抗菌低表面能复合型海洋防污涂料的研究进展

2022-05-28刘思琪刘斌宁玉杰刘术辉解辉宋轶涵

刘思琪,刘斌,宁玉杰,刘术辉,解辉,宋轶涵

抗菌低表面能复合型海洋防污涂料的研究进展

刘思琪,刘斌,宁玉杰,刘术辉,解辉,宋轶涵

(北京化工大学 材料电化学过程与技术北京市重点实验室 材料科学与工程学院,北京 100029)

海洋生物污损给海洋工程与装备带来了巨大的困难与挑战,低表面能型海洋防污涂料由于环境友好,近年来已发展成为防污涂料研究与开发的重点。通过在低表面能防污涂料中引入抗菌剂,制备具有复合功能的防污涂料,可进一步提高涂料的综合防污能力。针对该技术背景,首先对海洋防污涂料的技术原理和低表面能防污涂料的研究现状进行了简要介绍,分析了该类型防污涂料的技术优势,同时提出了其静态防污能力差、对细菌型污损生物抗污性能弱的技术短板;然后,围绕低表面能防污涂料抗菌复合改性这一焦点问题,从添加型和结构型2种抗菌复合改性方式入手,分别阐述了各自涂料的适用抗菌剂种类、主要制备方式和改性后涂料综合防污性能的相关研究成果;在此基础上,梳理了以上2类抗菌复合防污涂料存在的问题,并提出了针对性的解决途径;最后,提出了无机抗菌剂、有机抗菌剂和天然抗菌剂应用于防污涂料的未来研究方向,并对抗菌低表面能复合型海洋防污涂料的发展与应用前景进行了展望。

抗菌;低表面能;功能复合;海洋防污涂料

海洋占据了地球表面约70%的面积,蕴藏着极其丰富的各类资源,包括矿物资源、化学资源、生物资源等,海洋资源的开发与利用具有广阔的发展前景,海洋经济和海洋产业对人类社会的发展起着极为重要的作用。走向海洋是中国经济继续发展的重要战略步骤。海洋环境的特殊性使海洋生物种类繁多,部分海洋生物常会附着在船舶水线以下或海洋设备的表面,带来一系列的严重问题,如使船舶速度降低、油耗增加、水下结构被腐蚀破坏、浮标及航海设施质量增加、设备移动部件失灵、水下管线阻塞等[1-2],因此如何有效避免海洋生物污损是目前海洋科学领域的热点和难点问题。目前机械防污、电化学防污、超声波防污、涂层防污等防污技术均已得到实际应用,而在海洋装备或设备表面涂覆防污涂料,仍是解决海洋生物污染问题的重要技术途径。

海洋生物污损防护技术的需求与目前防污技术的发展水平呈现较为明显的不对称性,即防污需求日益迫切,技术要求日益提高,技术挑战性越来越大,而防污技术的研究与开发则难以与之匹配。近年来,低表面能防污涂料相关工艺由于具有环境友好性而取得了较快发展,也逐渐发展成为国际海洋防污的主流。但是,低表面能防污涂料尚存在一些技术短板,其中静态防污能力差、对细菌型污损生物抗污性能弱限制了其进一步的应用和发展。海洋生物附着的初始阶段是细菌等微生物的附着和繁殖,通过向低表面能涂料中引入抗菌剂,制备具有抗菌复合功能的防污涂料,可从源头抑制海洋生物的污染,提高涂料的防污性能。文中针对该技术背景,对抗菌型低表面能海洋防污涂料的研究进展进行了系统分析与评述。

1 海洋防污涂料技术

理想的防污涂料可提供一个在有效期内无生物附着的表面,起到防止海生物附着的作用,其防污的基本原理可分为2种:一种是防污涂层材料中释放出可杀死或干扰海生物幼体生长的物质,阻止污损生物在其表面生长;另一种是依据污损生物在附着过程中对涂层材料表面结构的选择性,来开发具有某些表面物理特性的材料,阻止污损生物在其表面附着生长[3-4]。

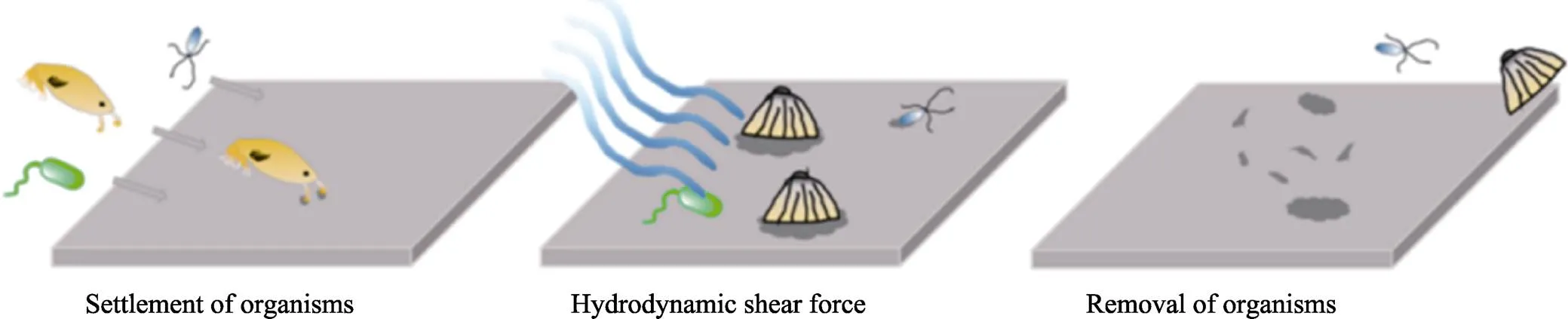

传统防污涂料中的防污剂通常为毒性较大的有机物、重金属及其化合物,但这些防污剂的大量使用严重污染了海洋环境,因而逐渐被禁用[5-6]。目前,国内外海洋船舶防污涂料的研究方向为环保低毒或无毒的防污涂料,主要包括:无锡自抛光防污涂料;以有机硅、有机氟聚合物为主的低表面能防污涂料;以生物激素或生物酶等为防污剂的生物防污涂料及仿生防污涂料;通过电解海水防污的导电防污涂料;以可溶性硅酸盐为主的高碱性表面无毒防污涂料等[7-9]。其中低表面能涂料的防污原理为利用涂层较低的表面能并在水流剪切力的共同作用下达到防污的效果(见图1),其实施过程中没有任何有毒物质的释放,是目前无毒环保海洋防污涂料领域的重点研究方向。

图1 低表面能防污涂料作用原理示意图[10]

2 低表面能防污涂料的研究现状

低表面能防污涂料具有很低的表面能,海洋生物难以在上面附着,即使附着后在水流或其他外力作用下也很容易脱落。因此,低表面能防污涂料可防止海洋生物附着,不存在毒性物质的释放,能起到长期防污的作用[11-12]。由Baier曲线(见图2)可知,材料表面的相对附着力随表面能的增大呈现出先减小后增大的趋势,约在20~25 mJ/m2时达到最低值。

图2 Baier曲线[13]

低表面能防污涂料自身性质对防污效果影响很大,除较低的表面能外,性能优良的低表面能涂料还需要具备以下特性:较高的链段柔性,有助于活性链段迁移到涂层表面;较低的弹性模量,利于已附着的污损生物在较小的外力作用下以剥离的方式脱落;适宜的涂层厚度,以降低附着生物脱落的临界剥离力;光滑的表面,避免因为涂层表面存在微孔等粗糙结构使污损生物附着[13-14]。船用低表面能防污涂料主要分为有机硅系列和有机氟系列,如聚硅氧烷、含氟聚氨酯、硅氧烷聚氨酯、氟有机硅等[15-17]。

有关有机硅低表面能涂料树脂的研究非常活跃,主要可分为向树脂中添加小分子硅油和对树脂基体进行有机硅改性2种类型。添加小分子硅油操作简单,且经测试发现硅油能够迁移到涂料表面,有效降低部分海洋生物的附着率,但硅油的种类和添加量会影响涂料的防污性能和力学性能,且使用过程中硅油会不断渗出造成海水污染以及防污效果的减退[13]。改性硅树脂尽管制备操作复杂且成本较高,但获得的涂料防污效果优良,使用寿命长,因而逐步受到研究人员的重视。

最简单的有机硅聚合物是聚硅氧烷,主链中的硅氧键使其具有优良的憎水性和耐候性,表现出优良的防污性能[18-19]。但聚硅氧烷力学性能较差和基体的黏结性能不好等问题导致其应用受到一定限制,而通过共混共聚、接枝等方法,用其他树脂对硅树脂进行改性可以解决该问题,例如借助聚氨酯改性硅树脂来提高力学性能,借助环氧树脂改性硅树脂来提高耐热性和对底材的附着力,借助丙烯酸树脂改性硅树脂来提高耐溶剂性等[20-23]。董耀华等[24]在丙烯酸树脂中引入聚硅氧烷侧链,经表征发现涂层具有良好的低表面能防污特性。Zhang等[25]、Sommer等[26]、Naghash等[27]发现聚硅氧烷–聚氨酯树脂涂层力学性能优良,同时具备优良的低表面能防污特性,但对有机硅树脂的改性过程可能会对涂料本身的性能产生影响,因而如何平衡改性有机硅涂料的防污性能与力学性能是目前研究的重点之一。

聚四氟乙烯的水接触角高达114°,但由于其涂层致密性差,表面有大量微孔,很容易被微生物附着,因而不能直接用于防污涂料,需借助其他树脂作为载体。国内外研究人员发现将聚四氟乙烯等氟化物添加至聚氨酯、环氧树脂中,制备出的涂料具有优良的防污性能[24]。将有机氟引入树脂基体的分子链中,利用氟原子电负性大、键能高的特点,使含氟树脂中的碳原子被氟原子包围,可以提高树脂的疏水性[28-29],如全氟烷基丙烯酸乙酯改性的丙烯酸树脂具有良好的硬度、抗冲击性能和较低的表面能[30]。然而有机氟树脂价格昂贵、成型温度高,且含氟树脂中的碳链刚性较大,清理表面附着的生物时需要较高的能量,因此在实际应用中也存在诸多限制[31]。

将有机硅和有机氟综合运用可以有效改善防污涂层的综合性能。有研究人员研发出了一种新型低表面能防污材料氟代聚硅氧烷[28],主链中的硅氧键具备高弹性和高流动性,侧链的含氟基团显著降低了材料的表面能,因而兼有机硅树脂和氟树脂的优良防污性能。Sun等[32]发现在丙烯酸树脂中同时引入有机硅和有机氟,得到的涂层综合性能较为优良。

低表面能防污涂料能够有效降低海洋生物的附着率,但其静态防污能力较差,对细菌等污损生物的防污效果较差。为了制备性能更加综合的防污涂料,研究人员开始尝试使用抗菌剂对低表面能涂料进行改性,得到的新型复合防污涂料能够从源头阻断海洋生物的附着过程,预期可获得更加优良的防污效果。

3 低表面能防污涂料的抗菌复合改性

低表面能防污涂料的技术已较为成熟,因此复合防污涂料的制备通常采用向低表面能涂料中引入合适的抗菌剂来实现。抗菌剂是具有杀菌或抑菌性能的化学试剂的统称,向涂料中引入合适的抗菌剂,能够有效提高涂料的抗菌性能。目前可以用作抗菌剂的物质主要分为无机抗菌剂、有机抗菌剂、天然抗菌剂等。

无机抗菌剂是利用银、铜、钛等金属及其离子的杀菌或抑菌功能制备的抗菌剂,根据抗菌机理的不同可分为以银系抗菌剂为代表的接触型抗菌剂和以氧化锌、二氧化钛为代表的光催化型抗菌剂2种。接触型抗菌剂中的金属离子在接触到细菌表面后,能够穿过细胞膜进入细菌内部,与细菌内部的羧基、羟基、氨基等官能团发生反应,使蛋白质变性,阻碍细菌的正常生命活动,从而达到杀菌效果[16,33]。光催化型抗菌剂在光的照射下发生电子跃迁,同时使周围环境中的水分子和氧气转化为羟基自由基和氧负离子,它们能够破坏细菌的细胞结构和细菌内的有机物,使其失去生命活性,达到杀菌的效果[33-34]。有机抗菌剂种类众多,主要有季铵盐、双胍类、酚、醇、异噻唑啉酮类等[33-35],其主要作用机理为通过化学作用破坏细菌的细胞膜等结构,例如季铵盐类抗菌剂或进入细菌内部破坏蛋白质等物质会影响其正常生命活动,从而起到杀菌作用,例如醇类抗菌剂[33,36-37]。天然抗菌剂是指直接从动植物或微生物中提取的具有抗菌活性的物质,是最早得到应用的抗菌剂,主要包括壳聚糖、鱼精蛋白、大蒜素、山梨酸等[33,35,38-39]。其中,壳聚糖及其衍生物是目前应用较为广泛的天然抗菌剂。研究表明,低分子的壳聚糖可以进入细菌内部,阻断细菌遗传物质的合成和转化,从而阻断细菌的繁殖;高分子的壳聚糖可以吸附在细菌表面,阻断细菌的物质交换,破坏细菌的细胞膜等结构,从而达到抗菌的目的[40-41]。

如何将较低的表面能和优良的抗菌作用结合起来制备性能更加综合的防污涂料,且不影响涂料的力学性能,是目前复合防污涂料的重点研究方向。根据向低表面能涂料中引入抗菌剂的方式不同,可分为添加型抗菌复合防污涂料和结构型抗菌复合防污涂料2种类型。

3.1 添加型抗菌复合防污涂料

最初得到应用的抗菌改性方式为将抗菌剂作为填料直接加入低表面能涂料基体中,制备出具有一定抗菌能力的新型复合防污涂料。制备添加型复合涂料的关键在于抗菌剂的选择,其中具有广谱杀菌效果且不易产生抗药性的无机金属抗菌剂是最常用的添加型抗菌剂。

Oktay等[42]将纳米银加入聚硅氧烷涂料中,在不影响涂层表面静态水接触角的同时,对大肠杆菌和金色葡萄球菌的杀菌率达到了99%以上。Zhai等[43]制备的疏水性全氟烷氧基树脂/纳米银涂层具备优良的低表面能特性和抗菌性能。李善文等[44]、Qu等[45]发现纳米二氧化钛改性的硅丙树脂涂料具有优良的复合防污效果。尤文卉[46]在氟硅改性的丙烯酸乳液中引入载银二氧化钛粉末,在改善涂层表面粗糙度、提高水接触角的同时,大幅提高了涂料的抗菌性能。

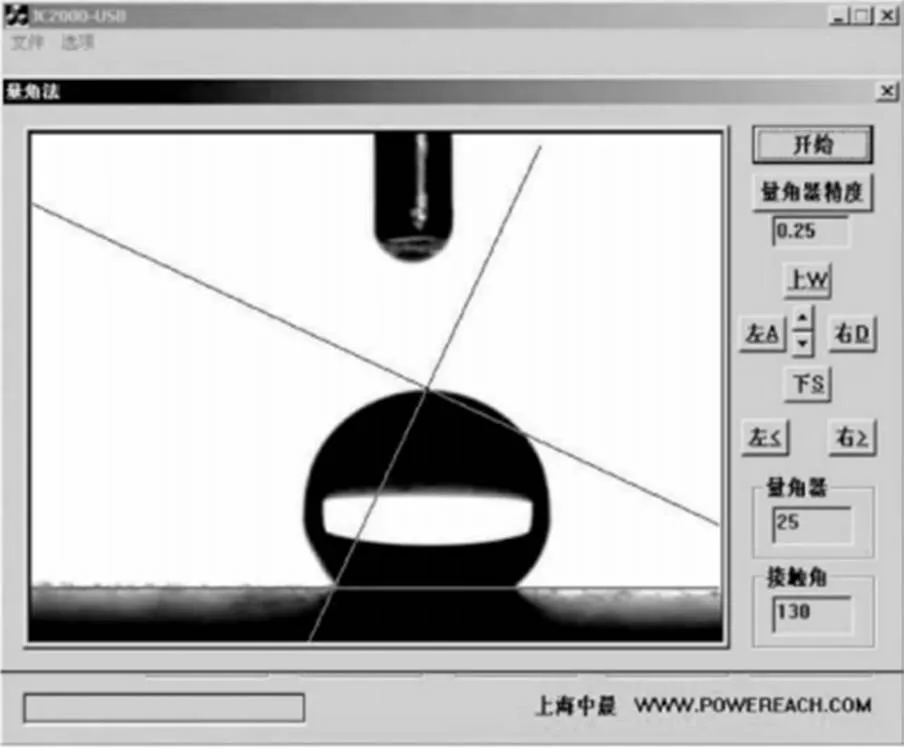

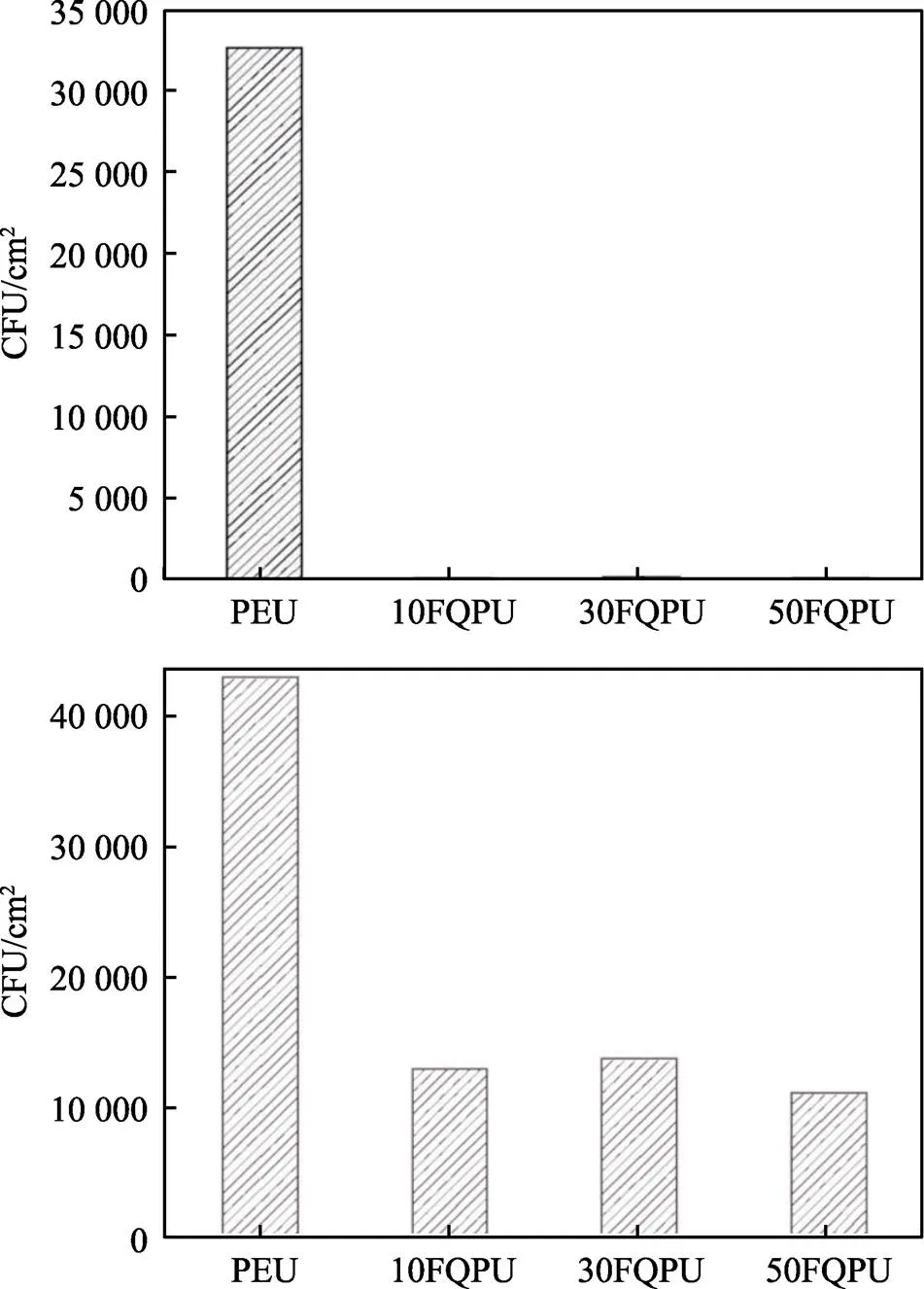

除无机金属抗菌剂外,有机抗菌剂和天然抗菌剂也能够作为填料应用在低表面能涂料中。仇春红[47]将3种不同季铵盐添加至有机硅树脂中,制得的涂料水接触角均在120°以上,同时对大肠杆菌的抑菌率达到了99%。赵萍萍[48]将改性后的2,4–噻唑烷二酮(TDZ)加入有机硅丙烯酸树脂中,经实验室和实海挂板测试验证,该涂料复合防污效果良好。廖道鹏等[49]利用天然抗菌剂间苯三酚的单宁特性,将其应用于改性丙烯酸树脂中,制备得到的涂层的水接触角达到了130°(见图3),同时抗菌效果优良(见图4),表现出了优良的复合防污特性。

图3 水接触角[49]

3.2 结构型抗菌复合防污涂料

结构型抗菌复合防污涂料的制备原理是借助化学反应将抗菌剂(多为小分子有机抗菌剂)引入涂料树脂的高分子链中,同时不破坏抗菌剂中的抗菌基团,这样制备得到的抗菌涂料使用寿命长,且避免了抗菌剂的析出损失和对环境造成的污染,制得的抗菌涂料更加绿色环保[50]。

图4 纯树脂涂层(a)和添加质量分数为6%的间苯三酚树脂涂层(b)的抑菌圈对比[49]

赵玻[51]将胍基型二羟甲基丙酰胺作为扩链剂引入氟化聚氨酯中,得到的聚氨酯涂层具有上层抗菌、次层疏水的优良防污性能。Wang等[52]在丙烯酸乳液中引入有机硅树脂和三甲基氯化铵,得到的涂层防污性能优良。付昱晨[53]采用季铵盐改性的含氟聚合物和聚脲醛纳米粒子来改性聚氨酯,制备的涂层在含氟聚合物和由纳米粒子形成的微观疏水结构的共同作用下具有优良的疏水性能,同时抗菌效果优良。Ferreira等[54]将溴代吡咯腈用异氰酸酯功能化后与聚硅氧烷反应构建防污涂层,实海挂板测试结果表明涂层表现出了优良的防污效果。Zhang等[55-56]、刘海龙[57]将季铵盐改性的聚硅氧烷和异佛尔酮异氰酸酯三聚体共聚,制备得到的涂层综合防污性能优良。罗建斌等[58]将侧链含有氟化双季铵盐的二胺引入聚氨酯硬段,得到的系列聚氨酯的水接触角均在100°以上(见表1),同时涂层对大肠杆菌和金色葡萄球菌均具有良好的杀菌效果(见图5)。

表1 不同氟化双季铵盐含量聚氨酯的水接触角[58]

Tab.1 Water contact angle of polyurethane with different content of fluorinated bis-quaternary ammonium salt[58]

除了将抗菌剂直接引入高分子主链外,还可以采用接枝的方式引入抗菌剂,这样可以最大程度避免破坏原分子链段结构,进而减小对原涂料力学性能的影响。例如对涂层进行表面功能化处理后,将有机硅接枝在涂层表面并进行季铵化处理,使涂层具备抗菌性能[59]。黄饶[60]合成了石墨烯接枝聚乳酸嵌段聚氨酯共聚物,通过引入石墨烯来提高涂料的抗菌性能,并在聚氨酯链段中引入羟基聚二甲基硅烷来降低材料的表面能,获得具有复合防污效果的涂层。Wang等[61]将聚硅氧烷和聚氨酯共聚并接枝到改性碳纳米管上,制备得到的涂料具有优良的低表面能特性和抗菌性能,同时避免了直接加入碳纳米管所引起的团聚现象[62]。

图5 氟化双季铵盐系列聚氨酯对(a)金色葡萄球菌和(b)大肠杆菌的抗菌效果[58]

目前,结构型抗菌复合防污涂料领域中应用较多的抗菌剂多为小分子有机抗菌剂,将壳聚糖等天然抗菌剂引入涂层高分子链的研究正在开展,预期在不久的将来也将取得令人满意的成果。

4 存在问题与解决途径

4.1 添加型抗菌复合防污涂料

将抗菌物质直接加入涂料中制备的添加型抗菌复合防污涂料操作简便,加工成本低,但由于工艺和抗菌剂本身的性质缺陷,使添加型防污涂料仍存在一定问题。

对于无机金属抗菌剂,二氧化钛抗菌剂只能在有一定光照强度的环境中使用,黑暗条件下几乎不具备抗菌效果;银系抗菌剂易团聚、分散效果不佳、不稳定、易变色且成本较高[34]。小分子有机抗菌剂毒性相对较高,易析出造成环境污染、降低涂层的使用寿命;高分子有机抗菌剂与涂料相容性不佳,使涂料的防污效果达不到预期。天然抗菌剂存在提纯工艺复杂、耐热性差、抗菌活性有限且易受环境因素影响、难以人工合成等问题,故不能规模化生产[34,36,63]。

为改善无机金属抗菌剂的作用效果,研究人员不断尝试对其进行改性处理。例如将金属抗菌剂制备成纳米粒子,通过增大表面效应来减少用量,进而改善抗菌剂在涂料中的分散性,避免应力集中现象对涂层造成破坏;将金属抗菌剂固定在涂层表面,或借助沸石等多孔材料制备载体金属抗菌剂,来减少抗菌剂的析出损失[64]。Song等[65]利用改性二氧化钛来负载纳米银离子,成功拓宽了二氧化钛的光催化响应区,提高了抗菌剂的作用效果。Tian 等[66]制备了纳米银复合水凝胶,减少银用量的同时,利用水凝胶改善了纳米银粒子在树脂基底中的分散性,使涂料具有优良的防污性能。Sileika等[67]、Xu等[68]在聚氨酯涂层表面涂覆聚多巴胺薄膜用以还原并固定纳米银粒子,有效避免了银离子的析出损失,提高了涂层的防污性能。有机抗菌剂和天然抗菌剂在添加型复合防污涂料中的应用较为有限,为拓宽其应用范围,研究人员在改性研究的过程中发现,若将2种及以上不同种类的抗菌剂复合使用,利用不同成分之间的协同作用,可制备得到性能更加优良的复合抗菌剂。姚剑松等[69]制备的季铵化壳聚糖微球的抗菌性能,相较于纯壳聚糖得到了有效提高,使壳聚糖能够在更加广泛的pH值范围内得到应用。吴会敏[70]制备的胍基化壳聚糖不仅具有优良的抗菌性能,还成功改善了材料的力学性能和壳聚糖在树脂中的相容性。

综上所述,尽管添加型抗菌复合涂料存在一定问题,但相关研究起步较早,因此相对发展较为完善,在海洋防污领域仍占据比较重要的位置。继续加强相关研究工作,可以有效解决目前存在的问题。制备纳米金属粒子抗菌剂和载体抗菌剂的技术手段日渐成熟,是目前应用最为广泛的金属抗菌剂改性方式,可以将其作为多数添加型复合防污涂料用抗菌剂的首选;多种抗菌剂协同使用的复合抗菌剂也因其综合性能显著优于单独使用抗菌剂时而逐渐受到重视,应进一步加大对其的研究和应用力度。

4.2 结构型抗菌复合防污涂料

将有机抗菌剂固定在分子链中能够有效解决抗菌剂的析出损失问题,延长涂层的防污寿命。但有机抗菌剂的引入通常会对涂料的其他性能造成一定程度的不良影响。例如季铵盐本身具有一定的极性和亲水性,引入后会影响涂层的表面能和稳定性[71];N–(2,4,6–三氯苯基)马来酰亚胺中的刚性苯环会增大涂层的模量,不利于涂层表面附着的海洋生物在海水冲刷下的剪切剥离,使涂层的防污性能受到影响[72]。因此,在向树脂基体的分子链中引入抗菌剂时,应着重考虑抗菌性能与表面能、力学性能等的平衡,通过试验筛选出综合性能优良的涂料配方。Zhang等[56]发现聚氨酯改性有机硅涂层的静态水接触角和抗菌性能,与涂层表面硅原子和氮离子的浓度基本呈正相关,并通过试验验证了共聚物中有机硅链段中链节数为90、季铵盐质量分数为20%时具有最佳的综合性能。

结构型复合抗菌防污涂料正逐步成为海洋防污涂料的研究热点,应加强和聚焦相关研究工作,以更好地解决以上问题。为避免抗菌剂对涂料性能造成不利影响,应根据性能需要选择合适的抗菌剂,同时在分子链结构中引入有机抗菌剂时,应严格控制其用量,通过实验确定抗菌性能和力学性能兼具的最佳配方;针对天然抗菌剂,由于从生物中直接提取天然抗菌剂的抗菌机理较为复杂,应将研究重点聚焦在如何将其引入涂料树脂的分子链后而仍能继续保持其抗菌性能和树脂的防污性能。另外,目前抗菌剂的选择主要集中在小分子有机抗菌剂领域,后续应加强针对其他抗菌剂引入树脂分子链的相关研究工作。

5 结论与展望

低表面能涂料技术已经取得实际应用成果,抗菌剂的研究也在不断进步,抗菌低表面能复合防污涂料的优点逐渐显露并已得到研究人员的重视。无机抗菌剂具备广谱杀菌效果且不易产生抗药性,已在复合防污涂料中得到应用,未来的研究方向主要为解决金属抗菌剂在涂料中的分散性和稳定性的问题,例如制备载体无机抗菌剂等。小分子有机抗菌剂具有一定毒性,析出后会对环境和人体带来危害,因此不适合用于制备添加型抗菌涂料;高分子有机抗菌剂和涂料基体的相容性较差,抗菌效果不好,而将有机抗菌剂引入结构型抗菌涂料可以避免以上问题,同时有效延长涂料的使用寿命。无毒环保的天然抗菌剂将会逐渐成为抗菌涂料研究领域的热点研究方向,但天然抗菌剂的应用尚在起步阶段,未来的主要研究方向为将壳聚糖等天然抗菌剂引入低表面能涂料树脂的高分子链中,构建无毒环保的结构型抗菌防污涂料,其中的难点为天然抗菌剂与涂料基体的反应,以及天然抗菌剂的活性保持等问题。

新型抗菌低表面能复合防污涂料对海洋防污领域有着非常重要的意义,我国在相关领域的研究尚处于起步阶段,相信在不久的将来,抗菌低表面能复合防污涂料能够顺利走出实验室,取得令人满意的实际应用业绩。

[1] 陶宇, 李亚冰. 海洋防污涂料技术的研究现状及展望[J]. 化学与黏合, 2012, 34(5): 67-71.

TAO Yu, LI Ya-bing. Present Status and Developing Prospect of Marine Antifouling Paints Technology[J]. Chemistry and Adhesion, 2012, 34(5): 67-71.

[2] ALI A, JAMIL M I, JIANG Jing-xian, et al. An Overview of Controlled-Biocide-Release Coating Based on Polymer Resin for Marine Antifouling Applications[J]. Journal of Polymer Research, 2020, 27(4): 1-17.

[3] CAO Shan, WANG Jia-dao, CHEN Hao-sheng, et al. Progress of Marine Biofouling and Antifouling Technologies [J]. Chinese Science Bulletin, 2011, 56(7): 598-612.

[4] COOPER S P, FINLAY J A, CONE G, et al. Engineered Antifouling Microtopographies: Kinetic Analysis of the Attachment of Zoospores of the Green Alga Ulva to Silicone Elastomers[J]. Biofouling, 2011, 27(8): 881-892.

[5] AMARA I, MILED W, SLAMA R B, et al. Antifouling Processes and Toxicity Effects of Antifouling Paints on Marine Environment. a Review[J]. Environmental Toxicology and Pharmacology, 2018, 57: 115-130.

[6] DAFFORN K A, LEWIS J A, JOHNSTON E L. Antifouling Strategies: History and Regulation, Ecological Impacts and Mitigation[J]. Marine Pollution Bulletin, 2011, 62(3): 453-465.

[7] CALLOW J A, CALLOW M E. Trends in the Development of Environmentally Friendly Fouling-Resistant Marine Coatings[J]. Nature Communications, 2011, 2(1): 244.

[8] SELIM M S, SHENASHEN M A, EL-SAFTY S A, et al. Recent Progress in Marine Foul-Release Polymeric Nanocomposite Coatings[J]. Progress in Materials Science, 2017, 87: 1-32.

[9] SILVA E R, FERREIRA O, RAMALHO P A, et al. Eco- Friendly Non-Biocide-Release Coatings for Marine Biofouling Prevention[J]. Science of the Total Environment, 2019, 650(2): 2499-2511.

[10] HU Peng, XIE Qing-yi, MA Chun-feng, et al. Silicone- Based Fouling-Release Coatings for Marine Antifouling [J]. Langmuir, 2020, 36(9): 2170-2183.

[11] 马英华, 宋振伟, 何遥, 等. 低表面能防污涂料防污机理探讨[J]. 上海涂料, 2013, 51(5): 15-18.

MA Ying-hua, SONG Zhen-wei, HE Yao, et al. Discussing about Antifouling Mechanism of Antifouling Coatings with Low Surface Energy[J]. Shanghai Coatings, 2013, 51(5): 15-18.

[12] MARLÈNE L, ANDRÉ M, CHRISTINE B. Fouling Release Coatings: A Nontoxic Alternative to Biocidal Antifouling Coatings[J]. Chemical Reviews, 2012, 112(8): 4347-4390.

[13] 桂泰江, 王科. 低表面能海洋防污涂料的现状和发展趋势[J]. 现代涂料与涂装, 2010, 13(11): 32-35.

GUI Tai-jiang, WANG Ke. The Present Situation and Development Trend of Low Surface Marine Antifouling Coating[J]. Modern Paint & Finishing, 2010, 13(11): 32-35.

[14] NURIOGLU A G, ESTEVES A C C, DE W G. Non-Toxic, Non-Biocide-Release Antifouling Coatings Based on Molecular Structure Design for Marine Applications[J]. Journal of Materials Chemistry B, 2015, 3(32): 6547- 6570.

[15] KRÓL B, KRÓL P, BYCZYŃSKI Ł, et al. Methods of Increasing Hydrophobicity of Polyurethane Materials: Important Applications of Coatings with Low Surface Free Energy[J]. Colloid and Polymer Science, 2017, 295(12): 2309-2321.

[16] CIRIMINNA R, BRIGHT F V, PAGLIARO M. Ecofriendly Antifouling Marine Coatings[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(4): 559-565.

[17] BUSKENS P, WOUTERS M, RENTROP C, et al. A Brief Review of Environmentally Benign Antifouling and Foul- Release Coatings for Marine Applications[J]. Journal of Coatings Technology and Research, 2013, 10(1): 29-36.

[18] HY D T, JEAN-FRANÇOIS B, ANDRÉ M, et al. Polysiloxane-Based Block Copolymers with Marine Bacterial Anti-Adhesion Properties[J]. ACS Applied Materials & Interfaces, 2015, 7(28): 15578-86.

[19] LEI H, XIONG M, XIAO J, et al. Fluorine-Free Coating with Low Surface Rnergy and Anti-Biofouling Properties [J]. Progress in Organic Coatings, 2018, 124: 158-164

[20] 刘广娟, 左禹, 赵景茂. 环氧改性有机硅涂料耐热耐蚀性研究[J]. 腐蚀与防护, 2004, 25(6): 238-241.

LIU Guang-juan, ZUO Yu, ZHAO Jing-mao. Heat Resistance and Corrosion Resistance of Epoxy-Silicone Based Coating[J]. Corrosion & Protection, 2004, 25(6): 238-241.

[21] 夏杰. 聚氨酯改性有机硅船舶防污涂料研究[D]. 北京: 北京化工大学, 2020: 31.

XIA Jie. Research of Silicone Modified Polyurethane Marine Antifouling Coatings[D]. Beijing: Beijing University of Chemical Technology, 2020: 31.

[22] LEJARS M, MARGAILLAN A, BRESSY C. Siloxy Silylester Methacrylate Diblock Copolymer-Based Coatings with Tunable Erosion and Marine Antifouling Properties[J]. ACS Applied Polymer Materials, 2020, 2(8): 3291-3300.

[23] SUN Xun, CHEN Rong-rong, GAO Xiang, et al. Fabrication of Epoxy Modified Polysiloxane with Enhanced Mechanical Properties for Marine Antifouling Application[J]. European Polymer Journal, 2019, 117: 77-85.

[24] 董耀华, 郭娜, 刘涛, 等. 载银自抛光/低表面能环保涂层的制备及其耐微生物附着性能研究[J]. 表面技术, 2015, 44(3): 100-106.

DONG Yao-hua, GUO Na, LIU Tao, et al. Research on the Preparation of Ag-Loaded Self-Polishing/Low Surface Energy Coating and Its Antifouling Ability[J]. Surface Technology, 2015, 44(3): 100-106.

[25] ZHANG Zhan-ping, SONG Xiao-fei, CUI Li-ying, et al. Synthesis of Polydimethylsiloxane-Modified Polyurethane and the Structure and Properties of Its Antifouling Coatings[J]. Coatings, 2018, 8(5): 157.

[26] SOMMER S, EKIN A, WEBSTER D C, et al. A Preliminary Study on the Properties and Fouling-Release Performance of Siloxane-Polyurethane Coatings Prepared from Poly (Dimethylsiloxane) (PDMS) Macromers[J]. Biofouling, 2010, 26(8): 961-972.

[27] NAGHASH H J, MOHAMMADIDEHCHESHMEH I, MEHRNIA M. Synthesis and Characterization of a Novel Hydroxy Terminated Polydimethylsiloxane and Its Application in the Waterborne Polysiloxane-Urethane Dispersion for Potential Marine Coatings[J]. Polymers for Advanced Technologies, 2013, 24(3): 307-317.

[28] 王强, 李昌诚, 闫雪峰, 等. 低表面能海洋防污涂层技术及其评价方法[J]. 材料导报, 2008, 22(10): 84-87.

WANG Qiang, LI Chang-cheng, YAN Xue-feng, et al. Marine Antifouling Coating Technology with Low Surface Energy and Its Evaluation Methods[J]. Materials Review, 2008, 22(10): 84-87.

[29] 许丽敏. 有机氟改性丙烯酸树脂的合成及其涂料的研究[D]. 大连: 大连交通大学, 2010: 5-45.

XU Li-min. Research of Synthetic Organic Fluorine Modified Acrylic Resin and Coating[D]. Dalian: Dalian Jiaotong University, 2010: 5-45.

[30] ZHANG Yan, ZHANG Zhan ping, QI Yu hong, et al. The Polymerization and Performance of Fluorinated Acrylic Copolymer with Low Surface Energy[J]. Materials Science Forum, 2011, 1300(687): 562-566.

[31] GITTENS J E, SMITH T J, SULEIMAN R, et al. Current and Emerging Environmentally-Friendly Systems for Fouling Control in the Marine Environment[J]. Biotechnology Advances, 2013, 31(8): 1738-1753.

[32] SUN X, ZHANG F, CHEN Y, et al. Preparation and Properties of Crosslinked Network Coatings Based on Perfluoropolyether/Poly(Dimethyl Siloxane)/Acrylic Polyols for Marine Fouling-Release Applications[J]. Journal of Applied Polymer Science, 2015, 132(17): 41860.

[33] 汪子翔, 张坤, 卫金皓, 等. 抗菌材料及抗菌剂的研究现状及前景展望[J]. 橡塑技术与装备, 2021, 47(12): 22-29.

WANG Zi-xiang, ZHANG Kun, WEI Jin-hao, et al. The Present Situation and Prospect of Antibacterial Materials and Antimicrobial Agents[J]. China Rubber/Plastics Technology and Equipment, 2021, 47(12): 22-29.

[34] 张小吉, 郑成. 抗菌涂料的研究应用进展[J]. 广东化工, 2016, 43(24): 83-84.

ZHANG Xiao-ji, ZHENG Cheng. The Research Progress of Antibacterial Coatings[J]. Guangdong Chemical Industry, 2016, 43(24): 83-84.

[35] MUÑOZ-BONILLA A, FERNÁNDEZ-GARCÍA M. Polymeric Materials with Antimicrobial Activity[J]. Progress in Polymer Science, 2011, 37(2): 281-339.

[36] 张国铭, 黎彧, 邹训重, 等. 抗菌涂料的研究进展[J]. 广东微量元素科学, 2015, 22(11): 6-9.

ZHANG Guo-ming, LI Yu, ZOU Xun-zhong, et al. The Research Progress of Antibacterial Coatings[J]. Guangdong Trace Elements Science, 2015, 22(11): 6-9.

[37] 敖晓娟, 杨育农, 王浩江, 等. 聚丙烯酸酯抗菌涂料研究进展[J]. 合成材料老化与应用, 2019, 48(5): 122-126.

AO Xiao-juan, YANG Yu-nong, WANG Hao-jiang, et al. Research Progress on Antibacterial Coatings of Polyacrylate[J]. Synthetic Materials Aging and Application, 2019, 48(5): 122-126.

[38] QIAN Pei-yuan, XU Ying, NOBUSHINO F. Natural Products as Antifouling Compounds: Recent Progress and Future Perspectives[J]. Biofouling, 2010, 26(2): 223-234.

[39] MA Chun-feng, ZHANG Wei-peng, ZHANG Guang-zhao, et al. Environmentally Friendly Antifouling Coatings Based on Biodegradable Polymer and Natural Antifoulant [J]. ACS Sustainable Chemistry & Engineering, 2017, 5(7): 6304-6309.

[40] 李恩宇. 天然壳聚糖的改性制备及其在防污涂层中的应用研究[D]. 哈尔滨: 哈尔滨工程大学, 2018: 12.

LI En-yu. Modification of Natural Chitosan and Its Application in Antifouling Coatings[D]. Harbin: Harbin Engineering University, 2018: 12.

[41] NIGMATULLIN R, KONOVALOVA V, POBIGAY G. Development of Antimicrobial Membranes via the Surface Tethering of Chitosan[J]. Journal of Applied Polymer Science, 2009, 111(4): 1697-1705.

[42] OKTAY B, KAYAMAN-APOHAN N. Polydimethylsiloxane (PDMS)-Based Antibacterial Organic-Inorganic Hybrid Coatings[J]. Journal of Coatings Technology and Research, 2013, 10(6): 785-798.

[43] ZHAI Meng-jiao, GONG Yong-feng, CHEN Xiu-yong, et al. Mass-Producible Hydrophobic Perfluoroalkoxy/Nano- Silver Coatings by Suspension Flame Spraying for Antifouling and Drag Reduction Applications[J]. Surface & Coatings Technology, 2017, 328: 115-120.

[44] 李善文, 陈美玲, 杨莉, 等. 环保友好纳米二氧化钛低表面能船舶防污涂料[J]. 功能材料, 2008, 39(5): 853- 856.

LI Shan-wen, CHEN Mei-ling, YANG Li, et al. Preparation of Environmentally Benign Low Surface Energy Antifouling Coatings with Nano-Titanium Oxide Powder on Seagoing Vessels[J]. Journal of Functional Materials, 2008, 39(5): 853-856.

[45] QU Yuan-yuan, HUANG Hao-fei. Study of Novel Low Surface Energy Antifouling Coating Prepared with Silicon- Modified Acrylic Resin and Nano-TiO2[J]. Asian Journal of Chemistry, 2015, 27(4): 1212-1214.

[46] 尤文卉. 银系疏水抗菌涂层制备及其性能研究[D]. 杭州: 浙江大学, 2014: 29-42.

YOU Wen-hui. Preparation and Properties of the Ag- Based Hydrophobic Antibacterial Coating[D]. Hangzhou: Zhejiang University, 2014: 29-42.

[47] 仇春红. 季铵盐海洋防污涂层研究[D]. 大连: 大连海事大学, 2012: 33-61.

QIU Chun-hong. Investigation of Marine Antifouling Coatings Based on Quaternary Ammonium Salts[D]. Dalian: Dalian Maritime University, 2012: 33-61.

[48] 赵萍萍. 噻唑烷二酮类抗菌剂在海洋防污涂料中的研究[D]. 淮北: 淮北师范大学, 2019: 21-28.

ZHAO Ping-ping. Application of TZDS Antimicrobials in Marine Antifouling Coatings[D]. Huaibei: Huaibei Normal University, 2019: 21-28.

[49] 廖道鹏, 陈美玲, 张羽生, 等. 天然防污剂间苯三酚在低表面能海洋涂料中的应用[J]. 化工新型材料, 2015, 43(4): 226-228.

LIAO Dao-peng, CHEN Mei-ling, ZHANG Yu-sheng, et al. Application of Natural Antifouling Agent Phloroglucinol in Marine Coatings with Low Surface Energy[J]. New Chemical Materials, 2015, 43(4): 226-228.

[50] KUGEL A, STAFSLIEN S, CHISHOLM B J. Antimicrobial Coatings Produced by “Tethering” Biocides to the Coating Matrix: A Comprehensive Review[J]. Progress in Organic Coatings, 2011, 72(3): 222-252.

[51] 赵玻. 纯水性聚氨酯纳米乳液及其抗菌与超疏水涂层的制备与研究[D]. 上海: 上海应用技术大学, 2019: 19-33.

ZHAO Bo. Preparation and Study of Waterborne Polyure- Thane Nano-Emulsion and Its Antibacterial and Superhydrophobic Coatings[D]. Shanghai: Shanghai Institute of Technology, 2019: 19-33.

[52] WANG B, WU Z, ZHANG D, et al. Antibacterial Silicylacrylate Copolymer Emulsion for Sntifouling Coatings [J]. Progress in Organic Coatings, 2018: 122-128.

[53] 付昱晨. 多功能超疏水抗菌材料的制备及其表面性能的研究[D]. 杭州: 浙江大学, 2017: 26-46.

FU Yu-chen. Synthesis of Multifunctional Superhydrophobic Antibacterial Materials and Studies on Their Surface Properties[D]. Hangzhou: Zhejiang University, 2017: 26-46.

[54] FERREIRA O, RIJO P, GOMES J F, et al. Biofouling Inhibition with Grafted Econea Biocide: Toward a Nonreleasing Eco-Friendly Multiresistant Antifouling Coating[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(1): 12-17.

[55] ZHANG Q, LIU H, CHEN X, et al. Preparation, Surface Properties, and Antibacterial Activity of a Poly(Dimethyl Siloxane) Network Containing a Quaternary Ammonium Salt Side Chain[J]. Journal of Applied Polymer Science, 2015, 132(14): 5-8.

[56] ZHANG Qing-hua, LIU Hai-long, ZHAN Xiao-li, et al. Microstructure and Antibacterial Performance of Functionalized Polyurethane Based on Polysiloxane Tethered Cationic Biocides[J]. RSC Advances, 2015, 5(95): 77508- 77517.

[57] 刘海龙. 抗菌改性聚硅氧烷低表面能涂层材料的制备与性能研究[D]. 杭州: 浙江大学, 2014: 25-69.

LIU Hai-long. Preparation and Performance of Polysiloxane Coating Material Modified by Antibacterial Groups [D]. Hangzhou: Zhejiang University, 2014: 25-69.

[58] 罗建斌, 马晨, 廖戎, 等. 硬段侧链含有氟化双季铵盐的聚氨酯表面性能及抗菌性能分析[J]. 高等学校化学学报, 2010, 31(6): 1268-1273.

LUO Jian-bin, MA Chen, LIAO Rong, et al. Surface and Antibacterial Properties of Polyurethane with Fluorinated Bis-Ammonium Salts Attached to Hard Segments[J]. Chemical Journal of Chinese Universities, 2010, 31(6): 1268-1273.

[59] YANG Wen-jing, NEOH K G, KANG En-tang, et al. Polymer Brush Coatings for Combating Marine Biofouling[J]. Progress in Polymer Science, 2014, 39(5): 1017- 1042.

[60] 黄饶. 可降解低表面能海洋防污聚氨酯复合材料的制备及性能研究[D]. 湘潭: 湖南科技大学, 2016: 27-36.

HUANG Rao. The Synthesis and Performance of Degradable Polyurethane Hybrid Materials with Low Surface Energy[D]. Xiangtan: Hunan University of Science and Technology, 2016: 27-36.

[61] WANG S, LIU X, YU L, et al. Low Surface Energy Self-Polishing Polymer Grafted MWNTs for Antibacterial Coating and Controlled-Release Property of Cu2O[J]. Journal of Applied Polymer Science, 2020, 138(16): 50267.

[62] ALEXANDRE B, ROSICA M, PETTITT M E, et al. Marine Fouling Release Silicone/Carbon Nanotube Nanocomposite Coatings: On the Importance of the Nanotube Dispersion State[J]. Journal of Nanoscience and Nanotechnology, 2010, 10(5): 2972-2978.

[63] 谭生, 郭军红, 崔锦峰, 等. 抗菌涂料的研究现状及发展趋势[J]. 中国涂料, 2011, 26(2): 16-20.

TAN Sheng, GUO Jun-hong, CUI Jin-feng, et al. Research Status and Development Trend of Antibacterial Coatings[J]. China Coatings, 2011, 26(2): 16-20.

[64] 高党鸽, 赵洲洋, 吕斌, 等. 超疏水抗菌表面的研究进展[J]. 精细化工, 2021, 38(5): 874-881.

GAO Dang-ge, ZHAO Zhou-yang, LYU Bin, et al. Research Process of Superhydrophobic Antibacterial Surfaces [J]. Fine Chemicals, 2021, 38(5): 874-881.

[65] SONG Yan-yan, YANG Ting, CAO Jing, et al. Protein- Mediated Synthesis of Antibacterial Silver Nanoparticles Deposited on Titanium Dioxide Nanotube Arrays[J]. Microchimica Acta, 2012, 177(1/2): 129-135.

[66] TIAN Shu, JIANG Dao-yi, PU Ji-bin, et al. A New Hybrid Silicone-Based Antifouling Coating with Nanocomposite Hydrogel for Durable Antifouling Properties[J]. Chemical Engineering Journal, 2019, 370: 1-9.

[67] SILEIKA T S, KIM H D, MANIAK P, et al. Antibacterial Performance of Polydopamine-Modified Polymer Surfaces Containing Passive and Active Components[J]. ACS Applied Materials & Interfaces, 2011, 3(12): 4602-4610.

[68] XU De-qiu, SU Yu-ling, ZHAO Li-li, et al. Antibacterial and Antifouling Properties of a Polyurethane Surface Modified with Perfluoroalkyl and Silver Nanoparticles[J]. Journal of Biomedical Materials Research Part A, 2017, 105(2): 531-538.

[69] 姚剑松, 左华江, 徐然, 等. 壳聚糖微球的季铵化及其抗菌性能的研究[J]. 化工新型材料, 2021, 49(2): 103- 106.

YAO Jian-song, ZUO Hua-jiang, XU Ran, et al. Quaternary Ammoniation of Chitosan Microsphere and Their Antimicrobial Property[J]. New Chemical Materials, 2021, 49(2): 103-106.

[70] 吴会敏. 含胍基化壳聚糖水性聚氨酯涂料的制备研究[D]. 天津: 天津大学, 2018: 39-49.

WU Hui-min. Preparation of Waterborne Polyurethane Coatings Modified by Guanidinated Chitosan[D]. Tianjin: Tianjin University, 2018: 39-49.

[71] MAJUMDAR P, LEE E, PATEL N, et al. Development of Environmentally Friendly, Antifouling Coatings Based on Tethered Quaternary Ammonium Salts in a Crosslinked Polydimethylsiloxane Matrix[J]. Journal of Coatings Technology and Research, 2008, 5(4): 405-417.

[72] XIE Qing-yi, MA Chun-feng, LIU Chao, et al. Poly (Dimethylsiloxane)-Based Polyurethane with Chemically Attached Antifoulants for Durable Marine Antibiofouling [J]. ACS Applied Materials & Interfaces, 2015, 7(38): 21030-21037.

Progress in the Antibacterial and Low Surface Energy Composite Marine Antifouling Coatings

,,,,,

(Beijing Key Laboratory of Materials Electrochemical Process and Technology, College of Materials Science and Engineering, Beijing University of Chemical Technology, Beijing 100029, China)

Marine economy and industry play an extremely important role in the development of human society, while the fouling problem of marine organisms brings great difficulties and challenges to marine engineering and equipment. How to effectively avoid marine biological fouling has become a hot and difficult issue. At present, antifouling technologies such as mechanical antifouling, electrochemical antifouling and antifouling coatings have been applied in practice. Among them, coating antifouling technology is the most widely used. Traditional antifouling coatings made use of antifouling agents to kill marine organisms, which will cause irreversible pollution to marine ecological environment. As a result, more research is being concentrated on developing more environmentally acceptable antifouling coatings. The low surface energy antifouling coatings could eliminate marine fouling organisms without releasing hazardous compounds, owing to its lower surface energy and the shear force by water flow. Due to the environment-friendly characteristic, low surface energy marine antifouling coatings have become the focus of research in recent years. To improve the antifouling coatings with more comprehensive properties, researchers try to modify the antifouling coatings with low surface energy unceasingly. Since the starting point of marine biological pollution is the attachment and growth of bacteria, antifouling coatings with antibacterial properties could prevent marine biological pollution at the initial stage. By introducing antimicrobial agents into low surface energy coatings, antifouling coatings with composite function could be prepared to further improve the comprehensive antifouling ability of coatings. According to this background, the technical principle of marine antifouling coatings and the research status of low surface energy antifouling coatings were briefly introduced firstly in this paper, and then the technical advantages of this type of antifouling coatings were analyzed. Meanwhile, the technical shortcomings of poor static antifouling ability and weak antifouling performance to bacterial fouling organisms were proposed. These disadvantages limit the wide application of low surface energy antifouling coatings, which need to be further modified to obtain better antifouling performance. Focusing on the antibacterial composite modification of low surface energy antifouling coatings and starting with two antibacterial composite modification methods of additives and structure, the applicable types of antibacterial agents, main preparation methods and relevant research results of comprehensive antifouling properties of modified coatings were described respectively. The research on adding antibacterial agents to low surface energy antifouling coatings started early, which is relatively well developed and occupies an important position in the field of marine antifouling. By fixing organic antibacterial agent in molecular chain, the problem of precipitation loss of antibacterial agent could be solved effectively and the service life of antifouling coatings could be prolonged. At the same time, the problems of the above two kinds of antibacterial composite antifouling coatings were discussed and the corresponding solutions were put forward. For example, nanoscale metal antibacterial agent and carrier antibacterial agent could be prepared and added to antifouling coatings. Finally, the future research directions of inorganic antibacterial agents, organic antibacterial agents and natural antibacterial agents in antifouling coatings were put forward, and the development and application of antibacterial low surface energy composite marine antifouling coatings have prospected.

antibacterial; low surface energy; composite function; marine antifouling coating

TQ637.2

A

1001-3660(2022)05-0265-09

10.16490/j.cnki.issn.1001-3660.2022.05.027

2021–11–03;

2022–04–28

2021-11-03;

2022-04-28

刘思琪(1999—),女,硕士研究生,主要研究方向为抗菌低表面能复合防污涂料。

LIU Si-qi (1999-), Female, Postgraduate, Research focus: antibacterial low surface energy composite antifouling coatings.

刘斌(1973—),男,博士,教授,主要研究方向为海洋装备防腐与防污。

LIU Bin (1973-), Male, Doctor, Professor, Research focus: anticorrosion and antifouling of marine equipment.

刘思琪, 刘斌, 宁玉杰, 等. 抗菌低表面能复合型海洋防污涂料的研究进展[J]. 表面技术, 2022, 51(5): 265-273.

LIU Si-qi, LIU Bin, NING Yu-jie, et al. Progress in the Antibacterial and Low Surface Energy Composite Marine Antifouling Coatings[J]. Surface Technology, 2022, 51(5): 265-273.

责任编辑:蒋红晨