Experimental investigation on the characteristics of molten lead–bismuth non-eutectic alloy fragmentation in water

2022-11-21ShaoJieTanYuBaoZhongHuiChengSongBaiCheng

Shao-Jie Tan • Yu-Bao Zhong• Hui Cheng• Song-Bai Cheng

Abstract To study the interaction between molten noneutectic alloys and subcooled water during severe nuclear accidents,an experimental investigation was carried out by injecting molten lead–bismuth non-eutectic alloy (LBNE,70%Pb-30%Bi)into the water in a free-fall style using the visualized thermo-hydraulic characteristics in melt coolant interaction (VTMCI) facility. The effects of various experimental parameters, including water temperature,melt temperature, melt penetration velocity, and water depth, on the molten LBNE jet fragmentation characteristics were studied. The research shows that compared with lead–bismuth eutectic, larger fragments, less spherical fragments, and more porous debris beds are generated for LBNE.Higher water or melt temperatures facilitate molten LBNE fragmentation, resulting in higher debris bed sphericity and lower debris bed porosity. A higher melt temperature leads to smaller fragment sizes, except that a cake-like debris bed is formed for very high alloy superheat and very low water subcooling. More approximate spherical particles were generated in the film boiling zone than in the thermal interaction zone. Fragment size decreases with an increase in the melt penetration velocity, but the debris bed porosity and sphericity variation was not obvious. The effect of water depth on molten LBNE fragmentation behavior was not obvious under the current experimental conditions. Compared with other fragmentation theories,the Weber number theory better predicted the fragment volume mean diameter. In addition, a melt-jet behavior mode diagram that describes the competition between the hydrodynamic and thermal interactions and diagrams of debris bed porosity and sphericity that show the influence of thermal factors were analyzed in this study.

Keywords Fuel–coolant interaction ∙Coolant–coolant interaction ∙Debris bed ∙Lead–bismuth non-eutectic alloy–water interaction ∙Fragmentation behavior

1 Introduction

Liquid–metal-cooled fast reactors, including the sodium-cooled fast reactor(SFR)and the lead-based alloycooled fast reactor (LFR), have huge application potential in the future nuclear energy field due to their high level of inherent safety,advantages in new fissile fuel breeding,and minimization of spent nuclear fuel.Although SFR and LFR have these advantages, some safety issues have been paid attention by researchers during the design process[1,2].In the hypothetical case of a core-disruptive accident (CDA)for SFR, the corium is considered to discharge from some potential paths(e.g.,the control rod guide tube)as a jet and tends to be removed into the sodium plenum,leading to the melt fragmentation and debris bed formation in the lower head of the reactor vessel[3–5],which is commonly called the fuel–coolant interaction (FCI). To ensure the completeness of the reactor vessel and prevent the impact of radioactive nuclear reaction products on the environment when FCI occurs, the corium jet should be sufficiently fragmented, and the debris bed should be easy to cool [6].Hence, it is of great importance to understand the corium jet fragmentation behavior and debris bed formation in sodium for the safe design of SFR [7]. In the hypothetical case of a steam generator tube rupture(SGTR)accident for LFR, the high-pressure water in the second circuit may be directly ejected into the high-temperature coolant in the primary circuit. This will lead to rapid vaporization of high-pressure water and may even cause violent steam explosions, which may have a significant impact on the structural components in the reactor [8, 9]. The consequences of an SGTR accident can be severe because radioactive materials may be released into the environment. Hence, it is essential to study the contact reaction between water and molten lead-based alloys, commonly called coolant–coolant interaction (CCI).

Multiple studies have focused on the characteristics of an FCI with prototypic and simulant molten metals over the last three decades [10]. On one hand, by releasing prototypical melt material UO2-ZrO2or UO2-ZrO2-Zr into saturated and subcooled water, a full view of the effects of various FCI states (with and without steam explosions) on debris formation and characteristics was gained [11–14].On the other hand,several studies paid attention to melt-jet behavior, debris bed formation, and steam explosion using the simulant melt materials, such as Sn, Bi–Sn–In alloy,Pb–Bi, Pb, Zn, In, Bi, WO3–Bi2O3, and WO3–ZrO2[10, 15–19]. Previous studies have revealed the important effects of molten metal and water temperatures on fragment size and debris bed morphology. The melt-jet fragmentation behavior is more complete with an increase in the water temperature or melt temperature. It has been shown that the average size of the fragment increases with decreasing melt penetration velocity[15–17].It is believed that a spontaneous steam explosion is almost impossible to take place when the water temperature is high because the vapor film is steady, whereas it is more likely to occur at lower water temperature [20–22].

According to previous studies, two-component melt materials involved in FCI have two forms,namely eutectic alloy and non-eutectic alloy, and the fragmentation behavior and steam explosion phenomena with water show significant differences.Cho et al.[23]found that the energy of the explosion interaction between molten zirconium alloy and water could be significantly increased by the reaction of zirconium–water, depending on the zirconium content in the alloy. Song et al. [24] concluded that a noneutectic mixture (80% UO2-20% ZrO2) has a lower steam explosion intensity than the eutectic mixture (70% UO2-30% ZrO2). Hansson et al. [25] indicated that the interaction between a non-eutectic melt droplet (WO3–CaO) with a low melt superheat and water is milder than the interaction between the eutectic melt and water. Because corium contains UO2, Zr, ZrO2, stainless steel, and B4C [26],its physical properties are closer to those of the non-eutectic. Therefore, it is more reasonable to use non-eutectic materials as simulation melt materials. Although many studies focusing on FCI have been conducted, the FCI characteristics of non-eutectic materials are very limited.

To study the characteristics of CCI in LFR, the contact reaction between the candidate primary coolant, including pure lead and Lead Bismuth Eutectic (LBE, 44.5% Pb-55.5% Bi) and water in melt injection mode (melt is injected into water) and water injection mode (water is injected into melt) with various experimental parameters,including water subcooling, melt superheat, melt penetration velocity, melt mass, and water depth was explored[16,17,22,27–31].Although these pioneering experiments enhanced our understanding of the CCI phenomena, these studies focused on the interaction of pure lead and LBE in water. For the candidate primary coolant Lead–Bismuth Non-Eutectic (LBNE) [32], the interaction between hightemperature LBNE and water has rarely been studied in the past.

In this paper,to obtain some experimental database and awareness for further understanding of FCI using non-eutectic simulant melt materials and CCI with non-eutectic coolant candidate in LFR, the melt-jet fragmentation behavior was investigated using the visualized thermohydraulic characteristics in melt coolant interaction(VTMCI)facility by releasing molten LBNE(70%Pb-30%Bi) jet into a subcooled water pool in a free-fall style.Effects of various experimental parameters, including water temperature, melt temperature, penetration velocity,and water depth, on the fragmentation characteristics of molten LBNE melt jet were studied. Moreover, the experimental data were compared with the LBE data from our previous experiments.

2 Experimental details

2.1 Experimental apparatus

The experimental apparatus VTMCI [15, 17] built at Sun Yat-Sen University is shown in Fig. 1. It is composed of a stainless-steel support structure, an integrated circuit control system,a backlight,an upper large heating furnace,a lower small heating tube,a release nozzle,two pneumatic valves,a 46 cm×46 cm×110 cm rectangular water tank,a stainless-steel fragment catcher, and a high-speed video camera. Thermocouples were installed in the heating furnace, heating tube, and water tank to control the temperatures of the melt jet and water.The water tank is made oftransparent heat-resistant glass to capture the melt-jet fragmentation process, which was recorded by a highspeed video camera.

Fig. 1 VTMCI facility [15, 17]

2.2 Mushy zone of lead–bismuth non-eutectic alloy

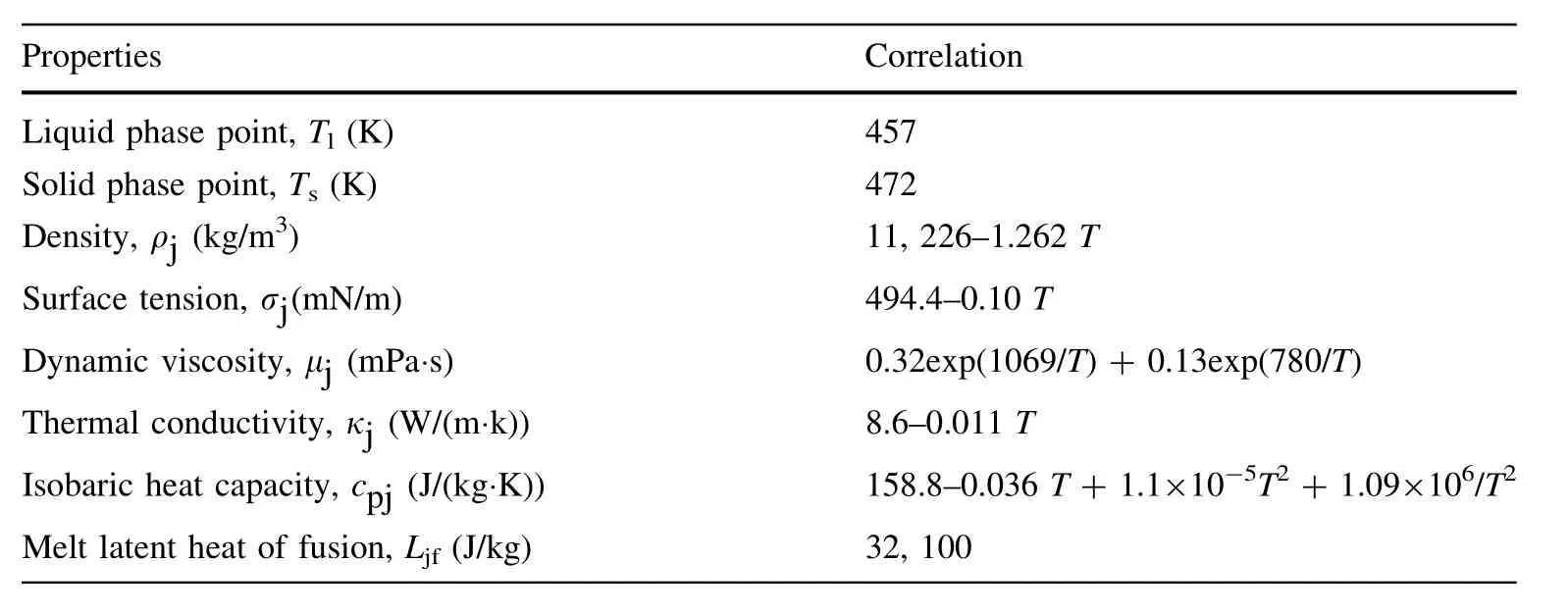

In this study, the interaction between molten LBNE(70% Pb-30% Bi) and water was studied. The most essential difference between eutectic and non-eutectic alloys is that the liquid phase and solid phase points of noneutectic alloys do not coincide, and there is a large temperature difference that corresponds to the mushy zone in the metallography[33].The material in the mushy zone is a suspension–solid mixture, which is composed of solid particles precipitated during the cooling process and the remaining liquid phase. Moreover, the viscosity of the material in this state is much higher than that in the liquid phase. Eventually, the liquid loses its fluidity and the fragmentation process of the alloy is suppressed. The physical properties of the LBNE depending on temperature T are shown in Table 1. For comparison, Table 2 presents the physical properties of LBE.

The subscripts l, s, and j represent liquid, solid, and jet,respectively. The subscript pj represents isobaric and jet.The subscript jf represents jet and fusion.

2.3 Experimental procedure and parameters

At the beginning of the experiment,the water and LBNE were heated. After the water and melt reached the target temperature, the sample was released into the water.Simultaneously, the melt-jet fragmentation process was captured by the high-speed video camera,and the fragment was collected by the fragment catcher for a series of measurements.

The melt penetration velocity V refers to the velocity when the melt reaches the water-free surface and is calculated as follows:

where g is the gravitational acceleration and h is the distance from the nozzle outlet to the water-free surface.

Water depth Hwis defined as the height from the waterfree surface to the fragment catcher.

To achieve a thorough understanding of the molten LBNE fragmentation behavior, the effects of water temperature Tw(298 K–353 K), melt temperature Tm(573 K–873 K), melt penetration velocity (1.98 m/s–3.43 m/s) and water depth (20 cm–80 cm) are investigated extensively.The mass of the molten LBNE was approximately 1.5 kg,and the nozzle diameter for molten LBNE release was 10 mm in every experiment. The detailed experimental conditions are listed in Table 3.

Table 1 Physical properties of LBNE (70% Pb-30% Bi) [34]

Table 2 Physical properties of LBE (44.5% Pb-55.5% Bi) [34]

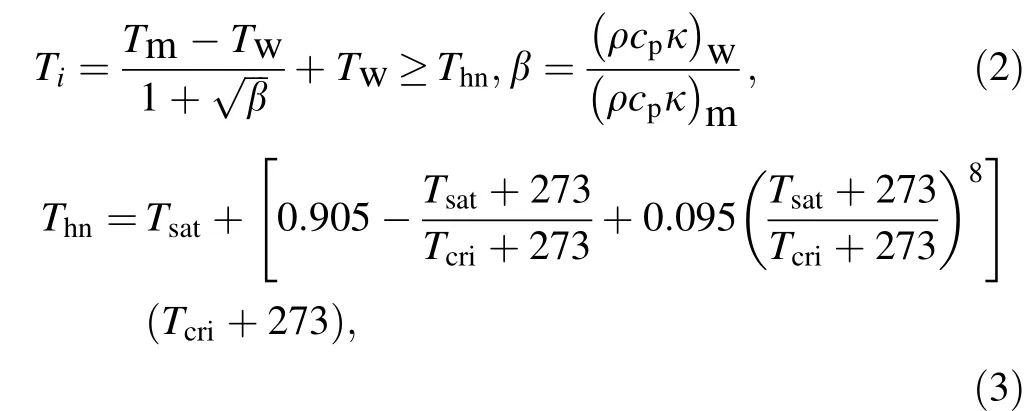

Figure 2 shows the film boiling zone and thermal interaction zone for the LBNE and water. Ti, Thn,and Tminrepresent the instantaneous interface temperature between the molten LBNE and water, homogeneous nucleation temperature, and minimum film boiling temperature,respectively [21, 35]. To study the fragmentation phenomena in different condition zones, two criteria were considered to define these condition zones.One criterion is the instantaneous interface temperature Tibetween the melt and water higher than the homogeneous nucleation temperature of water Thn. It is believed that when Tiis larger than Thn, steam bubbles are produced furiously due to the homogeneous nucleation [36]. Tiand Thnare obtained by[21]:

where ρ, cp, and κ denote liquid density, isobaric specific heat capacity, and thermal conductivity, respectively. Tsatis saturation temperature of water and at ambient pressure Tsat= 373 K. Tcriis the critical temperature of water and Tcri= 647 K. Hence, the homogeneous nucleation temperature for water is Thn= 587 K.

The other criterion is that if the instantaneous interface temperature Tiis larger than the minimum film boiling temperature Tmin, the vapor film is stable, and the zone is called the film boiling zone. The minimum temperature difference for vapor film stability can be obtained by [21]

By using Eqs.(2),(3),and(4),three different condition zones are obtained,as shown in Fig. 2.The high possibility of the steam explosion zone where Tiis larger than Thnand smaller than Tminis called the thermal interaction zone,and the fragmentation behavior could be greatly affected when a vapor explosion occurs.Figure 2 also shows that a broad range of thermal conditions was considered in this study.

2.4 Measurement quantities

2.4.1 Size distribution of the fragments

To estimate the fragmentation mechanism and particle morphology based on their size,fragments were divided into six size-intervals (0–0.8 mm, 0.8–1.5 mm, 1.5–3.0 mm,3.0–6.0 mm,6.0–9.0 mm and 9.0–12.0 mm,and those with sizes larger than 12.0 mm were not taken into account).Each interval fragment was weighed to calculate the volume mean diameter dvwhich was estimated as[37,38]

Table 3 Experimental conditions for LBNE

where dmidkand xkrepresent the mid-diameter(the average value of the lower and upper bounds of each size interval)of the k-th size interval fragment and the mass fraction of the fragments in the k-th size interval, respectively.

2.4.2 Melt-jet behavior modes

Based on the observations from the experiments, fragments larger than 12 mm were interlaced with each other,while fragments smaller than 12 mm were often separated from each other. Hence, fragments larger than 12 mm are defined as agglomerates. Based on the mass fraction of agglomerates (ratio of agglomerate mass to total fragment mass), the following four melt-jet behavior modes were proposed, as presented in Table 4 [15, 39], and typical pictures of these four modes are presented in Fig. 3.

Fig.2 (Color online)Film boiling zone and thermal interaction zone for LBNE and water [15, 22]

2.4.3 Debris bed porosity

The debris bed porosity ε is defined as the ratio of the void volume of the debris bed to the total debris bed volume.This is the key parameter to describe the morphology of the debris bed, which can be used to better evaluate the coolability of the debris bed. In this study, the drainage approach was employed to measure the porosity of the debris bed, which was calculated as [40, 41]

where Vtotal, Vparticle, and Vwaterrepresent the total volume of the debris, debris bed volume, and water volume,respectively. The volumes were measured using a cylinder with an error of 1%.

2.4.4 Debris bed sphericity

To quantitatively describe the particle morphology, the debris bed sphericity φ is defined as [40, 41]

Table 4 Four melt-jet behavior modes for LBNE

where A represents the surface area of the fragment and v represents the volume of the fragment. By following the Ergun equation [42]:

where ΔP, Hbl, ρf,μfand Ufrepresent the pressure drop across the debris bed, debris bed length, density of the fluid,viscosity and surface velocity of the fluid,and debris bed sphericity, respectively. An experimental apparatus was designed to measure the drop in pressure ΔP across the debris bed and surface speed Ufof the fluid [40, 41].

3 Experimental results and discussion

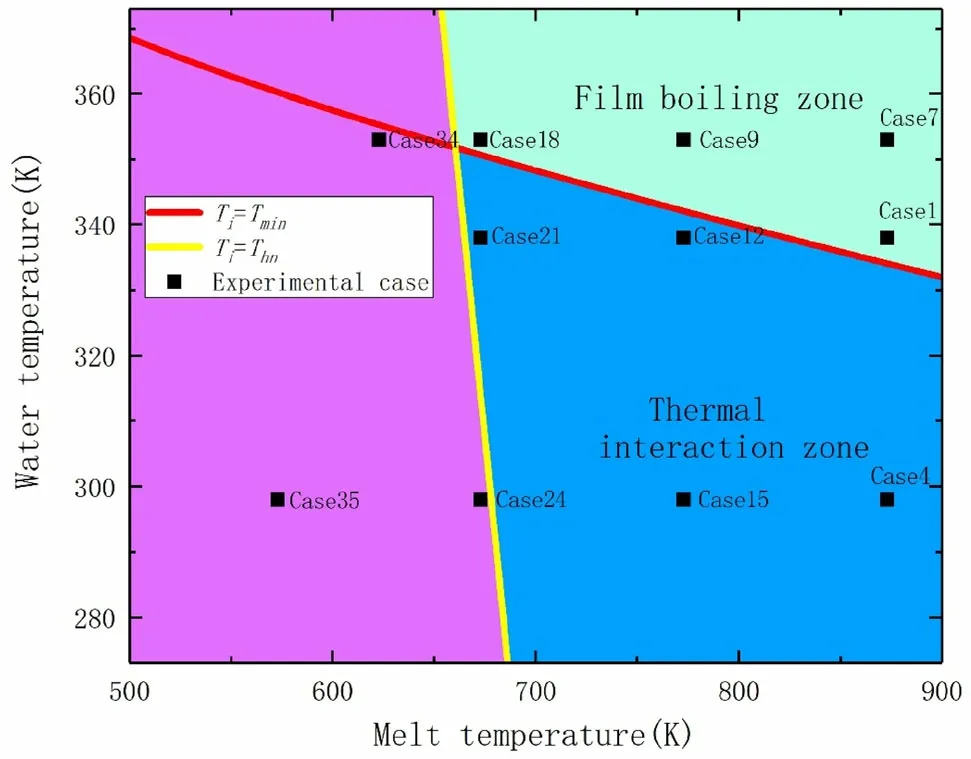

3.1 Effect of water temperature

Figure 4 shows the visual results of the fragmentation process of molten LBNE and a photograph of the debris bed at Tw= 298 K and Tw= 353 K. This indicates that fewer large fragments were generated as the water temperature increased. At higher water temperatures, the fragment size was smaller, and the debris bed was more compact,as shown in the fragment catcher.The reasons for this are as follows:when the water temperature was higher,vapor films were more easily produced.On one hand,these vapor films have a certain isolation effect on the jet fragments, which reduces the solidification speed of the jet fragments, so that the fragments maintain a relatively spherical shape before being completely solidified. On the other hand,when these vapor films collapse,they facilitate the breakup of the leading edge of the melt jet, and thus,more small-sized fragments are produced. Hence, the resulting fragment size is smaller,and the debris bed packs more compactly, as shown in Fig. 4b.

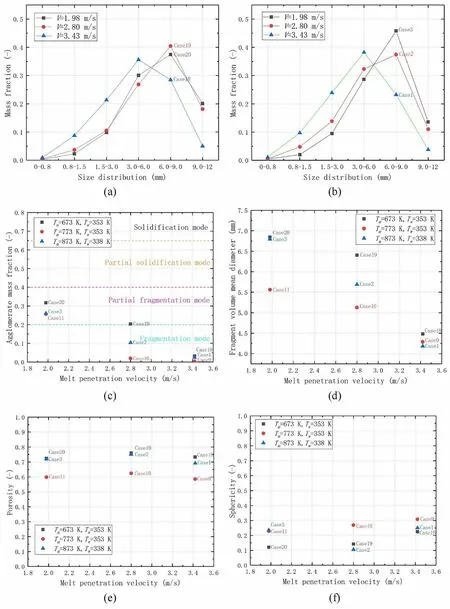

Figure 5 shows the distinct influence of water temperature on the physical properties of the debris bed. Figure 5a, b shows that the number of small fragments increases and large fragments decreases when the water temperature increases for LBNE. As shown in Fig. 5c, as the water temperature increased, the agglomerate mass fraction initially decreased and then increased for LBNE because a cake formation debris bed was formed when the alloy superheat was very high and the water subcooling was very low. With an increase in the water temperature,the volume mean diameter generally increased and then decreased, as shown in Fig. 5d, because the agglomerate mass fraction at a water temperature of 298 K was much larger than that at a water temperature of 338 K.Figure 5e shows that as the water temperature increased, the debris bed porosity decreased for LBNE, while the debris bed sphericity increased, as presented in Fig. 5f. These effects indicate that higher water temperatures facilitate molten LBNE fragmentation in water because solidification of the melt in the coolant is delayed when the water temperature is higher.

Fig. 3 Debris bed in four modes: a fragmentation mode,b partial fragmentation mode,c partial solidification mode,and d solidification mode

To study the influences of composition on the fragmentation behavior of two-component materials, based on our previous experiments with molten LBE [17], the differences in the agglomerate mass fraction, porosity of the debris bed, and sphericity of the debris bed (because the fragment intervals divided for LBNE differ from the LBE,the fragment size distribution and volume mean diameter are not compared)between LBNE and LBE were studied in detail, as presented in Fig. 5c–f. It should be noted that owing to limited experimental data,one parameter of water temperature for LBE is 333 K,while for LBNE it is 338 K.Figure 5c shows that under the same conditions, the agglomerate mass fraction of LBNE is larger than that of LBE. More porous debris beds and fewer spherical fragments were generated for the LBNE under the same conditions, as shown in Fig. 5e and f. This is because there exists a mush phase for LBNE; when the temperature of molten LBNE is below 457 K, the high viscosity suppresses its deformation and fragmentation process[33].Hence, the molten LBNE maintained this intermediate form and continued to cool until it was completely solidified and cooled.However,for the LBE,the mush phase did not exist. Thus, the fragmentation process continues for molten LBE until the LBE is completely solidified and cooled. This will assuredly influence the quantity of larger fragments,the spherical shape of fragments,and the porous debris bed. Therefore, the number of larger fragments for LBNE is greater than that for LBE, and more spherical particles and less porous debris beds were produced for LBE because fragmentation is more complete for LBE.

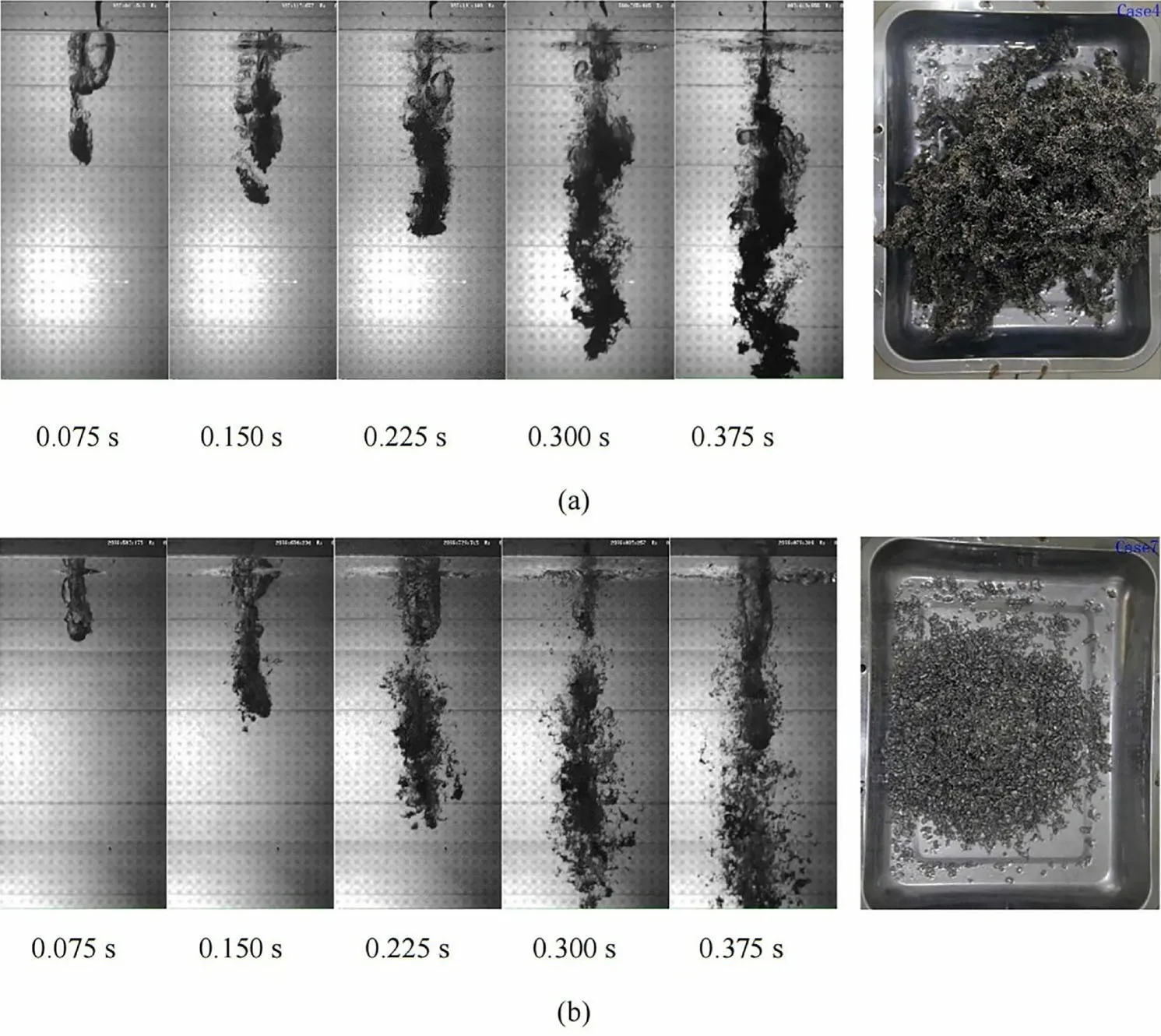

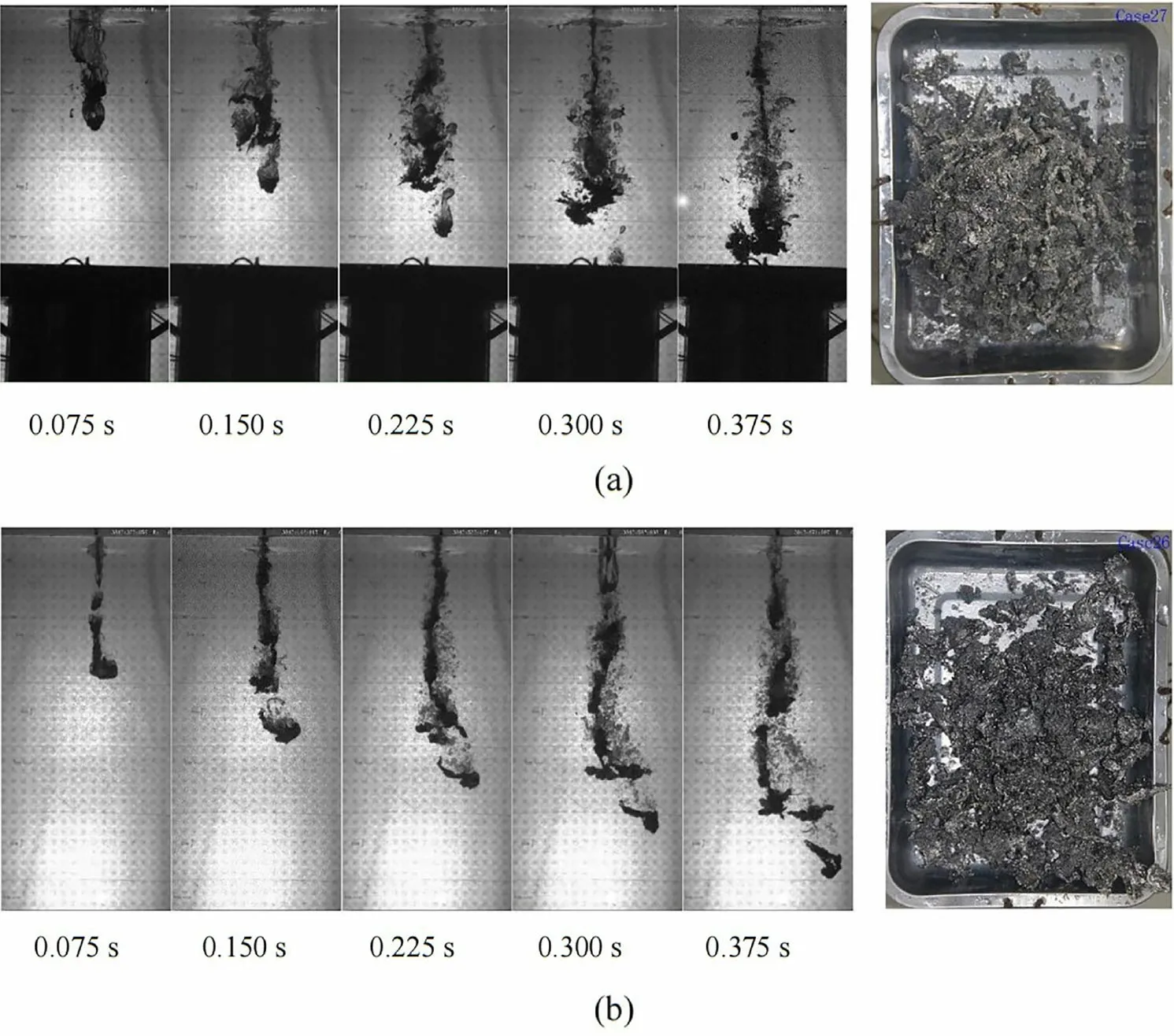

3.2 Effect of melt temperature

The visual results of the fragmentation process of the molten LBNE and a photograph of the debris bed with different melt temperatures are presented in Fig. 6. This shows that there is an obvious main column that continues at Tm= 673 K, suggesting that the fragmentation behavior is less complete at lower melt temperatures. Figure 6a and b shows that the fragment size was smaller when the melt temperature was higher. At Tm= 873 K and Tw= 353 K,the molten LBNE does not completely solidify before being deposited on the top of the debris bed, hence, the debris bed clump and form a ‘‘cake’’ as shown in Fig. 6c.

Figure 7 quantitatively depicts the influence of the melt temperature on the physical properties of the debris bed for the LBNE.Figure 7a and b depicts that the small fragments increase, and the large fragments decrease with the increase in melt temperature. As the melt temperature increased, the mass fraction of the agglomerate decreased and then increased, as shown in Fig. 7c. When the melt temperature was increased, the mean volume diameter decreased,as shown in Fig. 7d.Figure 7e shows that as the melt temperature increases, the debris bed porosity decreases, indicating that a more compact debris bed is generated at higher melt temperatures. Figure 7f suggests that the debris bed sphericity increases as the melt temperature increases,which indicates that more spherical tiny particles are produced at higher melt temperatures.

These results indicate that a higher melt temperature can facilitate the fragmentation of molten LBNE because the solidification of the melt in the coolant is delayed when the melt temperature is higher, except that the cake formation debris bed is formed for very high alloy superheat and very low water subcooling.

3.3 Effect of boiling mode

In Sects. 3.1 and 3.2,the influences of melt temperature and water temperature on the physical properties of the debris bed for LBNE were analyzed in several studies. In this section, the influence of the boiling mode, including the film boiling zone and the thermal interaction zone(nonfilm boiling), were studied, and the experimental conditions are presented in Fig. 2.Eight experimental conditions were tested to study the effect of the boiling mode,four of which (Tw= 353 K, Tm= 873 K; Tw= 353 K, Tm-= 773 K; Tw= 353 K, Tm= 673 K; Tw= 338 K, Tm-= 873 K) are located in the film boiling zone, and the other four (Tw= 338 K, Tm= 773 K; Tw= 338 K, Tm-= 673 K; Tw= 298 K, Tm= 873 K; Tw= 298 K, Tm-= 773 K) are located in the thermal interaction zone. As previously mentioned, the high possibility zone of steam explosion is located in the thermal interaction zone; steam explosion occurs in this study,as shown in Fig. 8a,and the fragments are loose and striped due to steam explosion, as presented in the fragment catcher.In the film boiling zone,numerous vapor bubbles were generated, as shown in Fig. 8b, and the fragments were more compact and spherical, as shown in the fragment catcher.

Fig. 5 (Color online) Influence of water temperature on physical characteristics of debris bed (Hw = 60 cm). a Fragment size distribution (Tm = 773 K, V = 3.43 m/s), b fragment size distribution(Tm = 873 K, V = 3.43 m/s), c agglomerate mass fraction, d volume mean diameter, e debris bed porosity, and f debris bed sphericity

Figure 9 quantitatively depicts the influence of the boiling mode on the physical characteristics of the debris bed for the LBNE. Figure 9a indicates that the fragment mass fraction with a diameter interval of 1.5–6.0 mm is generally smaller in the thermal interaction zone than in the film boiling zone.In the film boiling zone,the agglomerate mass fraction generally tends to 0 while in the thermal interaction zone, the agglomerate mass fraction is much larger than that, except that the cake formation debris bed is formed at a melt temperature of 873 K and a water temperature of 353 K. This is because these stable vapor films give the melt jet more time to interact with water before they are completely solidified,and more small-sized fragments are produced. Figure 9d shows that the debris bed porosity in the film boiling zone is smaller than that in the thermal interaction zone, whereas Fig. 9e shows that the debris bed sphericity in the film boiling zone is larger than that in the thermal interaction zone. This is also because these stable vapor films, which reduce the solidification speed of the fragments, can isolate the fragments and water so that the fragments maintain a relatively spherical shape before being completely solidified. In addition, the spherical fragments pack more compactly than the non-spherical fragments, which decreases the debris bed porosity.

Fig. 6 Visual results of molten LBNE fragmentation process and debris bed with different melt temperatures (Hw =60 cm). a Tm = 673 K,Tw = 338 K, V = 3.43 m/s,b Tm = 773 K, Tw = 338 K,V = 3.43 m/s, and c ‘‘cake’obtained at Tm = 873 K,Tw = 353 K, V = 2.80 m/s

Fig.7 Influence of melt temperature on physical properties of debris bed for LBNE (Hw = 60 cm). a Fragment size distribution (Tw-= 353 K, V = 3.43 m/s), b fragment size distribution (Tw = 353 K,V = 2.80 m/s), c agglomerate mass fraction, d volume mean diameter, e debris bed porosity, and f debris bed sphericity

3.4 Effect of melt penetration velocity

Figure 10 shows the molten LBNE fragmentation process and debris bed photographs at different melt penetration speeds. This indicates that smaller fragments were generated as the melt penetration velocity increased.

The influence of penetration velocity on the physical characteristics of the debris bed for the LBNE is quantitatively depicted in Fig. 11. Figure 11a, b shows that the number of small fragments increases and large fragments decreases as the penetration velocity increases. Figure 11c shows that the mass fraction of the agglomerate decreases with increasing velocity.For example,the mass fraction of agglomerate decreases from 0.32 to 0.03 as speed increases from 1.98 m/s to 3.43 m/s at Tm= 673 K and Tw= 353 K.Figure 11d shows that the volume mean diameter decreases with an increase in melt penetration velocity. Because the hydrodynamic interaction between molten LBNE and water is more violent when the speed is larger, these fragments are smaller [17].

Figure 11e and f reveals that even though the penetration velocity is different,the debris bed porosity and debris bed sphericity are similar and are mainly influenced by the water temperature and melt temperature [18, 19, 21, 43].Although the hydrodynamic interaction between molten LBNE and water is more violent when the melt penetration velocity is higher, the fragment shape is similar, and the accumulation pattern of the debris does not change significantly under the current experimental conditions.Hence,the variation in debris bed porosity and sphericity is small as the melt penetration velocity increases.

Fig. 8 Visual results of fragmentation process and debris bed photograph under different boiling zones for LBNE (Tm = 773 K,V = 3.43 m/s, Hw = 60 cm).a Tw = 298 K, thermal interaction zone, non-film boiling. b Tw = 353 K, film boiling zone

Fig. 9 (Color online) Influence of boiling mode on debris bed physical properties for LBNE (V = 3.43 m/s, Hw = 60 cm). a Fragment size distribution, b agglomerate mass fraction, c volume mean diameter, d debris bed porosity, and e sphericity of debris bed

Fig. 10 Photograph of fragmentation process and debris bed at different velocities for the LBNE (Tm = 873 K,Tw = 338 K, Hw = 60 cm).a V = 1.98 m/s and b V = 3.43 m/s

3.5 Effect of water depth

The visual results of the fragmentation process of the molten LBNE and a photograph of the debris bed at Hw-= 40 cm and Hw= 80 cm are shown in Fig. 12,where the difference is very slight.

Figure 13 quantitatively depicts the effect of water depth on the physical properties of the debris bed for the LBNE. Even though the water depths are different, the fragment size distribution, agglomerate mass fraction,fragment volume mean diameter, debris bed porosity, and debris bed sphericity are generally similar. It should be noted that the isobaric heat capacity of the molten LBNE is very small; if the LBNE superheat is not very high or the water subcooling is not very low, the molten LBNE completely solidified at a depth of 20 cm. Water cannot affect the solidified LBNE;therefore,the effect of water depth on the molten LBNE fragmentation behavior is negligible.

3.6 Theoretical analysis

To model the melt-jet fragmentation behavior, we theoretically explain the melt-jet behavior modes, fragment volume mean diameter, porosity, and sphericity of the debris bed.

3.6.1 Comparison between results and theories

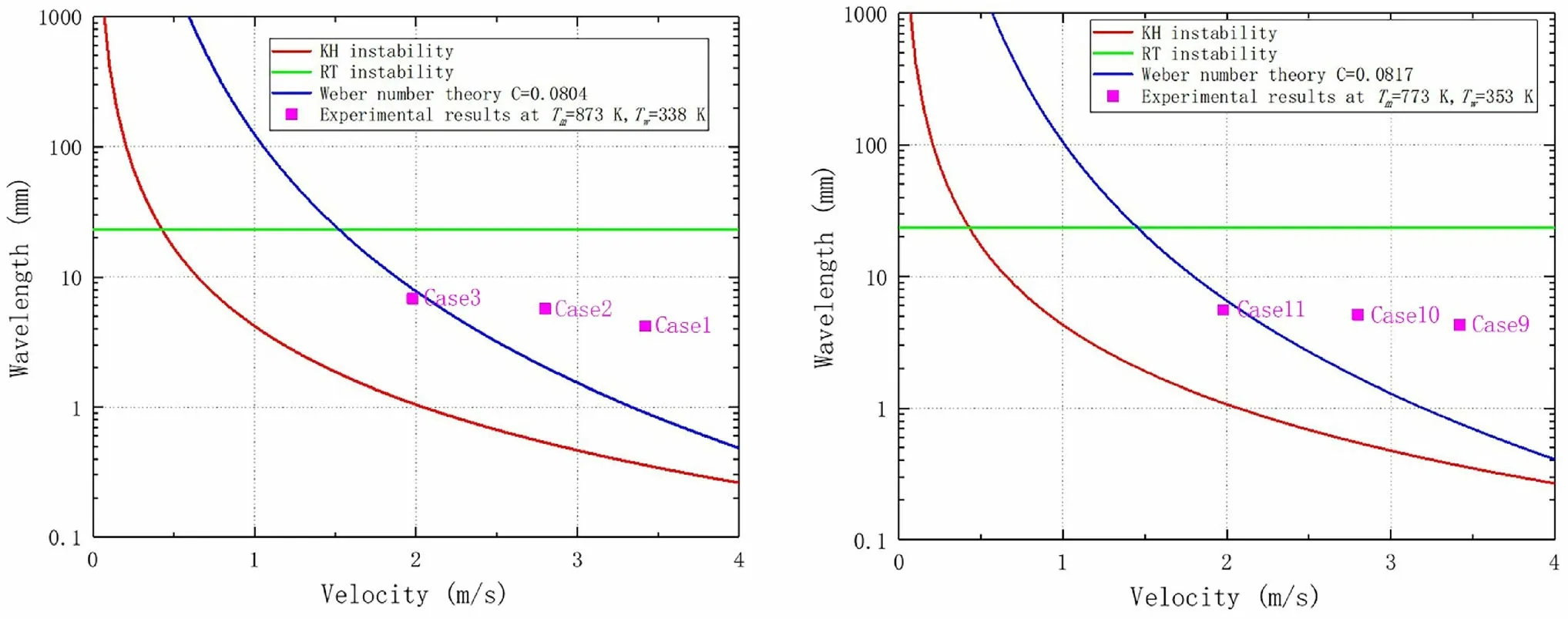

Fragmentation theories, including Kelvin–Helmholtz(KH) instability, Rayleigh–Taylor (RT) instability, and Weber number theory, are all considered in this study.

KH instability refers to instability that occurs inside a continuous fluid with a shear velocity or the interface between two different fluids with a velocity difference. In this unstable phenomenon, the most unstable wavelength for KH instability λmostis calculated as [39]:

where ρwrepresents water density.

RT instability refers to the erosion of fluids of different densities under the action of gravity.The wavelength at the most rapid development speed for the RT instability λ is defined as [44]

Fig. 11 (Color online) Influence of melt penetration velocity on physical properties of debris bed for LBNE(Hw = 60 cm).a Fragment size distribution (Tm = 673 K, Tw = 353 K), b fragment size distribution (Tm = 873 K, Tw = 338 K), c agglomerate mass fraction,d volume mean diameter, e debris bed porosity, and f debris bed sphericity

As the droplet moves through the fluid, its surface tension balances the shear force generated by the relative speed of the fluid [43]. The Weber number We is given by

where dunis the diameter of the unstable droplet. Here, it refers to the fragment volume mean diameter. The subscript un represents unstable.

Based on the fragment volume mean diameter, Saito et al. proposed an empirical formula to express the Weber number, which is given by the correlation [45]where Rew, μw, and C represent the Reynolds number of water at the characteristic length dv, the dynamic viscosity of water,and the undetermined coefficient of the equation,respectively.

Rewis calculated by the following formula:

Based on the KH and RT instabilities, the fragment volume mean diameter is associated with the wavelength,which is regarded as the characteristic length of the molten LBNE fragmentation process.The KH and RT instabilities,and Weber number theory, which is fitted by Eq. (12), are presented in Fig. 14,where the experimental volume mean diameters in this study are also shown.

Figure 14 shows that the experimental volume mean diameters for Tm= 873 K and Tw= 338 K are accepted by Weber number theory with C = 0.0804, and in the case of Tm= 773 K and Tw= 353 K, they agree with C = 0.0817.We also noticed that compared with other fragmentation theories, Weber number theory can better predict the fragment volume mean diameter since Weber number represents the competition effect between the surface tension of the melt and the shear force of the water.

Fig. 12 Visual results of fragmentation process and photograph of debris bed at Hw = 40 cm and 80 cm for LBNE (Tm = 673 K,Tw = 298 K, V = 2.80 m/s).a Hw = 40 cm and b Hw = 80 cm

Fig.13 Effect of water depth on physical properties of debris bed for LBNE (Tw = 298 K). a Fragment size distribution (Tm = 673 K,V = 2.80 m/s), b fragment size distribution (Tm = 773 K,V = 3.43 m/s), c agglomerate mass fraction, d volume mean diameter, e debris bed porosity, and (f) debris bed sphericity

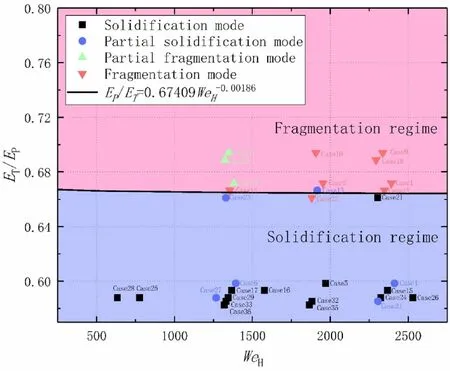

3.6.2 Melt-jet behavior mode

Factors that may affect melt-jet fragmentation behavior include hydrodynamic and thermal factors [15, 39]. The following modified Weber number WeHwas proposed to explain the hydrodynamic interaction behavior [39]:

where Djand Lbrrepresent jet diameter and breakup length of the jet, that is, the length from the water surface to the location where the front edge of the jet completely ruptures. In this study, Dj= 10 mm is used. The following empirical formula was proposed to calculate Lbr[46]:

Regarding thermal factors, the influence of coolant temperature and molten alloy temperature on fragmentation behavior can be explained as the ratio of the complete energy ETcontained in the melt and water to the energy transferred EPduring the phase transition, involving water boiling Lwvand molten alloy solidification Ljf[39]. The total energy in the molten alloy and water ETis calculated as

Fig. 15 (Color online) Illustration of melt-jet behavior mode

This ratio reflects the total ratio of the phase-change energy to the total energy. If the ratio is larger, the jet has higher energy [39]. Hence, when the debris bed is cooled,the process is slower, which results in a lower debris bed porosity and higher debris bed sphericity.

Fig. 14 (Color online) Most unstable wavelength for KH instability, RT instability, and Weber number theory based on dv (Hw = 60 cm)

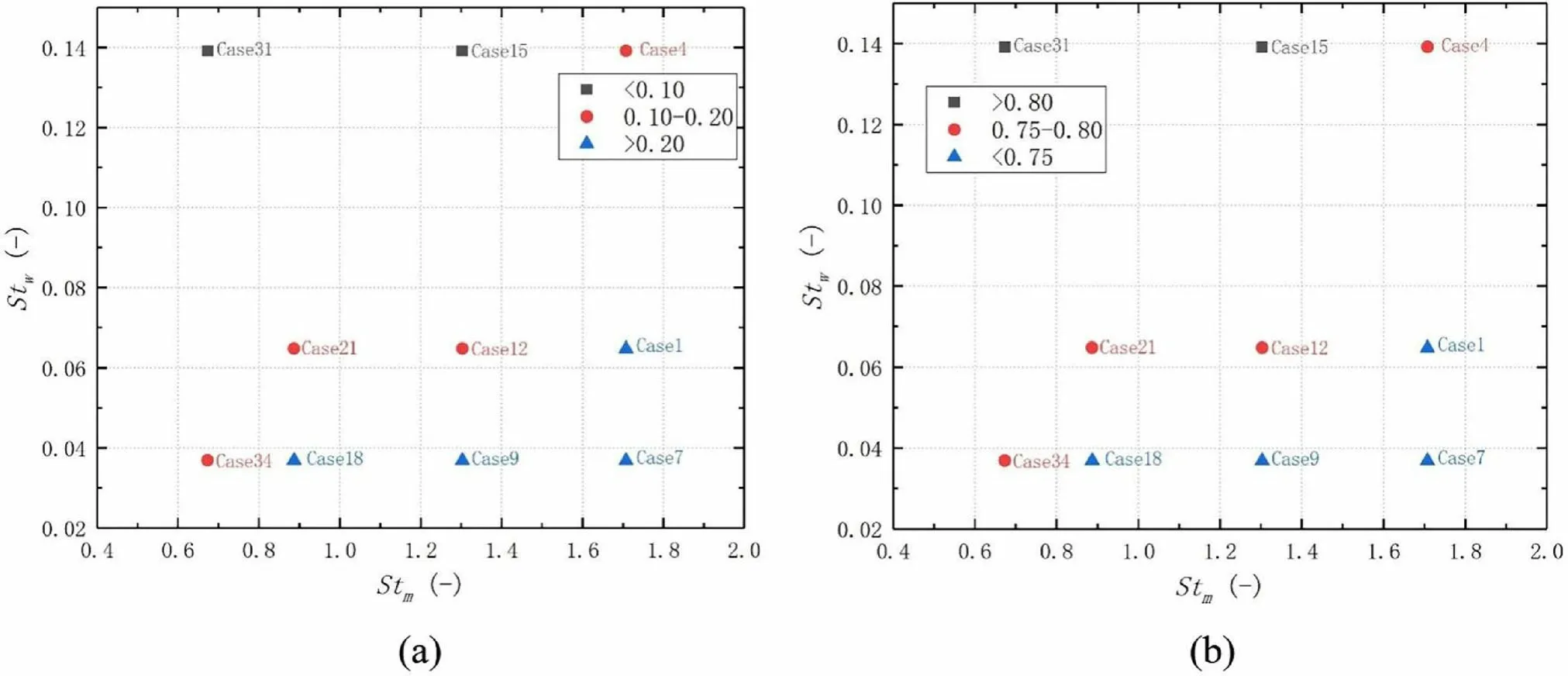

Fig. 16 Diagram of sphericity and porosity based on Stw and Stm. a Diagram of sphericity and b diagram of porosity

According to the melt-jet behavior modes acquired in the current study,the competition results of the thermal and hydrodynamic factors are shown in Fig. 15. This indicates that a higher WeHand higher ET/EPare favorable for the fragmentation mode,whereas a lower WeHis favorable for the solidification mode. This shows that the boundary between the partial solidification and solidification modes was not obvious.Based on the study of Iwasawa et al.[39],with least square fitting, the dividing line of the fragmentation and solidification regimes is tentatively suggested EP/ET= 0.67409WeH-0.00186.

3.6.3 Diagrams of sphericity and porosity

As shown in Sect. 3.1–3.5, the debris bed porosity and sphericity are strongly influenced by the water temperature and molten LBNE temperature.To analyze the influence of thermal factors on the porosity and sphericity of the debris bed, the Stephan number St was proposed as follows[15, 39]:

where L and TPrepresent the latent heat and temperature of the phase transition, respectively. The Stephan number compares the influence of enthalpy and latent heat, and expresses the significance of the phase transition influence.Based on Eq. (18),the Stephan number related to water Stwis calculated as

Based on the experimentally measured sphericity, the debris bed sphericity was segmented into three regions:under 0.10, 0.10–0.20, and above 0.20, as shown in Fig. 16a. We observed that when Stwdecreases or Stmincreases, the debris bed sphericity increases.

Similarly, based on the experimentally measured porosity, the debris bed porosity is divided into three ranges:below 0.75,0.75–0.80,and above 0.80 as presented in Fig. 16b. This shows that a higher Stmand lower Stware favorable for lowering the debris bed porosity.

The above results show that when Stwdecreases or Stmincreases, the melt-jet fragmentation behavior is more complete, with higher debris bed sphericity and smaller debris bed porosity.

4 Conclusion

In the current study, motivated to investigate the interaction between molten non-eutectic alloy and subcooled water during nuclear severe accidents, a series of simulation experiments were carried out by injecting the molten LBNE into the water in a free fall. Based on visual observation and quantitative physical properties of the debris bed, the characteristics of the molten LBNE fragmentation process at different water temperatures, melt temperatures, boiling modes, melt penetration velocities,and water depths were analyzed in detail, and the experimental data were compared with those of LBE. The conclusions are as follows:

1. Compared with the lead–bismuth eutectic (LBE),larger fragments, less spherical fragments, and more porous debris beds are generated for LBNE.

2. Increasing the melt temperature leads to smaller fragment sizes (except that the cake-like debris bed is formed for very high alloy superheat and very low water subcooling).

3. Increasing the melt temperature or water temperature contributed to a higher debris bed sphericity and smaller debris bed porosity.

4. More approximate spherical particles are generated,which contribute to higher debris bed sphericity and smaller debris bed porosity in the film boiling zone than in the thermal interaction zone.

5. Increasing the melt penetration velocity led to smaller fragment sizes, whereas the debris bed porosity and sphericity were similar as the melt penetration velocity increased.

6. The effect of water depth on molten LBNE fragmentation behavior is not obvious (except that a cake-like debris bed is formed for very high alloy superheat and very low water subcooling).

7. Compared with other fragmentation theories, the Weber number theory can better predict the fragment volume mean diameter.In addition,a melt-jet behavior mode diagram that presents the competition between the hydrodynamic and thermal interactions and diagrams of debris bed porosity and sphericity that show the influence of thermal factors were analyzed in the current research.

Author contributionsAll authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Shao-Jie Tan and Yu-Bao Zhong.The first draft of the manuscript was written by Yu-Bao Zhong,Hui Cheng,and Song-Bai Cheng and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

杂志排行

Nuclear Science and Techniques的其它文章

- Hard X-ray focusing resolution and efficiency test with a thickness correction multilayer Laue lens

- Monte Carlo study of the neutron ambient dose equivalent at the heavy ion medical machine in Wuwei

- Configurational information entropy analysis of fragment mass cross distributions to determine the neutron skin thickness of projectile nuclei

- Differences in MBUs induced by high-energy and medium-energy heavy ions in 28 nm FPGAs

- Thin-film approximate point scattered function and its application to neutron radiography

- Mechanical properties and surface characteristics of SiC fibers irradiated by swift heavy ions