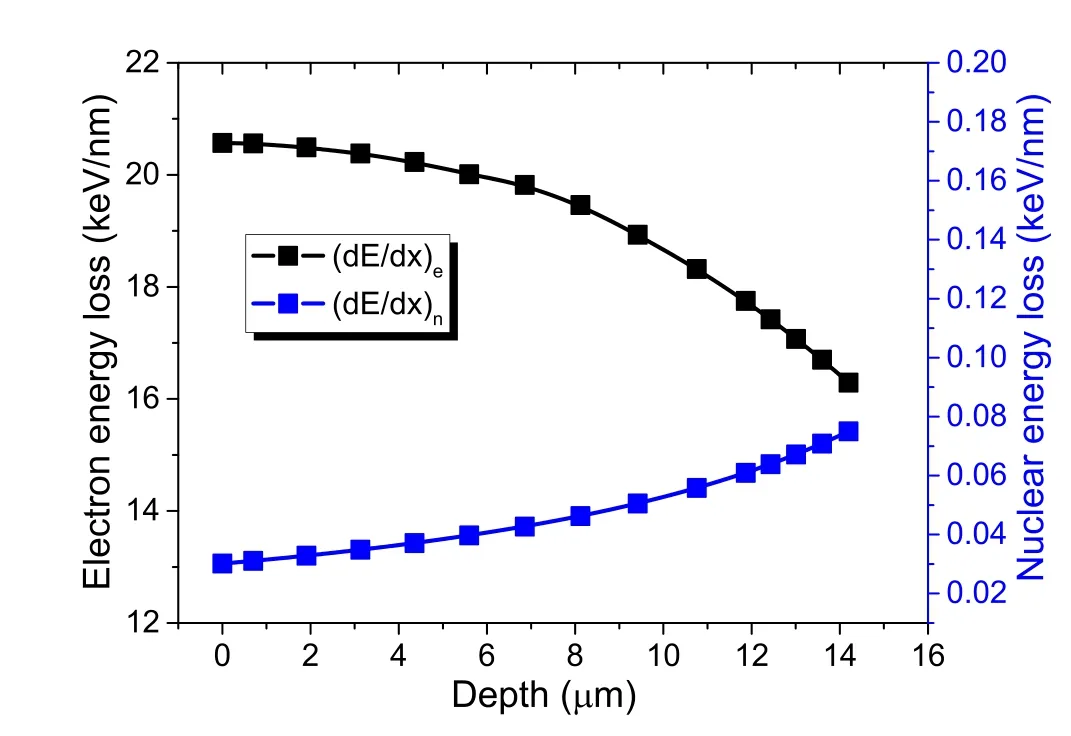

In this study, SiC fiber was prepared with polycarbosilane (PCS) grafted by low molecules, via a precursor pyrolysis process. The PCS contains a small amount of aluminum that acts as a crystal growth inhibitor. The atomic ratio of C/Si in the fibers was about 1.07. The concentration of oxygen mass in fibers was less than 0.5 wt%. The density of fibers was about 3.1 g/cm3. The SiC fiber was mainly composed of 3C-SiC, abundant carbon with graphite phase and some amorphous SiOC phase, as revealed by our previous study[25].The size of the 3C-SiC grain was from 100 to 300 nm, and the diameter of the fibers was about 10 μm. There were about 500 single filaments in each yarn. As-fabricated SiC fibers were twined around a cylindrical roller, and 50-mm-length segments were cut from the SiC fiber roller. They were mounted on nickel sheets for irradiation. Energetic Sn-ion irradiation experiment was performed at an irradiation terminal of the SFC (Sector-Focused Cyclotron) of Heavy Ion Research Facility in Lanzhou (HIRFL), located in Institute of Modern Physics(IMP),China.This irradiation terminal has been described in detail in our previous work [26]. The irradiation chamber is made up of three parts: the energy degrader, the cooling stage, and the heating stage. The energy degrader consists of aluminum foils of different thickness. The cooling stage has a container to fill the liquid nitrogen. This container is then connected to the sample holder. The heating stage is made up of electric heating wires which can reach 600°C.There is a picture of the irradiation chamber at the HIRFL-SFC, the cooling stages, and heating stages, together with energy degraders in our previous work [26]. Before entering the irradiation chamber, the beam line has a beam current monitor and two apertures. The beam current monitor is made up of aluminum foils with a thickness of 2 μm to collect the electric charge and monitor the beam current.One aperture with a diameter of 18 mm is used to supply a negative bias voltage to refrain from emitting the secondary electrons.The value of this bias voltage is about - 300 V. Another aperture with a 15 mm diameter is used to limit the region for irradiation.Sn ions go through the beam line and arrive at the specimen surface where their kinetic energy is 414.4 MeV. Based on the ‘‘quick calculation’’ estimation of SRIM-2012 code [27], Sn ions pass through the SiC fibers and finally rest in the substrate nickel plates. Depth distribution of energy deposition via electron and nuclear collisions is plotted in Fig. 1,corresponding to one Sn ion.The incident Sn ions cause energy deposition homogeneously mainly by electron energy loss through the SiC fibers.During irradiation,the temperature was kept around 25 ± 5 °C room temperature (RT), and the vacuum pressure was about 10–5Pa. To minimize temperature fluctuations with the beam intensity due to beam heating, we utilized liquid nitrogen to stabilize the temperature. It was within ± 5 °C during the steady state irradiation. The beam intensity was 0.8 μA or less. Four fluences of 5.0 × 1012,6.0 × 1013,1.6 × 1014,and 1.92 × 1015ions/cm2were achieved.Mechanical properties of materials are a bulk effect. In order to investigate fiber mechanical properties after112Sn27.3+ion irradiation, the trajectory of112Sn27.3+ions need an overlap in the damaged zones as best as possible. Once the ion fluence exceeds 1.0 × 1012ions/cm2, their trajectory will overlap. So, the irradiation fluence of112Sn27.3+ion was chosen from 5.0 × 1012to 1.92 × 1015ions/cm2.

Fig. 1 Electron energy loss and nuclear energy loss as functions of the depth for 414.4-MeV Sn ion in 10-μm SiC fiber

After irradiation with Sn ions at different fluences,surface features and tensile strength of SiC fibers were characterized by means of FE-SEM(Nano-SEM 450)and a specific electron tensile testing machine. The FE-SEM characterization and the tensile testing analysis were performed ex-situ. The Nano-SEM 450 was equipped with an X-ray energy dispersion spectrometry (EDS) to carry out the element analyses. Its electron energy is up to 35 keV.Under a high vacuum mode,electronic image scanning and element area scanning were performed at 15-keV electron energy. Textechno FAVIMAT+is the model of the electron tensile machine for single filaments. The electron tensile machine was equipped with two grips to fix the two ends of the fiber segment. During the tensile test, the span between two grips was 25 mm, and the tensile rate was 1 mm/min.

3 Results and discussion

3.1 Surface features

The surface morphology and the compositions of irradiated and un-irradiated SiC fiber specimens were examined by a FE-SEM. The un-irradiated SiC fiber specimen was mounted on aluminum foil, and the Sn-ion irradiated specimens were mounted on nickel sheets. The FE-SEM analyses were performed on the front side of fibers along the fiber length. According to the SRIM calculation(Fig. 1), the electron energy loss at the back side of SiC fiber is 19.5 keV/nm,which was slightly less than the front side (21.2 keV/nm). Thus, the back side of SiC fiber was slightly less damaged than the front side. Figure 2 shows SEM images, the EDS area scanning analysis, and the diameter analysis of the front side from the un-irradiated and the irradiated SiC fibers to a fluence ranging from

6.0 × 1013 to 1.92 × 1015 ions/cm2.

The surface morphology of the front side of the fiber specimens exhibits obvious changes (Fig. 2a–d) with increasing ion fluence. At 6.0 × 1013Sn/cm2, the fibers still remain smooth (Fig. 2a). Their surfaces are similar to those of un-irradiated ones (Fig. 2d). In the specimen irradiated to 1.6 × 1014Sn/cm2, coarse surfaces were observed, and a large number of large grains or bubbles appeared on the fiber surfaces but displayed no structural degradation (Fig. 2b). When the irradiation fluence was further raised to 1.92 × 1015Sn/cm2, some fibers were fractured and small fractured segments scattered on the fiber surface; however, no larger grains and/or bubbles were observed on the fiber surface (Fig. 2c).

Fig.2 (Color online)FE-SEM images and area scanning analysis as well as the diameter analysis of the front side of SiC fibers after 6.0 × 1013 ions/cm2, 1.6 × 1014 ions/cm2, 1.92 × 1015 ions/cm2 irradiation, and without irradiation, respectively

The stoichiometry on the front side of the fiber surface exhibits an imbalance due to the irradiation (Fig. 2a–d).With increasing ion fluence, the carbon content increased and the silicon content was reduced on the fiber surfaces,which was accompanied by an absorption of oxygen. The displacement threshold energy was 35 eV and 20 eV for Si and C atoms in SiC materials, respectively [28]. The component segregation between C and Si atoms is possibly due to the displacement threshold energy of carbon atoms is lower than that of silicon atoms [28]. Moreover, there are a large number of free carbons in the SiC fibers,besides the β-SiC phase and amorphous SiCxOyphase,revealed by the TEM and Raman analyses in our previous work [25].MD simulations performed by Gao et al. have shown that 40% of the carbon interstitials produced in collision cascade survive as freely migrating defects in SiC materials at room temperature [29].

The free carbon in SiC fibers plays a crucial role in stabilizing microstructures and the properties of the fibers.Above all, the free carbon may connect the separate SiC grains together to form a whole.The free carbon possesses flexible structures, and it can fill gaps between β-SiC or SiO2grains to maintain their structural integrity. Furthermore,the free carbon is in the form of amorphous graphite,which has high thermal conductivity. To some extent, it can improve the mechanical performance of SiC fiber at high temperatures.Meanwhile,free carbon can separate β-SiC grains to prevent them from growth and coalescence by filling their gaps due to its adaptable structure. The binding forces between the grain boundaries decrease due to the growth of β-SiC grains.This results in a reduction in the mechanical stability of SiC fibers. Finally, free carbon can remove the excessive oxygen introduced into the fibers during the fabrication and service processes.It degrades the mechanical strength of fibers at high temperatures.The free carbon can take away excessive oxygen contained in the fibers,and then they leave the fibers together in the form of gases (CO, CO2). In contrast to our previous Ar-ion-irradiated experiment[25],we conclude that the free carbon in the SiC fibers migrates towards the heavily damaged (high electron-energy-deposition) region under the electron energy loss of ionization and excitation from swift heavy ions. However, free carbon in the surface can agglomerate into the carbon nano-crystallines, and free carbon also can react with SiO gas, producing SiC crystals at high temperatures. These behaviors of free carbon inhibit the gas and grain boundary to further diffuse [30]. For the 1.6 × 1014Sn/cm2irradiated specimens (Fig. 2b), large grains and/or bubbles on the fiber surface were observed.This is perhaps due to the formation of carbon nano-crystallines and SiC crystals due to the thermal effects of electron energy loss by Sn ions. In addition, compared to silicon atoms,carbon atoms are more difficult to bond with oxygen.The increase in carbon content on the fiber surface may be attributed to more release of SiO gases than that of CO gases from the fiber surface (Fig. 2c).

The absorbed oxygen plays two important roles in the damage processes of SiC fibers under irradiation. One is the passivation reaction,the other is the activation reaction.Under the low damage degree, passive oxidations can lead to the formation of SiO2. The SiO2grows on the fiber surfaces and degrades them. On the other hand, passive oxidation can seal the small cracks (pits) on damaged surfaces and prevent the fibers from further oxidation attacks. As for the active oxidation, the formation rate of the SiO2is too low to seal the damaged surfaces due to the production of big pits (cracks). Thus, oxygen attacks the damaged fiber surfaces via the following chemical reaction[31]:

Active oxidation may induce aggravation of microstructural damages and degradation in mechanical stabilities of SiC fibers, accompanied by a severe imbalance in the element content. At low fluence (6.0 × 1013Sn/cm2) the irradiated specimen displayed a damaged surface dominated by passive oxidation mode through the formation of SiO2on the fiber due to mild damage, no occurrences of big cracks/pits from the low energy deposition of electron energy loss by swift heavy Sn ions.Hence, smooth surfaces were observed, as shown in Fig. 2a. With increasing ion fluences, the amorphous SiCxOyphase in fibers was broken down into four segments, according to this reaction [32]:

Besides generated carbon nano-crystallines and SiC crystals, the gases produced (SiO, CO) cannot be released in a timely manner through the dense SiO2layer by migration or diffusion. Many big grains or bubbles were observed on fiber surfaces owing to thermal decomposition and an agglomeration of the amorphous SiCxOystate and to the gas pressure from decomposed gases under high electron energy deposition by swift heavy Sn ions (Fig. 2b).Concurrently, big pits and cracks were produced because the formed SiO2was insufficient to seal the cracks/pits due to a reduction in Si element content after high fluence irradiation.Then,active oxidation occurs in the cracks/pits,leading to an obvious increase in surface roughness(Fig. 2b). That is, the surface damage promotes the permeation and diffusion of the oxygen in the damaged fibers.Oxygen always attacks the surface of the damaged fiber and the active oxidation occurs through a chemical reaction, as mentioned above in reaction (1) [31]. As a result,heavy damage was observed because the surface damage accelerates the permeability and the attack of oxygen in the fibers. When the irradiation fluence was further raised to 1.92 × 1015Sn/cm2,local fractures occurred(Fig. 2c),and some segments appeared on fiber surfaces owing to high thermal stress and high energy deposition of electron energy loss by swift heavy Sn ions and an adequate overlap of damage zones under high fluence irradiation. Meanwhile,the attack of oxygen promoted boundary diffusion in the gases and grain, resulting in the breakage of SiO/CO bubbles and disappearance of the larger grains and/or bubbles on the fiber surface (Fig. 2c). The transition from passive oxidation to active oxidation is dominated by many factors, such as sizes of cracks or pits, components of the fiber surface, as well as the damage degree of fibers and oxygen contents. Based on the surface morphologies in Fig. 2 and damage mechanisms, it may be concluded that the oxygen behavior is mainly dominated by passive oxidation before the formation of big cracks and pits. After they were produced, the active oxidation played a key role in the action of oxygen.

The influence of Sn-ion fluence on surface morphologies and compositions of fibers was investigated in detail.Since the Sn ion passed through the fiber,the dependence of fiber diameter on the Sn-ion fluence needs to be clarified.

3.2 Diameter analysis

SiC fibers were derived from a pyrolysis process of the PCS. They were composed of various phases, including SiC grains of different sizes, free carbon with graphite phase, and amorphous intergranular SiOxCyphase [25].Their diameter changes are different from other singlephase SiC materials after irradiation with various ions[33–36]. The diameter changes of SiC fibers also were tested by the FE-SEM after the SiC fibers were irradiated by Sn ions to fluences ranging from 5 × 1012to 1.92 × 1015Sn/cm2. At different irradiation fluence, the average diameter of SiC fibers exhibited different values.The diameter of the un-irradiated was 9.65 ± 0.83 μm.After irradiation at a fluence of 5 × 1012Sn/cm2, its diameter reduced to 9.42 ± 0.67 μm. As the irradiation fluence successively increased to 6 × 1013Sn/cm2, the diameter of fibers increased from 9.42 ± 0.67 μm to 9.44 ± 0.62 μm. The diameter of the specimen irradiated by 1.6 × 1014Sn/cm2increased to 9.83 ± 1.01 μm.When the irradiation fluence reached 1.92 × 1015Sn/cm2, the diameter of fibers finally increased up to 9.96 ± 0.92 μm.Based on our measured values, we can conclude that the mean diameter of SiC fibers displays a general increase after irradiation with Sn ions. However, at low fluence(5 × 1012Sn/cm2),the diameter shows a slight decrease.A similar phenomenon was observed in SiC fibers induced by swift heavy Ar ion in our previous study [25]. Polycarbosilane-derived SiC fibers containing a significant amount of SiOxCy(SiCxOy) [32, 37] began as amorphous and recrystallized under thermal effects of electron energy deposition by swift heavy Sn ions [38]. As mentioned above(2)[32],we can see that the decomposed gases(SiO and CO) could be evaporated from the fiber surface under heat effects from electron energy deposition by swift heavy Sn ions [32, 33]. Meanwhile, densification and crystallization in the fibers occur due to the release of these amorphous structures.Therefore,a slight shrinkage in fiber diameter occurred at the lowest fluence irradiated specimen.As the ion fluence increases successively,the SiCxOyamorphous phase inside the fiber was also divided into various segments under the effect of heat from electron energy loss of swift Sn ions. However, the dense surface,composed of SiO2and SiC,sealed the generated gases(SiO and CO) into fibers and suppressed them from diffusing/migrating out from surfaces, resulting in an increase in the diameter of fibers. Furthermore, an overlap of damage zones occurs with an increase in Sn ion fluence.SiC fibers were subjected to irradiation damage of Sn ions. The irradiation-induced swelling is a universal phenomenon in SiC materials [33]. Various defects, including vacancies,interstitials, stacking faults, and dislocations, were introduced into the lattices,leading to an occurrence of swelling in the diameter of fibers[34,35].Simultaneously,the longrange order of lattice atoms of fiber components was destroyed by the electron energy loss of swift heavy Sn ions. As a result, the disordered crystalline phase and distorted lattices were formed in conjunction with an expansion in their diameters [35]. As the irradiation fluence further increases, the formation of large grains, voids,vacancies, and bubbles (Fig. 2b) are also responsible for the increase in fiber diameter [34, 36].

The change in fiber diameter has a strong effect on its performance. SiC fiber is considered the candidate structural material for reactor systems.Its mechanical properties are favored under irradiations.The surface microstructures and diameter changes measured by the FE-SEM were used for the following tensile strength analysis.

3.3 Single filament tensile testing

To investigate the effects of the irradiation by swift heavy Sn ions on the mechanical properties of SiC fibers,we performed a tensile test using an electronic single filament tensile machine. Individual fibers were separated and fixed on a grip for the single filament tensile test. The online stress (σ)–strain (ε) curve was recorded until the fracture of the fiber specimen. The stress (σ)–strain (ε)curves of the single SiC fiber after it was irradiated by swift heavy Sn ions to different fluences were obtained via tensile tests. The dispersion of ultimate tensile strengths with strains was caused by the diameter divergence of SiC fibers. All SiC fiber specimens were tested by the same method. All the fibers, including the irradiated and unirradiated, presented a brittle fracture during the tensile test. They did not experience an obvious yield process before the fracture,and they all break within the process of elastic deformation. That is, the stress (σ)–strain (ε) curve is linear which coincides with the Hooke’s Law, because the deformation mechanism directly determines the corresponding shape of stress (σ)–strain (ε) curves.

The average tensile strength and the mean elastic modulus of SiC fibers can be obtained from the stress(σ)–strain(ε)curves of the single filament tensile test.Both can be calculated from the load (F), gauge length (L), and diameter (d) of the fibers. The tensile strength was calculated by 4Fmax/πd2, where Fmaxis the failure load and d is the fiber diameter. The failure load (Fmax) was obtained from stress–strain curves. The mean diameter (d) was achieved from above FE-SEM measurements (Fig. 2a).Using measured values of Fmaxand d, based on the equation:

we determined the value of the tensile strength (σ) for every single filament. For the same irradiation condition,both the failure load and the fiber diameter were estimated by arithmetic mean method. For the same irradiation case,in order to ensure statistical data, we tested more than twenty fiber specimens. During tensile tests, fibers that slide at the interface of grips and fibers were removed from the statistics.

For every irradiation fluence (20–30 specimens) we got a statistical average of its tensile strength. The calculated tensile strength value for the un-irradiated fibers was 1.94 ± 0.49 GPa.After irradiation to a fluence of 5 × 1012Sn/cm2, its value reduced to 1.79 ± 0.44 GPa. As the irradiation fluence successively increased to 6 × 1013Sn/cm2, the value of the tensile strength of fibers rapidly decreased from 1.79 ± 0.44 GPa to 1.35 ± 0.51 GPa.Above this fluence, the tensile strength increases slightly.At 1.6 × 1014Sn/cm2, the irradiated specimen had an increase in tensile strength to 1.38 ± 0.56 GPa. When the irradiation fluence reached 1.92 × 1015Sn/cm2,the tensile strength value of fibers increased to 1.59 ± 0.63 GPa.The calculated average value of the tensile strength from fiber specimens strongly depends on the ion fluences.According to our calculations,we can conclude that the fibers display about a 30% to 40% abrupt decrease in tensile strength value when the ion fluence raises to 6 × 1013Sn/cm2.After this fluence, the mean value of the tensile strength shows a slight increase with increasing ion fluence. Generally, the tensile strength of SiC fibers is reduced due to the irradiation of swift Sn ions.

The tensile test experiment also can deduce an average elastic modulus (E) of materials. According to stress (σ)–strain (ε) curves and Hook’s Law

where σ is the tensile strength,E is the elastic modulus,ε is the strain,and Lmaxis the fiber length at failure.The elastic modulus (E) was calculated by 4LFmax/πd2/(Lmax- L).Statistical average values of the elastic modulus of fibers corresponding to every irradiation fluence were achieved after they were irradiated to different fluences. For the unirradiated fiber, the calculated elastic modulus value was 356 ± 40 GPa. After irradiation at a fluence of 5 × 1012Sn/cm2, its value had reduced to 352 ± 39 GPa. As the irradiation fluence successively increased to 6 × 1013Sn/cm2, the value of the fiber’s elastic modulus rapidly decreased from 352 ± 39 GPa to 339 ± 41 GPa. Above this fluence, the elastic modulus decreases slightly. After irradiation at a fluence of 1.6 × 1014Sn/cm2, the value of the elastic modulus decreased to 338 ± 44 GPa.When the irradiation fluence reached 1.92 × 1015Sn/cm2,the elastic modulus value of fibers decreased to 334 ± 45 GPa. The calculated average value of the elastic modulus of fiber specimens also strongly depends on the ion fluences.Based on our results, we can deduce that the fibers exhibit an abrupt decrease in elastic modulus value when the ion fluence raises to 6 × 1013Sn/cm2. After this, the elastic modulus values show no significant change with the irradiation fluence. In summary, the elastic modulus of SiC fibers shows a general reduction with an increase in ion fluences, after they were irradiated by Sn ions to fluences ranging from 5 × 1012to 1.92 × 1015Sn/cm2. As stated above,based on the values of average tensile strengths and mean elastic modulus,the mechanical strength of SiC fiber presents a general degradation owing to the thermal effects of electron energy deposition by swift heavy Sn ions and to the increasing overlap of damage zones with respect to Sn ion fluence.

The tensile strength embodies the durability of fibers to the load,while the elastic modulus embodies the resistance of fibers to deformations caused by the load.Both of which strongly depend on the microstructures of fibers.Under the irradiation of SiC fibers by swift heavy ions, they suffered from various microstructure damages due to electron energy depositions by swift heavy Sn ions. Microstructure damages mainly include decompositions of amorphous SiCxOyphase, increases in diameters, and productions of bubbles/grains on surfaces, etc. These damages weaken their resistance to the load. So, a reduction in tensile strength and elastic modulus can be ascribed to these irradiation-induced damages. However, at the highest fluence (1.92 × 1015Sn/cm2), the tensile strength slightly increases.This may be attributed to the occurrence of local recrystallization of amorphous states, especially the free carbon phase,owing to high electron energy depositions by swift heavy Sn ions and to an increasing overlap of damage zones.

To analyze irradiation-induced degradation mechanisms in mechanical stabilities of SiC fibers caused by energetic Sn ions at different fluences, we characterized their tensile strength distribution by means of the two-parameter Weibull statistical model derived from the tensile test [39]. In this model, the failure frequency F was characterized by the equation:

where σfis the failure stress of the single filament;m is the Weibull modulus parameter and σ0is the scale parameter.By taking natural logarithms on both sides of the above equation and further rearrangement, we can obtain leastsquare linear regression:

where the m value characterizes the slope and the value –m(lnσ0)characterizes the intercept on the y axis.During the tensile test, we get the values of σfand Fi. The σfis the experimental tensile failure stress, and the Fiis the failure probability from a total of N specimens,

where N is the total number of specimens(data points),and i is the ith data point at the same irradiation case.Based on the Weibull equation [39]:

we can get the value of Weibull modulus (m) from the fitting result through the measured data points σfand Fi.

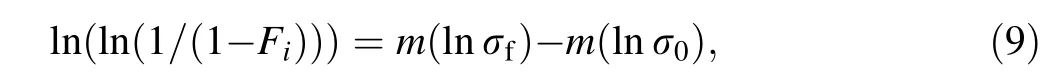

The fracture behavior of the single filament can be deduced from the m value. The Weibull plots and corresponding Weibull modulus (m value) for the fibers irradiated with Sn ion to fluences ranging from 5 × 1012to 1.92 × 1015Sn/cm2are presented in Fig. 3. We can see from Fig. 3 that with increasing irradiation fluence, the value of m generally decreases. However, the irradiatedspecimens at the highest fluence(1.92 × 1015Sn/cm2)had an m value exhibiting a slight increase compared with that of the other irradiated specimens. In the case of the unirradiated specimen, a big Weibull modulus value(m) means a relatively small discreteness in their tensile strengths and a uniformity in their fracture behaviors. The Weibull modulus decreases with an increase in irradiation fluence, suggesting a reduction in their mechanical stabilities. The mechanical retention of fibers depends more on the chemical bonds between the constituent grains than on the grains themselves [40]. Under irradiation with swift heavy ions, various decomposed fragments (SiC, C, SiO,CO) were produced via the dissociations of the intergranular amorphous SiCxOyphase due to the thermal effects of electron energy depositions by swift heavy Sn ions and to an overlap of damage zones [32]. Simultaneously, this thermal effect of electron energy loss also promotes the rearrangement and agglomeration of SiC and C phases,leading to the production of disordered structures and growth/coarsening of SiC/C grains [32]. The density of grain boundaries increases due to the agglomeration and growth of crystal grains. Compared to the chemical bonds between atoms in crystalline and amorphous states, the chemical bonds between the grains are much weaker[40, 41]. As a consequence, the mechanical strength of fibers is reduced.

Fig. 3 (Color online)Tensile strength distribution of SiC fibers after irradiation with Sn ions to different fluences: a un-irradiated,5.0 × 1012 Sn ions/cm2, and 6.0 × 1013 Sn ions/cm2; b 1.6 × 1014 Sn ions/cm2 and 1.92 × 1015 Sn ions/cm2

On the other hand, a decrease in m value of Weibull plots implies an increase in flaw number and size related to the stress. For a brittle material, such as SiC, the size of flaws scales with the size of grains. The SiC fibers composed of larger grains have a relatively lower strength in common. Under the high energy depositions of electron energy loss by swift heavy Sn ions, grain growth and coarsening occurred due to the decomposition and recombination of the intergranular amorphous SiCxOyphase.Meanwhile,a disordered structure was generated as a result of an occurrence of the chemical reaction between the free carbon (C) and the SiO segment, which comes from the intergranular amorphous phase (SiCxOy). Thus, the active oxidation was accelerated owing to a high permeability of oxygen in this disordered/damaged structure. Simultaneously, diffusion of C (Si) atoms at the grain boundary was also promoted, in conjunction with an acceleration in the chemical reaction between SiO and C, enhancing grain growth. As a result, the flaw population and flaw size increase with increasing irradiation fluence. Similar phenomena were observed in NiO thin films induced by swift heavy ions [42, 43]. The flaw directly leads to a degradation in fiber mechanical strength. Once flaws were produced, at the crack tip, the concentration of stress increases.At this time,the protective Si(SiO2)film on the fiber surface was ruptured/removed, leading to an enhancement in the active oxidation [44]. Moreover,surface damage may play an important role in producing the flaws and stresses. SEM observations (Fig. 2) revealed that many bubbles/large grains appeared and a coarse fiber surface was formed after irradiation with swift heavy Sn ions to higher fluences. The attack of oxygen to fibers was accelerated through these surface defects, leading to an obvious degradation in fracture strength(Fig.2b,c).These defects might function as an origin of flaws and lead to a degradation in fiber strengths.

In addition, the grain growth and coarsening not only introduce the flaws but also introduce the residual stresses into materials at the same time. Mallick et al. [42, 43]observed the residual stresses related to the cracks in NiO thin films under 200 MeV Au ion irradiation. For SiC fibers,during the dissociation-rearrangement process of the intergranular amorphous phase(SiCxOy),the residual stress between the SiC grains may be introduced. Especially,because the thermal expansion coefficient of SiC phase is larger than that of the free carbon phase, the potential differential irradiation-induced swelling under Sn-ion irradiation can introduce stresses into the fibers. Furthermore, the residual stresses were confirmed in stacking faults of SiC grains. These stresses increased with the coarsening of SiC grains after irradiation with swift heavy Sn ions. Concurrently, the transformation between the amorphous carbon phase and the graphite phase in fibers results in a high thermal expansion mismatch stress under the thermal effect of electron energy depositions by swift heavy Sn ions. The reason is that the thermal expansion coefficients in the directions normal to the hexagonal basal planes of the graphite are much larger than that parallel to the hexagonal basal planes of the graphite. These stresses also could induce degradation in the tensile strength of the SiC fibers. Generally, the failure in mechanical stabilities of SiC fibers also can be ascribed to the production of these stresses under irradiation.

As stated above, the degradation in mechanical properties of SiC fibers caused by swift heavy ions can be attributed to many factors, including the dissociation and agglomeration of the intergranular amorphous SiCxOyphase, grain growth and coarsening, the residual stresses and flaws, as well as surface damage.

4 Conclusion

An investigation of surface features and mechanical stabilities of the SiC fiber induced by 414.4-MeV112Sn27.3+-ion irradiation to different fluences was performed using FE-SEM and the special electronic single filament tensile test. FE-SEM observations exhibit that with increasing ion fluence,the percentage of carbon atoms increases and that of silicon atoms decreases at the surface,besides an absorption of oxygen. In contrast to energetic Ar-ion-irradiated SiC fibers, this phenomenon implies that carbon migrates towards the heavily damaged region under irradiation. Simultaneously, big grains/bubbles first were observed and then disappeared with the ion fluence.Moreover, some fibers brittle fractured at 1.92 × 1015Sn ions/cm2.As a result,the average tensile strength and mean elastic modulus of the SiC fiber reduce with the112Sn27.3+-ion fluence generally. This mechanical-stability degradation could be attributed to the surface damage due to the attack of oxygen and the segregation of Si and C elements under irradiation.Furthermore,this degradation also can be ascribed to the grain growth and coarsening,as well as the production of flaws and residual stress caused by the dissociation and the agglomeration of the amorphous SiOC phase due to the thermal effects of electron energy depositions by swift heavy112Sn27.3+ions and to the overlap of damaged zones. Our results imply that ion beam technology is a tool for tailoring multiphase material microstructure and properties. Our results also suggest that the radiation tolerance of SiC fibers perhaps could be improved by optimizing the fabrication process to decrease the content of amorphous SiOC phase in SiC fibers properly.

Author contributionsAll authors contributed to the study conception and the experiment design.Material preparations were performed by Chong-Hong Zhang and Qing Huang. Specimen irradiation experiments were carried out by Zheng-Dong Feng and Guo-Dong Hu.FE-SEM data collection and analysis were performed by Chen-Chun Hao and Jian-Yang Li. Tensile test and data analysis were carried out by Li-Qing Zhang and Wen-Kun Zhu. The first draft of the manuscript was written by Li-Qing Zhang and Yong-Jian Tang.All authors commented on previous versions of the manuscript. And all authors read and approved the final manuscript.

杂志排行

Nuclear Science and Techniques的其它文章

- Hard X-ray focusing resolution and efficiency test with a thickness correction multilayer Laue lens

- Monte Carlo study of the neutron ambient dose equivalent at the heavy ion medical machine in Wuwei

- Experimental investigation on the characteristics of molten lead–bismuth non-eutectic alloy fragmentation in water

- Configurational information entropy analysis of fragment mass cross distributions to determine the neutron skin thickness of projectile nuclei

- Differences in MBUs induced by high-energy and medium-energy heavy ions in 28 nm FPGAs

- Thin-film approximate point scattered function and its application to neutron radiography