In Situ Growth and Characterization of TiN/HfxZr1-xO2/TiN Ferroelectric Capacitors

2022-06-21YuhaoYinYangShenHuWangXiaoChenLinShaoWenyuHuaJuanWangYiCui

Yuhao Yin , Yang Shen , Hu Wang , Xiao Chen , Lin Shao , Wenyu Hua , Juan Wang , Yi Cui ,*

1 Vacuum Interconnected Nanotech Workstation, Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences,Suzhou 215123, Jiangsu Province, China

2 Nano Science and Technology Institute, University of Science and Technology of China, Hefei 230026, China

3 Wuxi Petabyte Technology Co. Ltd., Wuxi 214028, Jiangsu Province, China

4 Department of Physics and Engineering Physics, The University of Tulsa, Tulsa, OK 74104, USA.

Abstract:HfO2-based ferroelectric capacitors, particularly TiN/HfxZr1-xO2/TiN metal insulator metal (MIM) capacitors, have attracted considerable attention as promising candidates in the new generation of nonvolatile memory applications, because of their excellent stability, high performance, and complementary metal oxide semiconductor (CMOS) compatibility. At the electrode interface of TiN/HfxZr1-xO2/TiN MIM ferroelectric devices, the existence of the TiOxNy layer, which was formed during HfxZr1-xO2 film crystallization and TiN oxidization, can affect interface/grain boundary energy, film stress, and conduction band offset at the TiN/HfxZr1-xO2 interface, thereby affecting the ferroelectric device performance. Because the electrical performance of TiN/HfxZr1-xO2/TiN capacitors depends on both the ferroelectric HfxZr1-xO2 thin films and electrode TiN/insulator HfxZr1-xO2 interface, it is essential to control the fabrication of the TiN/HfxZr1-xO2/TiN heterostructure. Herein, we report a new method for preparing HfxZr1-xO2 ferroelectric thin films, sandwiched between TiN electrodes, by atomic layer deposition (ALD) and using ultra high vacuum(UHV) sputtering equipment interconnected with an ultra-high vacuum system. The quasi in situ characterization by transmission electron microscopy (TEM), time-of-flight secondary ion mass spectrometry (ToF-SIMS), and other analytical methods conducted in our study indicates that the surface of the bottom TiN electrode does not contain oxygen. Moreover,a flat signal for impurities at the interface suggests that the superior ferroelectric performance of HfxZr1-xO2-based device is mainly attributed to the pristine HfxZr1-xO2/TiN interface. Furthermore, the ferroelectric properties of TiN/HfxZr1-xO2/TiN heterostructures on silicon can be modulated by varying ZrO2 doping concentration and rapid thermal annealing (RTA)temperature, which can be well monitored and controlled by the interconnected system. We also investigate the ferroelectric properties of TiN/HfxZr1-xO2/TiN capacitors with different ZrO2 doping concentrations (30%-60% (x)) at room temperature by changing the ALD pulsing ratio within the vacuum interconnected system. Three identical 10 nm-thick Hf0.5Zr0.5O2 samples sandwiched between TiN electrodes are annealed in N2 ambient at 400, 450 and 600 °C for 5 min to investigate the effect of RTA on device performance. The evolution of P-E hysteresis at different applied voltages and RTA temperatures reveals that the saturation of P-E hysteresis and remanent polarization increase with RTA temperature. This increase is especially evident at low applied voltages such as 1.5 V. A higher remanent polarization of 21.5 μC·cm-2 than the previously reported value and a low coercive voltage of 1.35 V were achieved for the electric field of 3 MV·cm-1 by doping 50% (molar fraction, x) ZrO2 in HfO2 through RTA at 600 °C for film crystallization.

Key Words:Ferroelectrics;Surface;Interface;HfO2;Vacuum interconnection;In situ

1 Introduction

Most conventional ferroelectric materials considering as candidates for non-volatile semiconductor memory devices,such as Pb(Zr, Ti)O3, BaTiO3, and BiFeO3, have perovskite structure, which is challenging on integration with Si-based CMOS technology. The Si-compatible, environment friendly materials with simple fabrication approach and high ferroelectric performance are intensively demanded in the next-generation“green” data storage devices. Hafnium dioxide (HfO2) can not only be used as a high-k gate dielectric1and but also be integrated with TiN electrode2, indicating its high CMOS-compatibility. In addition, it can overcome the scaling problem3-6in industrial applications. These outstanding advantages have aroused tremendous’ interests in the use of HfO2-based thin films for data and energy storage applications7-10. Since the first reported ferroelectricity in Sidoped HfO2 films by Bösckeet al11, increasingly attentions have been drawn on the dopants to provoke ferroelectricity in doped HfO2films, such as Y, Gd, Al, La and the admixture of 50%(molar fraction,x) ZrO23,12-16. HfxZr1-xO2is one of the most promising HfO2-based ferroelectrics due to its high remanent polarization (Pr)3and lower crystallization temperature, and even at low thickness a wide range of ZrO2-doping concentrations in HfO2films can sustain orthorhombic phase17.

Over decades’ investigation, it has been indicated that the ferroelectricity in HfxZr1-xO22thin films results from a stable orthorhombic phase, which is crystallized during the thermal annealing of top capping TiN electrodes18,19. Due to the socalled interface-induced “wake-up” effect20,21, the pre-treatment of electric cycle is needed to fully exploit the ferroelectric characteristics of HfxZr1-xO2films22-25. The distribution and diffusion of oxygen vacancies and defect states at the electrode/ferroelectric films interface play an important role in“wake-up” effect20,26. For TiN/HfxZr1-xO2/TiN heterostructures,there are two interface regions: HfxZr1-xO2-TiN interface formed during HfxZr1-xO2films crystallization; TiN-O2interface(TiOxNy) formed during TiN oxidization27-29. There are two resources of oxygen for TiOxNylayer: exposure to air during the intermediate transport of sample preparation21,28,30, and TiN pulling out oxygen from the dielectric HfxZr1-xO2 layer during the annealing process21,28. The existence of the TiOxNylayer can affect the interface/grain boundary energy, film stress and the conduction band offset at the TiN/ HfxZr1-xO2interface, thereby the ferroelectric device performance31-34. Besides oxygen26,carbon35and nitrogen36impurities in the deposited HfxZr1-xO2 layer can also depress its ferroelectricity. Thein situcharacterization of oxygen vacancies at TiN/HfxZr1-xO2/TiN interfaces is significant for deep understanding the structuraldependent ferroelectric properties of HfxZr1-xO2films.

In this article we use the vacuum interconnected system to prepare andin situcharacterize the TiN/HfxZr1-xO2/TiN metal/insulator/metal (MIM) capacitors on Si(100) substrate.The vacuum interconnected system we employed in Suzhou Vacuum Interconnect Nanotechnology Workstation (Nano-X)can link multiple thin film deposition and characterization equipment in high vacuum. This interconnected approach in vacuum can ensure the individual equipment be elaborately controlled without cross-contamination. In our study, we use the ultra-high vacuum (UHV) magnetron sputter and atomic layer deposition (ALD) system to grow TiN electrodes and HfxZr1-xO2films respectively. The separating growth of TiN electrodes and HfxZr1-xO2ferroelectric films by the two isolated equipment can avoid HfxZr1-xO2films contamination during TiN deposition.The interface chemical states and element distributions of prepared TiN/HfxZr1-xO2/TiN ferroelectric capacitors werein situcharacterized by transmission electron microscope (TEM)and time-of-flight secondary ion mass spectrometry (TOFSIMS), for the first time, through the vacuum interconnected system37. The ferroelectric properties of the prepared MIM capacitors are investigated with different ZrO2mixture contents and annealing temperatures, which can affect the phase transition and thereby the ferroelectricity of HfxZr1-xO2films.

2 Materials and methods

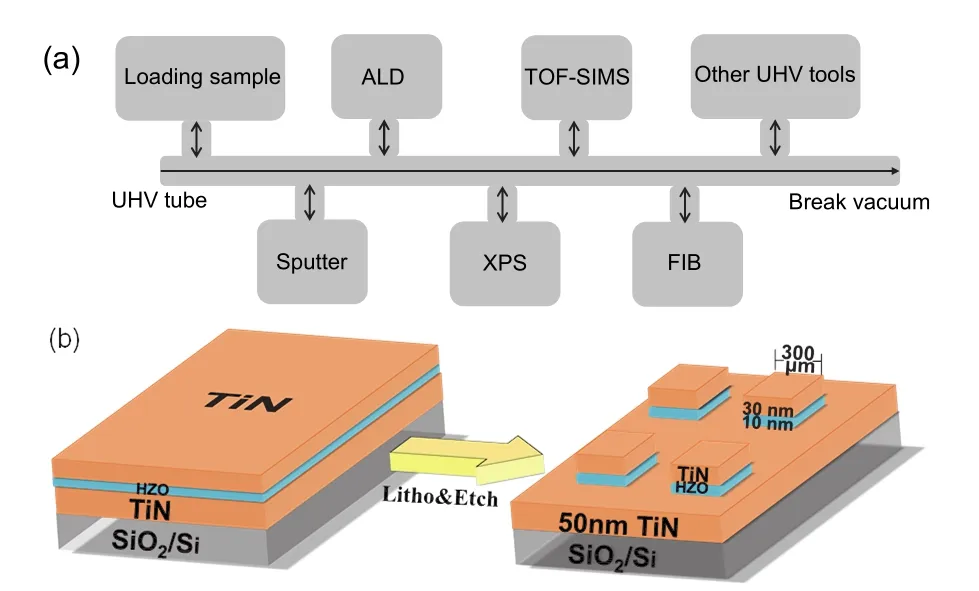

A 10 nm HfxZr1-xO2ferroelectric thin film, sandwiched between a 50 nm-thick TiN top and 30 nm-thick TiN bottom electrodes, was deposited at 300 °C by ALD on a Si(100)substrate capped with a 500 nm SiO2layer. The TiN top and bottom electrodes were grown at 200 °C by UHV DC sputtering with a deposition rate of 1.7 nm·min-1. The deposition was carried out with Ta anode target and a mixture of Ar (11 sccm(standard cubic centimeter per minute)) and N2(34 sccm). The base and working pressure in the deposition chamber were 5 ×10-9and 2.0 × 10-3Torr (1 Torr = 133.322 Pa), respectively. The sample was transferred between sputter and ALD chambers through high vacuum interconnected tubes as shown in Fig. 1a.The HfxZr1-xO2films were grown as alternating HfO2/ZrO2layers using Tetrakis (ethylmethylamino) hafnium (TEMA-Hf)and Tetrakis (ethylmethylamino) zirconium (TEMA-Zr) as the Hf and Zr precursors respectively, while N2was the carrier gas bubbled through the liquid precursor source into the main chamber and H2O was used as oxidant. The exposure time for precursors and H2O is 1.6 and 0.1 s, respectively. The growth rates of HfO2and ZrO2layers were kept as 1.0 and 0.9 Å·cycle-1(1 Å = 0.1 nm), respectively. Using HfO2-ZrO2cycle ratios of 3 : 2, 2 : 1, 1 : 1 and 1 : 2, respectively, the solid solution of HfxZr1-xO2with different mixture contents of ZrO2was obtained. After the deposition of TiN top electrode, HfxZr1-xO2thin films were crystallized by the rapid thermal annealing(RTA) process under N2ambient at a selected temperature for 5 min.

Fig. 1 (a) Schematic diagram of vacuum interconnected system and(b) sketch of layout and fabrication of TiN/HfxZr1-xO2/TiN ferroelectric capacitors.

The ZrO2content in HfxZr1-xO2films was characterized by X-ray photoelectron spectroscopy (XPS), equipped with a hemispherical electron energy analyzer (PHI 5000, VersaProbe II, ULVAC-PHI) and a monochromatic AlKαX-ray source of 1486.68 eV. Depth profiles of the chemical composition of the TiN/HfxZr1-xO2/TiN stack were obtained by ToF-SIMS(TOF.SIMS S5-100, ION-TOF GmbH) with the sputtering beam of 1 keV Cs+ions and the analysis beam of 30 keV Bi+ions. The crystal structure of HfxZr1-xO2films was analyzed using a grazing incidence X-ray diffraction (GIXRD, D8 Advance,Bruker). The cross-sectional specimens for TEM (Talos F200X,FEI) measurements were prepared by focused ion beam (FIB,Scios, FEI). Then, the crystal morphology and element (Ti, O,Hf, Zr) contents were studied by HR-TEM, which was preloaded with ultra-high resolution objective lens (Cs (sphericalaberration coefficient) = 0.5 mm) and an in- column energy filter to remove inelastic electrons at the acceleration voltage of 200 kV, and energy-dispersive X-ray spectroscopy (EDS)respectively.

Afterin situcharacterization of TiN/HfxZr1-xO2/TiN heterostructures, TiN top electrode was patterned by standard contact UV lithography with 7 μm AZ4620 resist. The elaborate pattern (as shown in Fig. 1b) was completed by ion beam etch(IBE) process, which is time based to ensure landing on TiN bottom electrode. The length of the square capacitors used for electrical measurements in this article is 300 micrometers. The polarization hysteresis was characterized by an Agilent 4200 system and a customer-designed setup.

In this study, ALD, UHV sputter, RTA, XPS, ToF-SIMS, and FIB equipped in the high vacuum interconnected system were used to fabricate andin situcharacterize the TiN/HfxZr1-xO2/TiN capacitors, while the IBE, TEM, EDS, GIXRD and ferroelectric polarization measurements were done outside the interconnected system.

3 Results and discussion

3.1 Structural properties of TiN/ HfxZr1-xO2/TiN heterostructure

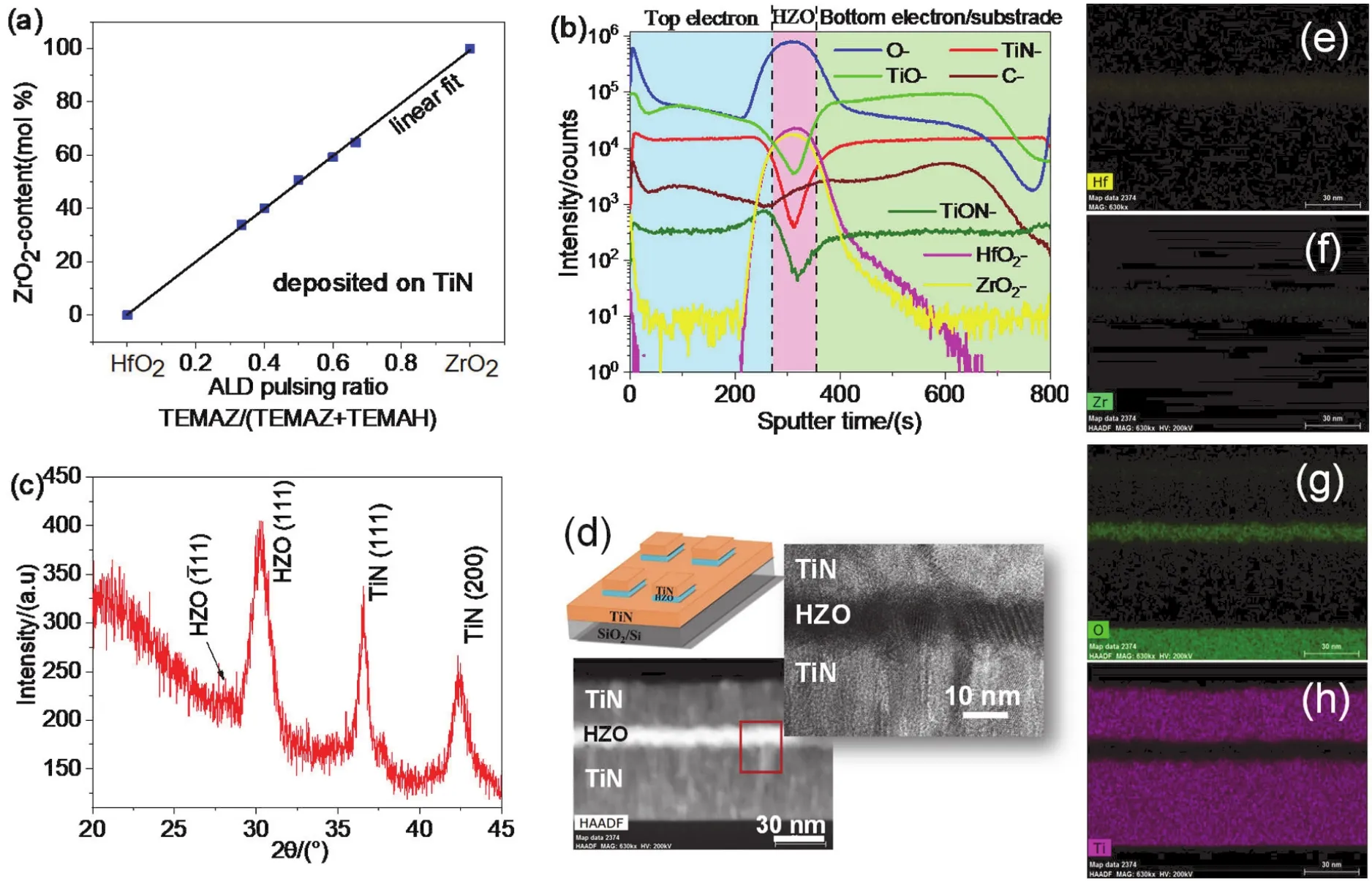

The structural characteristics of the prepared TiN/HfxZr1-xO2/TiN heterostructure are studied by XPS, ToFSIMS, GIXRD, TEM and EDS as shown in Fig. 2. To grow a wide composition range of HfxZr1-xO2thin films, the ALD pulsing ratio of the alkylamide precursors (TEMAH and TEMAZ) was used to determine HfO2and ZrO2contents in the HfO2-ZrO2solid solution by XPS measurement (Fig. 2a) (details of HfxZr1-xO2thin films with the ALD pulsing ratio in the Supporting Information, section S1). The direct stoichiometry control of HfxZr1-xO2films by ALD cycling can be indicated by the linear-dependence of the TEMAZ precursor ratio and ZrO2content. Specifically, the sample used for demonstration in Fig.2b-h is a TiN/Hf0.5Zr0.5O2/TiN (TiN/HZO/TiN) stack after RTA under N2ambient at 450 °C for 5 min.

Fig. 2 (a) ZrO2 and HfO2 content in the HfO2-ZrO2 solid solution dependence on the ALD pulsing ratio of the utilized alkylamide precursors(TEMAH and TEMAZ) measured by XPS. (b) ToF-SIMS spectrum of the TiN/Hf0.5Zr0.5O2/TiN (TiN/HZO/TiN) heterostructure. Bars on the y-axis indicate a factor of 10 in intensity ratio. (c) Grazing incidence X-ray diffraction characterization of Hf0.5Zr0.5O2 (HZO) films on TiN.The dominated orthorhombic HZO(111) and a small monoclinicHZO(111) diffraction peaks are observed. (d) Z-contrast STEM and cross-sectional HRTEM images of a TiN/HZO/TiN capacitor and (e-h) EDS mapping of individual elements (Hf, Zr, O and Ti) in TiN/HZO/TiN.

The TiN/HZO/TiN hetero interfaces werein situcharacterized by ToF-SIMS (Fig. 2b), which reveals the depth of chemical dopants and impurities in the sample. Carbon impurities at electrode/ferroelectric films interface are reported to depress the ferroelectricity in MIM devices19,34. The relative flat signal of carbon in Fig. 2b declares a high purity of the prepared TiN/HZO/TiN sample. The TiON-and TiO-chemical bonds at the HZO/bottom-TiN interface have no obvious bumps in reference to the bottom electrode, implying that Ti-O-N bonds are rarely formed at the HZO/bottom-TiN interface.Therefore, TiOxNylayer which exists to reduce the ferroelectric properties of HZO films is restrained in our sample. Whereas, a small bump of TiON- at top-TiN/HZO interface indicates TiN oxidation around the top electrodes, which could be due to the diffusion of oxygen from HZO to TiN top electrode during subsequent annealing process, or the binding between oxygen on HZO surface and the sputtering material in the initial deposition of top electrode20,34,38. The sharp signal of TiN- bond at TiN/HZO/TiN interfaces reveals a ultra-low diffusion of Ti and N atoms in HZO thin films. Additionally, the almost overlapping HfO2-and ZrO2-signals imply the well-defined stoichiometry of Hf0.5Zr0.5O2 films.

A crystal structural investigation by GIXRD suggests the existence of orthorhombic and monoclinic phases in the prepared HZO films (Fig. 2c). The (111)odiffraction peak of the orthorhombic phase at 30.27°, which related to ferroelectricity because of its non-symmetric feature39. The smallpeak around 28.1° suggests the non-ferroelectric monoclinic phase3,5,6,22. The high area ratio ofindicates a promising ferroelectric performance of the TiN/HZO/TiN device5,40.

The polycrystalline nature of a set of 50 nm-TiN/10 nm-HZO/30 nm-TiN heterostructures on SiO2/Si substrate is confirmed by the Z-contrast high angle annular dark field(HAADF) STEM and high-resolution TEM as shown in Fig. 2d.The EDS element mapping of the TiN/HZO/TiN stack is shown in Fig. 2e-h. Hf, Zr and Ti elements are homogeneously distributed in HZO and TiN layers, respectively. However, as shown in Fig. 2g, surface TiN oxidation due to the presence of oxygen in top TiN layer might result from the sample exposure to air during transportation or oxygen diffusion from the underneath HZO films20. In Fig. 2g, it is interesting that the surface of bottom TiN electrode is of absence of oxygen, which is different from normal HfO2/TiN interface. In fact, because the interface oxygen is important for electrical properties of MIM capacitors, the tuning of oxidation states of TiN can impact device properties41-43. So the absence of oxygen in bottom TiN electrode reveals higher quality of HZO/TiN interface achieved in this study compared to traditional MIM capacitors fabrication methods34.

3.2 Effect of ZrO2-doping content on ferroelectric properties of HfxZr1-xO2 thin films

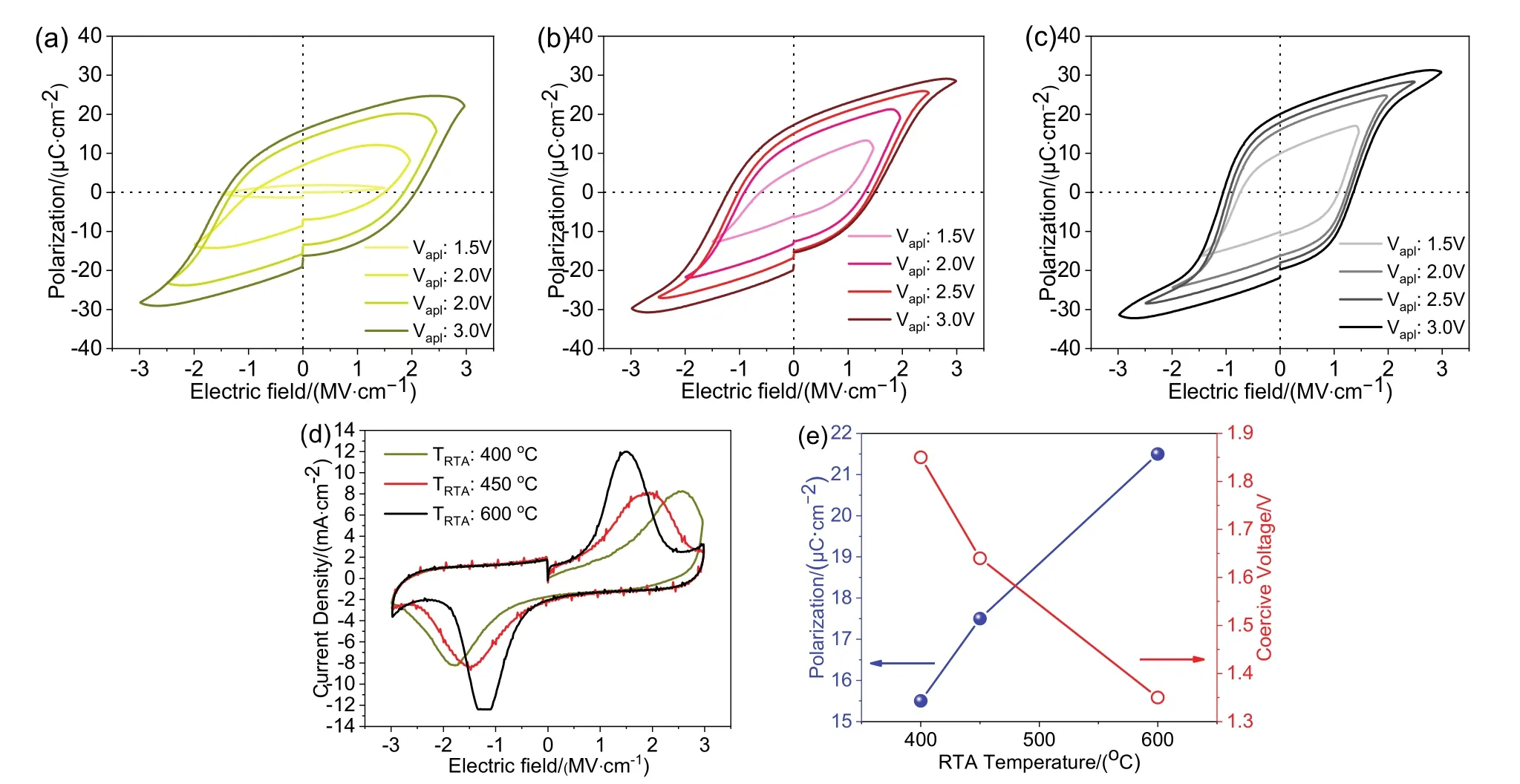

The ferroelectricity in HfxZr1-xO2thin film depends on its intrinsic symmetry, which can be modulated by the ZrO2and HfO2composition3,31,44,45. ZrO2doping in HfO2can prompt the centrosymmetric tetragonal phase transition to noncentrosymmetric orthorhombic phase, meanwhile provoking the ferroelectricity in doped HfO2films. In this study, we investigated the ferroelectric properties of TiN/HfxZr1-xO2/TiN capacitors with different ZrO2doping concentrations from 30% to 60% (x) at room temperature (Fig. 3). A triangular voltage waveform is applied to study the polarization-electric field (PE) dependence as shown in the inset graph of Fig. 3a.

Fig. 3 (a) Polarization hysteresis of different ZrO2 doped HfxZr1-xO2-based metal-insulator-metal (MIM) capacitors under 3 MV·cm-1 electric field at 2.5 kHz. The inset shows the triangular voltage sweep waveform for the hysteresis measurements with the amplitude of 3 V and period of 0.4 ms. (b) Current response to the triangular voltage stimuli reveals the ferroelectric switching current to be clearly separable from the leakage current contributions at high electric fields. (c) Summary of the Zr-doping concentration-dependent remanent polarization (Pr) and coercive voltage (Vc) of HfxZr1-xO2-based MIM capacitors.

The characteristic ferroelectricP-Ehysteresis arises with increasing ZrO2content and a maximum remanent polarization(Pr) of 17.5 μC·cm-2is reached for an equal mixture of ZrO2and HfO2, which agrees with the previous report3,26,31,45. However,the ferroelectric hysteresis of HfxZr1-xO2 films does not evolve wildly from lightly- to heavily-doping of ZrO2 (Fig. 3a). It means that ZrO2-doping can evoke ferroelectric phase in HfO2-based films but cannot fully dominate their ferroelectric performance.Fig. 3b represents theI-Vcurves of ferroelectric HfxZr1-xO2films revealing two opposite current peaks due to polarization switching. Except the Hf0.4Zr0.6O2 sample, all HfxZr1-xO2 films possess a small leakage current, indicating good electrical performance of the TiN/HfxZr1-xO2/TiN capacitors. In addition,the coercive voltage (Vc) shifts back-and-forth with ZrO2content as shown in Fig. 3b. A summary of the Zr composition-dependentPrandVcwitnessed in Fig. 3a, b is given in Fig. 3c. It can be found that a largePr of 17.5 μC·cm-2and a smallVc of 1.69 V can be simultaneously achieved in Hf0.5Zr0.5O2 films, indicating the optimum ZrO2content of 50% (x).

3.3 Effect of annealing temperature on ferroelectric properties of HfxZr1-xO2 thin films

Since ferroelectricity in HfxZr1-xO2films results from the composition-dependent phase transition during the films crystallization under RTA3,26,31,45,46, the annealing temperature is expected to affect the ferroelectric properties of TiN/HfxZr1-xO2/TiN capacitors. Considering the temperature limitation on ferroelectric HZO films crystallization and CMOS device contains for 1T1C ferroelectric random access memory(FRAM) applications, three identical 10 nm-thick Hf0.5Zr0.5O2samples sandwiched with TiN electrodes were annealed under N2 ambient at temperature of 400, 450 and 600 °C for 5 min,respectively, to investigate RTA impact on device performances.

The characteristicP-Ehysteresis andI-Vcurves of the TiN/Hf0.5Zr0.5O2/TiN capacitor at different RTA temperatures are shown in Fig. 4. The evolution ofP-Ehysteresis under different applied voltages and RTA temperatures shown in Fig. 4a-c reveals that the saturation ofP-Ehysteresis andPr increase with RTA temperature. This characteristic is especially evident at small applied voltage such as 1.5 V. At RTA temperature of 600 °C, a nearly rectangleP-Eloop with aProf 21.5 μC·cm-2under 3 MV·cm-1electric field is achieved, which is larger than the previous reportedPr3,31. It suggests that Hf0.5Zr0.5O2films have improved orthorhombic phases as the annealing temperature increases to 600 °C and the uncompleted phase transition under RTA temperature lower than 450 °C should be considered when creating Hf0.5Zr0.5O2-based electronic devices.The coercive voltage (Vc), however, shows an opposite relation to RTA temperature (Fig. 4d). The increase in annealing temperature resulted in an increase in leakage current in ferroelectric Hf0.5Zr0.5O2 films, which due to a higher RTA temperature increases the chance of leakage degradation40,47.Fig. 4e summarizes the annealing temperature-dependentPrandVcat electric field of 3 MV·cm-1. A maximumProf 21.5 μC·cm-2and a minimumVcof 1.35 V can be simultaneously obtained in Hf0.5Zr0.5O2 films at RTA temperature of 600 °C. Further increasing the annealing temperature may increase the relative ratio of the non-ferroelectric monoclinic phase and ferroelectric orthorhombic phase, reducing thePrvalue40. This finding is significant for Hf0.5Zr0.5O2-based electronic devices fabrication and usage in limited-budget industry since inferior Hf0.5Zr0.5O2films could require elevated electrical field to improve the ferroelectric memory window, increasing the unnecessary cost.

Fig. 4 (a-c) Polarization hysteresis evolutions of Hf0.5Zr0.5O2-based MIM capacitors annealed at 400, 450 and 600 °C, respectively.The frequency of the applied triangular voltage is 2.5 kHz. (d) Current-electric field responses of ferroelectric TiN/Hf0.5Zr0.5O2/TiN capacitors.(e) Remanent polarization (Pr) and coercive voltage (Vc) of TiN/Hf0.5Zr0.5O2/TiN capacitor dependence on RTA temperature.

4 Conclusions

In this work, we successfully fabricated TiN/HfxZr1-xO2/TiN ferroelectric capacitors, for the first time, by vacuum interconnected ALD and UHV sputter system. Thein situcharacterization reveals a pristine HfxZr1-xO2/TiN interface as a key effect in the superior ferroelectric performance of HfxZr1-xO2-based device. We studied the ferroelectric characteristics of TiN/HfxZr1-xO2/TiN capacitors with different ZrO2doping concentrations at different annealing temperatures.A higherProf 21.5 μC·cm-2than the previous reported value and a minimumVcof 1.35 V were achieved by doping 50% ZrO2in HfO2and annealing the HfO2-ZrO2solid solution at 600 °C for films crystallization. These findings prompt a new approach inin situgrowth and analysis of the binary HfO2-based electronic devices and tmore tests on device reliabilities will be launched in the future.

Acknowledgment:The authors are grateful for the support from Nano Fabrication Facility and Platform for Characterization & Test from Suzhou Institute of Nano-Tech and Nano-Bionics, CAS. Also thanks to the help from Prof. Rongxin Wang for fruitful discussion, Ms. Zhiyun Li with XPS experiments in Nano-X from Suzhou Institute of Nano-Tech and Nano-Bionics, CAS.

Supporting Information:available free of chargeviathe internet at http://www.whxb.pku.edu.cn.