Preparation of YBCO Films by Water-Based Sol-Gel Deposition

2021-11-03CNG

, , , CNG ,

(1.China Electronic Product Reliability and Environmental Testing Research Institute, Wuhu Division, Wuhu 241002, China;2.China Electronic Product Reliability and Environmental Testing Research Institute, Hefei Division, Hefei 230088, China;3.The Fifth Electronic Research Institute of MIIT, Guangzhou 511370, China)

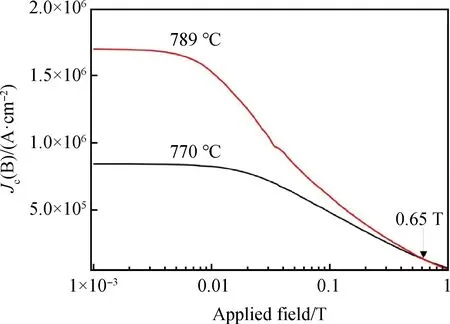

Abstract:The effects of annealing temperature on properties of YBCO films deposited on (100) LaAlO3 single crystal substrates derived from a water-based sol-gel process were investigated. In this paper, the in-plane texture is improved at higher temperatures but the out-of-plane texture follows an opposite trend. YBCO films annealed at 789 ℃ with homogeneous and smooth surface as well as Jc=1.7 MA/cm2 at 77 K and 0 T was obtained. Particles and holes observed on the other films could result in bad connections between superconducting grains and decrease the superconducting current in the films. Strain in these films is likely to enhance the pinning force and improve the transport properties under applied field.

Key words:water-based sol-gel; annealing temperature; YBCO; critical current density; defect; superconductivity

0 Introduction

YBCO coated conductors have been studied and developed as promising components for a variety of potential industrial applications[1-5]. The processing of coated conductors is based on the epitaxial growth of YBCO films on textured substrates. By now, various techniques have been employed for preparing YBCO films. Amongst these techniques, chemical solution deposition (CSD) is a method involving coating a precursor solution on substrates followed by a heat-treatment process to obtain the desired compounds. The CSD method has some advantages over vapor deposition routes for the fabrication YBCO films, such as low-cost, precise control of stoichiometric ratio and high deposition speed[6-7]. Residual carbon may present at the YBCO grain boundaries and severely suppress the superconducting current of the films. As a consequence, the critical current density (Jc) of YBCO films prepared from standard chemical solutions is usually quite low[8]. To eliminate BaCO3, Gupta et al[9]first used trifluoroacetate (TFA) precursors to grow YBCO films on single crystals. Then, Mclntyre et al[10]developed this method further and obtained YBCO films withJchigher than 1 MA/cm2. The primary advantage of the TFA process is that BaF2is formed during pyrolysis of the precursors and fluorine can be removed in a humid atmosphere at a relatively low temperature compared to that of the decomposition of BaCO3[11]. However, the interest in fluorine-free CSD approaches is high, because there are still some drawbacks in the TFA approach, e.g. expensive starting materials and complicated processes that lead to a rather high cost in large-scale industrial applications. Moreover, the toxic byproduct HF gas is not environmentally friendly, and can become a serious issue for large scale production[12].

Amongst a variety of fluorine-free routes, water-based sol-gel routes for preparing REBCO (RE=rare earth) films have been developed[13-15]. The main idea of this method is to dissolve metal organic salts in water and chelate with additives to form a three dimensional structural network. The greatest advantage of this method is using water, which is clearly cheap and non-toxic. Recently, YBCO films derived from water-based sol-gel processing using triethanolamine (TEA) as a complexing agent were reported by Vermeir et al[16], with promisingJcvalues at 77 K. Although the superconducting properties of these YBCO films is inferior to that of films prepared by the TFA method[17-18]as well as by using some other fluorine-free methods[12,19], it is believed that high performance YBCO films can be prepared via this simple water-based sol-gel route after optimizing the processing parameters. In this paper, the influence of annealing temperature on the properties of YBCO films prepared on (100) LaAlO3(LAO) single crystal substrates by a water-based route was studied and it will be shown that YBCO films withJc=1.7 MA/cm2can actually be prepared by this simple aqueous sol-gel method.

1 Experiments

For preparing the aqueous YBCO precursor sol-gel, stoichiometric amounts of Y acetate, Ba acetate and Cu acetate powders (Alfa Aesar) were dissolved in deionized water. After adding TEA(Alfa Aesar) in a molar ratio of cations∶TEA=1∶1.7, the mixture was heated at 90 ℃ for 1 h in a water bath until all solids were dissolved and a dark blue aqueous solution was obtained. To improve the wetting properties of the solution on single crystal substrates and obtain the desired film thickness, the as-prepared solution was heated at around 60 ℃ for several hours to obtain a stable and viscous YBCO precursor. LAO single crystal substrates with one polished side purchased from CrysTec GmbH were used. Before coating, the LAO substrates were heated at 650 ℃ in O2gas to eliminate surface defects.

A dip-coating process with a withdrawal speed of 5 mm/min was employed to coat the sol-gel precursor on the substrates. The wet films were dried first at 150 ℃ in a furnace under ambient atmosphere. After drying, the samples were heated to 500 ℃ with a heating rate of 5 ℃/min in flowing O2bubbled through water with a dew point of 30 ℃. Then the furnace temperature increases to between 745 ℃ and 817 ℃ and held for 1 h in dry flowing Ar gas with 1×10-4oxygen content. After dwelling, the carrier gas was switched to pure oxygen while the temperature decreased down to 550 ℃ at a cooling rate of 3 ℃/min. In the end, the YBCO films were oxygenated at 450 ℃ for 5 h followed by furnace cooling down to room temperature in flowing oxygen gas.

A Bruker D8 Advance X-ray four-circle diffractometer with Cu Kαradiation was used to analyze the phase content and texture of the YBCO films. The beam size is 6 mm×10 mm which is capable to illuminate the films completely. Forθ-2θscans, a step size of 0.02° and aquisition time of 1 s were used. The out-of-plane alignment of the YBCO films was obtained from rocking curves of the YBCO (005) reflection and quantified by the full width at half maximum (FWHM) (Δω) of the reflection peaks. The in-plane orientation was characterized by the FWHM value (Δφ) of the YBCO (103) reflection peaks recorded by φ-scans. The surface morphology of the YBCO films was observed by scanning electron microscope (Supra 35 SEM) equipped with an energy dispersive spectrometer (EDS) in secondary electron mode. The thickness of the films was determined by cross section image and amounts to about 150 nm.

The superconducting transition temperature (Tc) of the YBCO films was measured by AC susceptibility in a CRYOGENIC cryogen free measuring system (CFMS) with applied field of 0.1 mT and frequency of 20.4 Hz. Magnetization hysteresis loops of the films were measured at 77 K under magnetic field applied perpendicular to the YBCO (00l) planes. The critical current densityJcwas calculated using the extended Bean critical state model[20]according to:

(1)

Where, ΔMis the opening of the volume magnetization hysteresis loop,aandbare the width and length of the film (a Texture is a critical parameter for the transport property in high-temperature superconductor films. In-plane and out-of-plane grain alignment in the films annealed at different temperatures were characterized firstly. In Fig.1, the four pole points in the (103) pole figures of the YBCO films which is annealed at 789 ℃ distribute on the proper positions. It thus appears that all films have good in-plane textures. The full (103) pole figures of other films which are not shown are not significantly different from that in Fig.1. To investigate the texture of films further, one pole point from each of the full (103) pole figure was extracted (Fig.1(b)~(f)). Pole densities are very carefully compared. It is clearly shown that the intensity distribution in the pole point of film annealed at 817 ℃ is lower than that of the others. This fact implies that there are gains with other orientations in this film. Fig.1 (103) pole figures of films annealed at different temperatures. (a) Full (103) pole figure of the film annealed at 789 ℃; Extracted pole point from full (103) pole figures of films annealed at (b) 745 ℃, (c) 770 ℃, (d) 789 ℃, (e) 803 ℃, (f) 817 ℃ The X-ray diffraction (XRD)θ-2θscans of the YBCO films annealed at 789 ℃ and 817 ℃ are shown in Fig.2. The (00l) peaks indicate good out-of-plane texture, but the (103) reflection was also observed in the latter film (Fig.2(b)). This indicates that out-of-plane oriented islands are present and may reduce the critical current. Based on the X-ray diffraction intensity of (103) and (004) reflections, the volume content of (103) oriented islands can be simply estimated to be about 1.03% in this film. Fig.2 XRD patterns of YBCO films on LAO substrates annealed at different temperatures in 1×10-4 O2 atmosphere To quantify the in-plane and out-of-plane preferential orientation of the films,φ-scans andω-scans were measured and the FWHM values were reported in Table 1 for all prepared films. It is shown that all Δφvalues are in the range between 0.8° and 1.1°, so that there is no evident the in-plane orientation depend on annealing temperature. On the other hand, the film annealed at 817 ℃ has a Δωof 0.4° which is much broader than that of the films annealed at lower temperatures. The broader Δωvalue and the fact that the (103) oriented grains were observed byθ-2θscan (Fig.2) both imply poorer texture quality and lower critical current density (Table 1). Referring to the YBCO phase diagram[21-23],c-axis grain orientation is favored with increasing annealing temperature in a relatively wide temperature window under lower oxygen partial pressure atmosphere. However, in our case, the annealing condition of 817 ℃ with a 1×10-4O2partial pressure atmosphere is in the close vicinity of the instability line. Probably, the YBCO grains, which are notc-axis oriented, originate from the nucleation centers, whose epitaxial growth is disturbed by secondary phase crystallites forming during film crystallization. Table 1 Texture data and superconducting properties of the films annealed at different temperatures To compare the transport properties of the films in magnetic field, the dependence of the normalized critical current density at 77 K ((Jc(B)/Jc(0 T)) and different applied fields B at 77 K is displayed in Fig.3 for each YBCO film. The magnetic field was applied perpendicular to the YBCO (00l) planes during the measurements. Evidently, the curves of the films prepared at 789 ℃, 803 ℃ and 817 ℃ are steeper than that of films annealed at relatively lower temperatures. Generally, many different defects in pure YBCO films can enhance the pinning force to improveJcunder magnetic field[24-26]. Fig.3 Dependence of normalized Jc of different films on applied magnetic field at 77K (B∥c axis) In the present samples, theTcof all films are above 87.5 K (Table 1), which indicates that the oxygen deficiencyδof the YBCO phase is low in these samples[27]. This fact suggests that the defects do not result from oxygen deficiency. However, the strain (Table 1) obtained from X-ray diffraction patterns shows that the films annealed either at 745 ℃ or 770 ℃ have a strain of about 0.19% which is larger than that of other films. This residual strain probably results from stress originating from the mismatch between the LAO substrate and the YBCO crystals[25]. The strain can remain in the YBCO films annealed at relatively low temperatures where the thermal driving force is not sufficient to relax all stress. For the films annealed at 745 ℃ or 770 ℃, it is believed that the residual stress acts as a source of pinning, which improves the superconducting current densities under magnetic field. Although the film annealed at 789 ℃ has a faster relative decay ofJc(B)/Jc(0 T) than the film annealed at 770 ℃, it still maintains a higher value ofJc(B) at fields up to 0.65 T as shown in Fig.4. Fig.4 Jc of films prepared at 770 ℃ and 789 ℃ on applied magnetic field at 77 K (B∥c axis) YBCO films on LAO single crystal substrates were prepared through a fluorine-free water-based sol-gel route. AJc=1.7 MA/cm2(77 K and self field) was reached for the film annealed at 789 ℃ in 1×10-4O2partial pressure. The influence of annealing temperature on texture, morphology and superconducting behavior of the YBCO films has been investigated as well. No systematic dependence of texture on annealing can be detected according to theφ-scans andω-scans performed on the films. The broadest Δωof the film annealed at 817 ℃ and the (103) peak observed in the XRDθ-2θpattern indicate a poorer texture of this film. SEM images show that the YBCO film surface change from a granular to a plate-like morphology as the annealing temperature increases. The film annealed at 789 ℃ has the smoothest and densest surface. In contrast, particles and holes frequently appear on the other films which have lower critical current densities. In addition, the thickness of these YBCO films is not comparable to that of films derived from the other chemical routes. In further research, multi-coating process is suggested to be a better option to deposit thick YBCO films. TheJcof the films annealed at lower temperatures exhibits weaker dependence on applied field compared to that of films annealed at higher temperatures, it is proposed that flux pinning is enhanced by residual stress and improves the transport behavior in these films under applied magnetic field. Even so, the film annealed at 789 ℃ shows a betterJcthan that of the film annealed at 770 ℃ until the applied field rises to 0.65 T.2 Results and discussion

3 Conclusion