Design and implementation of gasifier flame detection system based on SCNN①

2022-02-11WUJinDAIWeiWANGYuZHAOBo

WU Jin(吴 进),DAI Wei,WANG Yu,ZHAO Bo

(School of Electronic Engineering,Xi’an University of Posts and Telecommunications,Xi’an 710121,P.R.China)

Abstract

Key words:support vector machine convolutional neural network(SCNN),support vector machine(SVM),flame detection,flame image processing,gasifier

0 Introduction

In the current industrial environment,as a large energy conversion equipment,gasifier has been widely used[1].Therefore,in order to make the gasifier work safely and efficiently,it is very necessary to study the flame detection method in the furnace[2-3].The monitoring and evaluation of combustion state in gasifier furnace are very important to the production process,any misjudgment will bring huge economic loss[4-5].In addition,the accuracy of gasifier detection method will directly affect the judgment result of flame state and subsequent fuel supply in the furnace,thereby greatly affecting the utilization of fuel resources[6].

Currently,there are three flame detection methods commonly used in industrial production,which are thermocouple method,digital signal processing method,and image processing method[7].Among them,the real-time performance of the gasifier thermocouple detection method is poor,and the traditional digital signal processing technology is insufficient for the accuracy of the furnace flame detection[8-9].The core technology of state monitoring based on flame images is to realize the characteristic judgment of the flame combustion state,but there is also a certain degree of contingency[10].Nowadays,safety production requirements are getting higher and higher,and more combustion status information needs to be extracted from flame images[11].Compared with the traditional method,the detection method based on computer vision is more intuitive and reliable.Therefore,Ref.[12]extracted flame features and used support vector machine(SVM)for classification.Ref.[13]proposed a flame area detection method by using the color and dynamic characteristics of the flame in the video sequence,and separated the dynamic object from the flame to extract the flame characteristics.Ref.[14]developed a real-time image acquisition and combustion diagnosis system based on a personal computer(PC)and a digital signal processor on a 200 MW boiler,but this method also has certain judgment errors.The National Key Laboratory of Coal Energy Efficient Utilization and Emission Reduction Technology used an image segmentation method based on gray-scale segmentation and background difference to extract and detect features of furnace flames[15].Some researchers have proposed a video flame detection method based on a dual-stream convolutional neural network(CNN)combined with temporal and spatial features to classify the flame area[16-17].Ref.[18]proposed a boiler furnace flame visual monitoring method based on the cascaded forward back propagation(BP)neural network model.This method realizes visual real-time detection,but there is a problem of inaccurate algorithm optimization.

In summary,the existing flame detection methods have problems such as low detection accuracy,poor real-time performance,and insufficient intuitive judgment results[19].Aiming at the problems of the abovementioned furnace flame detection method,this paper proposes a support vector machine convolutional neural network(SCNN)flame detection algorithm,and completes the detection of the gasifier furnace flame based on this model.Experimental results show that the detection accuracy rate can reach 99.53%.Through the designed graphical user interface(GUI),the flame state judgment result,flame intensity,area and other parameters of the SCNN model are displayed in real time to realize human-computer interaction.In the end,the algorithm has been applied to the burner nozzle detection system of aerospace gasifier.

1 The structure design of the furnace flame detection system

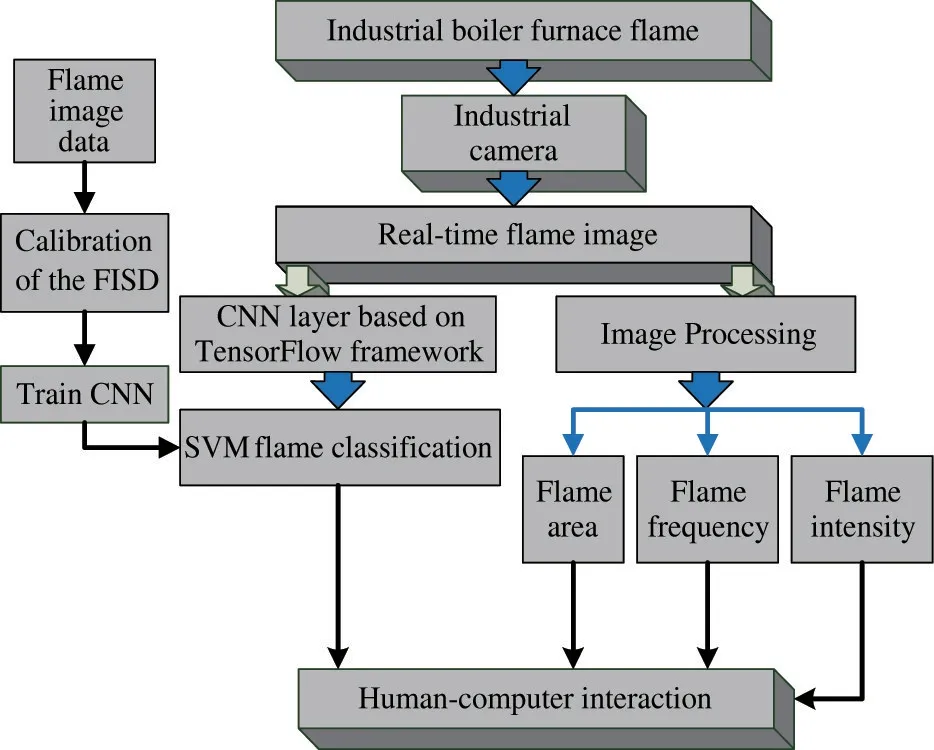

As shown in Fig.1,the design process of the flame detection system can be divided into the following steps,respectively.(1)Design,training and performance test of SCNN flame detection model.(2)An industrial camera is used to collect flame image data in the furnace of the gasifier.Subsequently,the flame image data is processed and named as FISD(flame image state dataset)flame state data set.(3)Aiming at the flicker problem of flame image,the intensity,area and flicker frequency of real-time flame state image are analyzed and processed.

Fig.1 System design process

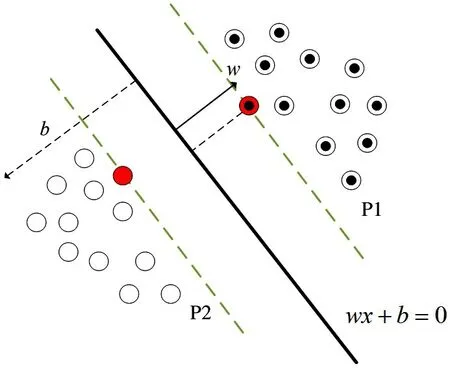

Fig.2 shows the burner ignition device,which is used to ignite the aerospace gasifier.The design of the SCNN flame detection system and the experimental test of the algorithm will be completed based on this device.

Fig.2 Aerospace gasifier ignition device

The industrial camera encapsulated in the ignition device is used to photograph the flame in the gasification furnace and collect flame video images.Each part of the ignition burner is connected by a flange.During ignition,a certain proportion of oxygen,nitrogen and fuel gas are introduced into each air inlet to mix,and an electric ignition device is used to ignite.

1.1 Flame image classification based on SVM

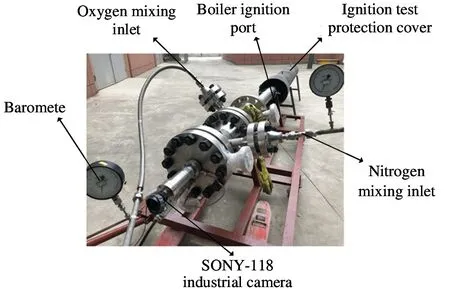

This flame detection model uses SVM method to classify flame image cases,as shown in Fig.3.Unlike the softmax classifier,SVM outputs the results of flame sample classification in the form of scores,and selects the category with the highest score as the judgment result.In this way,not only the best hyperplane is fitted,but also the network has better generalization ability,and at the same time,high precision can be obtained by using a small training set.

The hyperplane equation in the feature space can be expressed aswx+b=0,wherexrepresents the flame image sample point in the hyperplane,wis perpendicular to the hyperplane,andbrepresents the error value,as shown in Fig.3.

Fig.3 The basis of linearly separable SVM classification

For a separating hyperplane,when the class is defined asyi=1,it can be defined aswxi+b-1≥0;whenyi=-1,it can be defined aswxi+b+1<0,as shown in Eq.(1).

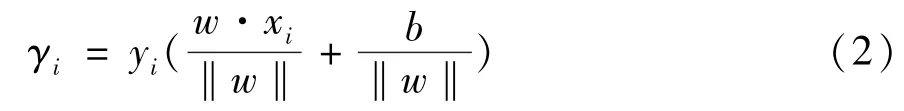

For the defined flame sample pointT={(xi,yi)},the geometric interval from the hyperplane is expressed asγishown in Eq.(2).

For all the flame sample points collected,the expression for the minimum geometrical interval of the hyperplane is shown in Eq.(3).

where the smallestγigeometrical interval is taken as the distance from the hyperplane to the support vector.

For the case where the final category is not linearly separable,introduce a slack variableξi,i=1,2,…,n,which represents the distance from the sample in the plane to the support hyperplane P1 or P2 of the support vector to which the sample belongs,as shown in Eq.(4).

whereCis the penalty parameter,which is a non-negative value and is positively correlated with the degree of penalty.Cis obtained by parameter tuning,and then the constraint conditions are used to find the optimal situation of flame classification.

1.2 SCNN network layer structure and parameter setting

This algorithm is based on the CNN model of flame detection to extract the real-time flame‘on’and‘off’characteristics in the furnace of the gasifier.Furthermore,the flame characteristics are recorded in a file named‘Feature_F’.Firstly,initialize two matrices called‘N_feat’and‘N2_num’to save the feature maps of all furnace flames and the number of flame features respectively.Subsequently,SVM is used for classification,which has a higher classification accuracy,and the generalization ability of the SCNN network using SVM is also better than Softmax classifier.Therefore,the SVM method is introduced in SCNN to replace the Softmax layer.Next,the Kmeans method is used to cluster all the characteristics‘N_feat’of the furnace flame into a total feature matrix,and each characteristics of flame is defined,the training set and the test set are extracted respectively.Ultimately,the training of the model and the classification of the flame image are completed.

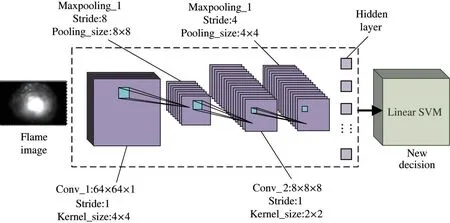

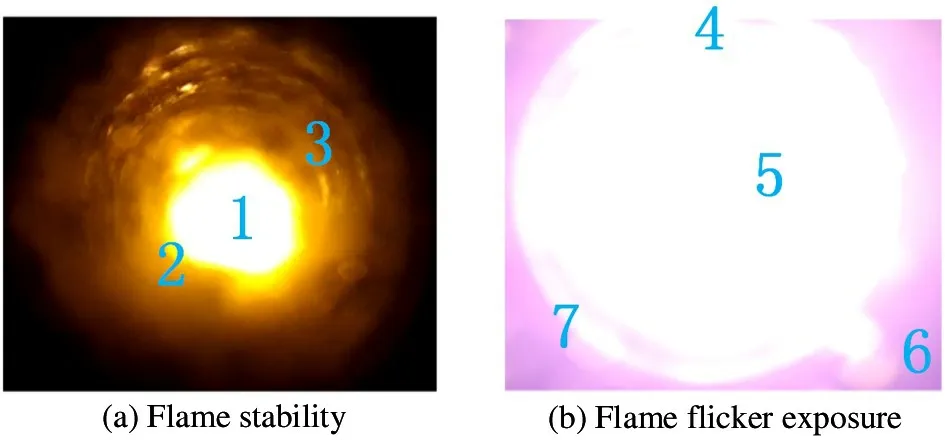

The framework of SCNN furnace flame detection algorithm is shown in Fig.4.First,reduce the dimensionality of the collected flame video image and convert it into a frame-by-frame flame gray-scale image,reduce the amount of data,and reduce the size of the image to a 64×64 matrix,then,perform batch normalization processing;use it as the input data of the CNN model,and use a 4×4 convolution kernel for convolution.Label the flame image data set.Based on the brightness of the flame image,the data is first divided into two categories:‘flame on’(furnace starting and operating state)and‘flame off’(gasifier stopped and unignited).The state of the flame in the furnace is represented by matrix[0,1]that the flame is off;[1,0]indicates that the flame in the furnace is bright,and then‘flame on’as the base class to subdivide.Its derived classes are‘Big flame’,‘Medium’,and‘Low’.The network includes the convolutional layer Conv_1,which contains a total of 8 convolution kernels with a size of 4×4,Conv_2 contains a total of 16 convolution kernels with a size of 2×2.The two convolution layers of Conv_1 and Conv_2 are pooled through Maxpooling_1 with a size of 8×8.The size of the fully connected layer is set to(2×2×16)×64,and the Dropout layer is introduced for random inactivation.

Fig.4 Framework diagram of SCNN network

The specific parameters of the network model are shown in Table 1.The SVM classifier is used to replace the Softmax function for the flame classification output.In order to make the classification results include all the flame states,this paper uses the OVRSVM multi-classification method to classify the flame states.After that,the SCNN network is used to detect the flame status of the gasifier furnace in real time,output the results of the first layer of the SVM decision tree,and display the furnace flame status obtained by classification.

Table 1 Convolutional neural network parameter se tting

2 Furnace flame image analysis and processing

Although the flame shape change in the furnace of the gasifier is not complicated,the flame state in the furnace will be affected by the fuel combustion state,and there will be flame flicker.This flicker change is unpredictable and may cause the detection algorithm to make abnormal judgments.Therefore,in view of such problems,the threshold setting of the flame image,the maximum value judgment interval of the flame area,and the flicker frequency of the flame must be considered to ensure that the real-time flame state detection system is normal during the ignition and operation of the gasifier work.

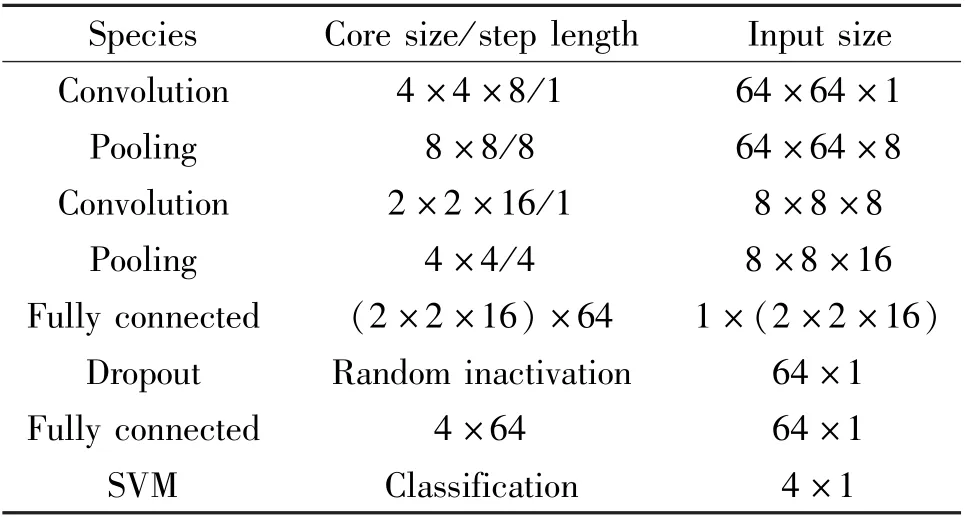

As shown in Fig.5,the flicker of the flame will cause the exposure of the flame image,which affects the accuracy of the detection system’s judgment value.Therefore,it is necessary to analyze the flicker frequency,intensity,and flame area of the image when the flame is burning,so as to perform parameter interaction.

Fig.5 Changing state of furnace flame flicker

2.1 Flame feature extraction

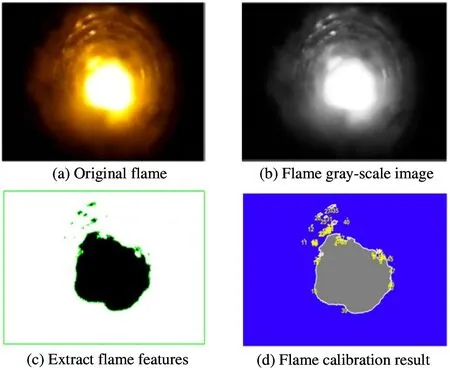

The main characteristics of the flame in the original image and the interference information of the reflected light in the ignition device are processed and analyzed,as shown in Fig.6.

Fig.6 Flame image features

Fig.6(a)shows the actual flame image when the gasifier is ignited,and Fig.6(b)shows the result of the gray-scale processing of Fig.6(a),which is also a dimensionality reduction of the original image.Fig.6(c)shows the flame characteristic boundary extracted by binarizing the flame gray image in Fig.6(b)and filtering most of the interference light on the tube wall,but there are still some small spots,which are reflections caused by the unevenness of the tube wall.This will cause the interference light and the flame to have a smaller brightness difference and be extracted at the same time.Use the cell array to store the data for demarcating the boundary,and then return a label matrix‘L’to demarcate a label for each flame target,as shown in Fig.6(d),and finally return the number of all flame targets in the image,showing the boundary and label.

2.2 Flame area analysis

The flame area feature is classified according to the threshold value to obtain the result shown in Fig.7.Analyze the flame image sample data coordinates,view the features with large gaps in each image line,and define the threshold value to make the classifier.

Fig.7 Threshold classification of flame area characteristics

The interference light from the tube wall of the ignition device is filtered out according to the threshold size of the flame area,and the sample point with an area of 2.7×105 in the figure is obtained,which is the effective burning area of the extracted furnace flame characteristic image.According to the threshold,the combustion critical point is divided,and the area of each combustion stage is defined,which is used as the flame area parameter.Finally,it is output as a percentage and displayed on the GUI interface.

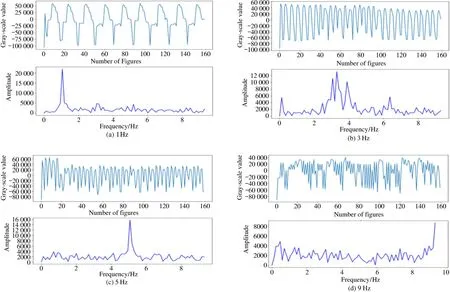

2.3 Flame spectrum analysis

Use an industrial camera to collect flame images of various flicker frequency ranges,convert the collected images into‘L’mode,and accumulate the grayscale value of each pixel of the image to approximate its brightness value.Next,input the brightness of 160 continuous flame images and perform frequency spectrum analysis.The result is shown in Fig.8.

Fig.8 Flicker frequency of flame image after Fourier transform

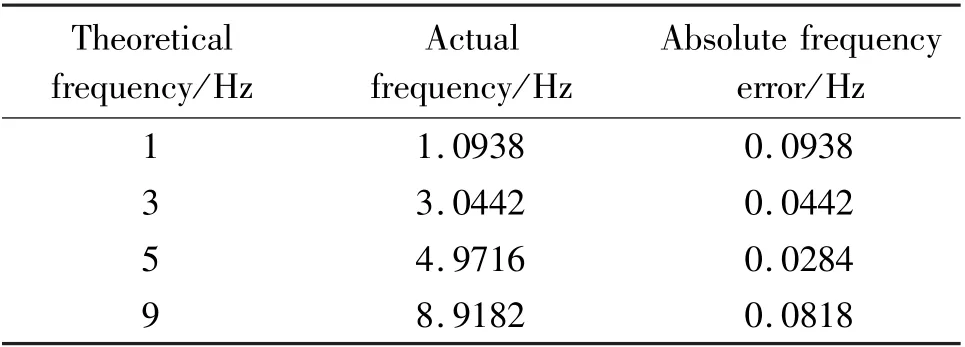

The brightness of the flame image is subjected to Fourier transform,and the flicker frequency of the flame can be judged by the obtained fundamental frequency.Analyze the four kinds of low flicker frequencies in Fig.8,and get the absolute error of detection based on the four flicker frequencies,as shown in Table 2.In actual application,the computing efficiency of the hardware system needs to be considered.Normally,the sampling frequency of an industrial camera is roughly 10 fps,so for the furnace flame detection system,consider selecting a sampling frequency of 7 Hz.

Table 2 Flicker frequency detection

3 Experimental process of flame detection system

3.1 Construction of the experimental environment

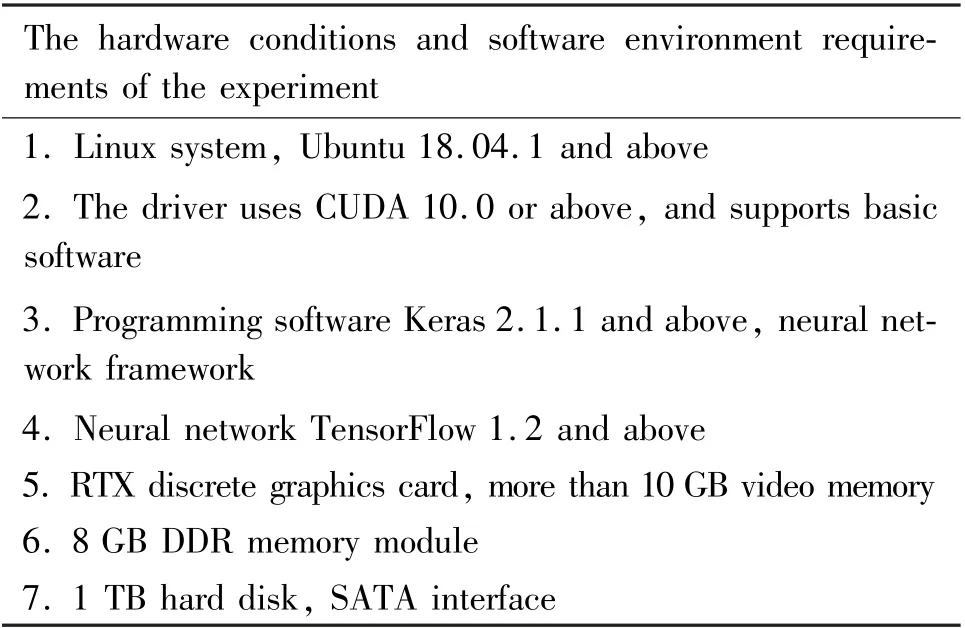

The construction of the experimental environment(Table 3)and the training of the flame detection model are completed based on the Linux system.The GUI interface is designed to complete the human-computer interaction.The flame detection model is cross-compiled to facilitate transplantation and application in embedded devices.

Table 3 Hardware and software environment

3.2 FISD data set preprocessing

SONY-118 industrial camera installed in the ignition devices is used to collect flame image data in real time.Test a complete ignition and combustion process,and collect a video of the flame state of the gasifier during the start and stop process.The video includes the entire process from electric ignition to intermittent flame flashing to flame stability and flame extinguishing in the furnace.First of all,the video sequence needs to be parsed into a picture format to speed up the training.Specifically,open the video capture device through the VideoCapture of the OpenCV library and obtain the frame rate.Subsequently,the frame size is obtained by modifying the parameters.Set the acquisition frame size of the data set to 3,and divide the video into 4 parts according to the time sequence,which are the furnace start and stop phase,the ignition phase,the flame stabilization phase,and the flame off phase.Finally,intercept 10 000 flame images,name the dataset FISD,classify and label the data.Fig.9 shows part of the flame state data during the ignition period.

Fig.9 FISD data set

In this paper,the methods of image flipping,random pruning,color dithering and noise disturbance are used to process the sample data of flame flicker stage,amplify the data and enhance the characteristics of the flickering flame.The detection algorithm can accurately judge and output the flame states in different periods.In this way,the stability and robustness of SCNN flame detection model are improved.

For the FISD data set,first of all,according to the flame state,it can be divided into two main categories:flame off and flame on.Secondly,according to the OVR-SVM multi-classification method,the flame state is divided into three states according to the threshold range,so that four types of‘Big flame’,‘Medium’,‘Low’,and‘Flame off’are obtained.In addition,after processing and analyzing the flame image,parameters such as flame intensity,area,and flicker frequency are obtained.

3.3 Training and testing of SCNN network

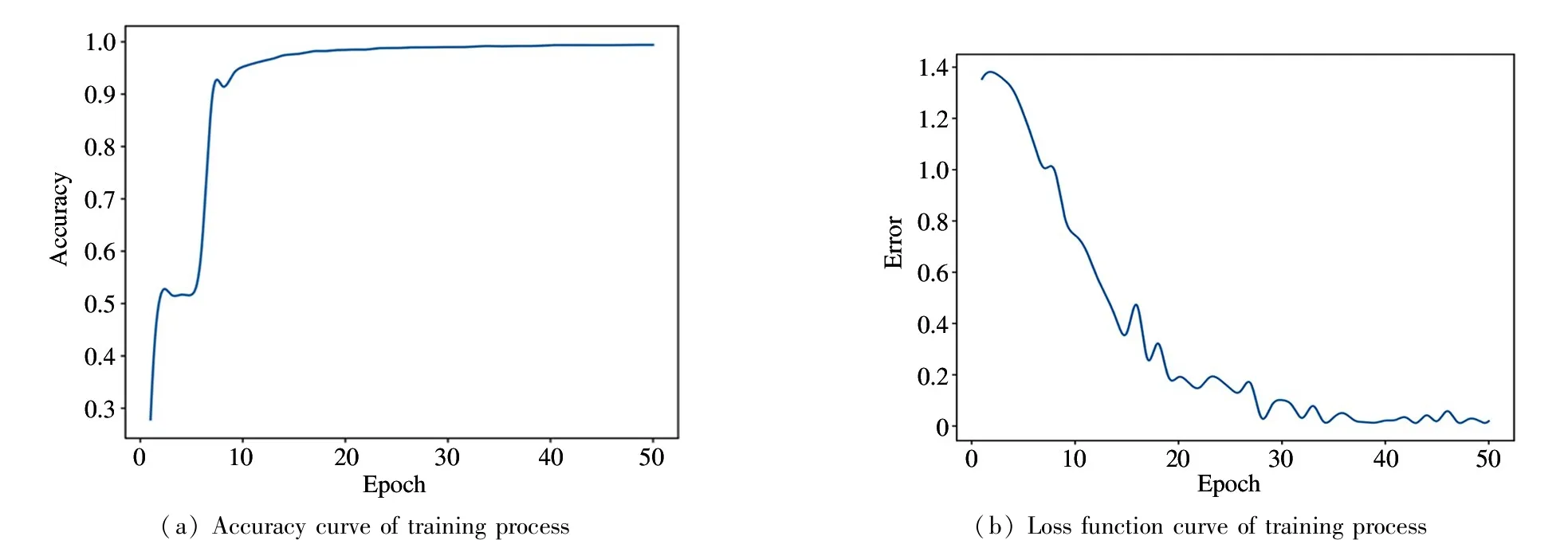

For the model training of the SCNN network,10 000 images of the flame burning state are used as the input of the network model.The specific parameters are set as follows:the batch size is 10,the pixels of the input video sequence converted into image frame data are 64×64,and the random dropout rate is 0.8.In this paper,the SVM classifier is introduced into the network structure,which can not only improve the training speed of the network,but also effectively improve the accuracy of the system model in the recognition and classification of the flame state.Based on the characteristics of the SCNN network model,in the training process,the learning_rate is 0.1 and the epoch is 50 times.

In the actual drawing process,the accuracy of the model will gradually increase with the training epoch.In the application of aerospace furnace flame detection system,the accuracy of the SCNN model will directly affect the safe start and stop process of the gasifier.Different training parameters are unpredictable in model training.Therefore,the accuracy of the model varies in multiple training sessions.However,in order to fit the background of the gasifier application,it is necessary to select appropriate training parameters.In the end,the accuracy of the SCNN model reached 99.53%,as shown in Fig.10(a).

As shown in Fig.10(b),the loss function curve gradually decreases as the training epoch increases.However,there will be a short rise during the overall downward trend.This is because in the process of finding the minimum value of the loss function,the cost function continues to fall after rising from its minimum point,which is a normal situation in the training process.During this training process,the final value of the loss function is 0.035.

Fig.10 SCNN model training process

In addition,the SCNN algorithm proposed in this paper uses SVM to replace Softmax layer,and uses OVR-SVM multi-classification method to classify and output each state of flame.Flame images in FISD flame dataset that have not been processed by data amplification are taken as the test set.SCNN using SVM is compared with the original CNN flame detection algorithm using Softmax,and the experimental results are shown in Fig.11.

It can be seen from Fig.11 that SCNN flame detection model has better judgment accuracy than CNN flame detection algorithm in the unknown original flame data set.Therefore,SCNN has better generalization ability than CNN flame detection algorithm.

Fig.11 Comparison of accuracy between SVM network and traditional CNN

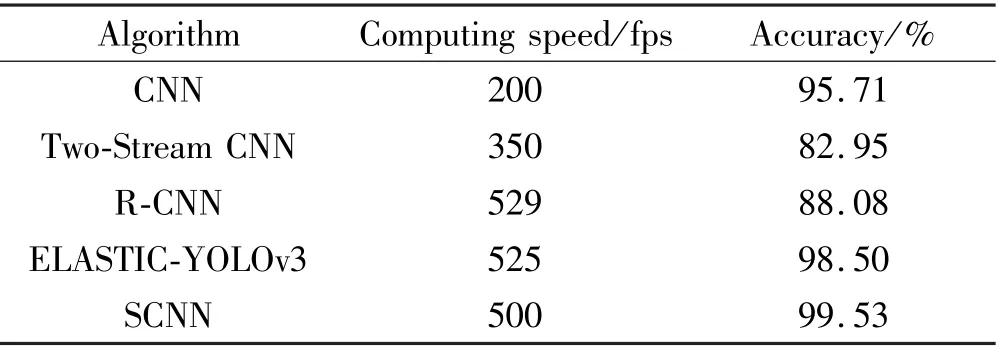

In order to further verify the feasibility of the SCNN flame detection algorithm,the performance of the SCNN flame detection algorithm proposed in this paper is compared in detail with that proposed in other literatures.The performance comparison results of each model on the flame data set are shown in Table 4.

Table 4 SCNN algorithm performance comparison

It can be seen from Table 4 that the Two-Stream CNN algorithm proposed in Ref.[17]and the R-CNN flame detection algorithm proposed in Ref.[20]have a judgment accuracy of 82.95% and 88.08% on flame video data respectively.The original CNN flame detection algorithm has an accuracy rate of 95.71%,while the SCNN flame detection algorithm proposed in this paper has a judgment accuracy rate of 99.53%,which is higher than other algorithms.In addition,the calculation speed of SCNN is 500 fps,which is greatly improved compared with the calculation speed of CNN model at 200 fps,but it is slightly lower than the calculation speed of the flame detection algorithm based on R-CNN and ELASTIC-YOLOv3[21].However,the flame detection method of aerospace gasifier requires a small delay to ensure the real-time detection results.Detection accuracy is also an important evaluation index.The calculation speed of SCNN flame detection algorithm is at the middle to upper level,and the accuracy is better than other algorithms.Therefore,based on the comparison results in Table 4,the SCNN flame detection algorithm has higher accuracy and real-time performance.

4 Application and verification analysis

4.1 Application of SCNN flame detection model

The training of the flame real-time state detection model is based on the Linux system environment,so that the subsequent algorithm can be transplanted to the embedded system.Use OpenCV library functions to collect size,RGB conversion and processing of continuous flame video,and set the limits of flame brightness and area threshold.

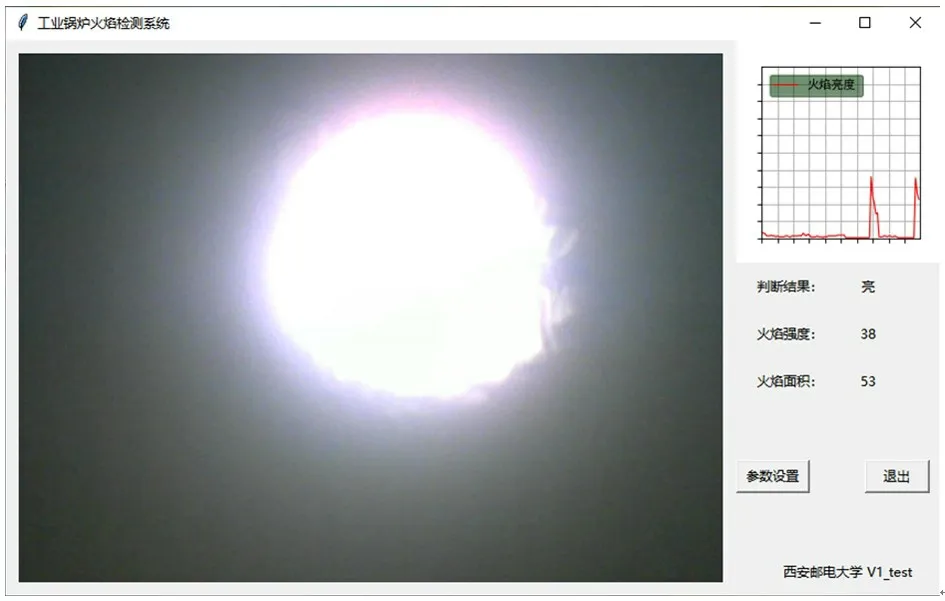

The GUI interface is designed as shown in Fig.12.Use the pop-up window function to set the parameters,including the delay of the result display and the threshold of each parameter.At the same time,the brightness of the collected flame image is displayed in real time using a line graph.Then use the trained SCNN model to classify the flame state in real time.Subsequently,a simulation experiment is performed to simulate the flame in the furnace,and it is obtained that the flame intensity of the detected simulated light source is 38,the flame area is 53,and the flame state is judged to be‘bright’.

Fig.12 Real-time detection results of simulated furnace flame

After several flame detection simulation experiments,the SCNN model can accurately identify and classify the combustion state of the furnace flame(on)and the state when the gasifier stops working(off),and display it on the GUI interface.This part is based on the first judgment of decision-making level.

4.2 Verification analysis

The main verification experiment is based on the ignition equipment of the aerospace gasifier.The furnace ignition test is carried out by electric ignition.The real-time state of the flame is detected during the ignition process and compared with the ultraviolet detection device.Analyze the flame detection data in the ignition state,and the analysis results are shown in Table 5.

Record a complete flame state cycle and intercept 21 judgment results for analysis.By comparing with the detection result of the ultraviolet flame detection equipment,it can be seen that the output result of the ultraviolet device is an analog signal of 4-20 mA,which indicates the state of the flame from small to large.In the historical data of the SCNN flame detection system,the flame state changed from bright to off,and the UV detection equipment began to decrease from 20 mA.Among them,due to the flickering of the flame,a‘Low’state judgment was generated,but the flame state was still judged to be a‘bright’state,which was consistent with the judgment of the ultraviolet device.When the analog output is 4 mA,the flame area is 0,which meets the testing requirements of aerospace gasifiers and meets industrial standards.

The data record of the continuous flame image judgment results of the SCNN flame detection system during the ignition process is shown in Table 5.Theanalysis frequency is 7 fps.This part is the output result of SCNN judgment,and the flame state is recorded in real time in the historical data.The categories are divided into:Big flame,Medium,Low,and Flame off.

Table 5 Comparison and verification of flame state during ignition of aerospace gasifier

After comparison and verification with the flame detection results of the ultraviolet device,the system can accurately determine the flame state of the furnace,display various parameters,and record real-time flame state data in the form of files.On the whole,human-computer interaction is completed.

5 Conclusion

A SCNN flame detection algorithm is proposed to detect the flame state in the aerospace gasifier.Moreover,the accuracy and reliability of flame detection are verified based on SCNN algorithm framework.Originally,an industrial camera is used to collect the flame video data in the furnace during the start and stop phase,and the data obtained are processed with grayscale to reduce the data dimension.The furnace flame data set FISD is used for network training and testing.Firstly,the CNN flame detection model is trained,and then the feature extraction of flame is set.Subsequently,SVM is introduced for flame classification.Through the above operations,the original Softmax layer is replaced,thus improving the generalization ability of the network.The SCNN flame detection model proposed in this paper has a judgment accuracy of 99.53% for the test set,which is higher than the CNN flame detection model.Therefore,SCNN network model can accurately judge the state of the furnace flame.Eventually,SCNN flame detection model,the brightness,frequency,intensity,area and other important parameters are introduced into the GUI interface to realize human-computer interaction and complete the real-time detection of gasifier furnace flame.However,for the blue flame generated during incomplete combustion and some high frequency flame,the accuracy of the current SCNN flame detection model will be reduced in the ignition of aerospace gasifier.Therefore,the SCNN flame detection algorithm will be constantly improved in the follow-up work.

杂志排行

High Technology Letters的其它文章

- Research on buffer structure and flow field simulation of swash plate plunger type hydraulic transformer①

- Effect of integral squeeze film damper on vibration and noise of spur gear with center-distance error①

- Workspace optimization of parallel robot by using multi-objective genetic algorithm①

- A simplified hardware-friendly contour prediction algorithm in 3D-HEVC and parallelization design①

- An efficient cross-layer buffer management optimization scheme for 5G protocol stack①

- Joint utility optimization algorithm for secure hybrid spectrum sharing①