Efficient Extraction of Tea Saponin from Tea Seed Meals by 60Co γ-Irradiation

2022-01-12ZHANGLepingSHAOSaiZHAOCaifengXIEHongkeZHOUYijiZHANGYuelongGUOFengLIHonggaoZHANGYongWANGXunhuai

ZHANG Le-ping, SHAO Sai, ZHAO Cai-feng, XIE Hong-ke, ZHOU Yi-ji, ZHANG Yue-long,GUO Feng, LI Hong-gao, ZHANG Yong, WANG Xun-huai

Hunan Institute of Nuclear Agricultural Science and Space Breeding, Hunan Academy of Agricultural Sciences, Changsha 410000, PRC

Abstract In order to simplify the extraction process of tea saponin and improve its extraction rate, tea seed meals was taken as materials to explore effects of 60Co γ-irradiation and H2O2 on the extraction rate of tea saponin. The results showed that the optimal crude extract condition of tea saponin was 6% H2O2 and an irradiation dose of 5 kGy, the extraction rate was 46.4%. However, when the irradiation dose and the H2O2 concentration continued to increase, the extraction rate of tea saponin decreased. After flocculate extraction, the tea saponin content increased from 40.80%to 48.32%. Foaming property test results showed that the higher the tea saponin content in the solution was, the higher the foaming height will be, and the foam had a certain stability. This work provided a new method for the extraction of natural products, using γ-ray irradiation and H2O2 pretreatment to improve the extraction rate, and this was of great significance for industrial extraction.

Key words Tea seed meals, Tea saponin, 60Co γ-irradiation, Extraction, Foamability

1. Introduction

Camellia oleifera

Abel is an evergreen tree and shrub camellia plant, which is a unique woody oil resource in China, and known as one of the 4 woody edible oil plants. Currently, there are 4 million hectares of camellia plantations in China, which can produce 150 thousand tons of edible oil every year. In the process of oil pressing,a large number of tea seed meals will be produced, and as the main byproduct in the process of oil production, tea seed meals is often buried or burned for treatment. While it has high economic value, and contains crude fiber, crude fat, carbohydrate, protein and tea saponin,etc

. Among these natural ingredient, tea saponin is the general name of saponin in camellia plants of the familyCamellia

, which is composed of organic acids, saccharides and sapogenins, and is widely used for sterilization and disinfection, adsorbing material, detergents,fire retardant, surfactant,etc

. Therefore, the efficient and economical extraction of tea saponin from oil extraction by-product of tea seed meals can not only improve the economic value ofCamellia oleifera

Abel., but also benefit the environmental protection.Tea saponin was first extracted by AOYAMA Sin 1931, and the crystalline compound was extracted by ISHIDATE M and TAKAMURA Kin 1953.Although the study of tea saponin started early, there is no efficient industrial extraction process due to the limited planting ofCamellia oleifera

Abel., that mainly grows in the high mountains and hilly areas of South Subtropical region of China. The main extraction of tea saponin methods are water extraction,organic solvent extraction, mixed solvent extraction,microwave-assistant extraction, ultrasonic extraction and supercritical extraction. Water extraction is the main method in industrial production due to its simple operation, low cost and nontoxicity. However,tea saponin will gradually decompose in hot water,and starch gelatinization and protein colloid in the extraction process will affect the further separation and purification of tea saponin. Organic solvents often cause high cost, toxicity and require strict extraction process, therefore, the use of organic solvent extraction in industrial production has some limitations. Microwave-assistant extraction and ultrasonic extraction are characterized by strong penetration, simple operation, high efficiency and wide applicability. However, because they cannot prevent the gelation of starches and proteins, the crude extraction rate is still low. Although high purity tea saponin can be obtained by using supercritical fluid extraction and there is no pollution in the process,the method is still unable to be used in large-scale production due to its expensive equipment. Hence,it is still necessary to develop new technologies and combine with traditional methods to improve the extraction rate of tea saponin and reduce industrial costs, so as to give full play to the economic value ofCamellia oleifera

Abel..γ-Rays is the high-energy stream of particles produced by nuclear decay in the nucleus of a wavelength less than 0.02 nm, and the commonly used γ-irradiation source isCo. As an important nuclear technology,Co γ-irradiation has been widely used in agriculture, food preservation, medical treatmentand material preparation. Because of the high energy and penetrating ability, γ-irradiation can decompose some natural compounds, such as agricultural residues, reed, bagasse,etc

. However,there are few studies on the specific extraction of natural products by using this characteristic ofCo γ-irradiation. In this paper,Co γ-irradiation was used to efficiently extract tea saponin from tea seed meals,so as to provide reference for industrial extraction.2. Materials and Methods

2.1. Testing materials

Tea seed meals purchased from Hunan Xiangshan Biological Technology Co. Ltd. were used as test materials.

2.2. Crude extraction

20 g tea seed meals and 12 mL HOwith different concentration were added to a polypropylene plastic bottle, and the mixture was stirred at 60 r/min for 20 min. Then, the bottles were irradiated at a certain dose usingCo γ-Rays irradiation. After irradiation, 120 mL water was added into the bottle and stirred slowly (60 r/min) at 60 ℃ for 1.5 h. Filtrate was obtained by filtration, and 150 mL water was added to the filtrate residue for the second extraction and filtration. This process was repeated twice to obtain 450 mL crude extraction. Experiment design was shown in Table 1.

2.3. Flocculation extraction

2 mL of 5% polyaluminium chloride solution,5 mL of 5% cationic polydimethyldialyl ammonium chloride (CPDMDAAC) solution, and 2 mL of 0.1%cationic polyacrylamide (CPAM) solution were added into the 450 mL crude extraction. With slow stirring(50 r/min), a large amount of flocculent precipitationgradually formed. After a period of time, the solution was filtered, and obtained the clear flocculation extraction.

Table 1 Experiment desigh

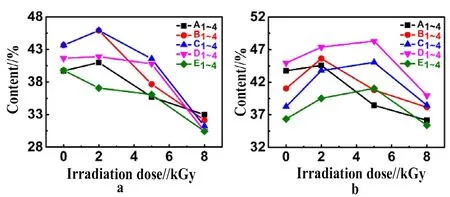

2.4. Determination of the (crude and flocculation)extract solid weight

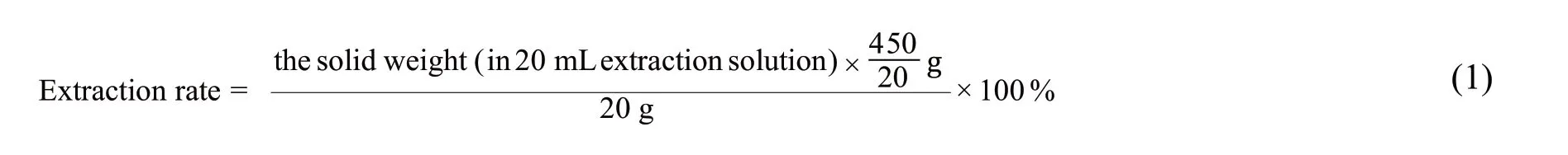

The solid in the solution was obtained by reduced pressure distillation of 20 mL crude extraction solution, and then the sample was dried in the vacuum oven. Because of the highly hydroscopicity of tea saponin, it should be quickly weighed after drying to obtain the solid weight. Then the extraction rate was calculate according to Formula (1).

2.5. Determination of tea saponin concentration in solution

The tea saponin content were determined by the vanillin-sulfuric acid method. Tea saponin standard sample was used to draw the UV standard curve. Tea saponin (20 mg) was dissolved in 20 mL 80% ethanol to obtain tea saponin solution (1 mg/mL).Tea saponin standard solution with concentration of 0.2, 0.4, 0.6, 0.8 and 1 mg/mL were obtained by diluting with 80% ethanol. Then 1 mL tea saponin solution, 1 mL 8% vanillin solution and 8 mL 77%HSOsolution were added, and the tea saponin concentrations were 0.02, 0.04, 0.06, 0.08 and 0.1 mg/mL respectively. After the mixture was evenly mixed,the product was placed in a 60℃ water bath for 30 min for color development reaction. After reaction, the solution was cool down to room temperature and measured the UV absorbance to obtain a UV standard curve.

The extracted tea saponin solution was diluted tenfold before testing its concentration, and then 1 mL diluted tea saponin solution, 1 mL 8% vanillin solution and 8 mL 77% HSOsolution were mixed together.After the mixture was evenly mixed, the product was placed in a 60℃ water bath for 30 min for color development reaction. After reaction, the solution was cooled down to room temperature and measured the UV absorbance.

2.6. Foaming property test

The foaming properties of the flocculation extract solution was measured by ISO 696-1975,surface active agents-measurement of foaming powermodified Ross-Miles method.

3. Results and Analysis

3.1. The extraction rate of tea saponin in the different treatments

Table 2 Extraction rate of tea saponin in the flocculation extraction and crude extraction

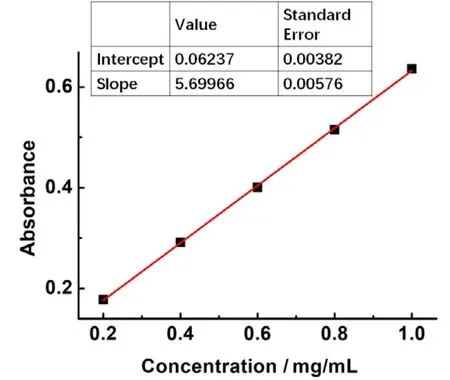

The concentration of tea saponin in crude extraction solution was obtained according to the UV standard curve (Fig. 1). As can be seen from Fig. 2 and Table 2, with the increase of HOconcentration,the crude extraction rate of tea saponin increased.This was mainly because the strong oxidation of HOcould oxidize the components in tea seed meals, and break down the intermolecular forces, thus improving the extract rate. When the concentration of HOincreased to 8%, the content of tea saponin decreased obviously. This was because the increase of hydrogen peroxide content will also destroy the structure of tea saponin, which led to the decrease of tea saponin content. Similarly, with the increase of irradiation dose, the crude extraction rate would increase, but when the radiation dose reached to 5 kGy, no matter what the concentration of HOwas, the maximum tea saponin extraction ratio was reached. Thus, the optimal crude extract condition of tea saponin was 6%HOand an irradiation dose of 5 kGy.

Fig. 1 UV standard curve of tea saponin at 389 nm

Fig. 2 Effect of H2O2 concentration and irradiation dose on the tea saponin concentration in crude extraction solution

3.2. Comparison of extraction rate between flocculation extraction and crude extraction

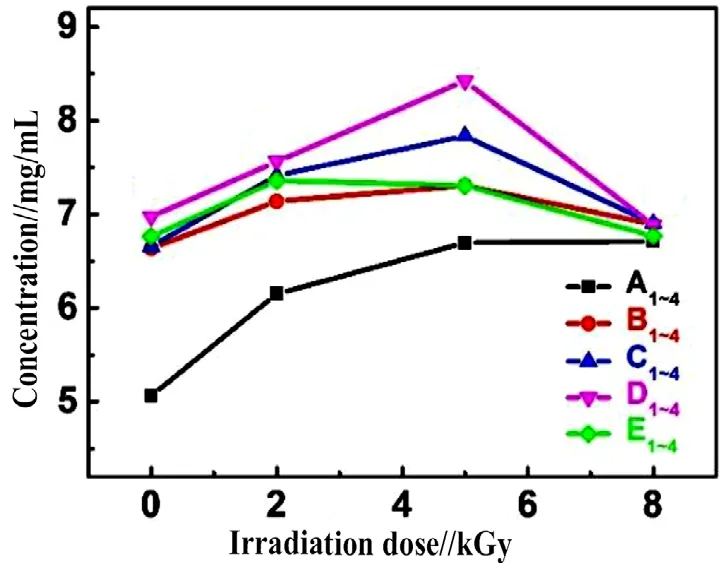

As shown in Table 2, the weight of flocculation extract solid did not show some regularity, which was speculated and caused by the quick process of flocculation, and made it difficult for substances in the solution to settle regularly. To further compare the effect of flocculation on samples, the ratio of tea saponin in coarse extract solids and flocculate extract solids were calculated, respectively (Table 2 and Fig. 3). As shown in Fig. 3, tea saponin content in the treatment of Dwas the highest, reaching 48.32%, which was 7.52% higher than the value of 40.80% before flocculation. This indicated that flocculation was conducive to greatly improving the concentration of tea saponin in extract solid. However,the flocculation process could cause a decrease in total tea saponin content. However, the flocculation process had less influence on tea saponin than that of others,such as crude fiber, crude fat, carbohydrate, protein,etc

. In all, the influence trend of HOand irradiation dose on tea saponin was similar, that was tea saponin content increased firstly, and then with the increase of HOcontent and irradiation dose, the tea saponin structure was damaged so that the concentration decreased.

Fig. 3 The content of tea saponin in extract solids(a: Before flocculation; b: After flocculation)

3.3. Foaming properties in the different treatments

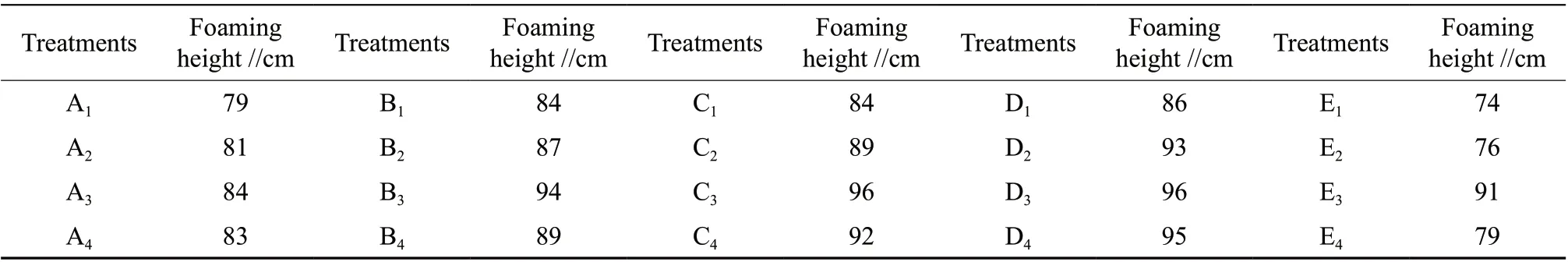

Furthermore, foaming property was one of the important characteristics of tea saponin. It was tested according to ISO 696-1975, and the results were shown in Table 3. The height of foaming was consistent with the content of tea saponin, and Dreached the maximum value of 96 cm. On the other hand, the foaming properties of tea saponin solution with different concentration did not differ significantly. The foaming test also verified the tea saponin content of different experimental groups in the extraction process in this paper was consistent with UV standard curve test.Furthermore, after foaming for 20 min, it was observed that the height of Dbubbles decreased by about 5 cm, indicating that the foaming of tea saponin had a certain stability, and it can be used as surfactants.

Table 3 Foaming properties in the different treatments

4. Discussion

Due to the existence of natural products in the tea seed meals, such as proteins, starches and the presence of some microbes, large amounts of hydrogen bonds are formed between different molecules, which makes tea saponin difficult to be extracted. In previous reports, high extraction rate is usually obtained by increasing the extraction temperature, adding organic solvent, microwaveassistant heating and other methods. However these methods also increase the cost of the process and make it difficult to extract large quantities. To solve this problem, a special treatment is often required.One is to add HOto destroy the chemical structure of some natural products and kill microorganisms, due to its strong oxidation property, and this method is widely used in the extraction of natural products.The pretreatment of tea seed meals with HOis conducive to the separation of tea saponin and other organisms, and accelerating the extraction process and improving the efficiency, whereas the amount of HOneeds to be controlled, because excess HOwill destroy the structure of target product. On the other hand, althoughCo γ-Rays has not been applied in the extraction of natural products, it has the advantages of sterling and degrading natural products. In this work, tea saponin was first extracted byCo γ-irradiation and HOpretreatment. SinceCo γ-irradiation and HOcan destroy the intermolecular forces and the structure of some substances, such as proteins, starches,etc

, the extraction rate of tea saponin increased with the increase of irradiation dose.However, when the irradiation dose was 8 kGy, the structure of tea saponin was destroyed and the content of tea saponin decreased. When the tea seed meals was treated with 5 kGy and 6% HO, the extraction rate was much higher than that of the untreated sample. In order to increase the content of tea saponin in extract solid, flocculation was used, and the content can reach up to 48.32%. Moreover, tea saponin had good foaming performance and stability, which was measured according to ISO 696-1975. Hence, the pretreatment with radiation had the advantages of high efficiency and low energy consumption for the extraction of natural products in industry, which was worth further study.杂志排行

Agricultural Science & Technology的其它文章

- Screening of an Antagonistic Strain of Phytophthora nicotianae and Its Application Potential

- Characterization of Specific Spoilage Bacteria and Volatile Flavor Compounds of Flavored Crayfish

- Protective Effect of Immaturue Bitter Orange (Citrus aurantium L.) Flavonoids Extracts on PC12 Cell Injury Induced by 6-Hydroxydopamine

- Effects of Boron Application on Growth and Quality of Flue-cured Tobacco NC297 under Different Potassium Supply Levels

- Community Characteristics of Cardamine in Brassicaceae

- Effects of 4 Types of Remediation Agents on Reducing Cd Contents in Soil and Rice on Cd-contaminated Farmland