Performances and direct writing of CL-20 based ultraviolet curing explosive ink

2022-02-15ShengKongDongjieLiaoYumengJiaChongweiAnDrprofessorChunyanLiBaoyunYeBiongWuJingyuWangHaoGuoZhiweiHong

Sheng Kong ,Dong-jie Liao ,Yu-meng Jia ,Chong-wei An,Dr.professor ,* ,Chun-yan Li ,Bao-yun Ye ,Bi-ong Wu ,Jing-yu Wang ,Hao Guo ,Zhi-wei Hong

a School of Environment and Safety Engineering,North University of China Taiyuan Shanxi,030051,PR China

b Shanxi Engineering Technology Research Centre for Ultrafine Powder,North University of China Taiyuan Shanxi,030051,PR China

c Huayin Norinco Group Test and Measuring Academy Co.,Ltd.,714200,Shanxi,China

d Zhongkexin Engineering Consulting Co.,Ltd.,100000,Beijing,China

Keywords:MEMS fuze CL-20 UV-curing Explosive ink Detonation performance

ABSTRACT A new type of explosive ink formulation that can be quickly cured was prepared with unsaturated polyester as binder,styrene as active monomer,2,4,6-trimethylbenzoyl-diphenylphosphine oxide as photoinitiator,and hexanitrohexaazaisowurtzitane(CL-20)as the main explosive.Then the explosive ink direct writing technology was used to charge the micro-sized energetic devices,the curing mechanism of the explosive ink was discussed,and the microstructure,safety performance and explosive transfer performance of the explosive ink molded samples were tested and analyzed.Results indicate that the composite material has a fast curing molding speed,its hardness can reach 2H within 8 min.The crystal form of CL-20 in the molded sample is still ε type.The CL-20 based UV-curing explosive ink formulation has good compatibility,its apparent activation energy is increased by about 3.5 kJ/mol.The composite presents a significant reduction in impact sensitivity and its characteristic drop height can reach 39.8 cm,which is about 3 times higher than the raw material.When the line width of charge is 1.0 mm,the critical thickness of the explosion can reach 0.015 mm,and the explosion velocity is 7129 m/s when the charge density is 1.612 g/cm3.

1.Introduction

In order to meet the needs of the development of informatization,miniaturization,multi-functionalization and high-precision weapon systems,the new concept of pyrotechnics-MEMS (Micro Electro-Mechanical Systems) fireworks,with the main characteristics of energy conversion information,structural miniaturization,and serial integration work products came into being.MEMS pyrotechnics integrates MEMS technology,micro-nano energetic material technology and pyrotechnics technology.It integrates micro-miniature,informatization,and multi-function.It not only has the functions of traditional pyrotechnics to ignite and transmit fire and detonation.It also combines higher accuracy,reliability and safety.The quantity of MEMS pyrotechnic devices is small,and traditional medicine formulations and charging processes can no longer meet the requirements of high-precision and high-quality charging [1-7].The direct writing charge technology compatible with MEMS charge technology has become a research hotspot in this field.

Explosive ink direct writing technology(including drop-shaped direct writing and linear direct writing[8])combines direct writing molding technology [9] (DIW,Direct ink writing) with explosives ink,through computer-aided design and precision machinery,the explosive ink is directly written or deposited on the surface or groove of the MEMS pyrotechnic product substrate,thereby realizing the layer-by-layer stacking of explosives.Explosive ink direct writing technology was first proposed by the Advanced Research Projects Agency of the US Department of Defense in 1979,and invested 40 million dollars in 1999 to promote its development[10].In recent years,relevant domestic colleges and research institutes have also conducted in-depth research on this technology,developed a variety of different types of explosive ink formulations,and achieved micro-scale explosion transmission [11-20].Curing molding is a key step in the direct writing process of explosive inks.It not only determines the curing efficiency,but also plays a vital role in the quality of the molded samples.Most of the existing adhesive systems for explosive inks are thermosetting adhesives or adhesive solutions,which need to be cured by thermally initiated polymerization or solvent volatilization,and the curing time is too long,which affects the accuracy and molding speed of the directwrite molding samples.How to increase the curing speed of explosive ink is a key technical problem faced by the direct writing process.

In recent years,the rapid development of ultraviolet polymer materials has provided a key to the rapid prototyping of explosive inks.The ultraviolet curing technology was first developed and applied by Bayer in 1968 [21].This technology uses a certain wavelength of ultraviolet light to irradiate a photoinitiator to excite it,and then polymerize the liquid photocurable resin at a high speed,and finally become a solid optical processing technology.Ultraviolet curing can achieve rapid curing at room temperature or even lower temperatures.It has the characteristics of green,energy saving,and excellent curing sample performance.Moreover,the resin can be cured in a timely manner and has a longer storage period.At present,ultraviolet curing technology has been widely used in many fields such as coatings,inks,adhesives,microprocessing and rapid prototyping [22-25].Substituting ultraviolet curing polymer materials for the traditional bonding system of energetic materials can not only improve the efficiency of curing and molding,but also conform to the theme of contemporary green environmental protection,and is of great significance to the emerging 3D printing of energetic materials.

In this study,unsaturated polyester is used as the bonding system,styrene is the active monomer,2,4,6-trimethylbenzoyldiphenylphosphine oxide is the photocuring initiator,and the submicron CL-20 is the main explosive.Then they are uniformly mixed to prepare CL-20 based ultraviolet curing explosive ink.The explosive ink is directly written by using the micro pen direct writing process.The curing mechanism is analyzed,and the direct writing molding effect,impact sensitivity and explosion transfer ability are also tested and analyzed.

2.Experimental part

2.1.Reagents and instruments

Reagents:Unsaturated polyester (PUA),industrial grade,Guangzhou Tongyi New Material Technology Co.,Ltd.;styrene,analytical grade,Tianjin Fengchuan Chemical Reagent Technology Co.,Ltd.;2,4,6-trimethylbenzoyl-diphenyl phosphine oxide;ε-CL-20 raw material,industrial grade,Liaoning Qingyang Chemical Co.,Ltd.

Instruments:Planetary Ball Mill (MITR-YXQM-2L),Changsha Miqi Instrument Equipment Co.,Ltd.;Vacuum Freeze Dryer(FD-1A-50),Beijing Bo Yikang Experimental Instrument Co.,Ltd.;Ultrasonic Cell Crusher,Ningbo Xinzhi Biotechnology Co.,Ltd.;MEEM-4 channel point light source ultraviolet curing machine,Shanghai Heqin Optoelectronics Technology Co.,Ltd.;DSC-800 differential scanning calorimeter,Shanghai Yingnuo Precision Instrument Co.,Ltd.;DX-2700 X-ray diffractometer,Liaoning Dandong Haoyuan Instrument Co.,Ltd.;Micro pen direct writing charge platform,selfmade by North University of China.

2.2.Preparation of sub-micron CL-20

The raw material ε-CL-20 is refined by mechanical ball milling.10 g of raw material ε-CL-20,200 g of oxide beads (0.1 mm in diameter),50 mL of absolute ethanol,50 mL of distilled water and a trace amount of surfactant were placed in a ball mill tank.The rotation speed of the ball mill was set to 450 r/min.After 6 h of ball milling,a CL-20 explosive suspension was obtained.After vacuum filtration and freeze-drying,a submicron CL-20 sample was obtained.

2.3.Preparation and direct writing of CL-20 based UV-curing explosive ink

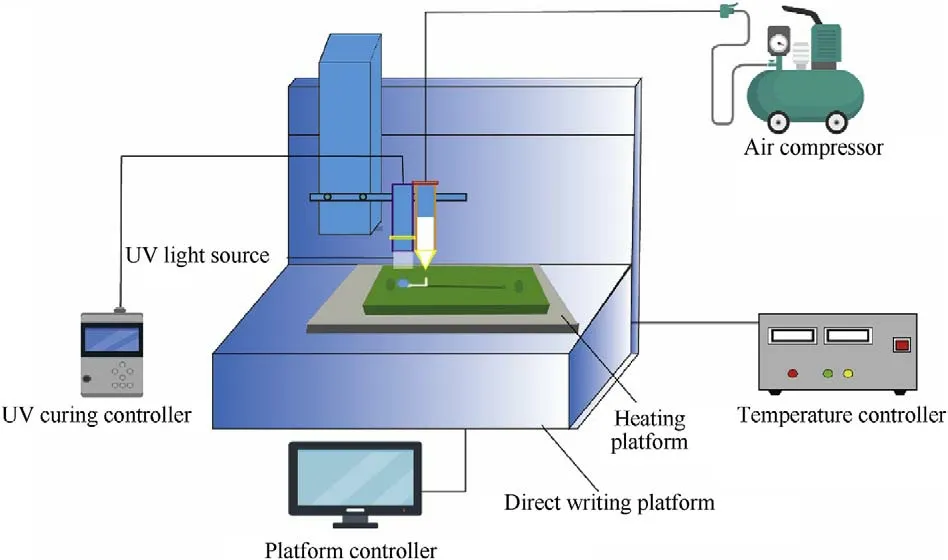

PUA was used as the ink binder in this paper.PUA contains acrylic functional groups and urethane bonds in the molecule.The cured adhesive has the high wear resistance,adhesion,flexibility,high peel strength and excellent low temperature resistance of polyurethane.Polyacrylate has excellent optical properties and weather resistance,and is a radiation curable material with excellent comprehensive properties.First,a ultraviolet curing bonding system composed of unsaturated polyester(60%),styrene(35%)and TPO (5%) was formulated in a certain proportion.After that,the prepared bonding system was stired by using a magnetic stirrer,and sub-micron CL-20 was added while stirring,and then ultrasonically stir it to form a ultraviolet curing bonding system 10 wt%and CL-20 90 wt% ultraviolet curing explosive ink,and they were put into a direct writing syringe with a needle inner diameter of 0.16 mm.Then the pneumatic micro pen direct writing platform and the MEEM-4 channel point light source ultraviolet curing machine were used to directly write the prepared ultraviolet curable explosive ink so that it is stacked in the aluminum plate channel.The device emits single-wavelength ultraviolet light with a long wavelength and a band of about 300-400 nm,which has high luminous efficiency and low energy consumption.The direct writing forming process is shown in Fig.1.

Fig.1. Schematic diagram of direct writing process of CL-20 based explosive ink.

3.Results and discussion

3.1.Microscopic morphology analysis

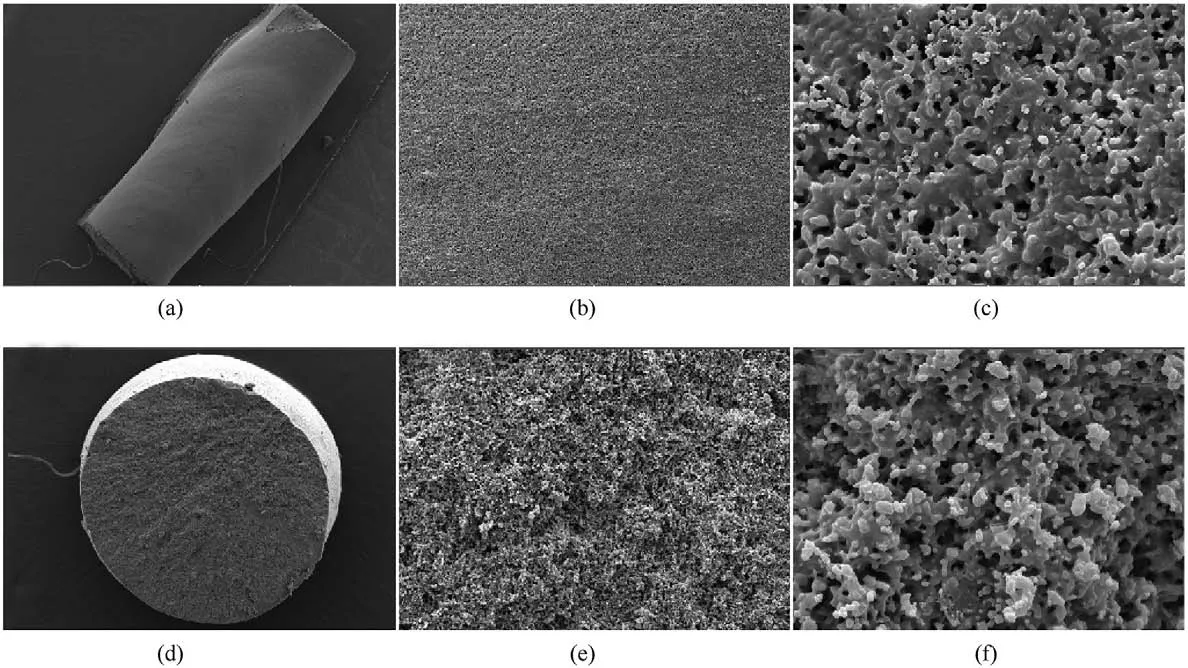

A random sampling method was used to freely cut a part of the molded sample of the UV-curing explosive ink,and the surface and cross-section were tested by SEM.The results are shown in Fig.2.Among them,(a,b,c) are surface pictures,and the magnifications are 100,1000,and 10000 times respectively;(d,e,f) are crosssectional pictures,and the magnifications are 200,2000,and 10000 times,respectively.From Fig.2(a,b,c),it can be seen that the surface of the explosive ink molded sample is smooth and flat,but when observed under higher magnification,some holes will still appear on the surface of the composite material.The possible reason is that the general ultraviolet light source has a lot of heat radiation.When UV curing is performed,the temperature of the explosive ink rises,the styrene inside it volatilizes and escapes,and the surrounding air enters quickly,making holes unavoidable.From Fig.2(d,e,f),it can be seen that after the UV-curing explosive ink is formed,the CL-20 particles and the binder are uniformly distributed,and the explosive particles basically do not agglomerate.CL-20 particles are connected together by a binder to form a honeycomb structure,which is conducive to the propagation of detonation waves under micro-size conditions.

Fig.2. SEM images of surface (a,b,c) and cross section (d,e,f) of CL-20 based composite.

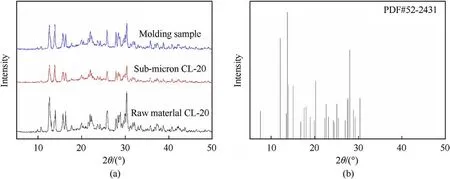

3.2.Analysis of the crystal form of the main explosive in the molded sample

CL-20 has four crystal forms (α,β,γ,and ε) under normal temperature and pressure.Among them,ε-CL-20 has the best overall performance,but the crystal form of CL-20 may change during the refinement and ink preparation process.In order to investigate whether the crystal form of CL-20 has changed during the preparation and direct writing of the CL-20 based UV-curing explosive ink,an X-ray powder diffractometer(XRD)was used to analyze the raw material CL-20 and refine the CL-20 sample and explosive ink molding samples for characterization testing.The test result is shown in Fig.3.It can be seen from Fig.3 that the CL-20 based explosive ink molded sample has corresponding characteristic peaks at the diffraction angles of 12.55,13.75and 30.3,which are consistent with the raw material CL-20 and refined CL-20 samples.These three diffraction angles correspond to the three crystal planes (1 1 -1),(2 0 0) and (2 0-3) of ε-CL-20.Therefore,CL-20 in the explosive ink molding sample still maintains the ε crystal form[26].This shows that the crystal morphology of CL-20 will not be affected by the preparation of explosive ink and the subsequent direct writing solidification molding process.

3.3.DSC analysis

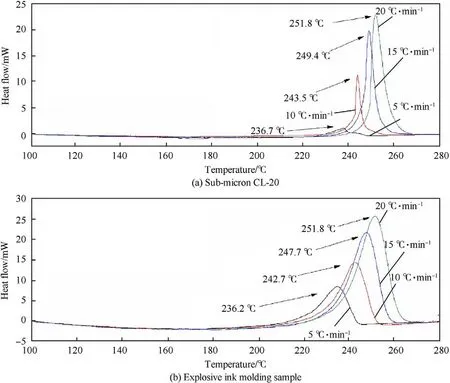

The thermal decomposition performance of the sub-micron CL-20 and Cl-20 based UV-curing explosive ink molding samples was tested and analyzed by using a differential scanning calorimeter DSC-800 with different linear heating rates (5,10,15,20C/min).The test results are shown in Fig.4.

Fig.3. X-ray diffraction spectra of raw CL-20,sub-micro CL-20,CL-20 based composite (a) and the standard XRD pattern of ε-CL-20 (b).

It can be seen from Fig.4 that the DSC curves of the sub-micron CL-20 and CL-20 based explosive ink molding samples before the decomposition peak temperature are relatively smooth,and the overall exothermic peak temperature of the two has little fluctuation under the same heating rate.The exothermic peak temperatures of sub-micron CL-20 at different heating rates are 236.7C,243.5C,249.4C and 251.8C respectively;while the exothermic peak temperatures of explosive ink molding samples are 236.2C,242.7C,247.7Cand 251.5C respectively,which indicated that the CL-20 based UV-curing explosive ink formulation has good compatibility.

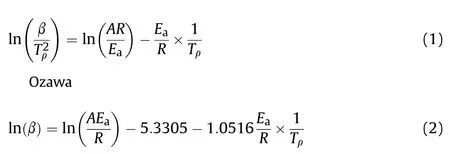

The Kissinger and Ozawa methods are commonly used to calculate the apparent activation energy (E).The formulas are as follows:

Kissinger

In the formula,β is the heating rate,C/min;Tis the decomposition peak temperature at the heating rate β,K;A is the prefactor;Eis the apparent activation energy,kJ/mol;R is the gas constant,8.314 J/mol·K.

Fig.4. DSC curve of sub-micron CL-20 (a) and CL-20 based UV-curing explosive ink molding.

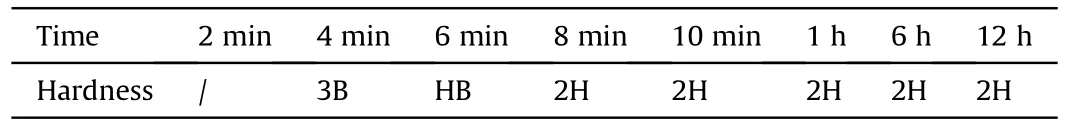

According to the above Eqs.(1) and (2),the different heating rates(5,10,15,20C/min)and their corresponding decomposition peak temperatures are substituted into them,and the ln(β)and 1/Tis linearly fitted by origin software.The calculated thermal decomposition kinetic parameters of sub-micron CL-20 and explosive ink molding samples are shown in Table 1.

It can be seen from Table 1 that the apparent activation energy(E) of the explosive ink molding samples calculated by Kissinger and Ozawa methods is slightly higher than that of the sub-micron CL-20,which is increased by about 3.5 kJ/mol,indicating that the explosive ink molding samples has better thermal stability.

3.4.Explosive ink curing rate and mechanism

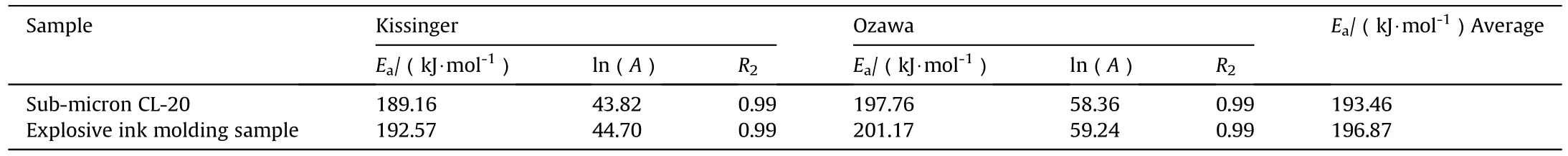

Refer to the GBT 6739-2006 method to indirectly determine the curing time of the explosive ink by testing the hardness of the UVcuring explosive ink sample at different times through a pencil hardness tester.The test temperature is 25C,and the test results are shown in Table 2.

It can be seen from Table 2 that in the first 8 min,the hardness of the UV-curing explosive ink gradually increased from 3B to 2H,and maintained at 2H until 12 h.In the first 8 min,the change in the hardness of the explosive ink is essentially a process in which the UV-curing bonding system in the composite material undergoes a UV-curing reaction to a solid transformation.This result shows that the CL-20 based UV-curing explosive ink has a faster curing speed,and the curing process can be completed within 8 min.However,the traditional thermally induced curing,also under normal temperature conditions,takes hours or even days to cure.

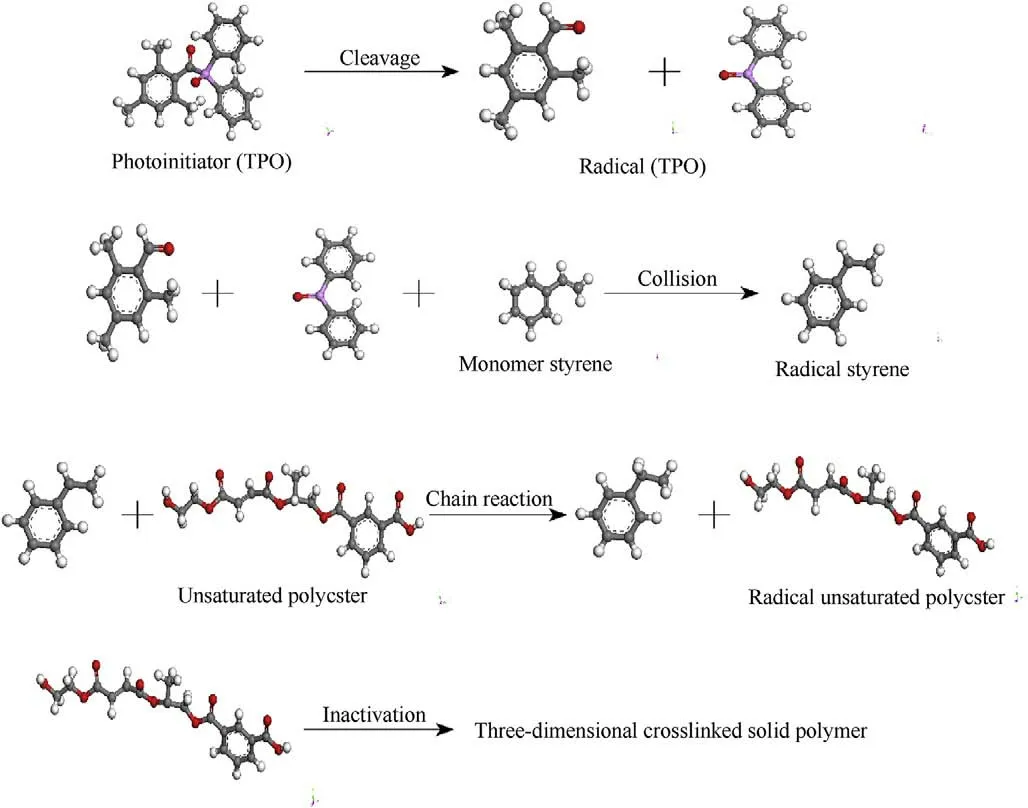

The reason why the CL-20 based UV-curing explosive ink has a faster curing speed is that under the action of UV light,the TPO molecules in the bonding system change from the ground state to the excited state,and rapidly decompose to generate excited primary free radicals.Primary free radicals collide with monomer styrene,transfer energy to destroy the double bond of styrene molecules,form monomer free radicals,and initiate a chain reaction.Afterwards,in the chain polymerization process,the chain radicals deprive a tertiary hydrogen atom from the oligomer unsaturated polyester to terminate,and make these molecules that have lost their atoms become new oligomer radicals,continuing the growth of the new chain,so that the polymerization reaction continues,and eventually the free radicals lose their activity,forming an irregular three-dimensional cross-linked solid polymer,which greatly shortens the curing time of the explosive ink.The curing mechanism is shown in Fig.5.

This reaction of free radicals is a chain reaction,and the molecular weight of the product increases rapidly in a short time to form a high polymer,thereby shortening the curing time.The final molded three-dimensional cross-linked polymer has a networklike body structure with a certain degree of hardness.

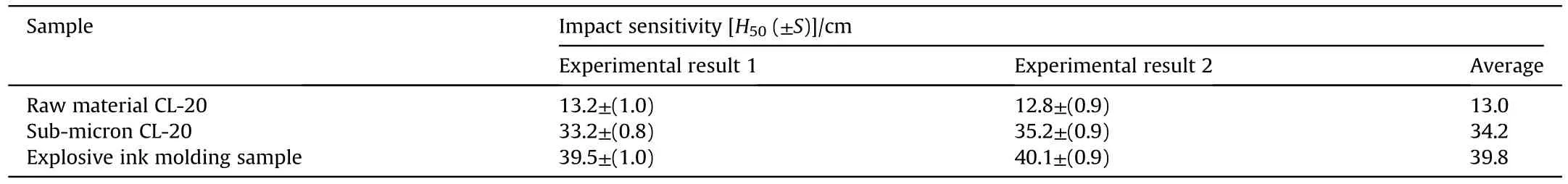

3.5.Impact sensitivity

The drop hammer method was used to test the impact sensitivity of the raw material CL-20,refined CL-20 and explosive ink molding samples.All test samples are in powder form.The test conditions are:test temperature (2025C),sample quality(35 mg ± 1 mg),relative humidity (≤80%),drop hammer weight(2.500 kg ± 0.002 kg).The experimental results are shown in Table 3.

Table 2 The change condition of CL-20 based explosive ink with time.

It can be seen from Table 3 that the Hvalues of the raw material CL-20,the refined CL-20 sample,and the explosive ink molding sample are 13.0 cm,34.2 cm and 39.8 cm,respectively.After refinement,the characteristic drop height Hvalue of the CL-20 sample is 21.2 cm higher than that of the raw material ε-CL-20,indicating that the impact sensitivity of the submicron CL-20 has been greatly reduced.This is because the refined CL-20 particle size becomes smaller,the specific surface area increases,the surface is smooth,the edges and corners become less,the heat generated when subjected to adiabatic compression is small,and it is not easy to form hot spots,so the impact sensitivity of CL-20 after refinement reduce.By comparing the raw material ε-CL-20 and CL-20 based composite materials,it is found that the Hvalue has increased from 13.2 cm to 39.8 cm,which is about 3 times higher.This is because the main explosives used in the CL-20 composite material are all refined CL-20,and the impact sensitivity has been greatly improved compared to the raw material CL-20.In addition,after direct writing,the UV-curing bonding system undergoes a cross-linking reaction.The bonding agent is wrapped on the surface of the CL-20 explosive particles,and the CL-20 particles are connected through the bonding system to form a honeycomb structure,which reduces the friction between particles,plays a certain buffering effect on external impacts,and greatly reduces the probability of hot spot formation [27].

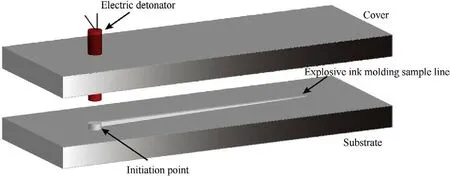

3.6.Critical transmission thickness

The critical diameter of an explosive is the smallest diameter that can make the detonation propagate without failure.The UVcuring explosive ink was cured and deposited in a wedge-shaped groove (length:100 mm,width:1 mm,slope:0.03) using microdirect writing technology and UV-curing technology,and under the condition of wedge-shaped charge,the critical transmission thickness of the CL-20 based UV-curing explosive ink molded sample was tested.The test assembly is shown in Fig.6.

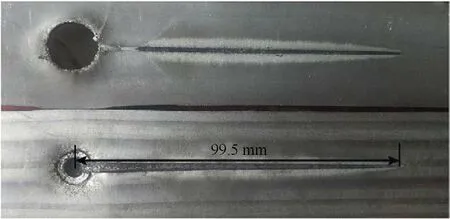

The test result is shown in Fig.7.After the test,the groove of the charge substrate has obvious deformation,and a certain explosion mark is also left on the cover plate.Moreover,after the detonator is detonated,the detonation wave propagates from the initiation point along the charge groove from deep to shallow,and is extinguished at a position closer to the end of the groove,indicating that the explosive ink sample can transmit the explosion stably and reliably under the condition of micro-size charge.

According to the calculation Eq.(3) [28],of the critical transmission thickness,

Table 1 The thermal decomposition kinetics parameters of sub-micron CL-20 and UV-curing explosive ink molding sample.

Fig.5. UV-curing mechanism.

Table 3 The special height (H50) of the raw CL-20,sub-micro CL-20 and UV-curing explosive ink composite.

Fig.6. Assembly diagram of the critical detonation size test.

In the formula,A-the length of the explosive line,mm;B-the length of the explosion trace,mm;C-the depth of the detonation point,mm.It is known from Fig.6 that the values of A,B and C are 100 mm,99.5 mm and 3 mm,respectively.Therefore,the critical transmission thickness of the UV-curing CL-20 based explosive ink molded sample is calculated to be 0.015 mm,indicating that the explosive ink composite material (charge width is 1.0 mm) can reliably transmit explosions when the charge thickness is greater than 0.015 mm.

Fig.7. Comparison chart of the critical detonation size of CL-20 based composite after detonation.

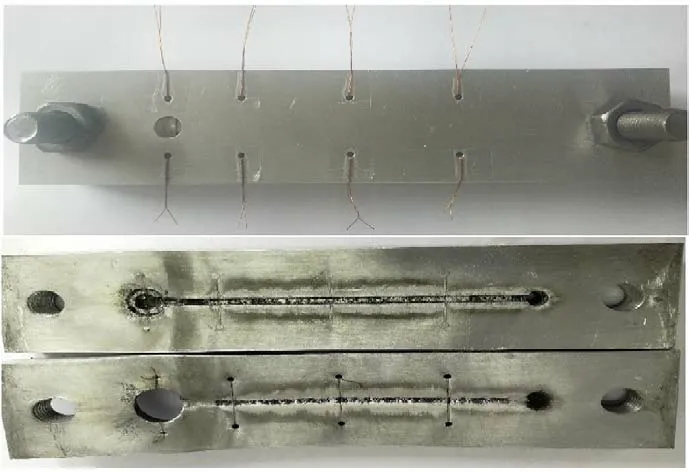

3.7.Detonation velocity

Firstly,the actual density of the molded sample is measured to be 1.612 g/cm.Then,the CL-20 based UV-curing explosive ink molded sample deposited in the groove(1.0×1.0×100 mm)of the substrate for the detonation test is detonated by simple structure,fast response,and reliable ionization conduction electric probe method.

The result of the detonation test is shown in Fig.8.It can be seen from Fig.8 that after the explosion,the charge substrate has undergone significant deformation and left obvious explosion trace.The detonation velocity of each segment can be calculated by formula (4),

In the formula,D-detonation velocity of each section,m/s δL-distance of each section of the charge line,mm;δt-detonation wave propagation time through the corresponding explosive line,ns.Since the detonation velocity of the first section of the explosive line will be affected by the detonation of the detonator,only the detonation velocity of the latter two explosive lines is averaged.

It is known that the values of δLand δLare both 30 mm,and the values of δtand δtare 4231 ns and 4185 ns,respectively.Therefore,the average detonation velocity of the UV-curing explosive ink is calculated to be 7129 m/s.The results show that the explosive ink has a good detonation velocity and can realize stable and reliable detonation transmission in a 1.0×1.0×100 mm charge groove.

Fig.8. Photograph of CL-20 based composite before and after detonation in the detonation velocity test.

4.Conclusion

This research introduces new UV-curing materials into the explosive ink formulation instead of the traditional bonding system,and designs a UV-curing explosive ink formulation that is suitable for the direct writing process and can be cured quickly.The micro-sized energetic device was charged to form by using explosive ink direct writing technology,the curing mechanism of explosive ink was discussed,and the microstructure,safety performance and explosion transfer performance of the explosive ink molded sample were tested and analyzed.The following conclusions were drawn:the molded sample has a good molding effect,the explosive particles and the binder are evenly distributed;the crystal form of CL-20 in the molded sample has not changed and is still ε type;the CL-20 based UV-curing explosive ink formulation has good compatibility,its apparent activation energy is increased by about 3.5 kJ/mol;the UV-curing explosive ink has a faster curing speed and can be completely cured within 8 min,and hardness can reach 2H;in terms of impact sensitivity,the characteristics drop height of the molded sample can reach 39.8 cm,which is about 3 times higher than the raw material,and the safety is improved;when the charge width of the explosive ink is 1.0 mm,the critical transmission thickness is 0.015 mm.When the charge density is 1.612 g/m,the detonation velocity is 7129 m/s,and it exhibits good detonation performance under micro-size conditions.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Equipment Development Department of China (61406190401).

杂志排行

Defence Technology的其它文章

- Numerical investigation of the failure mechanism of cubic concrete specimens in SHPB tests

- Experimental and numerical investigation of zirconium jet performance with different liner shapes design

- Effects of module number and firing condition on charge thermal safety in gun chamber

- Controllable combustion behaviors of the laser-controlled solid propellant

- Dual-steering mode based on direct yaw moment control for multiwheel hub motor driven vehicles:Theoretical design and experimental assessment

- Investigation of the shock compression behaviors of Al/PTFE composites with experimental and a 3D mesoscale-model