震动载荷下煤体瓦斯瞬时放散特征实验研究

2022-03-17孔祥国邓岱雨王恩元季鹏飞王旭周雨璇

孔祥国 邓岱雨 王恩元 季鹏飞 王旭 周雨璇

摘 要:深部煤炭開采受顶底板破断、断层活化、相邻采掘活动和工程爆破等扰动,引起煤体瓦斯短时间大量放散,进而造成采掘作业空间瓦斯超限。为研究扰动作用下煤体瓦斯异常放散规律,建立了含瓦斯煤分离式霍普金森压杆试验系统,进行了震动载荷下煤体瓦斯放散实验。结果表明:震动载荷下煤体瓦斯放散具有瞬时性,瓦斯放散持续时间在0~4 s内,震动载荷作用瞬间,最大瓦斯放散量随着轴向静载和围压的增加而减小,分别由0.171 0,0.208 0 L/min降低到0.094 4,0.021 0 L/min,随着瓦斯压力和震动载荷冲击速度的增加而增加,分别由0.025 0

,0.050 0 L/min增加到0.138 0,0.098 8 L/min;在瓦斯放散过程中,最大瓦斯放散速度随着轴向静载和围压的增加而减小,随着瓦斯压力和震动载荷冲击速度的增加而增加;为刻画瓦斯放散的难易程度,基于瓦斯渗流稳态法,提出瓦斯瞬时放散率,瓦斯瞬时放散率随着轴向静载和围压增大而呈线性减小,降低幅度分别达到44.80%和89.90%,随着瓦斯压力的增大呈非线性减小,减小幅度逐渐降低,随着震动载荷冲击速度增加而增大,增加幅度达90.89%。此研究将有助于揭示扰动诱导煤体瓦斯异常放散机制和预测不同开采环境中瓦斯放散趋势。关键词:瓦斯放散;震动载荷;含瓦斯煤;瞬时放散率中图分类号:TD 712

文章编号:1672-9315(2022)01-0040-07 文献标志码:A

DOI:10.13800/j.cnki.xakjdxxb.2022.0106开放科学(资源服务)标识码(OSID):

Experimental research on instant gas emission

characteristics of coal samples under shock load

KONG Xiangguo1,2,DENG Daiyu1,2,WANG Enyuan3,JI Pengfei1,2,WANG Xu1,2,ZHOU Yuxuan1,2

(1.College of Safety Science and Engineering,Xi’an University of Science and Technology,Xi’an 710054,China;

2.Key Laboratory of Western Mine Exploitation and Hazard Prevention,Ministry of Education,

Xi’an University of Science and Technology,Xi’an 710054,China;

3.School of Safety Engineering,China University of Mining and Technology,Xuzhou 221116,China)

Abstract:Deep coal mining is disturbed by roof and floor breaking,fault activation,adjacent mining and engineering blasting,resulting in a large amount of gas emission in a short time,which might lead to gas over-run in mining space.To study gas releasing laws of coal at the role of disturbance,the spilit hopkinson pressure bar experimental system of gas-bearing coal was established,and gas releasing experiments of coal under shock load were conducted.The results showed that gas releasing characteristics of coal under shock load were of instant feature,and gas releasing would last about 0~4 s.At the impact moment of shock load,the maximum gas releasing volume decreased with the increase of axial static load and confining pressure,and reduced from 0.171 0,0.208 0 L/min to 0.094 4,0.021 0 L/min respectively,while it increased with gas pressure and shock load,and increased from 0.025 0,0.050 0 L/min to 0.138 0,0.098 8 L/min respectively.During gas releasing process,the maximum gas releasing velocity decreased with the increase of axial static load and confining pressure,while it increased with gas pressure and shock load.In order to describe how hard the gas is releasing,the instant gas releasing rate was put forward based on the gas seepage steady method.Gas instant releasing rate decreased linearly with the increase of axial static load(reduction extent of 44.80%)and confining pressure(reduction extent of 89.90%),decreased nonlinear with the increase of gas pressure,but the decrease extent narrowed.In addition,the gas releasing velocity increased with the impact velocity of shock load,and the increase extent reached 90.89%.This study will be helpful to reveal the abnormal gas emission mechanism of coal induced by disturbance and predict the gas emission trend in different mining environments.Key words:gas emission;shock load;gas-bearing coal;instant gas releasing rate

0 引 言

随着煤矿开采深度的逐渐增加,地应力、瓦斯压力和瓦斯含量不断增大,采场结构越来越复杂,应力和瓦斯复合型动力灾害日趋严重及复杂[1-4]。含瓦斯煤层开采过程中,顶底板断裂、断层活化和煤体破坏,均会产生应力波扰动(动载),进一步引起瓦斯异常放散,甚至煤与瓦斯突出[5-6]。煤体瓦斯放散是煤基质瓦斯解吸、裂隙瓦斯渗流、基质裂隙瓦斯交互作用的结果[7]。林海飞等研究了煤的吸附孔结构对瓦斯放散的影响,平均孔径越大,瓦斯扩散阻力越小,瓦斯放散初速度越大[8];刘彦伟等采用压汞法研究了软、硬煤粒孔隙结构特征的差异,分析了粒径对软硬煤瓦斯扩散速度的影响[9];张小东等探讨了粒度、表面张力对原生结构煤和构造煤的瓦斯放散初速度的影响,发现吸附孔隙增多,煤基质的表面张力增大,吸附能力增强,不利于气体的解吸[10];秦跃平等根据煤粒瓦斯解吸放散的特点,建立了煤粒瓦斯放散方程,研究了瓦斯解吸速度和瓦斯累积解吸量变化规律,与试验结果一致[11-12];基于达西定律和菲克定律,王健建立了圆柱形煤粒瓦斯放散数学模型,证实了煤粒瓦斯放散服从达西定律[13];为了量化煤层瓦斯运移能力,刘永茜等探究了煤层瓦斯运移的关键参数,发现瓦斯运移速度和衰减系数取决于煤的吸附能力和煤质组分,煤体瓦斯质量增量与运移时间成负指数关系,且随煤阶升高而增大[14]。煤体瓦斯由基质解吸到裂隙渗流再到脱离煤体自由放散,受到应力场、瓦斯场和外在条件等多种因素影响。赵洪宝等研究了固定应力环境下瓦斯放散过程中煤样变形规律,轴向应变和横向应变均表现出明显的非线性特征,并与瓦斯放散速度呈关联性[15];张冰等开展了煤粒瓦斯非常压放散特征试验,发现放散环境压力越大,瓦斯放散速度越小[16];周宏伟等研究了采动应力下煤体渗透率演化,并认为强扰动因素是确定深部煤体渗透率的关键[17];任伟光等研究发现上保护层开采扰动力学行为使得被保护层煤体状态从弹性态变到塑性态,进而导致其渗透率显著变化[18];程远平等认为深部煤层地应力主导有效应力的变化,渗透率增加的根本原因是应力的降低[19];李铁等通过现场案例和试验证实了冲击地压会诱发煤与瓦斯突出,形成瞬时瓦斯涌出现象[20];谢广祥等研究表明深部含瓦斯煤采动扩容行为致使瓦斯压力突变是诱发动力灾害的本质特征[21]。前述研究为完善深部煤体瓦斯运移机制奠定了基础,解决了矿井生产中一系列安全问题。煤炭开采过程中,采动扰动行为有时并未引起煤体宏观破坏,但会出现瓦斯异常放散的现象。因此,震动载荷下三维含瓦斯煤瓦斯瞬间放散特征研究显得尤为必要。

1 试验系统及过程

1.1 试验系统自主搭建了含瓦斯煤霍普金森压杆试验系统,实现了含瓦斯煤受载过程中瓦斯放散的监测。该系统主要由軸向静载子系统、围压加载子系统、瓦斯充放子系统和动载荷加载子系统、超动态应变采集子系统(采样率40 Msps,采集开始时间-0.019 97 s,采集时间0.08 s,触发电平-0.094 V)和红外测速子系统构成,如图1所示。轴向静载主要通过固定入射杆,由缓冲装置一端加压推动透射杆前移,将试样夹在入射杆和透射杆的同心轴线上;围压通过独立的液压站向试样腔体内注入液压油加压,液压油和试样通过围压胶套进行隔离;瓦斯放散量通过接在放气管路上的流量计进行实时采集;动载荷通过压缩空气发射撞击杆向入射杆撞击以施加动载荷;超动态应变采集系统通过贴于入射杆和透射杆上的应变片采集应力波信号;红外测速子系统主要用来测试撞击杆的速度,以衡量动载荷的大小。

1.2 试验试样所选大块煤样根据煤岩动力学测试要求,制成

100 mm×50 mm的试样,经过打磨将试样两端平行度控制在0.02 mm公差范围内。为了减少试样的离散性,选择密度相近的试样进行试验,试验时在试样两端涂抹黄油以减少摩擦效应。

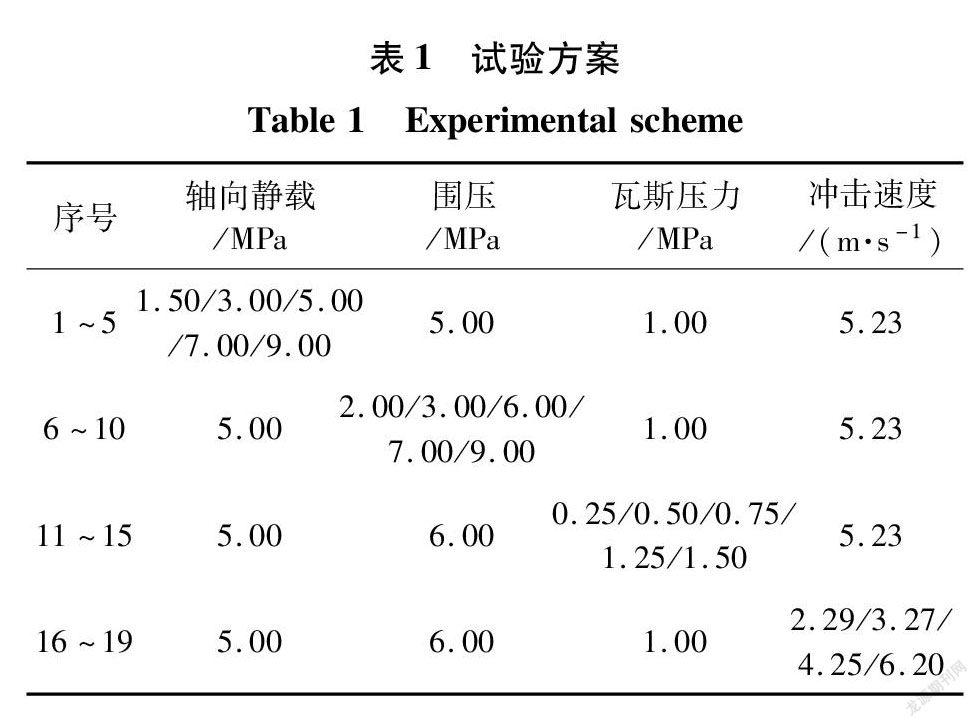

1.3 试验方案文中主要研究不同轴向静载、围压、瓦斯压力和震动载荷组合加载下含瓦斯煤受载过程中瓦斯放散特征,分析各因素对含瓦斯煤瓦斯最大放散量、瓦斯放散持续时间的影响,试验方案见表1。

2 试验结果及分析

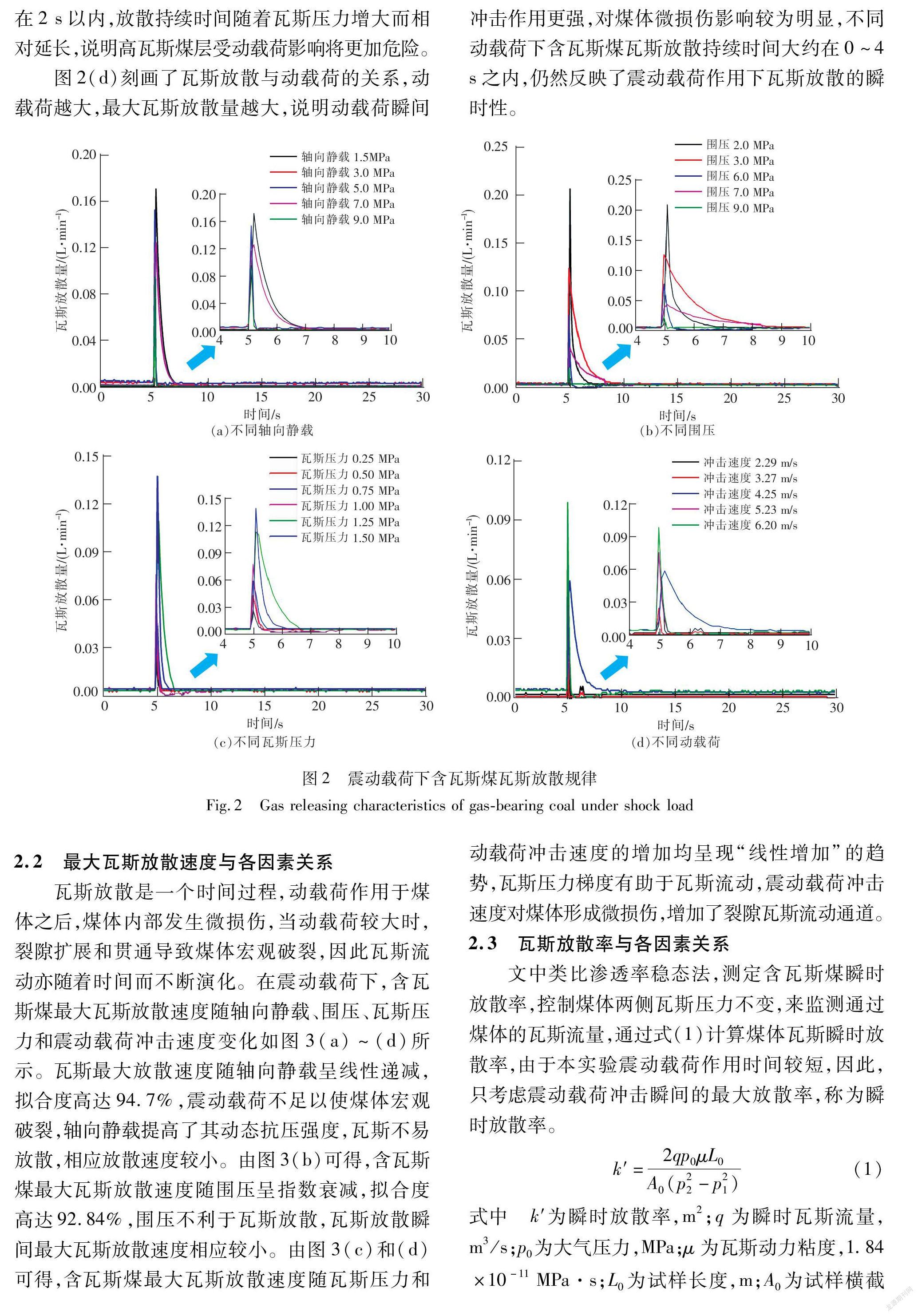

2.1 瓦斯放散随时间变化规律不同轴向静载、围压、瓦斯压力和动载荷组合加载下含瓦斯煤受载过程中瓦斯放散如图2(a)~(d)所示。图2(a)呈现了瓦斯放散随着轴向静载的变化规律,随着轴向静载的增加,最大瓦斯放散量逐渐减小,说明动载荷不足以引起煤体破裂时,轴向静载有助于提高煤体完整性使其不易破坏,轴向静载越大,原始裂隙越致密,动载荷不易引起煤体裂隙扩展而导致瓦斯放散;不同轴向静载下瓦斯放散持续时间大约在2 s之内,瓦斯放散持续时间与轴向静载关系不太明显,但是可以反映瓦斯放散的瞬时性,解释了震动诱导含瓦斯煤瓦斯异常放散的瞬时特性。图2(b)展现了瓦斯放散随围压的关系,最大瓦斯放散量随着围压的增加呈减小的趋势,

围压的作用使得煤体更加致密,而且围压限制煤体变形,围压越大,煤体新的裂隙越难形成,瓦斯不易放散,但是在动载荷作用瞬间仍然有瓦斯瞬时增大时刻,说明动载荷会引起煤体微损伤,但是在围

压的作用下,新生裂隙又闭合,瓦斯放散持续时间在0~4 s之内,围压越小,瓦斯放散持续时间相对越长。图2(c)反映了含瓦斯煤瓦斯放散随煤体内部瓦斯压力的关系,瓦斯压力越大,冲击瞬间瓦斯放散量越大,主要是瓦斯压力越大,放散时瓦斯压力梯度越大,促进瓦斯流动;瓦斯放散持续时间控制在2 s以内,放散持续时间随着瓦斯压力增大而相

对延长,说明高瓦斯煤层受动载荷影响将更加危险。

图2(d)刻画了瓦斯放散与动载荷的关系,动载荷越大,最大瓦斯放散量越大,说明动载荷瞬间冲击作用更强,对煤体微损伤影响较为明显,不同动载荷下含瓦斯煤瓦斯放散持续时间大约在0~4 s之内,仍然反映了震动载荷作用下瓦斯放散的瞬时性。

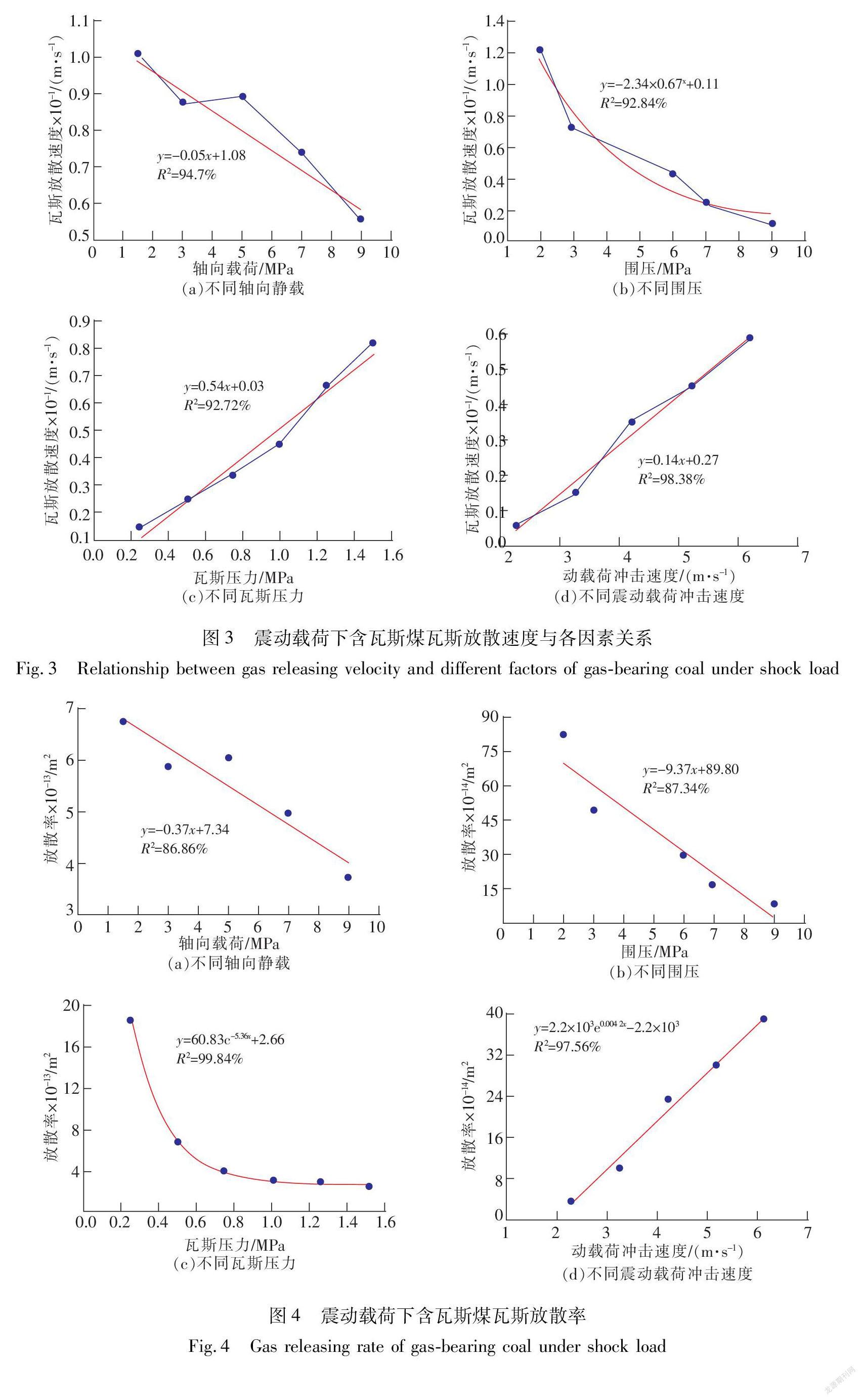

2.2 最大瓦斯放散速度与各因素关系瓦斯放散是一个时间过程,动载荷作用于煤体之后,煤体内部发生微损伤,当动载荷较大时,裂隙扩展和贯通导致煤体宏观破裂,因此瓦斯流动亦随着时间而不断演化。在震动载荷下,含瓦斯煤最大瓦斯放散速度随轴向静载、围压、瓦斯压力和震动载荷冲击速度变化如图3(a)~(d)所示。瓦斯最大放散速度随轴向静载呈线性递减,拟合度高达94.7%,震动载荷不足以使煤体宏观破裂,轴向静载提高了其动态抗压强度,瓦斯不易

放散,相应放散速度较小。由图3(b)可得,含瓦斯煤最大瓦斯放散速度随围压呈指数衰减,拟合度高达92.84%,围压不利于瓦斯放散,瓦斯放散瞬间最大瓦斯放散速度相应较小。由图3(c)和(d)可得,含瓦斯煤最大瓦斯放散速度随瓦斯压力和动载荷冲击速度的增加均呈现“线性增加”的趋势,瓦斯压力梯度有助于瓦斯流动,震动载荷冲击速度对煤体形成微损伤,增加了裂隙瓦斯流动通道。

2.3 瓦斯放散率与各因素关系文中类比渗透率稳态法,测定含瓦斯煤瞬时放散率,控制煤体两侧瓦斯压力不变,来监测通过煤体的瓦斯流量,通过式(1)计算煤体瓦斯瞬时放散率,由于本实验震动载荷作用时间较短,因此,只考虑震动载荷冲击瞬间的最大放散率,称为瞬时放散率。

(1)式中 k′为瞬时放散率,m2;q为瞬时瓦斯流量,m3/s;p0为大气压力,MPa;μ为瓦斯动力粘度,1.84×10-11 MPa·s;L0为试样长度,m;A0为试样横截面积,m2;p2为进气端瓦斯压力,MPa;p1为试样出气端瓦斯压力,MPa。由于试样出气端为自由端与大气联通,因此这里p1=p0。不同轴向静载、围压、瓦斯压力和震动载荷冲击速度组合加载下,含瓦斯煤瓦斯放散率如图4(a)~(d)所示。类似于瓦斯放散速度,轴向静载的作用使得煤体不易损伤,瓦斯放散率随着轴向静载的增加而减小;围压使煤体更加致密并限制变形造成瓦斯放散率降低;虽然瓦斯压力有助于体高瓦斯放散速度,但瓦斯压力平方差大于瓦斯放散量增加的程度,造成瓦斯放散率随瓦斯压力增加而非线性减小;震动载荷冲击速度越大,动载荷携带能量越多,对煤体损伤越严重,因此瓦斯放散率将随着动载荷的增大而增加。

3 结 论1)含瓦斯煤在震动载荷作用瞬间瓦斯放散表现出瞬时性特征,瓦斯放散持续时间在0~4 s内;震动载荷会诱导煤体微裂隙增加而引起瓦斯异常放散,但围压作用很快又使煤体微裂隙闭合。

2)当震动载荷不足以使煤体破裂时,轴向静载有助于提高煤体动态抗压强度,裂隙难以形成,最大瓦斯放散速度将随轴向静载增加而减小;围压的限制变形不利于瓦斯流动造成最大瓦斯放散速度随围压的增加而减小;瓦斯压力梯度促进瓦斯流动,震动载荷作用过程中最大瓦斯放散速度随着瓦斯压力增大而增加;震动载荷冲击速度越大,携带能量越多,煤体微损伤越严重,最大瓦斯放散速度将随震动载荷冲击速度增加而增大。

3)含瓦斯煤瞬时放散率随着轴向静载、围压的增大而线性减小,降低幅度分别达到44.80%和89.90%;随着瓦斯压力的增加呈非线性减小,主要是由于瓦斯压力的平方差增加程度大于瓦斯放散量的增加程度;随着震动载荷冲击速度增加基本呈增加的趋势,增加幅度达90.89%。

参考文献(References):

[1] 王恩元,冯俊军,张奇明,等.冲击地压应力波作用机理[J].煤炭学报,2020,45(1):100-110.

WANG Enyuan,FENG Junjun,ZHANG Qiming,et al.Mechanism of rockburst under stress wave in mining space[J].Journal of China Coal Society,2020,45(1):100-110.

[2]窦林名,何江,曹安业,等.煤矿冲击矿压动静载叠加原理及其防治[J].煤炭学报,2015,40(7):1469-1476.

DOU Linming,HE Jiang,CAO Anye,et al.Rock burst prevention methods based on theory of dynamic and static combined load induced in coal mine[J].Journal of China Coal Society,2015,40(7):1469-1476.

[3]來兴平,方贤威,崔峰,等.冲击荷载下煤岩损伤演化规律[J].西安科技大学学报,2019,39(6):919-927.

LAI Xingping,FANG Xianwei,CUI Feng,et al.Damage evolution of coal and rock under impact load[J].Journal of Xi’an University of Science and technology,2019,39(6):919-927.

[4]彭瑞东,薛东杰,孙华飞,等.深部开采中的强扰动特性探讨[J].煤炭学报,2019,44(5):1359-1368.

PENG Ruidong,XUE Dongjie,SUN Huafei,et al.Characteristics of strong disturbance to rock mass in deep mining[J].Journal of China Coal Society,2019,44(5):1359-1368.

[5]李文璞.采动影响下煤岩力学特性及瓦斯运移规律研究[D].重庆:重庆大学,2014.

LI Wenpu.Research on mechanical characteristics and gas migration law of coal influenced by mining[D].Chongqing:Chongqing University,2014.

[6]孔祥国,王恩元,李树刚,等.震动载荷下含瓦斯煤动力学特征[J].煤炭学报,2020,45(3):1099-1107.

KONG Xiangguo,WANG Enyuan,LI Shugang,et al.Dynamics characteristics of gas-bearing coal under shock load[J].Journal of China Coal Society,2020,45(3):1099-1107.

[7]KONG X G,WANG E Y,LIU X F,et al.Coupled analysis about multi-factors to the effective influence radius of hydraulic flushing:Application of response surface methodology[J].Journal of Natural Gas Science and Engineering,2016,32:538-548.

[8]林海飞,程博,李树刚.煤的吸附孔结构对瓦斯放散特性影响的实验研究[J].采矿与安全工程学报,2016,33(3):557-563.

LIN Haifei,CHENG Bo,LI Shugang,et al.Experimental study on the effect of adsorption pore structure on gas emission characteristics[J].Journal of Mining & Safety Engineering,2016,33(3):557-563.

[9]刘彦伟,刘明举.粒度对软硬煤粒瓦斯解吸扩散差异性的影响[J].煤炭学报,2015,40(3):579-587.

LIU Yanwei,LIU Mingju.Effect of particle size on difference of gas desorption and diffusion between soft coal and hard coal[J].Journal of China Coal Society,2015,40(3):579-587.

[10]張小东,李朋朋,张硕.不同煤体结构煤的瓦斯放散特征及其影响机理[J].煤炭科学技术,2016,44(9):93-98.

ZHANG Xiaodong,LI Pengpeng,ZHANG Shuo.Gas emission features of coals with different coalbody structure and their influencing mechanism[J].Coal Science and Technology,2016,44(9):93-98.

[11]秦跃平,王健.基于有限体积法的煤粒瓦斯放散无因次分析[J].煤炭学报,2016,41(2):399-405.

QIN Yueping,WANG Jian.Dimensionless analysis of gas emission in coal particles based on finite volume method[J].Journal of China Coal Society,2016,41(2):399-405.

[12]秦跃平,郝永江,王亚茹.基于两种数学模型的煤粒瓦斯放散数值解算[J].中国矿业大学学报,2013,44(6):923-928.

QIN Yueping,HAO Yongjiang,WANG Yaru.Numerical solution of gas emission in coal particle based on two kinds of mathematical model[J].Journal of China University of Mining & Technology,2013,44(6):923-928.

[13]王健.煤粒瓦斯放散数学模型及数值模拟[J].煤炭学报,2015,40(4):781-785.

WANG Jian.Mathematical model of gas emission in coal particles and its numerical solution[J].Journal of China Coal Society,2015,40(4):781-785.

[14]刘永茜,张玉贵,张浪.煤层瓦斯运移机制的关键参数表征[J].岩石力学与工程学报,2017,36(5):1145-1151.

LIU Yongqian,ZHANG Yugui,ZHANG Lang.Key parameters for gas migration mechanism in coal seam[J].Chinese Journal of Rock Mechanics and Engineering,2017,36(5):1145-1151.

[15]赵洪宝,曹光明,李华华.瓦斯放散过程中煤样力学特性演化试验研究[J].采矿与安全工程学报,2014,31(5):819-823.

ZHAO Hongbao,CAO Guangming,LI Huahua.Evolution law of coal mechanical properties in gas emission process[J].Journal of Mining & Safety Engineering,2014,31(5):819-823.

[16]张冰,王汉鹏,李术才,等.煤粒瓦斯非常压放散特征及放散模型修正[J].中国矿业大学学报,2018,47(3):512-519.

ZHANG Bing,WANG Hanpeng,LI Shucai,et al.Feature and mathematical model improvement of gas non-atmospherice mission in coal particles[J].Journal of China University of Mining & Technology,2018,47(3):512-519.

[17]周宏伟,荣腾龙,牟瑞勇,等.采动应力下煤体渗透率模型构建及研究进展[J].煤炭学报,2019,44(1):221-235.

ZHOU Hongwei,RONG Tenglong,MOU Ruiyong,et al.Development in modeling approaches to mining-induced permeability of coals[J].Journal of China Coal Society,2019,44(1):221-235.

[18]任伟光,周宏伟,薛东杰,等.上保护层开采下煤岩强扰动力学行为与渗透特性[J].煤炭学报,2019,44(5):1473-1481.

REN Weiguang,ZHOU Hongwei,XUE Dongjie,et al.Mechanical behavior and permeability of coal and rock under strong mining disturbance in protected coal seam mining[J].Journal of China Coal Society,2019,44(5):1473-1481.

[19]程遠平,刘洪永,郭品坤,等.深部含瓦斯煤体渗透率演化及卸荷增透理论模型[J].煤炭学报,2014,39(8):1650-1658.

CHENG Yuanping,LIU Hongyong,GUO Pinkun,et al.A therotical model and evolution on characteristic of mining-enhanced permeability in deeper gassy coal seam[J].Journal of China Coal Society,2014,39(8):1650-1658.

[20]李铁,梅婷婷,李国旗,等.“三软”煤层冲击地压诱导煤与瓦斯突出力学机制研究[J].岩石力学与工程学报,2011,30(6):1283-1288.

LI Tie,MEI Tingting,LI Guoqi,et al.Mechanism study of coal and gas outburst induced by rockburst in“Three-soft” coal seam[J].Chinese Journal of Rock Mechanics and Engineering,2011,30(6):1283-1288.

[21]谢广祥,殷志强,胡祖祥,等.深井瓦斯煤层采动扩容致灾力学机理[J].煤炭学报,2015,40(1):24-29.

XIE Guangxiang,YIN Zhiqiang,HU Zuxiang,et al.Disaster-causing mechanical mechanism of coal mining dilatancy of gassy seam in deep mine[J].Journal of China Coal Society,2015,40(1):24-29.

1296501186290