热处理温度对高速激光熔覆Ni/316L涂层组织及摩擦磨损性能的影响

2022-05-28董会郭鹏飞徐龙康凯祥

董会,郭鹏飞,徐龙,康凯祥

热处理温度对高速激光熔覆Ni/316L涂层组织及摩擦磨损性能的影响

董会,郭鹏飞,徐龙,康凯祥

(西安石油大学 a.材料科学与工程学院 b.西安市高性能油气田材料重点实验室,西安 710065)

研究海水腐蚀环境中热处理温度对高速激光熔覆Ni/316L涂层耐磨性能的提升作用。采用高速激光熔覆设备在Q235钢表面制备Ni/316L涂层,分别在650、700、750、800 ℃下热处理1.5 h,通过X射线衍射仪(XRD)、扫描电子显微镜(SEM)和能谱仪(EDS)对Ni/316L熔覆层微观组织结构和相组成进行表征,通过硬度测试和模拟海洋环境摩擦磨损试验,分析热处理温度对Ni/316L熔覆层硬度与耐磨性能的影响。Ni/316L熔覆层厚度约为2 mm,过渡层约为50 μm。熔覆态涂层晶粒包含枝状晶和等轴晶。随热处理温度升高,涂层等轴晶数量先增加、后减少,第二相含量先升高、后降低,熔覆层硬度先升高、后降低。在750 ℃时,熔覆层硬度达到最高,约为熔覆态涂层硬度的2.4倍。热处理后的4种熔覆层的摩擦系数约为0.31,稍低于熔覆态涂层摩擦系数(0.33)。熔覆态涂层的磨损率比750 ℃热处理的涂层约高5倍。5种涂层均以磨粒磨损为主。改变热处理温度可以改变高速激光熔覆Ni/316L涂层的组织结构和第二相的数量,进而影响其硬度与耐磨性,但是热处理温度过高会导致晶粒组化等问题。因此,高速激光熔覆Ni/316L涂层的热处理温度应控制在750 ℃以下。

热处理;高速激光熔覆;Ni/316L涂层;海洋环境;摩擦磨损

随着海上石油钻探、海洋资源开采和深海科学探索等深海装备的兴建和完善,工程材料同时受到风浪冲击、冲蚀、海洋生物附着、氯离子腐蚀、磨损等多重因素的影响[1-4],对零部件的耐蚀、耐磨性能提出了更高要求[5]。表面技术能够在保持碳钢低成本的基础上,提升碳钢构件的耐蚀耐磨性能,目前得到了广泛应用,譬如热喷涂、堆焊、激光熔覆等[6-7]。等离子喷涂耐蚀性涂层可以提升金属构件的耐蚀性,但涂层内部的穿透性孔隙为腐蚀性离子提供了快速通道,会导致碳钢与涂层的界面处发生腐蚀[8]。类似地,特定的堆焊层能赋予构件高的耐磨耐蚀性,但堆焊过程中的高热能量输入会导致构件的力学性能降低等问题出现[9]。常规激光熔覆可以制备致密涂层,但过大的热输入会导致熔覆过程能量密度不均匀,出现裂纹等缺陷[10-11]。高速激光熔覆改变了能量分配,粉末颗粒比基体吸收的能量高,光束汇聚直径小于1 mm[12-13]。随着激光扫描速度的增加,晶粒变得更细,导致涂层显微硬度升高,但热影响区深度和稀释率降低[14]。因此,高速激光熔覆涂层具有稀释率低[15-16]、经济环保[17]、力学性能好[18]等优点。

研究发现,316L不锈钢具有较好的耐腐蚀性,因其含有质量分数为2%~3%的Mo,具有良好的耐硫酸腐蚀和耐Cl-腐蚀性能[19-20]。但由于其硬度低、耐磨性差,在关键摩擦零部件上的应用受到了限制。为提高其耐磨性,最常见的方法是添加合金元素。例如,添加Ni元素后,铁基涂层的耐磨性提升了约80%[21]。研究发现,经过600 ℃的热处理,激光熔覆Ni60/ h-BN复合涂层的硬度上升,摩擦系数下降[22],而550 ℃的低温热处理能够显著提升超音速火焰喷涂WC-12Co和Cr3C2-25NiCr涂层的耐磨性[23]。因此,在316L涂层基础上添加Ni元素,并辅助热处理的方式,不仅可以保持涂层优良的耐蚀性,还可能提升涂层的硬度与耐磨性,进而拓宽高速激光熔覆316L涂层的服役范围。目前,热处理参数对高速激光熔覆Ni/316L涂层的组织结构、物相组成、硬度、耐磨性的影响尚不清楚。

基于此,本文采用高速激光熔覆技术在Q235表面制备Ni/316L复合涂层,并对涂层进行不同温度的热处理,研究热处理前后复合涂层的显微组织、硬度,以及在模拟海水环境中的摩擦磨损性能,为高速激光熔覆制备高耐蚀、高耐磨涂层,拓宽Ni/316L涂层服役范围提供理论依据。

1 试验

1.1 材料

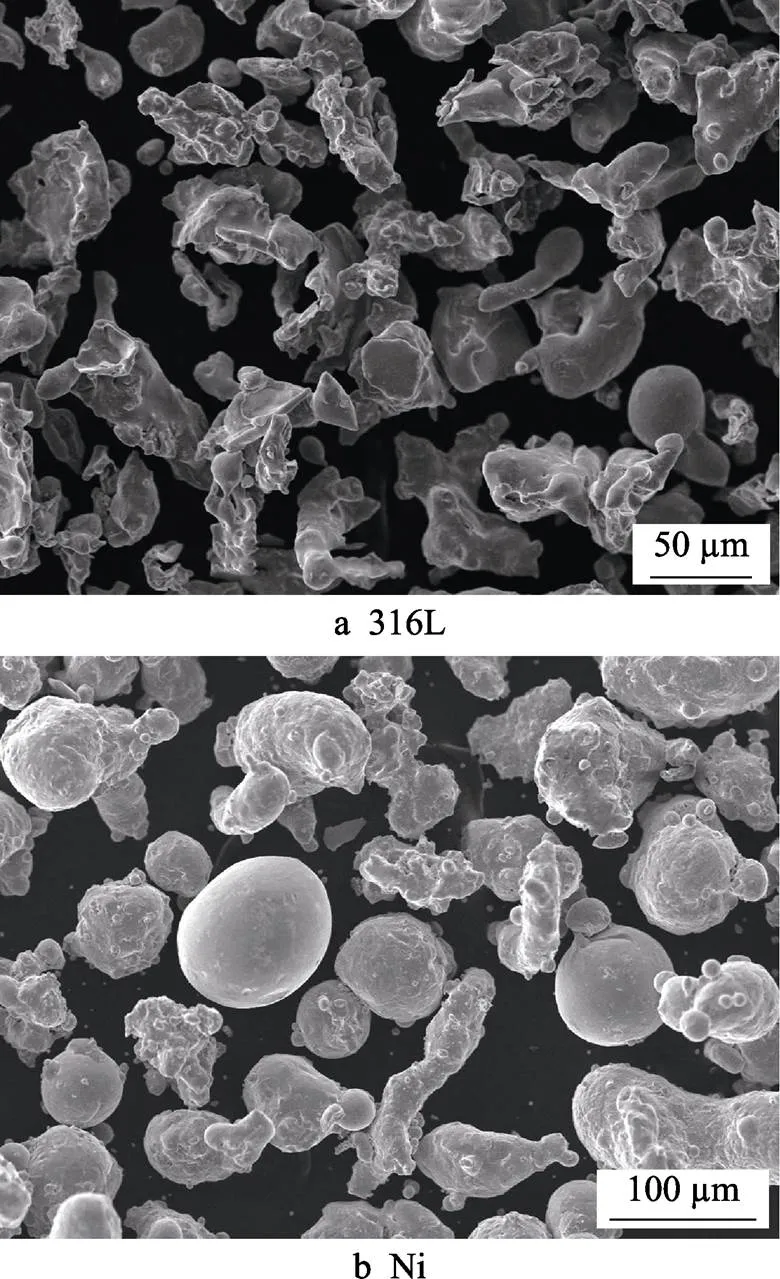

基体为Q235圆棒(50 mm×300 mm)。熔覆材料为316L不锈钢实心粉末和纯Ni粉的机械混合粉末(质量比2︰1混合充分),粒度分别为30~70 μm和30~80 μm。与热喷涂技术不同[24],激光熔覆的热输入较大,能够保证较大尺寸的粉末完全熔化,该粉末与球形粉末熔化后的液滴形貌相同,熔覆层质量与特征也完全相同。因此,在保证粉末流动性与送粉均匀性的基础上,本文选择的316L不锈钢粉末为不规则形状,如图1所示。Ni粉形貌为较规则的椭球状。采用机械搅拌的方式将2种粉末充分混合20 min,然后在105 ℃条件下干燥1 h。

图1 粉末形貌

1.2 试样制备及热处理

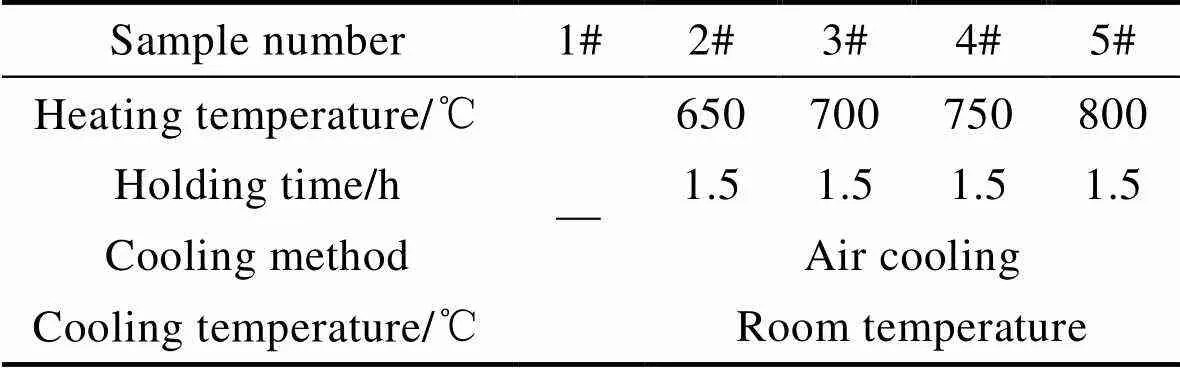

熔覆前,对Q235基体进行除锈和烘干。将烘干的Ni/316L粉末从烘干机中取出,置于送粉器中。高速激光熔覆设备由激光器、冷水机、送粉器、计控操纵台和计算机控制器等设备组成,激光熔覆参数见表1。待熔覆好的试样冷却后取出,利用电火花式线切割将试样切割成15 mm×15 mm×10 mm的金相试样,并用丙酮清洗。热处理温度分别为650、700、750、800 ℃,保温时间为1.5 h,而后空冷至室温,热处理参数见表2。

表1 高速激光熔覆工艺参数

Tab.1 Parameters of high-speed laser cladding process

表2 热处理参数

Tab.2 Parameters of heat treatment

1.3 显微组织与物相表征

热处理结束后,用金相镶嵌机镶嵌试样。用100#—2000#的砂纸对试样进行打磨,并抛光,再用王水腐蚀熔覆层,采用TESCAN-VEGA Ⅱ XMU型扫描电镜及OXFORD-7718型能谱仪对熔覆层进行形貌观察和元素分析。用熔覆层断面图片法来统计熔覆层的孔隙率,选取10个以上随机区域(不能重复)孔隙率的平均值。热处理结束后,用粗砂纸将熔覆层表面犁沟磨平,清洗后用XRD-6000型X射线衍射仪(XRD)对熔覆层表面进行物相表征,选用辐射波长为0.154 06 nm的Cu–K作为α靶材,测量角度为10°~90°。

1.4 力学性能表征

采用HRD-1000TMC/LCD型硬度计测试熔覆层硬度,设置保荷时间为15 s,载荷为300 g,测试温度为室温。同一热处理参数试样测试3个点,取平均值,测试点之间的距离为0.2 mm。

1.5 磨损性能测试

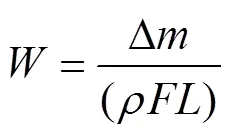

试样在模拟海水环境中的摩擦磨损示意图见图2。采用MMX-3G型多功能摩擦磨损试验机进行海水环境中的磨损试验,接触形式为销–盘滑动摩擦方式,磨损试样为销柱(4.8 mm×12.7 mm),对磨试样为GCr15钢,其尺寸为54 mm×38 mm×10 mm。磨损试验参数见表3。为模拟涂层在海水中的摩擦磨损行为,根据文献研究[25],本文的摩擦磨损试验在3.5% NaCl溶液中进行。试验后分别用丙酮、酒精超声 清洗试样,时间均为10 min。吹干后称量试样质量,采用SHIMADZU-AUW220D型分析天平(精度为0.1 mg)称量试样磨损前后的质量,并计算质量损失∆,通过式(1)计算磨损率[26]。

式中:W为磨损率,10–6 mm3/(N·m);Δm为磨损质量损失,g;ρ为密度,g/mm3;F为施加载荷,N;L为磨损距离,m。

表3 磨损试验参数

Tab.3 Parameters of the wear test

2 结果及分析

2.1 物相分析

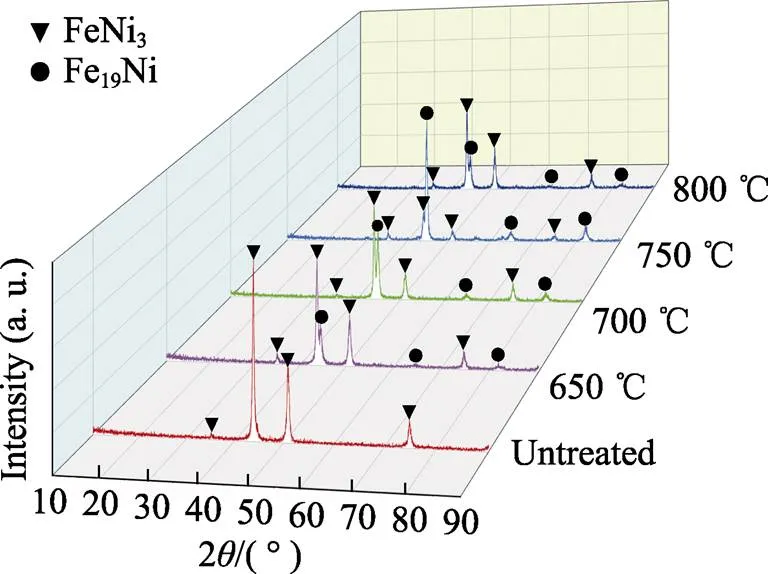

不同热处理温度下Ni/316L不锈钢涂层的XRD图谱见图3。结果表明,原始涂层由FeNi3单一相组成,涂层中Cr、Mo等元素以固溶的形式存在。因此,高速激光熔覆态Ni/316L涂层以FeNi3相为主,热处理过程中,涂层析出第二相。分析结果表明,4种不同热处理温度下,涂层生成的新相相同,均为Fe19Ni相。同时,基于各图谱的峰强比可知,随着热处理温度升高,Fe19Ni含量先增多、后减少。在750 ℃时,第二相的含量达到最大值。热处理过程中,温度升高,原子扩散能力增强,可显著提升新相的形成速率,但是过高的温度会导致形成的第二相发生一定程度的溶解[27]。因此,在800 ℃以内,涂层第二相的成分与热处理温度无关,但其含量取决于热处理温度。研究表明,加热到一定温度,Fe原子在固溶点阵的一定区域内聚集组成Fe19Ni相,使其硬度高于母相[28]。第二相硬度高于基体相时,能够大幅提高涂层的硬度与耐磨性能,温度持续升高会导致析出强化效果降低,涂层的峰值硬度逐渐降低,导致耐磨性减弱[29]。Fe19Ni相先增加、后减少,会使得涂层硬度先达到峰值,然后逐渐降低,耐磨性先增强、后减弱。

图3 不同热处理温度时Ni/316L熔覆层表面的XRD图谱

2.2 熔覆层形貌特征

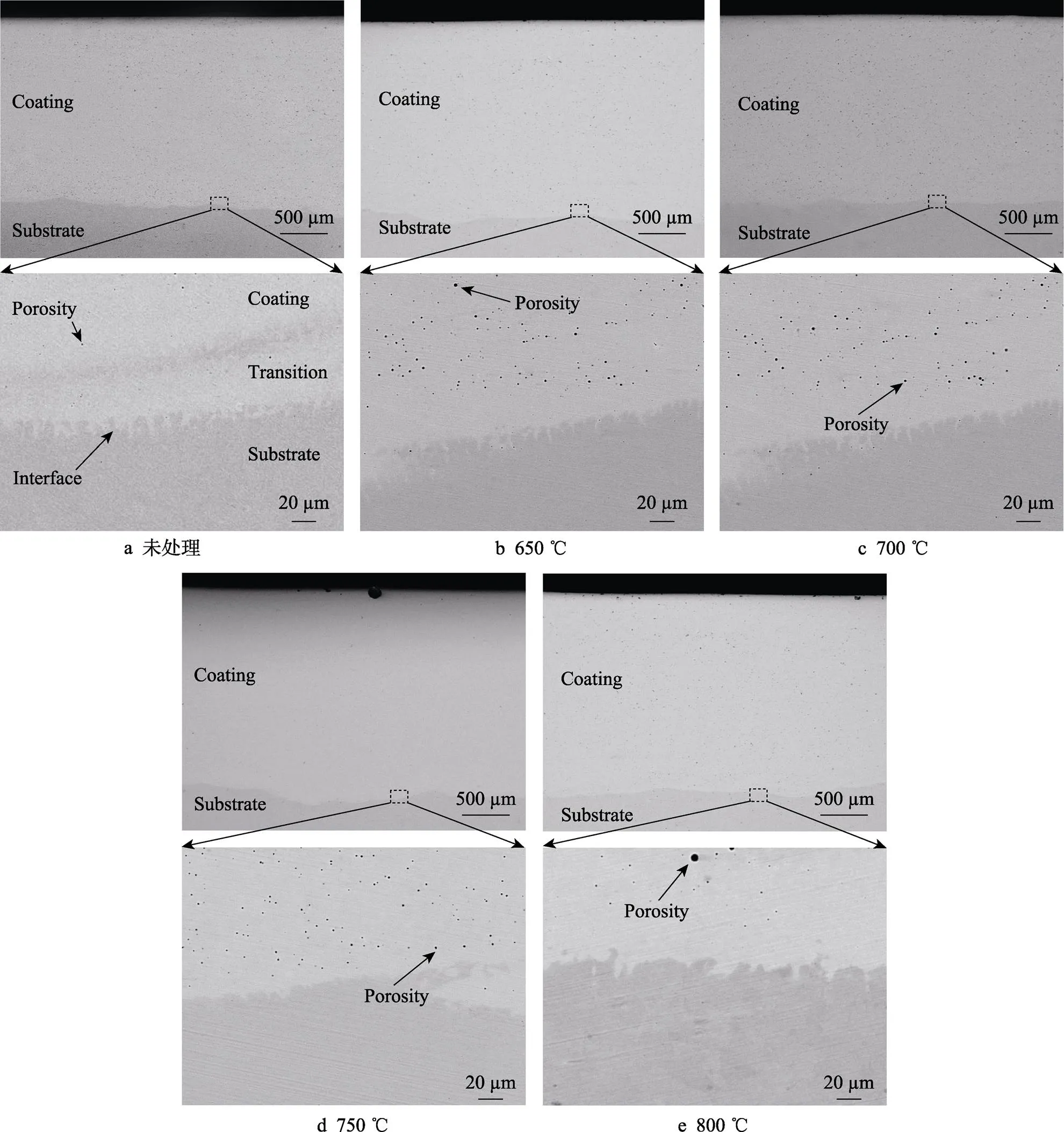

不同热处理熔覆层截面形貌如图4所示。由图4a低倍形貌可知,涂层与基体结合紧密,涂层厚度约为2 mm,致密均匀,无明显缺陷,但是高倍形貌显示,涂层内部出现了一定数量的气孔。这主要是由于高速激光熔覆扫描速率高,涂层凝固速率快,气体来不及逸出导致[30-31]。界面结合处呈现细微波浪状,出现厚度约50 μm的过渡层,高速激光熔覆制备Ni/316L涂层能够与基体达到冶金结合。图4b—e分别是热处理650、700、750、800 ℃涂层的截面形貌。在高倍镜下可以看出,界面结合程度高,结合处附近有细小的孔隙。孔隙主要集中在靠近熔覆层一侧,没有贯穿界面,说明高速激光熔覆在基体上方形成熔池,并快速凝固,与基体结合形成熔覆层。结合图4a—e低倍形貌可知,热处理工艺对涂层厚度无影响。通过分析测定和计算熔覆层界面结合处的孔隙率,发现5组试样的孔隙率均在1.00%左右。结合图4a可知,热处理及其参数对高速激光熔覆过程中产生的孔隙没有影响。激光增材制造过程中产生的孔隙无法避免,可以通过选择合适的送粉速度、在高温保护气体中干燥粉末或者在粉末中添加少量稀土元素等方法,将孔隙控制在标准范围内,从而提高熔覆质量[32]。

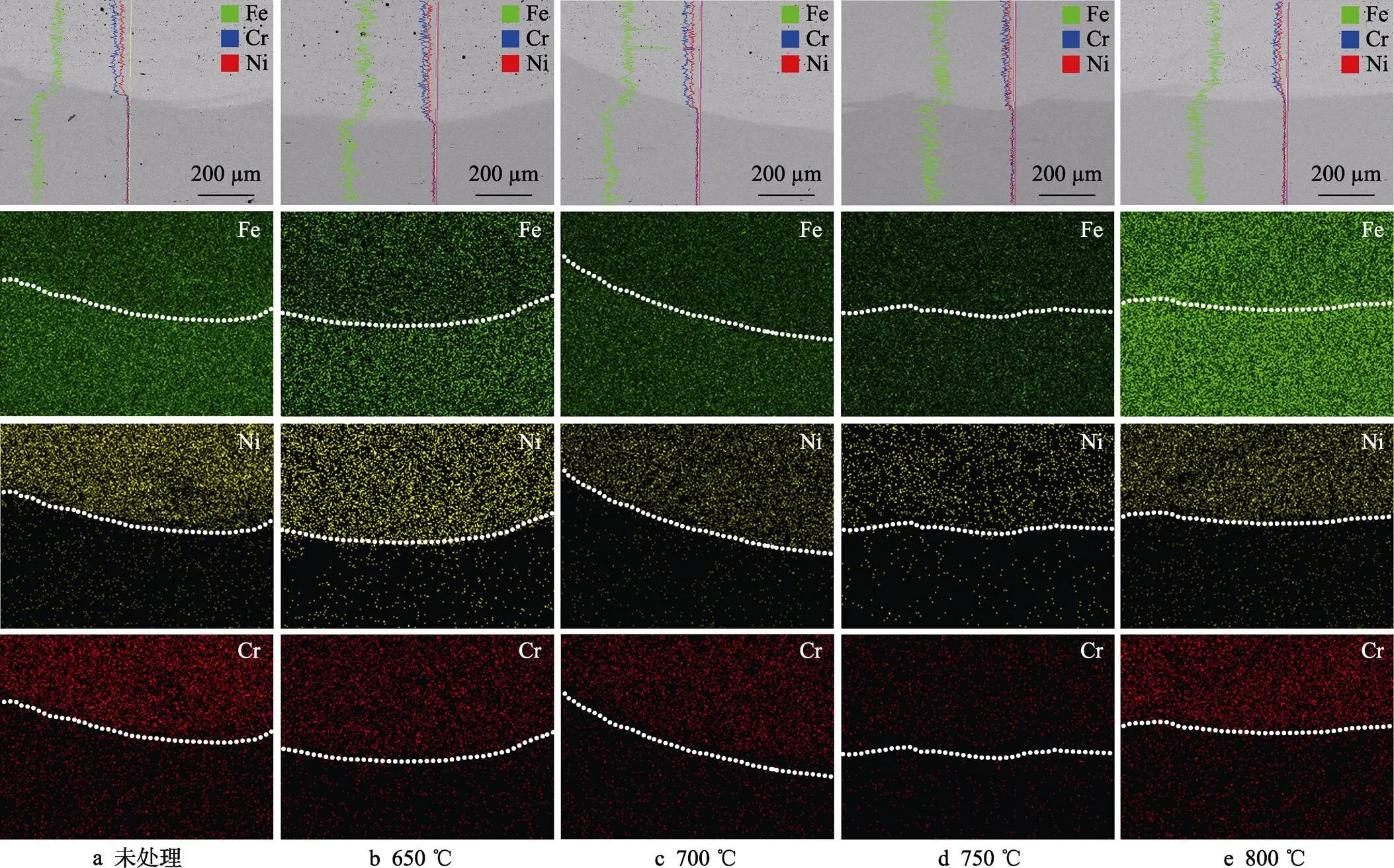

不同热处理条件下熔覆层与基体的能谱分析与元素分布如图5所示。涂层区3种主要元素(Fe、Cr、Ni)含量稳定,基体中主要以Fe元素为主,同时Fe元素相对强度变化曲线连续,且靠近基体一侧远高于熔覆层。由线扫可知,5种热处理温度下的基材与熔覆层界面附近均存在元素波动;由面扫可知,Fe、Cr、Ni元素分别在熔覆层和基体中均匀分布,无明显偏聚现象。热处理之后,熔覆层中的Cr、Ni元素并没有向基体扩散,这就充分保证了涂层的力学性能,热处理温度的变化对熔覆层和基体整体元素分布基本没有影响。

图4 不同热处理温度下熔覆层断面形貌

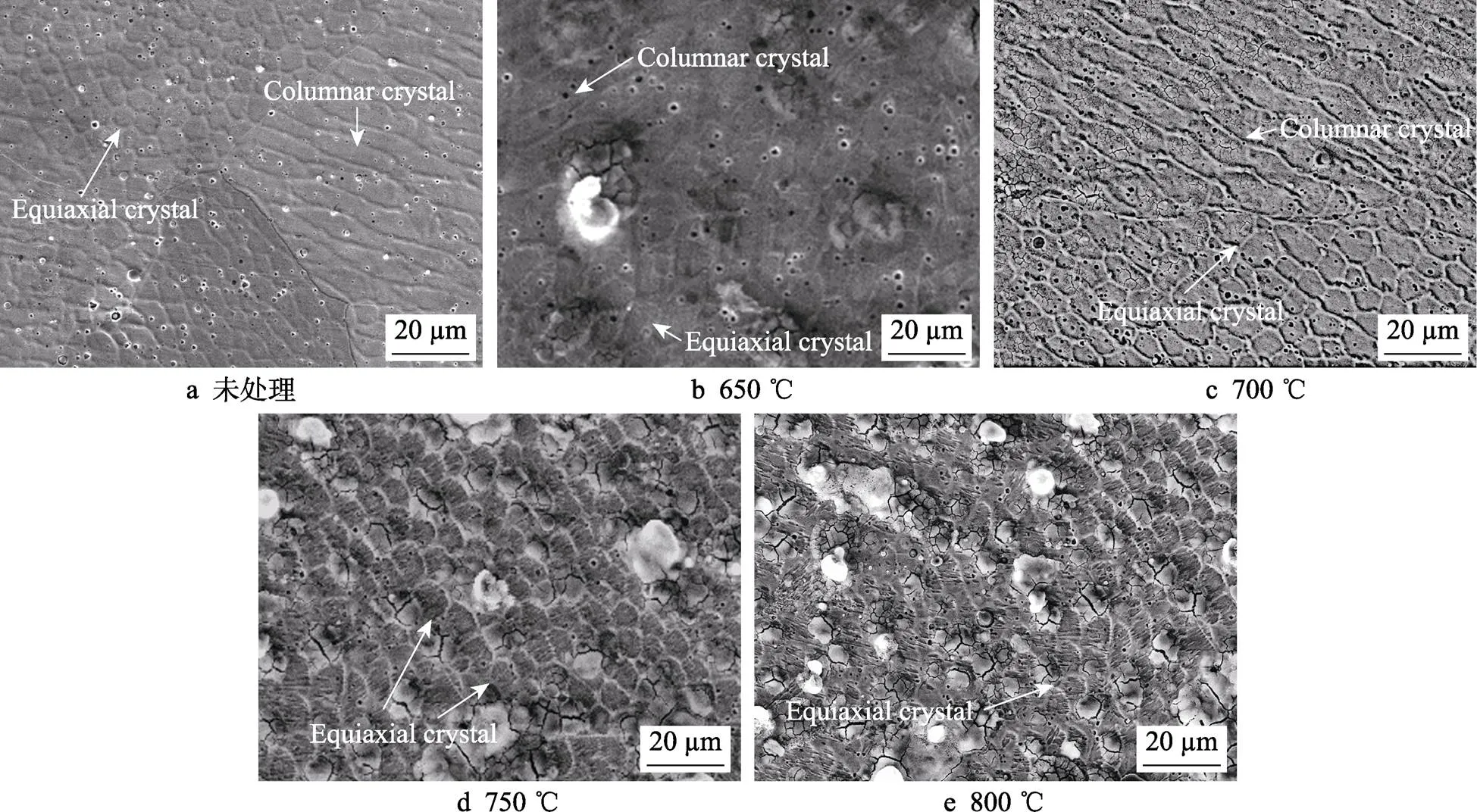

不同热处理温度后涂层中部显微组织的SEM形貌如图6所示。不锈钢涂层中间呈现粗细不一的柱状晶,在周围还出现了等轴晶粒。经热处理涂层的晶界比熔覆态涂层的晶界明显,棒状结构有逐渐分离的趋势,晶界间的距离变短。随着热处理温度升高,晶粒尺寸先降低、后增加。在750 ℃时,晶粒最为均匀细小。温度达到800 ℃时,相比750 ℃,晶粒有所增大。等轴晶粒结构能够显著提高材料的硬度及耐磨性,温度升高,均匀细小的等轴晶数量增多,使得材料的硬度及耐磨性大幅提高。温度继续升高,使析出强化效果下降,从而导致硬度与耐磨性下降[33-34]。

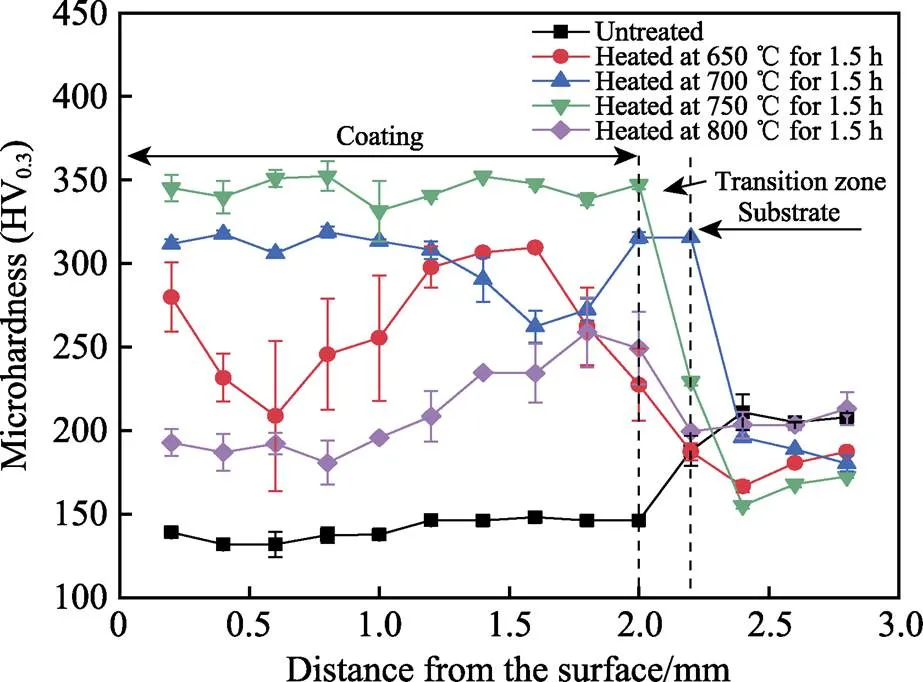

2.3 显微硬度

不同热处理工艺下,高速激光熔覆Ni/316L复合涂层的显微硬度分布如图7所示,分为熔覆层、过渡区和基体3个区。熔覆态涂层硬度明显比基体硬度低(最高值约为149.7HV0.3),过渡区的硬度介于基体硬度和熔覆层硬度之间。经热处理的4种涂层,硬度均高于熔覆态涂层,且随着热处理温度升高,涂层硬度先增大、后减小,750 ℃时硬度最高(最高值约为361.3HV0.3),约是熔覆态涂层硬度的2.4倍。结合XRD图谱和熔覆层形貌特征分析,750 ℃时Fe19Ni相的峰强最高,较小等轴晶粒分布均匀,使涂层的硬度大大提升,说明750 ℃保温1.5 h的热处理工艺具有良好的涂层强化效果。800 ℃时析出强化效果明显降低,Fe19Ni相数量减少,高温导致晶粒粗化,相同区域面积下的等轴晶数量较750 ℃变少,进而使得熔覆层显微硬度下降。

图5 不同热处理温度下熔覆层与基体的元素分布

图6 不同热处理温度后涂层中部的SEM形貌

2.4 熔覆层在模拟海水环境中的摩擦磨损行为

不同热处理温度下,Ni/316L涂层在海水环境中磨损形貌如图8所示。发现750 ℃的涂层磨损表面相对轻微,Fe19Ni相增多和晶粒细化能提高了涂层耐磨性,与前述分析结果一致。其他4种熔覆层磨损后的形貌大致相同,可以明显看到磨损后的熔覆层表面有裂纹、分层、犁沟和剥落。磨损形成的磨粒保留在磨痕处和周边时,会进入到涂层与摩擦副之间,形成磨粒磨损,导致涂层磨损率上升[35]。一方面,海水具有腐蚀性,不锈钢涂层在海水中首先形成一层钝化膜,磨损时导致钝化膜被破坏,进而加剧腐蚀,导致裂纹拓展。当裂纹拓展到一定程度时,会在此基础上剥落,并且在滑动摩擦的作用下,多个裂纹不断拓展和贯穿,最终产生层层剥落的现象[36]。另一方面,GCr15钢在海水中的耐蚀性很差,GCr15的硬度高于熔覆层,快速腐蚀后的产物在滑动摩擦时形成磨屑颗粒,进入到涂层与摩擦副之间,产生三体磨损,对熔覆层产生连续切削作用,表现为典型的磨粒磨损[37]。同时,在200 N的高载荷下,涂层表面产生塑性变形,切削后的磨屑和颗粒进入到滑动摩擦之中,导致切削作用加剧,形成一道道犁沟与塑性变形导致的外翻形貌,总体呈现出磨粒磨损特征。

图7 不同热处理温度下高速激光熔覆Ni/316L涂层的显微硬度分布

图8 不同热处理温度下Ni/316L复合涂层表面磨损形貌

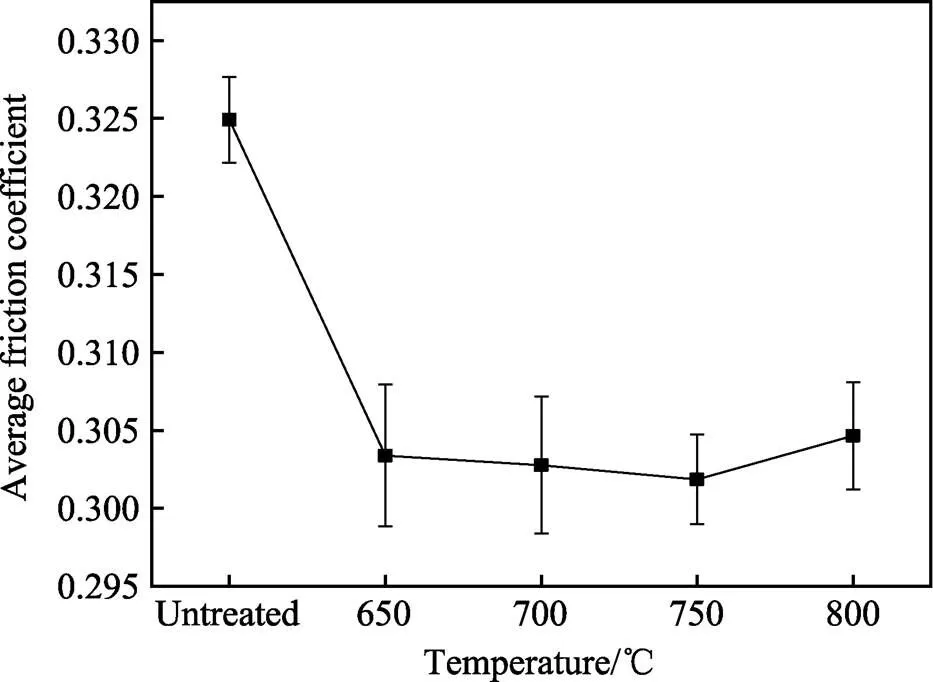

不同热处理工艺下,熔覆层的摩擦系数如图9所示。熔覆态涂层的摩擦系数约为0.33,4种热处理的涂层摩擦系数均低于熔覆态涂层,约为0.31。因此,通过改变Ni/316L涂层的相含量与晶粒大小,可以降低涂层在海水环境中的摩擦系数。

图9 不同热处理温度下熔覆层摩擦系数

不同热处理温度下Ni/316L涂层的磨损率如图10所示。750 ℃热处理涂层的磨损率(1.67×10–6mm3·N–1·m–1)最低,熔覆态涂层的磨损率(8.07×10–6mm3·N–1·m–1)最高,约为750 ℃热处理涂层的5倍。结合XRD图谱和显微硬度分析,发现Fe19Ni相数量越多,熔覆层的硬度越高,其磨损率越低。4组连续温度区间的磨损率表现出先降低、后升高的趋势,这与显微硬度结果一致。800 ℃的高温热处理在一定程度上影响了涂层的耐磨性。高温时晶粒长大,Fe19Ni相数量减少,导致涂层的耐磨性下降[38]。因此,涂层在750 ℃下经过1.5 h热处理后表现出更优异的耐磨性能,4种不同热处理工艺都能起到提高熔覆层耐磨性能的效果。

图10 不同热处理温度下熔覆层磨损率

3 结论

1)本文试验条件下,高速激光熔覆Ni/316L复合涂层厚约2 mm,过渡层约为50 μm,熔覆层具有致密、低孔隙、无裂纹等特点。

2)熔覆层孔隙率与热处理温度影响无关。熔覆态涂层以FeNi3相为主,热处理后涂层出现Fe19Ni相,且随着热处理温度升高,Fe19Ni相含量先增多、后减少。与新相含量变化趋势类似,随着温度升高,晶粒尺寸先减小、后增大。这导致涂层硬度先增大、后减小,在750 ℃时达到峰值硬度361.3HV0.3。

3)熔覆层热处理后在海水环境中的摩擦系数降低。在本文的模拟海水环境中,5种熔覆层的磨损机理相同,均以磨粒磨损为主。因此,硬度最高,对应750 ℃热处理涂层的磨损率最低,耐磨性最好。

[1] PORCHETTA S, CARLESI T, VETRANO M R, et al. Experimental Investigation of the Airflow Structure above Mechanically Generated Regular Waves for both Aligned and Opposed Wind-Wave Directions[J]. Experimental Thermal and Fluid Science, 2022, 133: 110578.

[2] LI Yang, LIAN Ying, SUN Yan-jun. Comparison of Cavitation Erosion Behaviors between the As-Cast and Friction Stir Processed Ni-Al Bronze in Distilled Water and Artificial Seawater[J]. Journal of Materials Research and Technology, 2021, 13: 906-918.

[3] LIU Meng-yue, LI Shao-nan, WANG Hao, et al. Research Progress of Environmentally Friendly Marine Antifouling Coatings[J]. Polymer Chemistry, 2021, 12(26): 3702-3720.

[4] LI Xue-wu, SHI Tian, LI Ben, et al. Subtractive Manufacturing of Stable Hierarchical Micro-Nano Structures on AA5052 Sheet with Enhanced Water Repellence and Durable Corrosion Resistance[J]. Materials & Design, 2019, 183: 108152.

[5] TSUGE S. Recent Advances in Stainless Steel[J]. Encyclopedia of Materials: Metals and Alloys, 2022, 2:200-207.

[6] 张津超, 石世宏, 龚燕琪, 等. 激光熔覆技术研究进展[J]. 表面技术, 2020, 49(10): 1-11.

ZHANG Jin-chao, SHI Shi-hong, GONG Yan-qi, et al. Research Progress of Laser Cladding Technology[J]. Surface Technology, 2020, 49(10): 1-11.

[7] 徐海岩, 李涛, 李海波, 等. 316L激光熔覆质量预测及路径选择研究[J]. 激光技术, 2018, 42(1): 53-59.

XU Hai-yan, LI Tao, LI Hai-bo, et al. Study on Quality Prediction and Path Selection of 316L Laser Cladding[J]. Laser Technology, 2018, 42(1): 53-59.

[8] DEHGHANI A, ASLANI F. A Review on Defects in Steel Offshore Structures and Developed Strengthening Techniques[J]. Structures, 2019, 20: 635-657.

[9] 邓德伟, 陈蕊, 张洪潮. 等离子堆焊技术的现状及发展趋势[J]. 机械工程学报, 2013, 49(7): 106-112.

DENG De-wei, CHEN Rui, ZHANG Hong-chao. Present Status and Development Tendency of Plasma Transferred Arc Welding[J]. Journal of Mechanical Engineering, 2013, 49(7): 106-112.

[10] PARTES K, SEPOLD G. Modulation of Power Density Distribution in Time and Space for High Speed Laser Cladding[J]. Journal of Materials Processing Technology, 2008, 195(1-3): 27-33.

[11] PARTES K, SEEFELD T, SEPOLD G, et al. High Efficiency Laser Cladding at Elevated Processing Speed [C]//International Congress on Applications of Lasers & Electro-Optics. Miami, Florida, USA: Laser Institute of America, 2005.

[12] 王慧琳, 郭亚雄, 蓝宏伟, 等. 光斑类型对激光熔覆MoFeCrTiWAlNb高熔点高熵合金涂层组织和性能的影响[J]. 表面技术, 2019, 48(6): 130-137.

WANG Hui-lin, GUO Ya-xiong, LAN Hong-wei, et al. Effect of Spot Type on Microstructure and Properties of MoFeCrTiWAlNb Refractory High-Entropy Alloy Coating Fabricated by Laser Cladding[J]. Surface Technology, 2019, 48(6): 130-137.

[13] LI Li-qun, SHEN Fa-ming, ZHOU Yuan-dong, et al. Comparative Study of Stainless Steel AISI 431 Coatings Prepared by Extreme-High-Speed and Conventional Laser Cladding[J]. Journal of Laser Applications, 2019, 31(4): 042009.

[14] CHEN J L, LI J, SONG R, et al. Effect of the Scanning Speed on Microstructural Evolution and Wear Behaviors of Laser Cladding NiCrBSi Composite Coatings[J]. Optics & Laser Technology, 2015, 72: 86-99.

[15] SCHOPPHOVEN T, GASSER A, BACKES G. EHLA: Extreme High-Speed Laser Material Deposition[J]. Laser Technik Journal, 2017, 14(4): 26-29.

[16] KELBASSA I, GASSER A, MEINERS W, et al. High Speed LAM[C]//International Photonics and Optoelectronics Meetings. Wuhan: OSA, 2012.

[17] SCHOPPHOVEN T, GASSER A, WISSENBACH K, et al. Investigations on Ultra-High-Speed Laser Material Deposition as Alternative for Hard Chrome Plating and Thermal Spraying[J]. Journal of Laser Applications, 2016, 28(2): 022501.

[18] YUAN Wu-yan, LI Rui-feng, CHEN Zhao-hui, et al. A Comparative Study on Microstructure and Properties of Traditional Laser Cladding and High-Speed Laser Cladding of Ni45 Alloy Coatings[J]. Surface and Coatings Technology, 2021, 405: 126582.

[19] 董会, 姚建洮, 周勇, 等. 碳钢表面等离子喷涂NiCrAl涂层的耐蚀性能研究[J]. 热加工工艺, 2017, 46(22): 135-138.

DONG Hui, YAO Jian-tao, ZHOU Yong, et al. Research on Corrosion Resistance of Plasma-Sprayed NiCrAl Coating on Carbon Steel Surface[J]. Hot Working Technology, 2017, 46(22): 135-138.

[20] WANG Z B, HU H X, ZHENG Y G. Synergistic Effects of Fluoride and Chloride on General Corrosion Behavior of AISI 316 Stainless Steel and Pure Titanium in H2SO4Solutions[J]. Corrosion Science, 2018, 130: 203-217.

[21] 张海瑜, 王芙蓉, 杜双明, 等. Ni元素对等离子喷涂铁基涂层组织和摩擦磨损性能的影响[J]. 矿冶工程, 2021, 41(4): 150-155.

ZHANG Hai-yu, WANG Fu-rong, DU Shuang-ming, et al. Effect of Ni Element on Microstructure and Tribological Properties of Plasma Sprayed Iron-Based Coatings[J]. Mining and Metallurgical Engineering, 2021, 41(4): 150-155.

[22] 陆小龙, 刘秀波, 余鹏程, 等. 后热处理对304不锈钢激光熔覆Ni60/h-BN自润滑耐磨复合涂层组织和摩擦学性能的影响[J]. 摩擦学学报, 2016, 36(1): 48-54.

LU Xiao-long, LIU Xiu-bo, YU Peng-cheng, et al. Effects of Post Heat-Treatment on Microstructure and Tribological Properties of Ni60/H-BN Self-Lubricating Anti-Wear Composite Coating on 304 Stainless Steel by Laser Cladding[J]. Tribology, 2016, 36(1): 48-54.

[23] VASHISHTHA N, SAPATE S G, BAGDE P, et al. Effect of Heat Treatment on Friction and Abrasive Wear Behaviour of WC-12Co and Cr3C2-25NiCr Coatings[J]. Tribology International, 2018, 118: 381-399.

[24] 付朗, 毛杰, 邓子谦, 等. PS-PVD制备锆酸钆热障涂层及其性能研究[J]. 表面技术, 2021, 50(10): 293-300.

FU Lang, MAO Jie, DENG Zi-qian, et al. Microstructure and Mechanical Properties of Gadolinium Zirconate Coatings Prepared by Plasma Spray-Physical Vapor Deposition[J]. Surface Technology, 2021, 50(10): 293-300.

[25] 王伟, 文怀兴, 陈威. 海水环境下材料摩擦学行为研究现状[J]. 材料导报, 2017, 31(11): 51-58.

WANG Wei, WEN Huai-xing, CHEN Wei. Research Status on Tribological Behaviors of Materials under Seawater Environment[J]. Materials Review, 2017, 31(11): 51-58.

[26] DU L M, LAN L W, ZHU S, et al. Effects of Temperature on the Tribological Behavior of Al0.25CoCrFeNi High- Entropy Alloy[J]. Journal of Materials Science & Technology, 2019, 35(5): 917-925.

[27] 胡家齐, 刘荣佩, 梁剑雄, 等. 调整处理对AM355不锈钢微观组织与力学性能的影响[J]. 金属热处理, 2015, 40(6): 91-96.

HU Jia-qi, LIU Rong-pei, LIANG Jian-xiong, et al. Effects of Intermediate Treatment on Microstructure and Mechanical Properties of AM355 Stainless Steel[J]. Heat Treatment of Metals, 2015, 40(6): 91-96.

[28] 吕昭平, 蒋虽合, 何骏阳, 等. 先进金属材料的第二相强化[J]. 金属学报, 2016, 52(10): 1183-1198.

LU Zhao-ping, JIANG Sui-he, HE Jun-yang, et al. Second Phase Strengthening in Advanced Metal Materials[J]. Acta Metallurgica Sinica, 2016, 52(10): 1183-1198.

[29] 卜林森, 王敏, 郝庆国, 等. 一种析出强化型Fe-C-Mn- Ni奥氏体合金钢的微观组织和力学性能[J]. 机械工程材料, 2020, 44(8): 57-62.

BU Lin-sen, WANG Min, HAO Qing-guo, et al. Microstructure and Mechanical Properties of a Precipitate- Hardened Fe-C-Mn-Ni Austenitic Alloy Steel[J]. Materials for Mechanical Engineering, 2020, 44(8): 57-62.

[30] LU Yi, SUN Gui-fang, XIAO Xian-feng, et al. In Suit Monitoring of Solidification Mode, Porosity and Clad Height during Laser Metal Deposition of AISI 316 Stainless Steel[J]. Journal of Manufacturing Processes, 2021, 68: 1705-1713.

[31] ZENG Chao, TIAN Wei, LIAO Wen he, et al. Microstructure and Porosity Evaluation in Laser-Cladding Deposited Ni-Based Coatings[J]. Surface and Coatings Technology, 2016, 294: 122-130.

[32] YANG Zhi-xiang, WANG Ai-hua, WENG Zhi-kun, et al. Porosity Elimination and Heat Treatment of Diode Laser- Clad Homogeneous Coating on Cast Aluminum-Copper Alloy[J]. Surface and Coatings Technology, 2017, 321: 26-35.

[33] CHOI S W, LI Cheng-lin, WON J W, et al. Deformation Heterogeneity and Its Effect on Recrystallization Behavior in Commercially Pure Titanium: Comparative Study on Initial Microstructures[J]. Materials Science and Engineering: A, 2019, 764: 138211.

[34] YANG Jiao-xi, BAI Bing, KE Hua, et al. Effect of Metallurgical Behavior on Microstructure and Properties of FeCrMoMn Coatings Prepared by High-Speed Laser Cladding[J]. Optics & Laser Technology, 2021, 144: 107431.

[35] 赵万新, 周正, 黄杰, 等. FeCrNiMo激光熔覆层组织与摩擦磨损行为[J]. 金属学报, 2021, 57(10): 1291-1298.

ZHAO Wan-xin, ZHOU Zheng, HUANG Jie, et al. Microstructure and Frictional Wear Behavior of FeCrNiMo Alloy Layer Fabricated by Laser Cladding[J]. Acta Metallurgica Sinica, 2021, 57(10): 1291-1298.

[36] DIOMIDIS N, CELIS J P, PONTHIAUX P, et al. Tribocorrosion of Stainless Steel in Sulfuric Acid: Identification of Corrosion-Wear Components and Effect of Contact Area[J]. Wear, 2010, 269(1-2): 93-103.

[37] ZHANG Q Y, WANG S Q, ZHOU Y, et al. Artificial Oxide-Containing Tribo-Layers and Their Effect on Wear Performance of Ti-6Al-4V Alloy[J]. Tribology International, 2017, 105: 334-344.

[38] GONG Fu-bao, SHEN Jun, GAO Run-hua, et al. Influence of Heat Treatment on Microstructure and Mechanical Properties of FeCrNi Coating Produced by Laser Cladding[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(8): 2117-2125.

Effect of Heat Treatment Temperature on Microstructure and Friction and Wear Properties of High-speed Laser Cladded Ni/316L Coating

,,,

(Xi'an Key Laboratory of High Performance Oil and Gas Field Materials, School of Material Science and Engineering, Xi'an Shiyou University, Xi'an 710065, China)

The effect of heat treatment temperature on the wear resistance of high-speed laser cladded Ni/316L coatings in seawater corrosive environment was illustrated in this case. Ni/316L coatings were prepared on the surface of Q235 steel by high-speed laser cladding equipment, and heat-treated at 650, 700, 750 ℃, and 800 ℃ for 1.5 h, respectively. X-ray diffraction (XRD), scanning electron microscope (SEM) The microstructure and phase composition of the Ni/316L cladding layer were characterized by energy dispersive spectrometer (EDS). In addition, the effect of heat treatment temperature on the hardness and the wear resistance of the Ni/316L cladding layer was analyzed via hardness test and wear test in a simulated marine environment. The thickness of as-cladded layer is about 2 mm, and the transition layer is about 50 μm. The cladding layer has the characteristics of compactness, low porosity and crack free. The cladding coating grains contain dendrites and equiaxed grains. With the increase of heat treatment temperature, the number of equiaxed crystal in the coating first increased and then decreased, similar to that of the new phase content, the second phase content first increased and then decreased. Correspondingly, as the heat treatment temperature increased, the grain size of the cladding layer decreased first and then increased, resulting in the hardness of the cladding layer increased first and then decreased. The hardness of the cladding layer reached the highest value at 750 ℃, which was about 2.4 times that of the as-cladded coating. It was found that the friction coefficient of the four cladding layers after heat treatment is about 0.31, which is slightly lower than that of the cladding coating (0.33). The wear rate of the as-cladded coating was about 5 times higher than that of the coating heat-treated at 750 ℃. Under the high load of 200 N, the coating surface was plastically deformed, and the wear debris and particles after cutting enter into the sliding friction, resulting in cutting effect intensified, forming a valgus morphology caused by furrows and plastic deformation. The seawater is corrosive, and the stainless steel coating first forms a passivation film in seawater, which will be destroyed and will intensify corrosion and lead to crack expansion. On the other hand, the resistance of GCr15 steel in seawater the corrosion resistance is poor. The products after rapid corrosion formed abrasive particles during sliding friction, which enter the coating and the friction pair to produce three-body wear. As a result, the particles has a continuous cutting effect on the cladding layer. 5 kinds of coatings wear mechanisms are mainly the abrasive wear. The four different heat treatment processes all could improve the wear resistance of the cladding layer, while C shows a better wear resistance. Thethe coating heat-treated at 750 ℃microstructure and the number of second phases of the high-speed laser cladding Ni/316L coating changes with the heat treatment temperature. However, the high temperature leads to some problems, such as grain growth. Therefore, the heat treatment temperature of the high-speed laser cladding Ni/316L coating should be controlled below 750 ℃.

heat treatment; high-speed laser cladding;Ni/316L coating; marine environment; friction and wear

TG174.4

A

1001-3660(2022)05-0111-10

10.16490/j.cnki.issn.1001-3660.2022.05.012

2022–02–18;

2022–04–19

2022-02-18;

2022-04-19

陕西省自然科学基金(2020JM540);西安交通大学金属材料强度国家重点实验室项目(20202210);西安石油大学《材料科学与工程》省级优势学科项目(YS37020203);西安石油大学研究生创新与实践能力培养计划资助项目(YCS20212124)

The Natural Science Foundation of Shaanxi Province (2020JM540); State Key Laboratory of Metal Material Strength, Xi'an Jiaotong University (20202210); Provincial Advantage Discipline Project of Materials Science and Engineering, Xi'an Shiyou University (YS37020203); Foundation of Postgraduate Innovation and Practice Ability of Xi'an Shiyou University Graduate Innovation and Practice Ability Training Project (YCS20212124)

董会(1981—),男,博士,副教授,主要研究方向为材料表面涂层(隔热、耐蚀、耐磨涂层)技术。

DONG Hui (1981-), Male, Doctor, Associate professor, Research focus: coating (thermal barrier, anti-corrosion and anti-wear) technology on material.

董会, 郭鹏飞, 徐龙, 等. 热处理温度对高速激光熔覆Ni/316L涂层组织及摩擦磨损性能的影响[J]. 表面技术, 2022, 51(5): 111-120.

DONG Hui, GUO Peng-fei, XU Long, et al. Effect of Heat Treatment Temperature on Microstructure and Friction and Wear Properties of High-speed Laser Cladded Ni/316L Coating[J]. Surface Technology, 2022, 51(5): 111-120.

责任编辑:刘世忠