镁合金微弧氧化复合膜研究进展

2022-04-25唐洋洋李林波王超杨潘杨柳王丹

唐洋洋,李林波,王超,杨潘,杨柳,王丹

镁合金微弧氧化复合膜研究进展

唐洋洋1,李林波2,王超2,杨潘1,杨柳1,王丹1

(1.西安建筑科技大学华清学院,西安 710045;2.西安建筑科技大学 冶金工程学院,西安 710055)

微弧氧化(MAO)表面处理技术常用于改善镁合金的特定性能,但MAO膜容易产生微孔和微裂纹从而降低镁合金的耐蚀性。为了提高镁合金微弧氧化膜的使用寿命,主要综述了国内外MAO工艺过程调节措施和MAO膜后处理技术的最新研究进展,重点介绍了近年来国内外镁合金MAO复合膜的研究热点。着重介绍了通过工艺过程调节提高镁合金MAO膜长期保护性能的几项措施:通过电参数和电源类型调节协同电解液成分调整提高MAO膜耐蚀性;通过加入电解液添加剂提高MAO电解液稳定性和电导率;利用具有自封孔作用的添加剂可以参与成膜的特点提高MAO膜致密性;通过复合工艺在MAO膜传统封孔后进一步封闭孔隙。此外,详细介绍了包括疏水涂层、化学镀、类金刚石涂层、生物膜涂层等复合膜工艺的研究进展,强调了复合膜不仅耐蚀性高而且具有功能化应用前景:超疏水复合膜对镁基底具有主动的腐蚀保护作用,超疏水膜协同MAO膜可以提高表面的疏水性;镀镍层致密无微孔且与MAO膜交错咬合能够改善镁MAO膜的导电性和耐蚀性;MAO涂层代替金属缓冲层能够提高类金刚石涂层和基体界面结合强度;生物复合涂层不仅耐蚀性高还具有促进细胞增殖和分化生物活性的作用。最后,基于镁合金MAO工艺研究现状,对MAO复合膜未来发展趋势进行了展望。

镁合金;微弧氧化;添加剂;封孔;复合膜

镁合金具有导电导热性能好、吸震性好、生物兼容性好等众多优势,应用领域广,但镁合金化学活性高,平衡电位低,耐蚀性和耐磨性较差,因此需要通过改善合金组织结构或使用表面改性技术以提高其特定性能。表面改性技术包括化学转化[1]、阳极氧化[2]、金属电镀[3]以及冷喷涂[4]等,这些技术多在基体表面制备涂层,以进一步提高镁合金的硬度、耐磨性、稳定性及氧化稳定性,因此,在镁合金的抗腐蚀和抗磨损方面受到了越来越多的关注[5]。采用上述表面处理技术制备的涂层存在与基体之间黏结强度低、厚度均匀性较差、操作复杂、成本高、污染环境等缺点[6]。此外,此类涂层还存在针孔、孔隙及柱间晶体等固有缺陷,这些缺陷为腐蚀提供了通道,会导致镁合金的腐蚀。针对此种情况,可在Mg合金上制备Al、Ti或Cr金属缓冲层,这是一种比较有效的解决方案[7],但缓冲层与衬底之间仍然存在分离现象。

微弧氧化(Micro-Arc Oxidation,MAO)也称为等离子电解氧化(Plasma Electrolytic Oxidation,PEO)技术,是指在基体表面借助微区火花放电而在有色金属表面原位生长多孔状结构的氧化薄膜的技术[8]。MAO膜具有附着力较好、耐腐蚀、耐磨、生物防腐、抗高温冲击、介电常数低等优点[9]。MAO技术是Mg、Ti、Al、Zr等金属及其合金常用的表面处理技术之一[10],可控制MAO膜的氧化层厚度、化学成分、孔径及粗糙度等。然而,强烈的高压火花放电使MAO薄膜容易产生微孔和微裂纹,这为水分子或氯离子的渗透提供了输送通道,从而进一步降低其耐蚀性[11]。MAO膜包括内部致密层和外部多孔层[12],内层是腐蚀介质的物理屏障,外层的微孔和微裂纹可增强有机物或聚合物在膜上的附着力,使外层膜具有机械联锁效应[13]。目前,多通过调节MAO工艺过程或进行MAO膜后处理来改善膜层致密度,从而提高其耐蚀性,而MAO工艺过程调节的研究多集中在电参数和电解液成分调节,MAO膜后处理是通过传统封孔或复合膜工艺来进一步提高MAO膜性能。由于MAO膜外层的微孔和微裂纹为有机物或聚合物提供了机械联锁位点,因此,可在镁合金MAO膜基础上开发具有良好结构和耐腐蚀性能的复合膜,镁合金MAO膜可结合低摩擦层或润滑膜,包括疏水膜、化学镀、类金刚石膜和硬涂层等[14-15]。文中基于MAO直接复合工艺过程调节的研究现状,重点介绍了近年来国内外镁合金MAO复合膜的研究热点,并展望了MAO复合膜工艺未来的发展趋势。

1 镁合金MAO工艺过程调节

近年来,改善镁合金耐蚀性的研究多集中在调节MAO电参数(电流模式、负电压、频率和占空比)和电解液成分(硅酸盐、磷酸盐和铝酸盐)上[16],希望可以进一步改善镁合金MAO膜致密性和耐腐蚀性能。另外,也可在MAO电解液中加入添加剂以影响MAO生长过程从而改善其性能[17]。添加剂直接参与成膜可实现封孔或调整陶瓷相组成,从而降低膜层缺陷,以直接复合技术提高材料耐蚀性并实现功能复合膜。

1.1 电参数

常规电参数(电压、电流密度、脉冲方式等)影响着MAO膜的组织性能,其中,电压的影响最大。MAO工艺分为4个阶段[18]:阳极氧化阶段、火花放电阶段、微弧快速生长阶段及弧光放电阶段。在前期阶段,膜向内和向外生长,形成致密层,但在后期阶段,膜向外生长出现疏松层,因此,弧光放电阶段会影响膜的质量[19]。增大电压会提高反应强度和驱动力,但电压过高会造成MAO膜层局部击穿,甚至会造成基体局部晶间液化,从而降低基膜结合的紧密程度,但电压过低会使膜层较薄。电流适当增大,使MAO膜厚度非线性增加,这种情况下,致密性会变好,但电流过大会导致局部击穿,膜层生长不均,且气体逸出使孔隙率较高,严重时甚至会引发烧蚀。截至目前,对影响MAO膜性能的电参数的研究主要集中在电流密度和工艺时间[20],而对电源类型(包括单脉冲和正负双极性脉冲)的研究较少[21]。双极性电源模式中脉冲频率增加,尤其是负脉冲的出现会引起更多放电并能降低击穿放电对MAO膜的影响,从而改善膜层的致密性。然而,电解液添加剂在MAO膜表面的聚集受双极性脉冲的抑制,一方面,负脉冲中和了MAO膜表面多余的正电荷,避免破坏性弧光的产生且减弱了火花放电,使喷射出的氧化物被电解液快速凝固而不重新熔炼,另一方面,负脉冲会引起膜层的溶解,在电场交替作用下颗粒难以在MAO表面聚集,而单脉冲则利于颗粒的吸附聚集。镁合金MAO工艺参数与电解液成分相互影响,未来应解决MAO电源的合理控制并寻求更适合电解液添加剂的电源模式,深入研究脉冲复合改性技术的作用机理并对电参数进行优化,实现在线实时控制,并提高成膜率以及MAO膜耐蚀性。

1.2 电解液调节

在MAO工艺中,镁合金微弧火花放电氧化常用的弱碱性电解液不仅构成了膜层的主要成分而且会影响膜层生长速率[22]。硅酸盐体系成膜率最高且膜层厚度大,但能耗大;铝酸盐体系MAO膜增厚较慢且厚度较小;磷酸盐电解液MAO层生长速率高,但其耐蚀性较低且粗糙度大。因此,复合电解液体系则有助于优化MAO膜特性并提高MAO膜质量,提高MAO电解液稳定性和电导率,或实现自封孔以改善镁合金MAO膜的性能和结构。目前,对MAO电解液的添加剂研究较多,如稀土配合物、颗粒类、无机盐等。

1.2.1 颗粒添加物

在电解液中加入WC、C纳米粒子、Si3N4或ZrO2等可以提高MAO膜致密性,从而改善其耐腐蚀和耐磨性[23]。电解液中C纳米粒子可增强材料导电率[24],且使涂层表面微弧强度降低,如图1所示,加入C后,微裂纹数量减少,碳纳米颗粒平均粒径小于30 nm,这些都阻止了基体元素的溶解并抑制沉积元素进入电解质,并促进少量MgAlO4和Mg3SiO4F2的形成。膜中C纳米粒子通过堵塞微孔,提高了膜在静态和动态浸泡环境中的耐腐蚀性。选择合适的电导率可降低MgO的黏度和熔点。颗粒添加剂可以降低起弧电压,提高溶液电导率、稳定性及MAO膜耐蚀相比例并改善膜层性能,但由于添加剂和膜层成分存在差异,导致改善效果有限,因此,可结合复合工艺以制备性能更优的复合陶瓷膜。CeO2和ZrO2纳米粒子具有很高的化学稳定性,可以防止裂纹扩展。Xiong等[25]研究发现,CeO2和ZrO2被电解液中OH−包围,并在强电场作用下以化合物形态移动并沉积在阳极表面。与MAO涂层相比,含有CeO2和ZrO2颗粒的–MAO膜具有较低的孔隙率和较高的耐蚀性。后经电泳沉积(EPD)在–MAO膜表面制备的HA涂层可提高材料生物相容性,且多孔层的微孔被HA颗粒填充。采用两步法在ZK60镁合金表面制备–MAO/EPD复合膜,电流比ZK60基体低3个数量级,具有更高的生物活性和长期防护能力,可用于生物降解的植骨材料。目前,对纳米颗粒添加剂的研究较少。在工业化过程中,可在镁合金MAO膜未达到工艺要求时,在电解液内选择性加入合适添加剂以提高膜层性能。

图1 MAO处理的涂层剖面图[24]

1.2.2 自封孔

溶液自封孔是指通过电解液配方调整或在电解液中加入添加剂后,添加剂直接参与成膜并形成与膜层为同一物质的微孔填充剂,从而改变镁合金MAO膜成分和性能。这种方法工艺流程简单且取得的效果较好,虽然目前国内外对这方面的研究较少,但仍有较好的发展前景。在电解液中添加醋酸银不仅能减小MAO膜微孔直径而且能提高其抗菌性[26]。梁锡炳等[27]在电解液中加入纳米α–Al2O3颗粒,结果表明,VW75镁合金MAO膜内火山状凸起减少,且在高温高压下纳米Al2O3熔融并填充MAO膜孔隙,不仅参与了成膜,而且实现了孔隙“自封孔”,这使极化曲线斜率变小,腐蚀电流下降。夏承森等[28]在电解液中加入羟基磷灰石包裹碳纳米管纳米(HA/CNTs)的复合粉体制备得到了MAO/HA/CNTs膜,研究发现,HA/CNTs参与成膜并起封孔作用,从而提高了镁合金MAO膜耐腐蚀性和生物活性。此外,在MAO过程中施加外加辅助电场也可以实现自封孔。陈宏等[29]发现在外加电场作用下,带负电的胶体Zr(OH)4以电泳形式向AZ91D的MAO膜的孔内移动并沉积,从而实现封孔。如图2所示,MAO膜截面的孔隙率和孔径都随着外加电场强度增大而减小,导致连通性下降(见图2b和2c),微孔几乎消失(见图2d),最终获得均匀致密的膜层。目前,自封孔的实现仍需形成完整可靠的溶液配方体系,外加电场自封孔工艺则需根据材料选择电压值,未来可使用复合膜工艺进行改善,从而实现封孔工艺简化。

1.2.3 其他添加剂

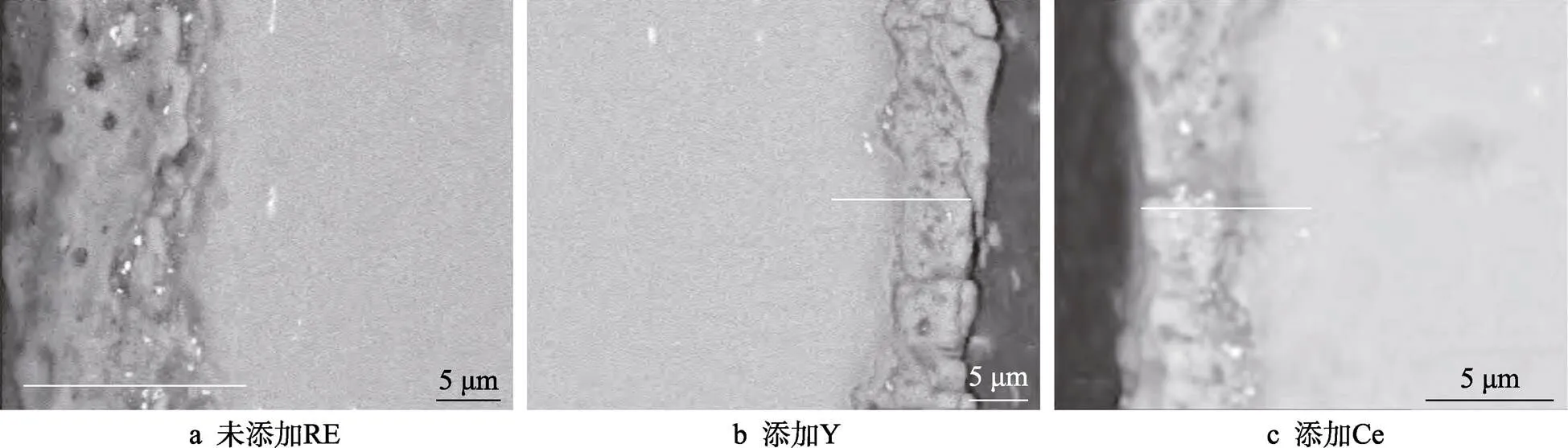

稀土元素(RE)可作为合金元素加入镁合金基体中,也可作为电解液添加剂或以稀土溶液的形式改善膜层致密性。目前,使用较多的稀土盐形成的MAO膜稳定性较差且容易产生胶体。在电解液中添加稳定性较强的稀土配合物可有效改善MAO膜层性能,例如,Y(NO3)3·6H2O和Ce(NO3)3·6H2O分别与乙二胺四乙酸二钠形成稀土配合物[30],作为添加剂加入AZ31电解液中,结果如图3所示,加入稀土配合物后,微孔孔径变小、陶瓷层更加致密均匀,产物稀土氧化物进入MAO膜内并电泳至孔隙内以提高膜致密度,但由于MAO膜的击穿电位降低,导致同参数下膜厚度减少。此外,MAO膜层耐摩擦和耐磨损性能提高,这说明Y配合物效果明显。

图2 不同外加电场电压下膜层的截面形貌[29]

图3 陶瓷层的截面形貌[30]

Wu等[31]在电解液中加入载有缓蚀剂的合成粉末〔埃洛石纳米管HNT作为纳米容器负载缓蚀剂2-氨基苯并咪唑(2–ABi),2–ABi–HNT〕,采用一步法成功制备了具有长期保护作用的自修复MAO膜。结果表明,2–ABi使金属表面积累了大量腐蚀性的产物并形成了厚的保护膜,2–ABi具有良好的缓蚀剂应用前景;2–ABi–HNT会引起电解液电导率下降和表面粗糙度增大,但腐蚀部位较致密的Mg(OH)2膜或较厚的腐蚀产物钝化层则会防止膜的进一步降解,具有良好的自修复功能,从而提高其长期耐蚀性。在电解液中加入添加剂的改善效果有限,但结合复合工艺可制备出性能更优的复合陶瓷膜或自封闭型陶瓷膜。因此,复合防腐膜具有良好的防腐性能,在轻金属工业中具有广阔的应用前景。

2 MAO膜后处理

2.1 传统封孔方法

MAO后处理封孔可降低MAO膜的孔隙率。常用的MAO后处理封孔方法包括无机物封孔、有机物封孔及沸水密封法[32-35]。沸水封孔法具有环保经济、操作简单、工业前景良好等优点。镁合金MAO膜沸水封孔后,MAO膜表面形成的Mg(OH)2使MAO表面平整且耐蚀性提高,但Mg(OH)2的生成会消耗膜内MgO,造成膜层变薄。随着封孔时间的延长,MAO膜层中粒子直径变大,且MAO内层孔洞并未完全消失,这些都会造成耐蚀性下降[36]。研究人员在沸水封孔基础上开发出不受酸碱度和水质影响的蒸汽封孔法,但由于需要使用高成本的专业高压容器而限制了其工业化生产。后来,研究人员又开发出微波水封技术[37],这种方法对样品要求较高。镁合金MAO膜通过水热反应处理后形成的Mg(OH)2可以达到封孔效果,从而提高MAO膜致密性和长久耐蚀性[38]。无机盐封孔是通过无机盐水解生成的沉淀填充到孔洞而实现封孔。Lee等[39]对AZ91D镁合金MAO膜层进行铈盐浸渍封孔后,其耐蚀性能提高,但仍有部分微孔并未完全封闭。Zhang等[40]通过铈盐对MAO膜封孔,溶液渗透到MAO层的孔隙中析出CeO2(质量分数为79%)和少量Ce(OH)3(质量分数为21%)封闭孔隙,后用水热处理在MAO膜上生成沉积层状双金属氢氧化物LDHs,复合膜解决了封孔不完全的缺点,耐蚀性和自愈能力均得到提高。有机物封孔是利用物理吸附作用实现封孔,但由于有机物与金属间结合力较差、封孔不完全,所以急需开发新的有机物封孔技术,有机物封孔结合硅烷化处理是实现复合封孔的一个发展方向,如低压浸渍或复合膜。综上所述,水封处理受限于较大孔径的封闭,无机盐离子在放电通道沉淀实现封孔,无机盐封孔技术可以与水热处理协同作用,MAO膜封孔后也可以通过复合工艺进一步改善其性能。

2.2 复合膜

镁合金MAO膜复合处理工艺能克服传统封孔工艺的缺陷,并进一步改善MAO膜性能,从而满足金属防腐的高要求,并日益受到人们的重视。李思思等[41]通过溶胶–凝胶技术在AZ31镁合金MAO膜表面浸渍SiO2溶胶,在溶胶半凝固后,形成一层半凝固胶膜,其在加热后会固化在MAO膜上从而实现封层,使MAO膜耐蚀性大幅提高。溶胶–凝胶技术虽然环保,但需要热处理,且凝胶对较小尺寸的微孔很难实现完全封闭,另外,膜表面还容易产生裂纹。目前,MAO膜外层的微孔和微裂纹提供了机械联锁位点,可以增强有机物或聚合物涂层的附着力。MAO膜复合疏水膜、低摩擦层或润滑膜等可进一步改善MAO膜的耐腐蚀和摩擦学性能,复合膜包括疏水膜、化学镀、类金刚石膜及生物膜等。

2.2.1 疏水膜

镁合金MAO膜可产生机械联锁效应。在制备超疏水膜的过程中,预先制备的MAO层具有比镁合金更粗糙的表面,这有利于制备超疏水膜。一方面,在制备超疏水膜过程中,可以防止镁合金受到不必要的侵蚀。另一方面,后期的超疏水膜又可以弥补MAO层的多孔缺陷。在MAO粗糙的表面低能化处理就可形成疏水膜,这比基体更利于防腐膜的形成。制备可提高耐腐蚀性疏水膜的常用方法有水热法、刻蚀法、溶液凝胶法及自组装等[42-44]。

将镁合金MAO膜浸入含新型有机硅偶联剂十六烷基三甲氧基硅烷(HTDMS)的溶液中,利用不同电荷阴阳离子在MAO表面交替沉积的自组装工艺,在镁合金MAO膜表面制得MAO/HTDMS复合膜[45]。HTDMS成功生长在MAO层表面且并未破坏基体属性,微孔和微裂纹被有效密封,外表面为低表面能物质硅烷,MAO/HTDMS接触角为145.07°,MAO/ HTDMS的腐蚀电流密度比MAO膜减小了2个数量级,盐雾试验和浸泡试验表明,MAO/HTDMS具有较好的耐腐蚀性能。螯合剂植酸(C6H18O24P6,PA)分子与Mg2+在螯合作用下形成的不溶性配位配合物吸附在MAO层多孔表面[46],镁合金MAO层通过在Ce(NO3)3溶液中多次组装[47],复合析出物PA@CeⅢ沉积在MAO层的孔隙和表面,形成微纳米层次结构,MAO层内火山状微孔由PA@CeⅢ配合物产生的少量不规则颗粒随机分布在MAO层表面,组装处理改变MAO层的表面形貌和孔隙结构,经过3个循环的装配,配合物可以完全覆盖整个系统表面并填充MAO层微孔,后用低表面能物质氟烷基硅烷(FAS)水解化学改性形成相对致密的超疏水复合膜,接触角增加到159°,制备的复合膜表面形貌基本保持不变。一方面,MAO层可以减少组装过程中析氢引起的裂纹密度;另一方面,超疏水外层也反过来可以修复MAO层内部多孔缺陷。因此,超疏水/MAO复合膜由于其协同效应可以有效地抑制腐蚀物质与MAO层的接触,赋予了镁合金优异的耐久耐蚀性。

自组装制备的超疏水表面以物理键结合,易老化且不耐磨损[48-49],所以针对AZ31镁合金MAO陶瓷层采用水热原位生长法制备具有较强附着力的层状双金属氢氧化物(LDH)涂层。李岩等[50]利用3种不同电解液制备MAO膜,后经水热处理在表面原位生成LDH膜。在硅酸盐体系复合膜中LDH垂直表面生长且结构致密,接触角为130.3°(微弧氧化过程中电压为430 V),然而,LDH未完全封闭微孔。高电压虽然可以增加MAO膜厚度,但也会导致微孔尺寸增大。为进一步提高MAO/LDH复合膜疏水性,Wang等[51]用硬脂酸对MAO/LDH复合膜进行表面改性获得超疏水性能,硬脂酸的羧基与LDH表面的羟基发生反应并通过化学键接枝到复合膜表面降低膜表面能,采用硬脂酸改性处理后不影响相组成并与LDH涂层协同作用改变材料疏水性,其接触角为151.21°,随着水热处理时间的延长,原位生长LDH逐渐封闭了MAO膜的微孔和裂纹,超疏水LDH/MAO膜的腐蚀电流密度最低、腐蚀电位最高、阻抗模量最高、具有密封多孔和吸收Cl−的能力,显著提高了MAO膜的长期腐蚀防护能力。因为在对MAO膜样品进行水热处理时,LDH层的生长依赖于MAO膜的溶解,所以在MAO膜上制备LDH层后,MAO层局部出现凹陷,厚度略有减少[52]。此外,Li等[53]以AZ31镁合金MAO微孔和纳米孔为N–16炔醇缓蚀剂的容器,并采用疏水蜡膜作密封隔离剂抑制金属腐蚀或氧化的发生形成疏水膜,膜保护效率达到99.7%。综上所述,MAO膜只能起到被动的腐蚀保护作用,而超疏水LDH/MAO复合膜对镁基底具有主动的腐蚀保护作用,超疏水LDH与MAO复合膜的协同作用提高了镁合金表面的疏水性,但目前超疏水表面腐蚀缺乏完整理论体系,工艺相对复杂且成本较高,难以大规模应用。因此,功能性膜MAO复合后处理工艺具有较大潜力,今后应侧重简单高效、适合大规模生产、膜基结合紧密且具有高稳定性和持久性复合材料的开发。

2.2.2 镀膜涂层

化学镀镍磷(Ni–P)具有沉积均匀、高耐腐蚀性、高耐磨性、良好的导电性和导热性、良好的润滑性和良好的延展性等优良性能,然而,化学镀Ni–P涂层与镁合金基体之间的电位差导致两者间存在电偶腐蚀,复合工艺使MAO膜可与随后的顶部层发生机械锁定从而提高膜的耐蚀性。为激活惰性MAO层以沉积化学镀镍涂层,以往需要使用危险的铬酸盐、HF和昂贵的PdCl2活化过程。Ezhilselvi等[54]采用硼氢化物NaBH4溶液代替传统的铬酸盐和HF活化过程来活化氧化层,采用碱碳酸浴法制备化学镀镍涂层,MAO/Ni–P复合膜覆盖了AZ31B镁合金表面。X射线光电子能谱(XPS)显示表面为均匀致密的结节状且无任何微裂纹或气孔,硼氢化物处理为Ni–P镀层的沉积提供了一个均匀的活性表面,在沉积60 min时可观察到致密且均匀的Ni–P镀层。在化学镀预处理过程中,NaBH4在MAO表面将镍离子还原为金属镍并作为化学镍沉积的形核位点。硼氢化物预处理加速了Ni–P在MAO层上的沉积速率,MAO/Ni–P腐蚀电流为1.44 μA/cm2,比基体提高2个等级,进一步说明膜的致密性得到提高。

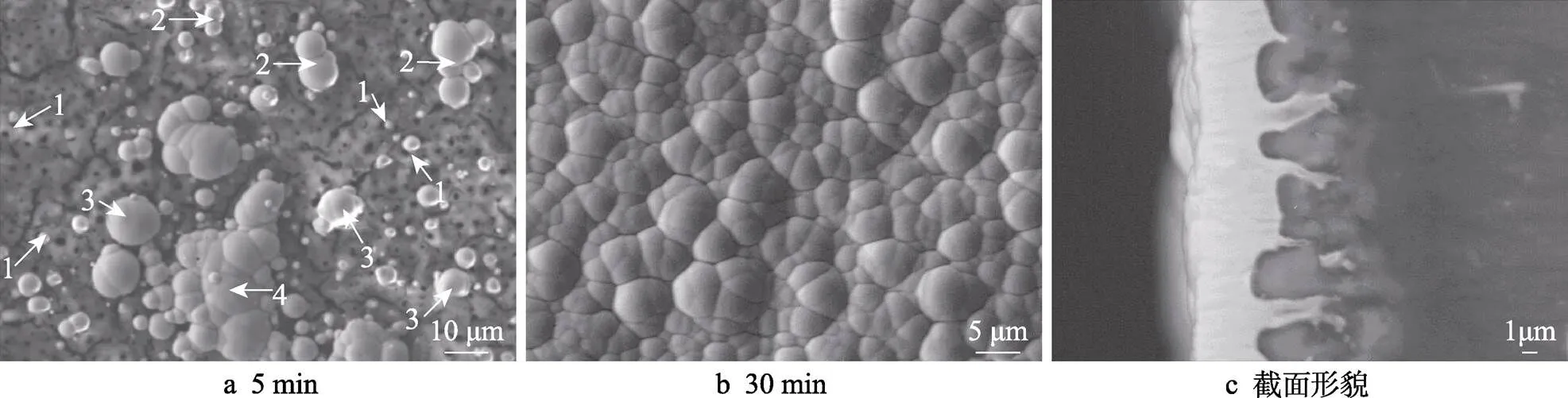

在镁合金MAO膜上制备TiN涂层方面的研究较少。Cui等[55]对AZ31B镁合金MAO膜进行离子镀TiN,在离子镀过程中,Ti渗入MAO膜多孔层,2种膜相互扩散,界面结合力很高,使整个膜层硬度和耐蚀性均得到提高。AZ91D镁合金MAO–化学镀镍复合处理过程符合Ostwald Ripening机制,初期微小镍在微孔处还原沉积长大,互连后形成岛状镍颗粒团并继续长大,如图4b[56]所示。镍完全覆盖MAO膜表面,如图4c所示,镀镍层致密无微孔且与MAO膜交错咬合,MAO膜具有化学镀镍催化活性作用,两者配合使用来改善镁合金MAO膜的导电性和耐蚀性。此后,应对MAO镀膜工艺进行深入研究以提高其耐蚀性能的同时降低成本,并侧重产业化应用。现代技术正专注于开发可靠、高性能、低成本、易于应用的、适用于恶劣环境条件的复合膜材料。

图4 镁合金MAO后不同时间化学镀镍层SEM形貌[56]

2.2.3 类金刚石涂层

类金刚石(DLC)具有硬度高、附着力好、摩擦因数低、化学惰性等优点,因此,DLC涂层可提高镁合金的耐腐蚀和耐磨性能[57]。然而,由于DLC涂层的弹性模量、熔点、内应力等材料性能与镁合金不同,DLC涂层的界面结合强度显著降低,一般是通过在DLC涂层与镁合金的界面上沉积Al、Ti、Cr、W、Si[58-59]等金属缓冲层以降低DLC涂层的内应力来提高其附着力。但是,膜基界面的结合强度提高程度有限,且膜基界面存在着明显的分离界面。如果用MAO膜代替金属缓冲层则可以提高界面结合强度,聚二甲基硅氧烷(PDMS)具有低表面能,优异的渗透性、化学惰性及热稳定性等特点。Jun等[60]用PDMS修饰AZ31B镁合金表面制备出MAO/DLC复合膜。首先采用MAO和不平衡磁控溅射复合工艺制备了双氧化石墨烯/DLC膜,然后通过传统的浸涂方法对MAO/DLC复合膜进行修饰,在MAO/DLC复合膜上形成黏弹性硅基有机聚合物层。改性后,MAO/DLC复合膜表面更加致密,具有疏水性和更高的结合强度,且其摩擦学行为得到了改善。经PDMS修饰的MAO/DLC膜的腐蚀电流密度比基体降低了5个数量级,而对镁合金的腐蚀防护效率得到大幅提高。因此,PDMS改性对制备耐腐蚀、耐磨损的镁合金保护材料是很有前途的。此外,金属掺杂可以有效改善DLC薄膜性能。Yang等[61]采用Ti和N共掺杂的方法,在MAO膜表面形成具有TiN晶相的DLC膜,以提高膜间结合力和复合膜的热稳定性,从而进一步提高MAO膜耐磨耐腐蚀性能。膜表面的微孔孔径减小,添加Ti或N原子的DLC薄膜残余应力得以释放,双相(Ti:N)–DLC/MAO膜具有最高的临界载荷,(Ti:N)–DLC膜在很大程度上抑制了MAO中间层与基体之间原电池的形成并减少腐蚀的发生。

此外,电解液中加入石墨并结合后续工艺处理也可以制备复合MAO膜,Ridvan等[62]采用MAO和热液氧化法(HT)在AZ91镁合金表面沉积形成复合膜。首先在含石墨粒径(5~10 μm和75 μm)的硅酸盐/磷酸盐电解质中对AZ91镁合金进行MAO处理,然后在150 ℃下对石墨–乙醇混合物进行水热处理得到MAO–HT复合膜,石墨的加入增加了膜的厚度和致密性,表面形貌相对均匀,MAO–HT复合膜的耐磨性得到明显提高。

2.2.4 生物防腐膜

镁合金在体液Cl−存在下降解加速、伴随析氢反应且耐蚀性较差[63],MAO膜虽在初期可以提高耐蚀性,但MAO膜一旦破坏后会加速基体降解。羟基磷灰石(HA)是人体硬组织中的主要无机成分,可作为植入金属材料的表面膜,在镁合金MAO膜表面制备HA复合膜可以提高表面致密度并提高耐蚀性和MAO膜表面生物活性。溶胶凝胶工艺中电流密度对复合膜表面结构影响较大,溶胶凝胶法制备HA工艺简单并得到广泛应用,或在MAO膜表面水热合成含HA成分的复合膜[64]。此外,在镁合金MAO膜表面载覆缓蚀剂涂层也可提高膜耐蚀性并减少MAO膜微孔,复合膜间结合紧密。缓蚀剂也可以称为腐蚀抑制剂,石梦佳等[65]选用姜黄素(Cur)作为MAO膜生物防腐膜的缓蚀剂,利用聚乳酸–羟基乙酸PLGA承载缓蚀剂Cur后对镁合金MAO膜以不同角度浸涂,Cur结合基体金属形成难溶络合物减小电偶腐蚀并在材料表面形成保护层。在浸涂角度为0°且PLGA质量分数为12%时,复合膜腐蚀电流密度比镁合金基体下降3个数量级。

壳聚糖(CS)以其独特的生物相容性及可降解性、良好的抗腐蚀能力和低成本而被广泛应用于生物材料领域,CS对MAO膜的微孔和微裂纹具有封闭作用[66-67]。将MAO与浸渍技术相结合,在Mg– 1.74Zn–0.55Ca合金上制备了浸渍时间不同的MAO/ CS膜[68],CS膜能有效地密封MAO膜。动电位极化试验表明,MAO/CS膜提高了MAO膜的耐蚀性,与其他复合镀层相比,CS溶液浸渍3次的MAO镀层微裂纹少、厚度大,耐蚀性明显提高。Li等[69]采用原子层沉积(ALD)技术在AZ31镁合金表面沉积致密且生物相容性好的氧化钽(Ta2O5)纳米膜,以有效封闭微孔并调节降解速率,复合膜的腐蚀电流密度比基体降低了3个数量级。生物复合膜不仅耐蚀性好且具有促进细胞增殖和分化生物活性的作用[70],未来有望成为生物医学骨植入物的有前途的替代品。

2.2.5 其他涂层

目前,对具有自修复作用的镁合金MAO–LDH膜的研究较多[71]。王彪等[72]利用共沉淀法制备缓蚀性离子MoO2−4插层MgAl–LDH浆料,并用水热法将其沉积在MAO膜表面提高膜层致密度,以阴离子交换作用有效抵抗Cl−侵蚀,该MAO–LDH复合膜具有缺陷自修复能力和长期耐蚀性(腐蚀抑制效率高达99.9%)。Li等[73]在较低温度(60 ℃)、较高pH(13.76)的水浴条件下,在MAO膜上完全覆盖LDH制得MAO–LDH自修复膜。复合后腐蚀电流密度比基体降低了4个数量级,复合膜有效抑制了阴极析氢反应和阳极α–Mg的溶解,插层的CO32−在点蚀处扩散到表层与溶解Mg2+结合生成MgCO3,而MgCO3在碱性环境下转化Mg(OH)2沉淀并在点蚀点处沉积覆盖,从而实现了膜的修复。MAO–LDH膜较少发生局部腐蚀并有利于成骨细胞的生长,但随着离子交换时间的延长或LDH膜表面吸附H2O后,形成相对光滑的O2和Cl−扩散路径,从而促进阴极反应,LDH膜表面产生间隙和凹坑后容易降解[74]。因此,需形成曲折的扩散路径并有效地防止腐蚀性物质通过LDH层。由于氧化石墨烯(GO)膜对水、氧和离子不渗透,因此,被广泛结合到金属表面膜中以提高阻隔性能。Chen等[75]在AZ31镁合金MAO膜表面采用一步水热原位合成法制备了GO–LDH膜。GO表面的负电荷及其片状结构可以作为带正电荷的LDH纳米片原位生长的结构支撑[76-77],LDH与GO结合填补了MAO的孔隙,大大提高了MAO膜的耐蚀性和抗渗性。0.1 GO/LDH– MAO膜(GO悬浮液浓度为0.1 mg/mL)的结构更加致密,几乎无孔洞,膜厚度的增加是由于GO表面的负电荷对金属阳离子吸附良好,但吸附过量会使GO发生迁移和聚集,从而导致膜厚度下降。GO可在任意方向随机生长,这使腐蚀介质的扩散路径更加曲折和漫长[78],从而具有良好的阻隔作用并能延长腐蚀时间。LDH保持离子交换能力能捕获Cl−,而GO的褶皱特性产生优良的迷宫效应,显著提高了GO/LDH–MAO膜的抗渗性。

Li等[79]将氧化锑锡(ATO)粒子掺杂到甲基三甲氧基硅烷(MTMS)膜中,在微弧氧化(MAO)镁合金AZ31表面制备了ATO–MTMS导电膜。MAO/ MTMS膜的电导率虽然降低,但膜表层形成了导电路径而增强了静电荷的转移,充分抑制了腐蚀介质通过导电路径对衬底的侵蚀,复合膜的腐蚀电流密度比基体小3个数量级,具有良好的耐腐蚀性能。物理隔离和化学惰性的静电粉末喷涂(EPS)涂层非常有利于保护镁合金基体与MAO膜[80],顶部EPS膜渗透到MAO膜多孔外层并表现出机械键合,致密内层对镁合金基体起到了保护作用,但2种工艺的微弧氧化(pH=14)和电泳(pH=5)电化学环境不同,导致2种工艺之间有必要进行洗涤。MAO–EPS复合膜表面形貌光滑且无微孔,以环氧树脂为主要成分的EPS膜覆盖MAO膜,顶部EPS膜与MAO膜之间具有较高的结合力和良好的耐蚀性。复合膜工艺虽然能够提高镁合金耐腐蚀性能,但工艺较复杂,因此,应在功能化发展的同时,简化工艺,降低成本。

3 展望

近年来,虽然MAO技术得以快速发展,但目前仍存在着国内外缺乏大型工业生产线、单一的MAO工艺无法满足实际要求、复合涂层缺乏完善的理论体系、工艺复杂且成本较高等问题,因此综合MAO膜耐蚀性能提高的研究现状,提出了未来MAO复合工艺发展趋势可集中在以下几个方向。

1)MAO复合膜防腐基础理论研究有待进一步完善。未来可利用最新的学科理论方法,结合现代分析测试手段原位捕捉MAO过程,深入系统研究膜生长机理、界面结构及基础理论问题。

2)对MAO高防腐性的电源工艺参数建立数据库,实现电源的合理控制以及探究更为理想的电源模式并对电参数进行优化,简化复合膜工艺操作步骤,发展智能化工艺设备。

3)选择合适的电解液添加剂以提高MAO膜耐蚀相比例并改善膜层性能或实现自封孔,并结合复合工艺制备性能更优的复合膜。

4)对MAO复合膜进行低成本的功能化研究,如低介电高绝缘、自修复、高催化活性、着色、热控、隐身、磁性、锂电等功能,并对复合膜使用寿命和膜层间结合进行深入研究。

[1] JIAN Shun-yi, CHU Yu-ren, LIN C S. Permanganate Conversion Coating on AZ31 Magnesium Alloys with Enhanced Corrosion Resistance[J]. Corrosion Science, 2015, 93(4): 301-309.

[2] ALEXANDRE Z, DELPHINE V R, LAURENT B, et al. Oxide Growth Mechanism on Mg AZ91 Alloy by Anodizing: Combination of Electrochemical and Ellipsometric In-Situ Measurements[J]. Journal of the Electrochemical Society, 2017, 164(14): C1059-C1066.

[3] ZHENG Tian-xu, HU Yao-bo, PAN Fu-sheng, et al. Fabrication of Corrosion-Resistant Superhydrophobic Coating on Magnesium Alloy by One-Step Electrodeposition Method[J]. Journal of Magnesium and Alloys, 2019, 7(2): 193-202.

[4] SUO Xin-kun, GUO Xue-ping, LI Wen-ya, et al. Preparation and Characterization of Magnesium Coating Deposited by Cold Spraying[J]. Journal of Materials Processing Tech, 2011, 212(1): 100-105.

[5] CUI C E, MIAO Q, PAN J D. Ti/Cr Multi-Layer Coating on Magnesium Alloy AZ91 by Arcadded Glow Plasma Depositing Technique[J]. Surface and Coating Technology, 2007, 201(9/10/11): 5400-5403.

[6] WU Guo-song, SHANAGHI A, ZHAO Ying, et al. The Effect of Interlayer on Corrosion Resistance of Ceramic Coating/Mg Alloy Substrate in Simulated Physiological Environment[J]. Surface & Coatings Technology, 2012, 206(23): 4892-4898.

[7] SUN Yong, LU Cheng, YU Hai-liang, et al. Nanomechanical Properties of TiCN and TiCN/Ti Coatings on Ti Prepared by Filtered Arc Deposition[J]. Materials Science & Engineering A, 2015, 625: 56-64.

[8] VLADIMIROV B V, KRIT B L, LYUDIN V B. Microarc Oxidation of Magnesium Alloys: A Review[J]. Surface Engineering and Applied Electrochemistry, 2014, 50(3): 195-232.

[9] REHMAN Z U, SHIN S H, HUSSAIN I, et al. Structure and Corrosion Properties of the Two-Step PEO Coatings Formed on AZ91D Mg Alloy in K2ZrF 6-Based Electrolyte Solution[J]. Surface & Coatings Technology, 2016, 307: 484-490.

[10] 宋仁国. 微弧氧化技术的发展及其应用[J]. 材料工程, 2019, 47(3): 50-62.

SONG Ren-guo. Development and Applications of Micro-Arc Oxidation Technology[J]. Journal of Materials Engineering, 2019, 47(3): 50-62.

[11] LI Xuan, SHI Chao, BAI Jing, et al. Degradation Behaviors of Surface Modified Magnesium Alloy Wires in Different Simulated Physiological Environments[J]. Frontiers of Materials Science, 2014, 8(3): 281-294.

[12] LEE K M, SHIN K R, NAMGUNG S, et al. Electrochemical Response of ZrO2Incorporated Oxide Layer on AZ91 Mg Alloy Processed by Plasma Electrolytic Oxidation[J]. Surface and Coating Technology, 2011, 205(13/ 14): 779-3784.

[13] ARRABAL R, MOTA J M, CRIADO A, et al. Assessment of Duplex Coating Combining Plasma Electrolytic Oxidation and Polymer Layer on AZ31 Magnesium Alloy[J]. Surface & Coatings Technology, 2012, 206(22): 4692- 4703.

[14] BAKHSHESHI-RAD H R, HAMZAH E, EBRAHIMI- KAHRIZSANGI R, et al. Fabrication and Characterization of Hydrophobic Microarc Oxidation/Polylactic Acid Duplex Coating on Biodegradable Mg-Ca Alloy for Corrosion Protection[J]. Vacuum, 2016, 125: 185-188.

[15] CUI X J, WEI J S, NING C M, et al. Effects of Nitrogen Volumetric Flow Rate on Properties of MAO/TiN Composite Coatings on AZ31B Magnesium Alloy[J]. China Surface Engineering, 2017, 30(2): 27-34.

[16] YANG Zhong, ZHANG Xu-zhen, WU Ye-kang, et al. The Correlation between the Na2SiO3·9H2O Concentrations and the Characteristics of Plasma Electrolytic Oxidation Ceramic Coatings[J]. Ceramics International, 2019, 45(15): 19388-19394.

[17] ZHANG Gen, WU Liang, TANG Ai-tao, et al. Sealing of Anodized Magnesium Alloy AZ31 with MgAl Layered Double Hydroxides Layers[J]. RSC Advances, 2018, 8(5): 2248-2259.

[18] DARBAND G B, ALIOFKHAZRAEI M, HAMGHALAM P, et al. Plasma Electrolytic Oxidation of Magnesium and Its Alloys: Mechanism, Properties and Applications[J]. Journal of Magnesium and Alloys, 2017, 5(1): 74-132.

[19] CHEN Wei-wei, WANG Ze-xin, SUN Lei, et al. Research of Growth Mechanism of Ceramic Coatings Fabricated by Micro-Arc Oxidation on Magnesium Alloys at High Current Mode[J]. Journal of Magnesium and Alloys, 2015, 3(3): 253-257.

[20] CHENG Y L, WANG T, LI S X, et al. The Effects of Anion Deposition and Negative Pulse on the Behaviours of Plasma Electrolytic Oxidation (PEO)—a Systematic Study of the PEO of a Zirlo Alloy in Aluminate Electrolytes[J]. Electrochimica Acta, 2017, 225: 47-68.

[21] KULKARNI J, RAVISHANKAR R, NAGABHUSHANA H, et al. Structural, Optical and Photocatalytic Properties of MgO/CuO Nanocomposite Prepared by a Solution Combustion Method[J]. Materials Today: Proceedings, 2017, 11(4): 11756-11763.

[22] ZHANG R F. Film Formation in the Second Step of Micro-Arc Oxidation on Magnesium Alloys[J]. Corrosion Science: the Journal on Environmental Degradation of Materials and Its Control, 2010, 52(4): 1285.

[23] NASIRIVATAN H, EBRAHIMI-KAHRIZSANGI R, ASGARANI M K. Tribological Performance of PEO-WC Nanocomposite Coating on Mg Alloys Deposited by Plasma Electrolytic Oxidation[J]. Tribology International, 2016, 98: 253-260.

[24] HUA You-lu, ZHANG Zhi-guo, LI Wei. Microstructure and Degradation Properties of C-Containing Composite Coatings on Magnesium Alloy Wires Treated with Micro- Arc Oxidation[J]. Surface and Coatings Technology, 2016, 291(15): 70-78.

[25] XIONG Ying, LU Chao, WANG Chao, et al. The N- MAO/EPD Bio-Ceramic Composite Coating Fabricated on ZK60 Magnesium Alloy Using Combined Micro-Arc Oxidation with Electrophoretic Deposition[J]. Applied Surface Science, 2014, 322: 230-235.

[26] 陈传忠, 陈阳, 于慧君. 镁合金含银微弧氧化电解液、生物陶瓷膜层及制备方法: CN110331426B[P]. 2020- 08-28.

CHEN Chuan-zhong, CHEN Yang, YU Hui-jun. Magnesium Alloy Silver-Containing Micro-Arc Oxidation Electrolyte, Biological Ceramic Membrane Layer and Preparation Method: CN110331426B[P]. 2020-08-28.

[27] 梁锡炳, 李兴刚, 张奎, 等. 纳米Al2O3添加剂对VW75稀土镁合金微弧氧化膜层的影响[J]. 稀有金属, 2021, 45(7): 812-820.

LIANG Xi-bing, LI Xing-gang, ZHANG Kui, et al. Micro-Arc Oxidation Coatings Formed on VW75 Mg Alloy with Al2O3Nano-Additive[J]. Chinese Journal of Rare Metals, 2021, 45(7): 812-820.

[28] 夏承森, 温翠莲, 詹晓章, 等. 微弧氧化法制备镁基羟基磷灰石/碳纳米管复合生物涂层及其性能研究[J]. 科技导报, 2016, 34(8): 60-66.

XIA Cheng-sen, WEN Cui-lian, ZHAN Xiao-zhang, et al. Synthesis and Properties of Hydroxyapatite/CNTS Composite Coating on Magnesium Alloy by Micro-Arc Oxidation[J]. Science & Technology Review, 2016, 34(8): 60- 66.

[29] 陈宏, 黄杰, 陈永楠, 等. AZ91D镁合金外加电场下自封孔微弧氧化膜层微观形貌及耐蚀性[J]. 稀有金属材料与工程, 2017, 46(10): 3098-3104.

CHEN Hong, HUANG Jie, CHEN Yong-nan, et al. Morphology and Corrosion Resistance of Self-Sealing Micro- Arc Oxidation Coatings of AZ91D Magnesium Alloys under External Electric Field[J]. Rare Metal Materials and Engineering, 2017, 46(10): 3098-3104.

[30] 陈海燕, 缪倩倩, 蒋永锋, 等. 稀土配合物对增强AZ31镁合金微弧氧化陶瓷层性能的作用[J]. 材料保护, 2018, 51(5): 7-11.

CHEN Hai-yan, MIAO Qian-qian, JIANG Yong-feng, et al. Effect of Rare Earth Complexes on Enhancing the Properties of Micro-Arc Oxidation Ceramic Coating on AZ31 Magnesium Alloy[J]. Materials Protection, 2018, 51(5): 7-11.

[31] WU W X, WANG W P, LIN H C. A Study on Corrosion Behavior of Micro-Arc Oxidation Coatings Doped with 2-Aminobenzimidazole Loaded Halloysite Nanotubes on AZ31 Magnesium Alloys[J]. Surface & Coatings Technology, 2021, 416: 127116-127129.

[32] WANG X S, GUO X W, LI X D, et al. Effect of Different Micro-Arc Oxidation Coating Layer Types on Fatigue Life of 2024-T4 Alloy[C]// 13th International Conference on Fracture, Beijing, 2013: 2022-2026.

[33] ZHENG Zhong-ren, CHUN Zhao ming, TAN Li-li, et al. Corrosion Behavior of a Self-Sealing Coating Containing CeO2Particles on Pure Mg Produced by Micro-Arc Oxidation[J]. Surface & Coatings Technology, 2020, 386(C): 125456.

[34] TOORANI M, ALIOFKHAZRAEI M. Review of Electrochemical Properties of Hybrid Coating Systems on Mg with Plasma Electrolytic Oxidation Process as Pretreatment[J]. Surfaces and Interfaces, 2019, 14(3): 262-295.

[35] 刘朋, 刘群峰, 黄德群, 等. 微弧氧化膜封孔技术研究进展[J]. 表面技术, 2019, 48(7): 61-71.

LIU Peng, LIU Qun-feng, HUANG De-qun, et al. Research Progress of Pore Sealing Technology for Micro- Arc Oxidation Films[J]. Surface Technology, 2019, 48(7): 61-71.

[36] 翟彦博, 陈红兵, 梅镇. 封孔方式对AZ31B镁合金微弧氧化膜耐腐蚀性的影响[J]. 西南大学学报: 自然科学版, 2014, 36(4): 173-179.

ZHAI Yan-bo, CHEN Hong-bing, MEI Zhen. Effect of Sealing Treatment on Corrosion Resistance of Micro-Arc Oxidation Coatings for AZ31B Mg Alloy[J]. Journal of Southwest University: Natural Science Edition, 2014, 36(4): 173-179.

[37] TAKEBAYASHI K, SHIOMI H, NAKA S, et al. Utility of a Microwave Surgical Instrument in Sealing Lymphatic Vessels[J]. American Journal of Surgery, 2013, 206(2): 229-233.

[38] 王志虎, 张菊梅, 白力静, 等. AZ31镁合金微弧氧化陶瓷层表面Mg(OH)2膜层的制备及耐蚀性[J]. 无机材料学报, 2020, 35(6): 709-716.

WANG Zhi-hu, ZHANG Ju-mei, BAI Li-jing, et al. Mg(OH)2Film on Micro-Arc Oxidation Ceramic Coating of AZ31 Magnesium Alloy: Preparation and Corrosion Resistance[J]. Journal of Inorganic Materials, 2020, 35(6): 709-716.

[39] LEE J H, KIM S J. Enhancement of Wettability by Wet Surface Modification and Application of Rare-Earth Element in Sealing of Ceramic Oxide Thin Film on Al Alloy[J]. Journal of Nanoscience and Nanotechnology, 2016, 16(11): 11797-11801.

[40] ZHANG Gen, WU Liang, TANG Ai-tao, et al. Active Corrosion Protection by a Smart Coating Based on a MgAl-Layered Double Hydroxide on a Cerium-Modified Plasma Electrolytic Oxidation Coating on Mg Alloy AZ31[J]. Corrosion Science, 2018, 139: 370-382.

[41] 李思思, 王维, 吴玉锋, 等. 镁合金表面微弧氧化-溶胶凝胶复合膜层的结构及其耐蚀性[J]. 中国表面工程, 2013, 26(3): 40-44.

LI Si-si, WANG Wei, WU Yu-feng, et al. Structure and Corrosion Resistance of Composite Coating Prepared by Micro-Arc Oxidation and Sol-Gel Methods on the Surface of Magnesium Alloy[J]. China Surface Engineering, 2013, 26(3): 40-44.

[42] ZHOU Meng, YAN Lu-chun, LING Hao, et al. Design and Fabrication of Enhanced Corrosion Resistance Zn-Al Layered Double Hydroxides Films Based Anion-Exchange Mechanism on Magnesium Alloys[J]. Applied Surface Science, 2017, 404: 246-253.

[43] KAMIYAMA N, PANOMSUWAN G, YAMAMOTO E, et al. Effect of Treatment Time in the Mg(OH)2/Mg-Al LDH Composite Film Formed on Mg Alloy AZ31 by Steam Coating on the Corrosion Resistance[J]. Surface & Coatings Technology, 2016, 286: 172-177.

[44] PENG Feng, LI Hua, WANG Dong-hui, et al. Enhanced Corrosion Resistance and Biocompatibility of Magnesium Alloy by Mg-Al-Layered Double Hydroxide[J]. ACS Applied Materials & Interfaces, 2016, 8(51): 35033-35044.

[45] 蒋世权, 吴方, 王媛媛, 等. 镁合金表面微弧氧化/自组装复合膜的耐蚀性能[J]. 表面技术, 2021, 50(4): 294- 303.

JIANG Shi-quan, WU Fang, WANG Yuan-yuan, et al. Corrosion Resistance of Micro-Arc Oxidation/Self-Assembled Composite Coating on Magnesium Alloy[J]. Surface Technology, 2021, 50(4): 294-303.

[46] GAO H F, TAN H Q, LI J, et al. Synergistic Effect of Cerium Conversion Coating and Phytic Acid Conversion Coating on AZ31B Magnesium Alloy[J]. Surface & Coatings Technology, 2012, 212: 32-36.

[47] JIANG Dan, ZHOU Huan, WAN Shan, et al. Fabrication of Superhydrophobic Coating on Magnesium Alloy with Improved Corrosion Resistance by Combining Micro-Arc Oxidation and Cyclic Assembly[J]. Surface and Coatings Technology, 2018, 339(8): 155-166.

[48] ZHANG Fen, ZHANG Chang-lei, ZENG Rong-chang, et al. Corrosion Resistance of the Superhydrophobic Mg(OH)2/Mg-Al Layered Double Hydroxide Coatings on Magnesium Alloys[J]. Metals, 2016, 6(4): 85.

[49] ZHOU M, PANG X L, WEI L, et al. Insitu Grown Superhydrophobic Zn-Al Layered Double Hydroxides Films on Magnesium Alloy to Improve Corrosion Properties[J]. Applied Surface Science, 2015, 337(5): 172-177.

[50] 李岩, 章晴云, 卢小鹏, 等. 微弧氧化工艺参数对镁合金表面水滑石复合膜层耐蚀性的影响[J]. 表面技术, 2021, 50(8): 327-336.

LI Yan, ZHANG Qing-yun, LU Xiao-peng, et al. Effect of Process Parameters on Corrosion Resistance of MAO/ LDH Composite Coatings[J]. Surface Technology, 2021, 50(8): 327-336.

[51] WANG Z H, ZHANG J M, LI Y, et al. Enhanced Corrosion Resistance of Micro-Arc Oxidation Coated Magnesium Alloy by Superhydrophobic Mg-Al Layered Double Hydroxide Coating[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(10): 2066-2077.

[52] CHEN J F, LIANG S Y, FU D B, et al. Design and In-Situ Prepare a Novel Composite Coating on Mg Alloy for Active Anti-Corrosion Protection[J]. Journal of Alloys and Compounds, 2020, 831(16): 154580-154589.

[53] LI Z X, YU Q L, ZHANG C Y, et al. Synergistic Effect of Hydrophobic Film and Porous MAO Membrane Containing Alkynol Inhibitor for Enhanced Corrosion Resistance of Magnesium Alloy[J]. Surface Coatings Technology, 2019, 357(1): 515-525.

[54] EZHILSELVI V, BALARAJU J N, SUBRAMANIAN S. Chromate and HF Free Pretreatment for MAO/Electroless Nickel Coating on AZ31B Magnesium Alloy[J]. Surface and Coatings Technology, 2017, 325(18): 270-276.

[55] CUI Xue-jun, PING Jing, ZHANG Ying-jun, et al. Structure and Properties of Newly Designed MAO/TiN Coating on AZ31B Mg Alloy[J]. Surface and Coatings Technology, 2017, 328(22): 319-325.

[56] 付明, 李均明. 镁合金表面微弧氧化/化学镀镍的复合改性作用[J]. 材料保护, 2019, 52(6): 79-83.

FU Ming, LI Jun-ming. Surface Modification of Microarc Oxidation Combined with Electroless Nickel Plating for Magnesium Alloys[J]. Materials Protection, 2019, 52(6): 79-83.

[57] CUI Xue-jun, NING Chuang-ming, SHANG Lun-lin, et al. Structure and Anticorrosion, Friction, and Wear Characteristics of Pure Diamond-Like Carbon (DLC), Cr-DLC, and Cr-H-DLC Films on AZ91D Mg Alloy[J]. Journal of Materials Engineering and Performance, 2019, 28(2): 1213-1225.

[58] WU Y M, ZHOU S G, ZHAO W J, et al. Comparative Corrosion Resistance Properties between (Cu,Ce)-DLC and Ti Co-doped (Cu, Ce)/Ti-DLC Films Prepared via Magnetron Sputtering Method[J]. Chemical Physics Letters, 2018, 705: 50-58.

[59] VISWANATHAN S, MOHAN L, BERA P, et al. Corrosion and Wear Behaviors of Cr-Doped Diamond-Like Carbon Coatings[J]. Journal of Materials Engineering and Performance, 2017, 26(8): 3633-3647.

[60] JUN Cui-xue, MING Ning-chuang, AN Zhang-guang, et al. Properties of Polydimethylsiloxane Hydrophobic Modified Duplex Microarc Oxidation/Diamond-Like Carbon Coatings on AZ31B Mg Alloy[J]. Journal of Magnesium and Alloys, 2020, 9(4): 1285-1296.

[61] YANG Wei, KE Pei-ling, FANG Yong, et al. Microstructure and Properties of Duplex (Ti: N)-DLC/MAO Coating on Magnesium Alloy[J]. Applied Surface Science, 2013, 270: 519-525.

[62] RIDVAN K, EBRU E Ş, YAŞAR T, et al. Investigation of Wear Behavior of Graphite Additive Composite Coatings Deposited by Micro Arc Oxidation-Hydrothermal Treatment on AZ91 Mg Alloy[J]. Surfaces and Interfaces, 2021, 22: 100894-100901.

[63] HU D J, ZHANG J, HANG R Y, et al. Effects of Solid Diffusion Zinc Treatment on Corrosion Behavior, Antibacterial Ability, and Cytocompatibility of AZ31B Magnesium Alloy[J]. Materials Letters, 2019, 251(18): 30-33.

[64] GUO J W, SUN S Y, WANG Y M, et al. Hydrothermal Biomimetic Modification of Microarc Oxidized Magnesium Alloy for Enhanced Corrosion Resistance and Deposition Behaviors in SBF[J]. Surface and Coatings Technology, 2015, 269: 183-190.

[65] 石梦佳, 李伟杰, 马小爽, 等. 骨植入镁合金表面缓蚀剂覆载的微弧氧化/PLGA复合涂层的制备与表征[J]. 表面技术, 2021, 50(2): 30-38.

SHI Meng-jia, LI Wei-jie, MA Xiao-shuang, et al. Preparation and Characterization of Corrosion Inhibitor- Loaded Micro-Arc Oxidation/PLGA Composite Coating on Biodegradable Magnesium Alloy[J]. Surface Technology, 2021, 50(2): 30-38.

[66] AVCU E, BAŞTAN F E, ABDULLAH H Z, et al. Electrophoretic Deposition of Chitosan-Based Composite Coatings for Biomedical Applications: A Review[J]. Progress in Materials Science, 2019, 103(3): 69-108.

[67] BAI K F, ZHANG Y, FU Z Y, et al. Fabrication of Chitosan/Magnesium Phosphate Composite Coating and the in Vitro Degradation Properties of Coated Magnesium Alloy[J]. Materials Letters, 2012, 73(2): 59-61.

[68] DOU Jin-he, YU Hui-jun, CHEN Chuan-zhong, et al. Preparation and Microstructure of MAO/CS Composite Coatings on Mg Alloy[J]. Materials Letters, 2020, 271(4): 127729.

[69] LI Chang-yang, YU Chi, ZENG Rong-chang, et al. In Vitro Corrosion Resistance of a Ta2O5Nanofilm on MAO Coated Magnesium Alloy AZ31 by Atomic Layer Deposition[J]. Bioactive Materials, 2020, 5(1): 34-43.

[70] DOU Jin-he, WANG Jing, LU Yu-peng, et al. Bioactive MAO/CS Composite Coatings on Mg-Zn-Ca Alloy for Orthopedic Applications[J]. Progress in Organic Coatings, 2021, 152(3): 106112-106123.

[71] ZHANG Gen, WU Liang, TANG Ai-tao, et al. Effect of Micro-Arc Oxidation Coatings Formed at Different Voltages on the in Situ Growth of Layered Double Hydroxides and Their Corrosion Protection[J]. Journal of the Electrochemical Society, 2018, 165(7): C317-C327.

[72] 王彪, 李汉周, 董泽华. 微弧氧化-水滑石复合涂层的制备及其在AZ91镁合金防腐蚀中的应用[J]. 材料保护, 2020, 53(11): 26-31.

WANG Biao, LI Han-zhou, DONG Ze-hua. Fabrication and Corrosion Resistance of MAO-LDH Composite Coating on AZ91 Mg Alloy[J]. Materials Protection, 2020, 53(11): 26-31.

[73] LI Chang-yang, GAO Ling, FAN Xiao-li, et al. In Vitro Degradation and Cytocompatibility of a Low Temperature in-Situ Grown Self-Healing Mg-Al LDH Coating on MAO- Coxated Magnesium Alloy AZ31[J]. Bioactive Materials, 2020, 5(2): 364-376.

[74] LUO Xiao-hu, YUAN Song, PAN Xin-yu, et al. Synthesis and Enhanced Corrosion Protection Performance of Reduced Graphene Oxide Nanosheet/ZnAl Layered Double Hydroxide Composite Films by Hydrothermal Continuous Flow Method[J]. ACS Applied Materials & Interfaces, 2017, 9(21): 18263-18275.

[75] CHEN Yan-ning, WU Liang, YAO Wen-hui, et al. One-Step in Situ Synthesis of Graphene Oxide/MgAl- Layered Double Hydroxide Coating on a Micro-Arc Oxidation Coating for Enhanced Corrosion Protection of Magnesium Alloys[J]. Surface & Coatings Technology, 2021, 413(10): 127083-127095.

[76] YAN Lu-chun, ZHOU Meng, PANG Xiao-lu, et al. One-Step in Situ Synthesis of Reduced Graphene Oxide/ Zn-Al Layered Double Hydroxide Film for Enhanced Corrosion Protection of Magnesium Alloys[J]. Langmuir: the ACS Journal of Surfaces and Colloids, 2019, 35(19): 6312-6320.

[77] YAO Wen, WANG Jian, WANG Peng-yi, et al. Synergistic Coagulation of GO and Secondary Adsorption of Heavy Metal Ions on Ca/Al Layered Double Hydroxides[J]. Environmental Pollution, 2017, 229(10): 827-836.

[78] LUO Xiao-hu, ZHONG Jia-wen, ZHOU Qiu-lan, et al. Cationic Reduced Graphene Oxide as Self-Aligned Nanofiller in the Epoxy Nanocomposite Coating with Excellent Anticorrosive Performance and Its High Antibacterial Activity[J]. ACS Applied Materials & Interfaces, 2018, 10(21): 18400-18415.

[79] LI Chang-yang, FAN Xiao-li, CUI Lan-yue, et al. Corrosion Resistance and Electrical Conductivity of a Nano ATO-Doped MAO/Methyltrimethoxysilane Composite Coating on Magnesium Alloy AZ31[J]. Corrosion Science, 2019, 168(5): 108570-108582.

[80] YANG Wei, XU Da-peng, WANG Jian-li, et al. Microstructure and Corrosion Resistance of Micro Arc Oxidation Plus Electrostatic Powder Spraying Composite Coating on Magnesium Alloy[J]. Corrosion Science, 2018, 136: 174- 179.

Research Progress of Micro-arc Oxidation Composite Films for Magnesium Alloys

1,2,2,1,1,1

(1. Xi'an University of Architecture and Technology Huaqing College, Xi'an 710045, China; 2. College of Metallurgical Engineering, Xi'an University of Architecture and Technology, Xi'an 710055, China)

Micro-arc oxidation (MAO) surface treatment is often used to improve specific properties of magnesium alloys, but MAO films tend to produce micropores and microcracks, which deteriorate corrosion resistance of magnesium alloy. In order to improve the service life of magnesium alloy micro-arc oxidation (MAO) film, the latest research progress of MAO process adjustment measures and MAO film post-treatment technology at home and abroad was reviewed, and the research hotspot of MAO composite film at home and abroad in recent years was mainly introduced. Several measures to improve the long-term protection performance of magnesium alloy MAO film by process adjustment were mainly summarized. The adjustment of electrical parameters and power supply type combined with the adjustment of electrolyte composition can improve the corrosion resistance of MAO film. Adding additives into the electrolyte can improve the stability and conductivity of MAO electrolyte. Adding self-sealing hole additives can participate in the film formation to improve the compactness of MAO film. The pores were further sealed by composite process after traditional pore-sealing for MAO film. Furthermore, the research progress of composite coating technology was introduced in detail, including the hydrophobic coatings, electroless plating, diamond-like coating and biological membrane coating. It is emphasized that the composite film not only had high corrosion resistance but also had the prospect of functional application. Super hydrophobic composite film had active corrosion protection effect on magnesium substrate, so it can assist MAO film to improve the surface hydrophobicity. The nickel plating layer was compact and has no micropores, improving the conductivity and corrosion resistance of magnesium MAO film by cross bite with MAO film. MAO coating replaced the metal buffer layer to improve the interface bonding strength between diamond-like coating and matrix. The biological composite coating not only had high corrosion resistance but also had biological activity to promote cell proliferation and differentiation. Finally, based on the research status of MAO process of magnesium alloy, the future development trend of MAO composite film was prospected.

magnesium alloy; micro-arc oxidation; additive; sealing hole; composite film

TG174.4

A

1001-3660(2022)04-0066-11

10.16490/j.cnki.issn.1001-3660.2022.04.006

2021-05-06;

2021-08-05

2021-05-06;

2021-08-05

陕西省科技统筹创新工程计划(2011KTDZ01-04-01);陕西本科和高等继续教育教学改革研究项目(21BY196)

Shaanxi Provincial Science and Technology Innovation Project (2011KTDZ01-04-01); Shaanxi Undergraduate and Higher Continuing Education Teaching Reform Research Project (21BY196)

唐洋洋(1989—),女,讲师,主要研究方向为冶金资源综合利用、冶金新技术。

TANG Yang-yang (1989—), Female, Lecturer, Research focus: comprehensive utilization of metallurgical resources and new metallurgical technology.

唐洋洋, 李林波, 王超, 等. 镁合金微弧氧化复合膜研究进展[J]. 表面技术, 2022, 51(4): 66-76.

TANG Yang-yang, LI Lin-bo, WANG Chao, et al. Research Progress of Micro-arc Oxidation Composite Films for Magnesium Alloys[J]. Surface Technology, 2022, 51(4): 66-76.

责任编辑:蒋红晨