Technical Evaluation of Hybrid Clones of Corymbia spp.to Produce Market Pulp

2022-07-21MarceloMoreiradaCostaRicardodeCarvalhoBittencourtThalesAugustoPintoCoelhoNogueiraLarissaSoaresSilvaWeslleyHenriqueMartinsdaSilvaSebastiRenatoValverdeGleisonAugustoDosSantosDanielAlexanderFernandesCoelhoClaudileneAparecida

Marcelo Moreira da Costa,Ricardo de Carvalho Bittencourt,Thales Augusto Pinto Coelho Nogueira,Larissa Soares Silva,Weslley Henrique Martins da Silva,Sebastião Renato Valverde,Gleison Augusto Dos Santos,Daniel Alexander Fernandes Coelho,Claudilene Aparecida Alves Pena

1.Department of Forest Sciences,Federal University of Vicosa,Vicosa,Minas Gerais,36570900,Brazil

2.Aperam BioEnergia Co.,Capelinha,Minas Gerais,39680000,Brazil

Abstract: This study presents hybrid clones of Corymbia spp.developed by Aperam BioEnergia as potential substitutes for Eucalyptus wood in the pulp industry.The biomass of Eucalyptus spp.was compared with that of Corymbia spp.by performing modified kraft pulping and basic density analyses.Comparisons were made by analyzing their respective mean annual increments of cellulose (MAIcel) and specific wood consumption (SWC),estimated using a kappa number of (19 ± 1).The results showed that one of the hybrid clones (Corymbia citriodora × Corymbia torelliana, ID 4) had higher basic wood density, higher screened yield, better MAIcel#k19, and lower SWC than the other samples,reaching values of 0.608 t/m3,54.1%,24.6 ADt/ha/year (i.e., air dry ton/hectare/year), and 2.74 m3/ADt, respectively.Consequently, clone ID 4 had the highest MAIcel/SWC ratio score (8.98).Given its high forest productivity and low industrial cost compared with other samples, as well as its advantages over Eucalyptus spp.wood, we concluded that clone ID 4 has great potential as an alternative biomass for pulp production.

Keywords: Corymbia hybrids; modified kraft pulping; mean annual increments of cellulose(MAIcel); specific wood consumption(SWC)

1 lntroduction

The Brazilian pulp sector has aimed to significantly increase its production scale.In recent years,Brazil has regularly ranked as the largest exporter of bleached kraft pulp in the world,mainly produced fromEucalyptusspp.[1].In Brazil, short-fiber pulp is used to produce different types of paper (printing and writing, tissue,and packaging), with an annual export volume of 15 million air dry tons (ADt).The trade balance of the planted forest sector is equivalent to US$12.5 million/year, 75.2% of which stems from the pulp and paper industry[2].Therefore, there is considerable demand for wood with operating costs equal to or lower than those of theEucalyptusspp., especially of equal or superior quality,to be used as a fibrous source in Brazil.

Wood fromCorymbiaspp.hybrid clones has rarely been explored in the pulp and paper industry.InterspecificCorymbiahybrids tend to have high biomass production,high density,and rapid growth[3].Furthermore,they are tolerant to biotic and abiotic stresses such as wind, water deficit, frost, and most pests and diseases that cause economic damage to planted forests[4].Such superiority is believed to be due to heterosis (hybrid vigor), an important phenomenon for improving forest productivity that allows alleles of interest from different species to be combined[5].

Despite the high performance ofCorymbiaclones,the forest sector still has strong restrictions and concerns regarding the use ofCorymbiawood[6].Therefore, it is necessary to develop new technologies and processes to utilizeCorymbiawood.Parameters, such as the mean annual increment of cellulose (MAIcel, ADt/ha/year),which relates to forest productivity[7-8], and specific wood consumption (SWC, m3/ADt), which contributes to predicting operating costs[9], are important for material assessment.Such data will facilitate the ranking of commercial clones based on their pulp production capacity per unit of planted area throughout the planting period.

In recent decades, environmental pressure and the need to increase pulp delignification to improve efficiency and quality has stimulated the development of new pulping technologies, including modified cooking methods[10].Modified kraft pulping can produce pulp fromCorymbiaspp.and increase the selectivity of pulping processes for high-density wood.This method provides adequate woodchip impregnation by dividing the alkali charge and preventing carbohydrate degradation[11].Modified kraft pulping involves hemicellulose dissolution, terminal depolymerization reactions, and alkaline hydrolysis of glycosidic bonds, increasing yield and leading to a loss of viscosity[12].

Therefore, this study aimed to develop technological alternatives for mitigating the major bottlenecks associated with the use ofCorymbiaspp.hybrid clones with a high basic wood density.We also aimed to rank commercial clones ofEucalyptusspp.and hybrids ofCorymbiaspp.based on indicative parameters for forest yield (MAIceland SWC) using an industrial modified kraft pulping protocol.

2 Experimental

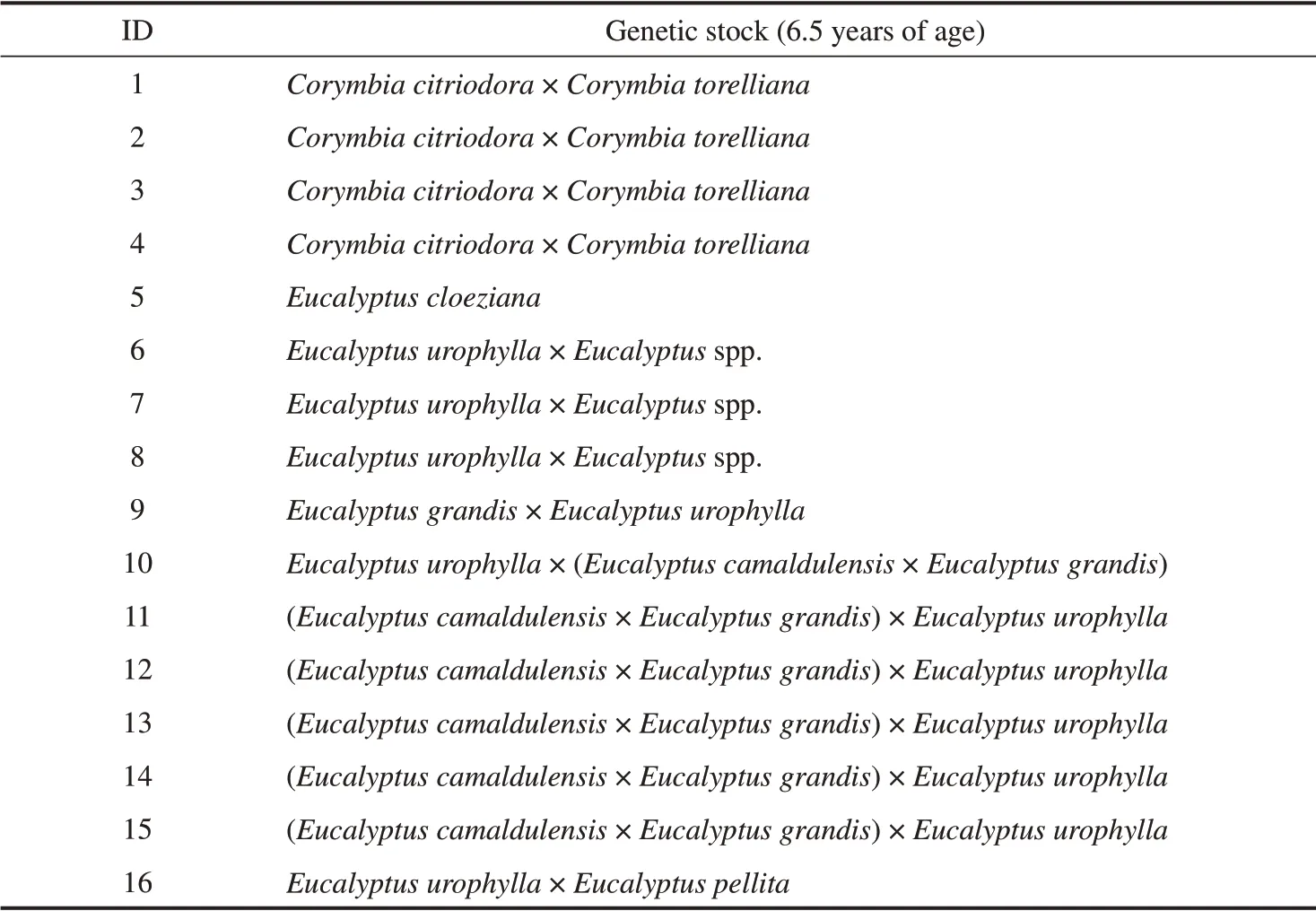

We analyzed 16 woodchip samples from trees aged 6.5 years, obtained from the industrial unit of Aperam BioEnergia,Vale do Jequitinhonha,Minas Gerais State,Brazil.The samples were identified according to their genetic stocks(Table 1).

Table 1 Genetic stocks used for lab-scale evaluation of wood and pulp properties

2.1 Modified kraft pulping

After exploratory tests, we selected a target kappa number of (19 ± 1) for effective alkali charge (EA, %),determined as NaOH consumption on a dry wood basis.Modified kraft pulping was performed according to the following steps:

(1) The woodchips were pre-vaporized under lowpressure steam (0.35 MPa) for 15 min, and the woodchip surface temperature was increased to approximately 105℃.

(2) Woodchips were impregnated by adding 55% of the total EA, followed by increasing the temperature from 105℃ to 135℃(15 min ramp) and maintaining it at 135℃ for 90 min.

(3) Woodchips were cooked by draining the impregnation liquor followed by injection of the white liquor,reaching 45% of the total EA.The temperature wasincreased from 135℃ to 165℃ over 10 min and maintained at 165℃ for 90 min with a liquor/wood ratio of 4∶1.

(4) Washing occurred at the end of the process and the black liquor was extracted by displacement.The washing process was performed in two phases.The first consisted of an alkaline wash with 3% EA, followed by extraction.During this phase,the temperature was reduced to 90℃ and maintained for 60 min.In the second phase, hot water (90℃, 9 m3/ADt) was applied for 15 min and the temperature was reduced to 40℃.

2.2 Analytical procedures

For woodchip characterization, the resulting brown pulp was analyzed using the following parameters:basic wood density[13], lignin S/G ratio[13], effective alkali[14],kappa number,and screened yield by gravimetry.

The EA consumption (EA#k19) and screened yield(SY#k19)for kappa number(19±1)were estimated from three modified kraft pulping tests, in which the applied EA charge was varied and the other conditions kept constant.MAIcelwas calculated as the product of the mean annual increment, screened yield of pulp, and basic density (BD) of the woodchip samples.The samples were ranked according to their MAIcel/SWC ratio.

Morphological analyses of the brown pulp fibers resulting from kraft pulping were performed using the Valmet FS5 Fiber Image Analyzer, which uses ultrahigh definition(HD)technology and artificial intelligence for fiber analysis.Dry pulp (10 mg) from the samples was weighed and suspended in demineralized water for a total volume of 500 mL according to the conditions required by the equipment for short fiber analysis.For each sample, two replicates were performed, and the average was taken.

3 Results and discussion

3.1 Results

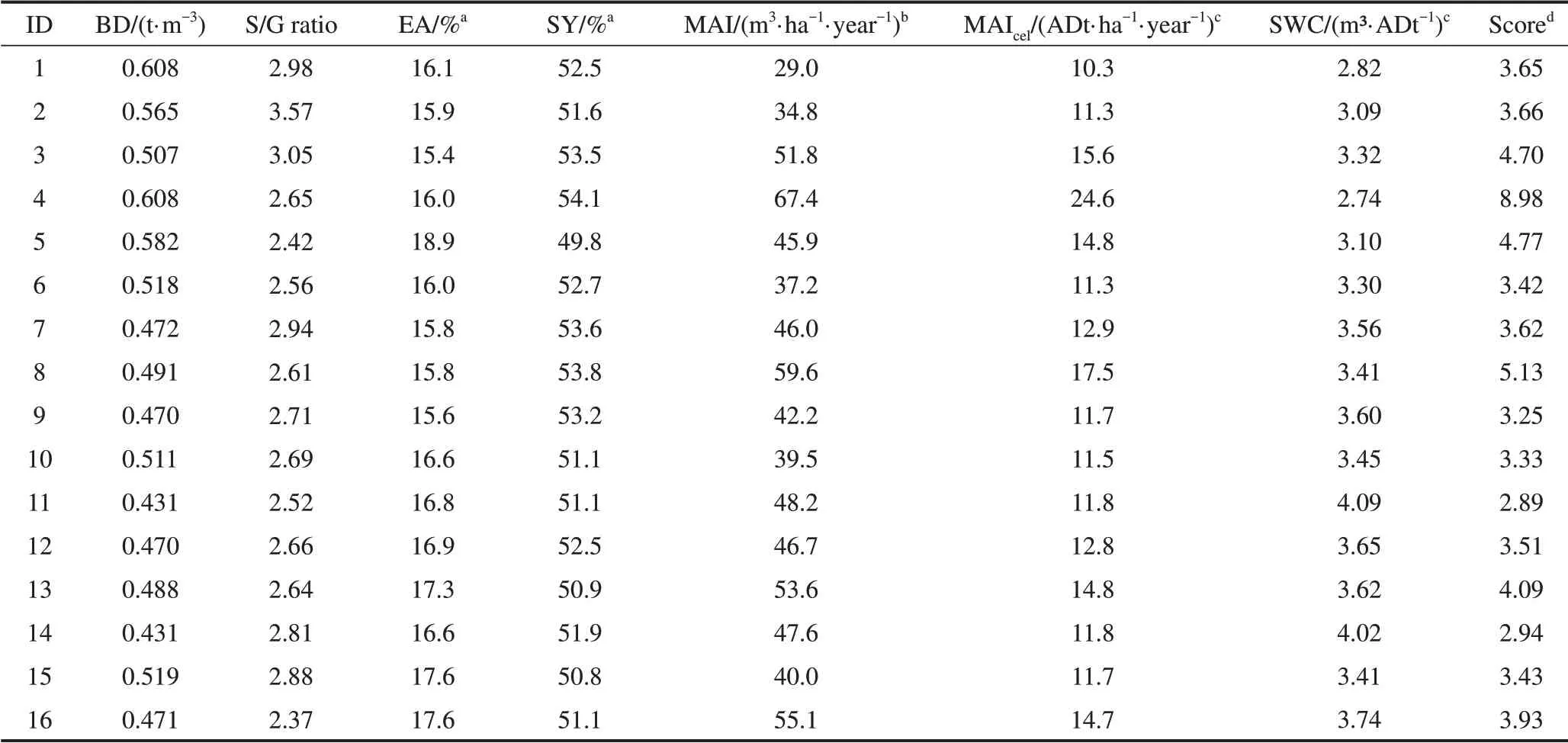

Corymbia citriodora×Corymbia torellianawoodchips(IDs 1 and 4)had the highest basic density(0.608 t/m3)(Table 2).The second-highest basic density (0.582 t/m3)was that ofEucalyptus cloeziana(ID 5).The lowest basic density was clone ID 14(Eucalyptus camaldulensis×Eucalyptus grandis)×Eucalyptus urophylla.

Corymbia citriodora×Corymbia torelliana(ID 3)had the lowest EA#k19consumption(15.4%)(Table 2),whereas ID 4 had the highest SY#k19(54.1%).Eucalyptus cloeziana(ID 5) had the lowest performance as it required the highest EA charge, resulting in the lowest yield(49.8%).

Table 2 Results for BD, lignin S/G ratio, EA, SY, mean annual increment (MAI), MAIcel, and SWC of genetic stocks, as estimated using a kappa number of(19±1)

The highest MAIcelvalues were forCorymbia citriodora×Corymbia torelliana(ID 4) andEucalyptus urophylla×Eucalyptusspp.(ID 8),at 24.6 and 17.5 ADt/ha/year, respectively.The lowest MAIcelvalue was for a clone ofCorymbia citriodora×Corymbia torelliana(ID 1), with 10.3 ADt/ha/year.Furthermore, ID 4 exhibited the lowest SWC value (2.74 m3/ADt).Thus, ID 4 was ranked first as it obtained the highest MAIceland lowest SWC values.

Knowing the morphological characteristics of the fibers is extremely important to establish the most suitable purpose for them.The means of the main characteristics of the brown pulp fibers from the kraft pulping are shown in Table 3.The highly ranked clone ID 4 had the second-longest fiber length, shorter than only ID 1 (also aCorymbiaspp.hybrid).Despite the lower fiber lengths reported, the analyzed values of the otherCorymbiaspp.samples are in accordance with the described values of 0.943-1.140 mm for juvenile wood ofCorymbiaspp.[15-16].

Table 3 Main characteristics of the brown pulp fibers resulting from the kraft pulping for a kappa number of (19±1)

Other characteristics such as width, cell wall thickness (CWT), coarseness, fibrous population fibers, and fines have a significant influence on the physical and mechanical properties of the pulp[17].The fines content favors the bonds between fibers[18]and it is possible to infer the presence of a more consolidated wall for the hybrids ofCorymbiaspp.in relation toEucalyptusspp.from the analysis of Fines B.Furthermore, because high coarseness can lead to papers with low cohesion[19],consolidation, and poor bonding between fibers, ID 4 stands out again among the hybrids ofCorymbiaspp.

3.2 Discussion

The results of this study revealed the potential ofCorymbiaspp.wood for commercial pulp production and analyzed the relationship between basic wood density, EA consumption, and screened yield.Through the modified kraft pulping protocol, we were able to combine optimal temperature and time conditions to obtain the best yields without requiring a high alkali charge for the sample with the highest basic density(ID 4).

Modified kraft pulping allows for better distribution of the alkali charge, thereby avoiding intense chemical activity at the beginning and end of the procedure[20].Thus,some of the advantages of the method include good impregnation of woodchips before delignification,uniformity, reduced cooking temperatures in the digester,reduced active alkali consumption, increased screened yield, low reject generation, and enhanced pulp quality and bleaching[21-23].

A higher basic wood density had a significant positive impact on MAIceland SWC inCorymbiaspp.In particular, the hybridCorymbia citriodora×Corymbia torelliana(ID 4) showed excellent forest productivity and kraft pulping performance, reporting good EA#k19and SY#k19values.Basic density is used to select genetic stocks according to the intended purpose,and is a relevant parameter for the standardization of raw materials received by the industry[24].High basic wood density is generally associated with increased yield,reduced logistics costs,low SWC,and low EA[25].

SWC during production is also important, as it is directly related to density and yield and associated with several wood quality parameters[9].Corymbiahybrids exhibited the lowest SWC values.This can be explained by the high basic density of these samples,as denser wood has more cellulose, favoring a higher yield.In other words, smaller volumes of wood are required to produce a unit weight of cellulose[26].

The particularity of each species and clone was analyzed by considering the MAIcelvalues.MAIcelconsiders the wood volume, basic density, and yield,which reflects the amount of pulp that can be produced.Leading companies in the pulp and paper industry in Brazil report average MAIcelvalues of 10-12 ADt of bleached pulp per hectare per year[7].Here, ID 4 achieved a MAIcelof 24.6 ADt/ha/year, indicating that this clone may be a good choice for commercial applications aimed at achieving high performance in the forest and pulp industries.

4 Conclusions

The ranking of commercial clones can be applied to distinguish woods with different behaviors in industrial manufacturing processes.Ideally, ranking should be done following industrial kraft pulping protocols to minimize differences between laboratory and industrial conditions.Corymbia citriodora×Corymbia torellianahybrids, specifically ID 4, ranked the highest, proving to be excellent high-performance alternatives toEucalyptusspp.in the forest and pulp industries.

Because of their higher basic wood density,Corymbiaspp.hybrids have clear advantages in terms of logistics costs and specific wood consumption.In addition to providing numerous benefits to forested areas, thesegenetic stocks have lower wood production costs per volume(US$/m3)and lower production costs per ton of pulp(US$/ADt).

杂志排行

Paper and Biomaterials的其它文章

- Nanocomposite Hydrogel Materials for Defective Cartilage Repair and Its Mechanical Tribological Behavior—A Review

- Review of Carbon Dots from Lignin:Preparing,Tuning,and Applying

- Octadecylamine Graft-modified Cellulose Nanofiber and Its Reinforcement to Poly(butylene adipate-co-terephthalate)Composites

- NIR-responsive Collagen-based Sponge Coated with Polydimethylsiloxane/Candle Soot for Oil-Water Separation

- Formation and Collapse of Cellulose Nanocrystals and Hydrophobic Association-induced Dual Cross-linked Nanocomposite Hydrogels:A Rheological Study

- Stabilizing Pickering Emulsions Using Octenyl Succinic Anhydride Modified with Cellulose Nanofibrils