纬编导电织物多重性能及其制备的研究进展

2022-06-22王盼王朝晖

王盼 王朝晖

摘要:为促进智能针织产品的设计与研发,文章系统归纳了纬编导电织物及其类别,综述了3种不同性能导电织物作用机理及应用进展,并对其制备要点进行探讨。电-力学性能织物对线圈结构依赖性极强,因其影响因素过多,无法形成统一的性能评判标准;湿度传感织物利用织物自身、湿敏材料或导电材料亲水性来实现电阻变化,因外力拉伸与湿度变化均能影响织物电阻,故制备时可增加复合层以防两者产生耦合效应;电热性能织物受导电材料、制备工艺及加载电压影响,可采用镀银纱线或聚吡咯进行制备且前者性能优于后者。进一步指出,加强高性能纤维材料研发、改善制备工艺、加快自供电技术应用,以及建立完善的安全测试标准是智能针织产品未来的发展方向。

关键词:纬编;导电织物;电-力学性能;湿度传感;电热性能;智能可穿戴;自供电技术

中图分类号:TS186.2文献标志码:A文章编号: 10017003(2022)06005008

引用页码: 061107

DOI: 10.3969/j.issn.1001-7003.2022.06.007(篇序)

基金項目: 中央高校基本科研业务费专项资金资助项目(2232020G-08);上海市科学技术委员会国际合作项目(21130750100)

作者简介:王盼(1991),女,博士研究生,研究方向为服装先进制造。通信作者:王朝晖,教授,wzh_sh2007@dhu.edu.cn。

近年来,随着科技的进步与经济的发展,人们对现代纺织品的需求不再局限于防寒保暖,智能化设计已成为消费者的新需求[1-2]。智能纺织品正受到各界人士的广泛关注,其应用领域也逐渐涉及到人们日常生活的各个方面。纬编导电织物因其独特的组织结构与服用性能[3],成为智能纺织领域的研究重点之一。针织线圈结构不仅为导电织物提供了极好的全向拉伸性能[4],还使其具备了梭织、刺绣、无纺等其他织物无法比拟的弹性及柔软贴体性[4]。目前研究的纬编导电织物主要利用外界刺激引起的电阻变化来实现智能化与功能化,具有结构简单、易成形、质地轻巧、柔韧性好且可设计性强等特点[5]。其中,电-力学性能导电针织物可通过监测织物总电阻变化规律来了解织物外界受力情况,湿度传感性能导电针织物可采用电阻率改变来表征环境湿度变化,电热性能导电针织物可利用织物内部电阻网络将外部电源提供的电能直接转化为热能。各类纬编导电织物在医疗保健、汗液监测及智能调温等领域均具有广泛的应用前景。

鉴于纬编导电织物具有诸多优点且应用广泛,本文归纳了纬编导电织物的定义及其分类,综述了纬编导电织物的电-力学性能、湿度传感性能与电热性能的作用机理及应用进展,探讨了不同性能导电织物的制备原则与要点,并对智能针织产品未来的发展方向进行了展望。

1 纬编导电织物及其分类

1.1 纬编导电织物

纬编导电织物是指具有一定导电性能的纬编针织物,其主要通过两种方式进行制备:一种是利用导电纱线在纬编针织机上直接编织而成[6],另一种则是在普通纬编针织物表面进行特殊处理(涂覆、印刷、浸渍等),赋予其导电性,通常以前者为主。前者多采用针织圆纬机、电脑横机等设备进行制备,但要实现导电区域的局部定位编织时,编织设备必须具备提花与剪线功能,因无缝圆纬机可实现多处局部定位编织,可作为首选设备;电脑横机利用其纱嘴配置及嵌花功能可实现局部区域的精确定位编织,但因其织针偏粗,在编织轻薄贴体针织物时不如圆纬机应用广泛。后者是先将某些导电物质与分散剂、还原剂及黏合剂等按照一定比例进行混合[7],再采用涂层、浸渍等方法,将其均匀附着于针织物表面,形成连续稳定的导电层。该制备方式生产的导电针织物较前者而言缺乏整体稳定性,难以确保其附着导电物质的均匀度及耐久性。

1.2 按照导电成分进行分类

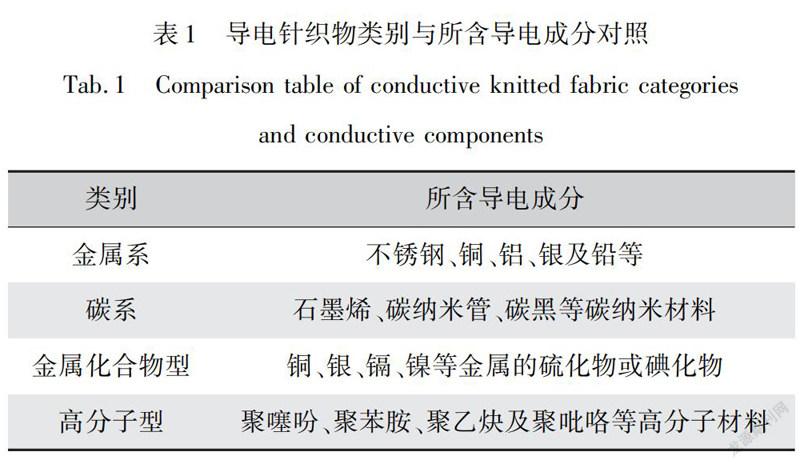

纬编导电织物根据所含导电成分不同,主要分为金属系导电针织物、碳系导电针织物、金属化合物型导电针织物及高分子型导电针织物四大类,如表1所示。

金属系导电针织物具有良好的导热性和导电性,其多采用金属混纺纱线或外镀金属纱线直接编织而成,其中不锈钢混纺与镀银导电针织物在纺织领域应用最为广泛;碳系导电针织物主要利用涂层法、掺杂法或碳化处理等获得导电性,颜色通常为黑色,导电物质容易脱落且手感较差;金属化合物系导电针织物多采用吸附法、混合纺丝法或化学反应法制备,其导电性不如碳黑系但牢度较好;高分子型导电针织物是利用导电高分子材料实现导电行为,由于高分子型导电纤维刚度过大、难溶、难熔且成型困难[8],故该类织物主要通过涂层法制备。

2 纬编导电织物多重性能及作用机理

随着纺织品不断地向智能化、功能化发展,导电针织物也逐渐被赋予多重性能,目前主要包括电-力学性能、湿度传感性能及电热性能,这三个性能均需设计外加电路才可实现。

2.1 电-力学性能及作用机理

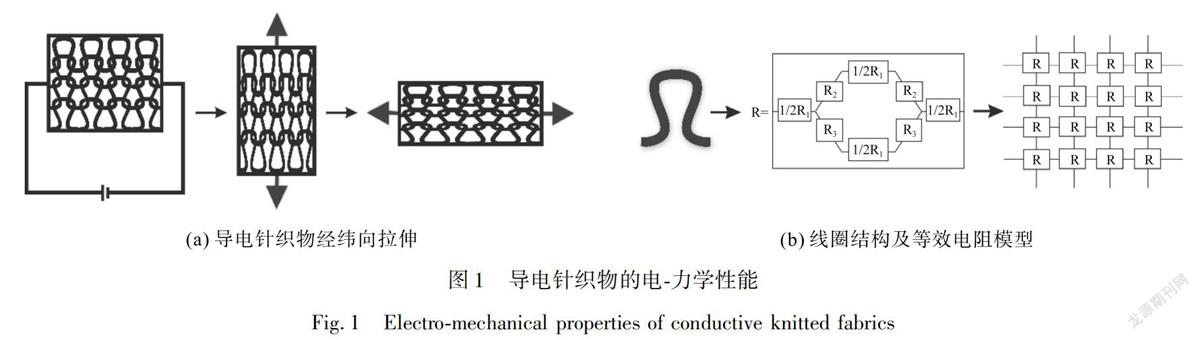

导电针织物的电-力学性能是指具有大应变和高弹回复性的导电针织物在承受各种外力作用时,因发生形变而呈现

出相应的电学特征。该类织物对针织线圈结构的依赖性极强,如图1(a)所示,导电针织物在外力作用下线圈结构发生形变导致电阻变化[9]。在整个受力过程中,线圈间接触电阻与长度电阻变化导致织物电信号发生改变,通过监测织物总电阻变化规律即可了解织物外界受力情况。该性能可实现人体生理数据(运动、呼吸、心跳等)的实时、无感采集[10],多应用于医疗保健及运动健身领域。B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

因导电针织物经纬向组织结构不同[11],其不同拉伸方向和横纵尺寸所造成的电阻变化也存在一定差异。通常,同一导电针织物经向拉伸电阻变化范围大于纬向[12];导电针织物的横列数与纵行数之比越大,其灵敏度越高、性能越好;当横纵列数相同时,纬平针组织的灵敏度最佳,1×1罗纹组织次之,2×1罗纹组织最差;纬编导电织物在经向拉伸时,其电阻先随织物伸长呈线性上升,随后呈缓慢上升至电阻值稳定,再呈线性下降直至趋于稳定。如图1(b)所示,为了简化导电针织物的线圈电路分布[13],先将线圈单元简化为电阻六角模型(R1和R2为线圈自身长度电阻,R3为线圈间接触电阻),再将其看做一个电阻结构单元并按照导电针织物组织结构进行横、纵向排布,最终形成一个复杂的串并联电路网。利用基尔霍夫电流定律(KCL)和电压定律(KVL)对该非线性电路进行分析求解,可得到固定橫纵列数导电针织物的等效电阻。

虽然纬编导电织物电-力学性能的相关研究很多,但因其受影响因素太多(纱线种类、织物密度、组织结构、横纵尺寸及编织工艺等),且其中任一因素发生改变均会影响现有电阻网络模型,使得此性能织物灵敏度、线性度及应变范围等相关性能参数难以形成统一的评判标准,因此,该类智能针织产品尚未实现大规模推广。

2.2 湿度传感性能及作用机理

导电针织物的湿度传感性能是指具有一定吸水性的导电针织物在周围湿度发生变化时,其电阻也会产生相应改变。该性能对针织结构不具依赖性,主要依靠织物自身、湿敏材料或导电材料的亲水性来实现湿度传感。该类织物主要通过电阻率改变来表征环境湿度变化[14-15],可用于监测尿失禁、伤口愈合、出汗量或服装微气候等方面。

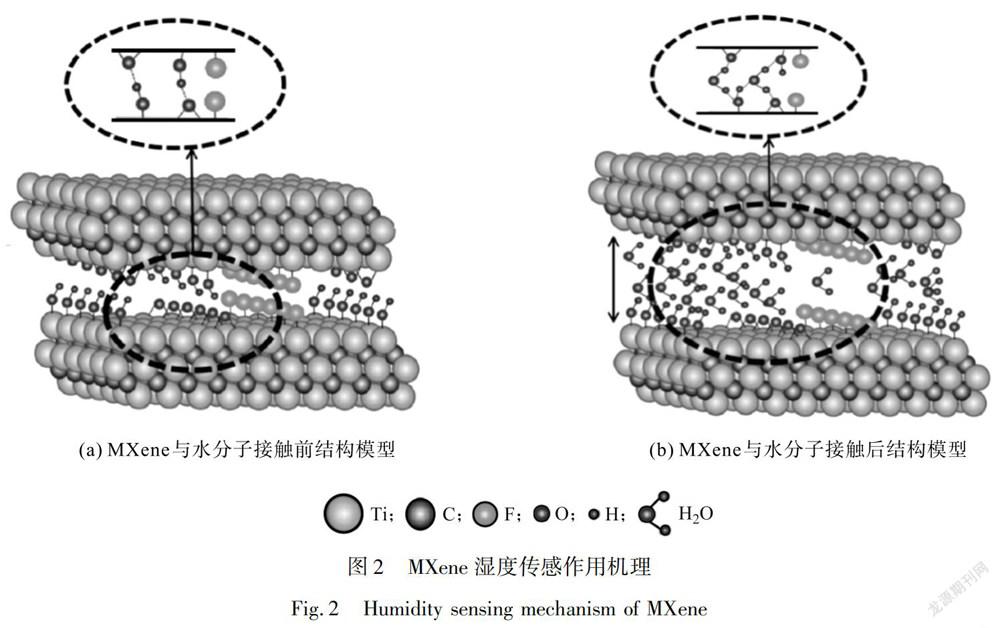

导电针织物所含导电成分不同,其作用机理亦不相同。针对大多数导电针织物而言,通常湿度越大,导电性能越好,其电阻越小,但存在少数导电针织物随湿度增加,导电性能变差,其电阻愈来愈大。例如,用碳纳米管(SWCNT)与聚乙烯醇(PVA)长丝制备的导电针织物,SWCNT具有极好导电性,而PVA长丝不导电但容易吸水膨胀[16],两者结合后,可利用PVA在潮湿环境下发生溶胀来增加碳纳米管间隙,从而使织物电阻增大。另外,经新型二维类石墨烯结构MXene处理制备的导电针织物同样可利用MXene的导电性和亲水性来实现湿度传感[17],其作用机理如图2所示。MXene未接触水分子时,其上下层结构间距由—OH之间的键能决定;当MXene与水接触后,水分子进入其结构层中间,与MXene的含氧官能团形成新的—OH,使得MXene结构层间的距离增加,且周围环境湿度越大,其距离越大,从而导致含MXene导电针织物电阻增大。在潮湿条件下,导电针织物的经向和纬向表现出不同的电学行为,鉴于其纬向灵敏度和线性度更佳,故多采用导电针织物的纬向来监测电阻变化[18]。

目前纬编导电织物湿度传感性能的研究相对较少,仍处于起步阶段。因针织结构的柔软贴体性,未来可考虑将其集成于服装上或者利用针织全成形技术实现一体成形,以代替传统测试方法,实现皮肤表面湿度与出汗量的实时测量。另外,若能在该性能织物表面增加一层离子选择性薄膜或生物分子酶膜,甚至可以实现汗液成分的检测。

2.3 电热性能及作用机理

导电针织物的电热性能是指导电针织物在外加电路作用下,由于电阻存在而产生通电发热现象。该性能是利用织物内部电阻网络将外部电源提供的电能直接转化为热能[19],其多应用于极地防寒服、智能家居及体育防护等领域。

若将导电针织物视作纯电阻电路,由焦耳定律(式(1))可知,电流通过织物产生的热量与电流的平方、织物电阻均成正比,这说明可通过改变电流或织物电阻来控制织物的产热量,电流大小依靠外接电源控制,织物电阻由导电材料和制备工艺共同决定。以镀银纱线导电针织物为例,可采用镀银纱线与非导电纱线横列间隔编织方式[20],来增加织物内部电阻,其织物结构及等效电阻如图3所示。由热传递相关理论(式(2))可知[21],电加热导电针织物可达到的平衡温度与其表面积、电阻成反比,而与加载电压成正比,这表明可通过适当增大加载电压、减小织物电阻及表面积的方式,提高导电针织物的平衡温度。另外,导电针织物电热性能还与其最大负载电流、热稳定性、电热温升及发热均匀性等指标相关。最大负载电流是导电针织物允许通过的最大电流[22],该值越大则织物能达到平衡温度越高;热稳定性可通过导电针织物达到平衡温度时电阻变化率进行表征(式(3)),可反映织物电阻受温度影响程度,该值越小代表织物热稳定性越好;电热温升是导电针织物平衡温度与环境温度的差值[23],用于反映导电针织物的调温幅度大小;发热均匀性是衡量导电针织物电热性能的重要指标,可通过观测导电针织物表面温度分布情况进行评价。

Q=I2Rt (1)

式中:Q为热量;I为电流;R为导电针织物电阻;t为通电时间。

T=PhS+Ta=U2hSR+Ta(2)

式中:T为平衡温度;P为消耗功率;S为导电针织物表面积;U为加载电压;h为对流传感系数;Ta为环境温度。B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

φ/%=ΔRR0×100 (3)

式中:φ为电阻变化率;ΔR为电阻变化量;R0为导电针织物的初始电阻。

目前纬编电加热针织物的研究较多且一些较为成熟的电加热针织产品已经投入市场,但现有产品仍存在一些不足之处。比如,电加热针织产品的温控系统不够智能化,产品多采用分档手动调温模式,无法根据温度变化自动调节加热量;电加热针织产品主要使用充电宝进行能源供应,存在便携性差、工作时间较短等问题。因此,未来电加热针织产品可在全自动温控系统设计和无线电能传输方面进行研究,以提升产品性能和用户体验。

3 纬编导电织物的制备要点

纬编导电织物性能不同,其制备工艺、原则及侧重点各不相同,要根据实际应用需求,进行合理设计,以生产出性能优良的纬编导电针织产品。

3.1 电-力学性能导电针织物的制备要点

纱线原料选择、组织结构设计、编织工艺及电压加载方式均对导电针织物的电-力学性能具有重要影响,故其制备原则主要围绕以下几点展开。

1) 在纱线原料选择方面,因该性能导电针织物需要具备优良的导电性、弹性及高度回复性[24-25],故在实际生产中,通常采用镀银导电纱线或不锈钢混纺导电纱线加入氨纶弹性纱、涤纶纱等普通纱线共同执行编织,不但能增加导电织物的保形性,还能改善其电-力学性能。

2) 在织物组织结构设计方面,由于当前现有的电力学模型较为单一[26-27],故导电针织物的组织结构设计不宜过于复杂,一般采用常见的基本组织,如纬平针组织、罗纹组织及正反针组织等。

3) 在编织工艺选择上,主要采用提花添纱和嵌花添纱两种工艺,采用工艺不同,电压加载方式亦不相同,如图4所示。因采用嵌花添纱工艺编织的导电针织物,背面不存在浮线[28],故提高了导电针织物的灵敏度、稳定性与美观性。

3.2 湿度传感导电针织物的制备要点

与电-力性能导电针织物相比,湿度传感导电针织物除了要具备良好的导电性外,还要具备一定吸水性、耐腐蚀性及尺寸稳定性,在其制备过程中需注意以下几点。

1) 为避免导电针织物因长期处于潮湿环境下生锈或被氧化导致灵敏度降低[29],要选择化学性能稳定的原料进行制备。

2) 为提高导电针织物的吸水性,要对导电针织物进行亲水处理,但在选择亲水助剂时要保证其不会与导电物质产生化学反应,还要具备良好的耐久性。

3) 由于外力拉伸变形与湿度变化均能影响导电针织物电阻变化规律,故在进行织物结构设计时,可在导电针织物背面增加复合层,以限制织物横纵向拉伸变形,防止两者产生耦合效应。

当利用金属导电纱线制备湿度传感织物时,可选用不锈钢涤纶混纺纱线以质地紧密厚实的组织结构(罗纹组织、毛圈组织等)进行制备,织片下机后将其浸入温度为25 ℃、质量分数为20%的聚酯聚醚型亲水整理剂溶液中进行亲水处理[18],隨后在160 ℃的高温下进行干燥处理,最后可获得具有良好吸水性与导电性的湿度传感针织物;当采用MXene制备湿度传感织物时,先将针织物样片置于蒸馏水中用超声波清洗半小时进行除杂处理[30],然后将织物放入65 ℃的烘箱中烘干,随后将其放入质量浓度为5 mg/mL的MXene溶液中,待织物表面完全被MXene颗粒包覆[31],颜色变为黑色,将其捞出并置于65 ℃烘箱中再次烘干,取出即可得到基于MXene的湿度传感针织物。

3.3 电热性能导电针织物的制备要点

导电针织物发热效果主要受导电材料、制备工艺及加载电压影响。在导电材料选择上,多采用镀银纱线或聚吡咯来进行制备,两种导电加热织物对比如表2所示。聚吡咯涂层加热织物在制备难易、热稳定性方面较优,但在耐水洗性、服用性能及平衡温度方面较差,故两者综合比较,镀银纱线制备的电加热织物具有更大优势。

采用镀银纱线与涤纶纱线制备导电发热织物时,织物发热均匀度跟镀银纱线与涤纶纱线横列间隔排布方式相关[32],两横列间隔越小,发热均匀性越好,但间隔过小会降低织物整体电阻,使其发热效率降低,经研究发现两者横列比为1︰2时发热均匀性最佳。在组织结构设计时,多采用纬平针组织、罗纹或双罗纹组织,较少使用提花组织、衬纬组织,因衬纬组织将导电纱线作为纬纱直接衬入[33],其发热效率较低,可根据实际需要,确定具体组织结构类型。在进行加载电压设计时,主要考虑两点:一是要注意不能超过导电纱线的最大负载电流[34];二是要找到最佳电压加载位置,因电压加载位置不同,会影响织物平衡温度与升温速率,所以要经过多次尝试来确定最佳电压加载位置。

利用液相原位聚合法进行聚吡咯涂层织物制备时[35],其基本制备步骤如下:先将针织物样片(纯棉或黏胶纤维织物)进行除杂晾晒,再将其置于一定摩尔浓度的吡咯单体溶液中进行预湿,半小时后加入适量FeCl3·6H2O溶液,使溶液中FeCl3与吡咯单体摩尔质量比为1︰2并不断搅拌,等充分反应后,将样布取出放入2%乙醇溶液中进行洗涤,最后将样布捞出控干[36]。在整个制备过程中,聚吡咯涂层织物电阻随吡咯单体溶液摩尔浓度增大而减小;随反应时间的增加先减小后增大;随反应温度升高而增大,但反应温度过高会阻碍聚合反应的进行。实践证明,当采用0.4 mol/L的吡咯溶液、反应时间为2 h、反应温度为室温时,即可制备出发热效果良好的聚吡咯涂层织物。B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

4 结 语

本文综述了纬编导电织物电-力学性能、湿度传感性能及电热性能的作用机理与应用进展,并探讨了不同性能纬编导电织物的制备原则及要点,为导电针织产品后续的设计研发提供了理论依据与技术指导。

纬编导电织物的诸多优点使其在智能可穿戴领域占有绝对优势,智能针织品的普及与应用已成为必然趋势。随着智能针织产品应用领域的拓展与大规模市场化,其在材料耐久性、结构稳定性、能源供应及产品安全性等方面的问题日益显著,针对这些问题,本文指出了解决途径。

1) 加强高性能纤维材料的研发。纤维材料是导电针织物的基础,对智能针织产品的各项性能具有直接影响,研发高性能纤维材料不仅能解决材料耐久性问题,还能提高产品的其他性能,如高导电性、高弹性、耐高温性及抗辐射性等。

2) 改善现有的制备工艺。导电针织物因其线圈结构的特殊性,经反复拉伸、洗涤会发生一定程度变形而影响自身性能,因此要采取一系列的改革措施对现有的制备工艺进行优化,以提高产品的结构稳定性。

3) 加快自供电技术应用。自供电技术可利用特殊织物将周围环境中的各种能量(人体运动、摩擦、光能或太阳能等)收集起来并将其转化成电能,为低功耗电子元件供电。如果将其与智能针织产品结合,既能实现零电能消耗,又能节约成本、保护环境。

4) 建立完善的安全测试标准。智能针织产品的安全性主要包括化学成分安全性、电路安全性、信息安全性、阻燃性及电磁辐射等,通过制定出相应的测试标准,以规范智能针织产品市场。

参考文献:

[1]蔡倩文, 王金凤, 陈慰来. 纬编针织柔性传感器结构及其导电性能[J]. 纺织学报, 2016, 37(6): 48-53.

CAI Qianwen, WANG Jinfeng, CHEN Weilai. Structures and electrical properties of weft-knitted flexible sensors[J]. Journal of Textile Research, 2016, 37(6): 48-53.

[2]陈斌, 李娜娜, 蔡璐, 等. 导电针织物结构设计及性能研究[J]. 针织工业, 2015(6): 23-25.

CHEN Bin, LI Nana, CAI Lu, et al. Structure design of conductive fiber knitted fabric and its property analysis[J]. Knitting Industries, 2015(6): 23-25.

[3]钱鑫, 苏萌, 李风煜, 等. 柔性可穿戴电子传感器研究进展[J]. 化学学报, 2016, 74(7): 565-575.

QIAN Xin, SU Meng, LI Fengyu, et al. Research progress of flexible wearable electronic sensors[J]. Acta Chemica Sinica, 2016, 74(7): 565-575.

[4]SEYEDIN S, ZHANG P, NAEBE M, et al. Textile strain sensors: A review of the fabrication technologies, performance evaluation and applications[J]. Materials Horizons, 2019, 6(2): 219-249.

[5]王棟, 卿星, 蒋海青, 等. 纤维材料与可穿戴技术的融合与创新[J]. 纺织学报, 2018, 39(5): 150-154.

WANG Dong, QING Xing, JIANG Haiqing, et al. Integration and innovation of fiber materials and wearable technology[J]. Journal of Textile Research, 2018, 39(5): 150-154.

[6]KADIR O, OAGUR A, ASLI A, et al. Textile based sensing system for lower limb motion monitoring[J]. Biosystems & Biorobotics, 2019, 21(1): 395-399.

[7]CHEN Z F, WANG Z, LI X M, et al. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures[J]. ACS Nano, 2017(11): 4507-4513.

[8]ZHAO C, SHU K, WANG C, et al. Reduced graphene oxide and polypyrrole /reduced graphene oxide composite coated stretchable fabric electrodes for super capacitor application[J]. Electrochimica Acta, 2015, 172(1): 12-19.

[9]田明伟, 李增庆, 卢韵静, 等. 纺织基柔性力学传感器研究进展[J]. 纺织学报, 2018, 39(5): 170-176.

TIAN Mingwei, LI Zengqing, LU Yunjing, et al. Recent progress of textile-based flexible mechanical sensors[J]. Journal of Textile Research, 2018, 39(5): 170-176.B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

[10]韩晓雪, 缪旭红. 氨纶纬编导电织物纵向电力学性能[J]. 纺织学报, 2019, 40(4): 60-65.

HAN Xiaoxue, MIAO Xuhong. Longitudinal electrical physical properties of spandex weft-knitted conductive fabric[J]. Journal of Textile Research, 2019, 40(4): 60-65.

[11]HANG Y J, LONG H R. Resistive network model of the weft-knitted strain sensor with the plating stitch-Part 2: Resistive network model during the elongation along course direction[J]. Journal of Engineered Fibers and Fabrics, 2020, 15(35): 1-16.

[12]SEYEDIN S, MORADI S, SINGH C, et al. Continuous production of stretchable conductive multi-filaments in kilometer scale enables facile knitting of wearable strain sensing textiles[J]. Applied Materials Today, 2018, 11: 255-263.

[13]谢娟. 针织物传感器双向延伸电-力学性能及肢体动作监测研究[D]. 上海: 东华大学, 2015.

XIE Juan. Research into Electro-Mechanical Properties of Knitted Sensor under Strip Biaxial Elongation and Application in Monitoring Body Movements[D]. Shanghai: Donghua University, 2015.

[14]吴雪颜, 盛斌, 黄元申. 石墨烯湿度传感器研究进展[J]. 传感器与微系统, 2020(9): 1-3.

WU Xueyan, SHENG Bin, HUANG Yuanshen. Research progress on graphene-based humidity sensor[J]. Transducer and Microsystem Technologies, 2020(9): 1-3.

[15]熊莹, 陶肖明. 智能传感纺织品研究进展[J]. 针织工业, 2019(7): 8-12.

XIONG Ying, TAO Xiaoming. Research progress of smart sensing textiles[J]. Knitting Industries, 2019(7): 8-12.

[16]ANABEl R, LUISA F G, JORGE A D, et al. Fabrication of bulk alumina structures with humidity sensing capabilities using direct ink write technique[J]. Rapid Prototyping Journal, 2021, 27(4): 11-20.

[17]王丽红. 基于柔性包芯纱的应变/湿度传感器制备及其智能可穿戴应用研究[D]. 青岛: 青岛大学, 2020.

WANG Lihong. Preparation of Strain/Humidity Sensor Composed by Flexible Core-Sheath Yarn and its Application in Smart Wearable Clothing[D]. Qingdao: Qingdao University, 2020.

[18]CHEN Q, SHU L, FU B L, et al. Electrical resistance of stainless steel/polyester blended knitted fabrics for application to measure sweat quantity[J]. Polymers, 2021, 13(7): 1-20.

[19]李雅芳. 基于镀银纱线的加热织物制备及其热力学性能研究与仿真[D]. 天津: 天津工业大学, 2017.

LI Yafang. Research and Simulation of Heating Fabric Preparation Based on Silver-Plated Yarn and its Thermodynamic Properties[D]. Tianjin: Tiangong University, 2017.

[20]李潔琼, 马大力. 镀银导电纱线智能电加热针织毛衫的设计开发[J]. 针织工业, 2020(10): 62-65.

LI Jieqiong, MA Dali. Development of intelligent electric heating knitted sweater with silver plated conductive yarn[J]. Knitting Industries, 2020(10): 62-65.B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

[21]HAMDANI S T A, POTLURI P, FERNANDO A. Thermo-mechanical behavior of textile heating fabric based on silver coated polymeric yarn[J]. Materials, 2013, 6(3): 1-8.

[22]张阿真, 郑瑞平, 刘皓. 电加热服装服饰的研究进展[J]. 材料科学与工程学报, 2020, 38(6): 1032-1040.

ZHANG Azhen, ZHENG Ruiping, LIU Hao. Research progress of flexible heating element and its application in wearables[J]. Journal of Materials Science and Engineering, 2020, 38(6): 1032-1040.

[23]KIM H, LEE S. Characterization of electrical heating performance of CFDM 3D-printed graphene/polylactic acid (PLA) horseshoe pattern with different 3D printing directions[J]. Polymers, 2020, 12(12): 2955.

[24]TOGNETTI A, LORUSSI F, MURAG D, et al. New generation of wearable goniometers for motion capture systems[J]. Journal of Neuro Engineering and Rehabilitation, 2014, 11(1): 56-73.

[25]RAJI R K, MIAO X H, WAN A L, et al. Knitted piezoresistive smart chest band and its application for respiration patterns assessment[J]. Journal of Engineered Fibers and Fabrics, 2019, 14(4): 1-14.

[26]QIU Q, ZHU M M, LI Z L, et al. Highly flexible, breathable, tailorable and washable power generation fabrics for wearable electronics[J]. Nano Energy, 2019, 58(1): 750-758.

[27]刘婵婵, 缪旭红, 李煜天. 基于针织的肘部弯曲传感器传感性能研究[J]. 丝绸, 2019, 56(12): 16-21.

LIU Chanchan, MIAO Xuhong, LI Yutian. Research on sensing performance of knitted elbow bending sensor[J]. Journal of Silk, 2019, 56(12): 16-21.

[28]张佳慧, 王建萍. 圆形纬编针织物电极导电性能及电阻理论模型构建[J]. 纺织学报, 2020, 41(3): 56-61.

ZHANG Jiahui, WANG Jianping. Electric conduction and resistance theory model of circular weft knitted electrodes[J]. Journal of Textile Research, 2020, 41(3): 56-61.

[29]BI S Y, HOU L, LU Y X. An integrated wearable strain, temperature and humidity sensor for multifunctional monitoring[J]. Composites Part A, 2021, 149(5): 99-103.

[30]GIUSEPPE R, VALENTIAN T, CLAUDIO C, et al. Structural and morphological characterizations of MWCNTs hybrid coating onto cotton fabric as potential humidity and temperature wearable sensor[J]. Sensors & Actuators B: Chemical, 2017, 252: 428-439.

[31]ZHANG X H, CHAO X J, LOU L, et al. Personal thermal management by thermally conductive composites: A review[J]. Composites Communications, 2021, 23(1): 100585-100595.

[32]李雅芳, 劉皓, 赵义侠. 基于镀银纱线的电加热织物温度场模拟与电热性能[J]. 材料工程, 2019, 47(2): 68-75.

LI Yafang, LIU Hao, ZHAO Yixia. Electric heating fabrics based on silver plated yarn and simulation of temperature field[J]. Journal of Materials Engineering, 2019, 47(2): 68-75.B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

[33]盧俊宇, 陈莉, 刘皓. 针织加热织物的设计及其电热性能测试[J]. 上海纺织科技, 2017, 45(3): 31-34.

LU Junyu, CHEN Li, LIU Hao. Design and electrothermal performance of knitted heating fabric[J]. Shanghai Textile Science & Technology, 2017, 45(3): 31-34.

[34]王宏付, 张海棠, 柯莹. 智能防寒服装研究进展[J]. 服装学报, 2021, 6(1): 29-35.

WANG Hongfu, ZHANG Haitang, KE Ying. Research progress on intelligent cold protective clothing[J]. Journal of Clothing Research, 2021, 6(1): 29-35.

[35]李萍, 蒋晓文. 智能电加热服的研究进展[J]. 棉纺织技术, 2019, 47(9): 79-84.

LI Ping, JIANG Xiaowen. Research progress of intelligent electric heating clothing[J]. Cotton Textile Technology, 2019, 47(9): 79-84.

[36]KIM H, LEE S, KIM H. Electrical heating performance of electro-conductive para-aramid knit manufactured by dip-coating in a graphene/waterborne polyurethane composite[J]. Scientific Reports, 2019, 9(1): 2-11.

Research progress on multiple properties and preparation of weft-knitted conductive fabrics

WANG Pan, WANG Zhaohui

(a.College of Fashion and Design; b.Key Laboratory of Clothing Design and Technology, Ministry of Education; c.Shanghai Belt andRoad Joint Laboratory of Textile Intelligent Manufacturing, Donghua University, Shanghai 200051, China)

Abstract:Weft-knitted conductive fabrics have become one of the research focuses in the field of smart textiles due to their unique organizational structure and wearability. The knitted loop structure not only provides the conductive fabric with excellent omnidirectional stretch properties, but also provides elasticity, softness and fit that other fabrics cannot match. In recent years, the researched weft-knitted conductive fabrics, which mainly use resistance changes caused by external stimuli to achieve intelligence and functionalization, have the characteristics of simple structure, easiness to form, light texture, good flexibility and strong designability. They have broad application prospects in fields such as healthcare, sweat monitoring, and smart temperature regulation.

At present, weft-knitted conductive fabrics are endowed with multiple properties. Among them, conductive knitted fabrics with electro-mechanical properties can help us understand the external force by monitoring the change law of the total resistance of the fabric. The selection of yarn raw materials, the design of weave structure, the weaving process and the way of voltage loading have important effects on the electro-mechanical properties during preparation. This type of fabric can realize real-time, non-inductive acquisition of human physiological data, and is mostly used in the fields of medical care and sports and fitness. Conductive fabrics with humidity sensing properties do not depend on the knitted structure, but mainly rely on the hydrophilicity of the fabric itself, humidity sensitive materials or conductive materials to achieve humidity sensing. This type of fabric mainly characterizes environmental humidity changes through resistivity changes. Since both external stretching and humidity changes can affect fabric resistance, a composite layer to prevent coupling effects between the two can be added during preparation. This type of fabric can be used for monitoring incontinence, wound healing, sweating or microclimate of garments and other related fields. Conductive knitted fabrics with electrothermal properties can directly convert electrical energy provided by external power sources into thermal energy by using the internal resistance network of the fabric, and are mainly affected by conductive materials, preparation processes and loading voltage during preparation. Silver-coated yarn or polypyrrole can be used as the conductive material, and the former has better performance than the latter. This type of fabric is mostly used in such fields as polar winter clothing, smart home and sports protection.B48DEDB0-EFB8-41B5-B6E2-27DDC842923C

Weft-knitted conductive fabrics with electro-mechanical properties are a hot research topic because of many factors (such as yarn type, fabric density, weave structure, horizontal and vertical dimensions, and weaving process, etc.). Any change of any of these factors will affect the existing resistance network model, so there is no unified evaluation standard for the related performance parameters such as sensitivity, linearity and strain range of this kind of fabrics. There are relatively few studies on weft-knitted conductive fabrics with moisture sensing properties. However, due to the softness and fit of the knitted structure, it is expected to replace the traditional test method and realize the real-time measurement of skin surface humidity and sweat amount. In addition, if a layer of ion-selective film or biomolecular enzyme film can be added to the surface of fabrics with such properties, the detection of sweat components can even be realized. At present, some relatively mature electric heating knitted products have been put into the market, but there are still some deficiencies in the existing products. For example, the temperature control system of electric heating knitted products is not intelligent enough, and the electric heating knitted products have problems of poor portability and short working time. Therefore, the future research direction of such products mainly lies in the design of automatic temperature control system and wireless power transmission to improve product performance and user experience.

The multiple advantages of the weft-knitted conductive fabric make it an absolute advantage in the field of smart wearables, and the popularization and application of smart knitwear have become an inevitable trend. With the expansion and large-scale marketization of the application field of smart knitted products, the problems of material durability, structural stability, energy supply and product safety have become increasingly prominent. The key to solving these problems lies in the following points: First, the research and development of high-performance fiber materials should be strengthened. The development of high-performance fiber materials can not only solve the problem of material durability, but also improve other properties of the products. Second, the existing preparation process should be improved. Due to its structural characteristics, conductive knitted fabrics will deform and the performance will be affected after repeated stretching and washing. Therefore, the preparation process should be optimized to improve its stability. Third, the application of self-powered technology should be accelerated. If the self-powered technology is combined with smart knitted products, it can not only achieve zero power consumption, but also save costs and protect the environment. Finally, a sound security testing standard should be established. The market of smart knitted products should be regulated by developing corresponding test standards.

Key words:weft-knitted; conductive fabrics; electro-mechanical properties; humidity sensor; electrothermal property; smart wearables; self-powered technologyB48DEDB0-EFB8-41B5-B6E2-27DDC842923C